Patents

Literature

117results about How to "Flexible clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

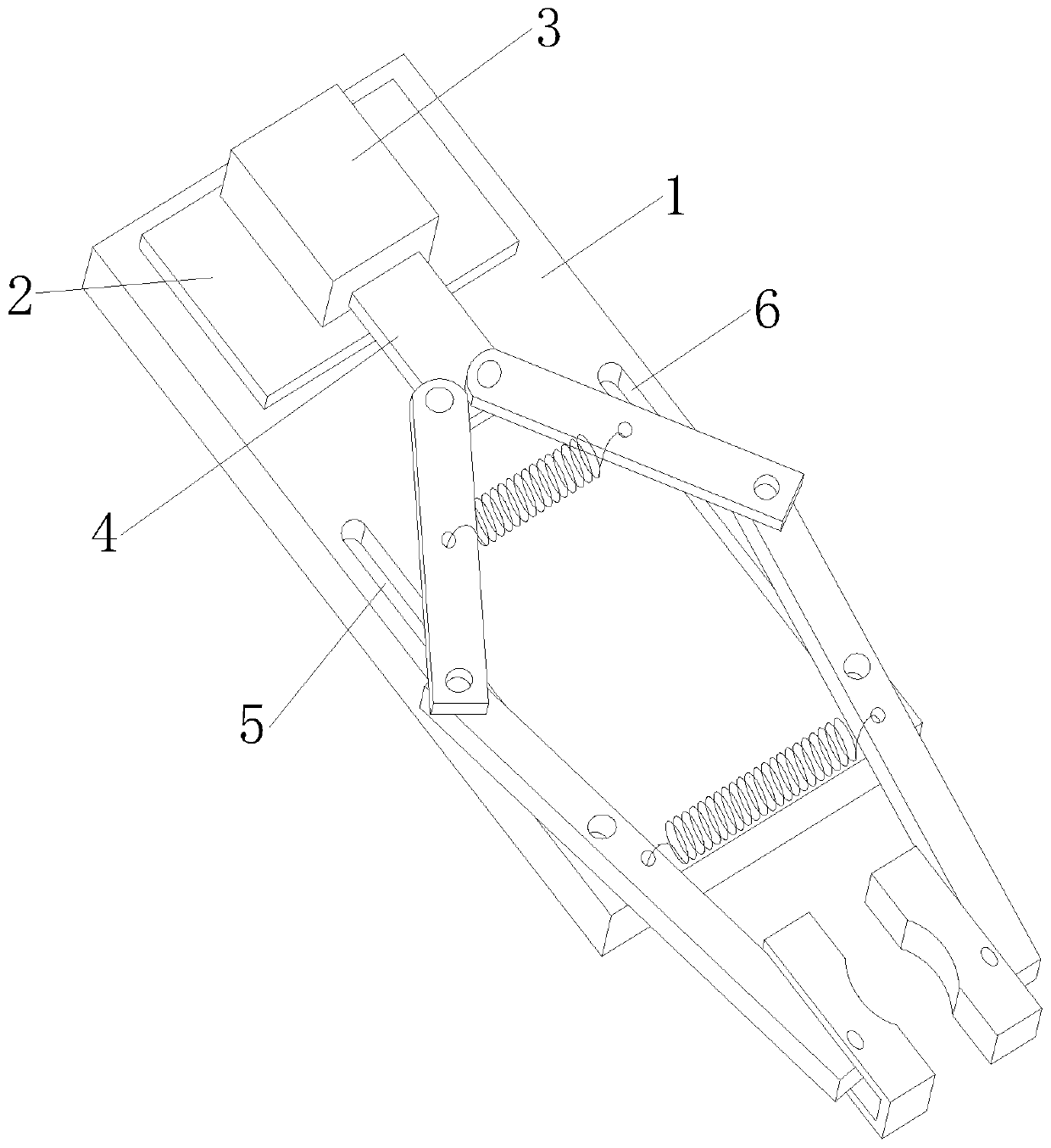

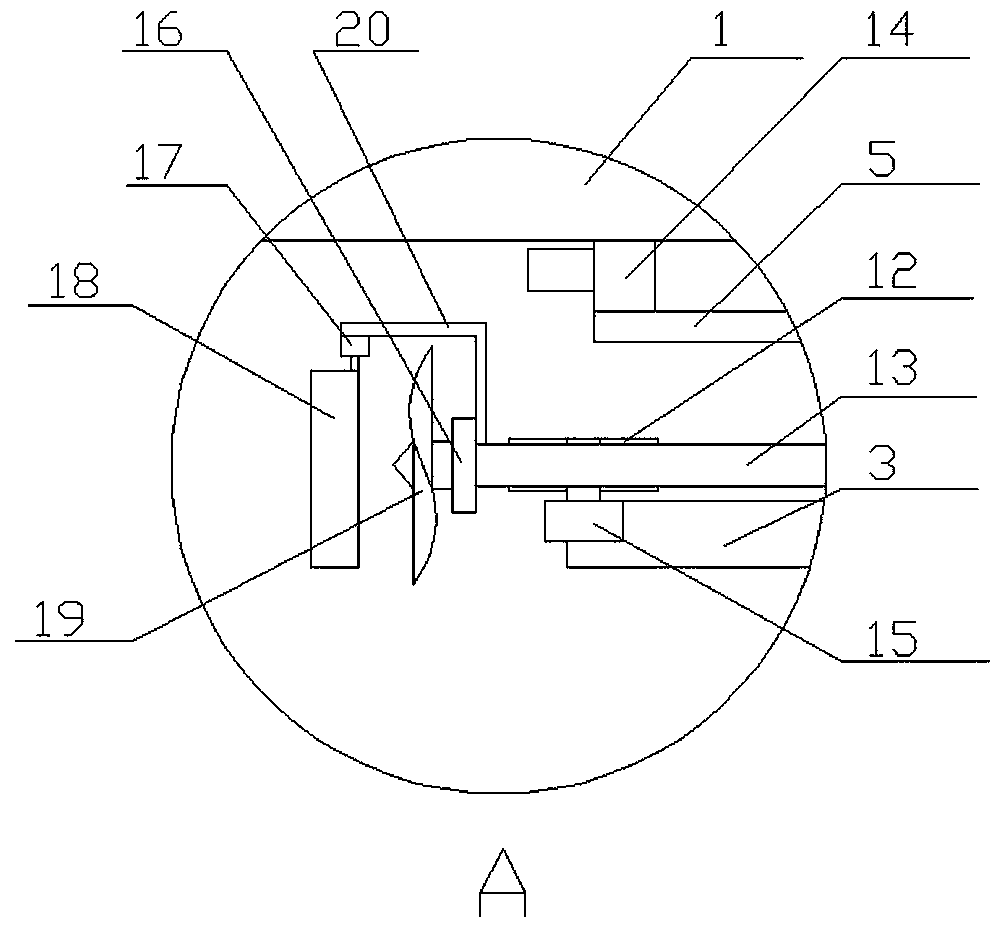

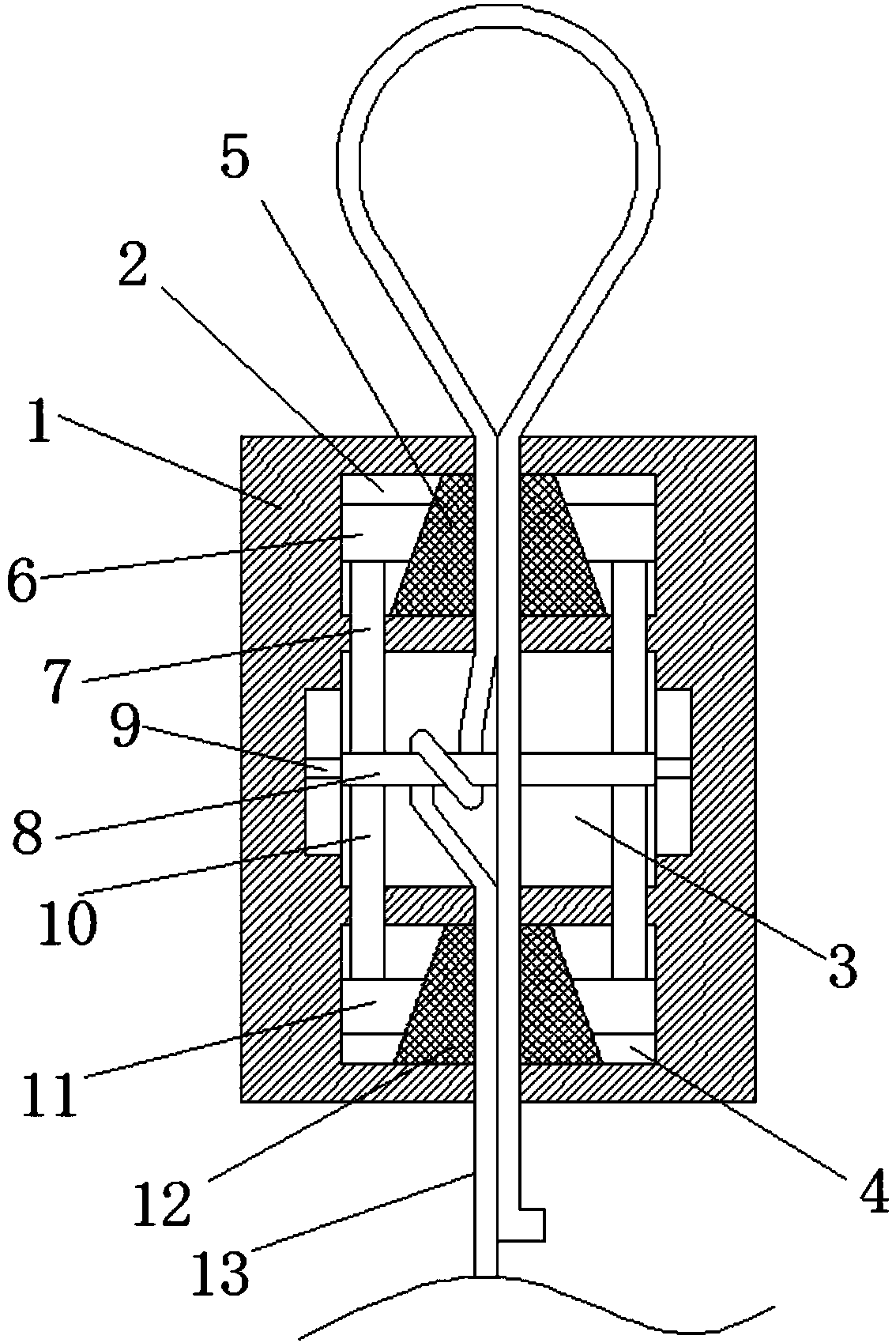

Flexible gripper with two fingers

The invention relates to a two-finger clamper, which is formed by a mechanical body, a driving device, a transmission device and a driving unit. Wherein, the driving device, transmission device and driving unit are mounted on the finger base of mechanical body; said mechanical body comprises a finger base, a left-and-right slide element, and a left-and-right finger element; said driving device is formed by a motor and a code disc; said transmission device is formed by a large gear wheel, a small gear wheel and a leading screw; and said driving unit is formed by a sensor, a single chip and a driving circuit. The invention uses single chip to send control signal to the driving circuit to control the clamper; at the same time, the signals of sensors at different parts of clamper via the driving plate are transmitted to the single chip, to be checked and realize loop-closed control; the mechanical body is powered by motor, to rotate leading screw after being reduced speed via gear wheel, therefore, the left-and-right finger element can be translated; and the clamper can be opened and closed.

Owner:BEIHANG UNIV

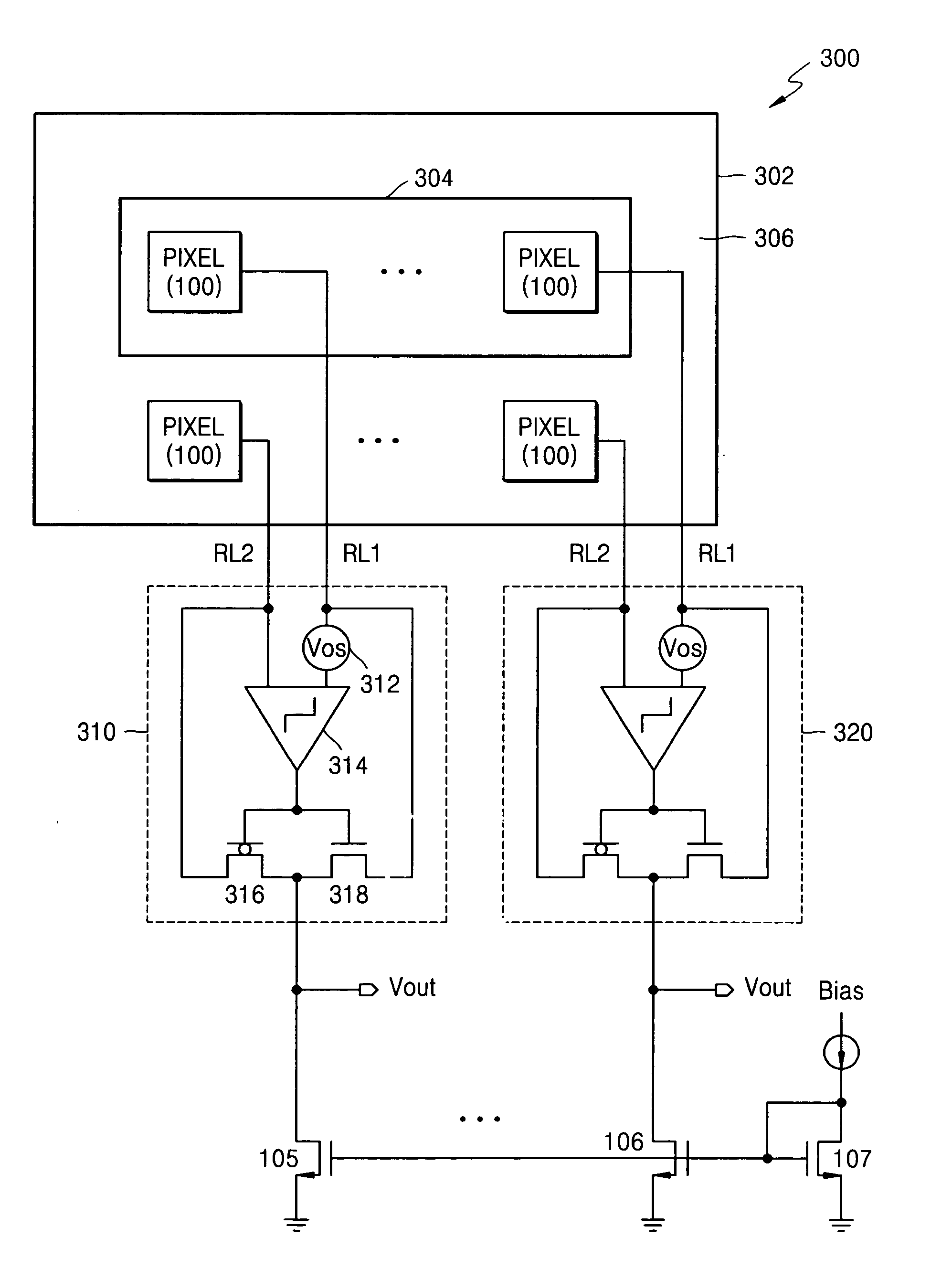

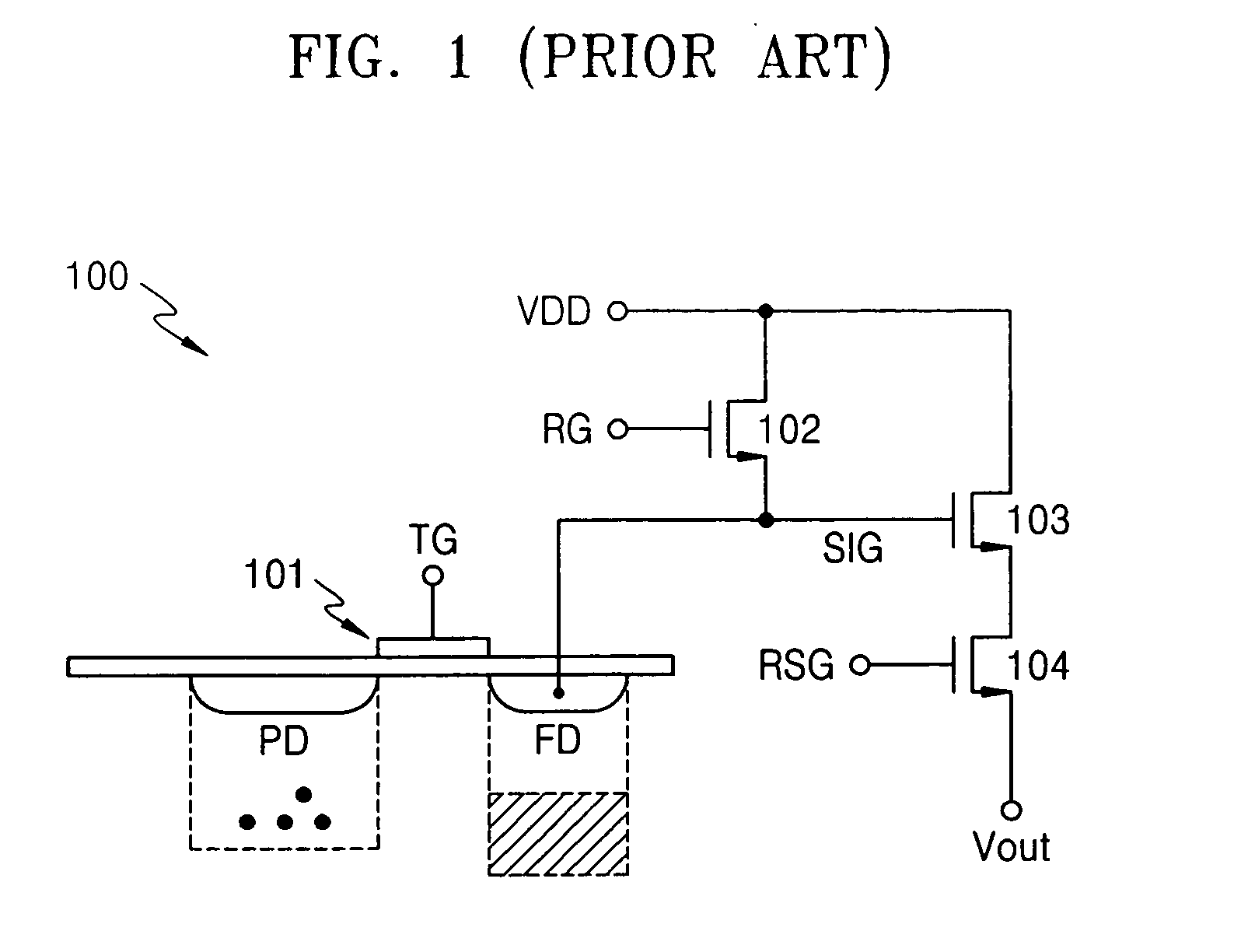

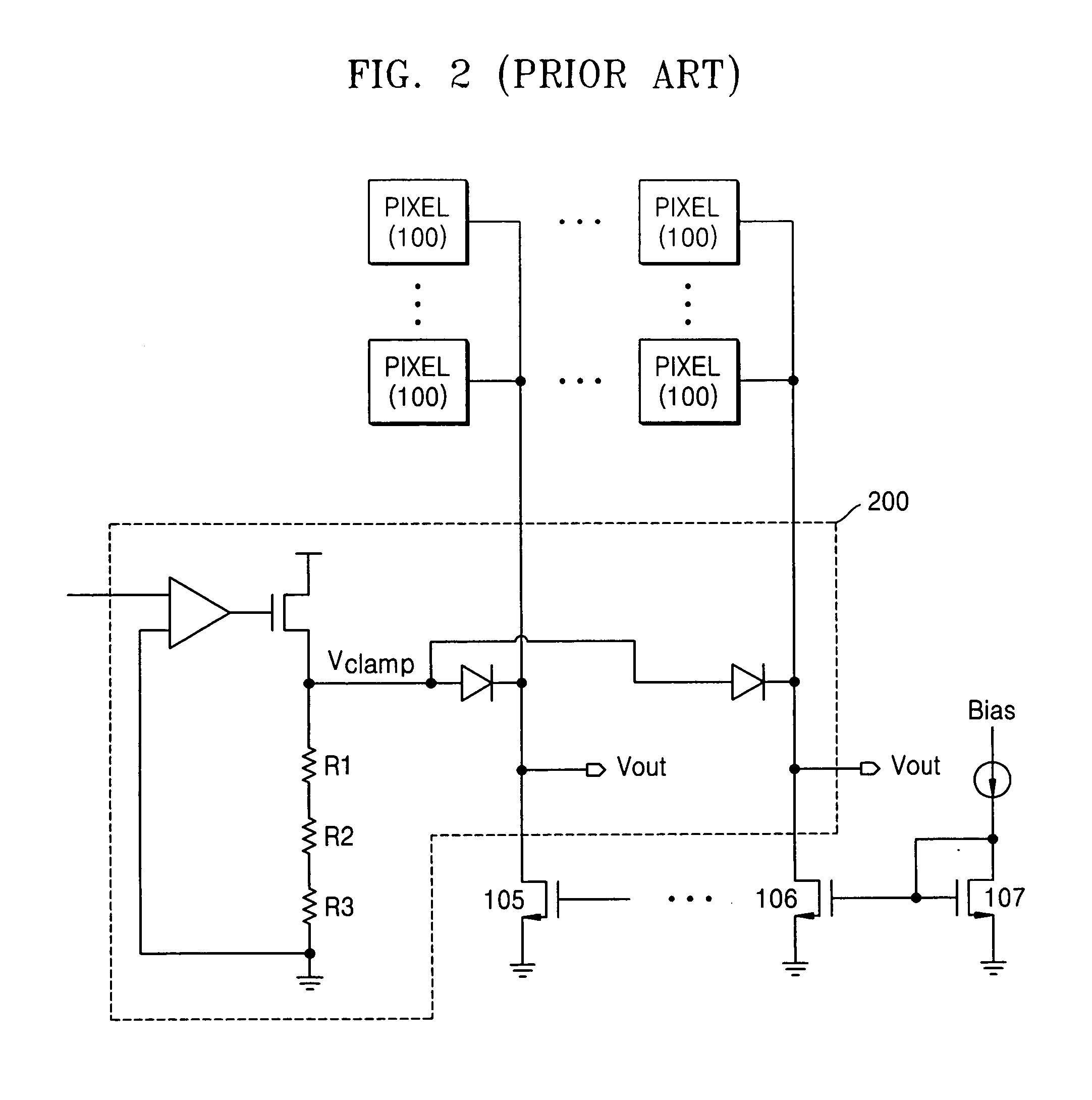

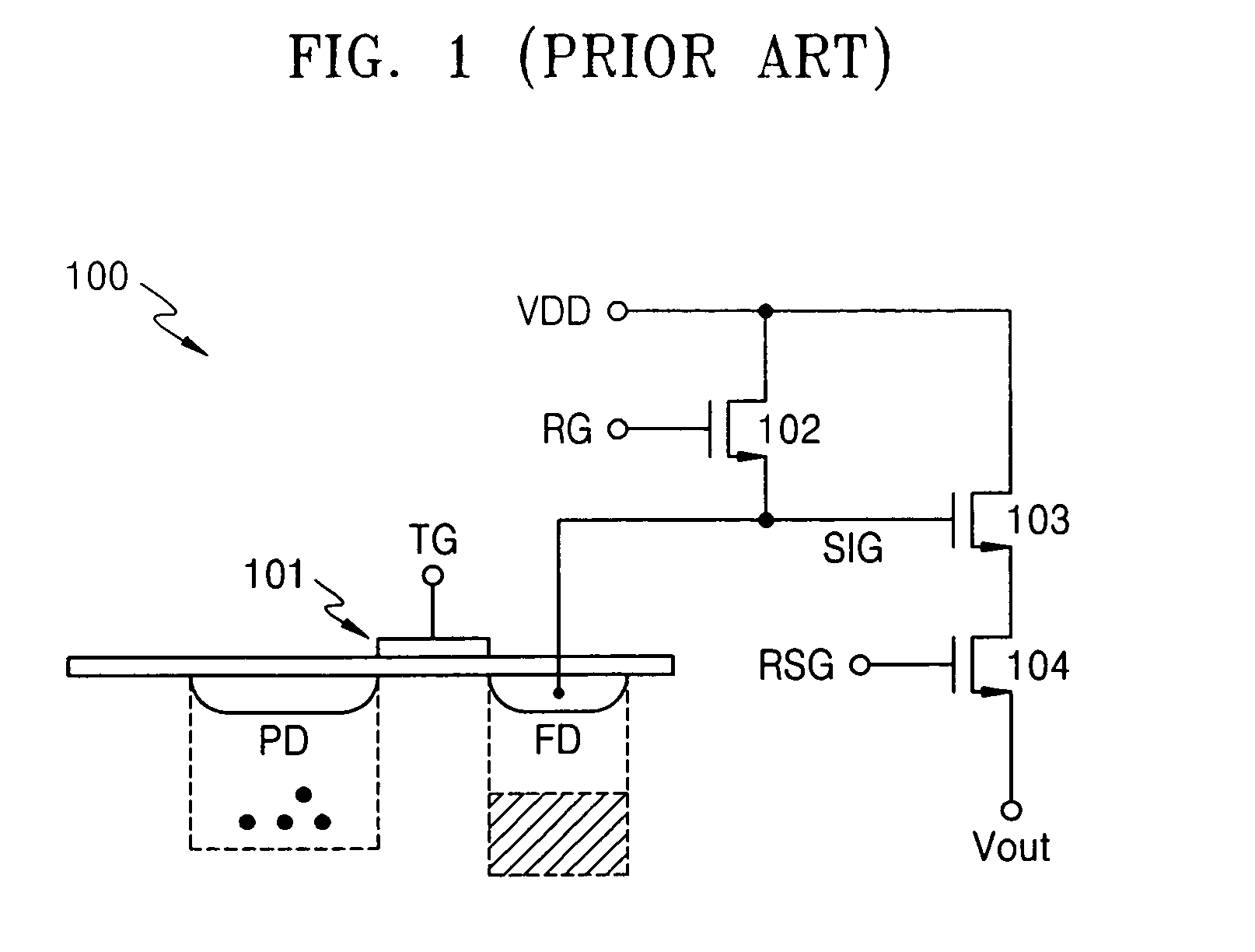

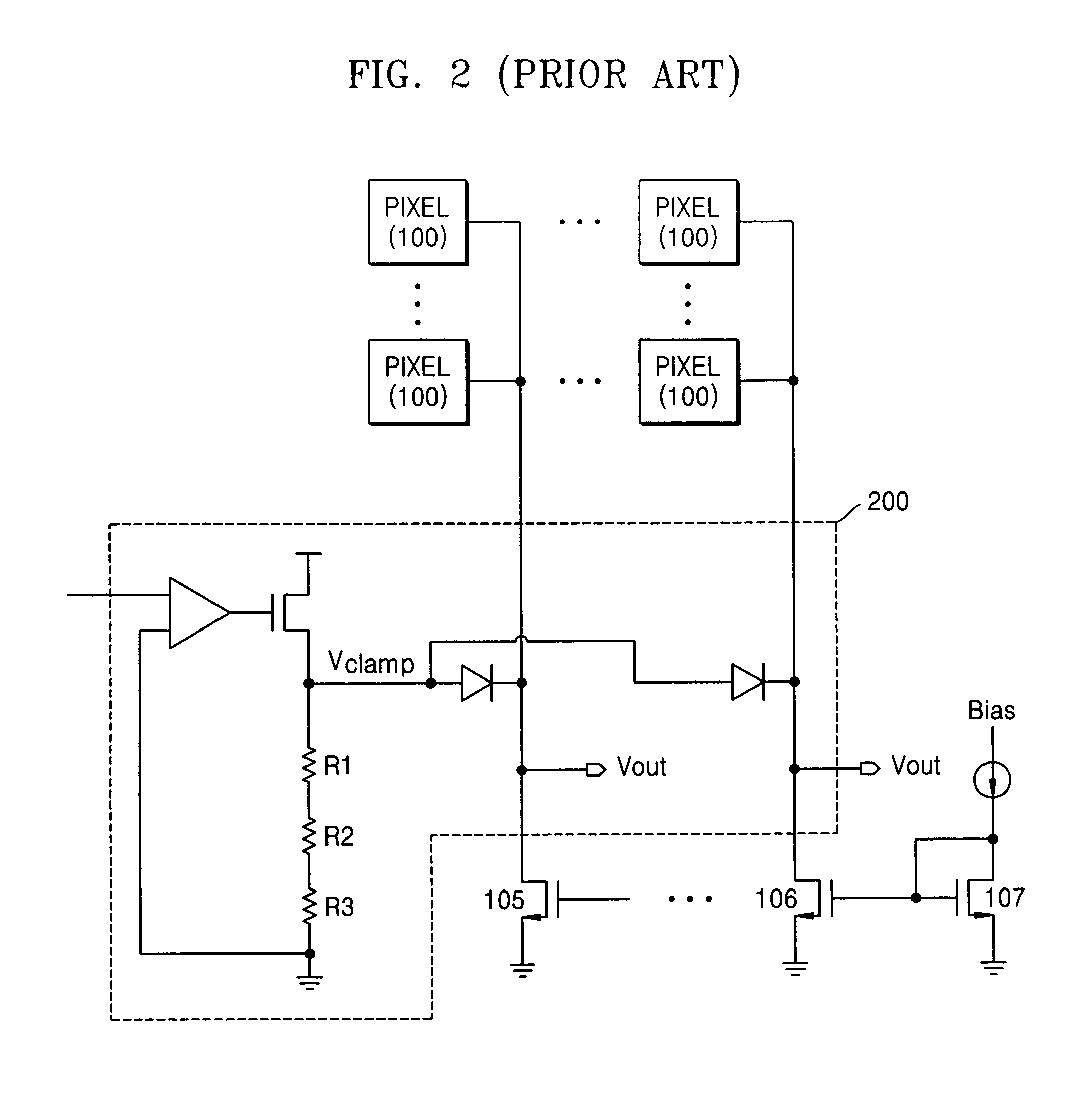

Apparatus and method for clamping reset voltage in image sensor

InactiveUS20050168607A1Accurate accountingFlexible clampingTelevision system detailsTelevision system scanning detailsVoltageImage sensor

For clamping a reset voltage within an image sensor, an active pixel generates a first reset voltage, and an optical black pixel generates a second reset voltage. In addition, a reset voltage selector selects one of the first and second reset voltages as a selected reset voltage. Such a selected reset voltage is generated separately for each column of the array of pixels in the image sensor for more accurately and flexibly accounting for fabrication variations.

Owner:SAMSUNG ELECTRONICS CO LTD

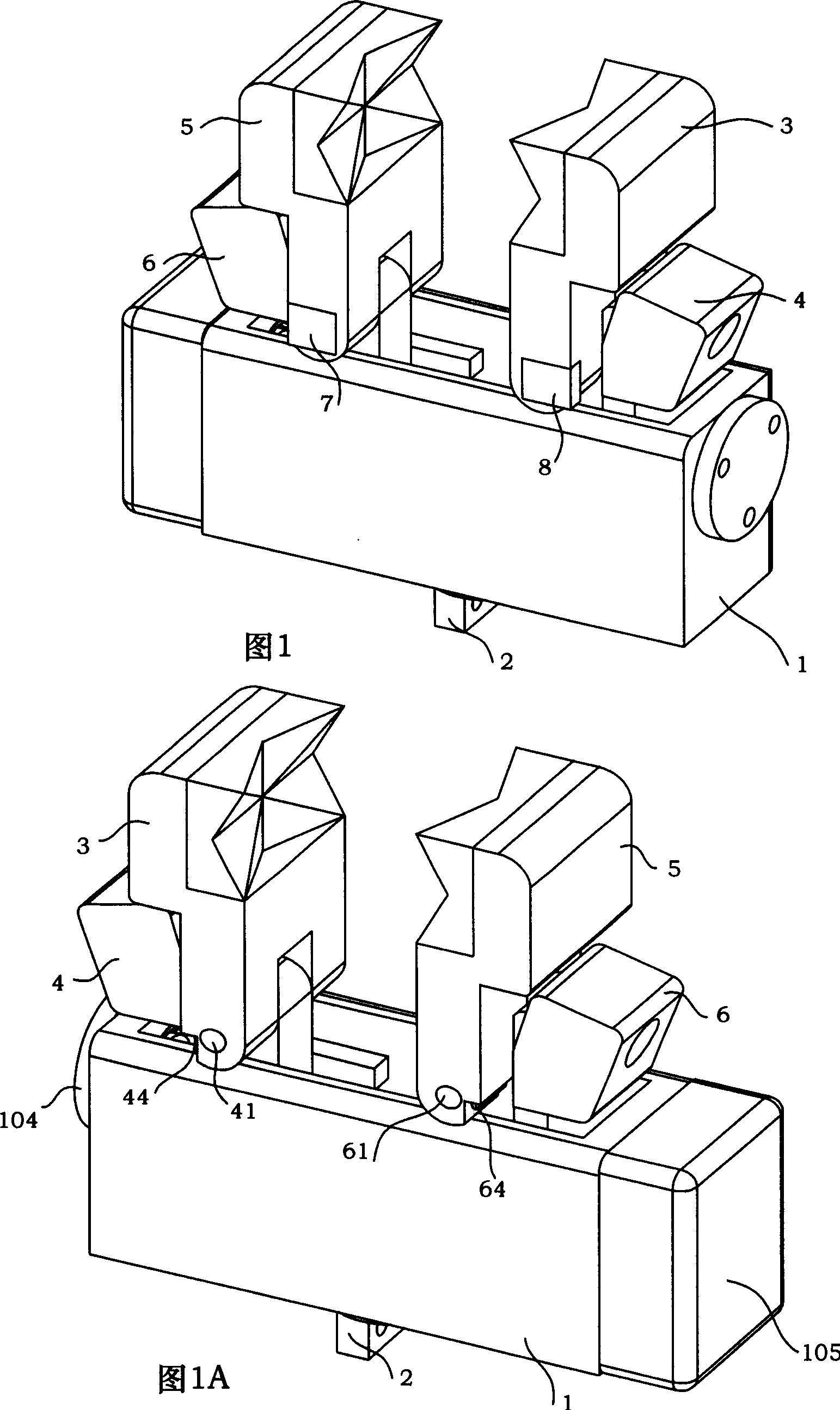

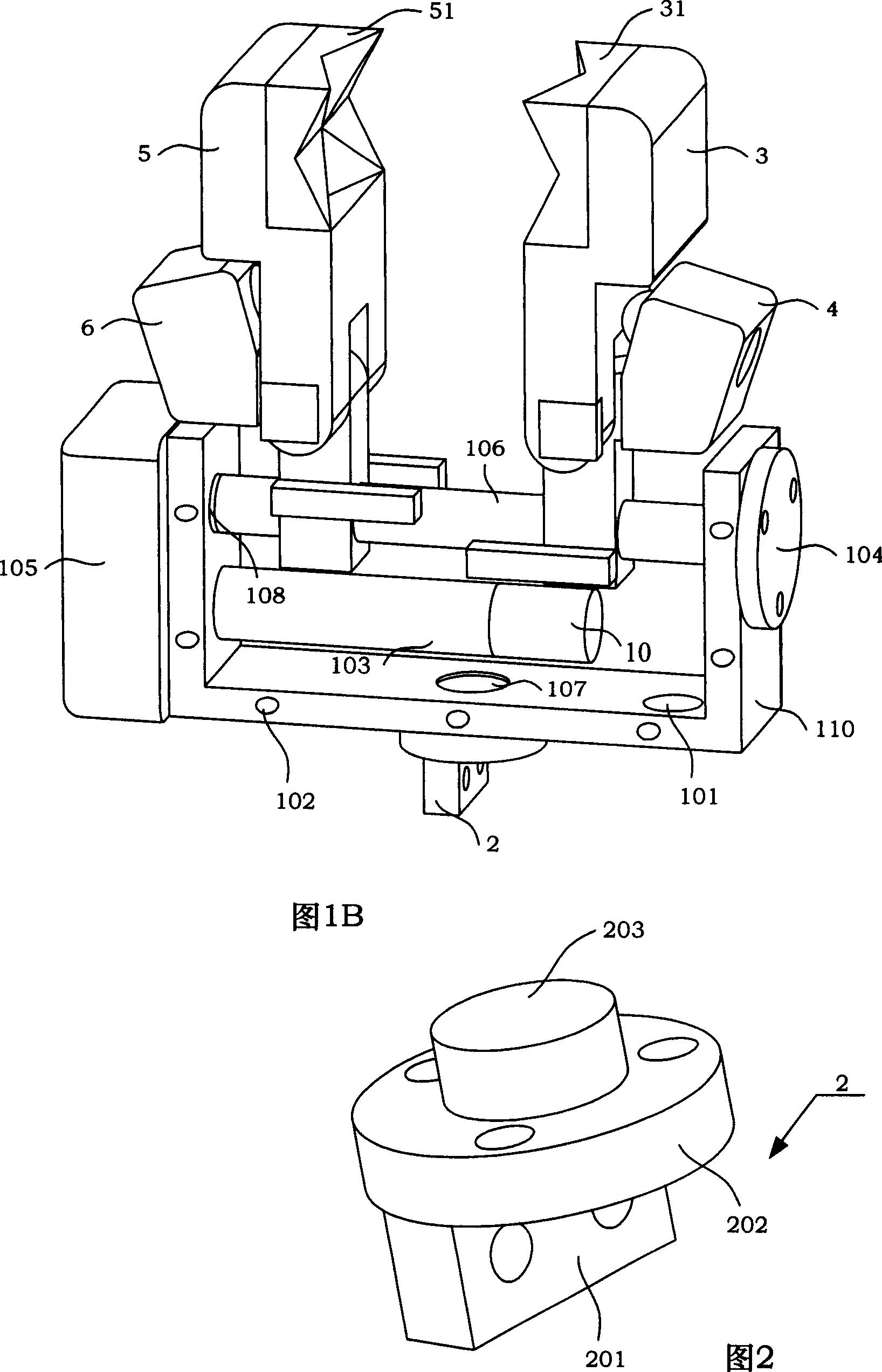

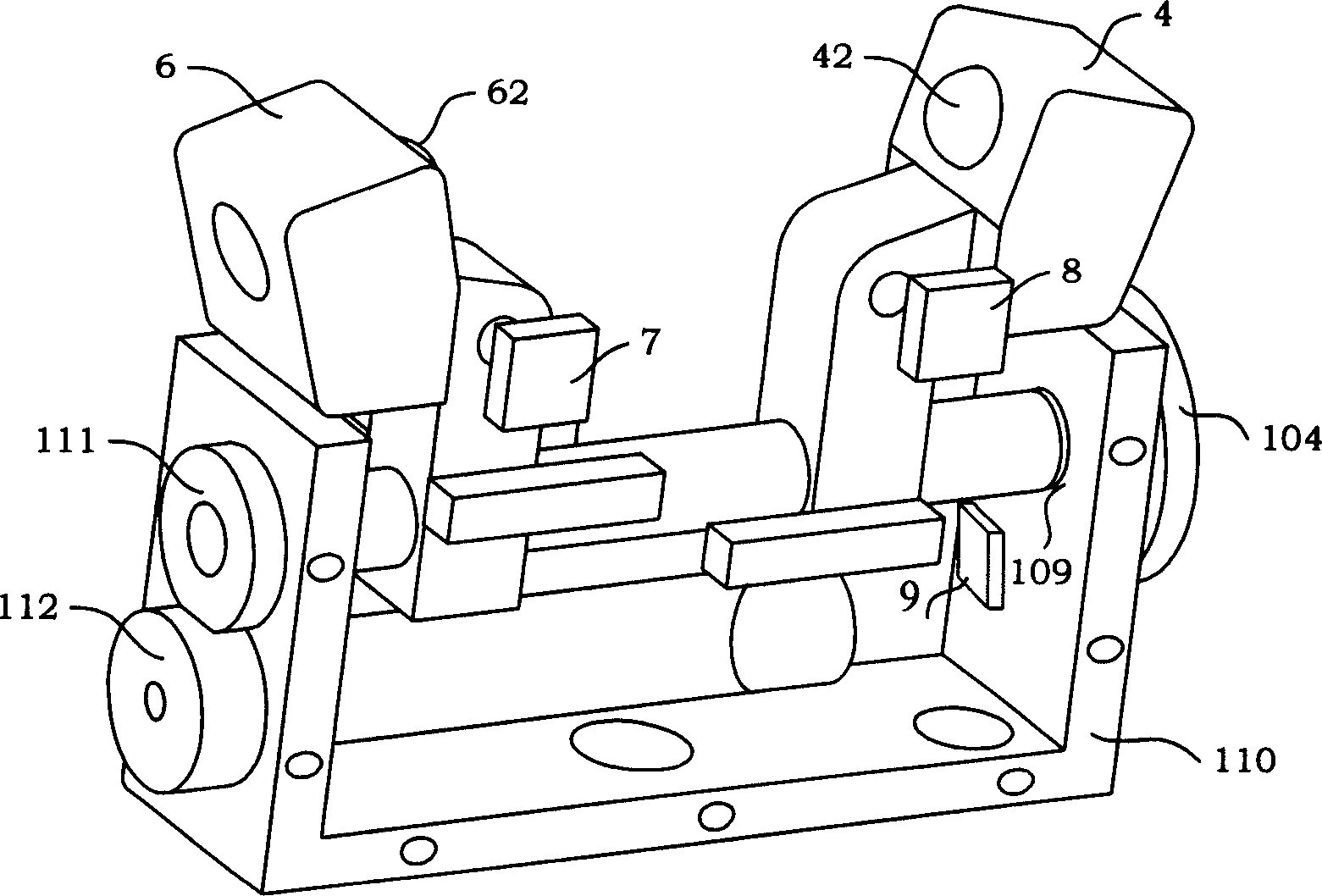

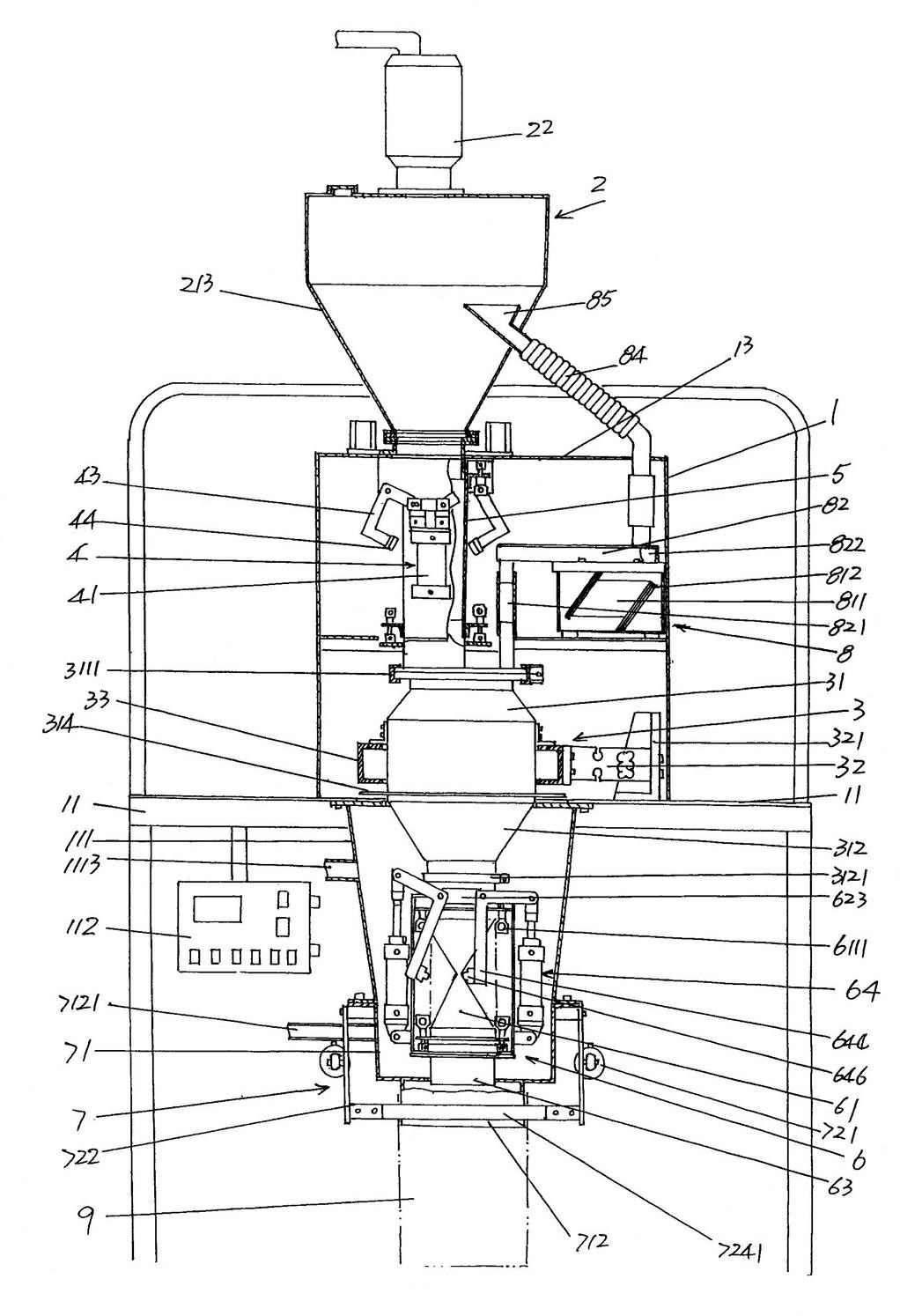

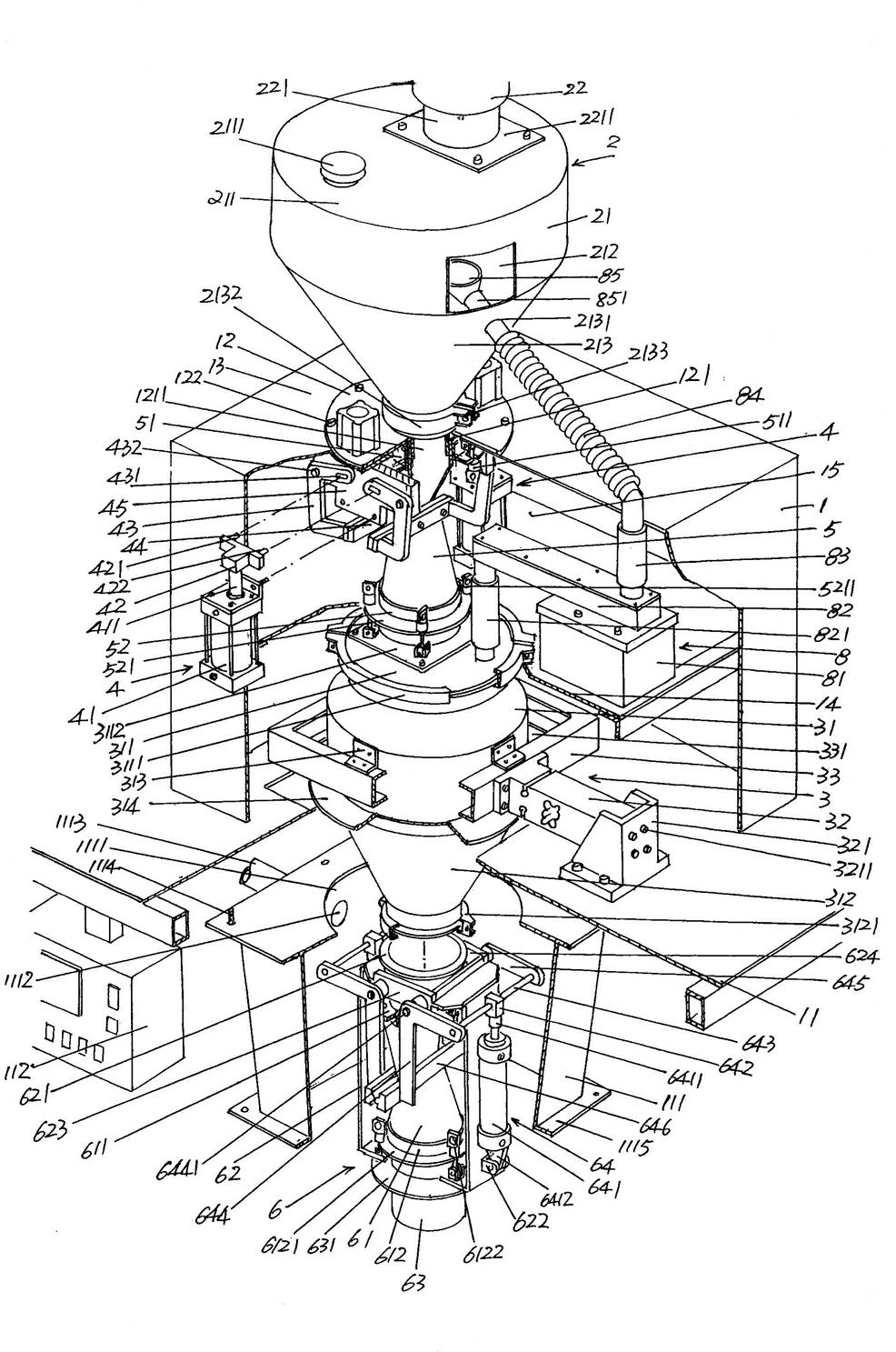

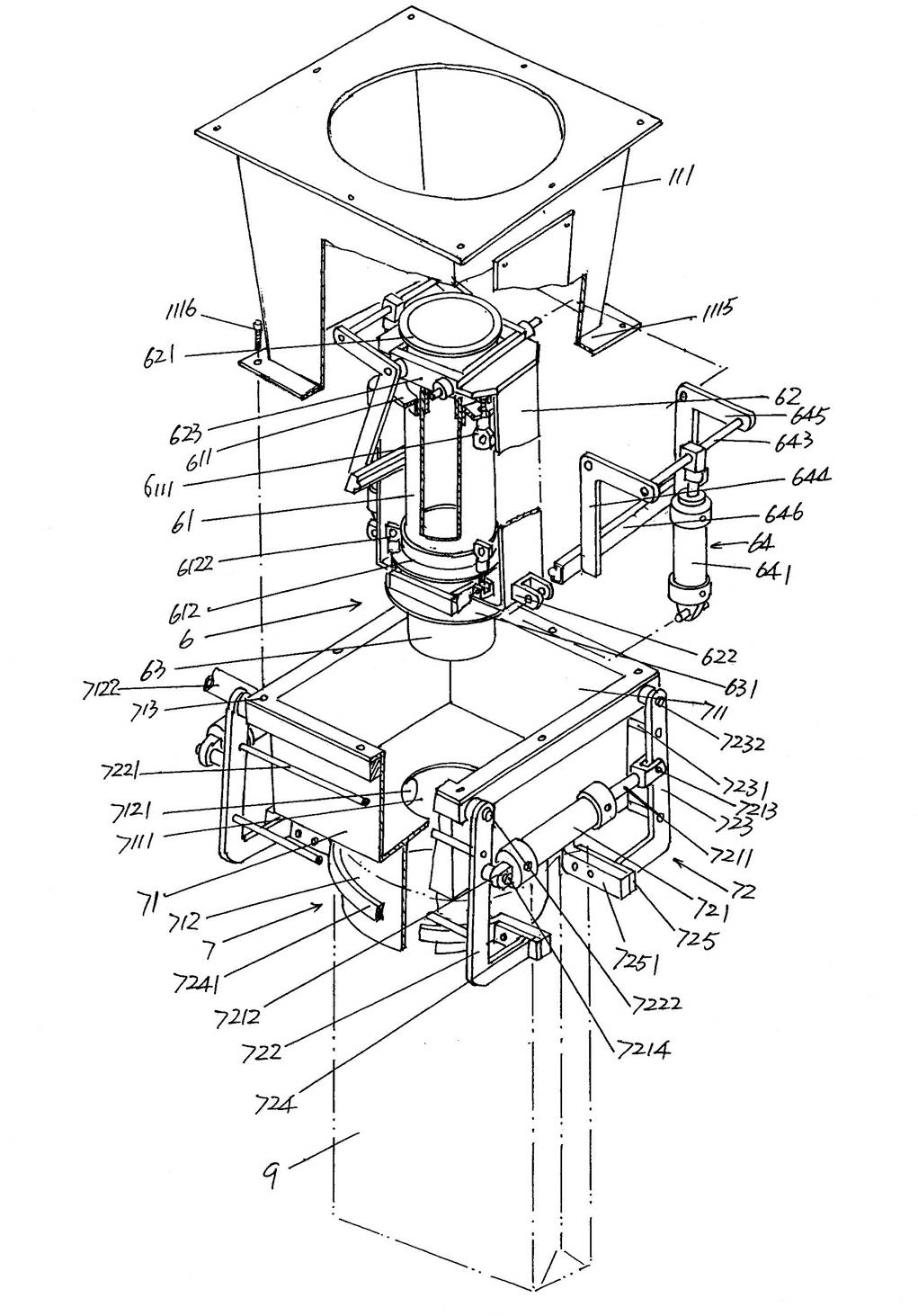

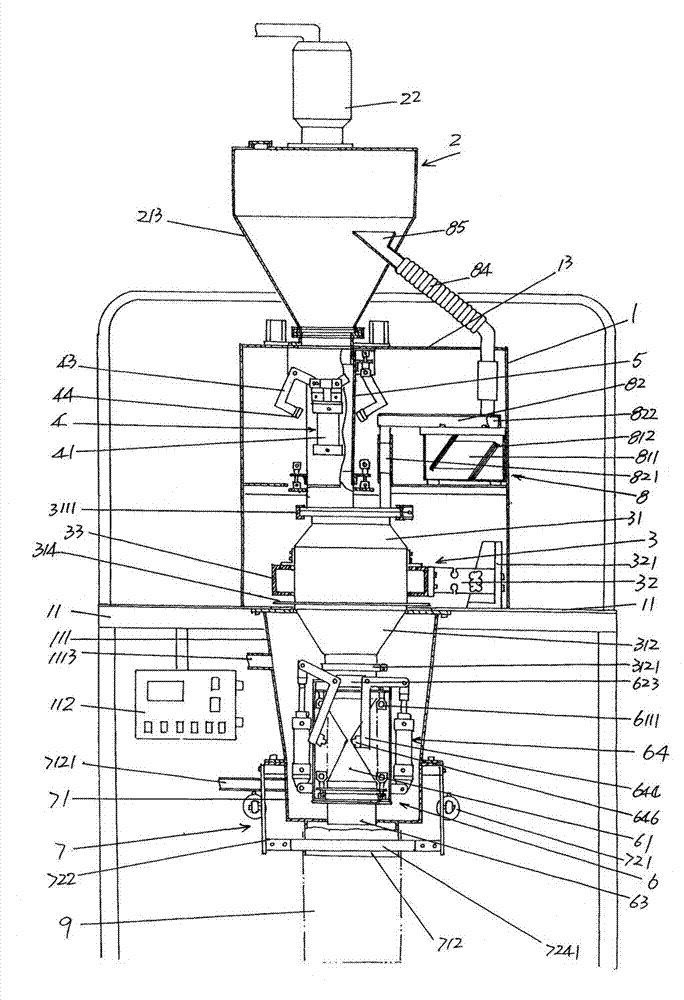

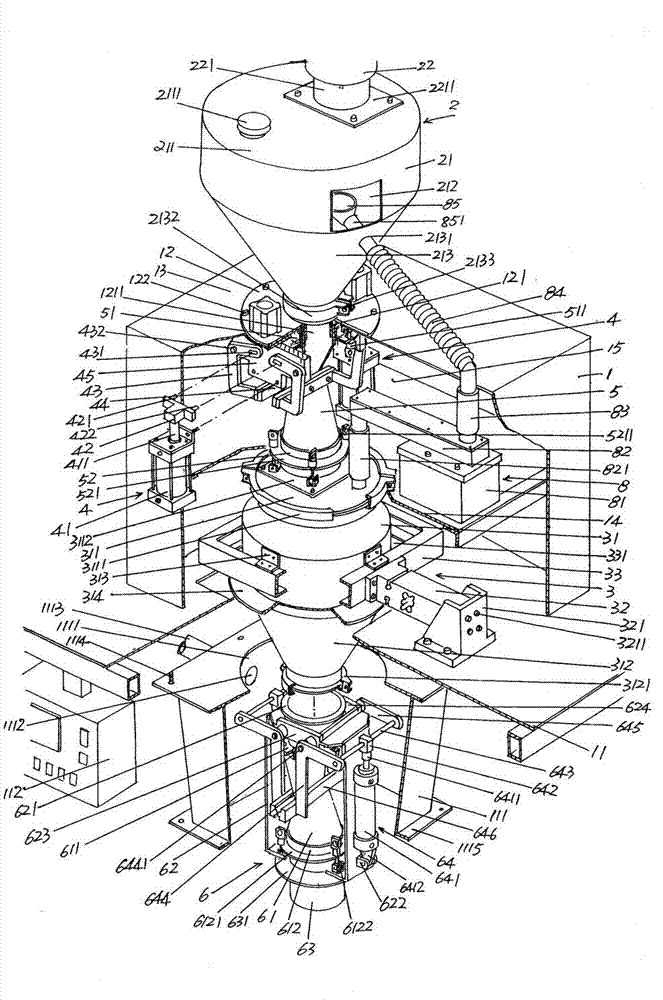

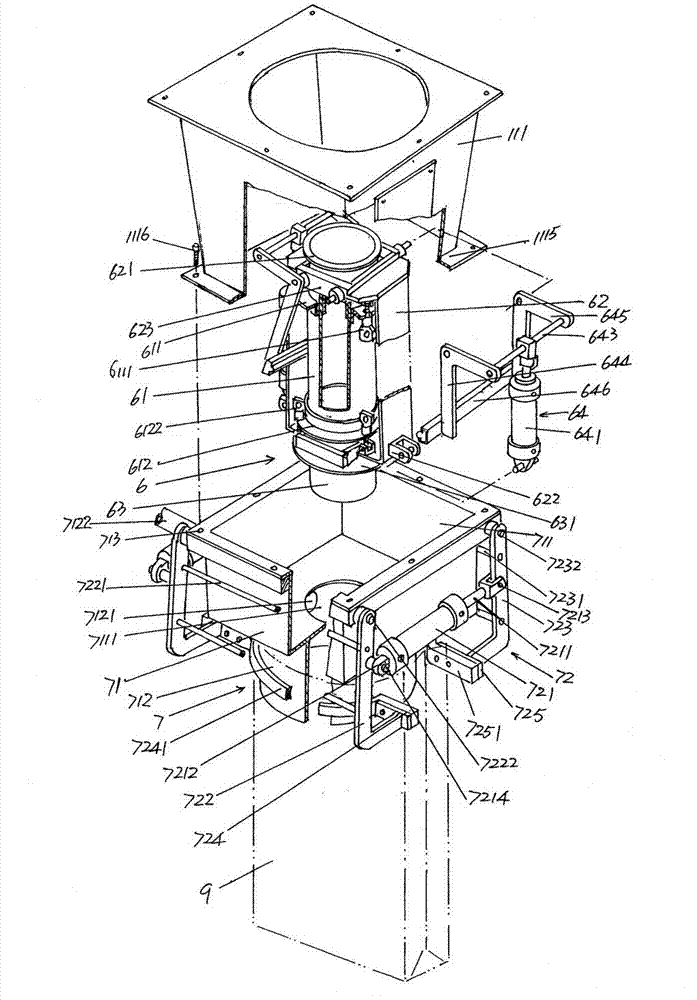

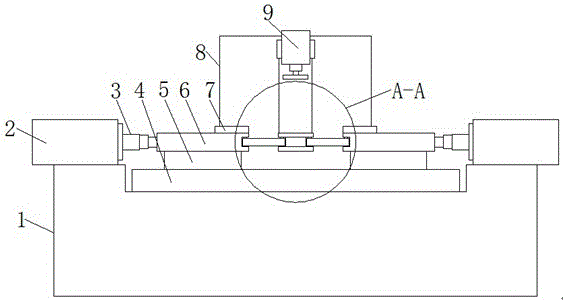

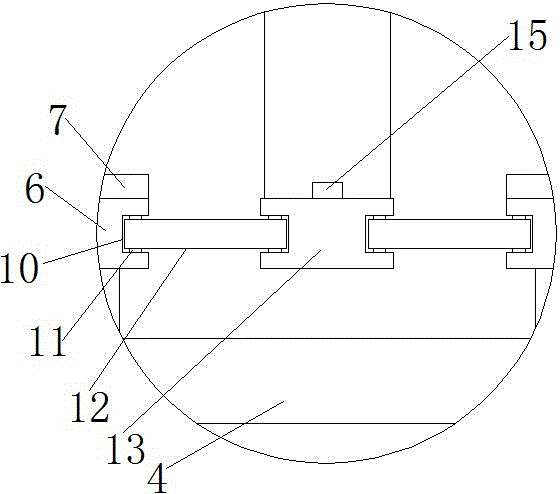

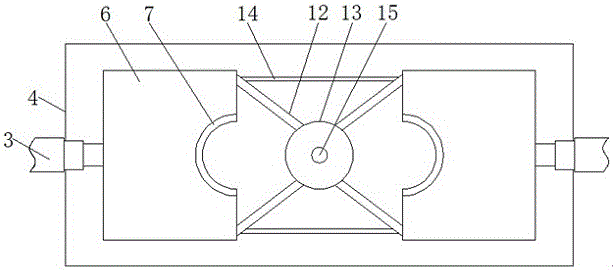

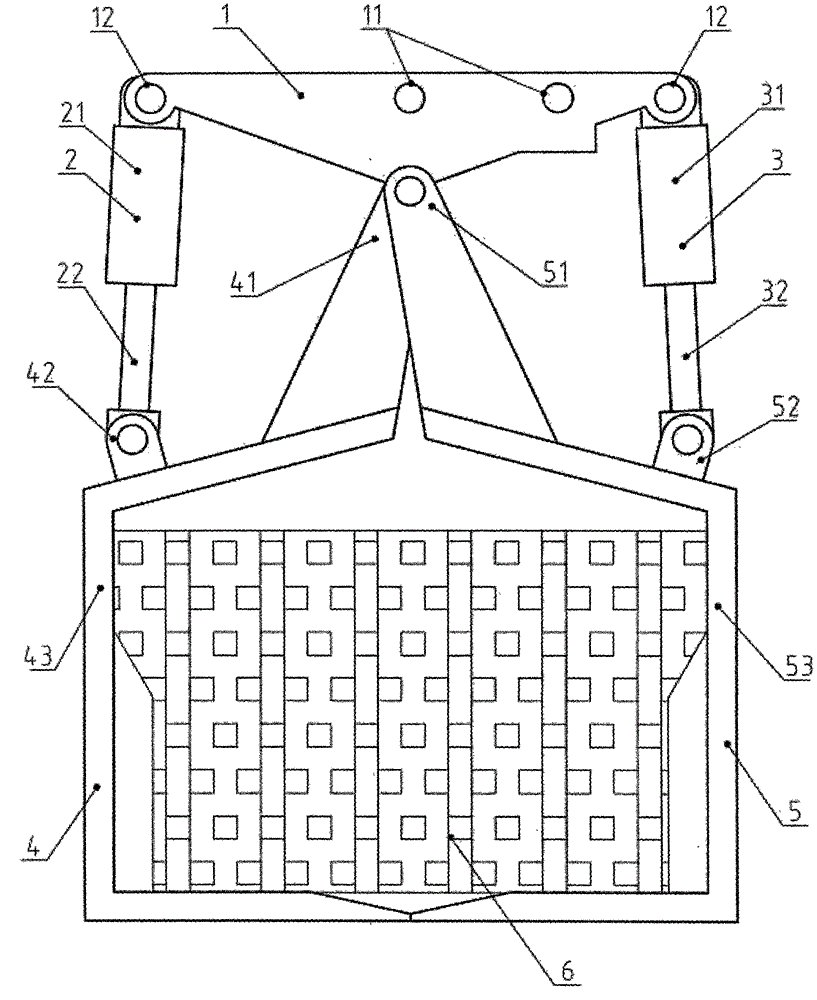

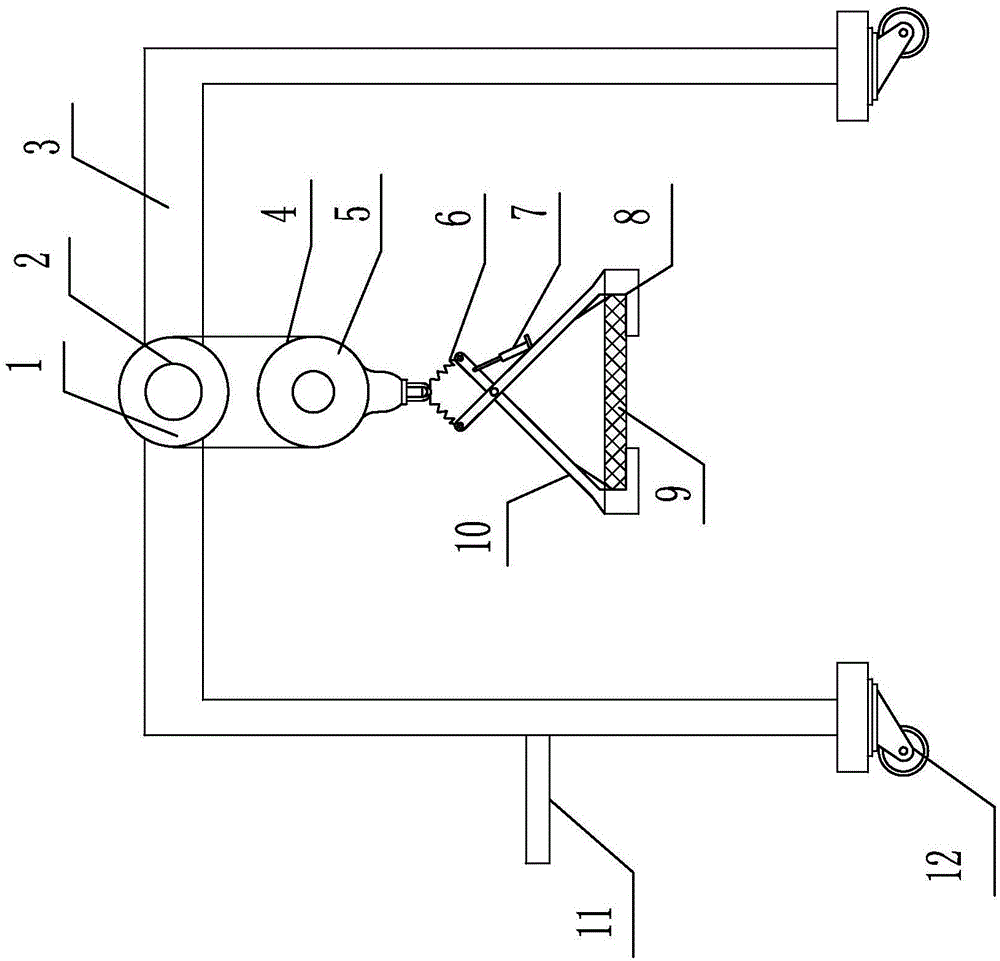

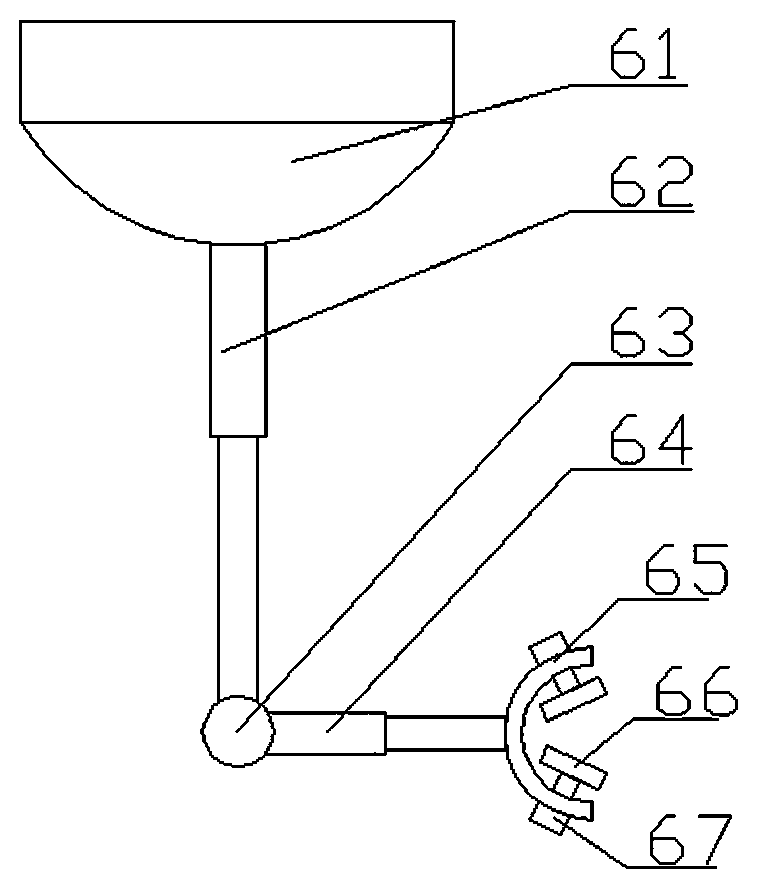

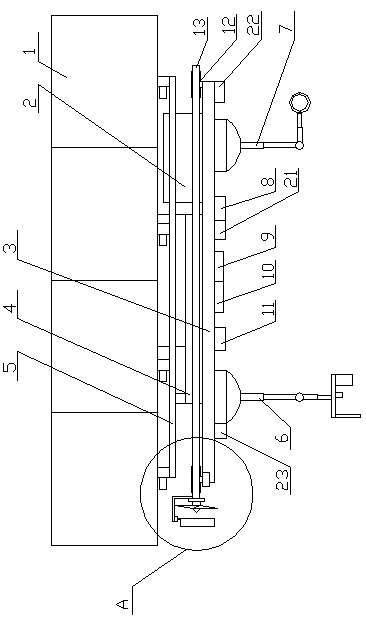

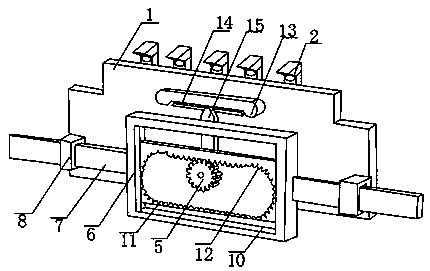

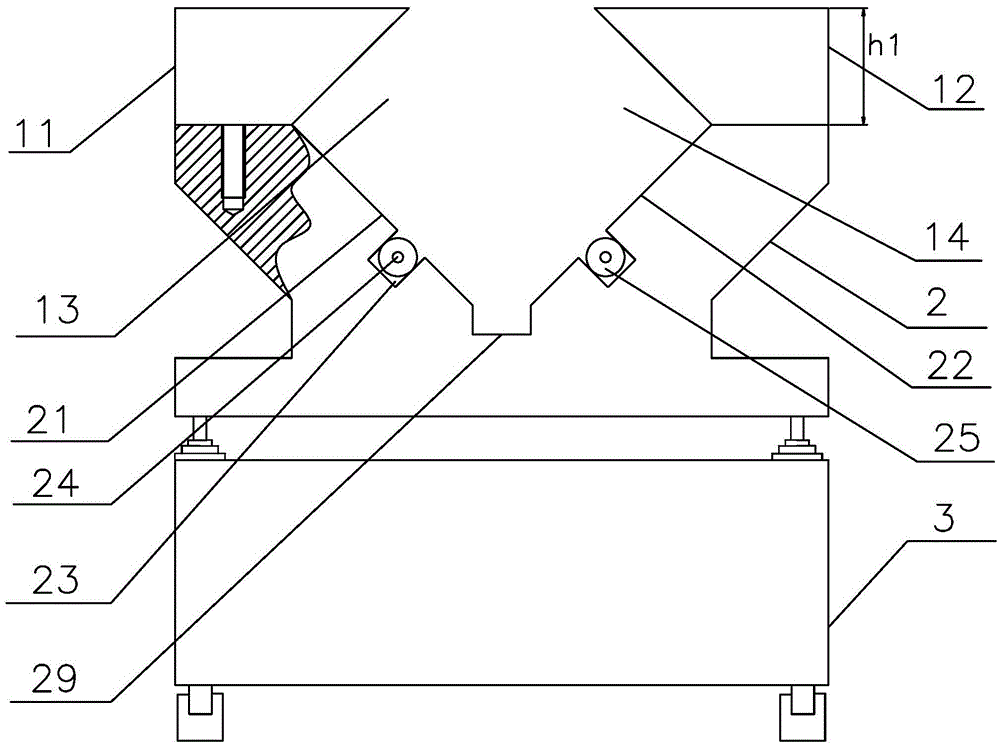

Discharged material filling bag-clamping mechanism for full-automatic quantitative packaging machine

InactiveCN102398701ASimple structureFlexible clampingPackaging automatic controlSolid materialStructural engineeringIndustrial engineering

The invention discloses a discharged material filling bag-clamping mechanism for a full-automatic quantitative packaging machine, and belongs to the technical field of packaging machines. The full-automatic quantitative packaging machine comprises a frame with a frame platform, a material storage mechanism, a weighing feed pipe, a weighing feed pipe clamping mechanism, a weighed material discharging mechanism and a material compensation mechanism; and the discharged material filling bag-clamping mechanism comprises a discharged material filling bag-clamping mechanism body comprising a rectangular body material receiving box and a pair of packaging bag opening clamping devices, wherein the material receiving box has a material receiving box cavity; the bottom of the material receiving box cavity is provided with a matched hole; a packaging bag opening sleeve extends outside the bottom wall of the material receiving box; one of the pair of packaging bag opening clamping devices is arranged on the outer wall of one side of the material receiving box; and the other of the pair of packaging bag opening clamping devices is arranged on the outer wall of the other side of the material receiving box. The invention has the advantages that: the discharged material filling bag-clamping mechanism is butted with the weighed material discharging mechanism through the material receiving box; and packaging bags are clamped or released flexibly; and the structure is simple.

Owner:常熟市贝普包装机械有限公司

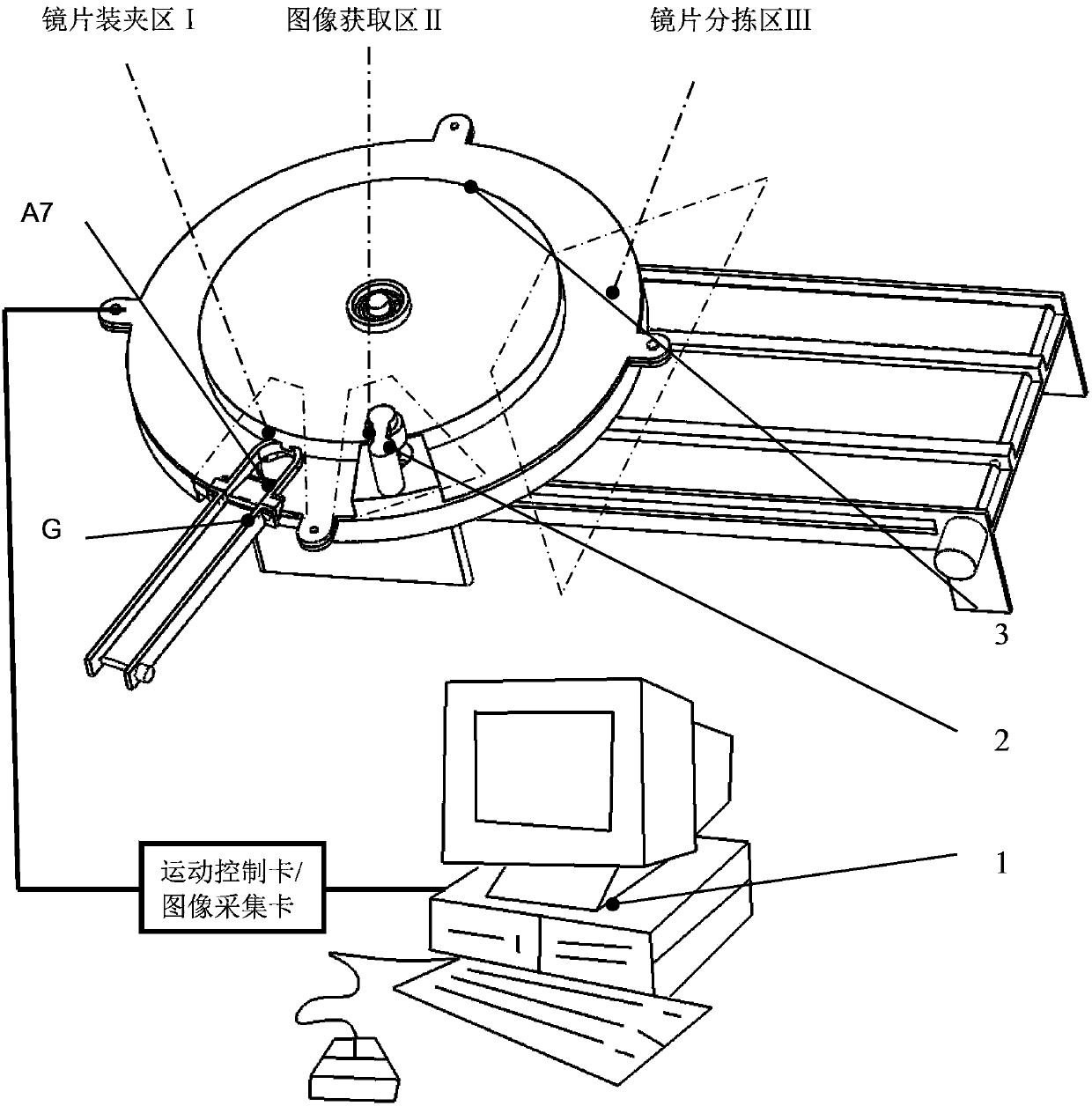

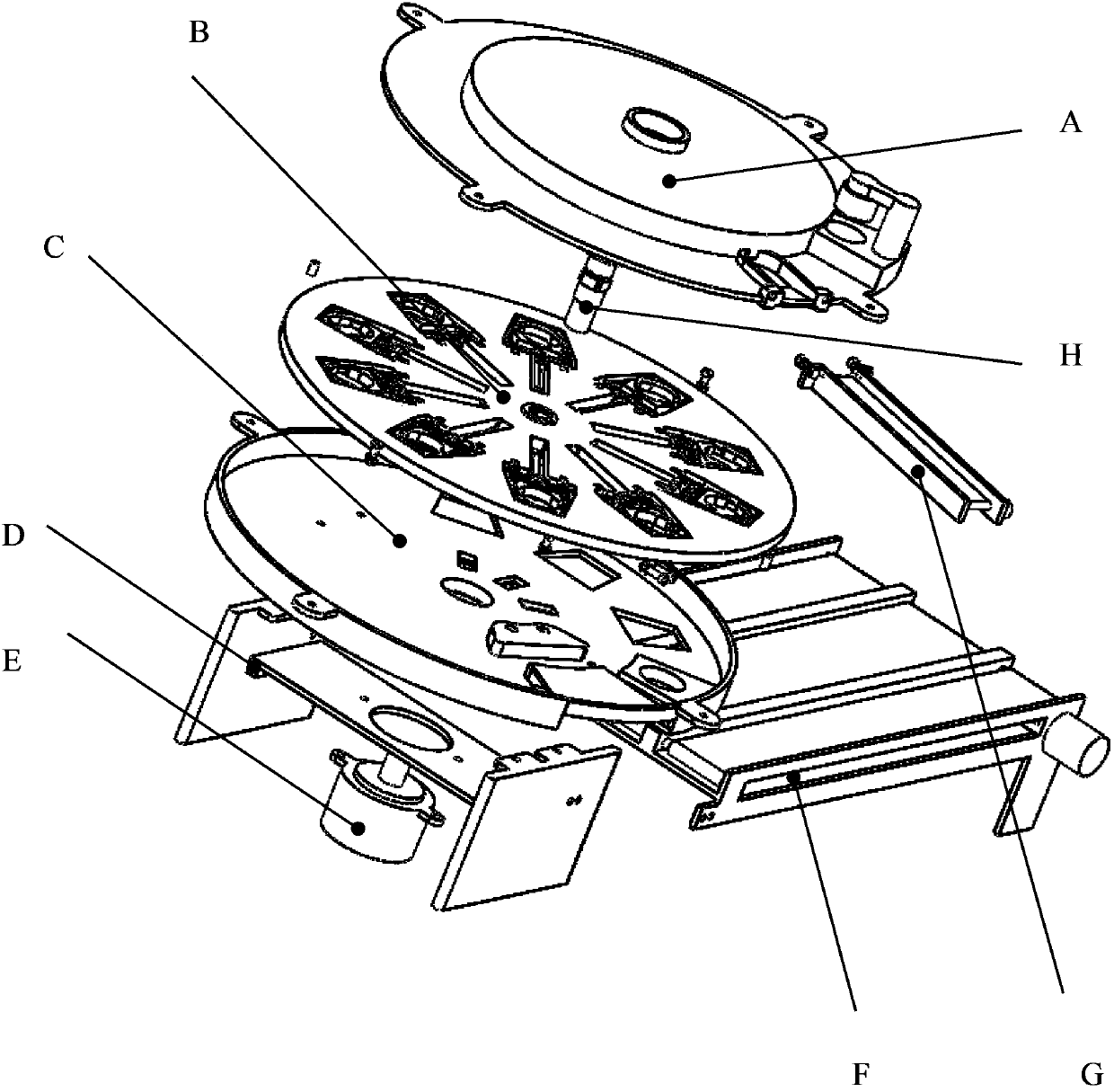

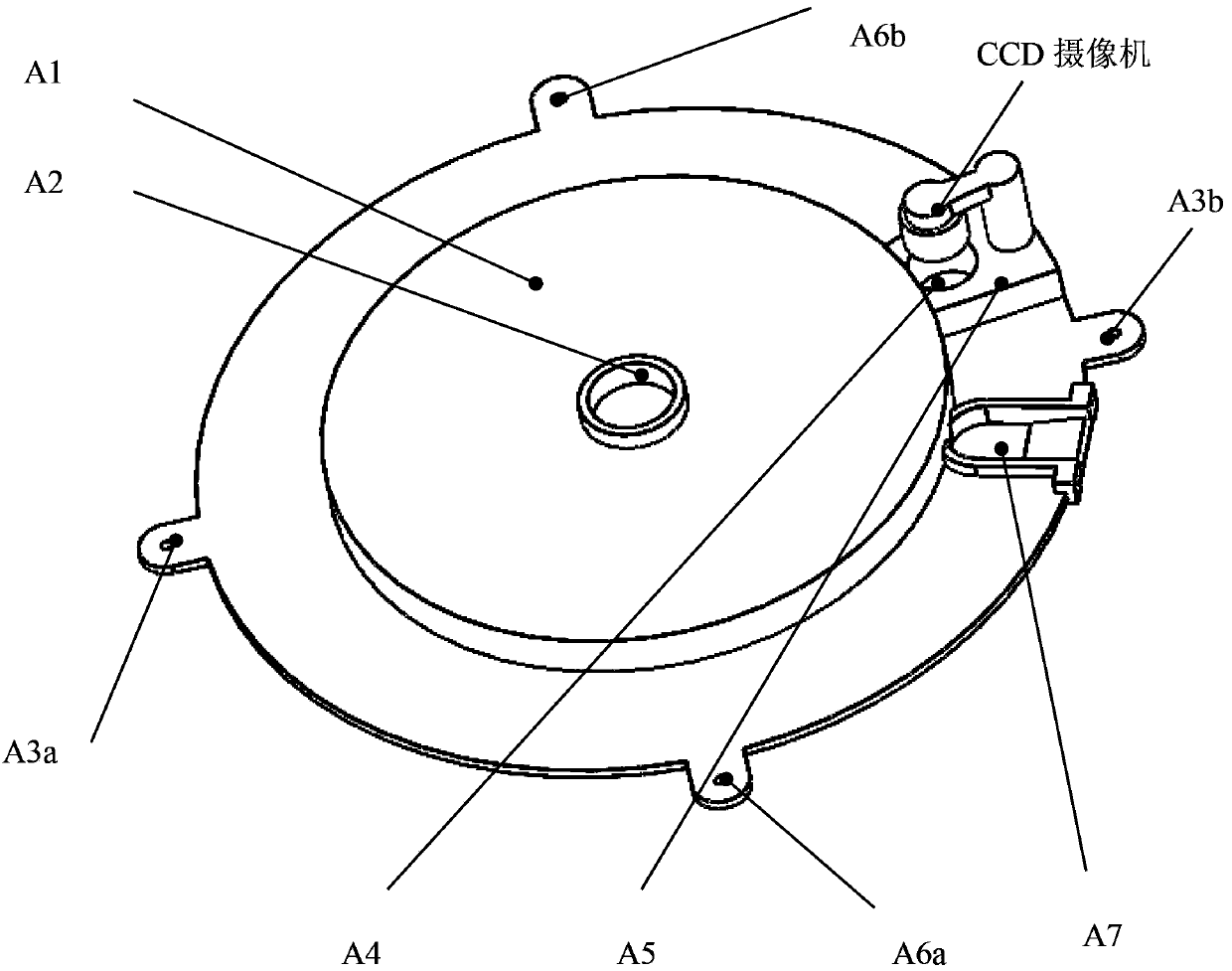

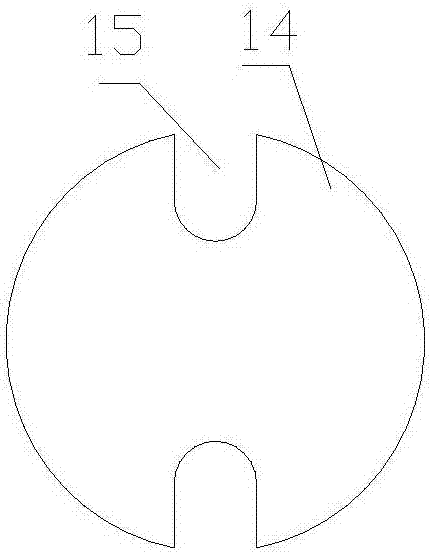

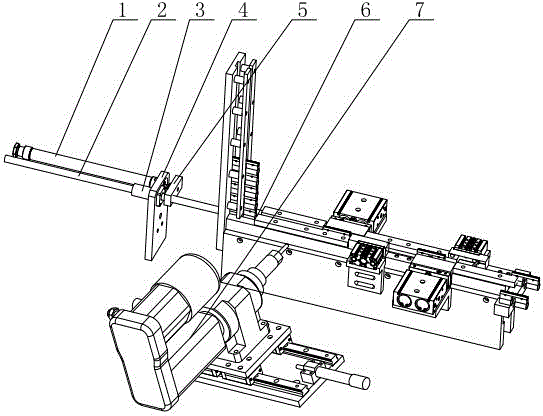

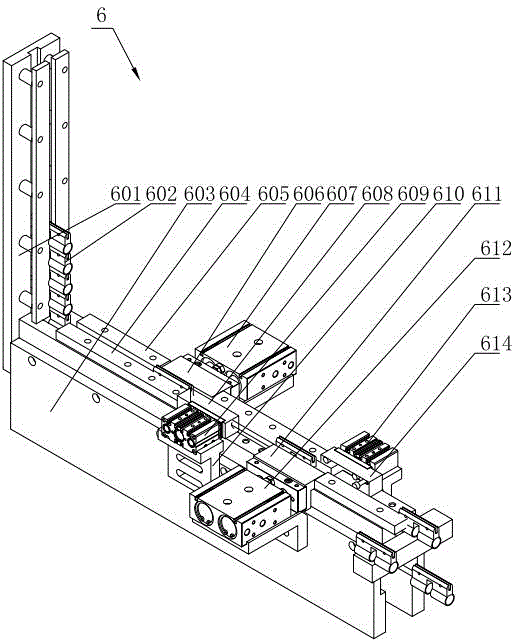

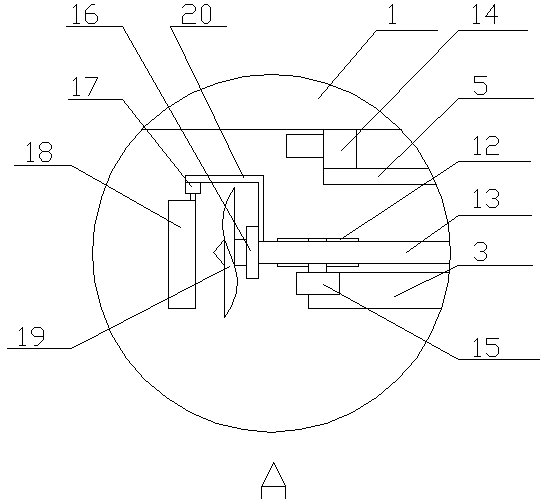

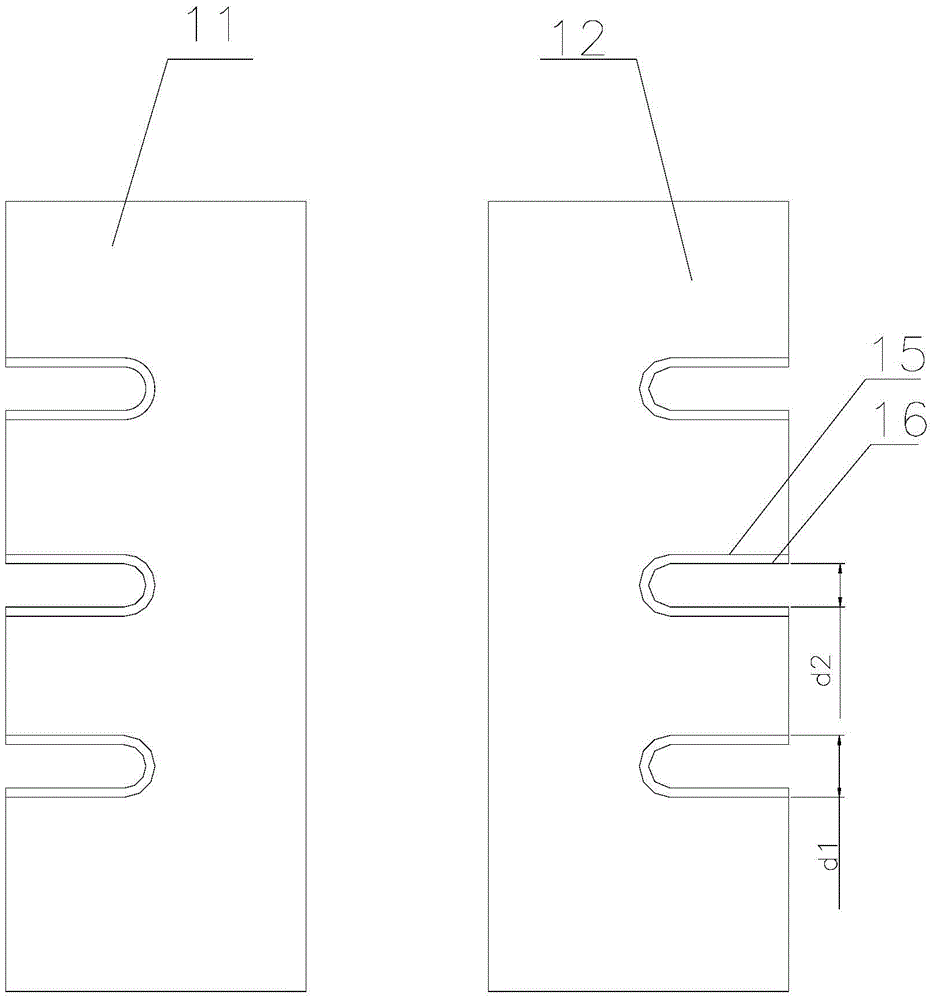

Three-disc eyeglass sorting system

ActiveCN103418555ACompact structureStrong station expandabilitySortingImaging processingFinger structure

The invention discloses a three-disc eyeglass sorting system and belongs to the technical field of electromechanical integration. The eyeglass sorting system adopts a three-disc sorting mechanism, adopts an industrial PC as an image processing center and the control center of the three-disc sorting mechanism, and adopts a CCD camera and the like as image acquisition devices, wherein the three-disc sorting mechanism comprises a top disc part, a main disc part, a control disc part and an auxiliary transport device. The three-disc eyeglass sorting system has the characteristics of high man-machine interactivity, stability and simplicity in control. According to the eyeglass sorting system, the whole system is high in continuity, and the image acquisition of an eyeglass, the sorting of the former eyeglass and the clamping of the latter eyeglass are realized synchronously. The eyeglass transfer manipulators of the eyeglass sorting system has the advantages that the clamping force and the stroke of fingers can be adjusted flexibly, and the finger structures of two V-shaped blocks can be used for clamping eyeglasses of various specifications. The automatic transporting and sorting device of the eyeglass sorting system can transport eyeglasses to an eyeglass clamping area one by one; a number of eyeglasses can be placed in the automatic transporting and sorting device once; reminding signals of eyeglass shortage can be fed back to the control center.

Owner:指南者品牌管理(苏州)有限公司

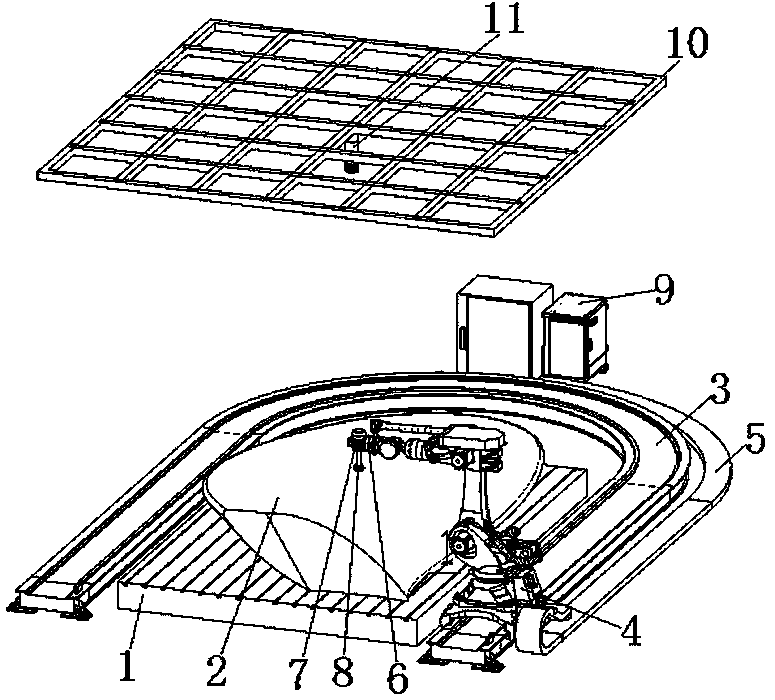

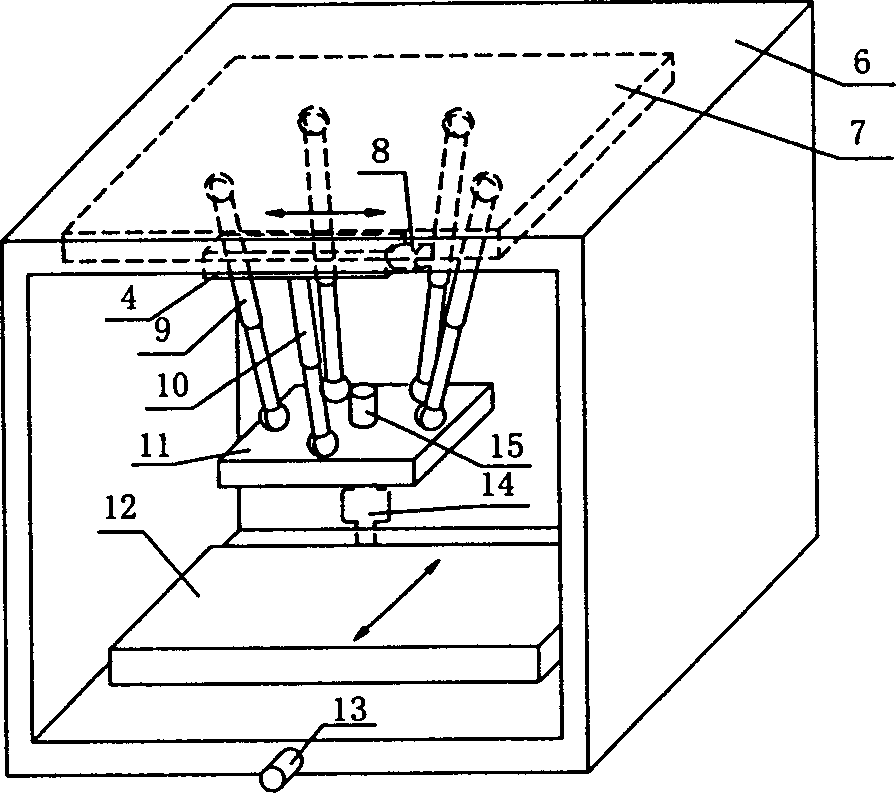

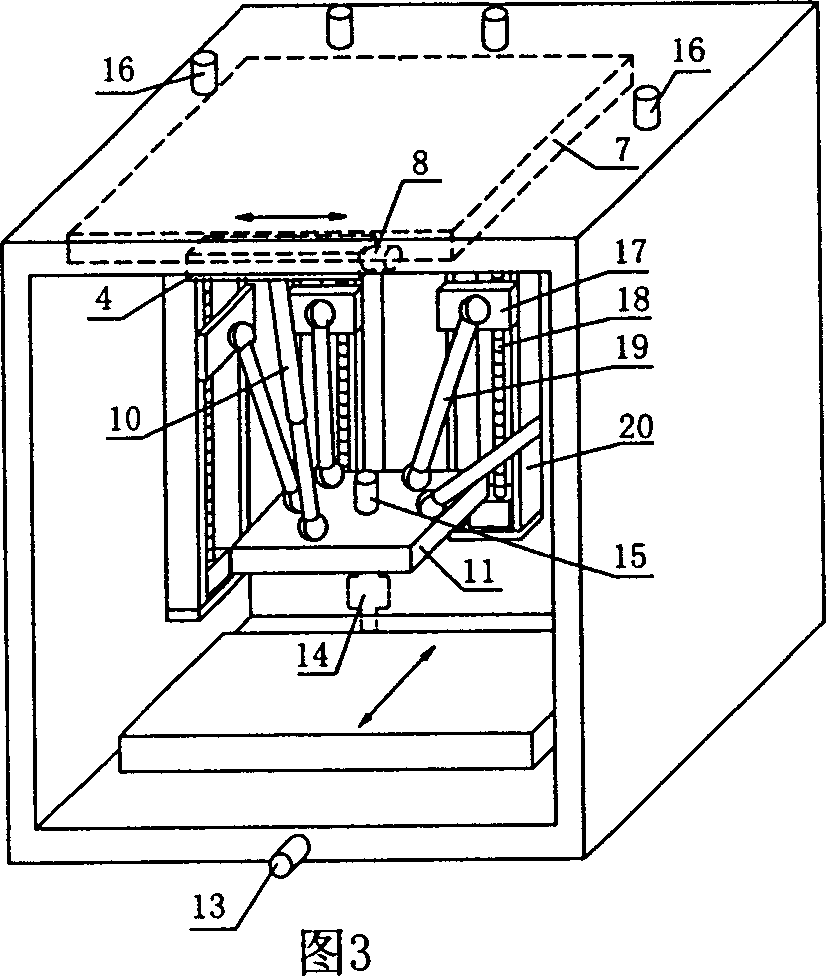

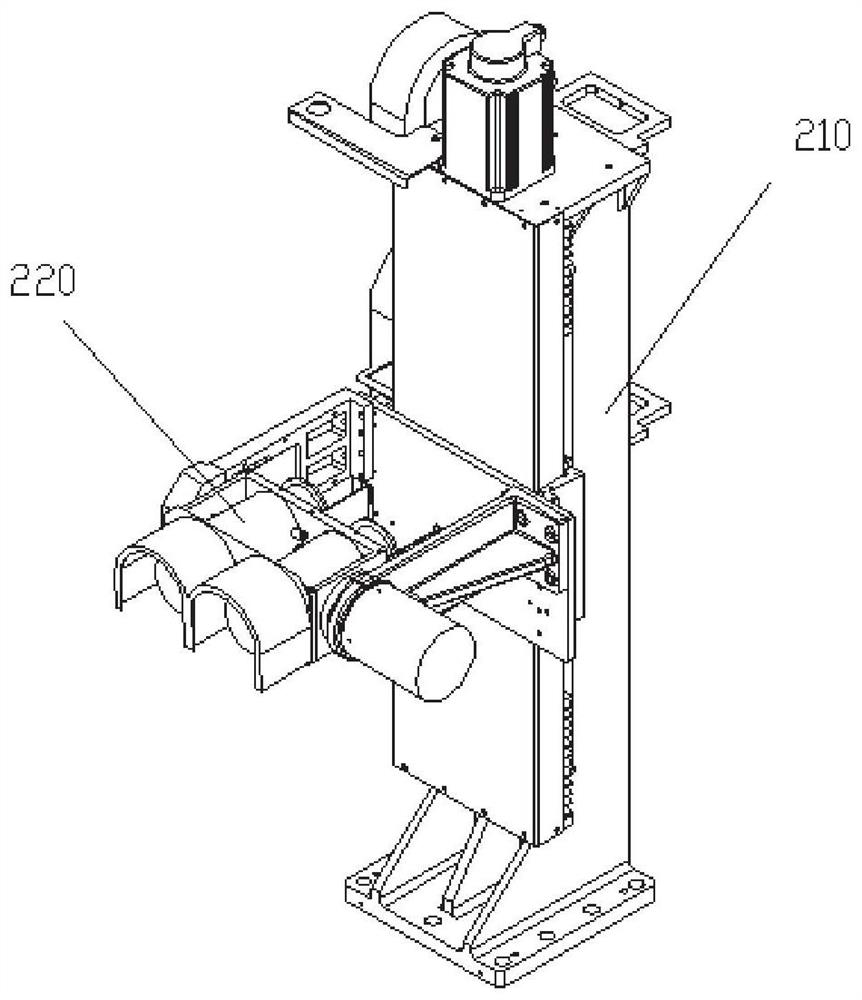

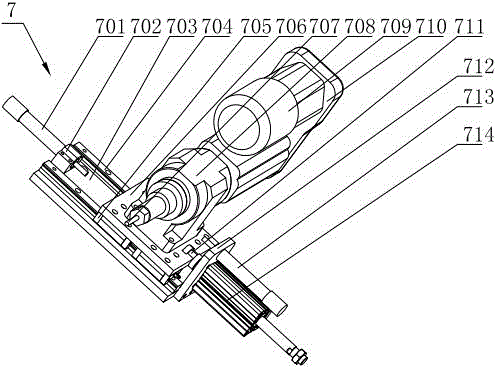

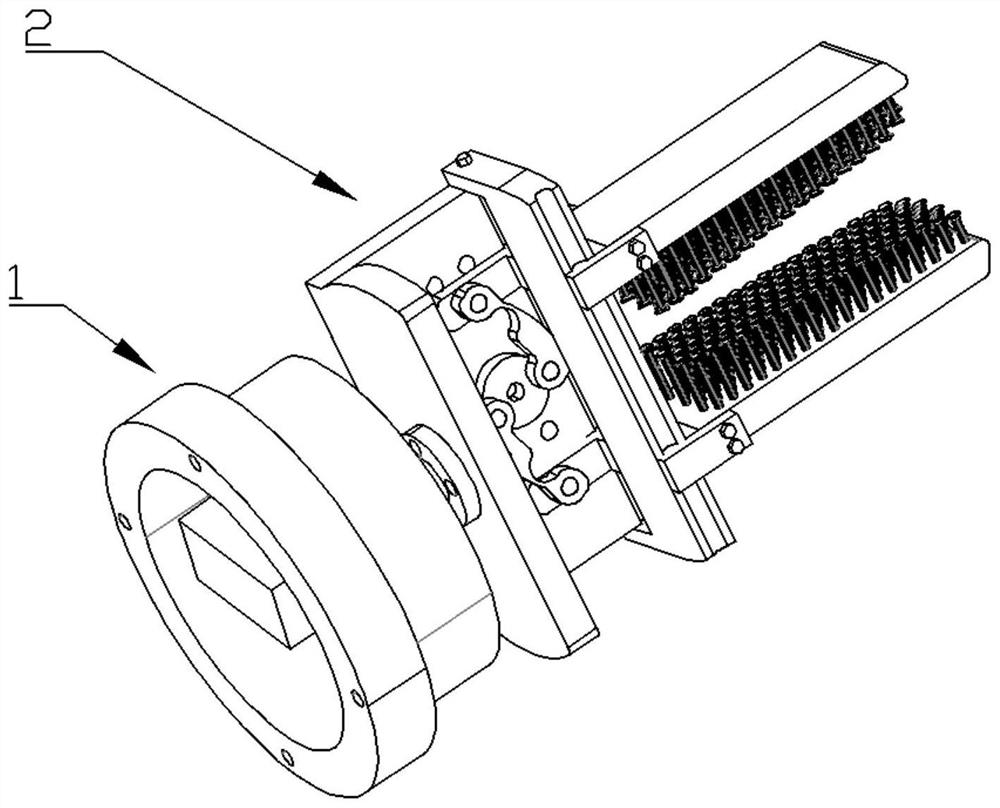

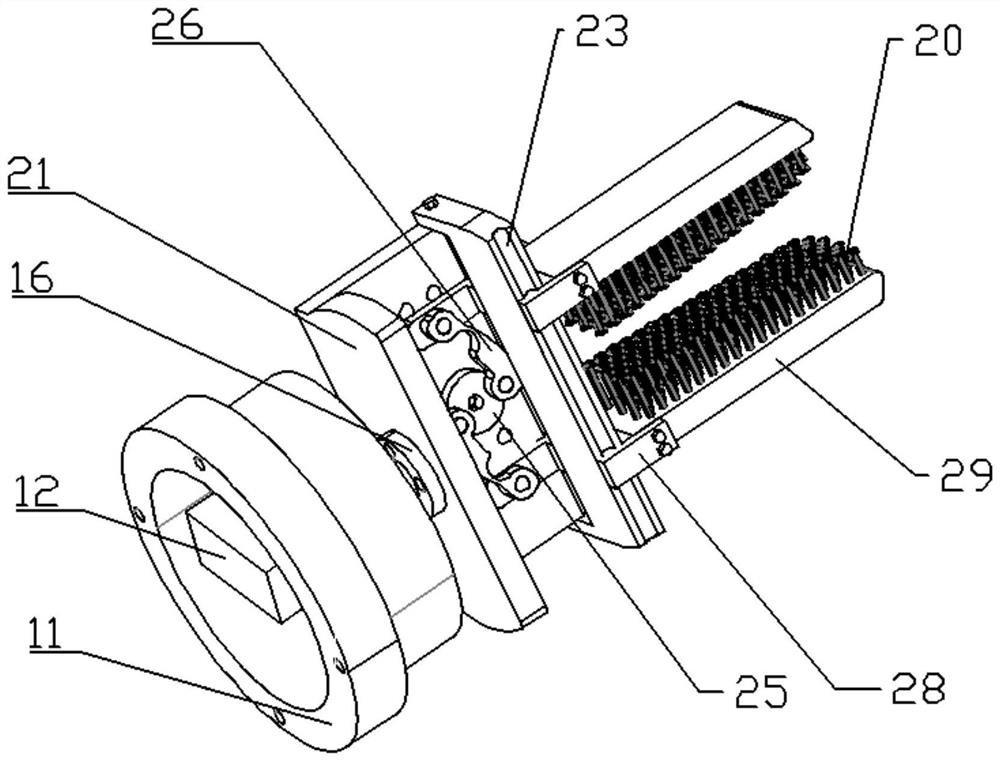

Automatic polishing system for water turbine blades

InactiveCN107866717AEffective sandingImprove sanding qualityAutomatic grinding controlGrinding machinesWater turbineControl system

The invention discloses an automatic polishing system for water turbine blades. The automatic polishing system for the water turbine blades comprises a clamping platform, an industrial robot, a polishing control system and a visual image system, and wherein the clamping platform is used for positioning and clamping the water turbine blade to be polished; the industrial robot is provided with a polishing mechanism, and the industrial robot is controlled by a polishing control system and is used for polishing the blade clamped on the clamping platform; and the polishing control system directs atthe current polishing surface of the blade to be polished and is used for planning a corresponding polishing path, then the planned polishing path is converted into a polishing action control programof the industrial robot and is conveyed to the industrial robot, and the visual image system is used for detecting the polishing quality and feeding back the polishing quality to the polishing control system. According to the automatic polishing system for the water turbine blades, the surface of the impact-type water turbine blade formed by precision casting can be provided with an automatic, intelligent and unified polishing treatment; and thus the polishing quality of the surface of the blade can be improved accurately and reliably.

Owner:SICHUAN ENG TECHN COLLEGE

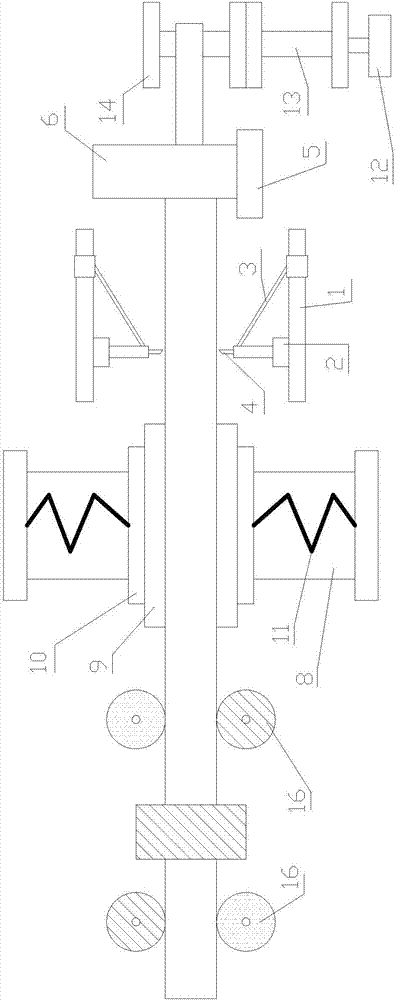

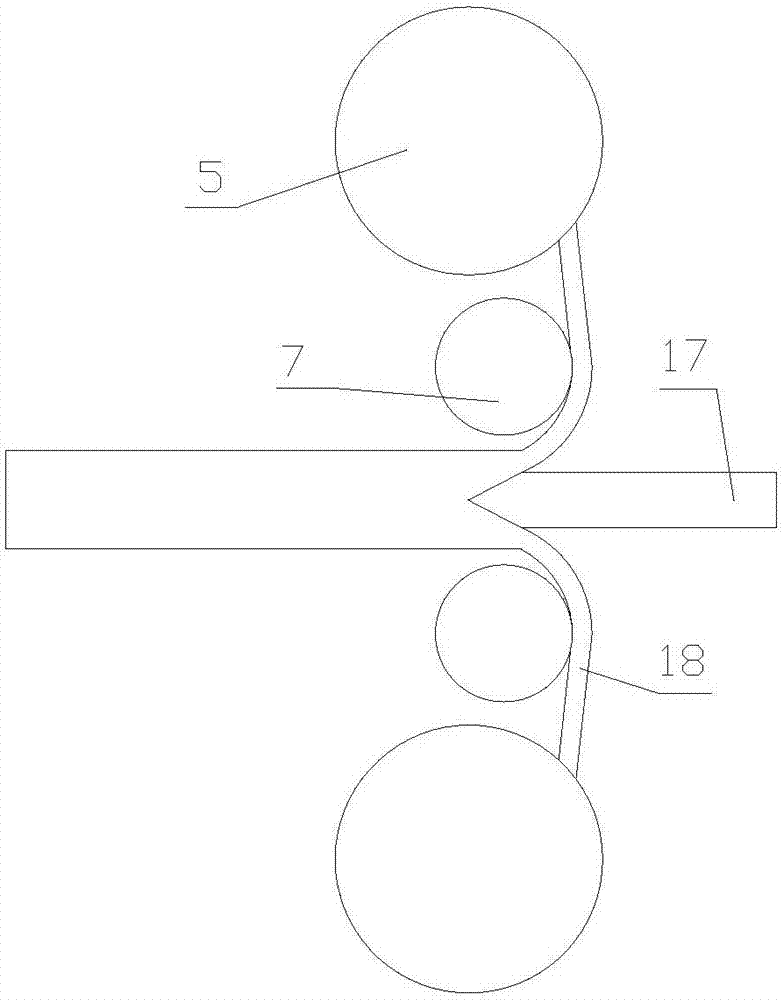

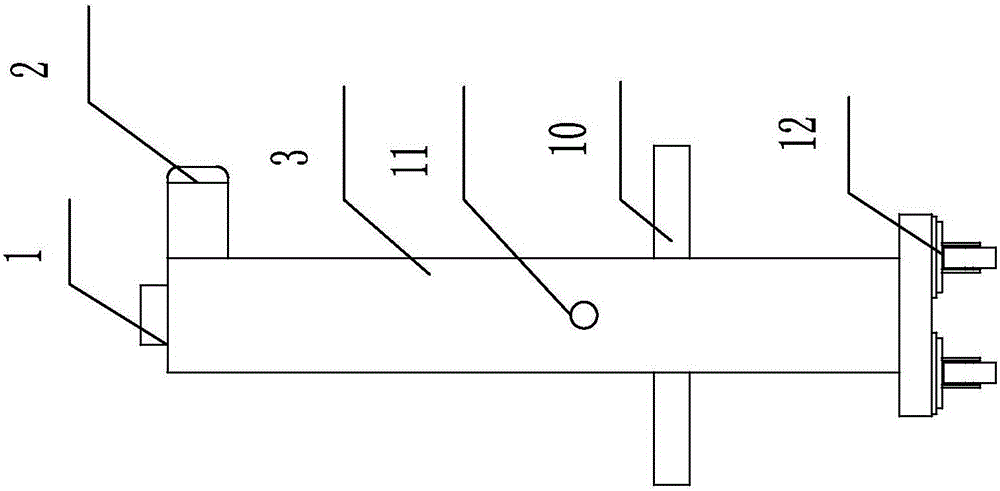

Cable processing equipment

InactiveCN107481814AImprove flexibilityGuaranteed peeling effectBasic electric elementsApparatus for removing/armouring cablesInsulation layerEngineering

The invention discloses cable processing equipment comprising a clamping mechanism used for clamping a cable, a processing mechanism used for removing an insulation layer on the cable, and a first recycling mechanism used for recycling the cable core; the processing mechanism is arranged between the clamping mechanism and the first retrieve mechanism, and comprises N processing units; the processing unit comprises a crossbar having a cylinder and a connecting rod; the cylinder output end is provided with a blade; the cylinder drives the blade to radially move along the cable; the cylinder is hinged to the crossbar; one end of the connecting rod is hinged to the cylinder, and the other end is connected with the crossbar in a slide manner. The cable processing equipment uses a flattening unit to properly extrude and flatten the cable, thus flattening the cable bending portions, and effectively removing the cable skin; the processing mechanism can flexibly enable the blade to destroy the cable insulation layer according to different angles, thus ensuring the peeling effect.

Owner:TONGLING CITY TONGDOU SPECIAL CABLE CO LTD

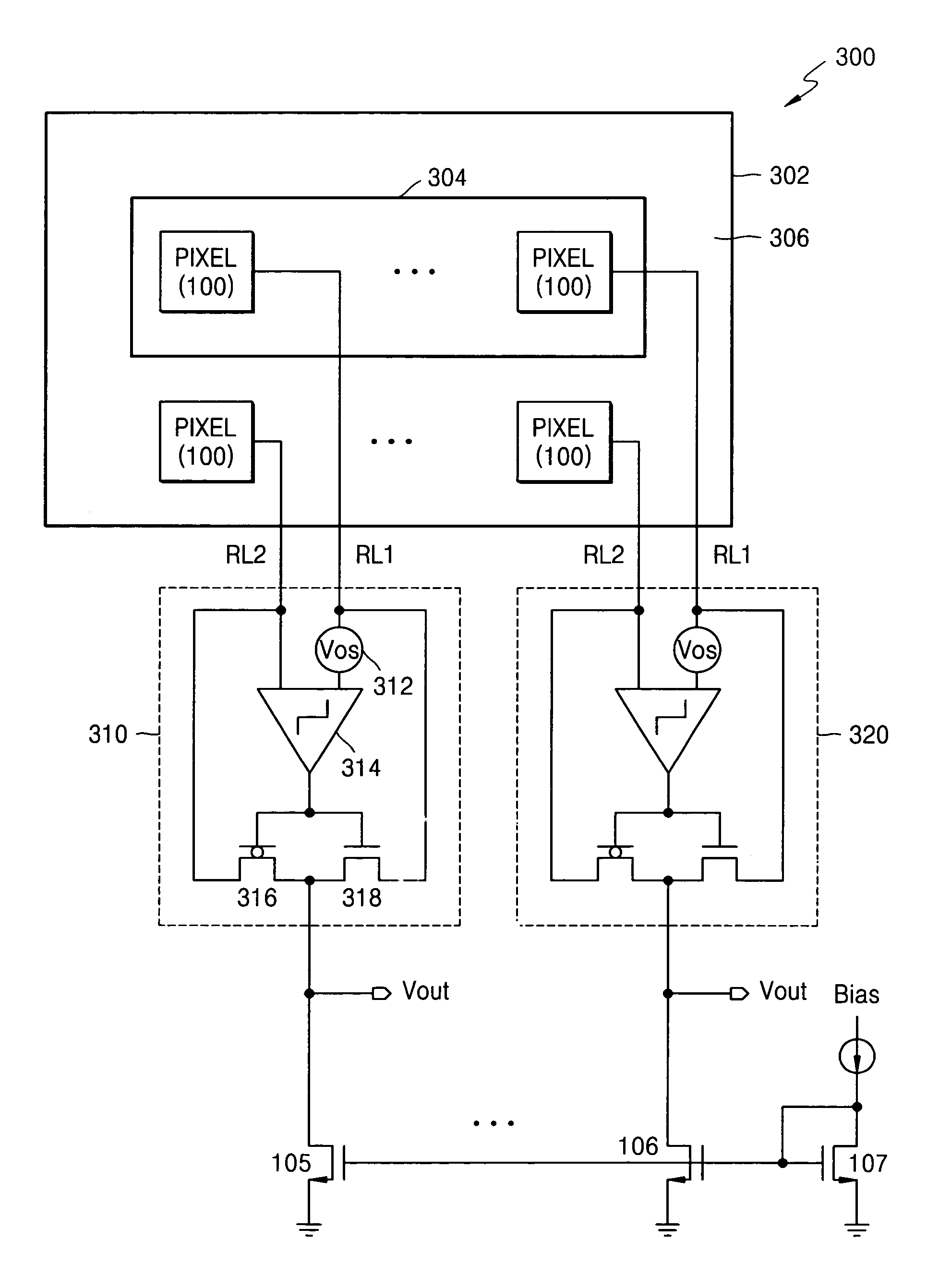

Apparatus and method for clamping reset voltage in image sensor

InactiveUS7423680B2Accurate accountingFlexible clampingTelevision system detailsTelevision system scanning detailsEngineeringVoltage

For clamping a reset voltage within an image sensor, an active pixel generates a first reset voltage, and an optical black pixel generates a second reset voltage. In addition, a reset voltage selector selects one of the first and second reset voltages as a selected reset voltage. Such a selected reset voltage is generated separately for each column of the array of pixels in the image sensor for more accurately and flexibly accounting for fabrication variations.

Owner:SAMSUNG ELECTRONICS CO LTD

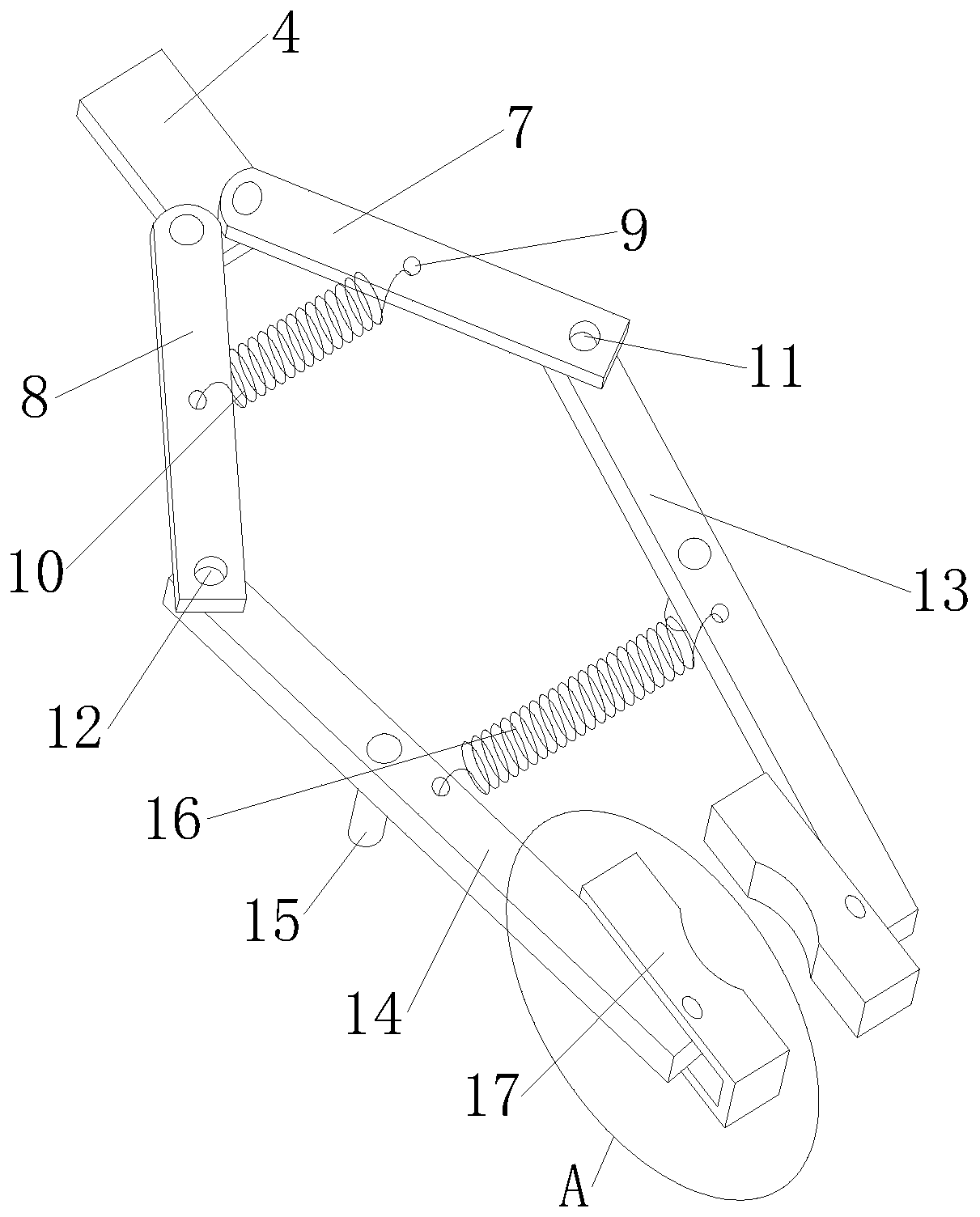

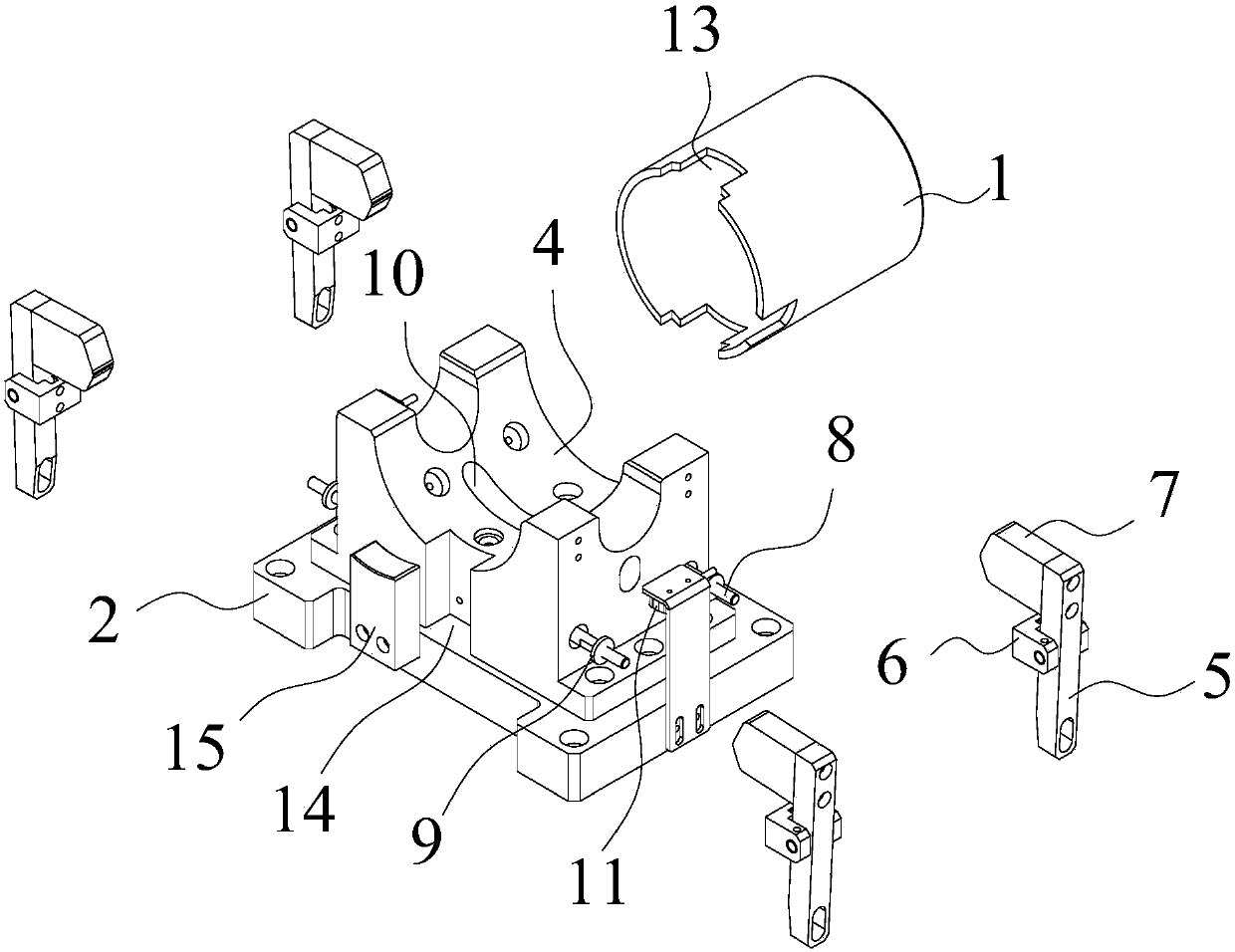

Cylinder clamping jaw for clamping-screwing warhead

InactiveCN109867138AImprove stabilityAvoid Jaw TwistingConveyor partsHinge angleArchitectural engineering

The invention discloses a cylinder clamping jaw of a clamping-screwing warhead. The cylinder clamping jaw comprises a mounting bottom plate, a backing plate is fixedly mounted at one end of the upperside of the mounting bottom plate, a cylinder is fixedly mounted at the upper end of the backing plate, a telescopic rod is arranged at the front end of the cylinder, and a first connecting arm and asecond connecting arm are movably connected to the upper end of the telescopic rod through bolts. The cylinder clamping jaw of the clamping-screwing warhead can improve the stability of the hinge connection between connecting rods and the connecting arms, the stable connection between the connecting rods and the connecting arms is maintained at all times, the extension and contraction of the telescopic rod can be limited and controlled, the vertical extension and contraction of the telescopic rod are maintained to avoid the distortion of a clamping jaw caused by the bending of extension and contraction of the telescopic rod under the action of external force, a groove is formed in one end of the clamping jaw and movably connected with a first connecting rod and a second connecting rod through rotating shafts, so that the clamping jaw can be flexibly clamped, the bottom ends of the first connecting rod and the second connecting rod abut against the inner wall of the groove, the clampingjaw is not affected by the size of a clamped object, so that the clamping is better realized.

Owner:安徽玄离智能科技股份有限公司

Discharged material filling bag-clamping mechanism for full-automatic quantitative packaging machine

InactiveCN102398701BSimple structureFlexible clampingSolid materialPackaging automatic controlStructural engineeringIndustrial engineering

The invention discloses a discharged material filling bag-clamping mechanism for a full-automatic quantitative packaging machine, and belongs to the technical field of packaging machines. The full-automatic quantitative packaging machine comprises a frame with a frame platform, a material storage mechanism, a weighing feed pipe, a weighing feed pipe clamping mechanism, a weighed material discharging mechanism and a material compensation mechanism; and the discharged material filling bag-clamping mechanism comprises a discharged material filling bag-clamping mechanism body comprising a rectangular body material receiving box and a pair of packaging bag opening clamping devices, wherein the material receiving box has a material receiving box cavity; the bottom of the material receiving box cavity is provided with a matched hole; a packaging bag opening sleeve extends outside the bottom wall of the material receiving box; one of the pair of packaging bag opening clamping devices is arranged on the outer wall of one side of the material receiving box; and the other of the pair of packaging bag opening clamping devices is arranged on the outer wall of the other side of the material receiving box. The invention has the advantages that: the discharged material filling bag-clamping mechanism is butted with the weighed material discharging mechanism through the material receiving box; and packaging bags are clamped or released flexibly; and the structure is simple.

Owner:CHANGSHU BEIPU PACKING MASCH CO LTD

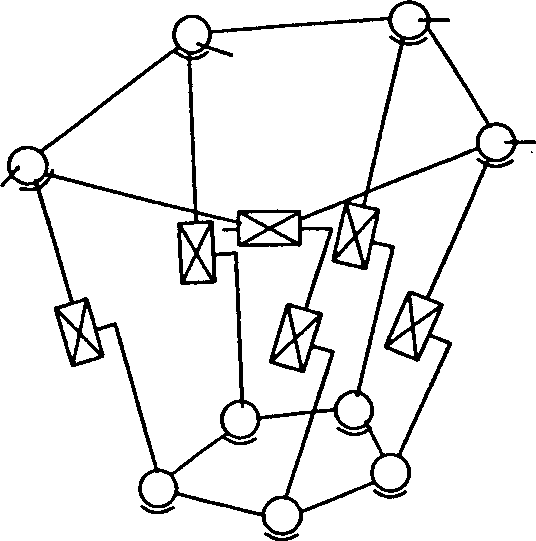

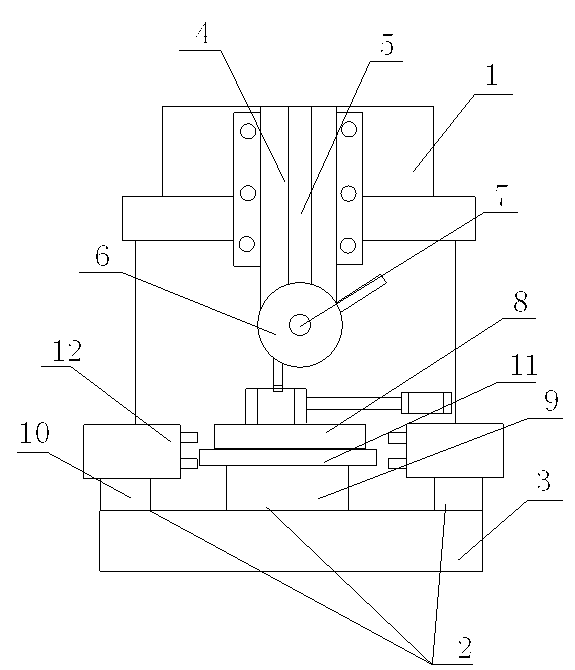

Two dimension moving three dimension rotating virtual shaft machine tool

InactiveCN1410224AIncrease stiffnessGuaranteed machining accuracyMetal working apparatusEngineeringMachine tool

A machine tool with 2D-moving and 3D-rotating virtual shafts is composed of a fixed platform, a movable platform for installing cutting tool to it, and a bench carrying workpiece to move in single direction. The fixed and movable platforms are linked via 5 legs containing moving pairs. One of 5 legs has two moving pairs and one ball joint to be linked to the movable platform. One of two moving pairs is linked with the fixed platform. Another 4 legs are linked to the fixed platform via Hooke's hinges and to the movable platform via ball joints. Its advantages are five-shaft linkage, simple structure,and high stability and precision.

Owner:SICHUAN UNIV

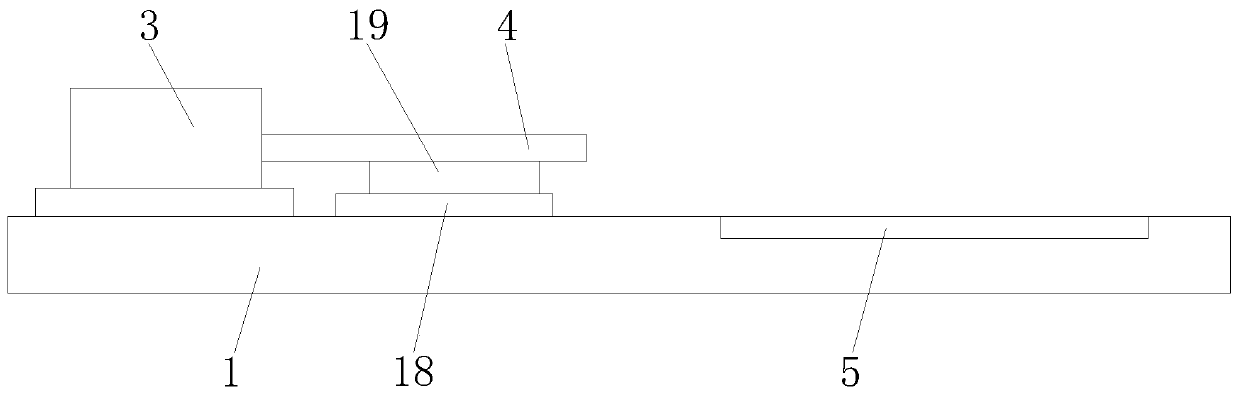

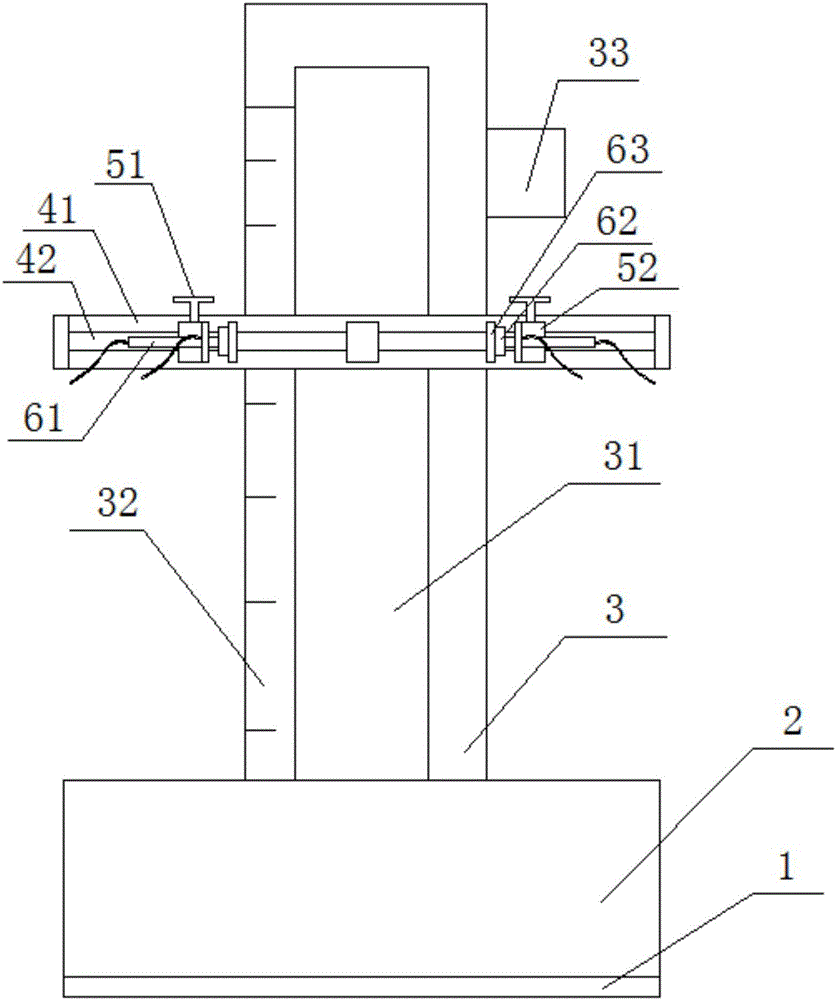

Polishing clamping device for sealing elements

ActiveCN105904341ASimple structureEasy to useGrinding work supportsEngineeringMechanical engineering

The invention discloses a polishing clamping device for sealing elements. The polishing clamping device comprises a work table, a plate base is arranged in the middle of the top of the work table, two hydraulic telescoping devices are installed at the top end of the work table and are located on the two sides of the plate base, one end of a telescoping rod of each hydraulic telescoping device is fixedly connected to a clamping plate, a sealing element fixing base is arranged in the gap between the two clamping plates, grooves are formed in the right sides of the clamping plates, first rotating shafts are arranged in the grooves, the surfaces of the first rotating shafts are connected to folding supports in a sleeved mode, the right ends of the folding supports are connected to the sealing element fixing base, and clamping rings are arranged at the middle parts of the tops of the clamping plates and are located on one sides of the folding supports. The polishing clamping device for the sealing elements is simple in structure, convenient to use, capable of automatically clamping the sealing elements and more flexible when the clamping plates release or clamp the sealing elements, has better limiting effect on the positions of the sealing elements in the clamping process and has better clamping effect.

Owner:无锡市东特机械科技有限公司

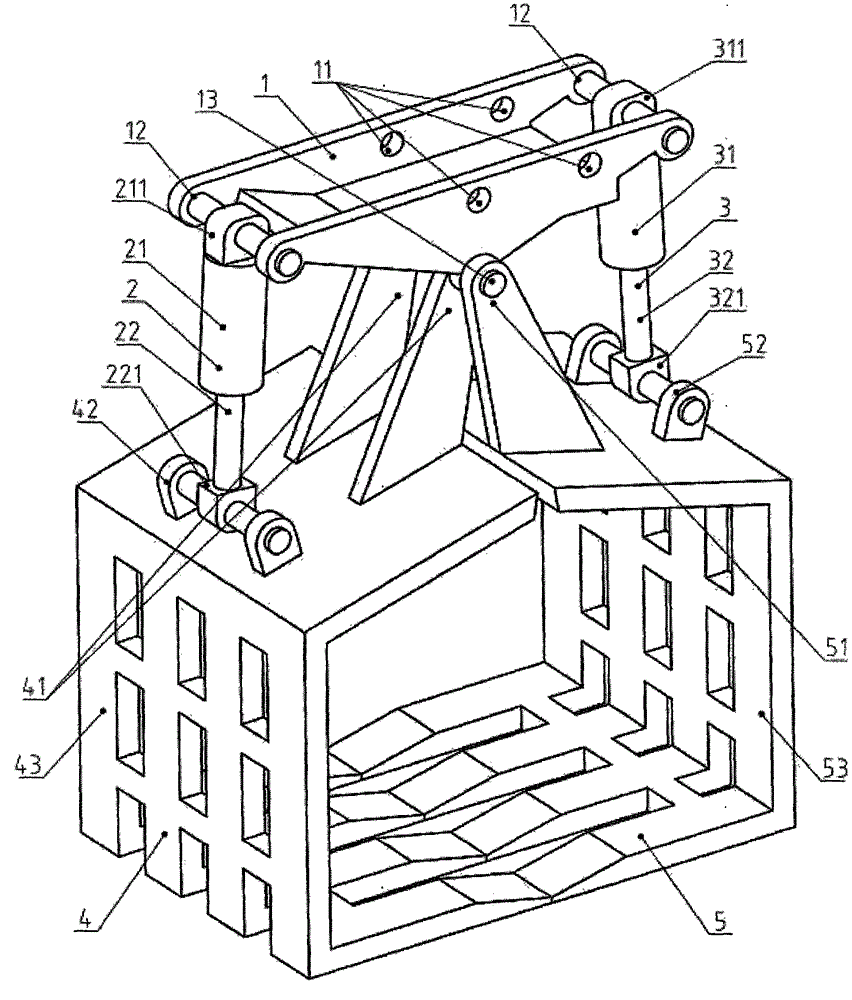

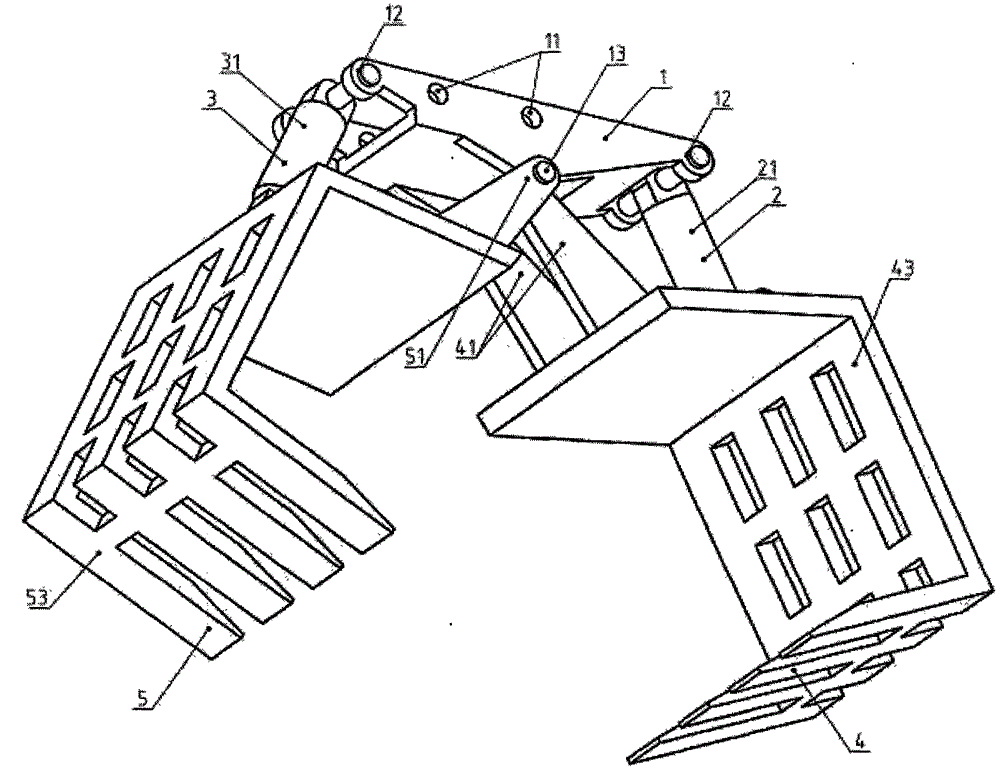

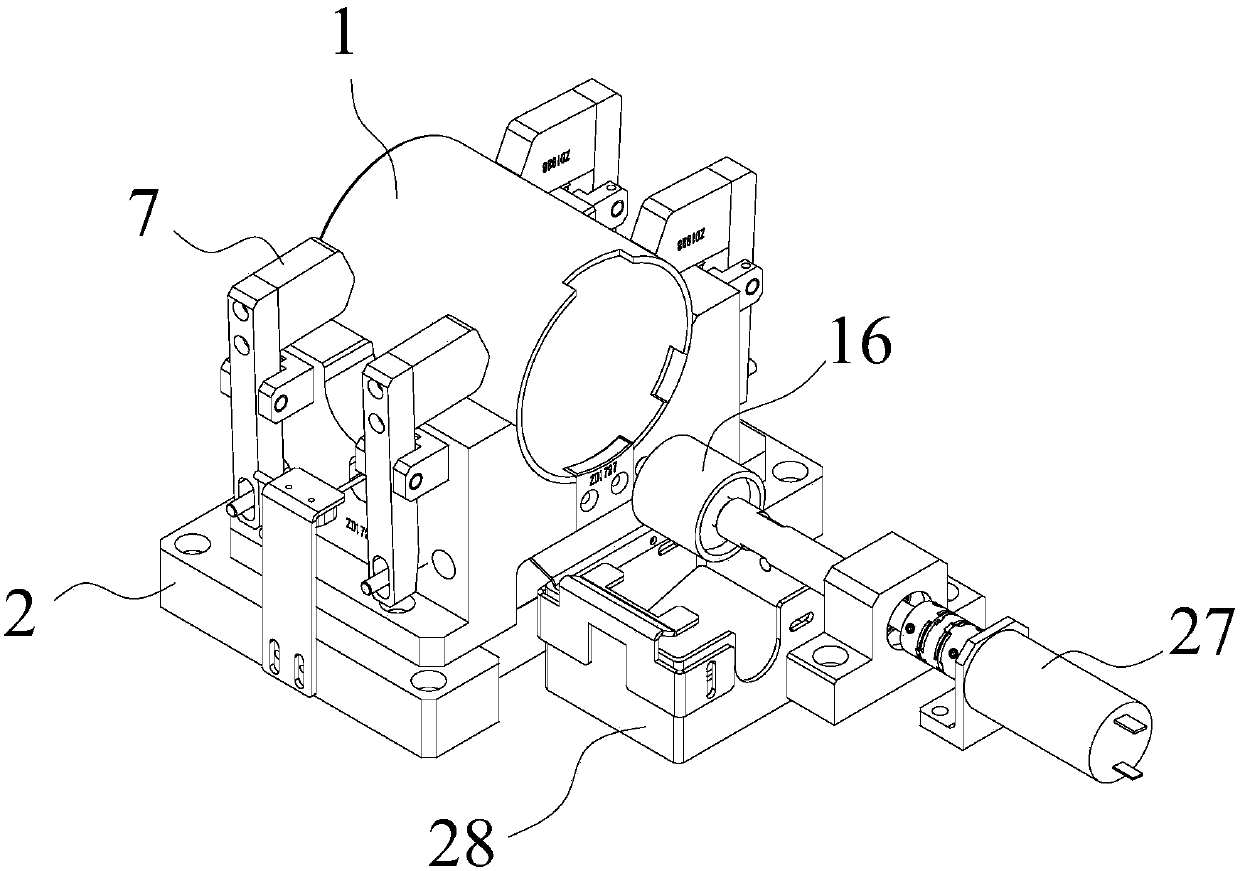

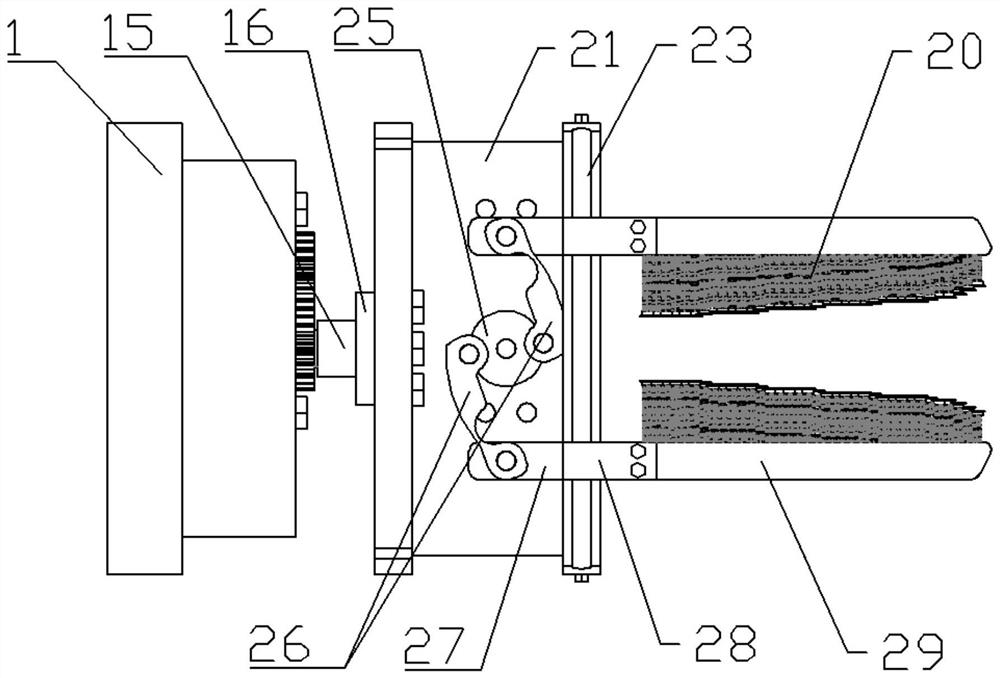

Rescue manipulator

InactiveCN104944280AWon't fall offFlexible clampingLoad-engaging elementsHydraulic cylinderRemote manipulator

The invention belongs to the technical field of disaster rescue equipment, and particularly relates to a rescue manipulator. The rescue manipulator comprises a connecting piece, a left hydraulic cylinder, a right hydraulic cylinder, a left manipulator assembly and a right manipulator assembly, wherein the left manipulator assembly comprises a semicircular left manipulator, a left hand earring and a left cylinder earring; the right manipulator assembly comprises a semicircular right manipulator, a right hand earring and a right cylinder earring; a connecting hole, two bilaterally symmetric cylinder tail connecting holes and a manipulator connecting shaft are formed and arranged on the connecting piece; the connecting hole is connected with the tail end of an excavating arm of an excavator; the left hand earring and the right hand earring are connected with the manipulator connecting shaft simultaneously to form a hinge; a left cylinder tail earring and a right cylinder tail earring are connected with the two cylinder tail connecting holes to form a hinge; a left rod tail earring and the left cylinder earring form a hinge; a right rod tail earring and the right cylinder earring form a hinge. The rescue manipulator clamps flexibly, and is high in clamping efficiency, and a clamped object cannot fall off, so that the rescue manipulator is relatively safe and reliable.

Owner:NORTH CHINA INST OF AEROSPACE ENG

Detection device for detecting screen and shell of mobile phone

ActiveCN106453771ARealize hardness testingEasy to operateSubstation equipmentStands/trestlesSteel ballEngineering

The invention belongs to the field of mobile phone performance detection and setting, and particularly relates to a detection device for detecting a screen and a shell of a mobile phone. The detection device comprises a bottom plate and a supporting seat, wherein a protective plate is arranged around the bottom plate; a lifting frame and a measure gauge are mounted on the supporting seat; two adjustment plates are mounted on the lifting frame and are mounted on the lifting frame through locking pieces; the locking pieces are loosened to adjust the adjustment plates to horizontally move along the lifting frame; clamping mechanisms are mounted on the adjustment plates; and the clamping mechanisms on the two adjustment plates are opened and closed to clamp the mobile phone or a steel ball. The detection device has the beneficial effects that by the arrangement of a measure gauge testing machine matched with the clamping mechanisms capable of being adjusted to rise up and fall down, the hardness of the mobile phone shell and the hardness of the mobile phone screen can be detected; and the detection device is easy and convenient to operate and can meet different demands for detection, and functional diversification is realized.

Owner:重庆哈迪斯科技有限公司

Rivet inserter

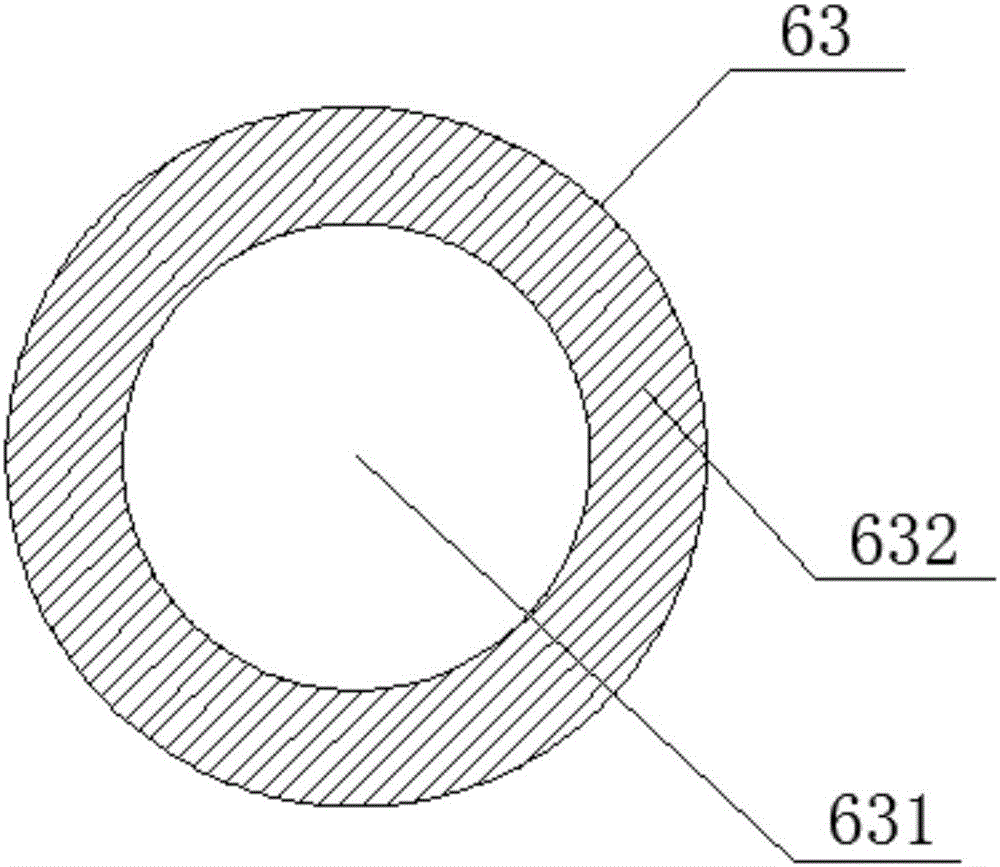

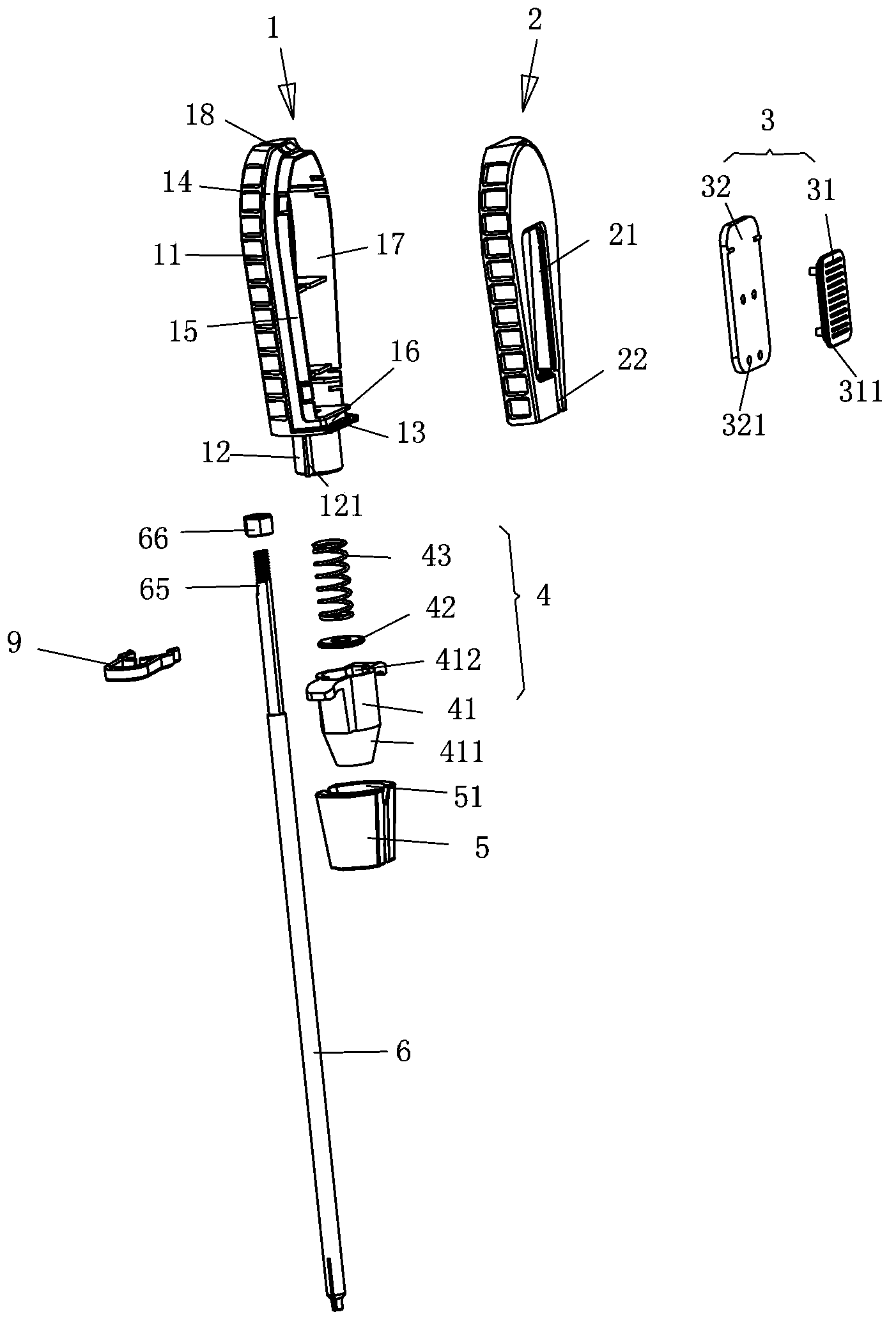

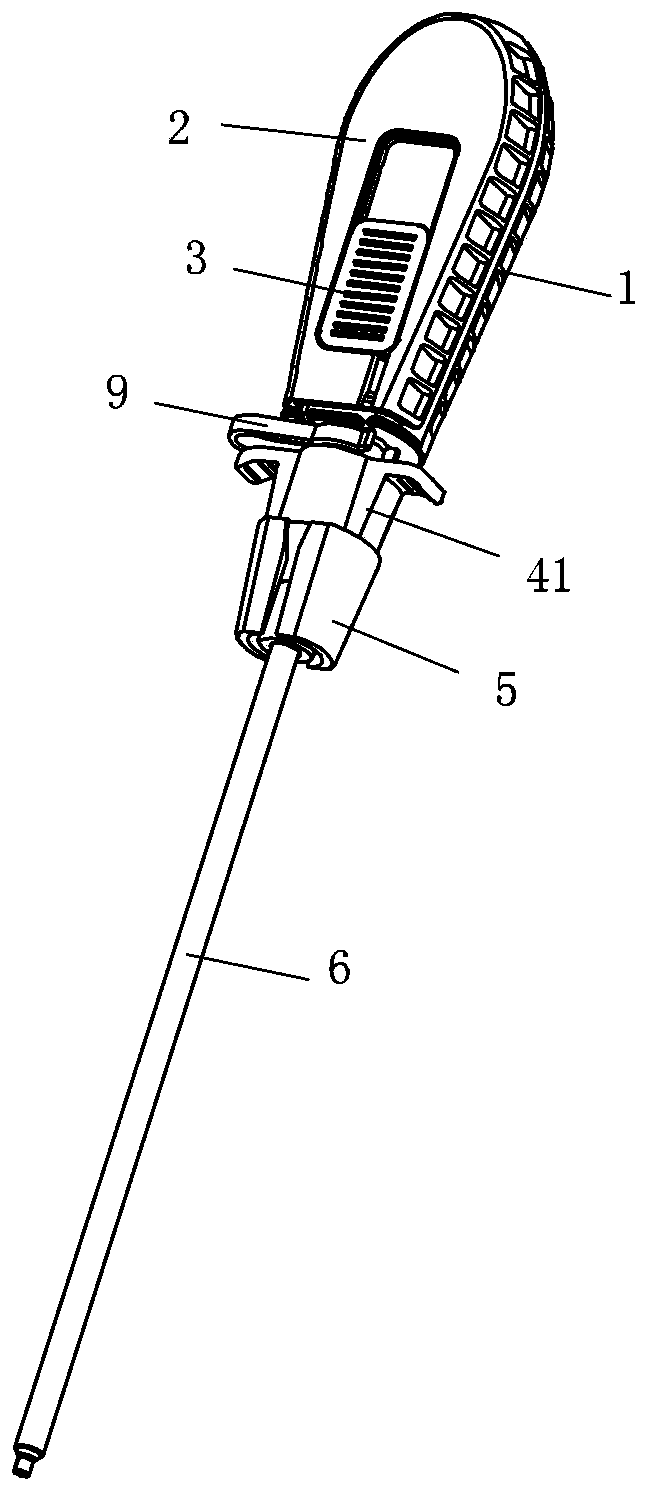

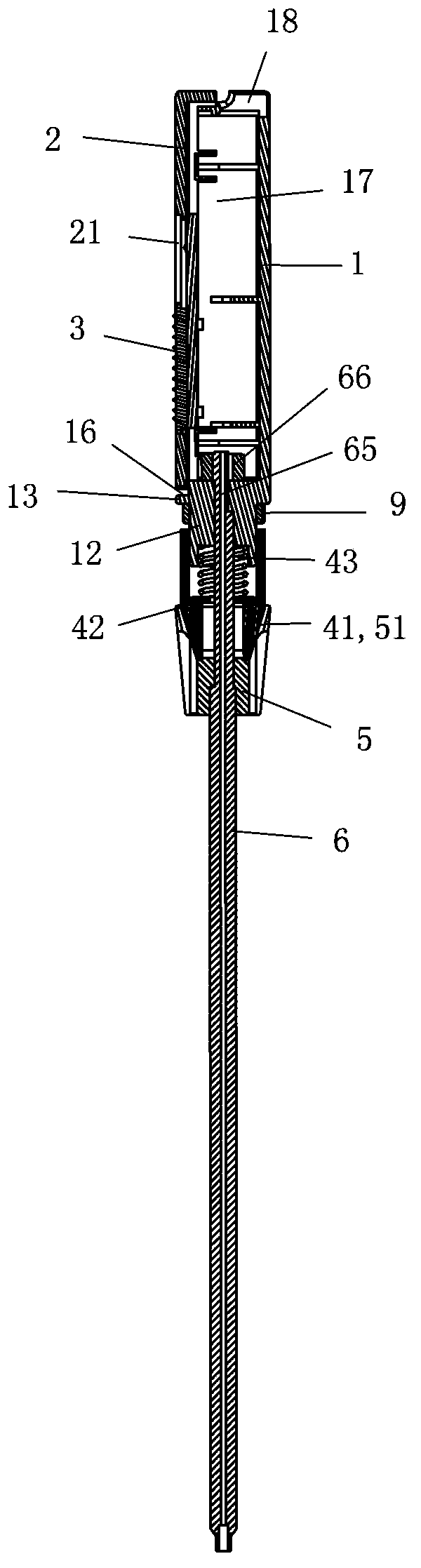

The invention discloses a rivet inserter and relates to ligament stitching operation auxiliary apparatus. The rivet inserter comprises a thread pressing clamp seat, a spring, a fixing seat, a gripping handle and a main rod. The front end of the main rod is provided with a short circular pipe radially penetrating a cutting groove. The front end of a tubular body of the thread pressing clamp seat forms a conical face, the rear end of the tubular body is provided with a handle, and an inner hole of the tubular body is of step shape with big rear and small front. A fixing seat body is mounted at the rear portion of the main rod, T-shaped fins are disposed on two sides of the fixing seat body, and the rear portion of each T-shaped fin extends out of the fixing seat body and is provided with an inner flange on the inner surface. The front end of the thread pressing clamp seat is inserted into the two fins of the fixing seat. The gripping handle is provided with a recessed closed groove, and a stitching thread can be wound on the groove. A guide tube inserting into the rear section of the inner hole of the thread pressing clamp seat is disposed at the front end of the gripping handle. The part, located behind the fixing seat, of the main rod enters the inner hole of the thread pressing clamp seat, penetrates the spring, and is fixed in the inner hole of the guide tube. Two ends of the spring press the bottom of the rear section of the inner hole of the thread pressing clamp seat and the guide tube to allow the conical face of the thread pressing clamp seat abut against the inner flanges on the inner surface of the two fins of the fixing seat.

Owner:DABO MEDICAL TECH CO LTD

Mobile sponge shear type carrying device

InactiveCN106113134ASolve the problem of large volume and laborious handlingSimple structureMetal working apparatusEngineeringLarge size

The invention provides a movable sponge scissors type handling device, including a rope wheel, a motor, a frame, a traction rope, a spreader, a steel wire rope, an electro-hydraulic telescopic rod, a lifting claw A, a sponge, a lifting claw B, a push rod and a universal The upper end of the frame is fixedly connected with a motor and a sheave through bolts, the output shaft end of the motor is connected with a sheave, and the traction rope is coiled around the sheave, so The lower end of the traction rope is connected to the top of the sling, and the two sides of the suspension ring at the lower end of the sling are respectively connected to the tops of the hanging claws A and B via a steel wire rope, and the upper ends of the hanging claws A and B are hinged Together, the invention has a simple structure, and uses two lifting claws in a scissors-like structure to clamp the sponge, which solves the problem of large volume of the sponge and laborious handling, is convenient to use and labor-saving, flexible in clamping and unloading, and flexible in movement without laying guide rails. Small footprint, low equipment manufacturing cost and good economy.

Owner:ZHEJIANG CHUANYANG SPONGE

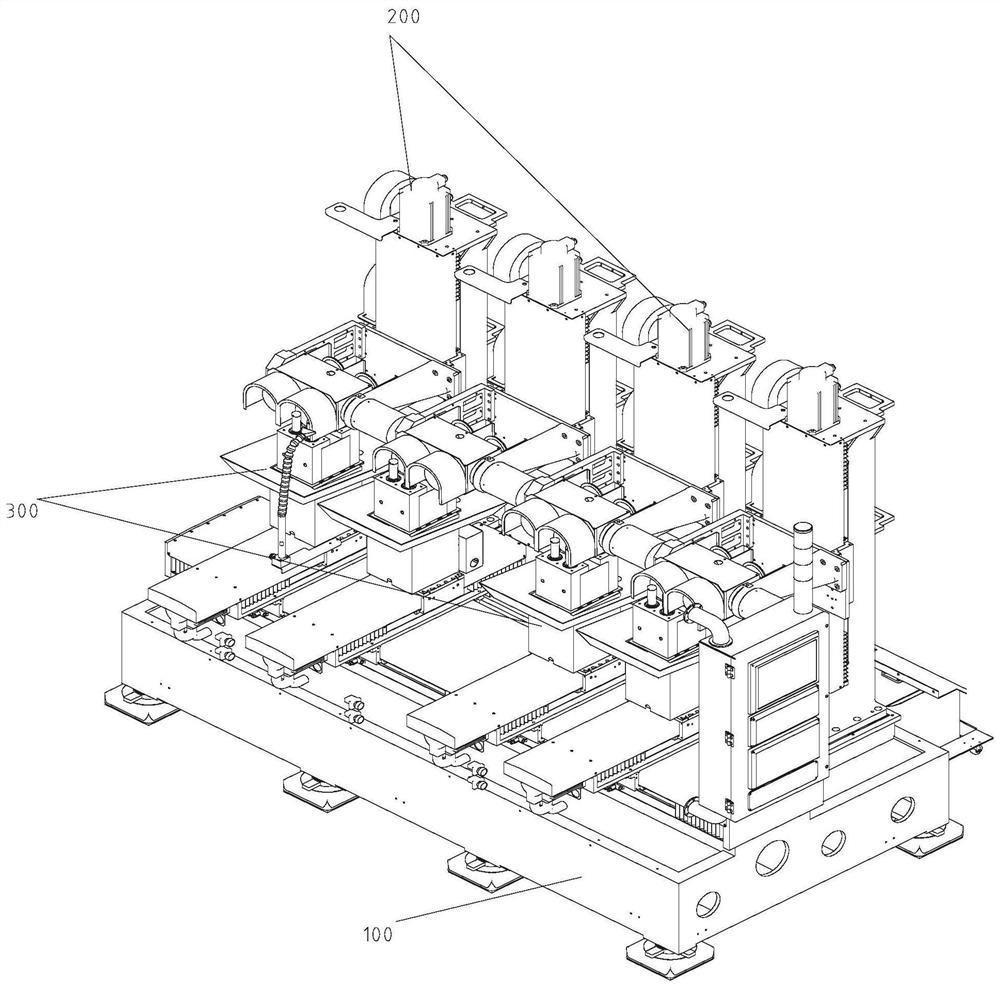

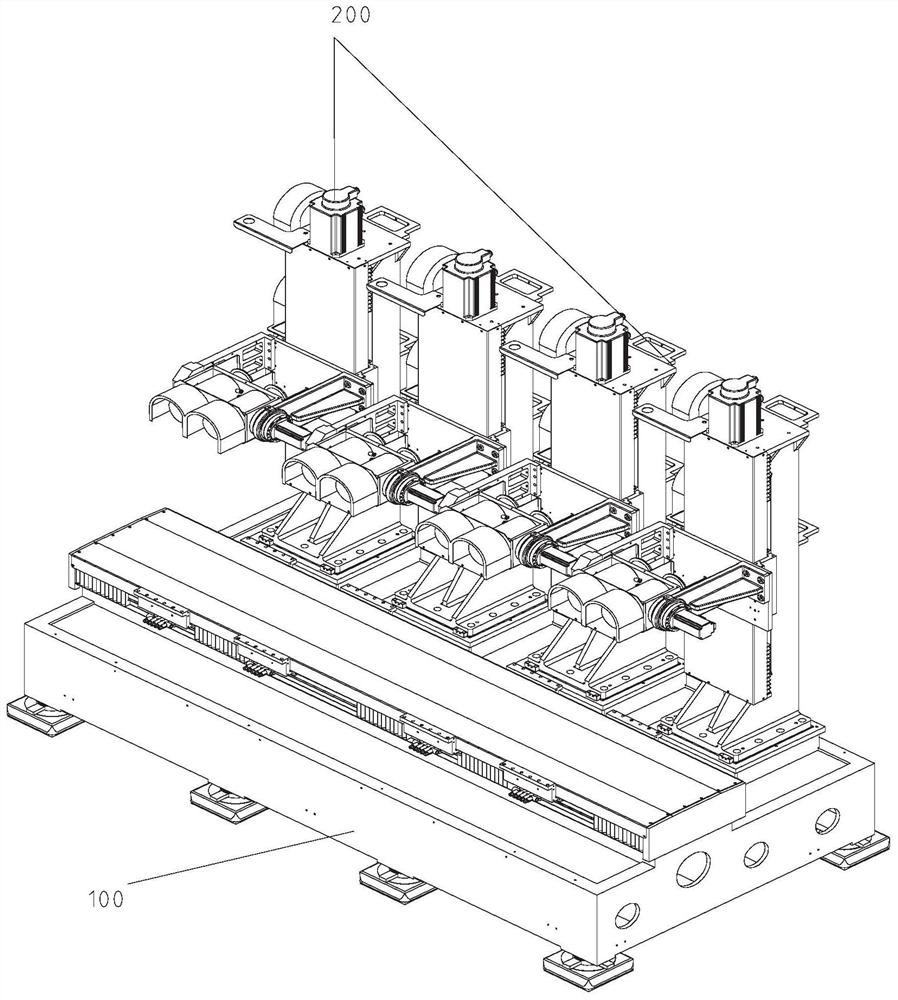

Multi-station polishing and grinding equipment

PendingCN111775012AImprove work efficiencyAchieving Process ContinuityGrinding carriagesGrinding drivesElectric machinerySpring steel

Multi-station polishing and grinding equipment comprises a machine table and polishing and grinding machines and fixtures arranged on the machine table in one-to-one correspondence, wherein the polishing and grinding machines comprise Z-axis linear modules and grinding head assemblies that are arranged on the machine table, the grinding head assemblies comprise grinding head supports, grinding head seats are rotatably arranged on the grinding head supports, and at least one double-head motor is arranged on each grinding head seat; the fixtures comprise XY linear modules and fixture bodies; thetop of the C axis is in transmission connection with a rotating main shaft, the rotating main shaft is provided with a driving wheel, a sleeve is provided with a driven wheel, and the driving wheel is in transmission connection with the driven wheel through a timing belt. When the C axis drives the driving wheel to rotate, the driven wheel is driven to rotate through the timing belt, and the sleeve is driven to rotate on the upper support frame, so that a product clamped in a spring steel sheet is driven to rotate, and the polishing and grinding machines can grind the products on the matchingfixtures through polishing discs. The multiple sets of polishing and grinding machines and multiple fixtures in the invention are matched, synchronous processing can be achieved, the unified regulation of the control system is facilitated, and individual control is also realized. All sets of polishing and grinding machines do not affect each other, thereby realizing multiple technological processes, and having high operating efficiency.

Owner:深圳市永霖科技有限公司

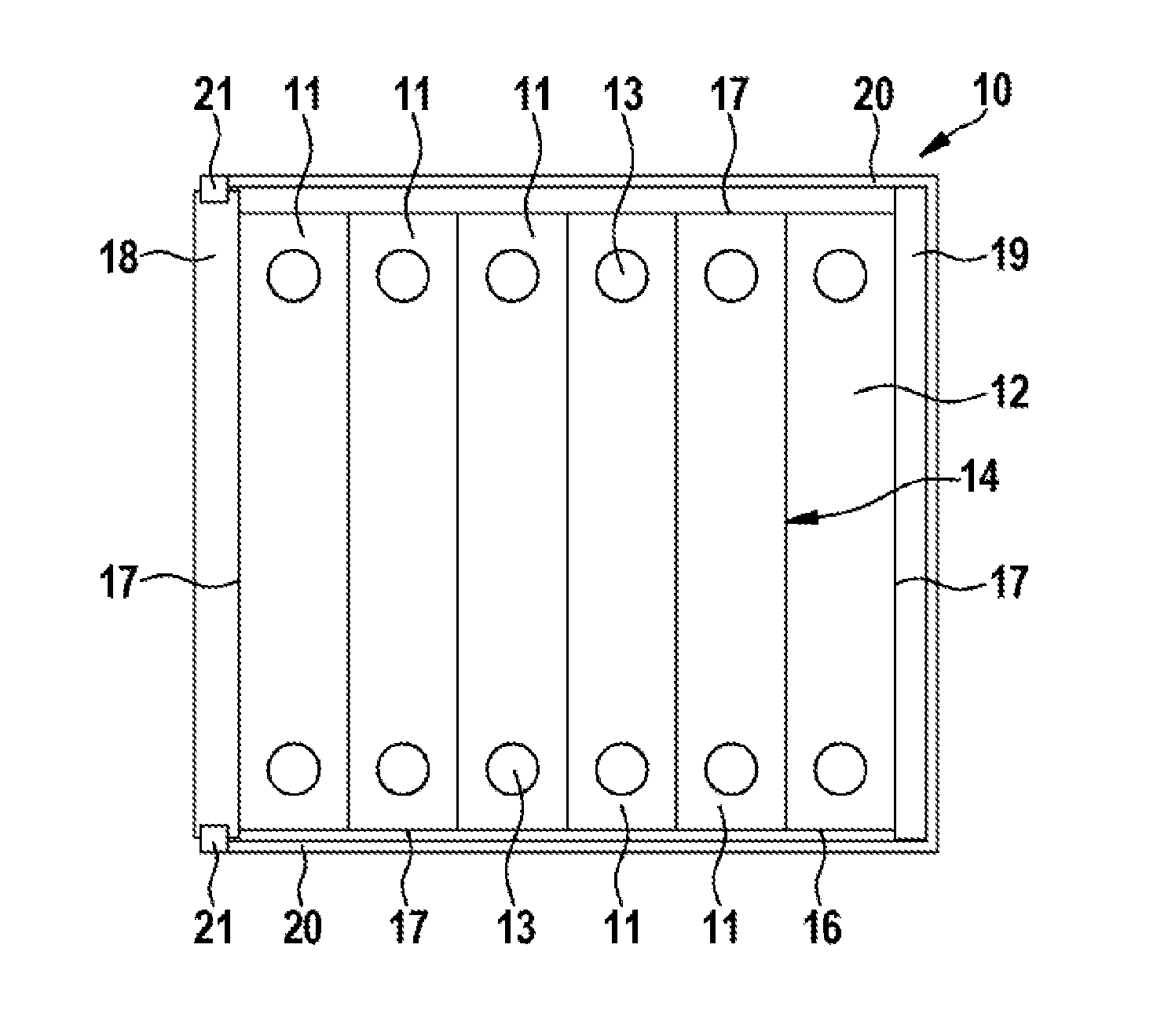

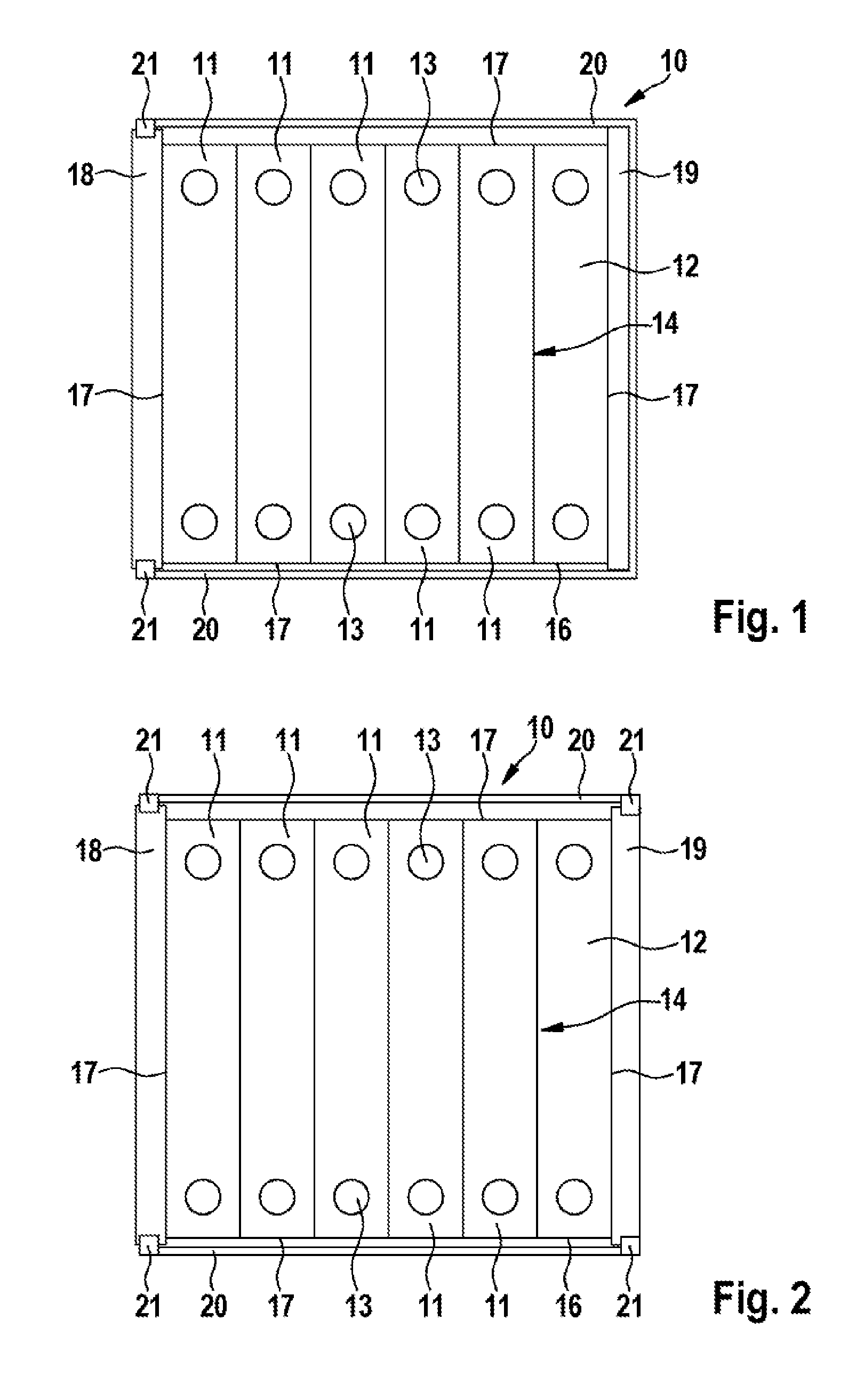

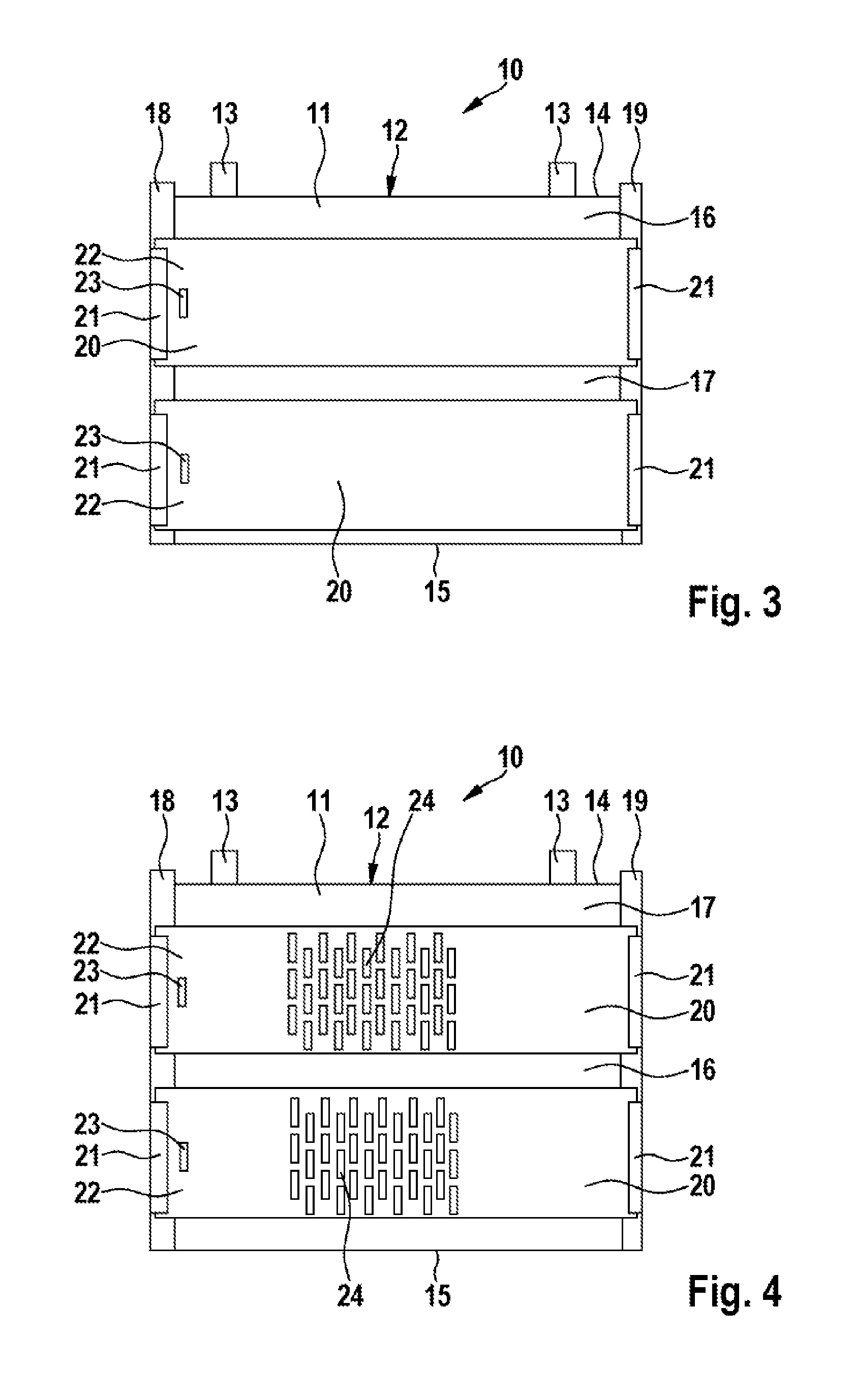

Method for Clamping a Lithium Ion Accumulator, Lithium Ion Accumulator and Motor Vehicle Having a Lithium Ion Accumulator

ActiveUS20130309538A1Increase energy densityLess spaceFinal product manufactureSecondary cellsLithiumPhysical chemistry

The disclosure relates to a method for clamping a lithium ion accumulator, which has a lithium ion accumulator cell stack having a top surface, a base surface opposite the top surface and a peripheral surface having four side surfaces, and at least two prismatic lithium ion accumulator cells. The lithium ion accumulator cell stack is clamped by at least one tension strap apparatus which is arranged and tensioned in the region of the peripheral surface, the ends of the tension strap meanwhile being kept free of tension. While free of tension, the ends of the tension strap are connected to each other directly or indirectly by using one or two plates, which are arranged on a side surface or two mutually opposite side surfaces of the peripheral surface. The disclosure further relates to a lithium ion accumulator and a motor vehicle having a lithium ion accumulator.

Owner:ROBERT BOSCH GMBH +1

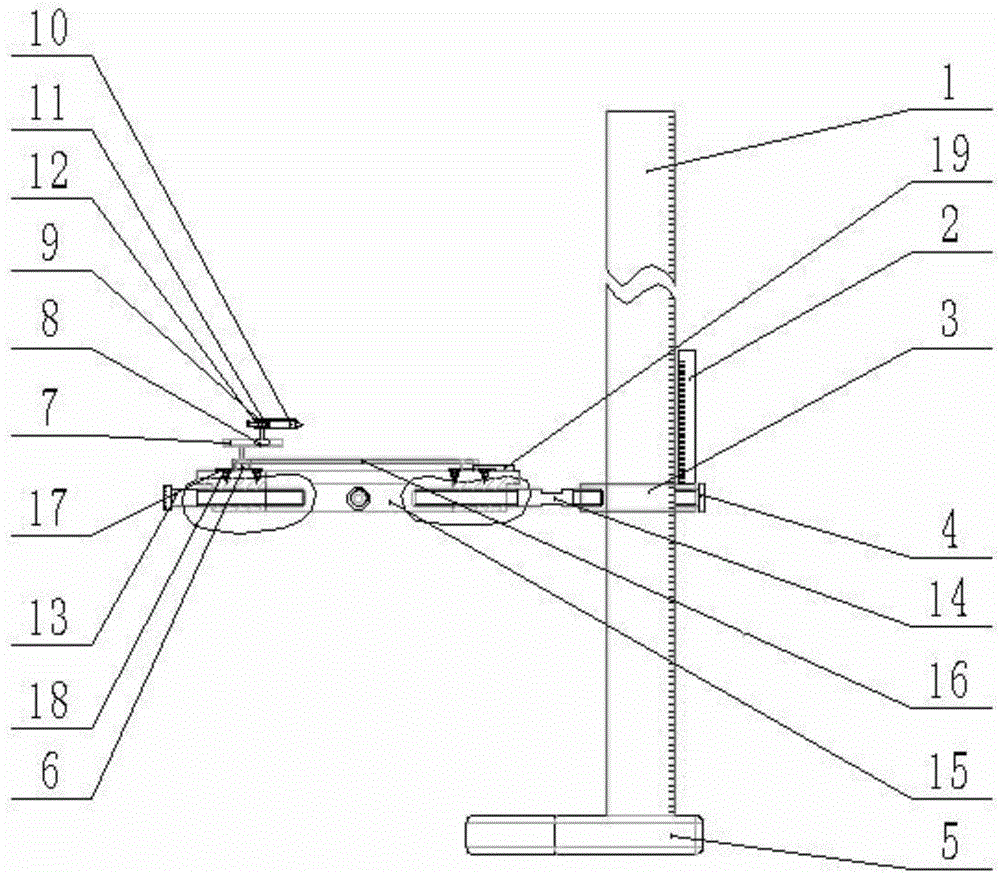

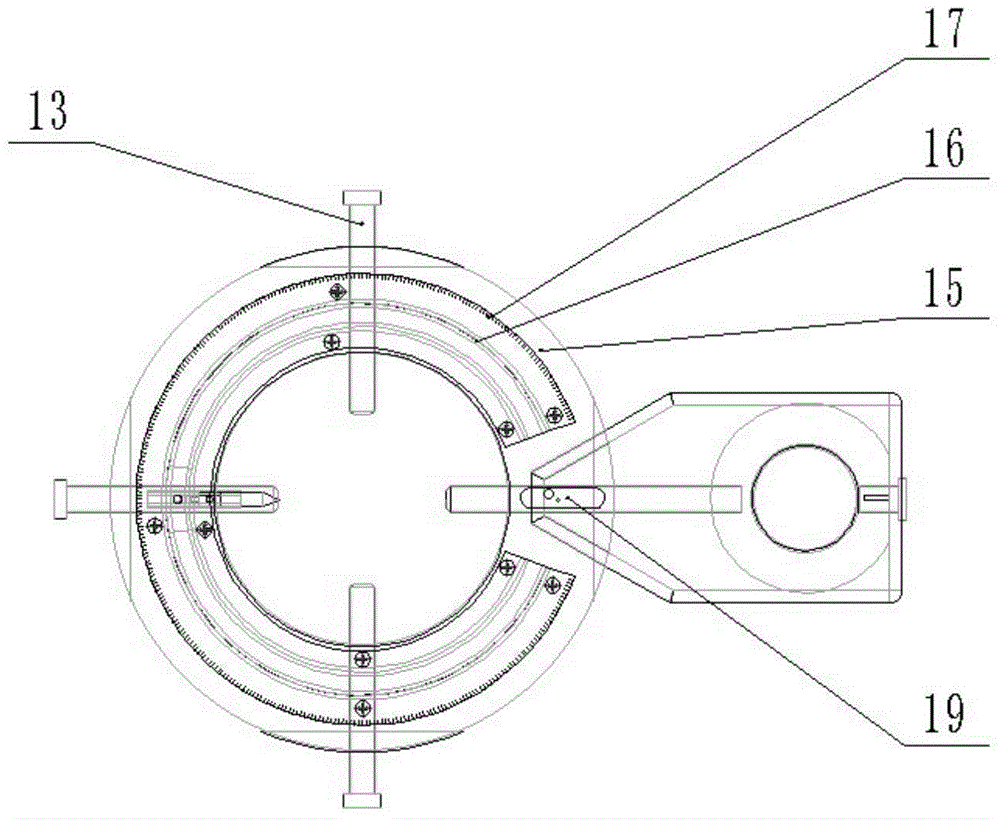

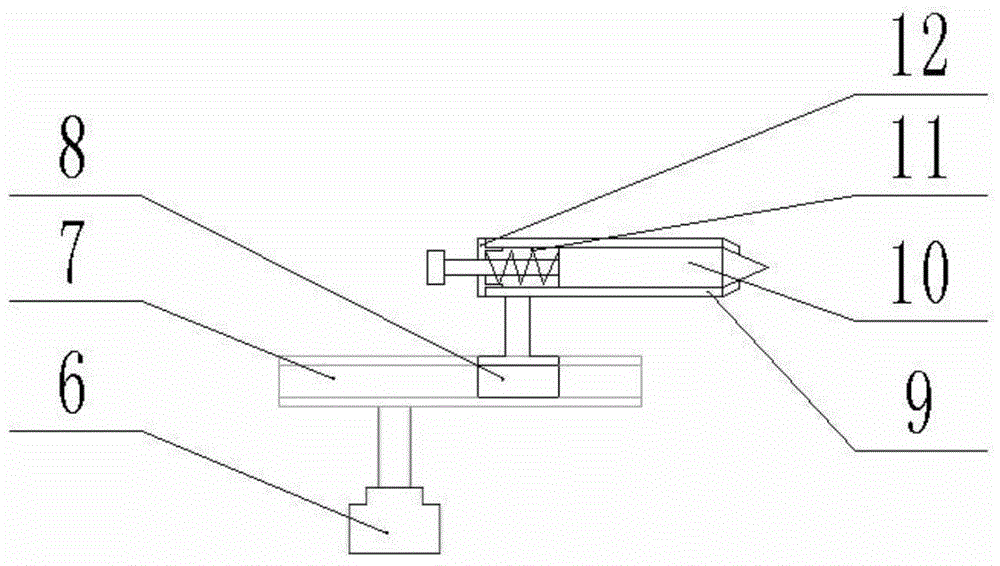

Welding positioning dotter of pipe fittings

ActiveCN104400264AEasy to operateHigh positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesCircular discPipe fitting

The invention discloses a welding positioning dotter of pipe fittings. A height gauge of the dotter is welded on a base; a vernier gauge is welded on a fixed ring; a fastening screw is in threaded connection into the fixed ring; a fixed disc is connected with the fixed ring through a stud, and can vertically move along with the fixed ring; an adjustable screw is in threaded connection to the fixed disc; a first slide block is inlaid in a circular chute, and can slide in the circular chute; the circular chute is in spot welding with an angle measuring disc, and is connected to the fixed disc through a self-tapping screw; a second slide block is inlaid in a linear chute; a dotting pen is inlaid in a dotting pen shell; a spring is placed between the dotting pen and a dotting pen end cover; and a level is glued on the fixed disc. The dotter can precisely position welded points of the pipe fittings without a welded bracket.

Owner:GUANGXI UNIV

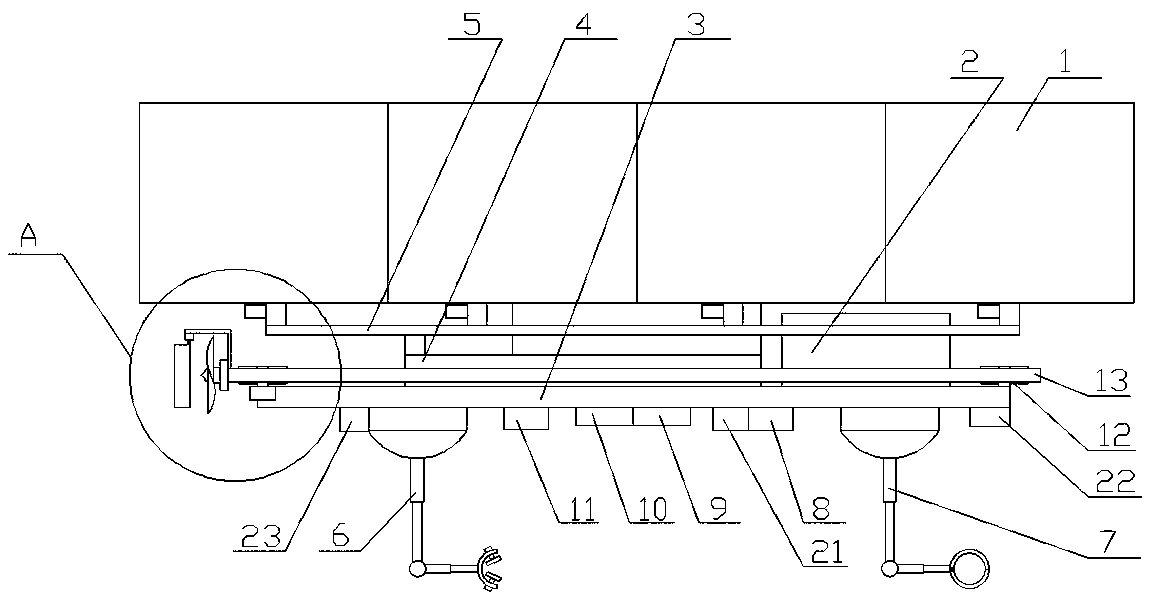

Floated transmission line deicing device

ActiveCN108832575AGuaranteed stabilityAvoid damage and transmission line damageOverhead installationApparatus for overhead lines/cablesTransmission lineEngineering

The present invention provides a floated transmission line deicing device. The device comprises a deicing substrate, a suspension mechanism arranged on the deicing substrate, a mobile mechanism arranged on the deicing substrate, a support mechanism arranged on the deicing substrate, a deicing mechanism arranged on the deicing substrate and a control mechanism arranged on the deicing substrate andconfigured to perform coordination control of the suspension mechanism, the mobile mechanism, an auxiliary sustaining mechanism and the deicing mechanism. The floated transmission line deicing devicecan perform smooth deicing without increasing the load quality of the transmission line and can reduce the difficulty of the suspension.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN +1

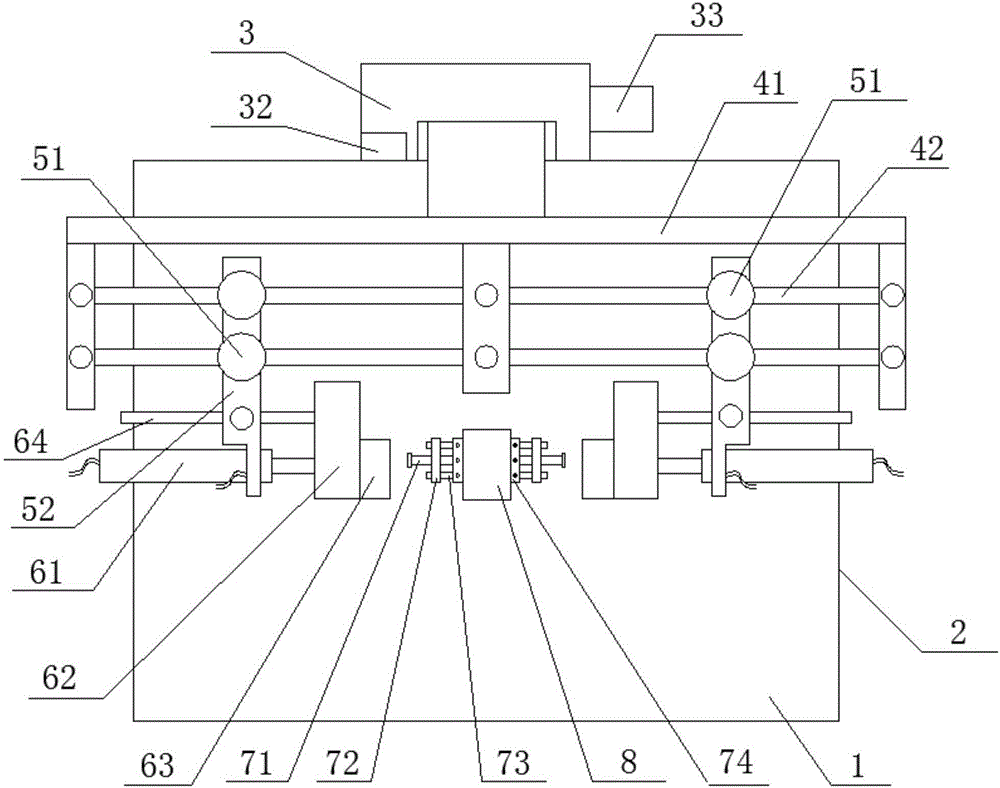

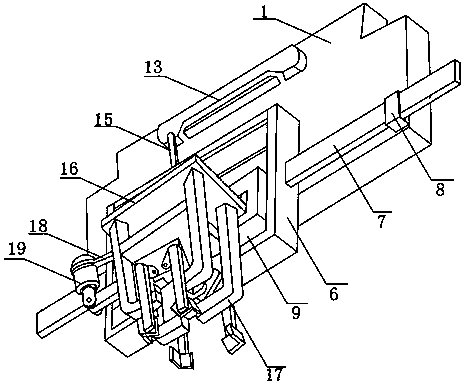

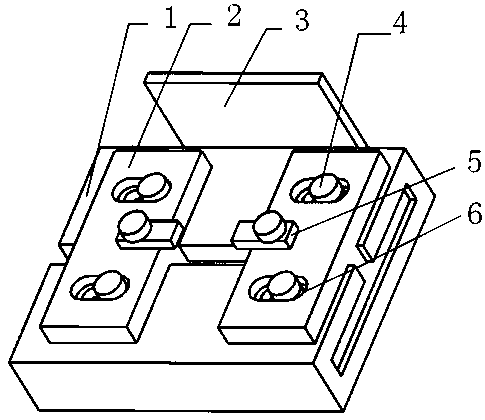

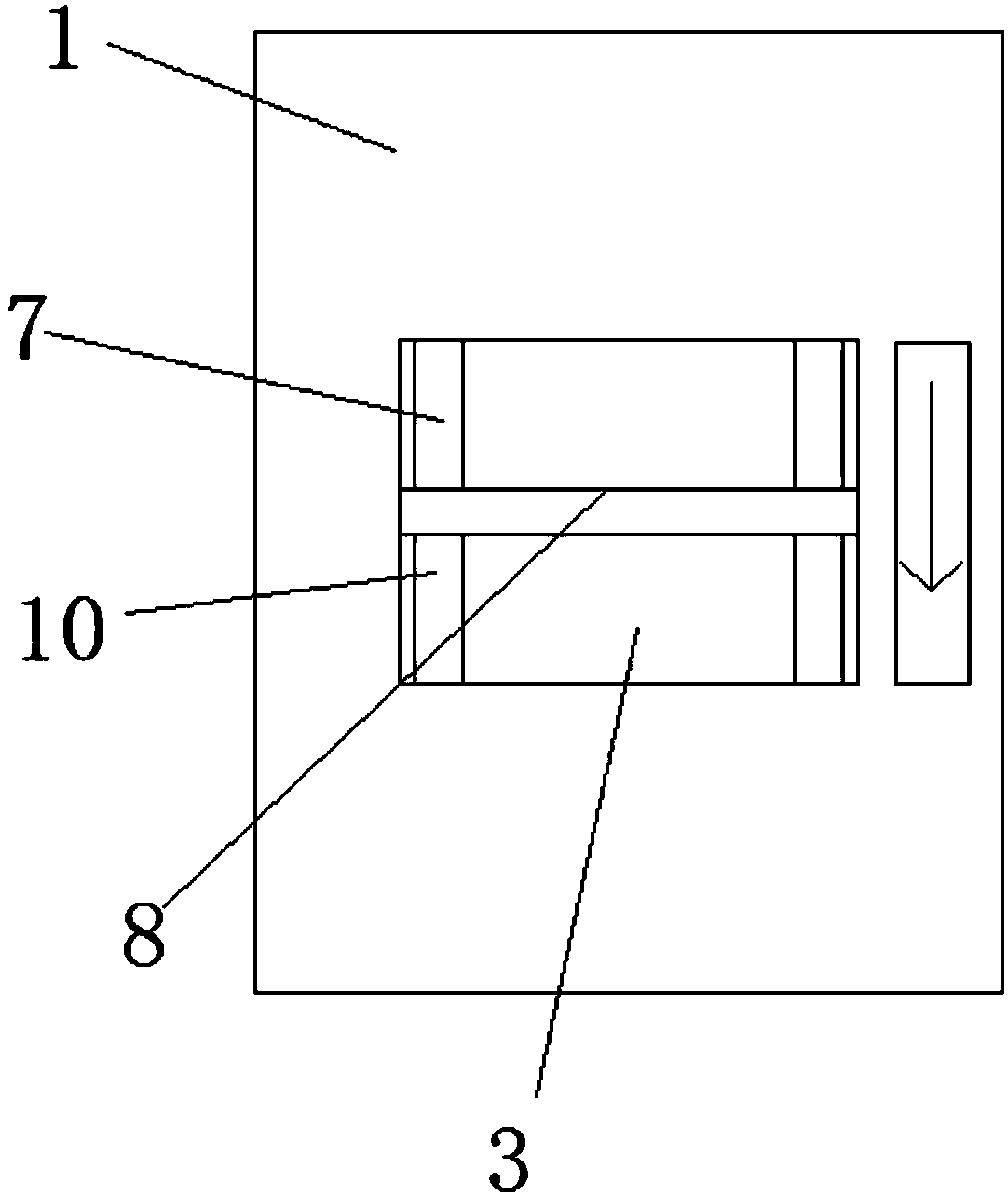

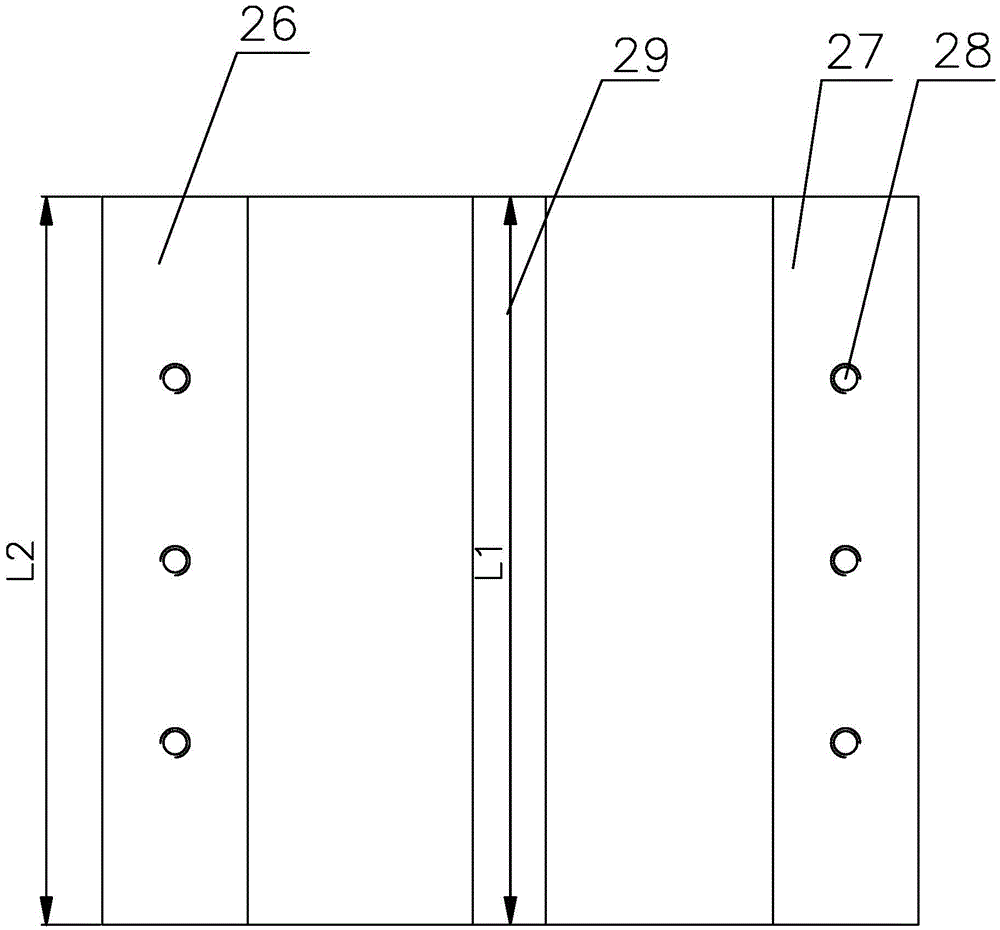

Multi-station punching mechanism

ActiveCN104148973AEasy clampingFlexible clampingMetal working apparatusPositioning apparatusPunchingEngineering

The invention relates to a multi-station punching mechanism which comprises a conveying clamping mechanism. The conveying clamping mechanism comprises clamping bases which are arranged in a parallel and spaced mode, a first clamping strip and a second clamping strip are installed on the clamping bases respectively, a discharging mechanism is installed at one end of each clamping base, and workpieces falling from the discharging mechanisms are clamped between the first clamping strip and the second clamping strip; a second clamping air cylinder and a third clamping air cylinder are located on the first clamping strip in a spaced mode, a first clamping air cylinder and a fourth clamping air cylinder are located on the second clamping strip in a spaced mode, and the four clamping air cylinders are arranged in a staggered mode and fixed to the clamping bases through installation bases. An installation plate is arranged on the outer side of each clamping base, a starting air cylinder and a guide rod are respectively installed at the upper end of each installation plate, piston rods of the starting air cylinders penetrate through the installation plates to be fastened to fixing plates, the guide rods penetrate through the installation plates and the fixing plates through shaft sleeves, and the heads of the guide rods abut against the workpieces in a connected mode. A punching mechanism is further installed on the outer side of the conveying clamping mechanism. The multi-station punching mechanism is good in using flexibility and low in cost.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

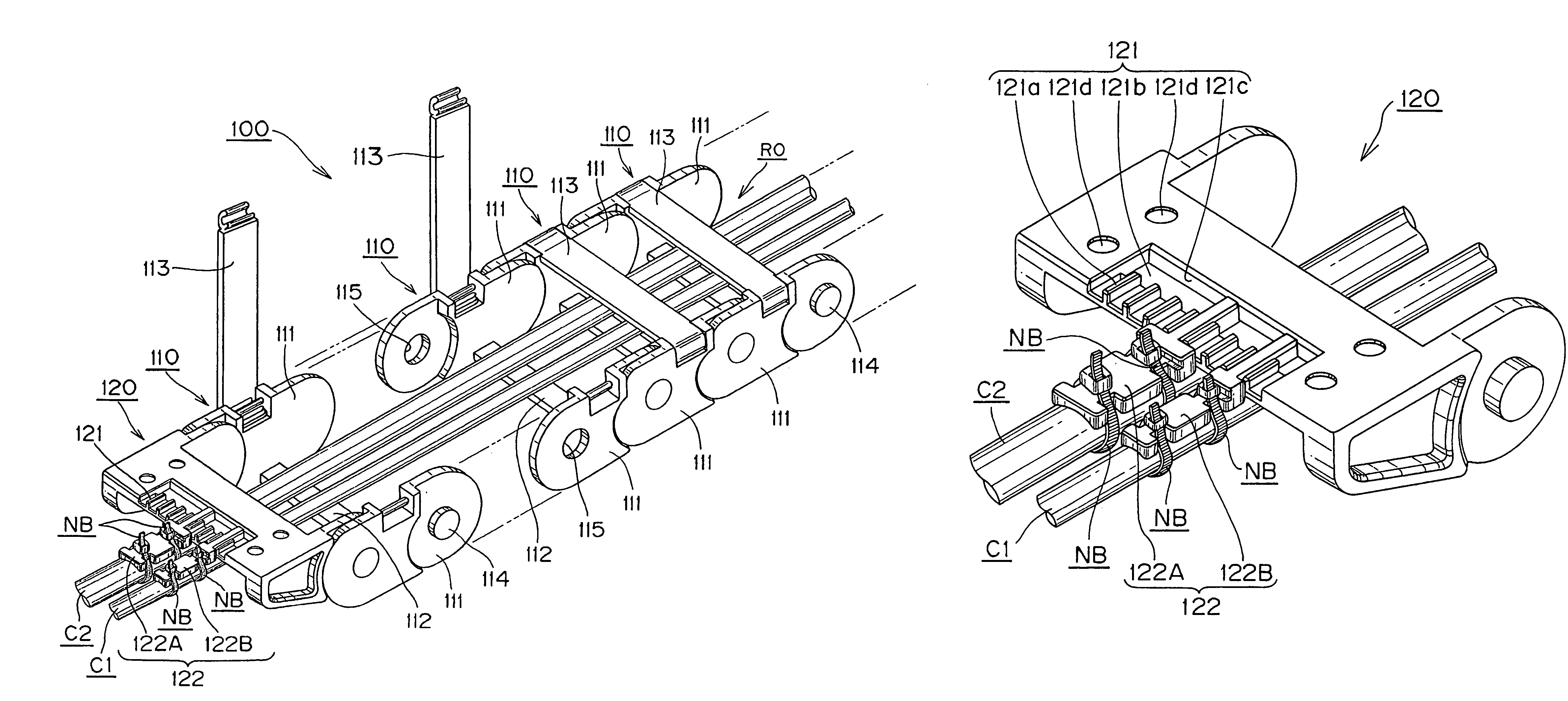

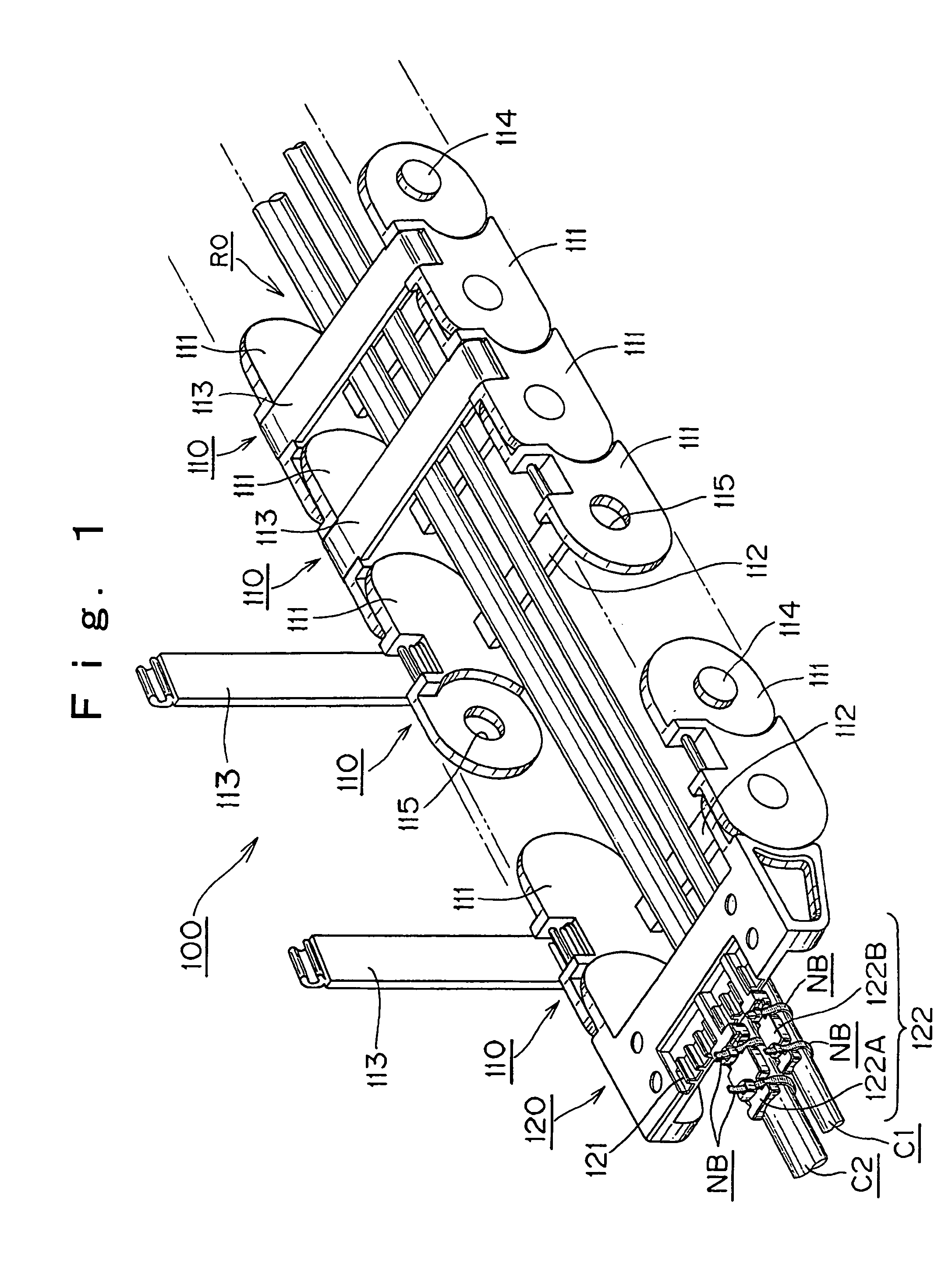

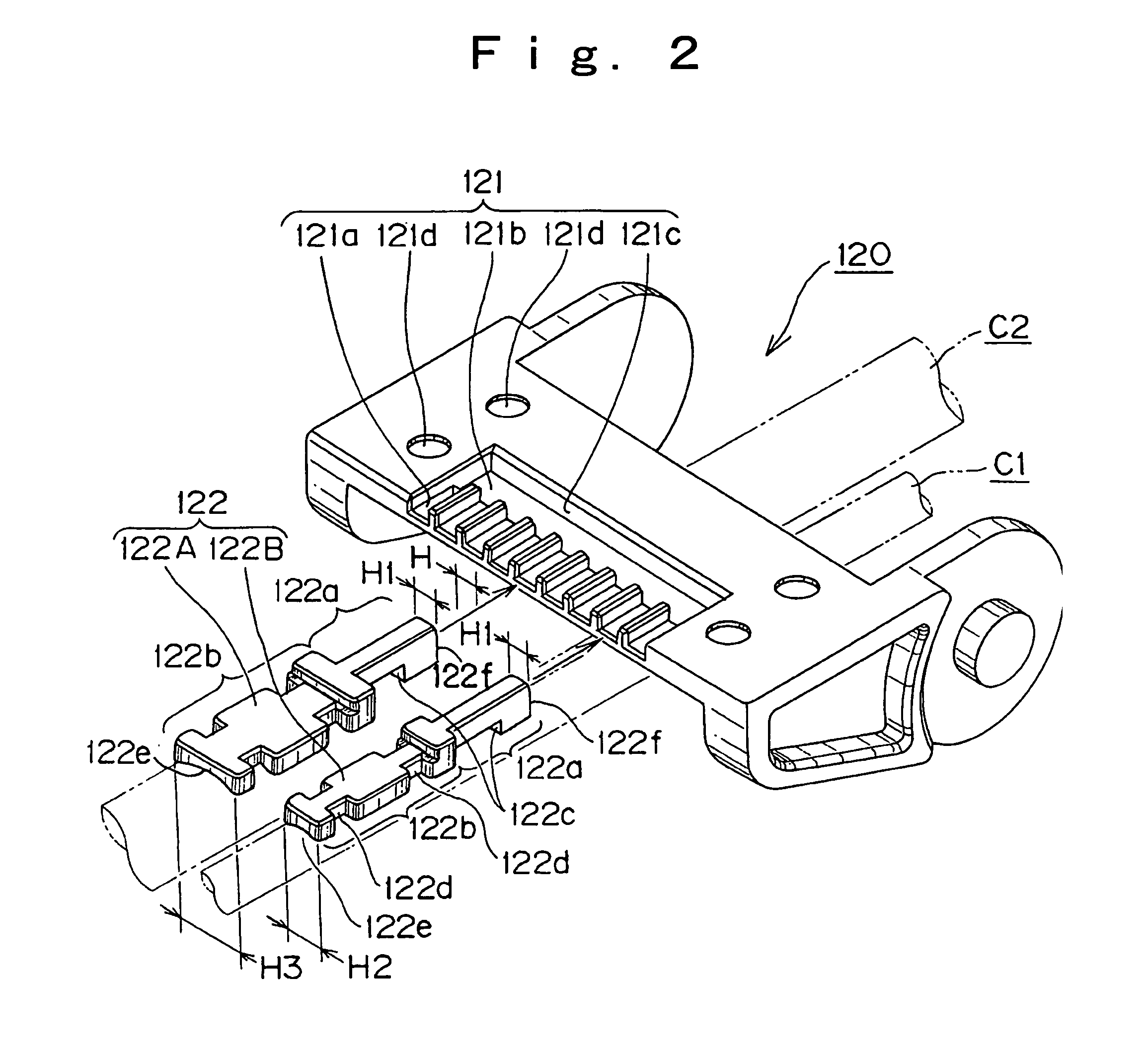

Cable clamp member for cable protective guide device

ActiveUS7250572B2Reduce manufacturing costEliminate wasteInsulated cablesStands/trestlesEngineeringMechanical engineering

The present invention provides a cable clamp member capable of reducing the providing cost or manufacturing cost of a device and surely clamping stored cables to a moving end or a fixed end flexibly in conformation to the size or layout of stored cables. The cable clamp member comprises a comb-tooth unit installation receiving member 121 provided on an end part 120 at a fixed end or a moving end and having a plurality of engaged parts 121a provided in a width direction so that a comb-tooth installation position is changeable, and a clamp comb-tooth unit member 122 to be detachably engaged with and installed to any one of the plurality of engaged parts to clamp a cable mounted in the installed state to the device. The plurality of engaged parts 121a are provided on the comb-tooth unit installation receiving member 121 at narrow intervals so as to minutely adjust the installation pitch of the clamp comb-tooth unit member 122.

Owner:TSUBAKIMOTO CHAIN CO

Vertical grinder

InactiveCN102990485AIncrease machining radiusGuaranteed machining accuracyRevolution surface grinding machinesEngineeringKnife holder

The invention discloses a vertical grinder, which comprises a grinder body, a worktable and a base, wherein the worktable is fixedly arranged on the grinder body, and the grinder body is arranged on the base; a vertical tool rest guide rail is arranged on the grinder body, and a slide groove is arranged in the guide rail; a longitudinally moving electric rotary grinding head is arranged on the vertical tool rest guide rail, and a rotating shaft on the electric rotary grinding head can slide up and down in the slide groove; the lower part of the electric rotary grinding head is aligned with the worktable, and the worktable comprises a main worktable and two auxiliary worktables; and the main worktable is positioned between the two auxiliary worktables, and a rotating chuck is arranged on the main worktable and a chuck is arranged on each auxiliary worktable. The vertical grinder provided by the invention has the advantages that an ordinary workpiece can be clamped by the chucks on the auxiliary worktables, and the main worktable can rotate and lift to flexibly clamp workpieces of various sizes, so that the machining radius of the workpiece is improved, and the machining accuracy is also ensured.

Owner:施新风

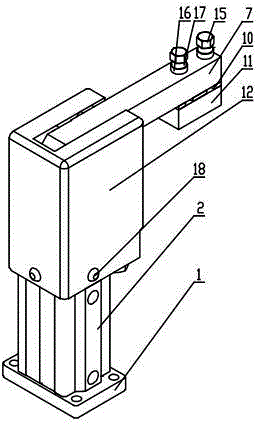

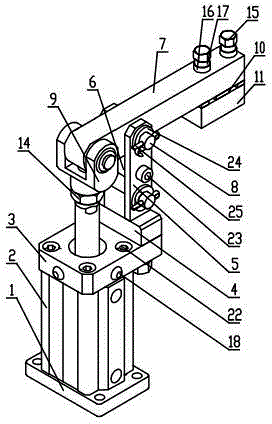

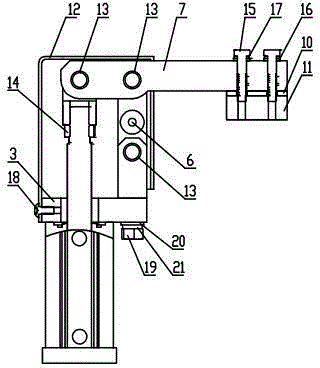

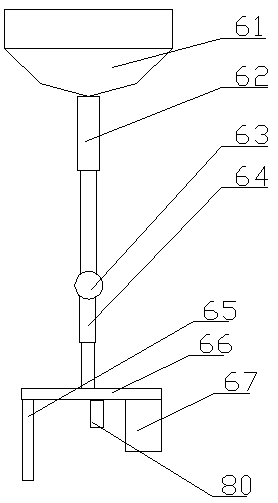

An automatic clamping device

InactiveCN105798506AReduce partsReduce volumeWelding/cutting auxillary devicesWork holdersEngineering

The invention provides an automatic clamping device which is flexible to operate. The automatic clamping device comprises a pedestal, an air cylinder, a connecting base, a connecting rod base, connecting rods, and a connecting pillar. The air cylinder is installed at the upper end of the pedestal; the connecting base is fixedly installed to the upper end of the air cylinder via C screws; a protection shield is installed on the upper end of the connecting base via round head screws; B screws penetrate a B spring washer and a B flat washer to install the connecting rod base to the upper end of the connecting base; the two connecting rods are arranged on the upper end of the connecting rod base symmetrically; the connecting pillar is fixedly installed between the two connecting rods via D screws to fixedly connect the two connecting rods together; a Y-shaped joint is installed on the upper end of the air cylinder via a locking nut. The pneumatic device is used as the connecting member, so that the parts of the structure are reduced and the size of the structure is reduced; the automatic clamping device is simple in structure; the weight and the size are reduced; based on the lever principle, the 90-degree rotation movement of a pressing arm is realized, so that clamping movement and releasing movement are more flexible.

Owner:TIANJIN WEIKE WODE TECH

Device for cleaning dirt on surface layer of high-tension transmission line

ActiveCN109225961AGuaranteed stabilityAvoid the phenomenon of fallingDirt cleaningCleaning using toolsElectricitySurface layer

The invention provides a device for cleaning dirt on the surface layer of a high-tension transmission line. The device includes a dust removal base, a suspension mechanism arranged on the dust removalbase, a moving mechanism arranged on the dust removal base, an auxiliary support mechanism arranged on the dust removal base, a dust removal mechanism, a collection mechanism, and a control mechanism, wherein the dust removal mechanism and the collection mechanism are arranged on the dust removal base, and the control mechanism is arranged on the dust removal base and used for coordinated controlof the suspension mechanism, the moving mechanism, the auxiliary support mechanism and the dust removal mechanism. The device can carry out large-scale ash removal operation on the transmission line,the dust removal effect is better, workers do not need to climb up and down, the safety is high, the dust removal operation is achieved by taking power from the line, and the device is light, long inservice life, low in cost and use cost, and very good in effect.

Owner:STATE GRID CORP OF CHINA +1

Automatic gluing apparatus

PendingCN107716228AGood positioning stabilityFixed position is accurateLiquid surface applicatorsCoatingsManufacturing engineeringAutonomation

The invention discloses an automatic gluing apparatus, which comprises a gluing part and a clamping and positioning tool for clamping and fixing a case. The clamping and positioning tool comprises a tool base. A tool installation plate is fixed on the tool base. The upper end face of the tool installation plate is provided with an arc groove match with the case. Two ends of the groove are providedwith at least one clamping mechanism. The gluing part comprises a rolling brush and a tri-axial transplanting mechanism for moving the rolling brush. The automation degree of the gluing apparatus ishigh, the glue is more evenly painted, and the production efficiency is high.

Owner:SUZHOU SUNMICRO AUTOMATION TECH CO LTD

Automatic clamping and mounting mechanism of mattress surrounding edge rim

InactiveCN109941953ASolve the problem of excessive volume, time-consuming and laboriousFrame fixedUpholstery manufactureReciprocating motionFixed frame

The invention discloses an automatic clamping and mounting mechanism of a mattress surrounding edge rim. The automatic clamping and mounting mechanism comprises a working table and a movable frame, wherein five groups of fixed frames are mounted at the upper end part of the working table in an equal spacing manner; the middle position at the bottom of the back surface of the working table is fixedly connected with a support; a motor is erected on the support; an output shaft of the motor penetrates through interior of the working table, and extends towards the front end, so as to be rotatablyconnected with an operation gear. The automatic clamping and mounting mechanism of the mattress surrounding edge rim, disclosed by the invention, provides a motion structure for regular motion of a similar robot; the operation gear meshes with an elliptical inner tooth ring, and the elliptical inner tooth ring is caused to do a similarly elliptical reciprocating motion to drive a lower clamping mechanism to move synchronously to meet the requirement of displacement in a mattress rim mounting process; furthermore, the automatic clamping and mounting mechanism is fully automatic; the problems oftime consumption and labor consumption of manual operation due to an extremely large volume of the surrounding edge rim are solved; the automatic clamping and mounting mechanism is applicable to different working conditions, and brings a better use prospect.

Owner:利辛县爱侣家俱加工有限公司

T-shaped adjustable clamp of linear cutting machine

InactiveCN110405297AFlexible clampingDoes not affect processing efficiencyElectrical-based machining electrodesElectrical-based auxillary apparatusWire cuttingEngineering

The invention provides a T-shaped adjustable clamp of a linear cutting machine, and relates to the field of clamps. The T-shaped adjustable clamp can be used for clamping the workpiece on an electricspark wire cutting machine. The clamp comprises clamp blocks, a guide rail with a T-shaped groove, a compression bolt, a gasket and a pressing piece, a transverse T-shaped groove matched with the shape of the lower part of the clamp block is machined in the guide rail, the clamp block is arranged in the T-shaped groove, the clamp block slides relative to the T-shaped groove, workpieces are fixed on the two sides, the pressing piece can be installed on the clamp block, and the compression bolt can rotate up and down relative to the two shoulders of the clamp blocks. Due to the fact that the sizes of the workpieces are different, the positions of the two clamp blocks are adjusted through the tightness of the compression bolts. Therefore, the clamp can be flexibly clamped along with the compression bolt, the machining efficiency is not affected, and the clamp is easy to machine.

Owner:HARBIN UNIV OF SCI & TECH

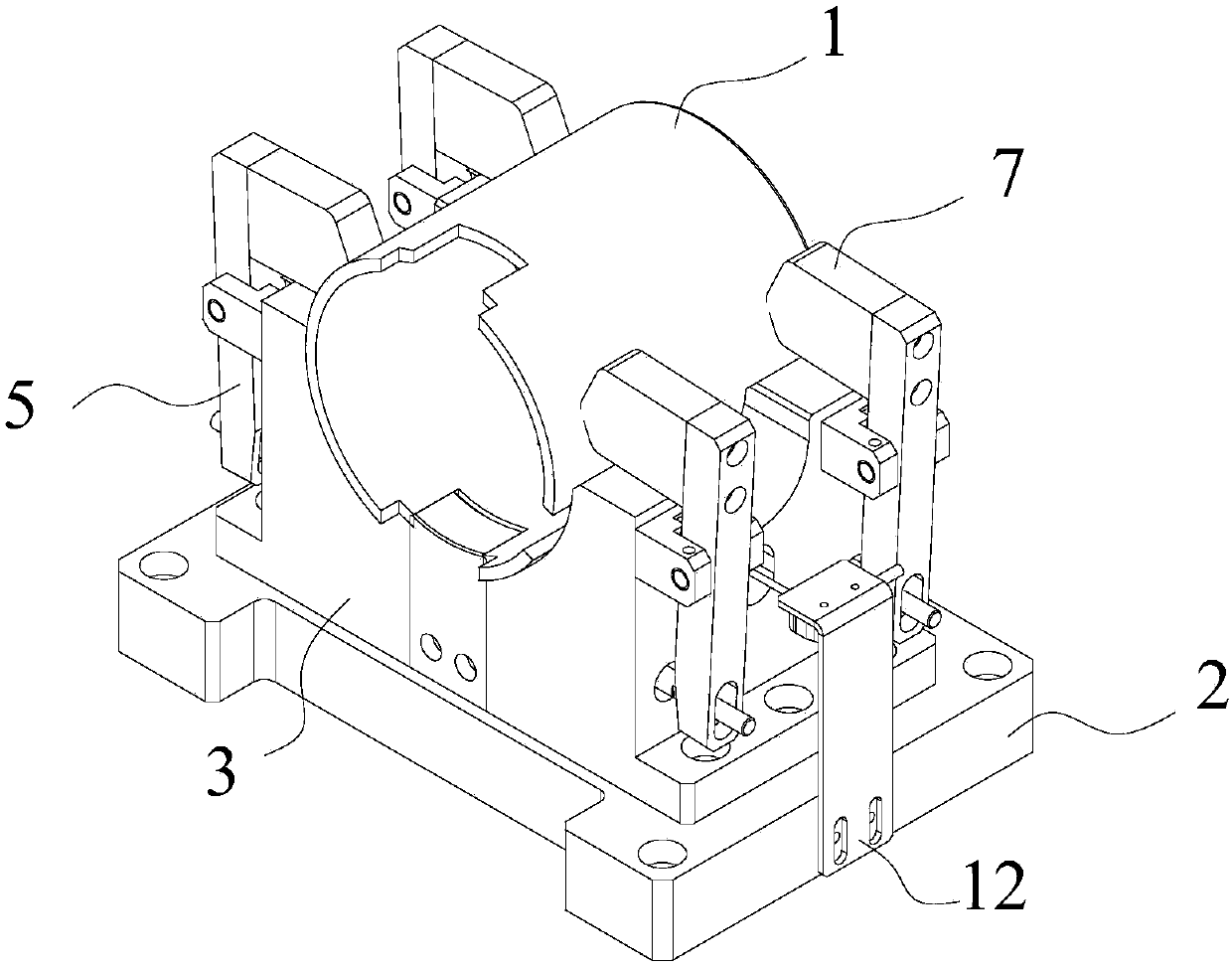

Mechanical arm clamp capable of automatically adjusting object shapes

InactiveCN112372660AEnsure balanceGuaranteed processing reliabilityGripping headsElectric machineryEngineering

The invention relates to the technical field of robots, and discloses a mechanical arm clamp capable of automatically adjusting object shapes. The mechanical arm clamp comprises a seat body and a clamping mechanism. One end of the seat body is connected with the tail end of a mechanical arm of an external robot or other clamping machines, and the other end of the seat body is fixedly connected with the clamping mechanism. The clamping mechanism comprises a sliding adjusting mechanism, clamping plates and telescopic components. The number of the clamping plates is two, the clamping plates are oppositely arranged, multiple mounting holes are formed in the clamping plates and used for mounting of the telescopic components, and the telescopic components comprise supporting columns, springs andsuction cups. During work, the upper clamping plate and the lower clamping plate are driven to move linearly through the sliding adjusting mechanism, due to the shapes of clamped objects are different, force borne by springs of clamping points are different, and the clamp keeps large-area contact clamping to the different clamped objects through spring deformation and supporting column stretchingand retracting, and therefore the machining reliability is guaranteed. In addition, the seat body is further provided with a first motor, a rotational degree of freedom is added to the clamping mechanism, and clamping is more flexible and convenient.

Owner:GUANGZHOU UNIVERSITY

Adjusting equipment used in building field

InactiveCN109899451AEasy to disassembleFlexible clampingRopes and cables for vehicles/pulleyTextile cablesEquipment useWire rope

The invention discloses adjusting equipment used in the building field. The adjusting equipment comprises an equipment appearance, wherein a placing chamber I, a placing chamber II and a placing III are arranged inside the equipment appearance, moreover, the placing chamber I, the placing chamber II and the placing chamber III are arranged in sequence from top to bottom, tightening and shrinking rings which are symmetrically arranged are arranged inside the placing chamber I, the tightening and shrinking rings comprise U-shaped shrinking rings I and U-shaped shrinking ring jacking positions, the U-shaped shrinking ring jacking positions are located on one sides of the U-shaped shrinking rings I, and placing columns are welded at the bottoms of the U-shaped shrinking ring jacking positions.According to the adjusting equipment used in the building field, a movable column, the placing columns, secondary placing columns, the U-shaped shrinking ring jacking positions, U-shaped lower arrangement devices and other structures are arranged for use in a cooperative mode, therefore, both the two U-shaped shrinking rings I and two U-shaped shrinking rings II can clamp a steel wire rope, then,the tightening and shrinking degree can be effectively and conveniently controlled, and use is convenient and simple.

Owner:任宗俊

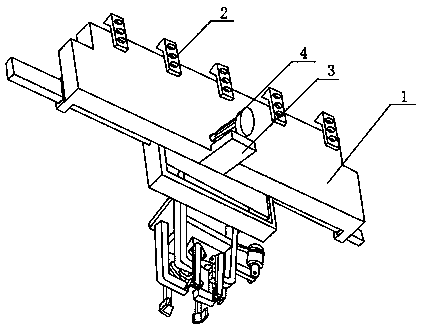

Automatic orientation fixture for OF surface processing of sapphire crystal bar

InactiveCN105459278AAdjustable positionAccurate locationWorking accessoriesFine working devicesSynchronous motorEngineering

The invention relates to the technical field of crystal bar fixtures, in particular to an automatic orientation fixture for OF surface processing of a sapphire crystal bar. The automatic orientation fixture comprises an upper fixture and a lower fixture detachably connected; a V-shaped groove is formed in the upper surface of the lower fixture; the upper fixture is used for fixing the sapphire crystal bar in the V-shaped groove; the V-shaped groove includes a left inclined surface and a right inclined surface symmetrically distributed on two sides; the left inclined surface and the right inclined surface are both provided with symmetric pulley grooves; rotating shafts are mounted in the pulley grooves, and are coated with rollers; the rotating shafts are parallel to the length direction of the lower fixture; and the rollers are tangential to the left inclined surface / the right inclined surface, or are slightly projected out of the left inclined surface / the right inclined surface. The rotating shafts on the left inclined surface and the right inclined surface are both connected with synchronous motors. The sapphire crystal bar positioning fixture is divided into upper and lower two parts; and the rollers are added on the left inclined surface and the right inclined surface, so that the crystal bar can automatically rotate to adjust the position, the position of the sapphire crystal bar before processing is conveniently adjusted, the positioning is precise, and labors are saved.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com