Mechanical arm clamp capable of automatically adjusting object shapes

A technology of object shape and mechanical arm, which is applied in the field of mechanical arm fixtures, can solve problems such as single fixing form, small clamping surface, and poor clamping effect, and achieve the effect of increasing the contact area, good bonding force, and good clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The present invention will be described in further detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

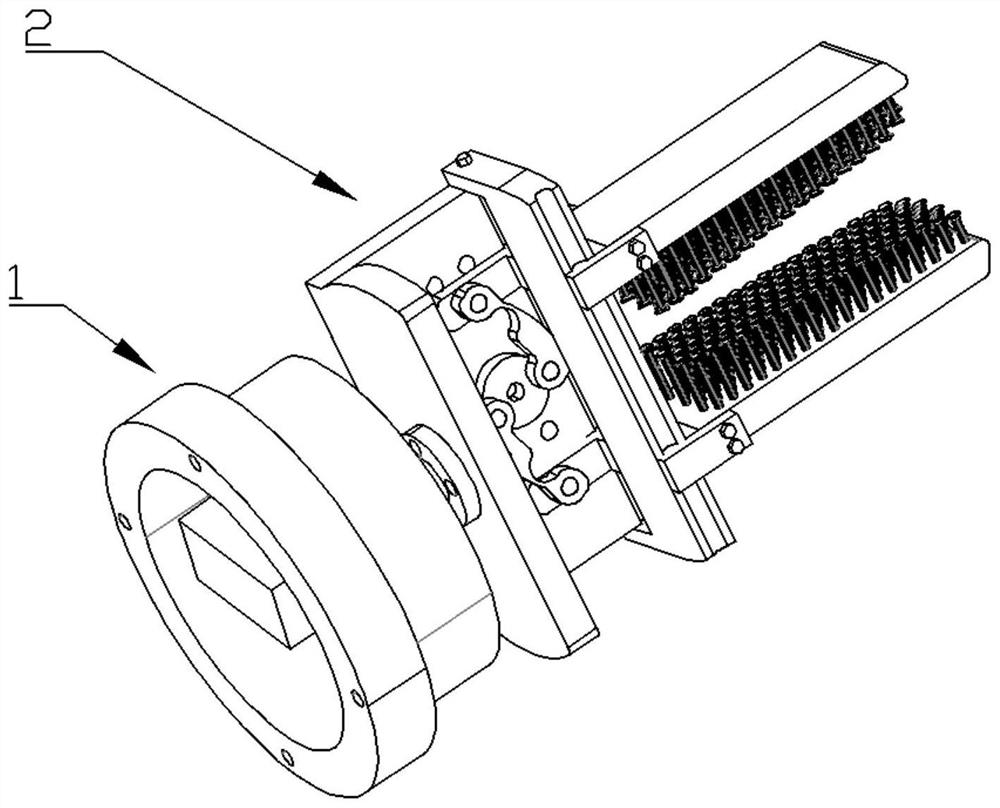

[0035] Such as figure 1 It is a structural schematic diagram of an embodiment of a mechanical arm clamp that self-adjusts the shape of an object, including two parts, a fixedly connected base 1 and a clamping mechanism 2. Usually, the clamping mechanism 2 passes through the base 1 and an external robot or other The ends of the mechanical arms with clamping function are connected;

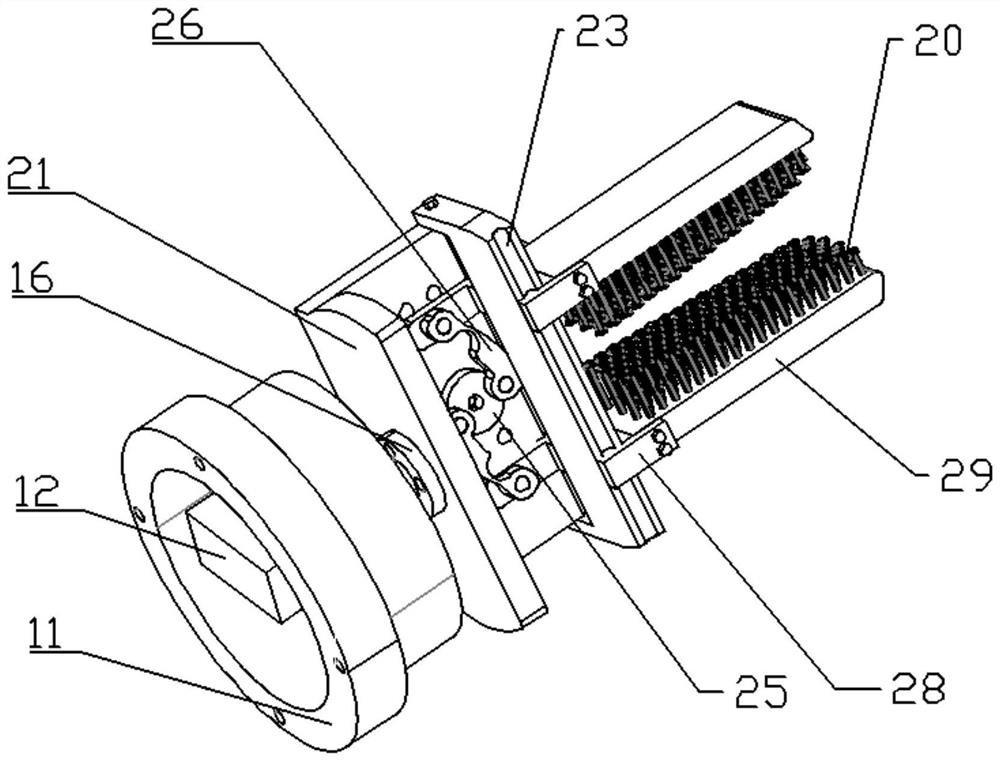

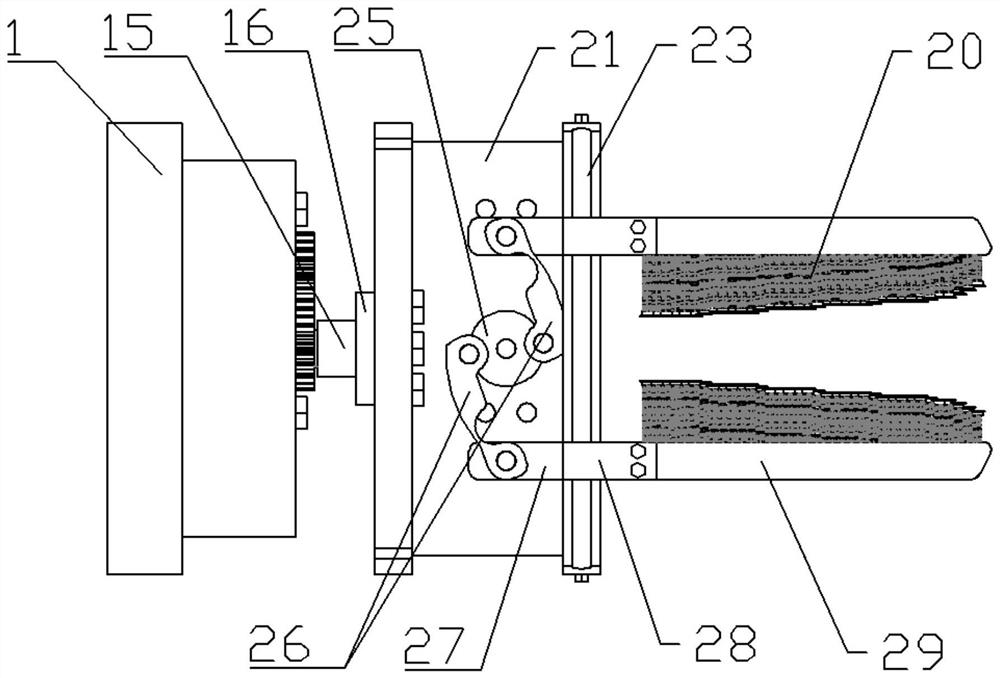

[0036] figure 2 The names of the specific structures of each part of an embodiment of a self-adjusting mechanical arm clamp for object shape are indicated. image 3 is the front view of this embodiment, Figure 4 is the rear view of this embodiment, Figure 5 It is a three-dimensional structure diagram of the clamping mechanism 2. The splint 29 is divided into upper and lower two, which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com