Patents

Literature

53results about How to "Increased rotational freedom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Targeted costimulatory polypeptides and methods of use to treat cancer

InactiveUS20110223188A1Function increaseIncreased rotational freedomAntibacterial agentsOrganic active ingredientsBinding domainWilms' tumor

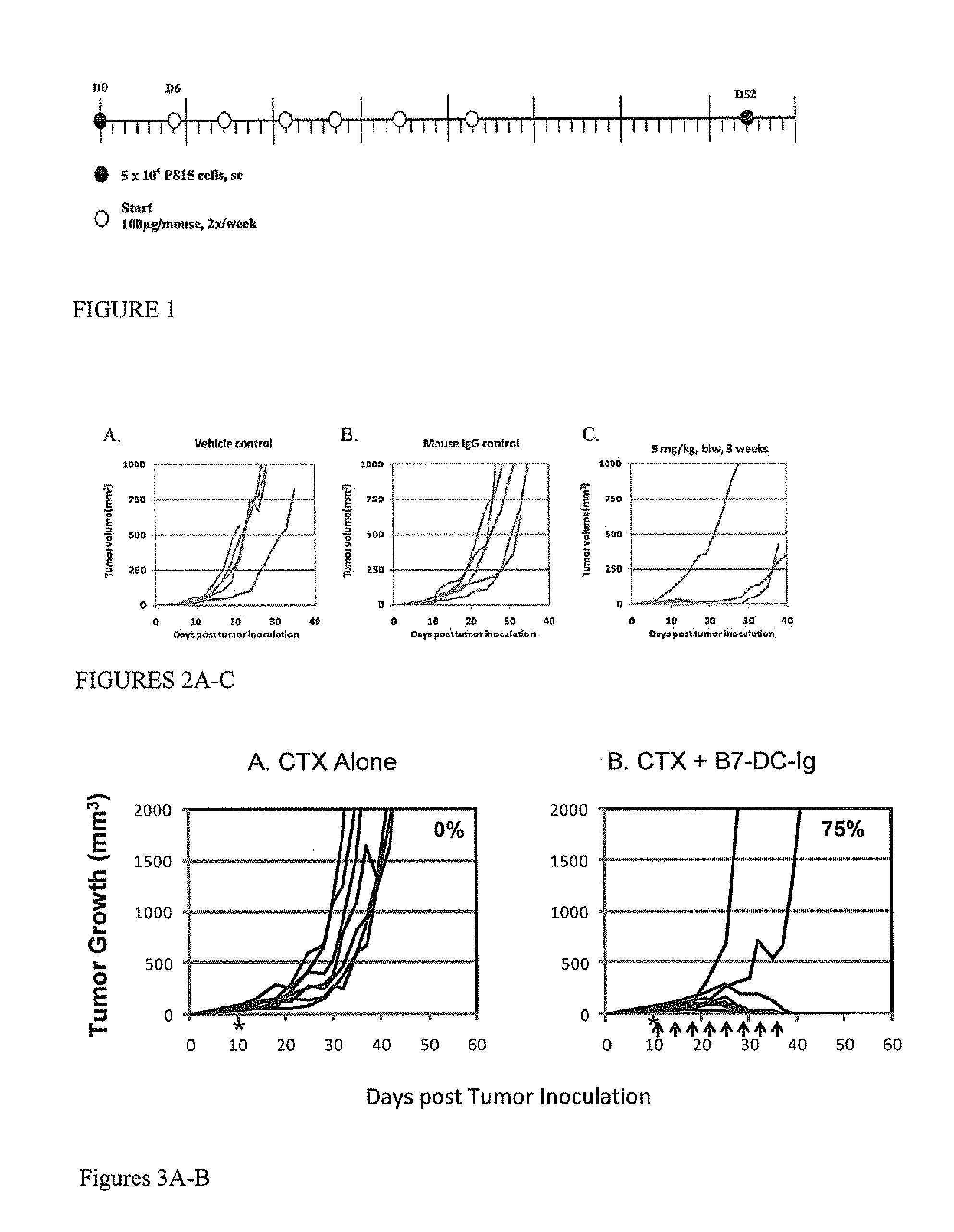

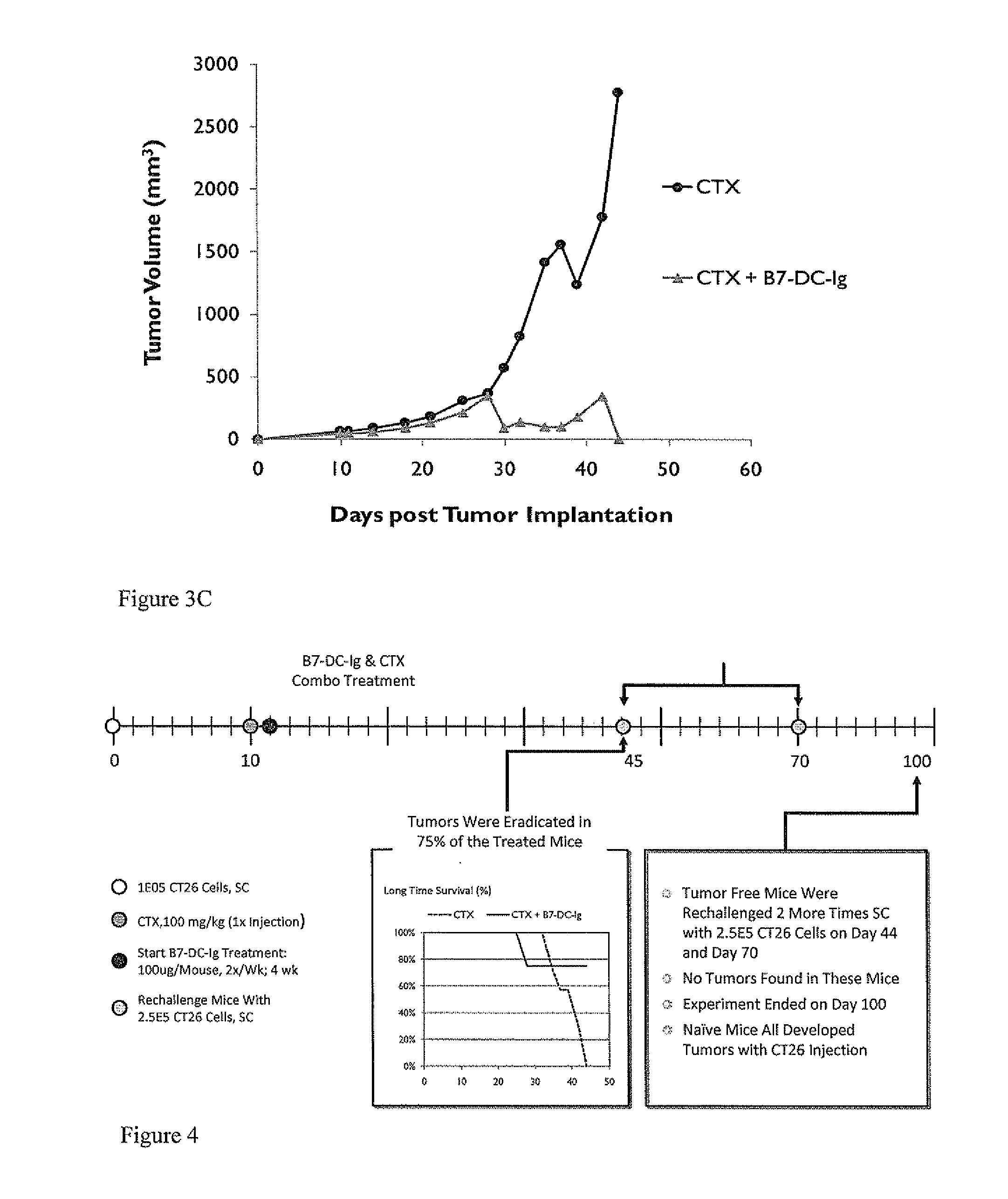

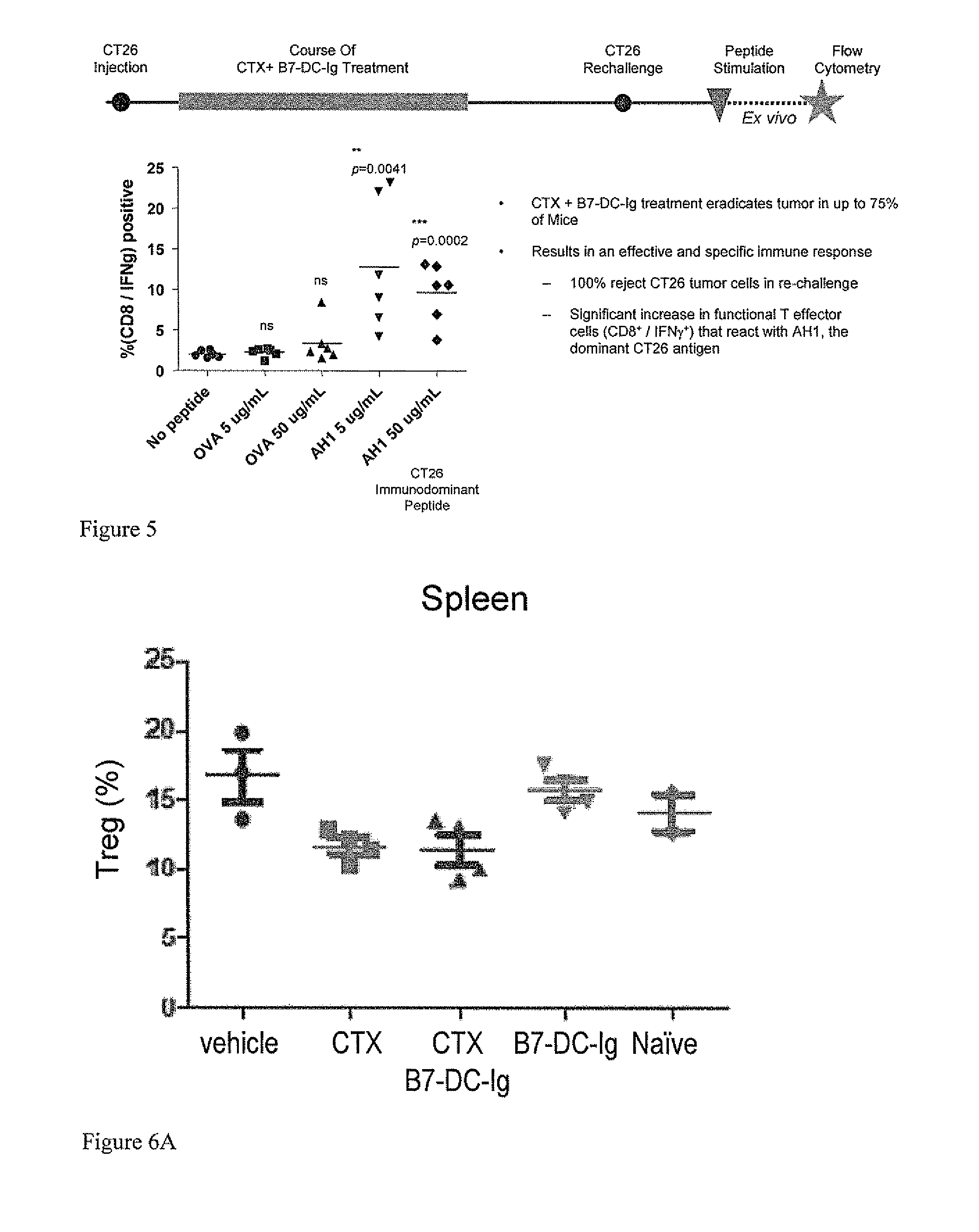

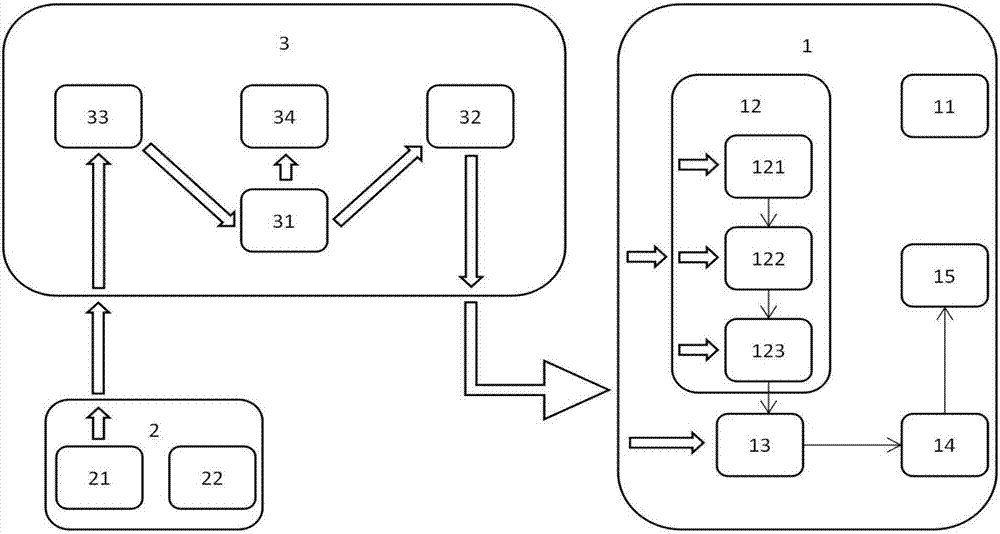

Compositions are provided that are targeted to tumors or tumor-associated neovasculature and enhance the function of tumor-infiltrating T cells. The compositions include fusion proteins that contain a T cell binding domain and a tumor / tumor-associated neovasculature targeting domain. The fusion proteins optionally contain a peptide / polypeptide linker domain and a domain that mediates dimerization or multimerization. The T cell binding domain can be a costimulatory molecule. Methods for using the fusion proteins to enhance an immune response are provided. Therapeutic uses for the disclosed compositions include the induction of tumor immunity.

Owner:AMPLIMMUNE

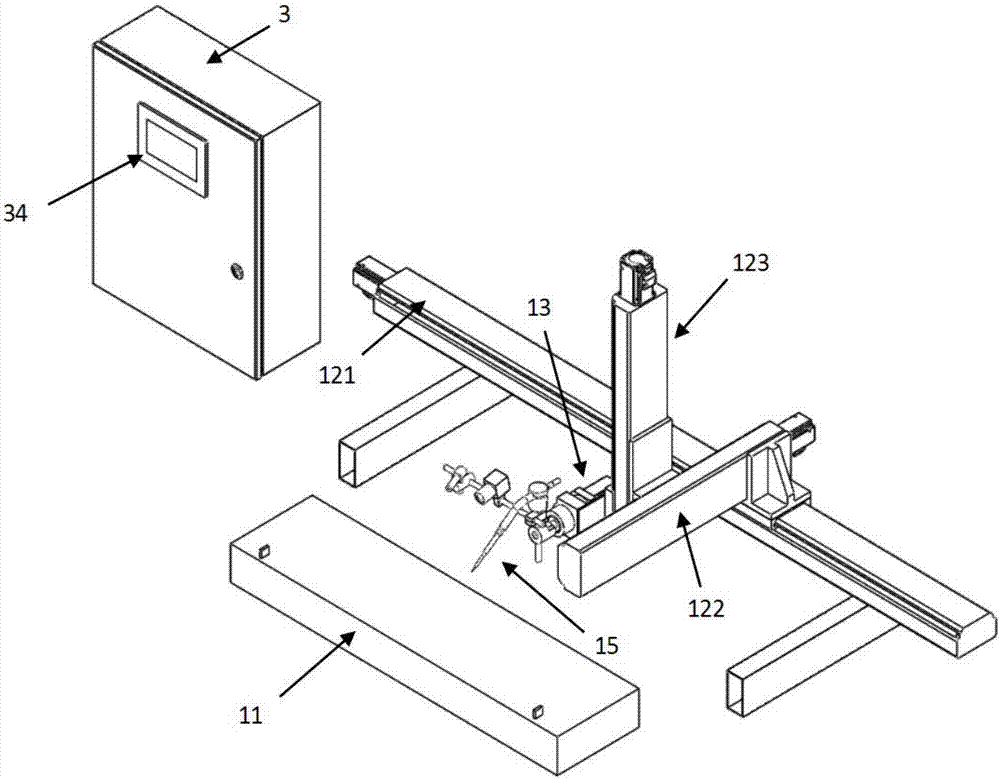

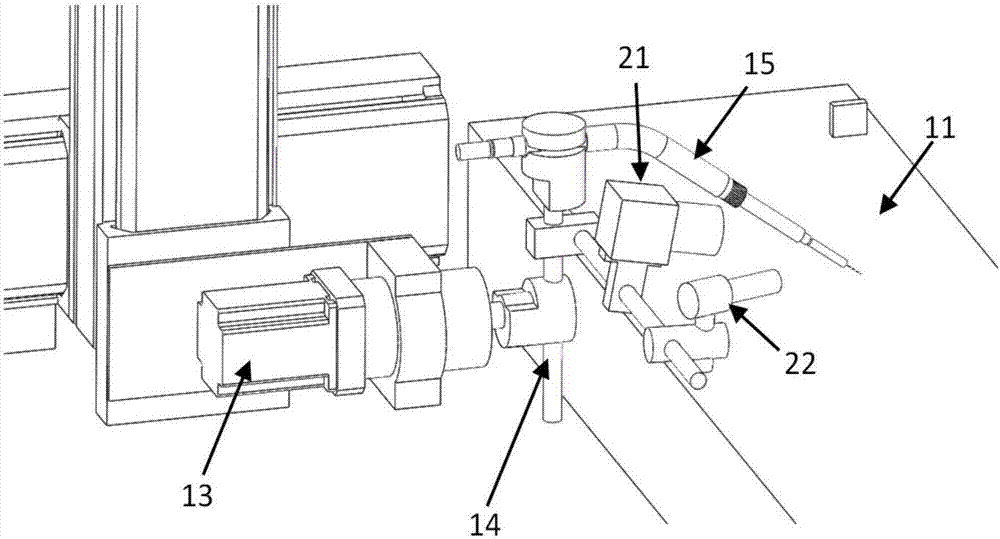

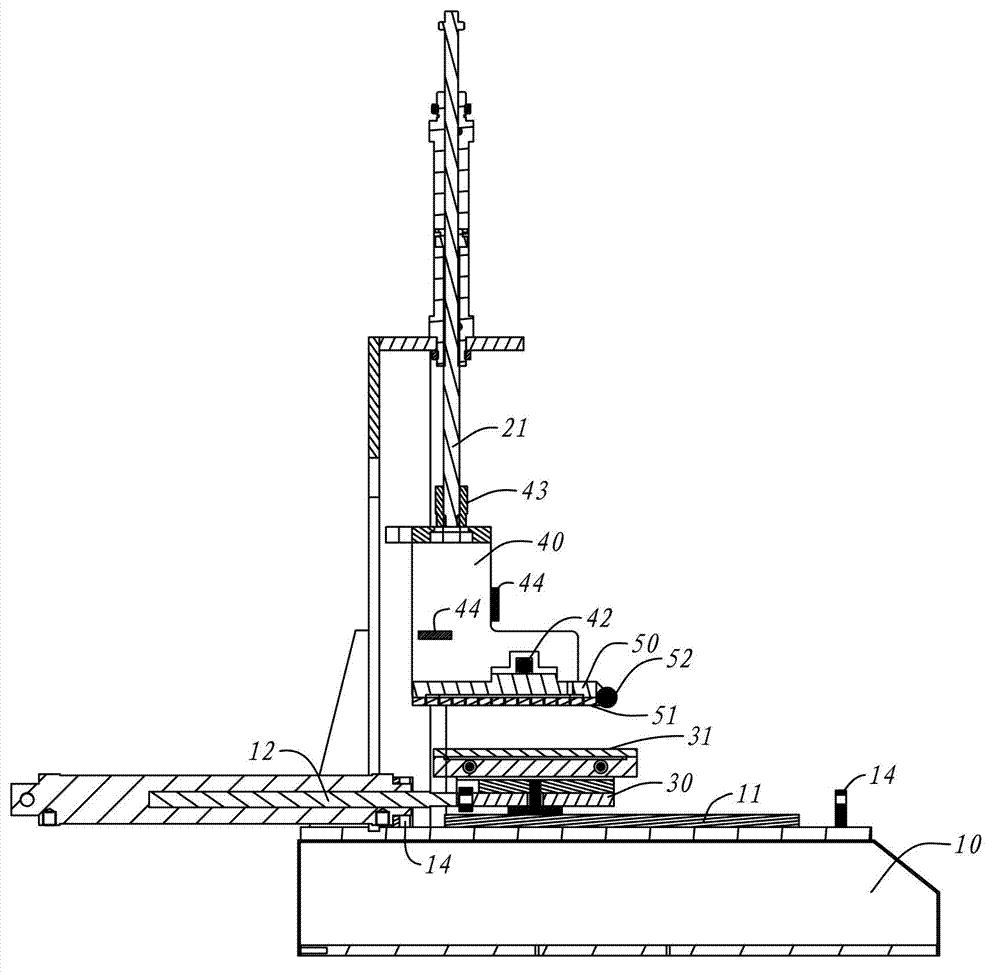

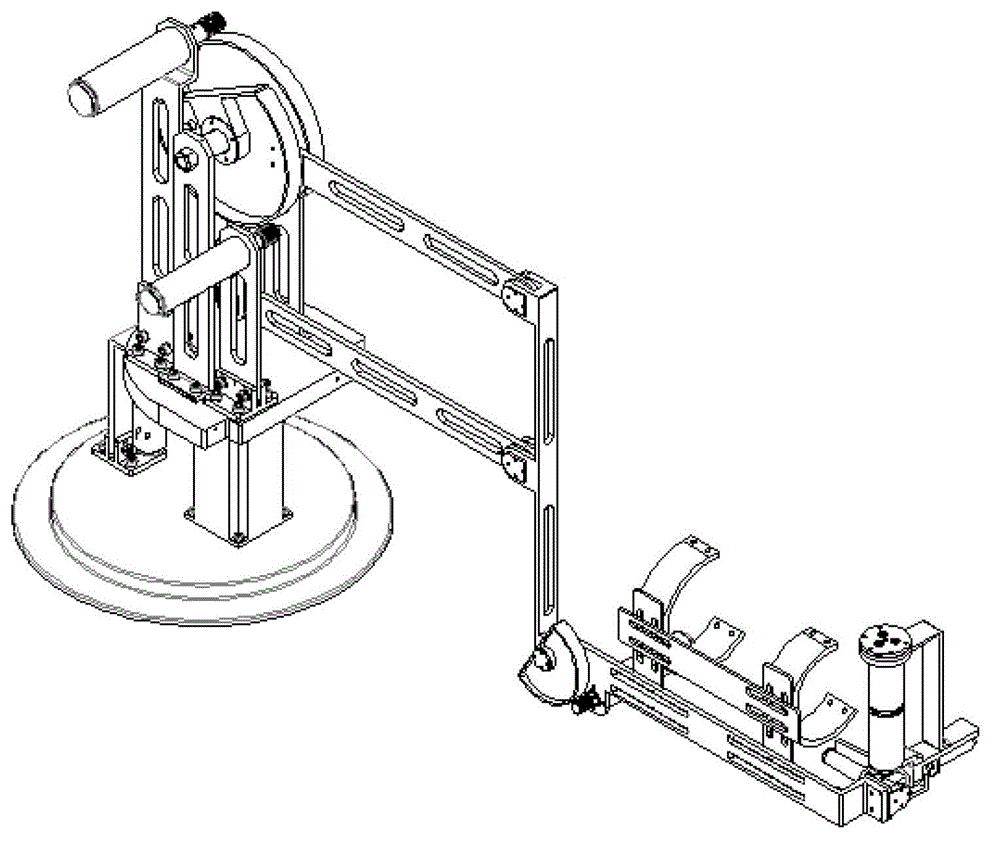

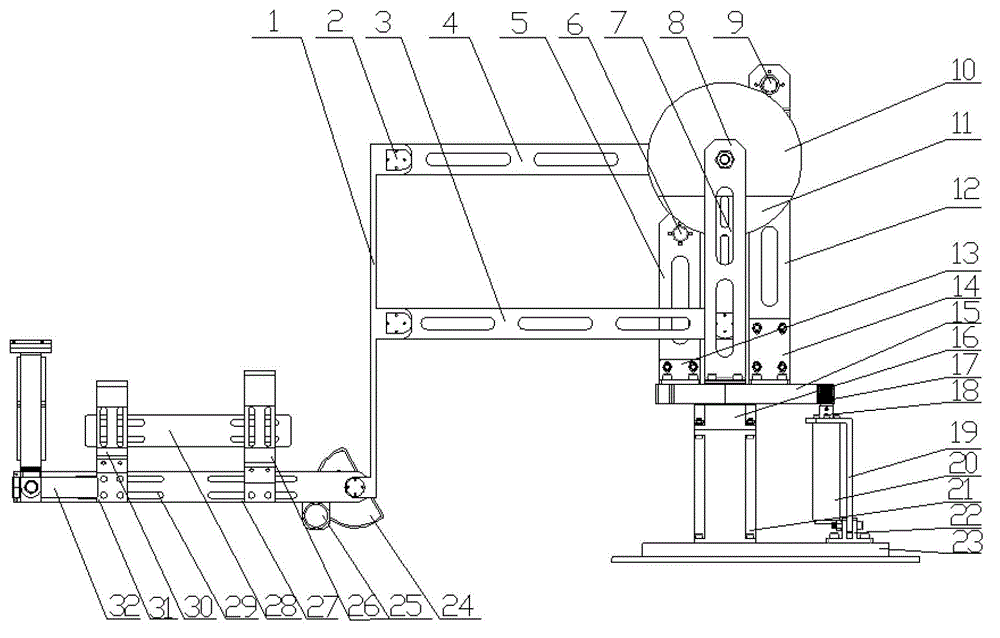

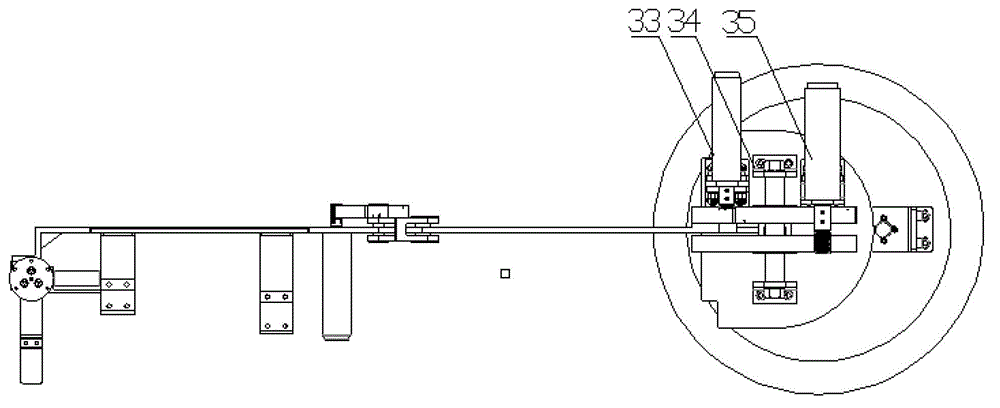

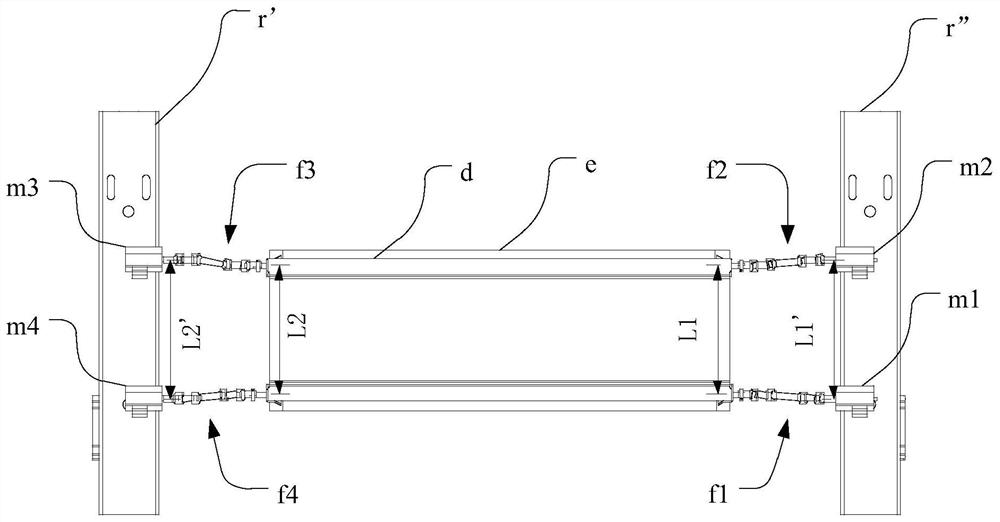

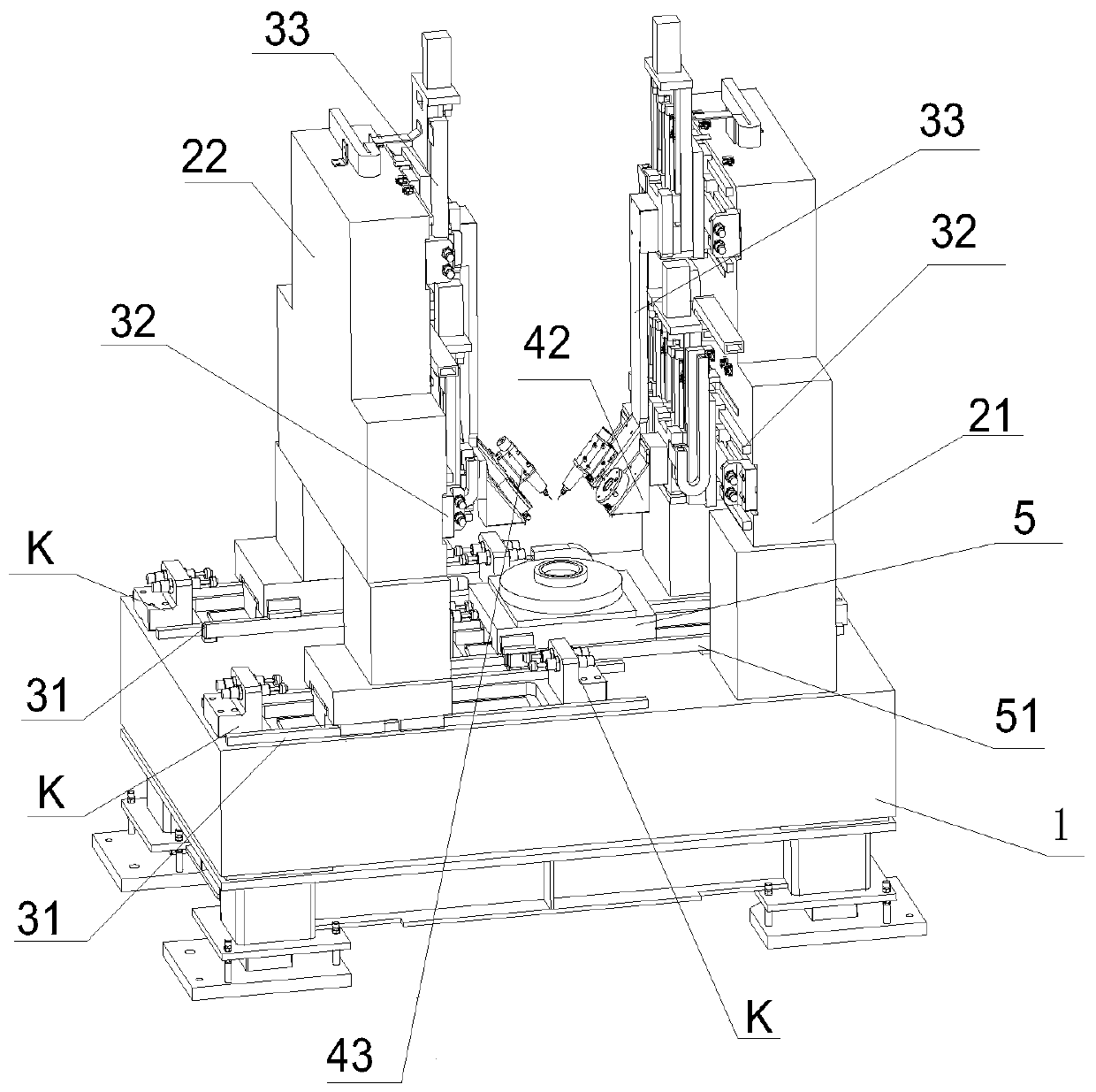

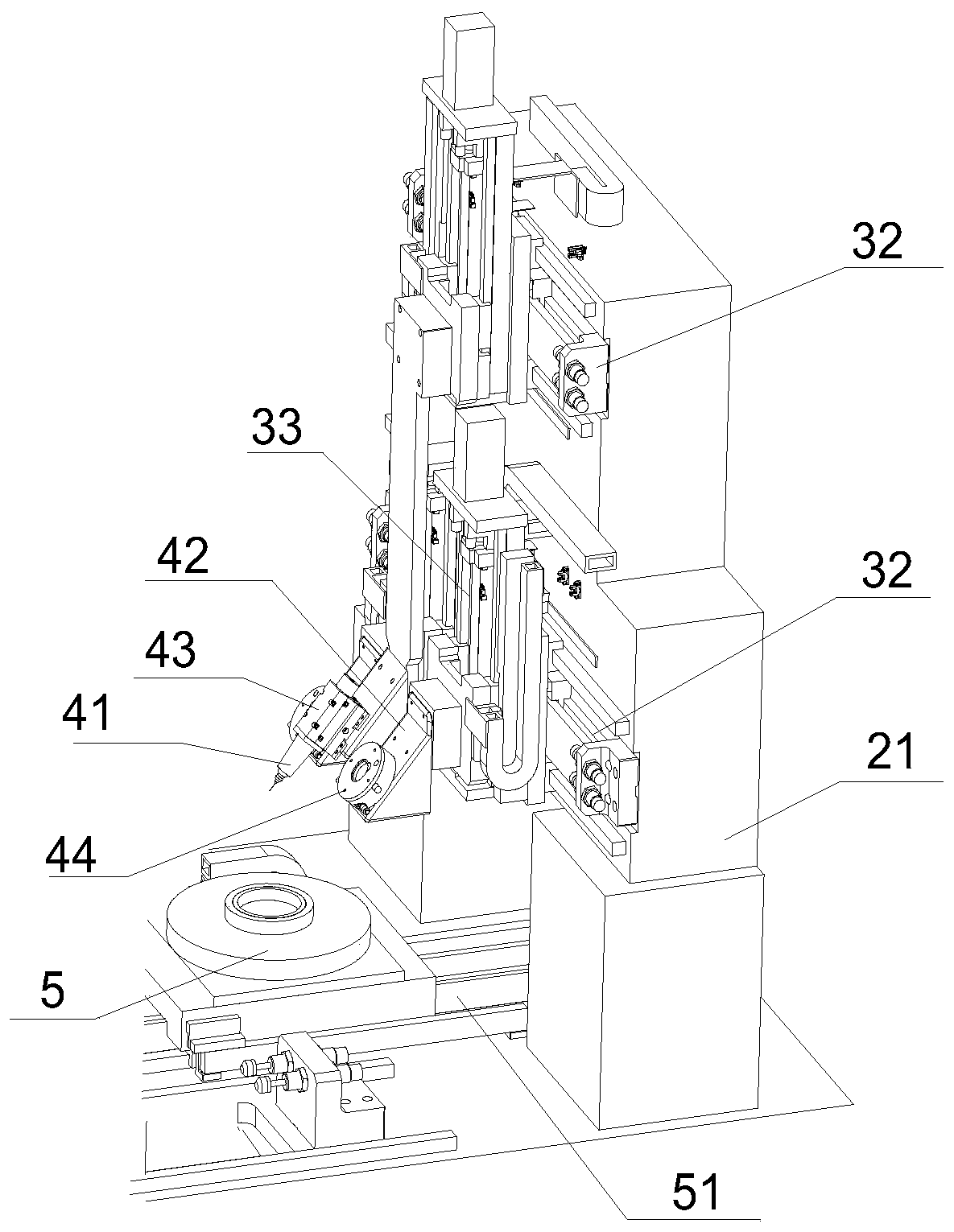

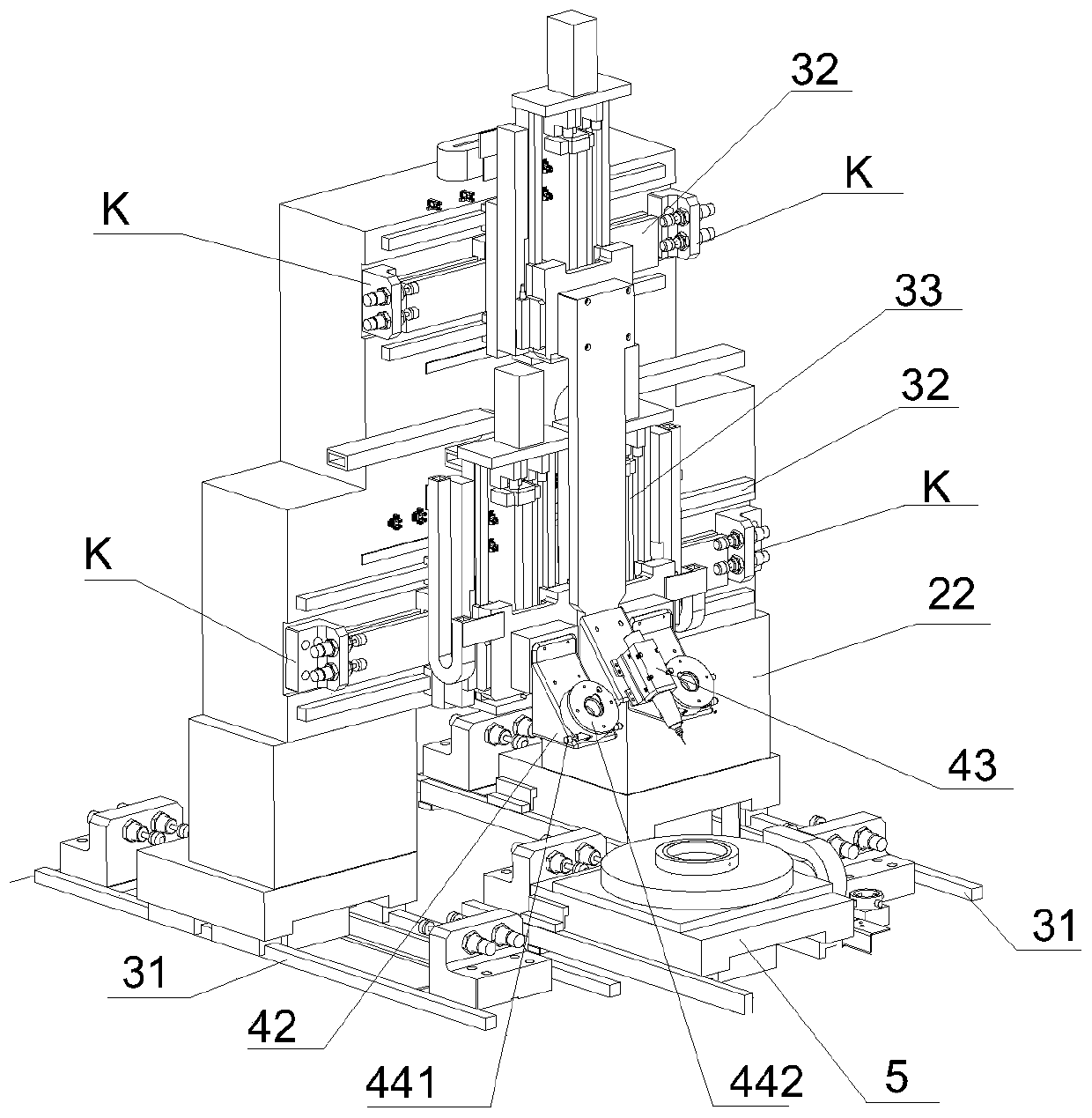

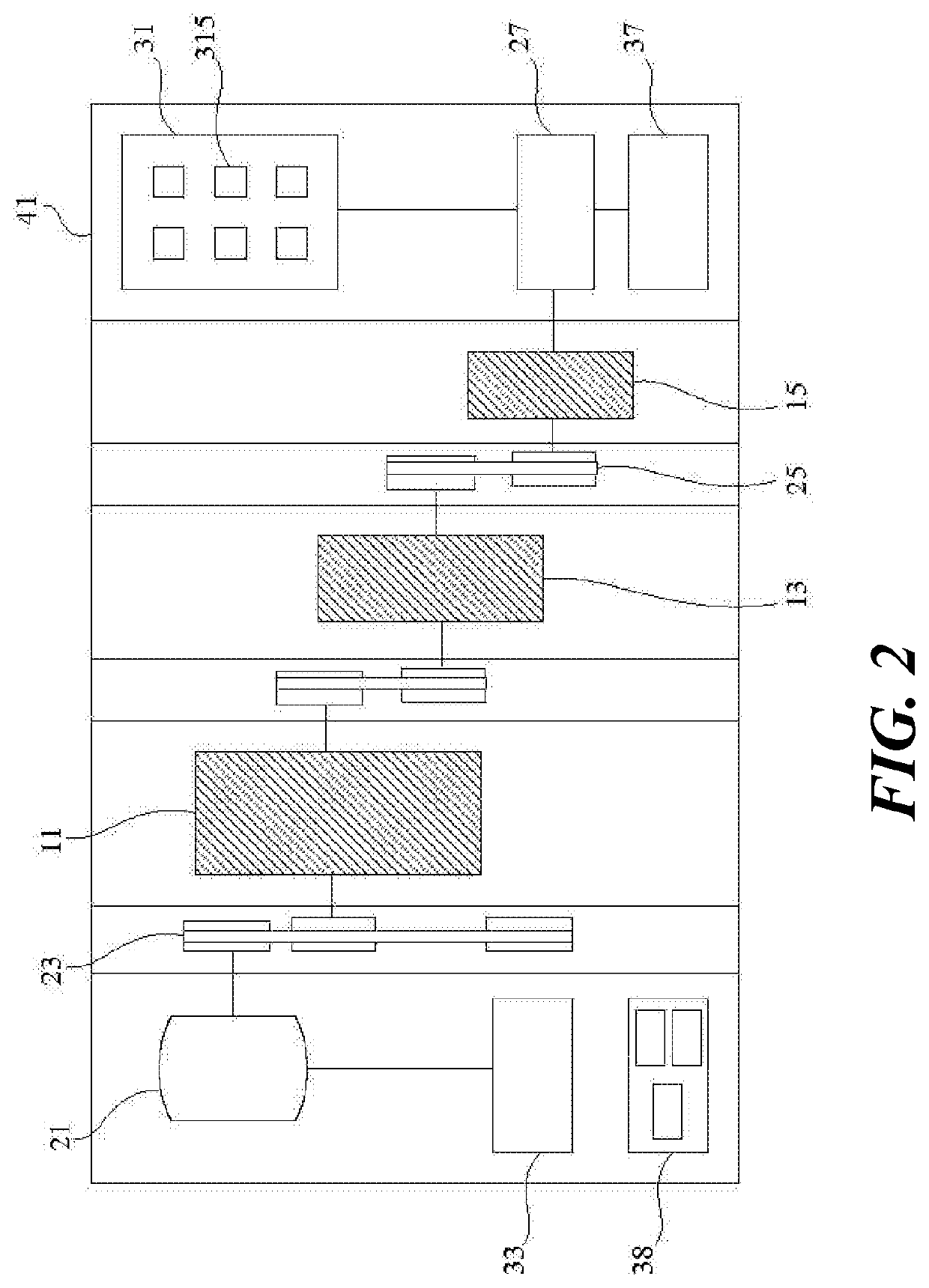

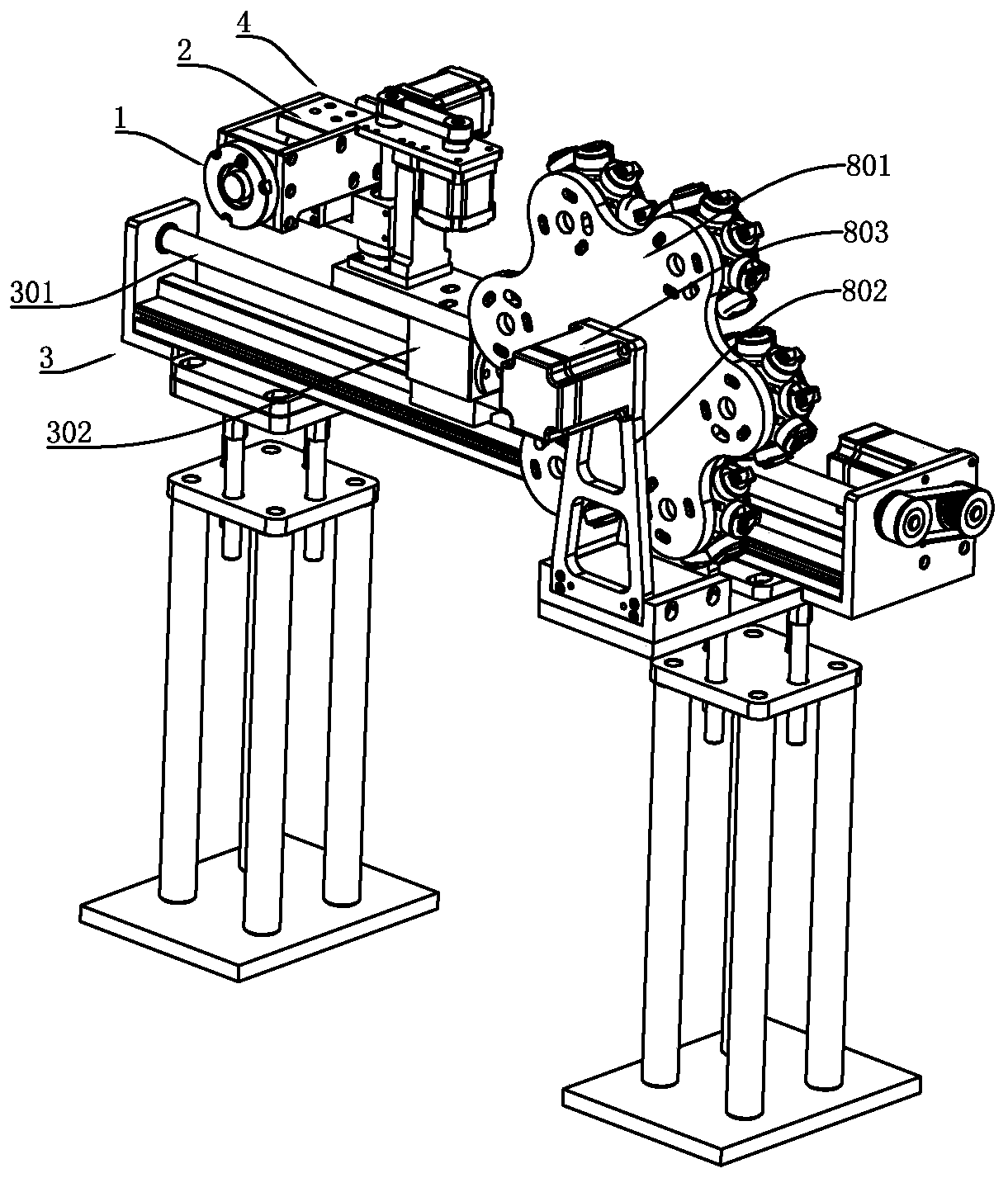

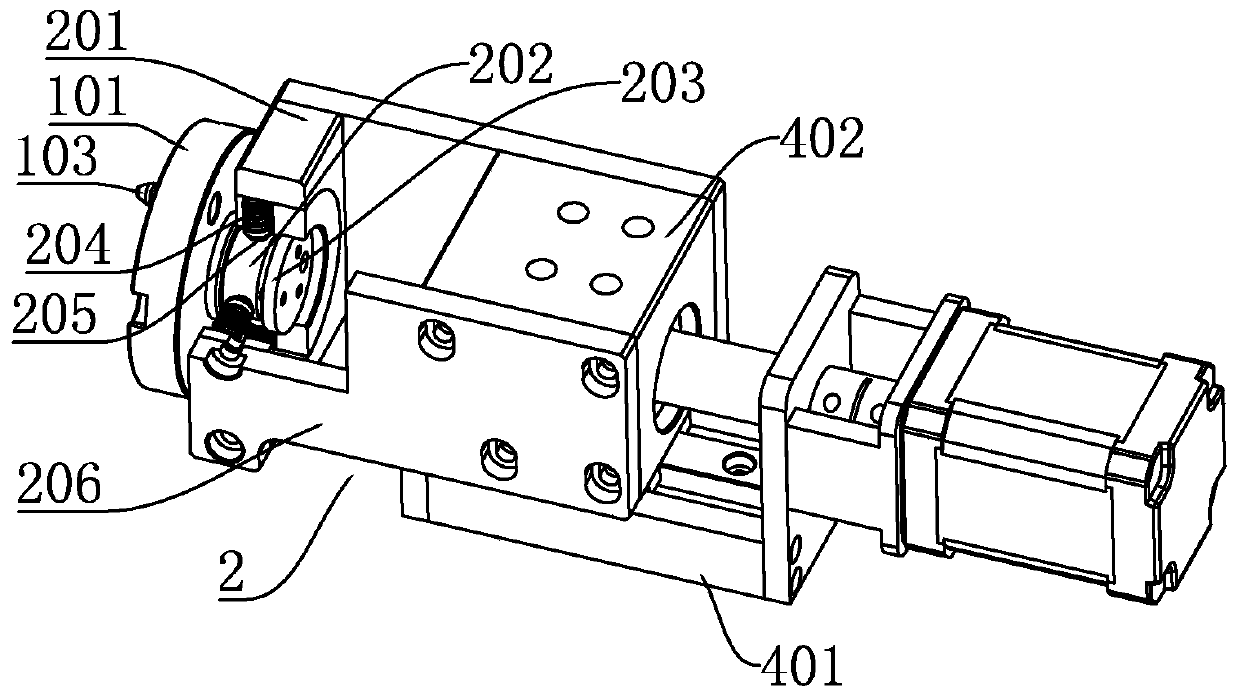

Welding seam tracking control device and method based on cross laser device

ActiveCN107414253AImprove detection accuracyReduce random errorWelding accessoriesEngineeringWeld seam

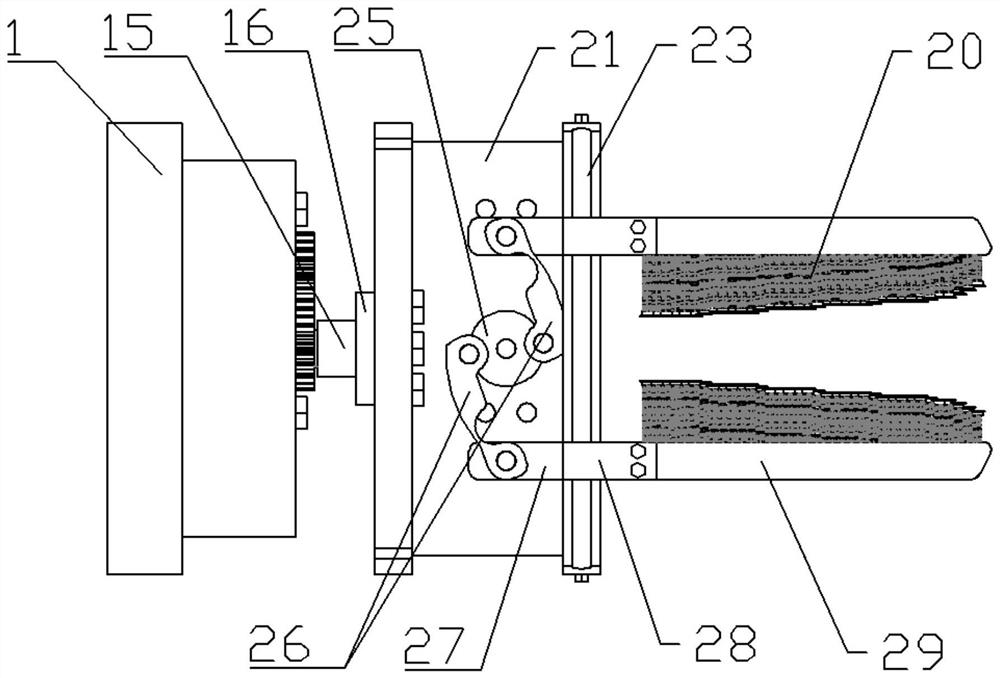

The invention discloses a welding seam tracking control device and method based on a cross laser device. The welding seam tracking control device is characterized by comprising a four-freedom-degree robot, a visual sensor and an integrated control cabinet; the four-freedom-degree robot comprises a working platform, a moving module, a Y-axis stepping motor, a bracket and a welding gun; the Y-axis stepping motor is fixed to a Z-axis slide table of a Z-axial moving module body, and a rotary shaft of the Y-axis stepping motor is parallel to the moving direction of a Y-axial moving module body; the bracket is used for fixing the visual sensor and the welding gun; the visual sensor comprises a camera and the cross laser device; and cross laser rays emitted by the cross laser device are irradiated on a to-be-welded workpiece and shot by the camera. The welding seam tracking control method is used for conducting vision measurement on fillet welding seams, three-dimensional position information of the welding seams, the inclined angle of the plane of the welded workpiece and the directions of the welding seams can be obtained accurately, and the welding gun can conduct high-precision self-adapting tracking control over the welding seams.

Owner:HEBEI UNIV OF TECH

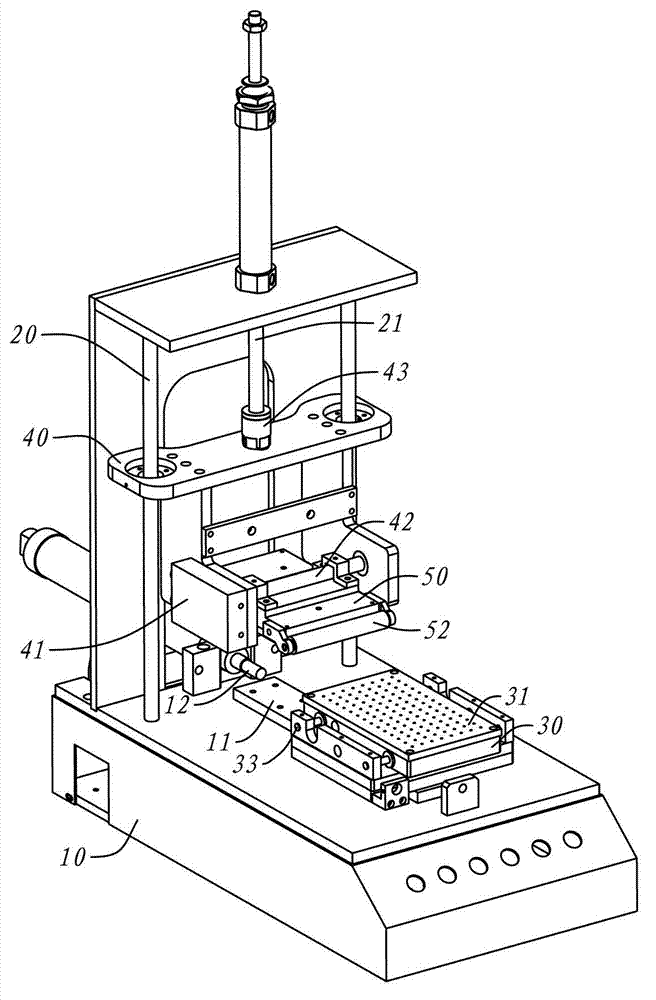

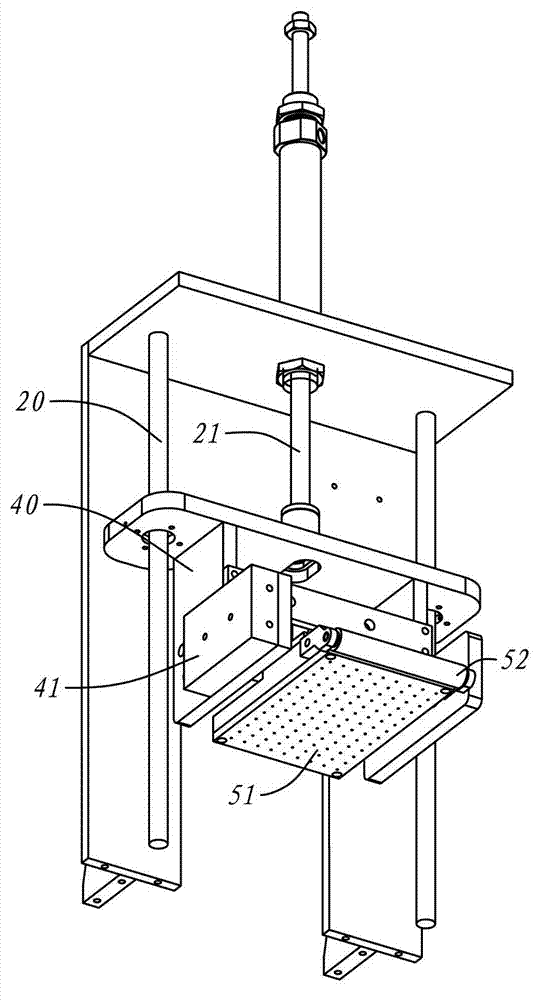

High-precision laminating machine

InactiveCN103192581APrecise positioningUniform pressureLamination ancillary operationsLaminationTransverse axisEngineering

The invention discloses a high-precision laminating machine which is characterized by comprising a base and a vertical rail, wherein a transverse rail is arranged on the base, a lower platform is movably cooperated with the transverse rail, the top of the lower platform is provided with a lower laminating surface, the vertical rail is vertically fixed above the base, a sliding support is upward and downward slidingly cooperated with the vertical rail, an upper platform is rotatably cooperated with a transverse shaft of the sliding support, and the lower end of the upper platform is provided with an upper laminating surface. The sliding support is positioned at a high place of the vertical rail, and a to-be-laminated part is vac-sorbed on the upper laminating surface; then another to-be-laminated part is vac-sorbed on the lower laminating surface; the upper platform is rotated around a transverse axis thereof until the upper laminating surface is parallel to the lower laminating surface, then the sliding support falls along the vertical rail and applies a pressure until the two to-be-laminated parts are tightly bonded together through optical cement carried by the two parts, and therefore, a laminated product is obtained. According to a scheme in the invention, when the upper platform presses downwardly, the upper platform has uniform pressure relative to the lower platform, the downward pressing stroke of the upper platform is individually controlled by the sliding support, so high precision is obtained, and the laminating machine can rapidly adapt to laminated products with different thicknesses.

Owner:WENSHAN KETAIFENG ELECTRONICS CO LTD

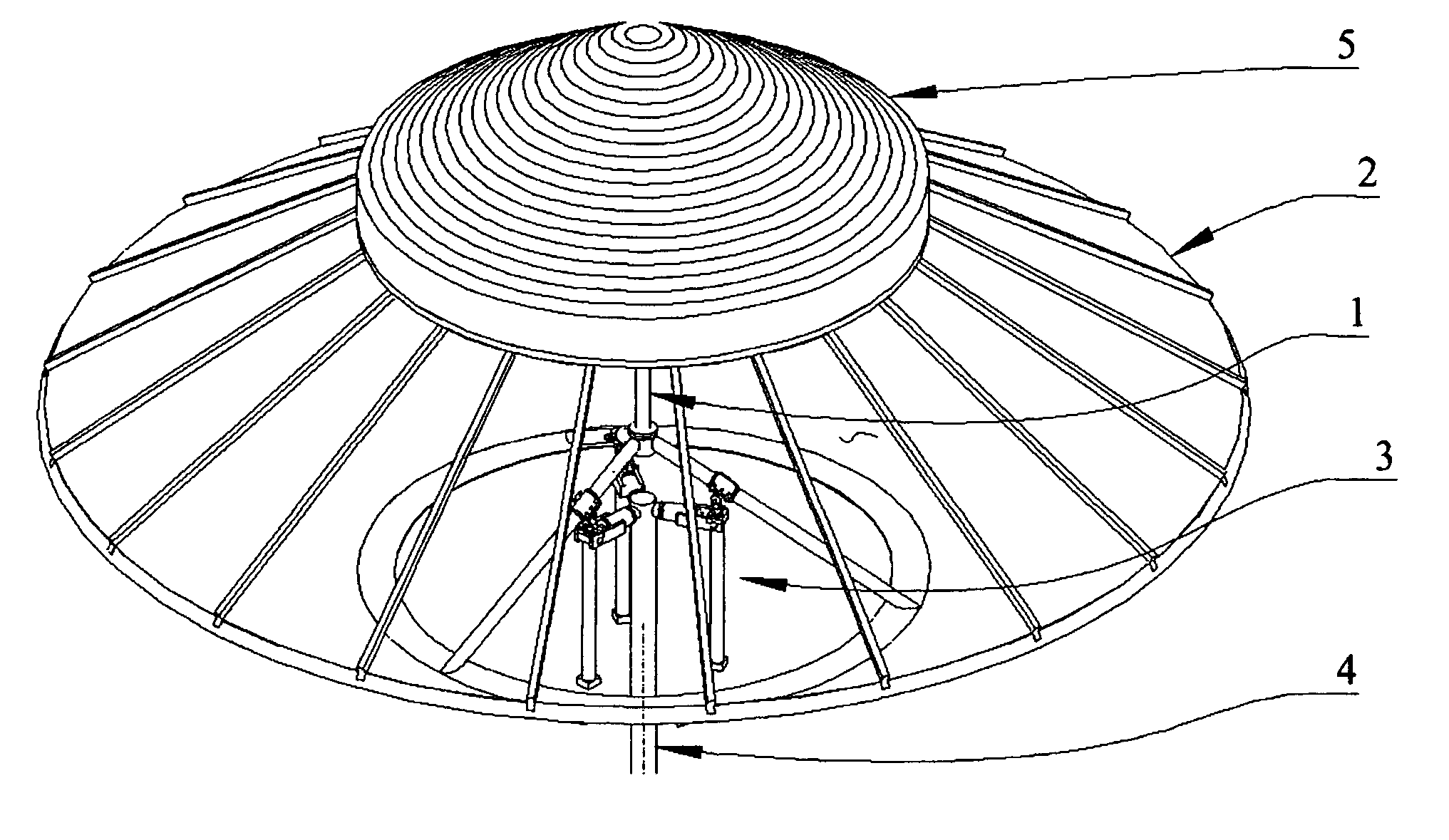

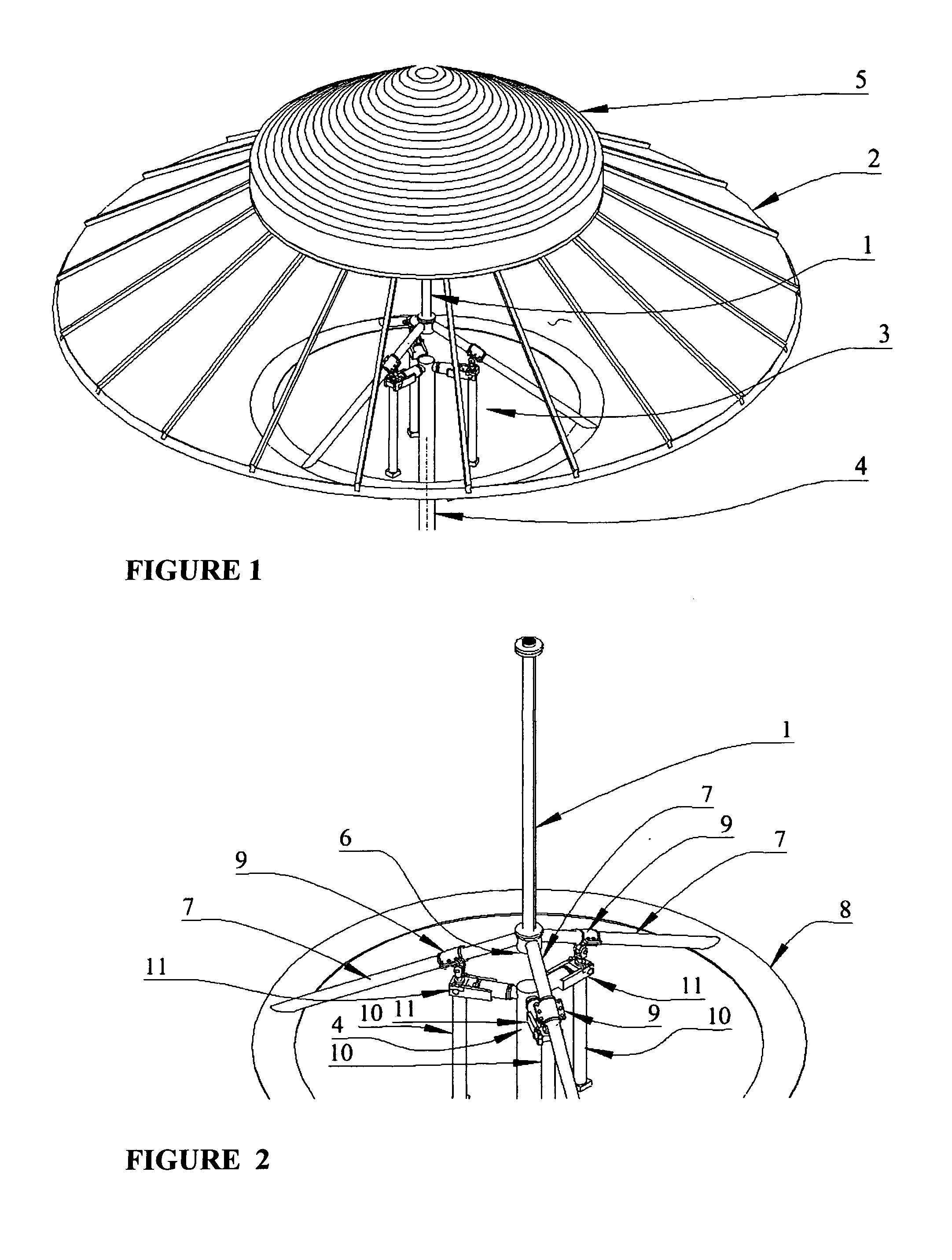

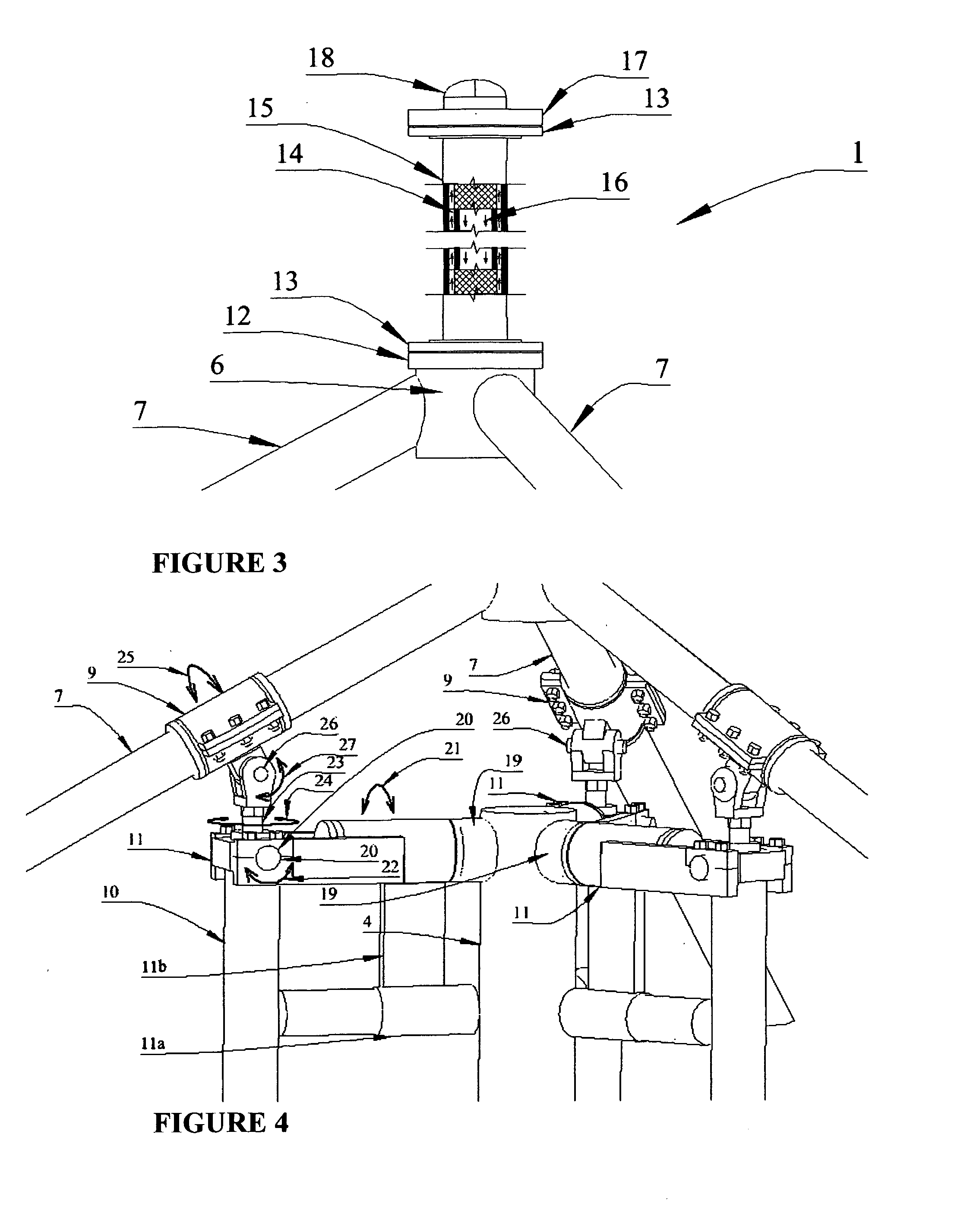

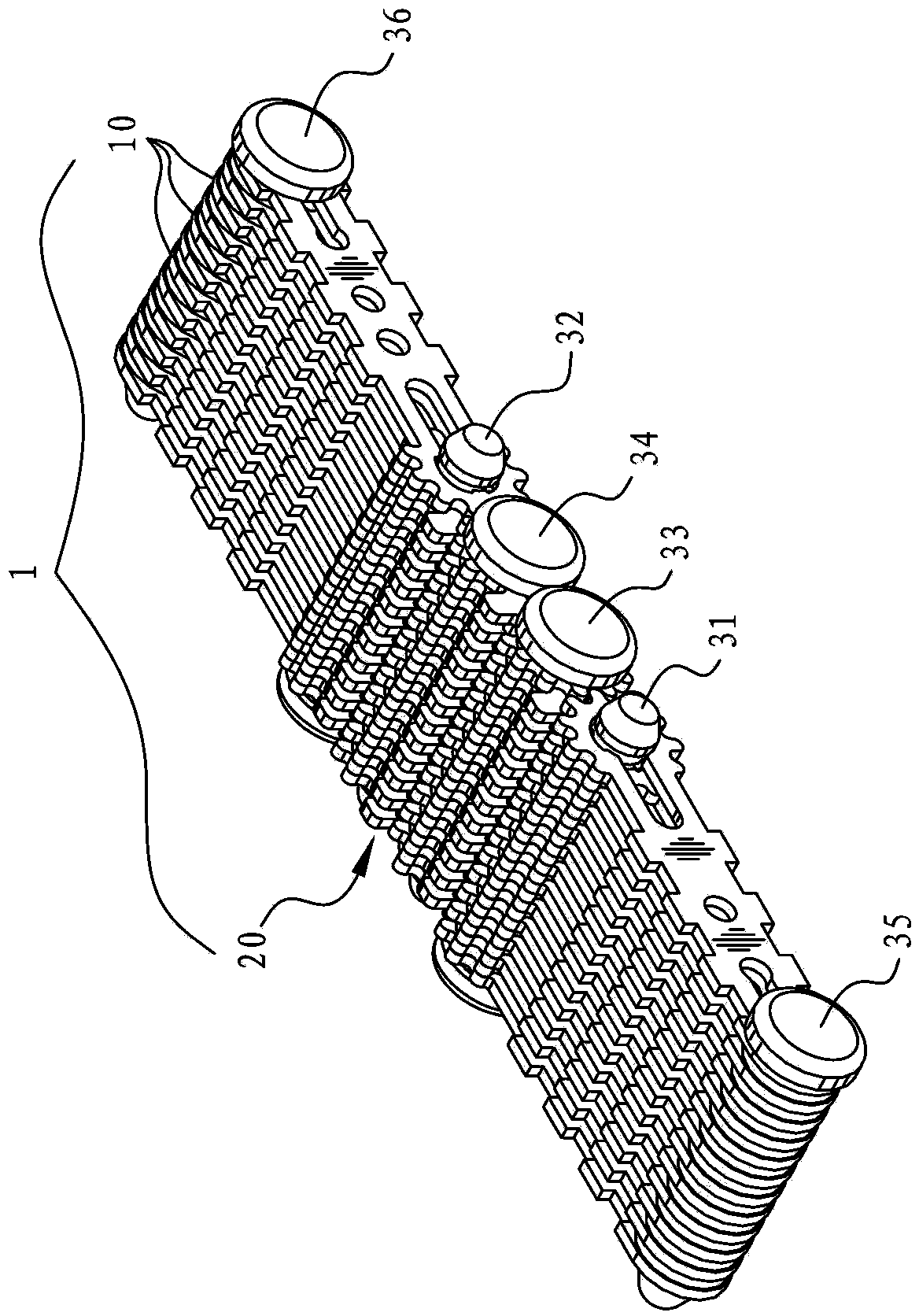

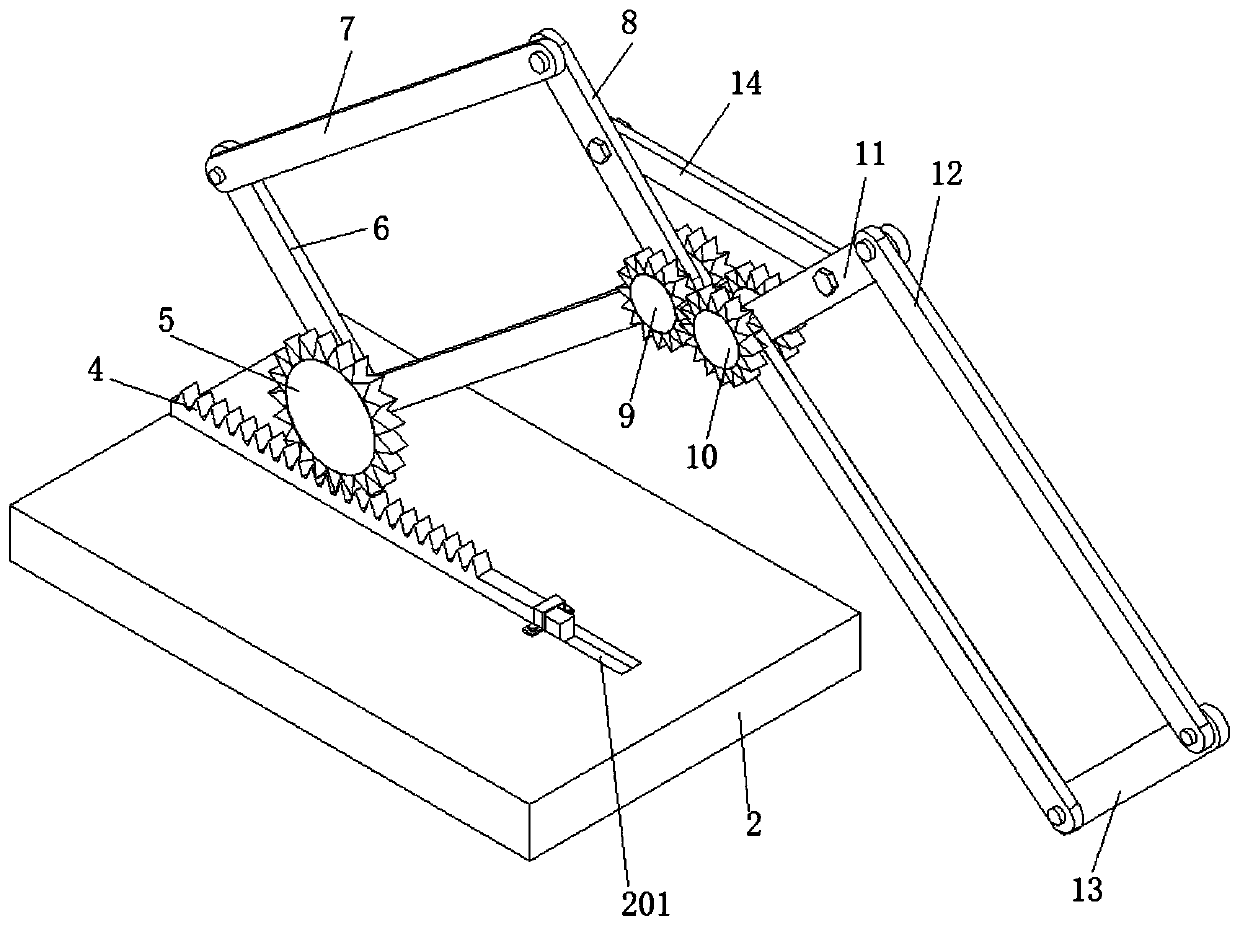

Concentrating tracking solar energy collector

InactiveUS20120174966A1Improve automationIncreased rotational freedomPhotovoltaic supportsSolar heating energyHigh concentrationThermal energy

A Conical reflecting, concentrating, two-axis tracking solar energy collector is disclosed.An inverted multi-segmented conical reflecting surface concentrates and focuses solar energy at very high concentrations onto a very thermodynamically efficient receiver tube or absorber pipe assembly.The receiver tube consists of a cylindrical array of HCPV solar cells mounted onto a polygonal extruded Aluminum tube. These HCPV solar cells are 36% efficient and can receive solar concentrations as high as 1000 SUNS. A heat transfer fluid is pumped through the receiver tube in contact with the interior surface of the Aluminum tube to remove the heat from the HCPV solar cells. In cooling the HCPV cells, the heat transfer fluid is heated. The resulting thermal energy, ⅔ of the available solar energy, can be utilized for ammonia absorption air conditioning and home heating, about ⅔-¾ of a home's energy requirement.The absorber pipe assembly encloses a black surfaced absorber pipe within a larger diameter transparent glass pipe and a heat transfer fluid is pumped through the annulus in direct contact with the black absorbing surface. A very efficient transfer of heat is effected.This conical concentrator and receiver combination is caused to track the by three hydraulic cylinders.The concentrating solar energy collector disclose is intended to and is capable of economically providing for all of the energy needs of a home or building.

Owner:SNIPES BRADFORD JOEL

Wearable six-dimension force sense interaction device with redundant freedom degrees

InactiveCN103331746ARealize free conversionIncreased fatigueManipulatorClassical mechanicsElectric machinery

The invention discloses a general type six-dimension force sense interaction device with seven freedom degrees. The device is composed of a Z axis rotation substrate, a shoulder joint mechanical arm, an elbow joint mechanical arm, a bias spherical wrist holding mechanism, a six-dimension force sensor and drive motors. The shoulder joint mechanical arm is installed on the Z axis rotation substrate through a revolute pair, the elbow joint mechanical arm is installed at the tail end of the shoulder joint mechanical arm, the bias spherical wrist holding mechanism is fixed at one end of the elbow joint mechanical arm, the six-dimension force sensor is fixed on the holding mechanism, and the seven freedom degrees of the interaction device respectively exert feedback force through seven sets of drive motors. An operator achieves complex interactive operation through the bias spherical wrist holding mechanism. The general type six-dimension force sense interaction device with the seven freedom degrees is simple in structure, flexible in operation, free of singular points in mechanism motion, simple in mechanical kinetic model and convenient to control, and moreover, a U-type support at the elbow can reduce fatigue of the operator and increase comfort of the operation.

Owner:BEIHANG UNIV

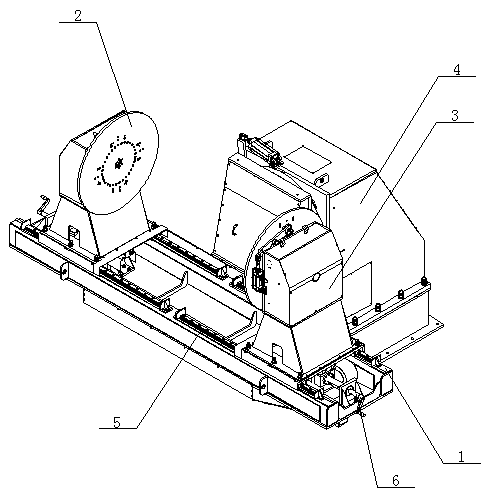

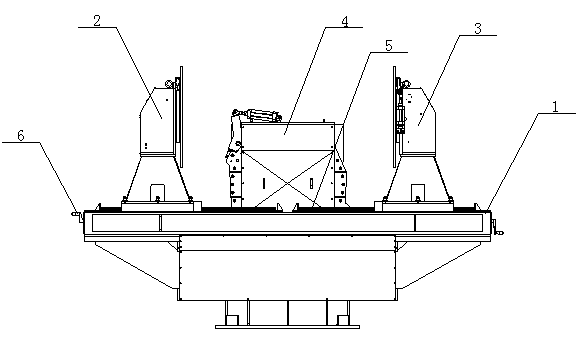

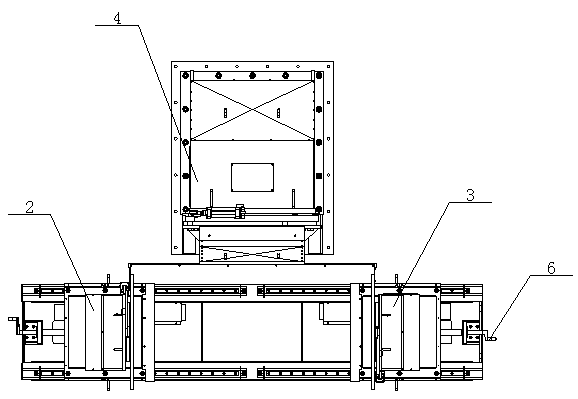

Double-shaft positioner

InactiveCN103769790AVarious locationsRich postureWelding/cutting auxillary devicesAuxillary welding devicesVertical planeDegrees of freedom

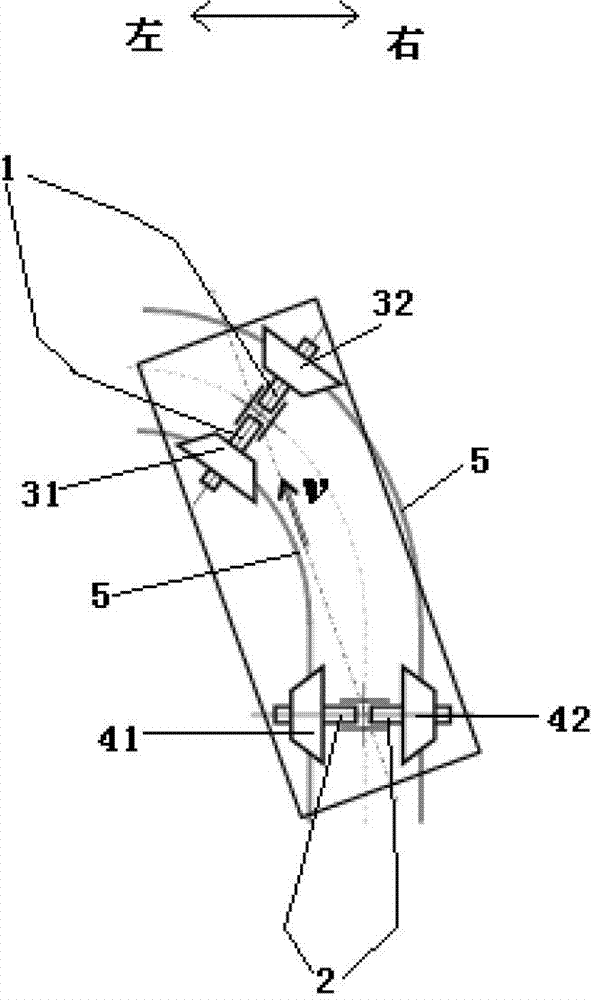

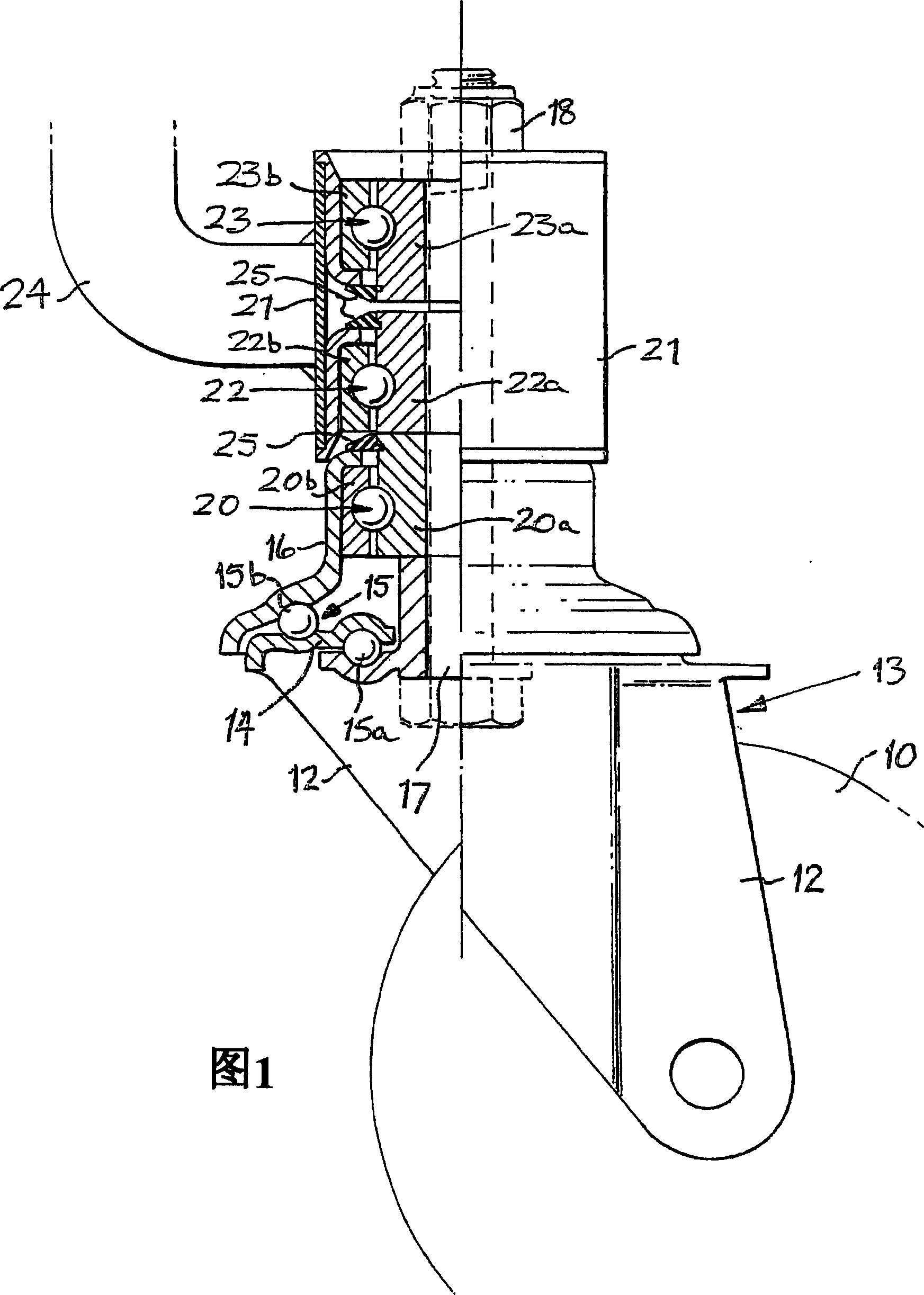

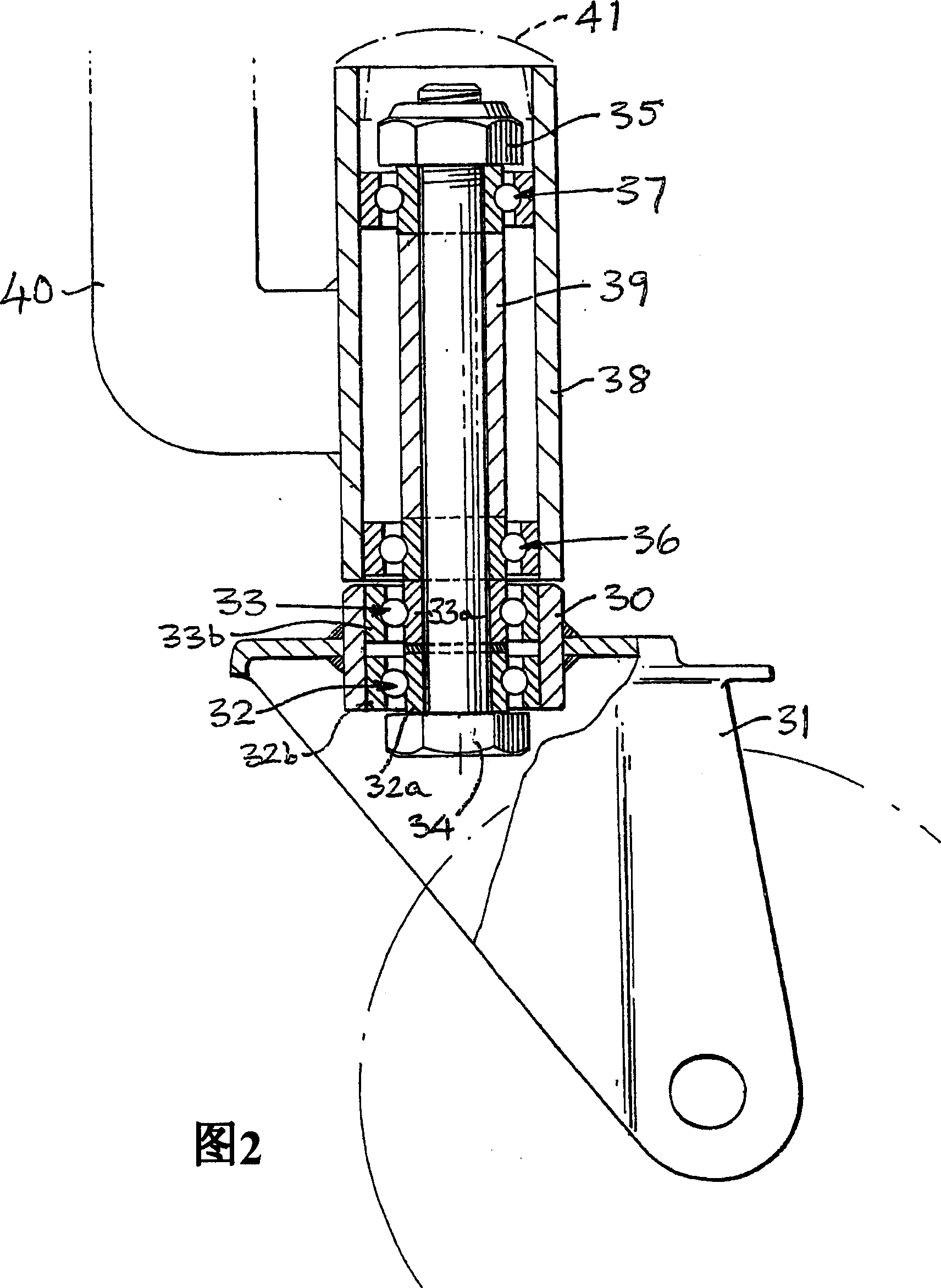

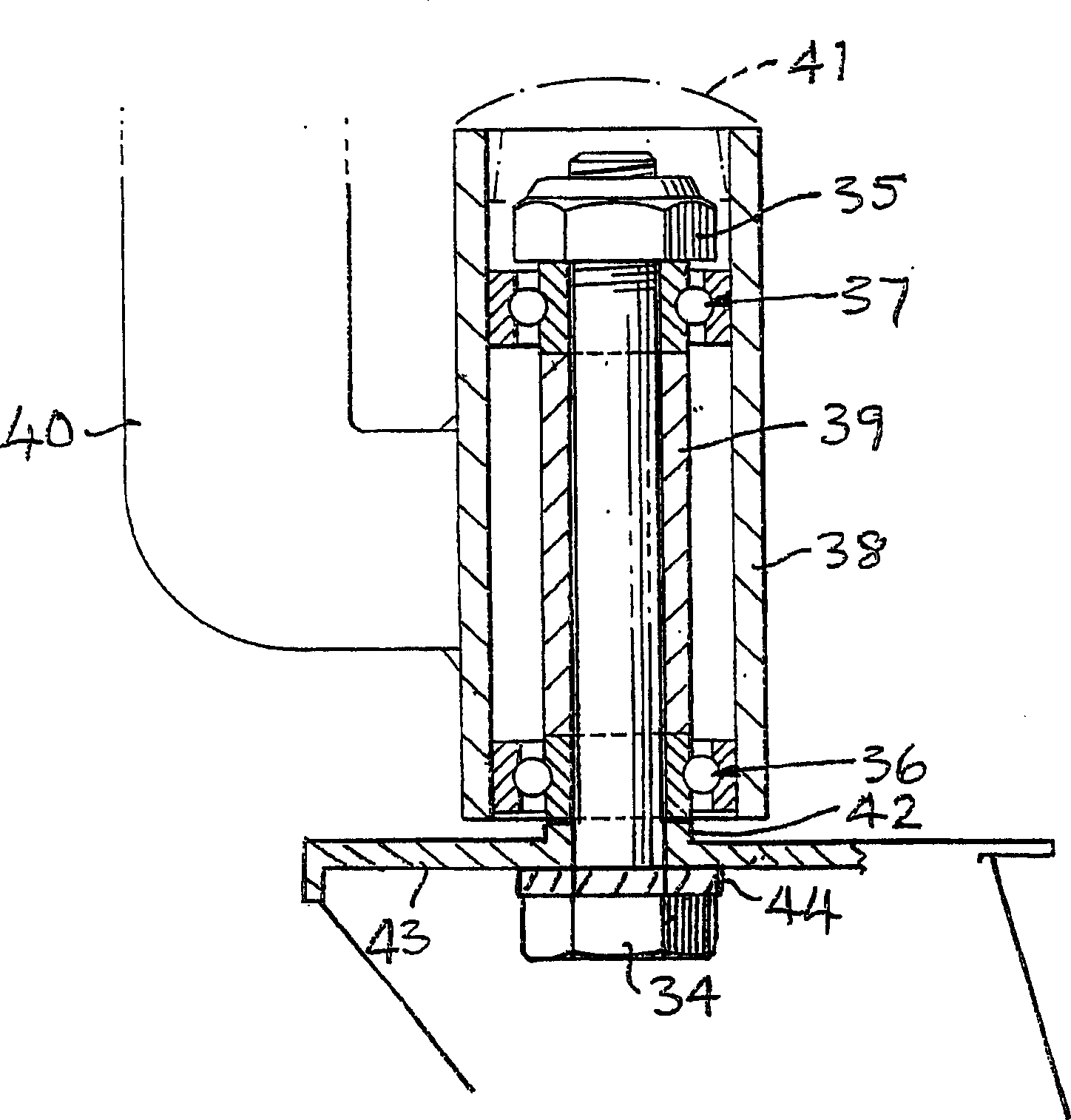

A double-shaft positioner relates to the technical field of automatic welding workpiece position adjusting equipment. One end of a positioner support platform (1) is provided with a single-shaft positioner tailstock (3), one side of the positioner support platform (1) is provided with a single-shaft positioner (4), linear slide rails (5) are arranged between a single-shaft positioner headstock (2) and the single-shaft positioner tailstock (3) and on the positioner support platform (1), both ends of the positioner support platform (1) are respectively provided with a screw transmission mechanism (6), and the screw transmission mechanisms (6) are connected with the single-shaft positioner headstock (2) and the single-shaft positioner tailstock (3). The double-shaft positioner adds rotating degree of freedom to the degree of freedom of an original positioner, enables a workpiece to rotate on the vertical plane, and meanwhile, can clamp the workpiece at both ends of the workpiece, so that the positions and the postures that the workpiece can reach become richer to meet different welding requirements.

Owner:REIS ROBOTICS KUSN

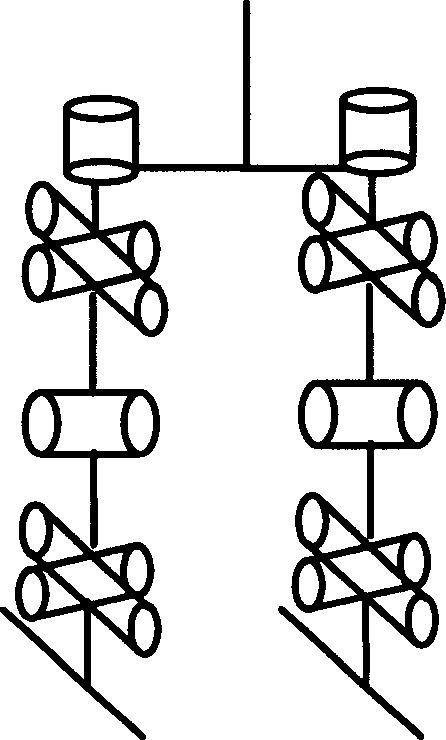

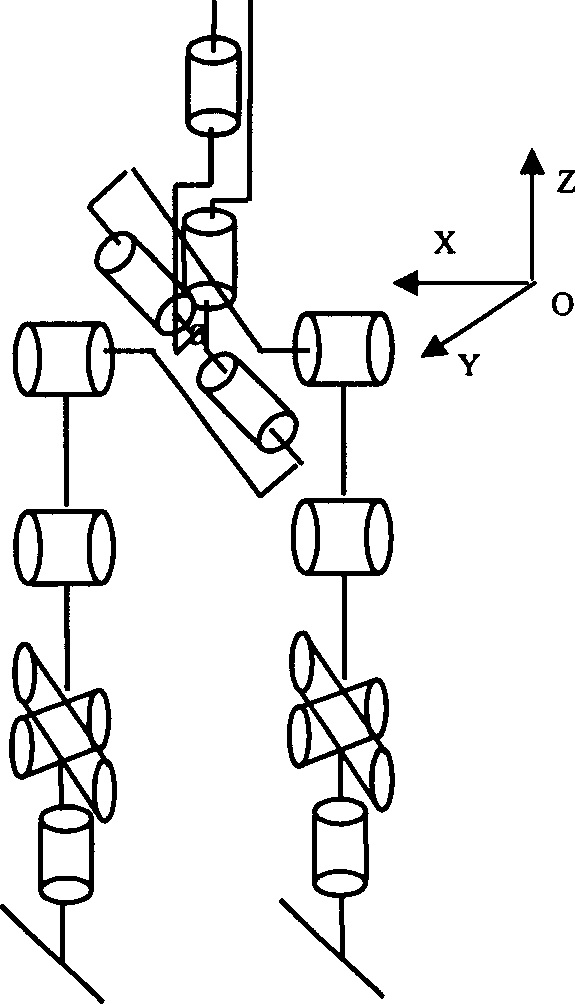

Two-feet walking robot having hip joint adopted with two-ball shape gear for 7-freedom legs

InactiveCN1833829ADoes not increase the number of jointsIncreased rotational freedomManipulatorRotational axisCoxal joint

A two-foot walking robot with 7-freedom legs and dual-spherical hip joint features that its hip joint with dual-spherical structure has 3 freedoms, its knee joint has one freedom, and its ankle joint has 3 freedoms. As a result, said robot has the waist bending function and said ankle joint has a rotary freedom.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

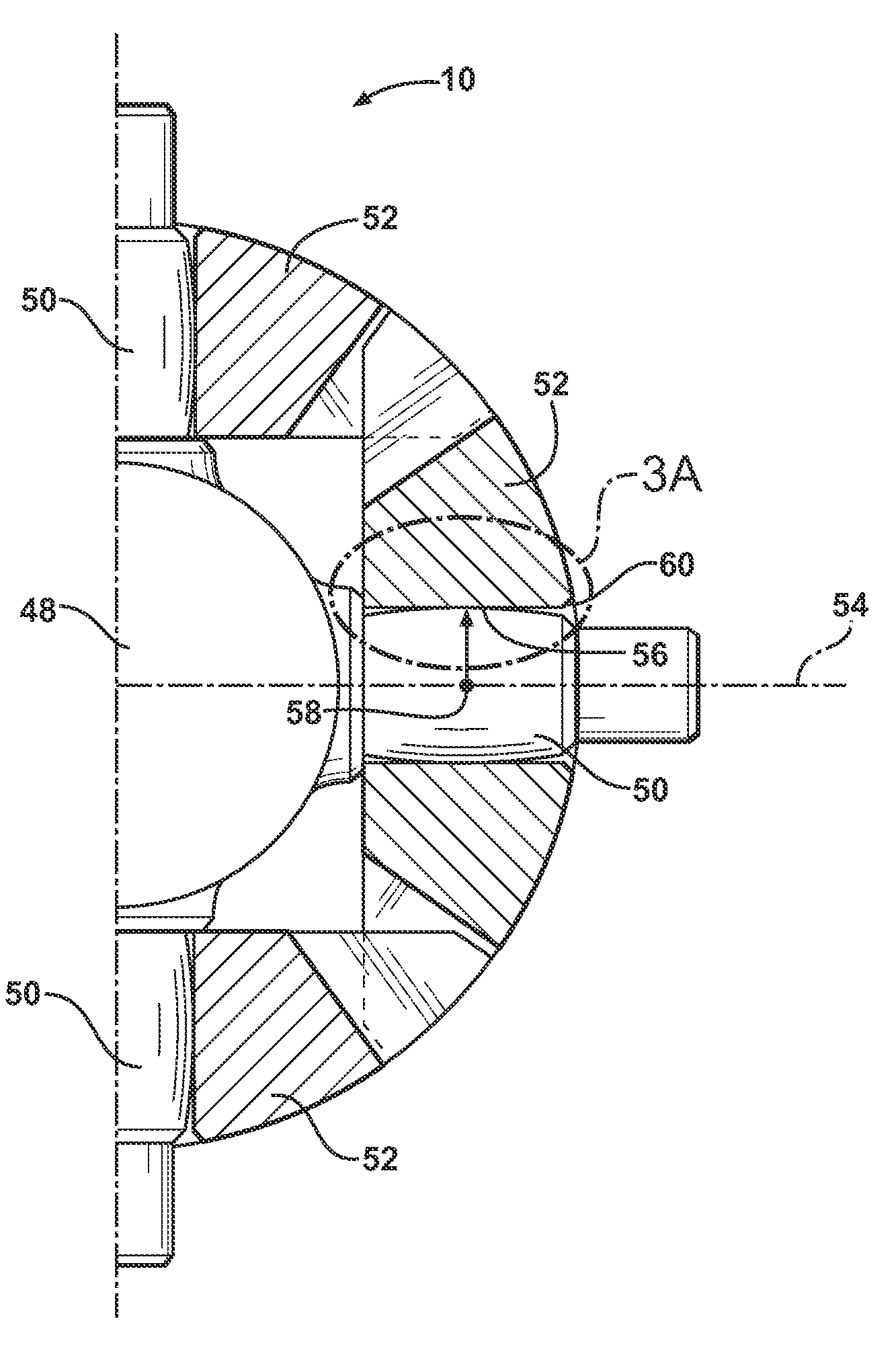

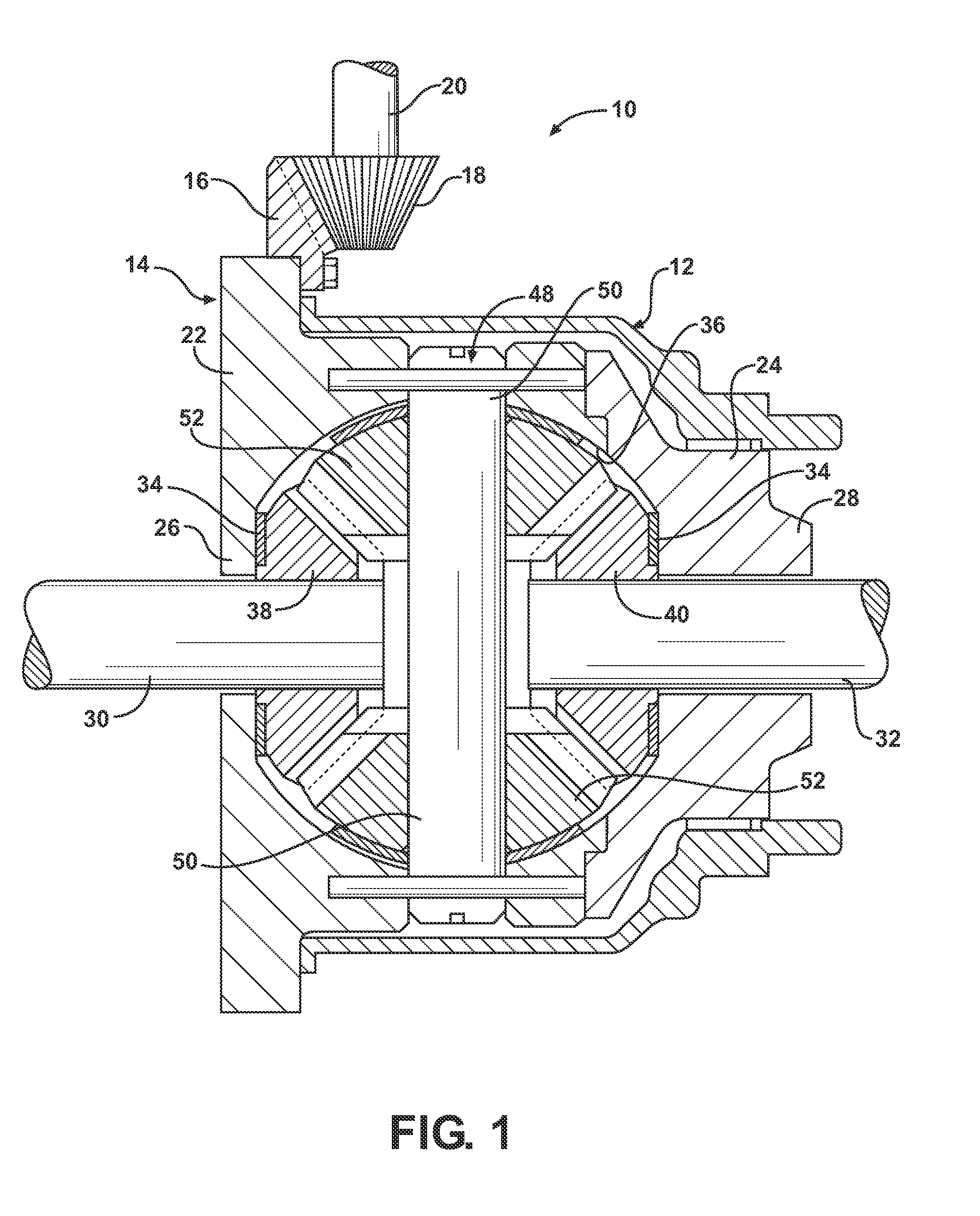

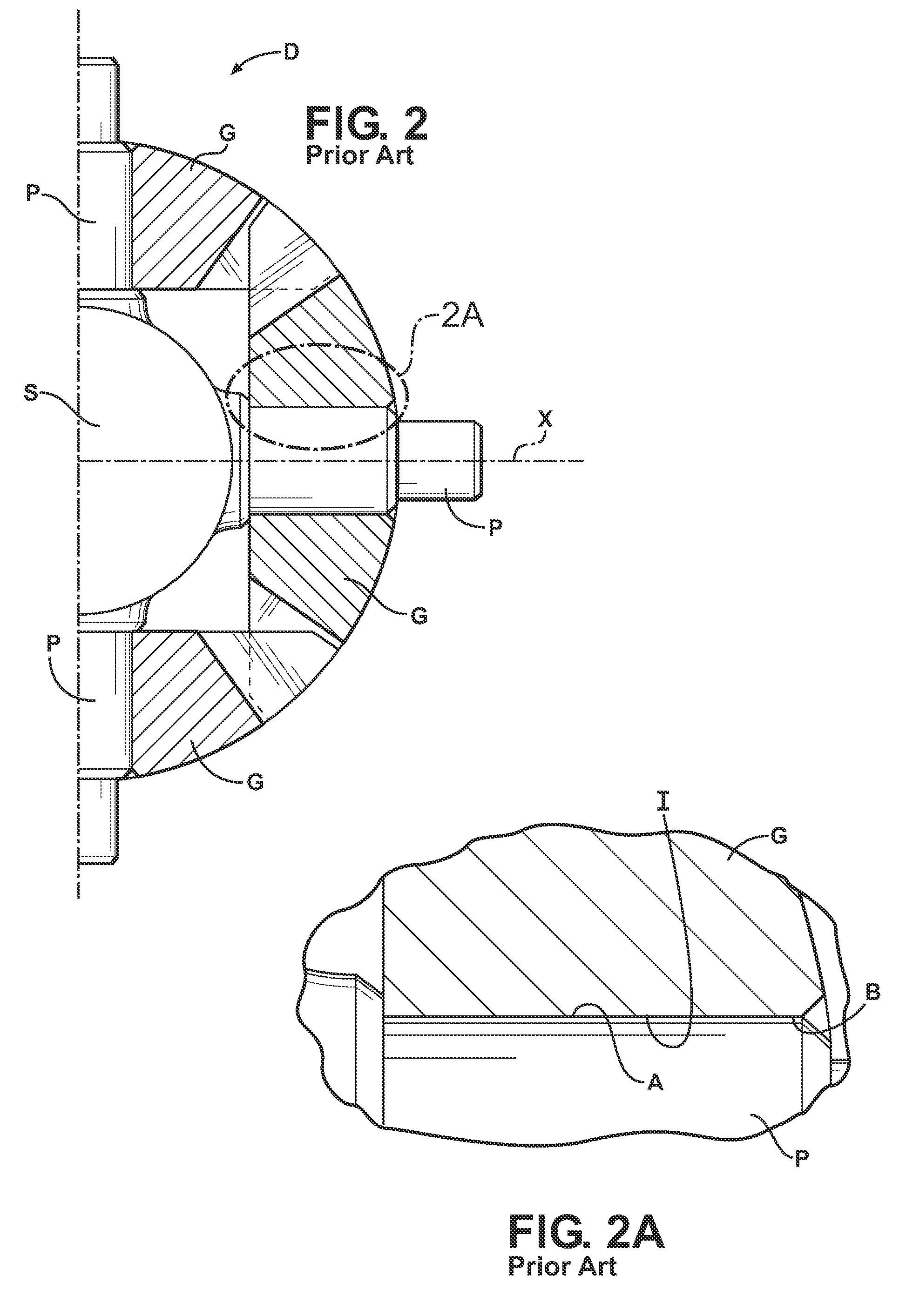

Differential having self-adjusting gearing

InactiveUS20110021305A1The degree of freedom becomes largerConducive to stable operationToothed gearingsDifferential gearingsRotational freedomRotational degrees of freedom

A differential for use in a vehicle drive train including a gear case that is operatively supported in driven relationship with respect to the drive train and a spider mounted for rotation with the gear case. The spider includes at least one pair of cross pins. Each cross pin defines a longitudinal axis and an outer surface that is convex about an axis extending perpendicular to the longitudinal axis of the cross pin. Pinion gears include a central bore where the cross pins are received in the central bore of the pinion gears such that the gears are mounted for rotation with the spider and in meshing relationship with side gears with an increased degree of rotational freedom of the pinion gears about the convex surface of the cross pin. Alternatively, the central bore of the cross pin may have an inner surface that is convex along the axis of the central bore.

Owner:EATON CORP

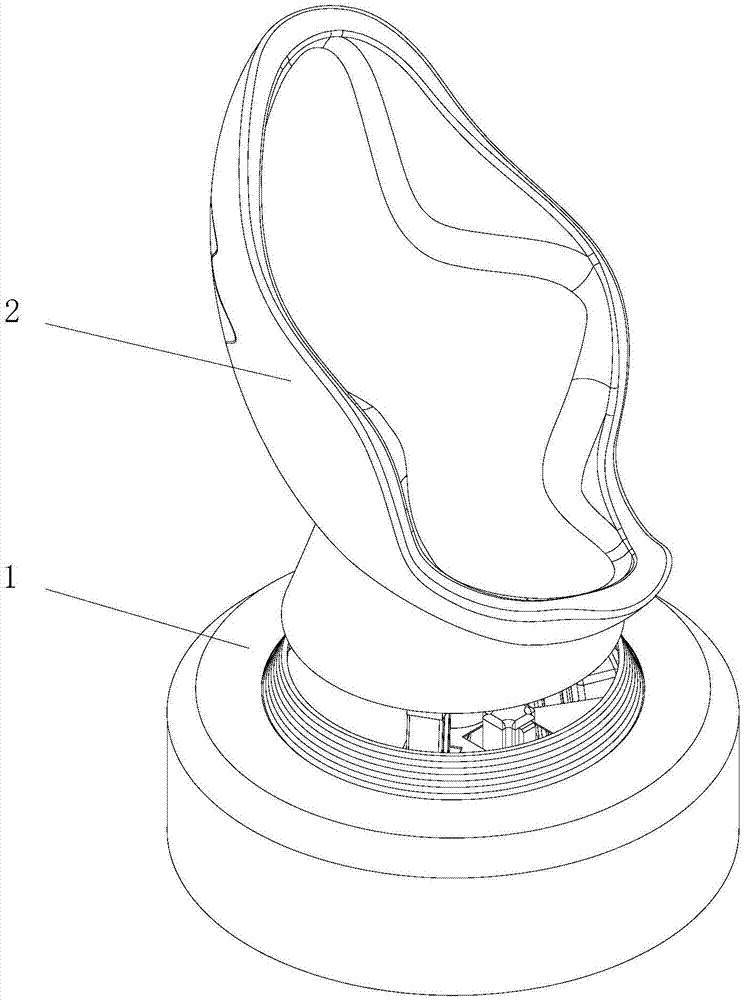

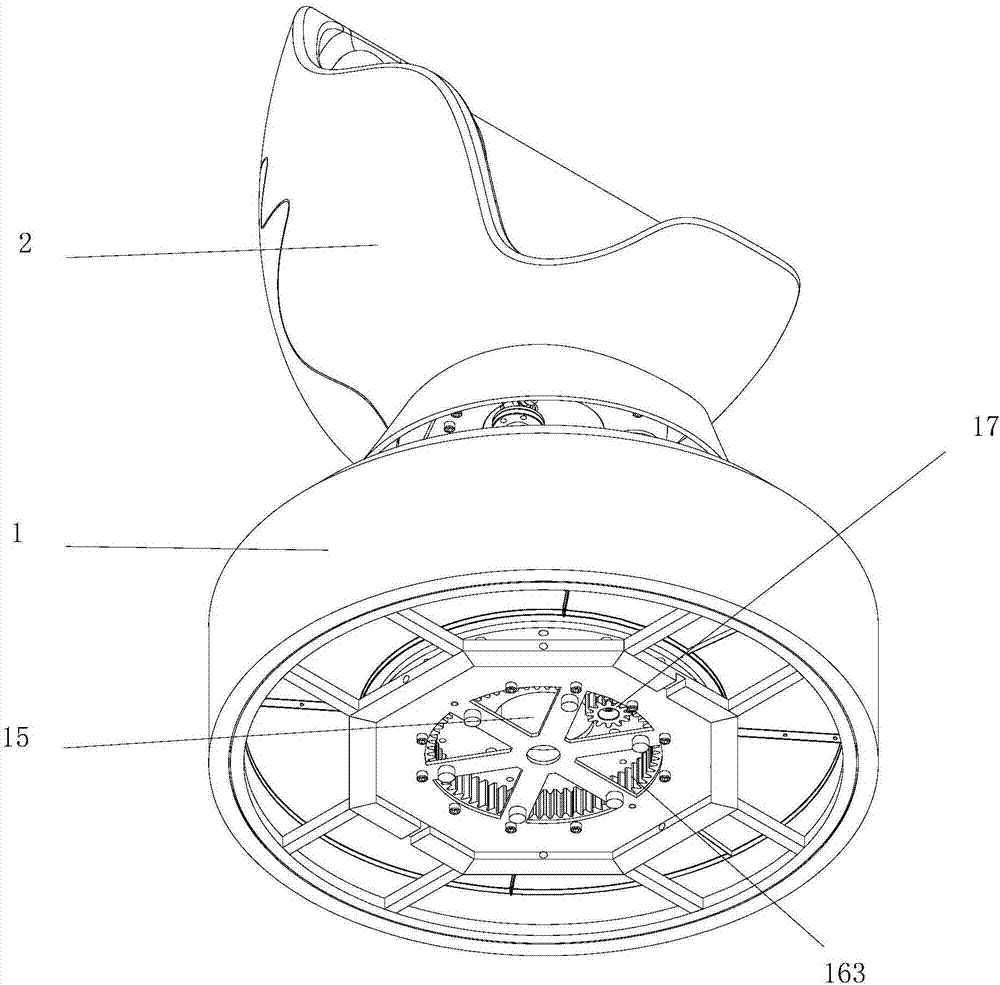

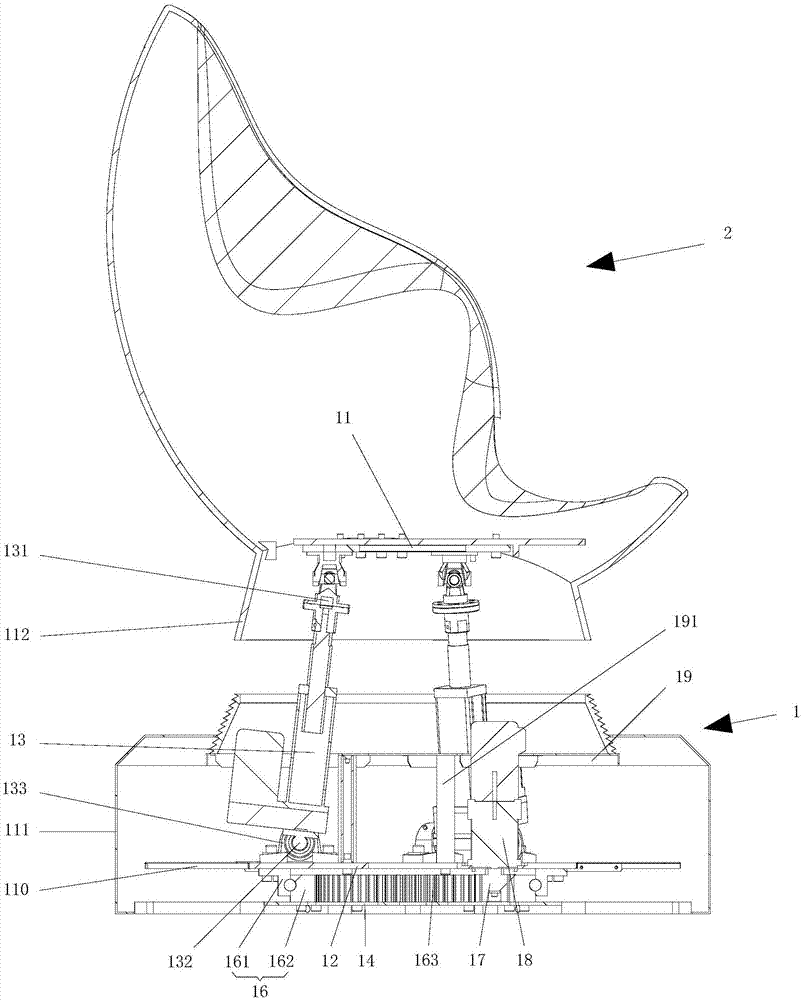

Multi-freedom-degree and rotatable VR seat

PendingCN107485870AAvoid electromagnetic interferenceAvoid interferenceCinema apparatusVideo gamesMechanical engineeringPhysics

The invention discloses a multi-freedom-degree and rotatable VR seat which comprises a multi-freedom-degree motion platform and a seat body installed on the multi-freedom-degree motion platform. The multi-freedom-degree motion platform comprises a movable platform, a rotatable platform, telescopic action cylinders and a fixed platform, wherein the seat body is fixed to the movable platform, the movable platform and the rotatable platform are connected through multiple telescopic action cylinders, two ends of each telescopic action cylinder are hinged to the movable platform and the rotatable platform respectively, the rotatable platform is installed on the fixed platform, and thus the movable platform and the seat body are driven to perform multi-freedom-degree motions through telescoping motions of the telescopic action cylinders and rotation of the rotatable platform. Wire passing slide rings are coaxially installed at the center of the rotatable platform. The multi-freedom-degree and rotatable VR seat can flexibly achieve forward and backward bending, left-right swing and other actions and meanwhile can achieve rotation, and the experience effect of a player is improved.

Owner:北京盗梦空间科技有限公司

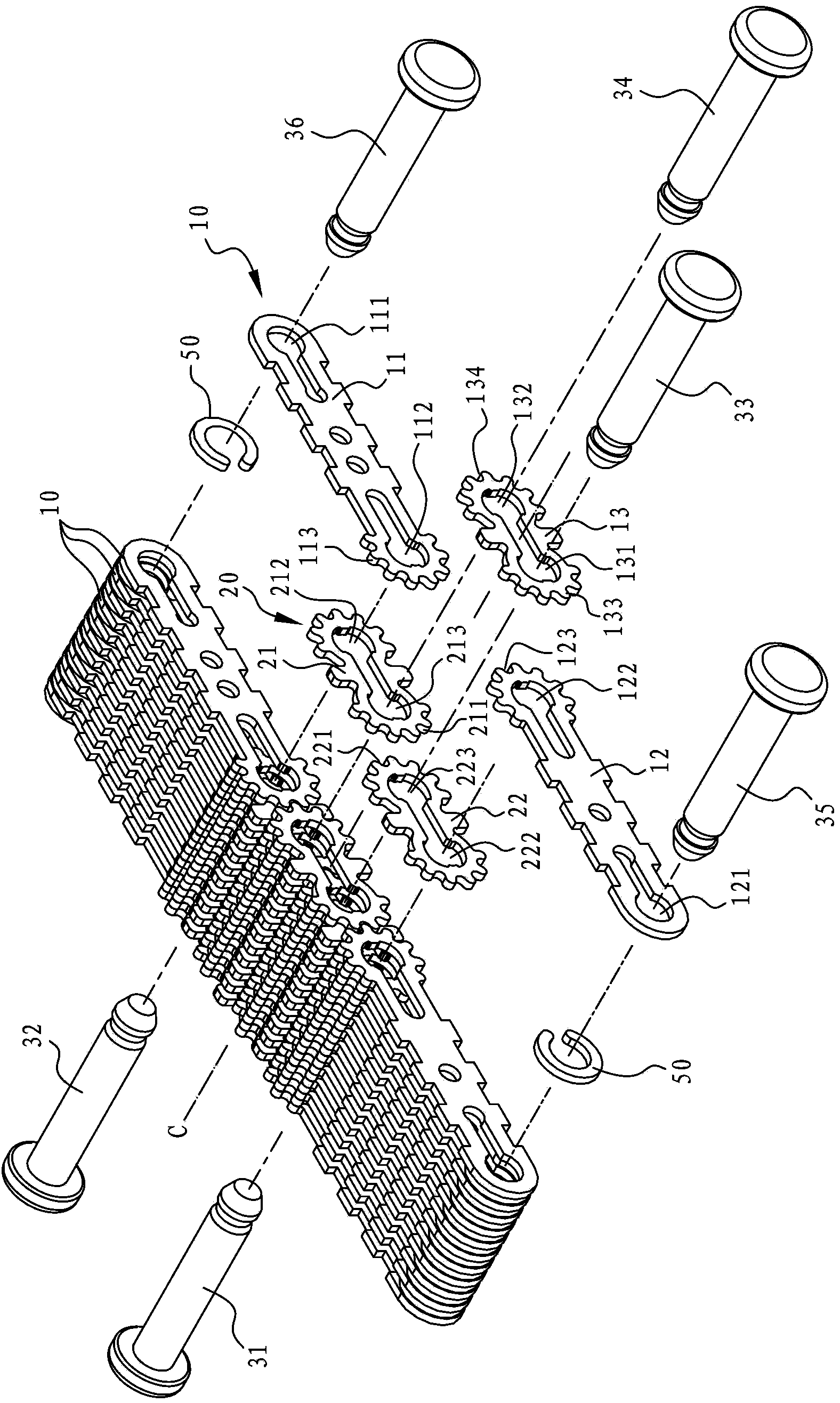

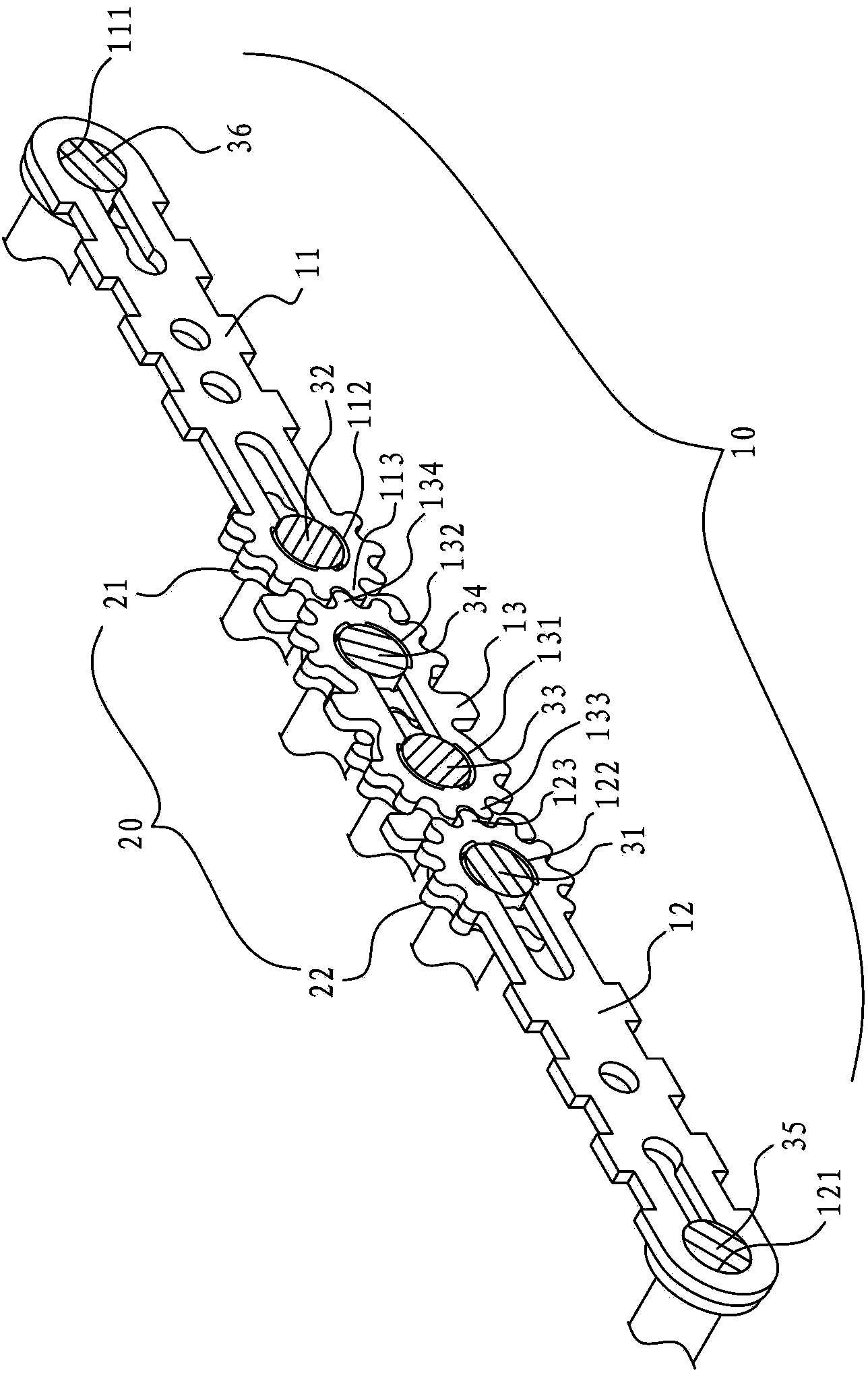

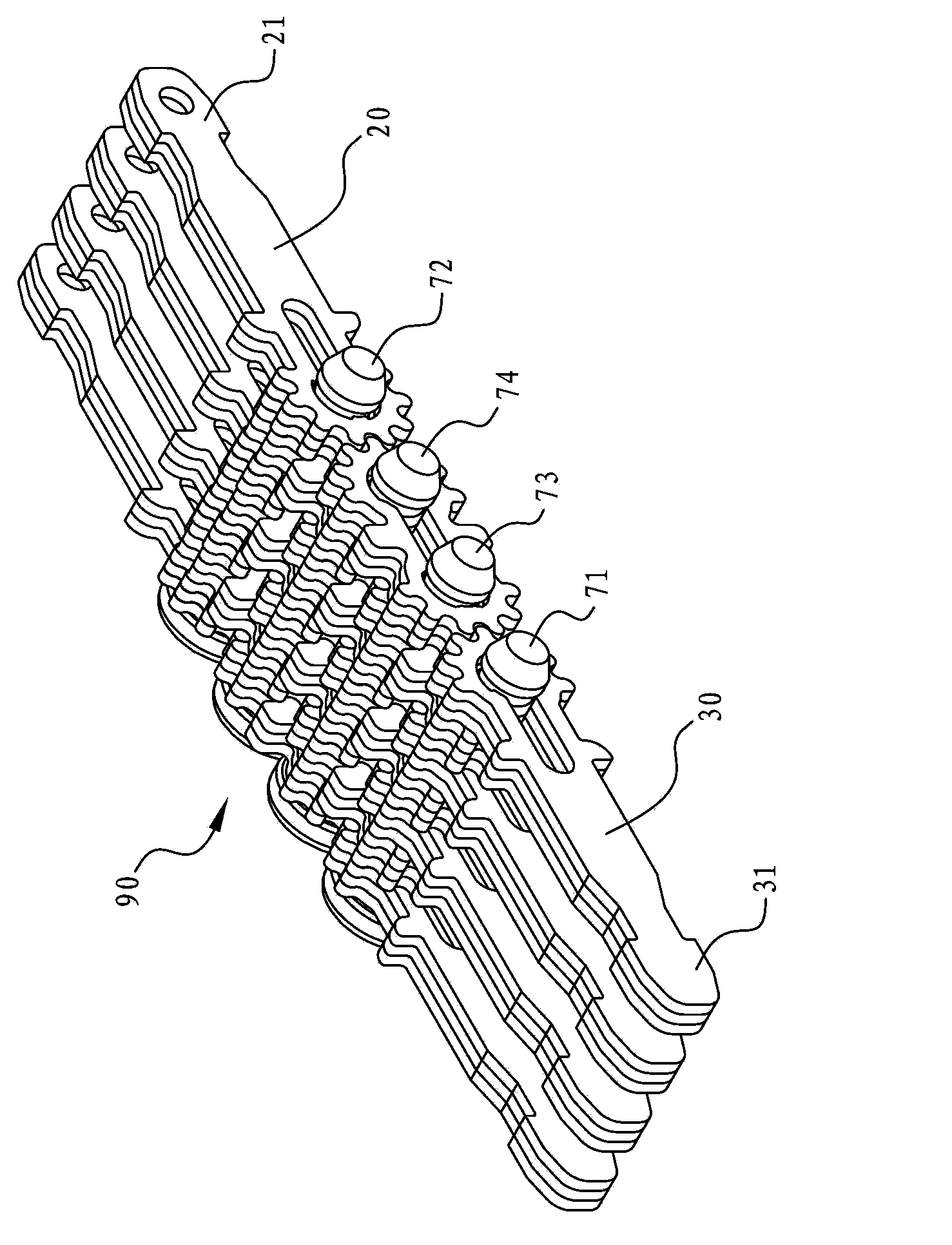

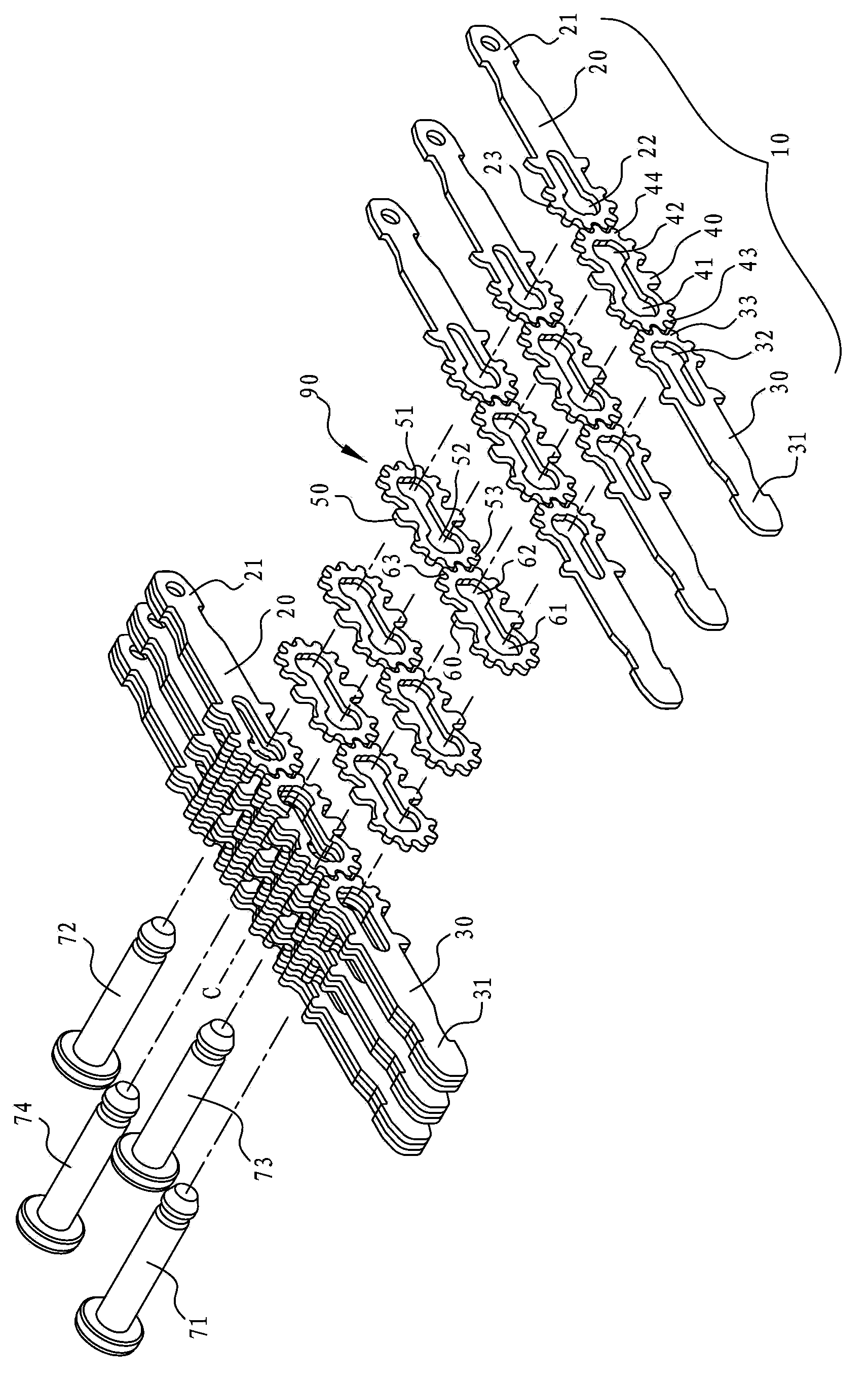

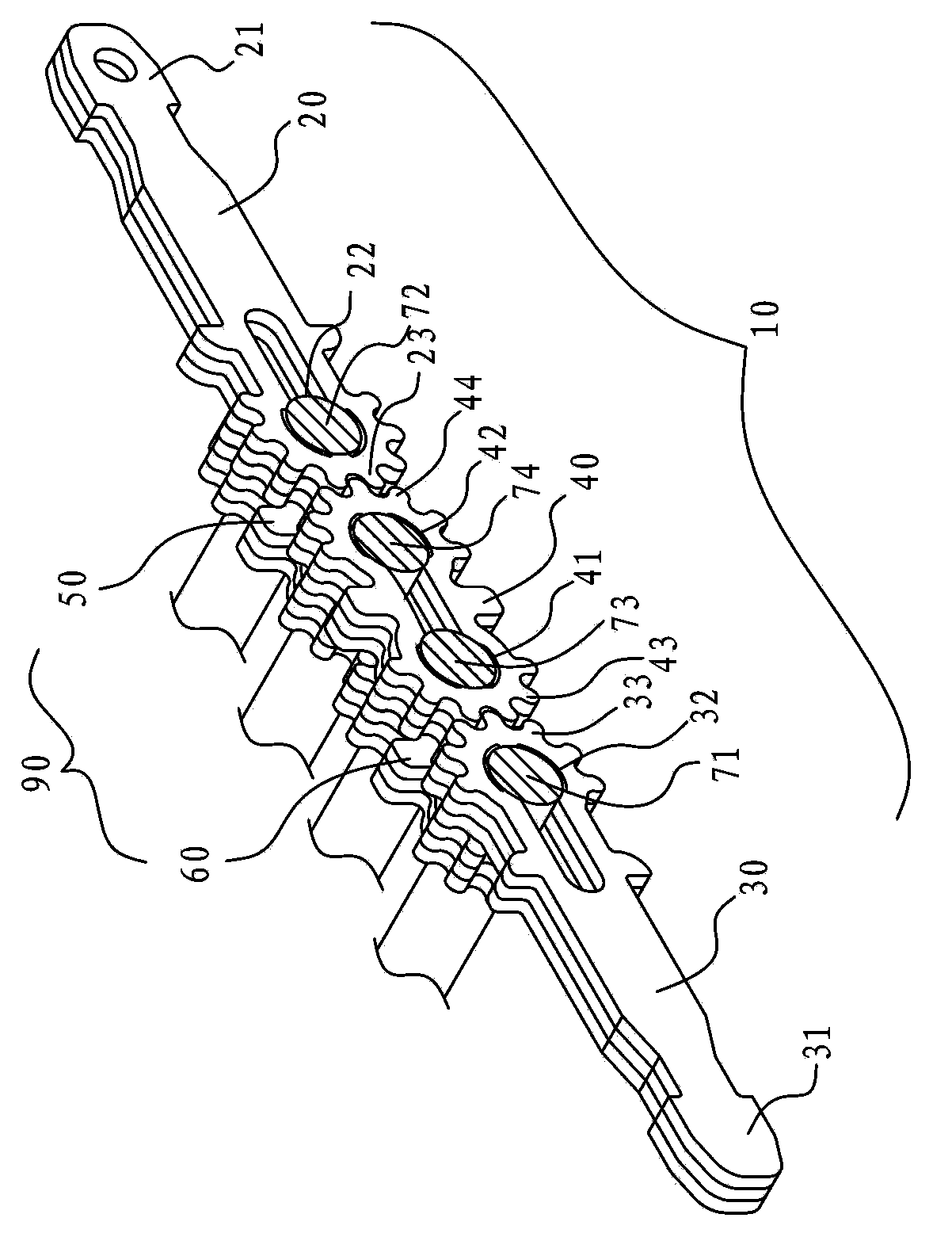

Synchronous unfolding and folding apparatus

ActiveCN103899636AIncreased rotational freedomImprove accuracyPivotal connectionsEngineeringMulti joint

Owner:FIRST DOME

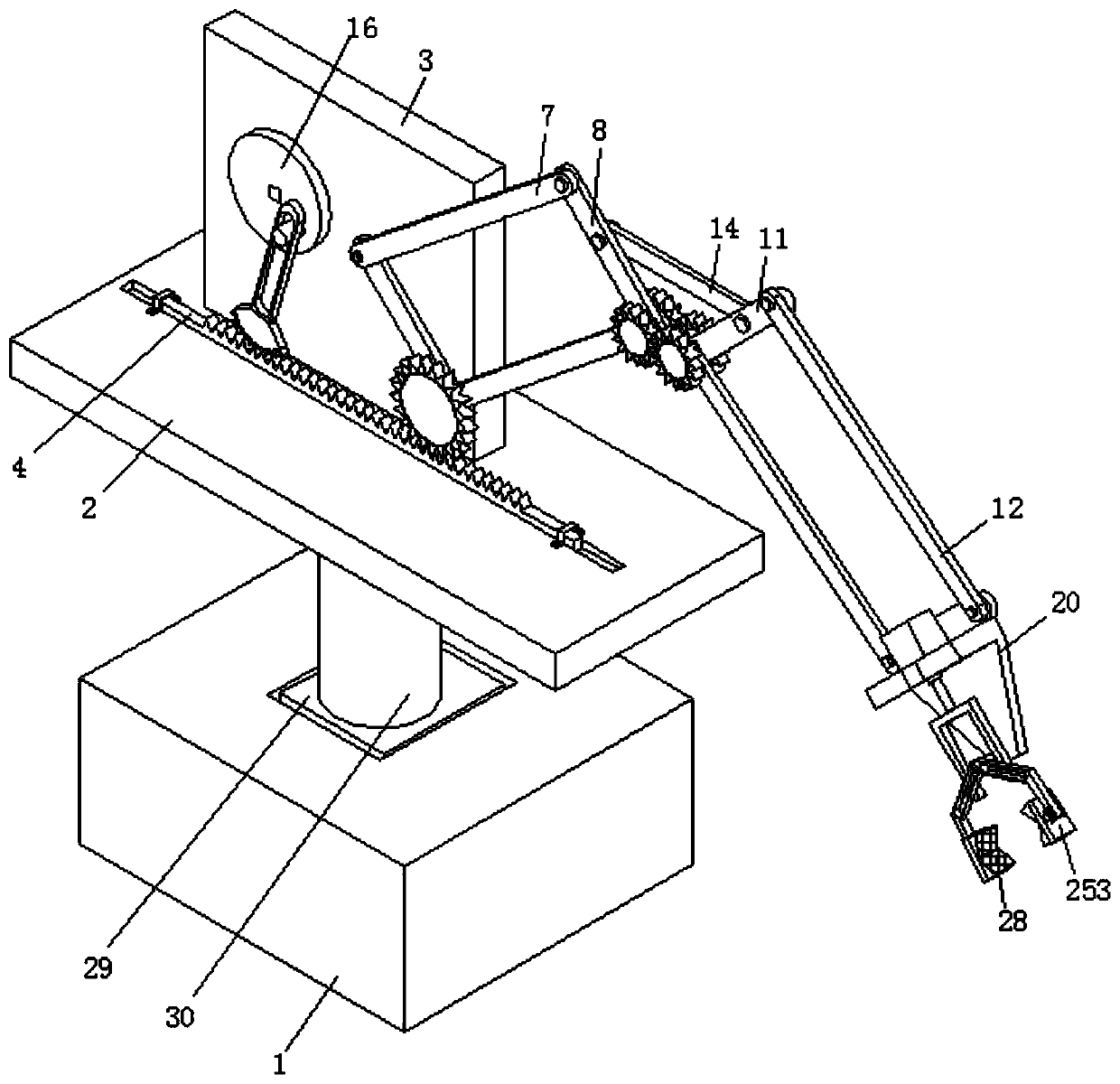

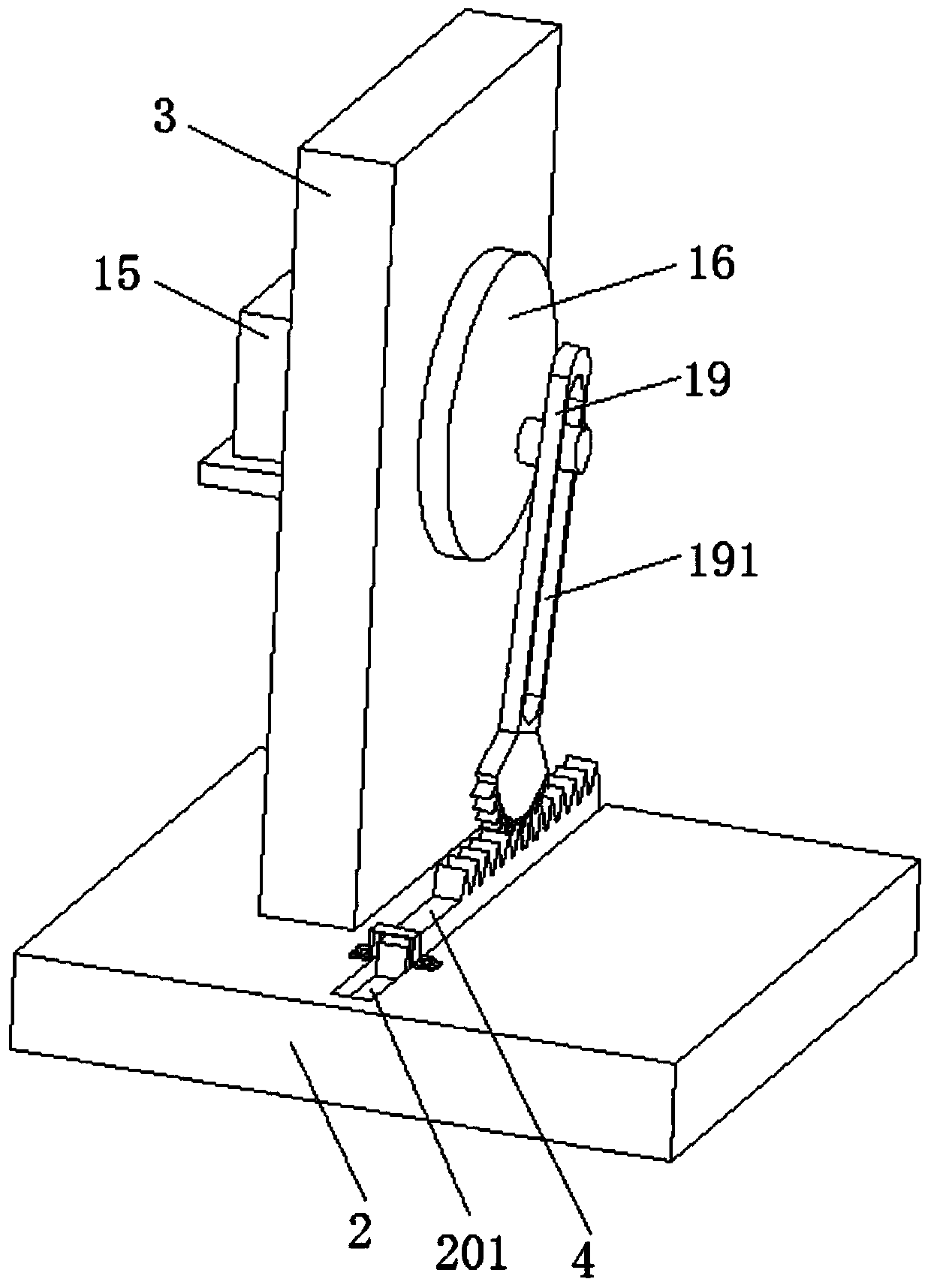

Arm stretching and bending mechanism for industrial robot

ActiveCN110315522AImprove crawling efficiencyIncreased rotational freedomProgramme-controlled manipulatorControl engineeringEngineering

The invention discloses an arm stretching and bending mechanism for an industrial robot, and belongs to the technical field of robot arms. The arm stretching and bending mechanism for the industrial robot comprises a base. A workbench is connected to the top of the base. A fixing plate is connected to the top of the workbench. A conveying rack is slidably connected to the outer wall of the workbench. A first gear is connected to the outer wall of the conveying rack in an engaged mode. A first connecting rod is connected to the outer wall of the first gear. Second connecting rods are rotatablyconnected to the two ends of the first connecting rod. A third connecting rod is connected to the end, away from the first connecting rod, of each second connecting rod. A second gear is connected tothe joint of each third connecting rod and the corresponding second connecting rod. A third gear is connected to the outer wall of each second gear in an engaged mode. A fourth connecting rod is connected to the outer wall of each third gear. Fifth connecting rods are connected to the two ends of the fourth connecting rods. Sixth connecting rods are connected to the ends, away from the fourth connecting rods, of the two fifth connecting rods. Clamping mechanisms are connected to the outer walls of the sixth connecting rods. According to the arm stretching and bending mechanism for the industrial robot, the flexibility of robot arms can be improved through the rotation of the connecting rods.

Owner:LONGHE INTELLIGENT EQUIP MFG CO LTD

Insert-assembling type multi-section rotating shaft structure

ActiveCN103899637AIncreased rotational freedomSmooth opening and closing actionPivotal connectionsEngineeringLinkage concept

The invention discloses an insert-assembling type multi-section rotating shaft structure, which includes driving joint groups and servo joint groups, wherein at least two relative joint sheets and a middle linkage sheet group connected between the relative joint sheets are arranged on each driving joint group; each servo joint group is arranged between the two relative joint sheets, and comprises at least two servo sheets used for presetting cohesion linkage of synchronous initiation parts, at the mutually relative inward ends; the inward ends of the relative joint sheets are aligned with the outward ends of the servo sheets, and the outward ends of the two joint sheets form an insertion end; the outward end of each middle linkage sheet of the middle linkage sheet group is aligned with the inward end of each servo sheet of the servo sheet group, and the various parts are combined with each other through shaft pins; and the driving joint groups and the servo joint groups are arranged in a combination manner and are connected in series with the shaft pins, so that each relative joint sheet of the driving joint groups can perform free rotation around multiple rotation centers, and a smooth rotating shaft structure with two opening and closing ends is formed.

Owner:深圳市富世达通讯有限公司 +1

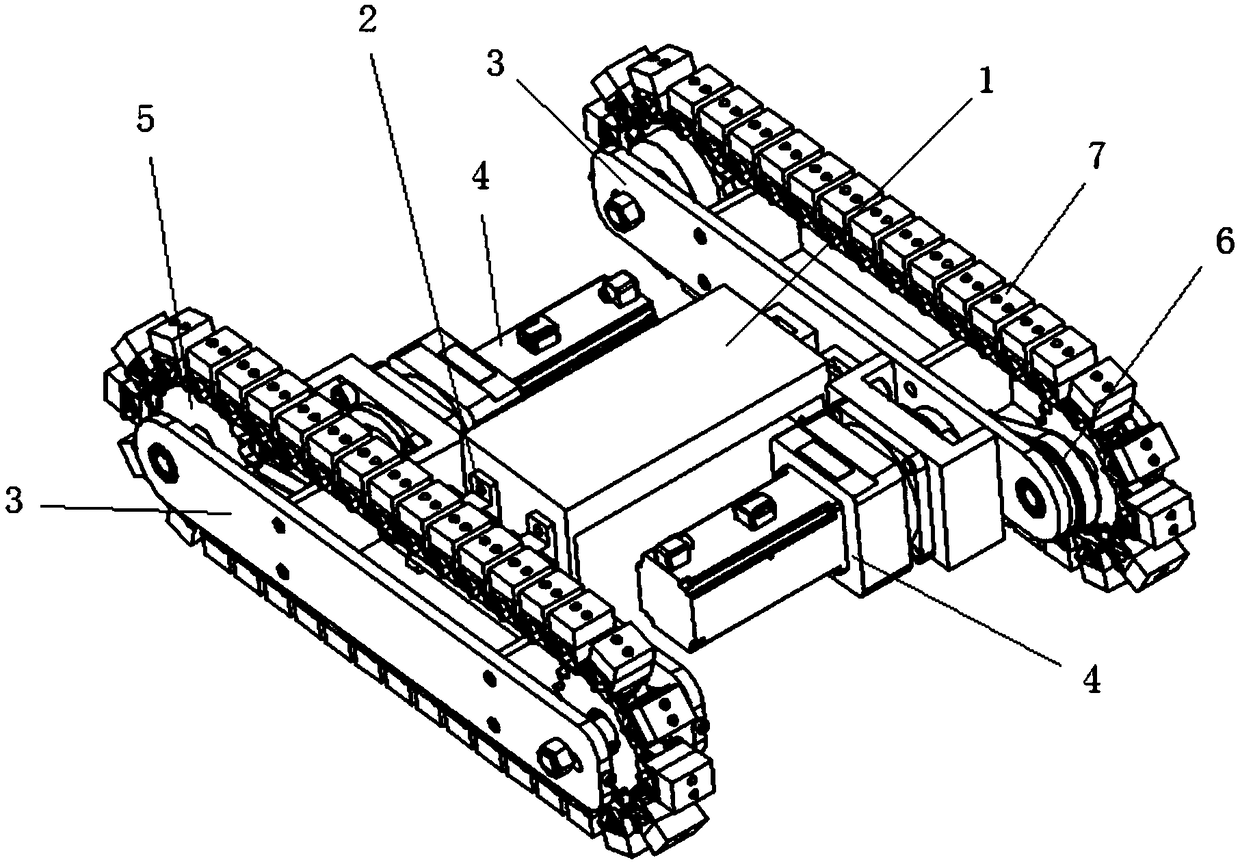

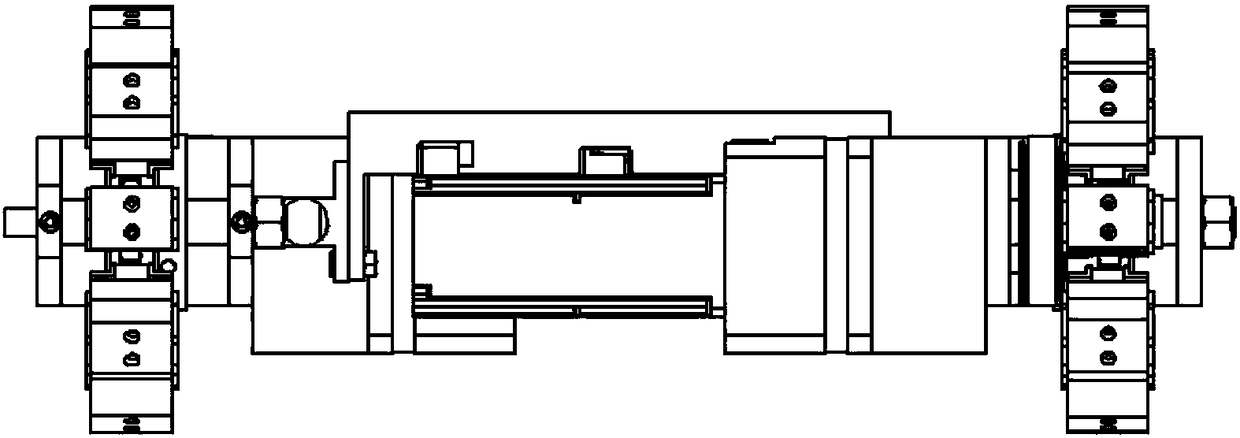

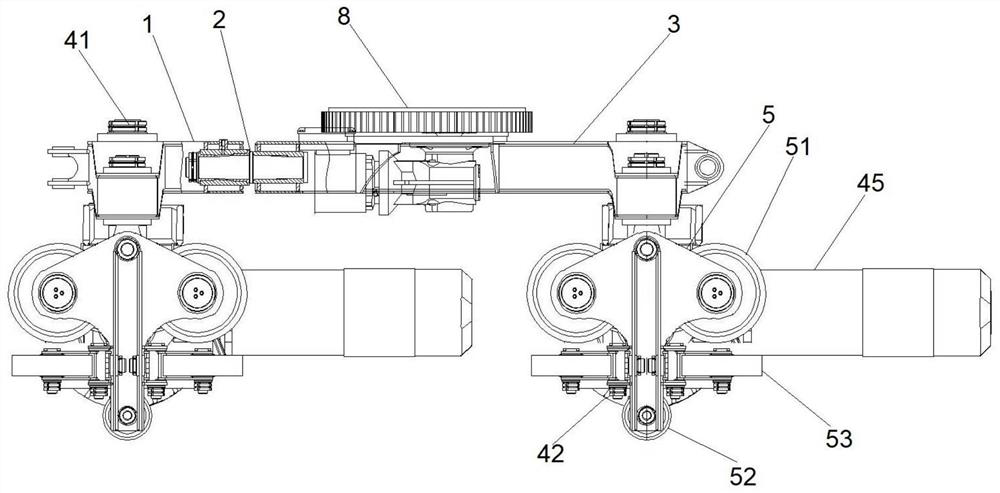

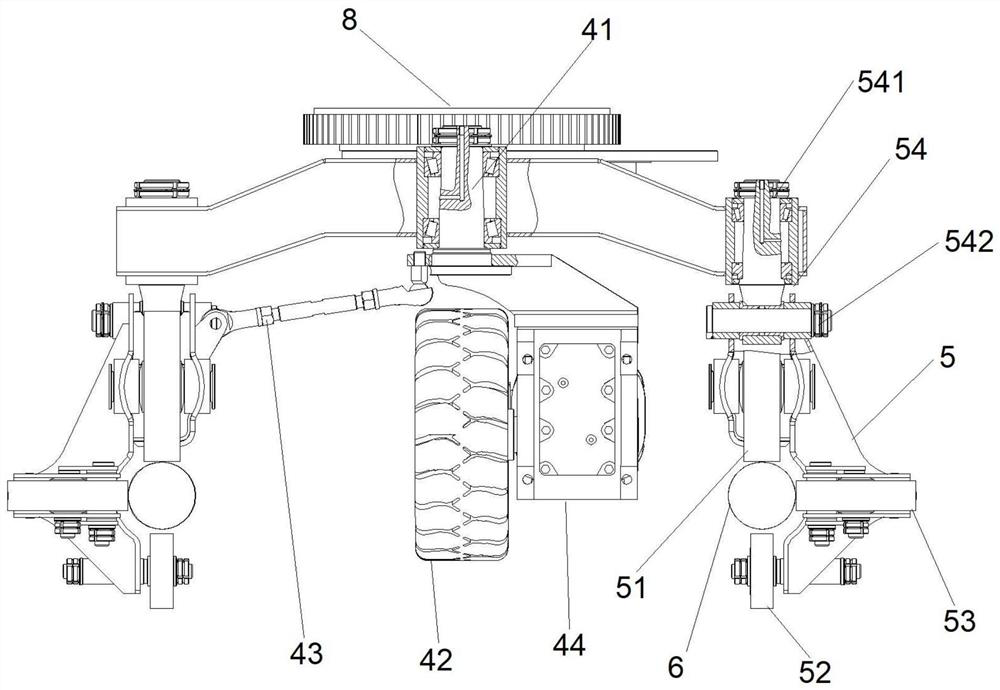

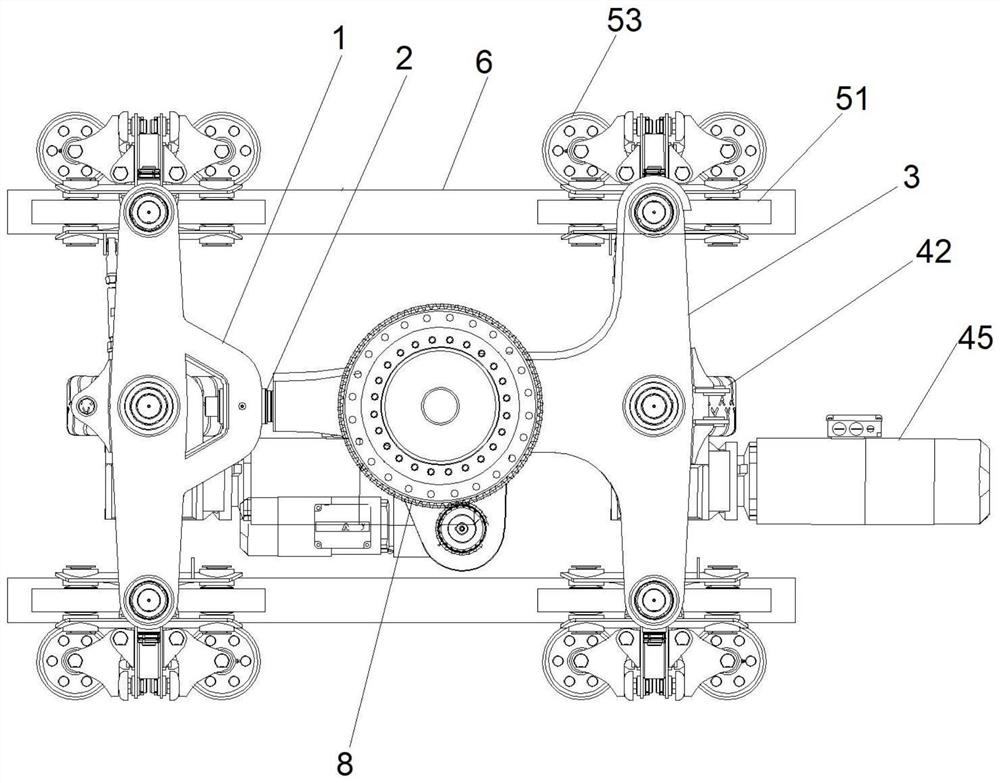

Track vehicle

ActiveCN103318215AIncreased rotational freedomReduce wearSpeed controllerWheel axle self-adjustmentsAgricultural engineeringBogie

The invention discloses a track vehicle which comprises a vehicle body, a front bogie, a back bogie, a driving device and a controller, wherein the front bogie is arranged at the lower part of the vehicle body; a left front wheel is arranged on the left side of the front bogie, a right front wheel is arranged on the right side of the front bogie, and the two front wheels can rotate independently; the back bogie is arranged at the lower part of the vehicle body; a left back wheel is arranged on the left side of the back bogie, a right back wheel is arranged on the right side of the back bogie, and the two back wheels can rotate independently; the driving device is connected with the left back wheel and the right back wheel respectively; the controller is connected with the driving device and used for controlling the output rotating speed of the driving device, so as to enable the rotating speed difference between the left back wheel and the right back wheel when the back bogie passes by a certain position to be identical with the rotating speed difference between the left front wheel and the right front wheel when the front bogie passes by the same position. According to the track vehicle provided by the embodiment of the invention, the decoupling to the wheels in the rotation direction is realized, the abrasion loss is reduced, and meanwhile, the identical rotating speed differences between the front wheels and between the back wheels are realized through controlling the output rotating speed of the driving device, so that the curve negotiating performance of the track vehicle is greatly improved.

Owner:TSINGHUA UNIV

A castor

Owner:大卫·哈克特

Poly-vinyl versatate-vinyl acetate-ethylene emulsion and emulsion polymerization preparation method

The invention discloses poly-vinyl versatate-vinyl acetate-ethylene emulsion and an emulsion polymerization preparation method. The poly-vinyl versatate-vinyl acetate-ethylene emulsion is copolymer emulsion with the solid content of 55.0-57.0 percent, which is prepared via free radical emulsion polymerization with vinyl versatate, vinyl acetate and ethylene as monomers, compound polyvinyl alcoholas protective colloid, octylphenol polyoxyethylene ether as an emulsifier and with the presence of redox initiators. The weight-average molecular weight of the terpolymer emulsion is 122,984-130,000,and the molecular weight distribution width is 5.295-6.000. The film prepared with the copolymer emulsion has good weathering resistance, alkali resistance, hydrolysis resistance, uniform particle size, appropriate molecular weight and distribution, low glass transition temperature (T is equal to below 2 DEG C), good film-forming performance, excellent performance and wide scope of application.

Owner:ANHUI WANWEI UPDATED HIGH TECH MATERIAL CO LTD +1

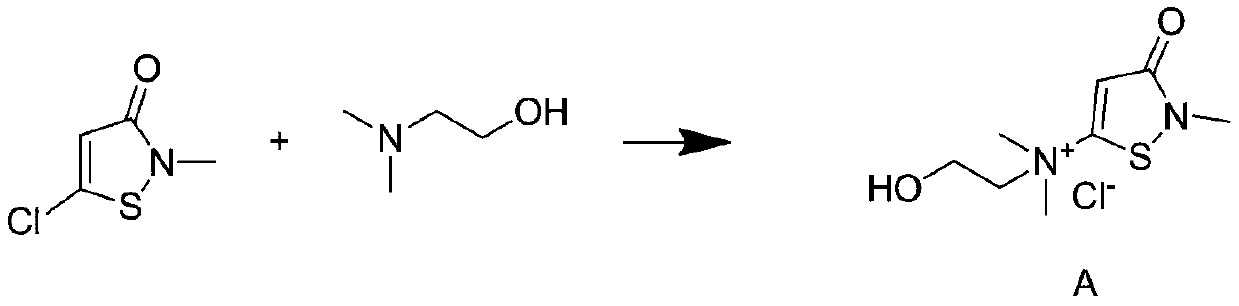

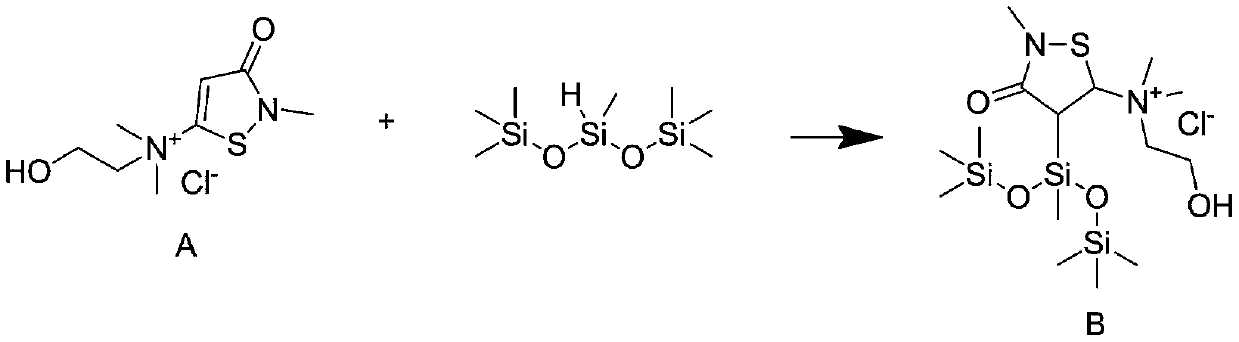

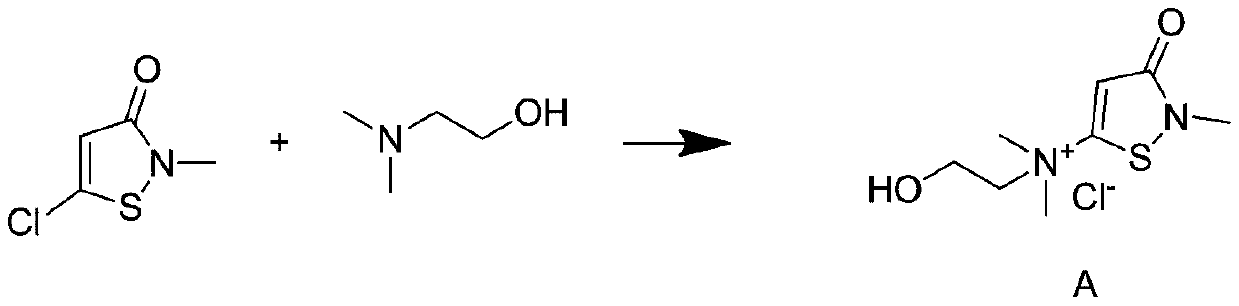

Antibacterial powder coating

ActiveCN110157294AImprove thermal stabilityIncreased rotational freedomAntifouling/underwater paintsPaints with biocidesEpoxyAntibacterial activity

The invention discloses an antibacterial powder coating which is prepared from the following raw materials in parts by weight: 25-35 parts of an epoxy resin, 25-35 parts of a polyester resin, 0.8-1.5parts of a flatting agent, 0.8-1.5 parts of a smooth degassing agent, 15.5-49 parts of pigments and fillers and 0.5-1.5 parts of an antibacterial agent. The film formed after spray curing has excellent antibacterial property, the antibacterial ability is long-term and lasting, the antibacterial active group thiazolone has an excellent effect of inhibiting and killing common bacteria, fungi, algaeand the like, and due to synergistic antibacterial and bacteriostatic abilities of quaternary ammonium salts, the prepared powder coating is capable of resisting many bacteria and fungi. The antibacterial agent B contains alcoholic hydroxyl groups, so that the compatibility and adhesiveness to other components of the coating are increased, and dispersion of the antibacterial agent in the powder coating is facilitated.

Owner:六安科瑞达新型材料有限公司

Preparation method of high-water-resistance gypsum-based thermal insulation composite board

The invention relates to a preparation method of a high- water- resistance gypsum-based thermal insulation composite board and belongs to the technical field of building materials. A high-water-resistance gypsum thermal insulation material is prepared by adding organic silicon modified paraffin emulsion, and the molecular main chain of organic silicon contains Si groups or a silicon-containing compound with certain reaction activity, so that a cross-linked network film structure can be formed in gypsum and can be attached to an internal pore wall to fill the internal defects of the gypsum thermal insulation board; due to the fact that the silicon-containing molecular chain is high in rotational freedom degree and low in surface energy, an organosilicon waterproofing agent is endowed with good hydrophobic performance, and the water absorption rate of the board can be obviously reduced; after paraffin is prepared into the emulsion, the paraffin can be uniformly adsorbed on a plate, so that the waterproof performance is improved.

Owner:苏木兰

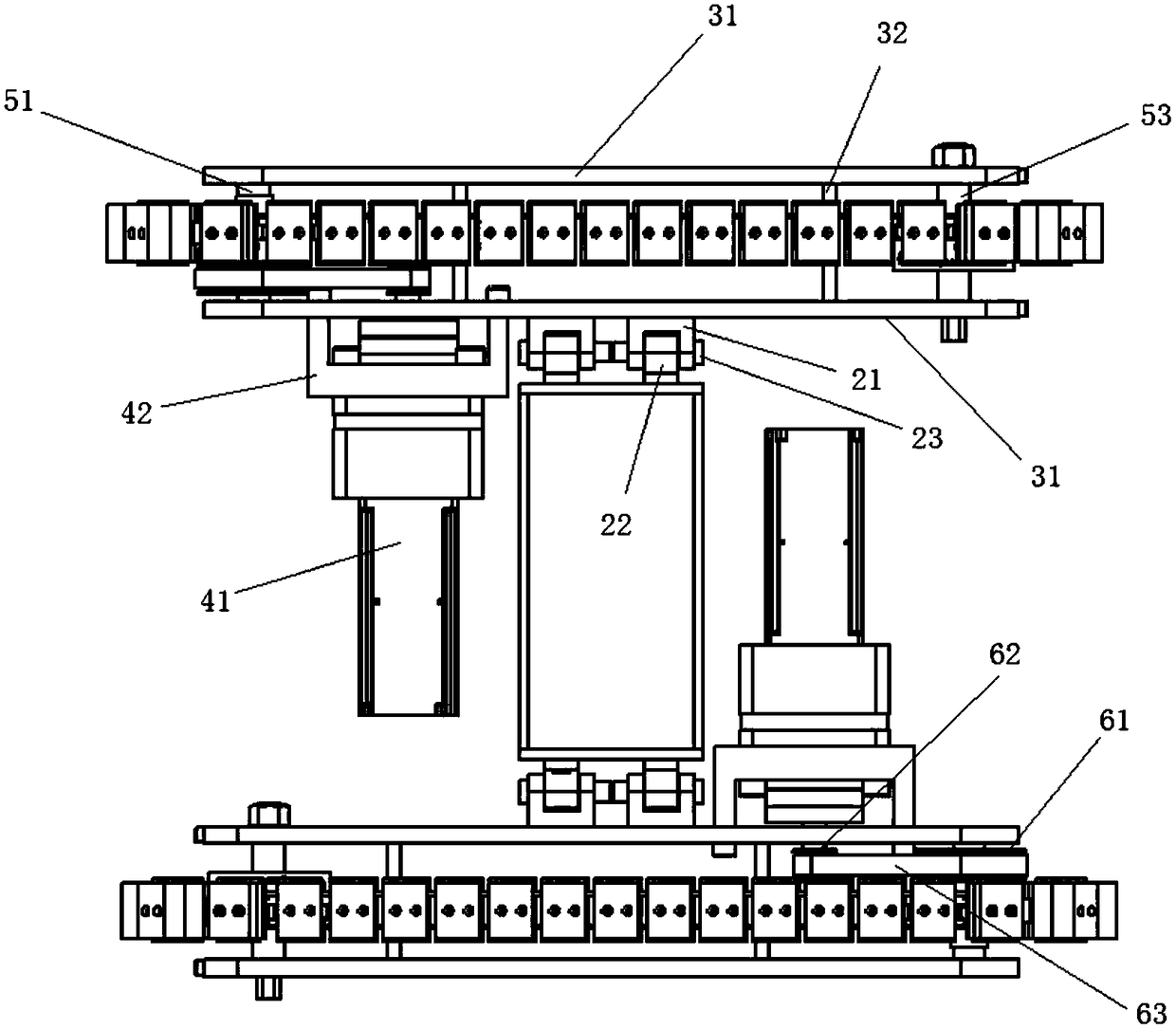

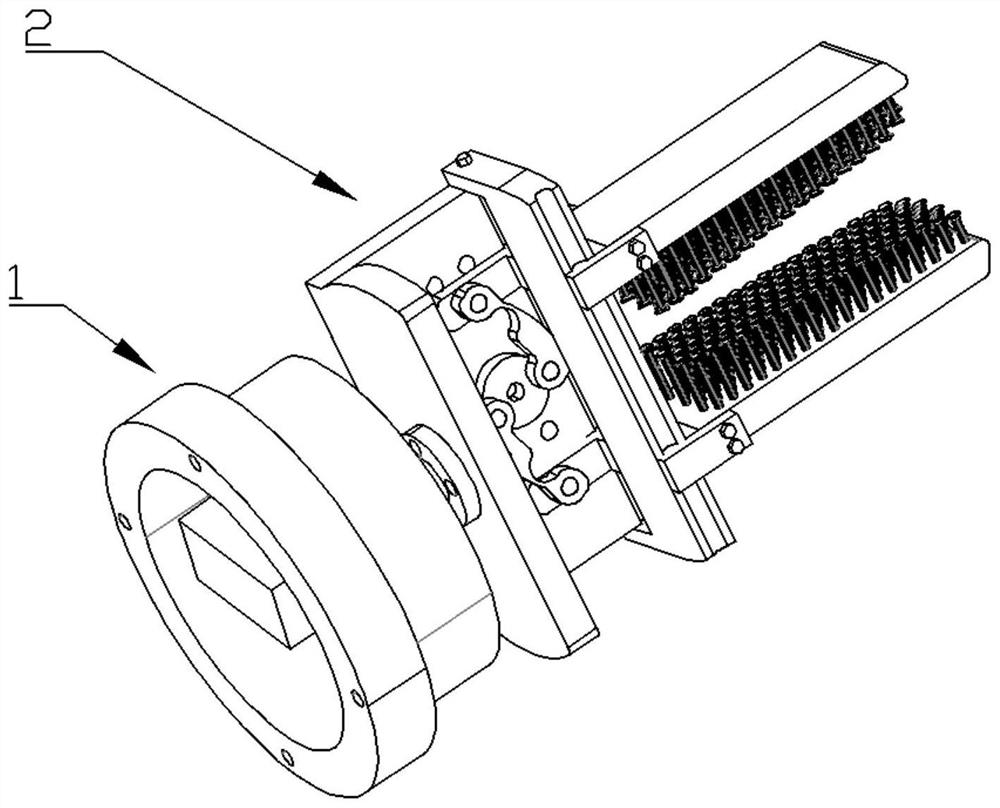

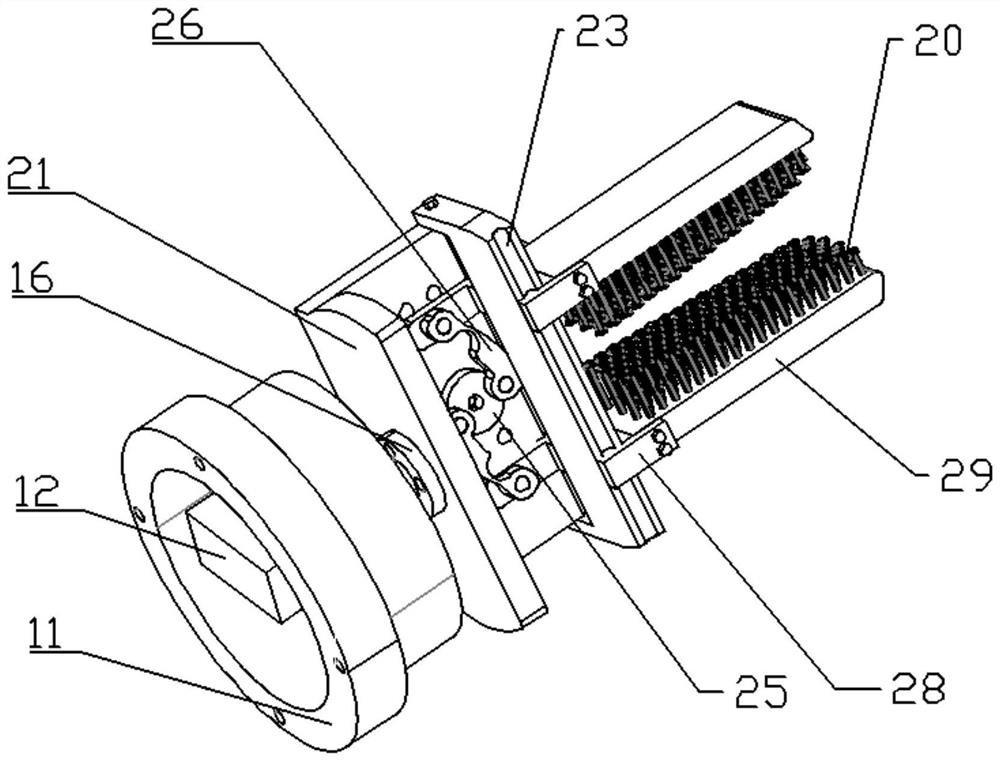

Chassis mechanism of variable diameter adsorbent wall climbing robot and working method

ActiveCN108177702AIncreased rotational freedomImprove adsorption capacityVehiclesInstabilityEngineering

The invention relates to a chassis mechanism of a variable diameter adsorbent wall climbing robot and a working method. The chassis mechanism of the variable diameter adsorbent wall climbing robot includes a tool mounting platform, wherein an adsorption mechanism framework is installed on both sides of the tool mounting platform through rotary joints. A power mechanism, a power transmission mechanism and a chain drive mechanism are installed on the adsorption mechanism framework, and the power mechanism drives the chain transmission mechanism to work through the power transmission mechanism. The chain transmission mechanism is provided with a plurality of rotating adsorption units, and the rotating adsorption units include rotating assemblies fixed on the chain transmission mechanism and magnet assemblies fixed on the rotating assemblies. The adaptive adjustable adsorption of the outer wall of a wind power tower can be achieved, the adsorption is stable, and the falling phenomenon of instability is avoided.

Owner:SHANDONG UNIV

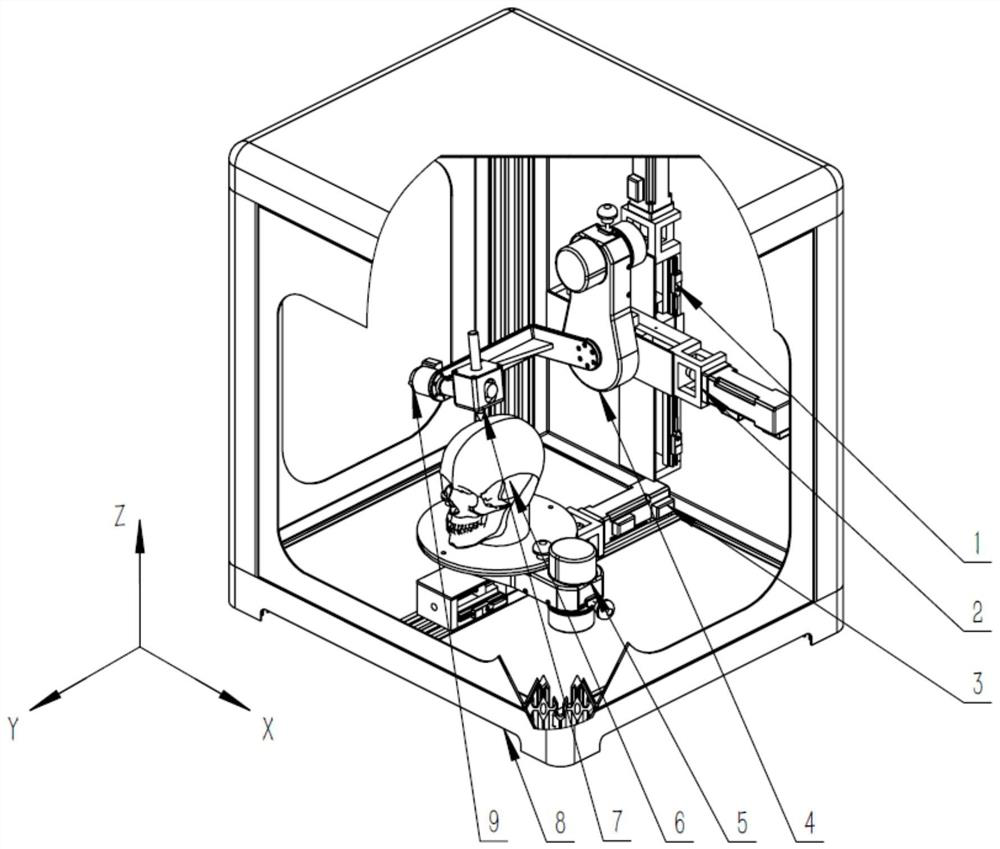

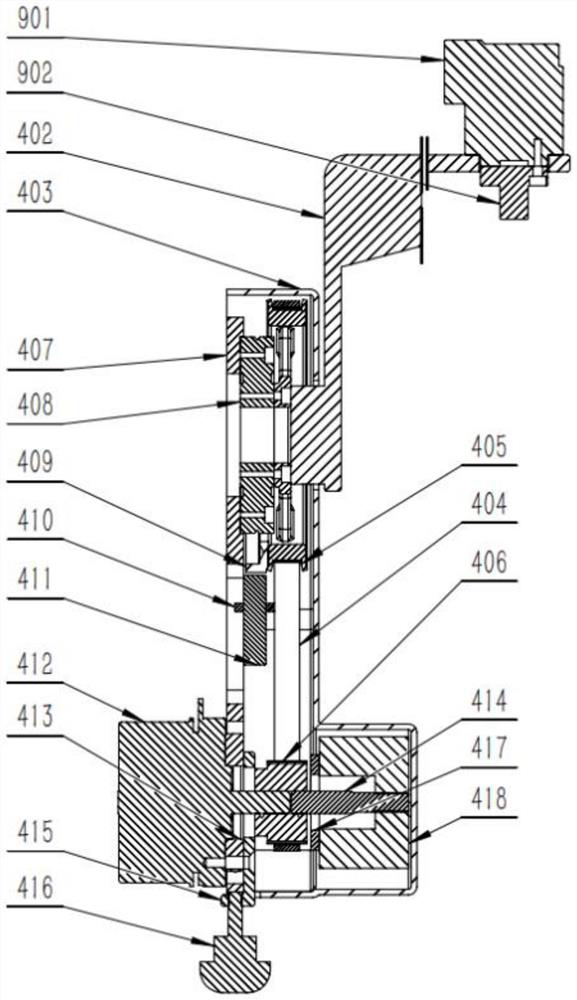

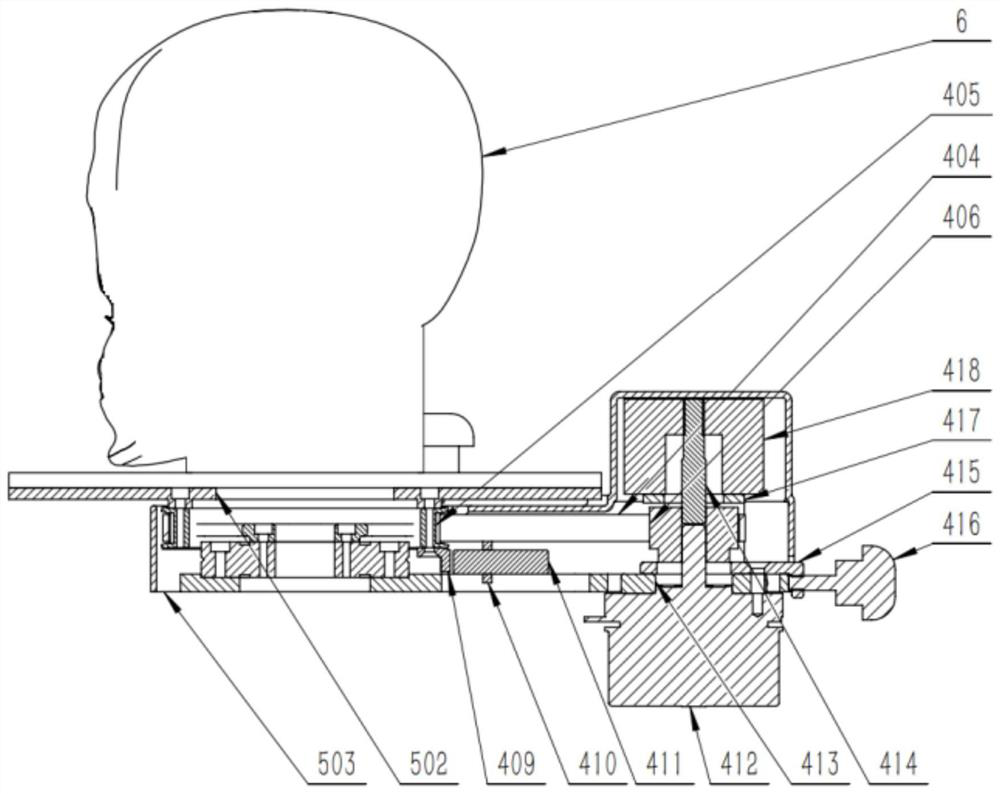

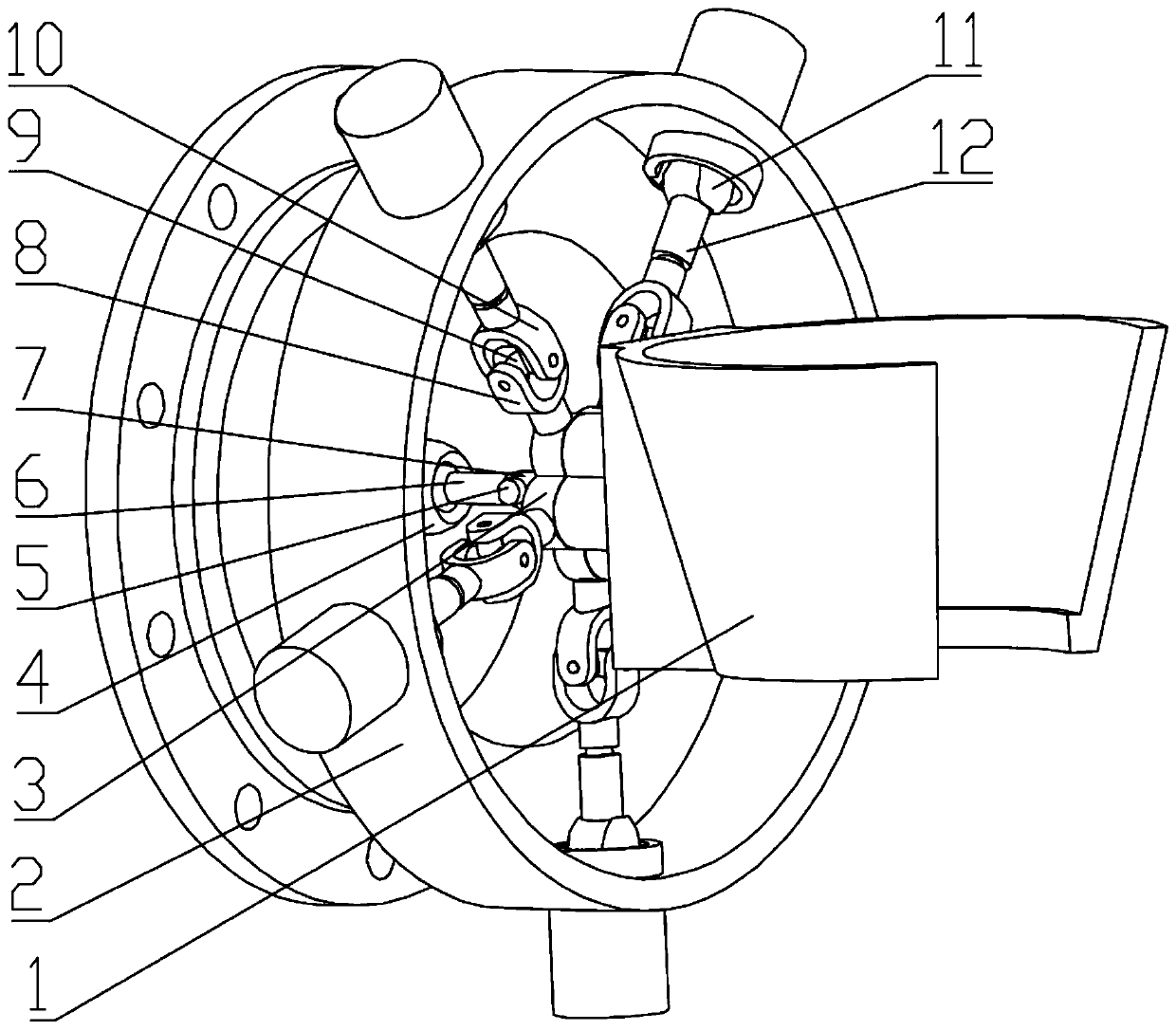

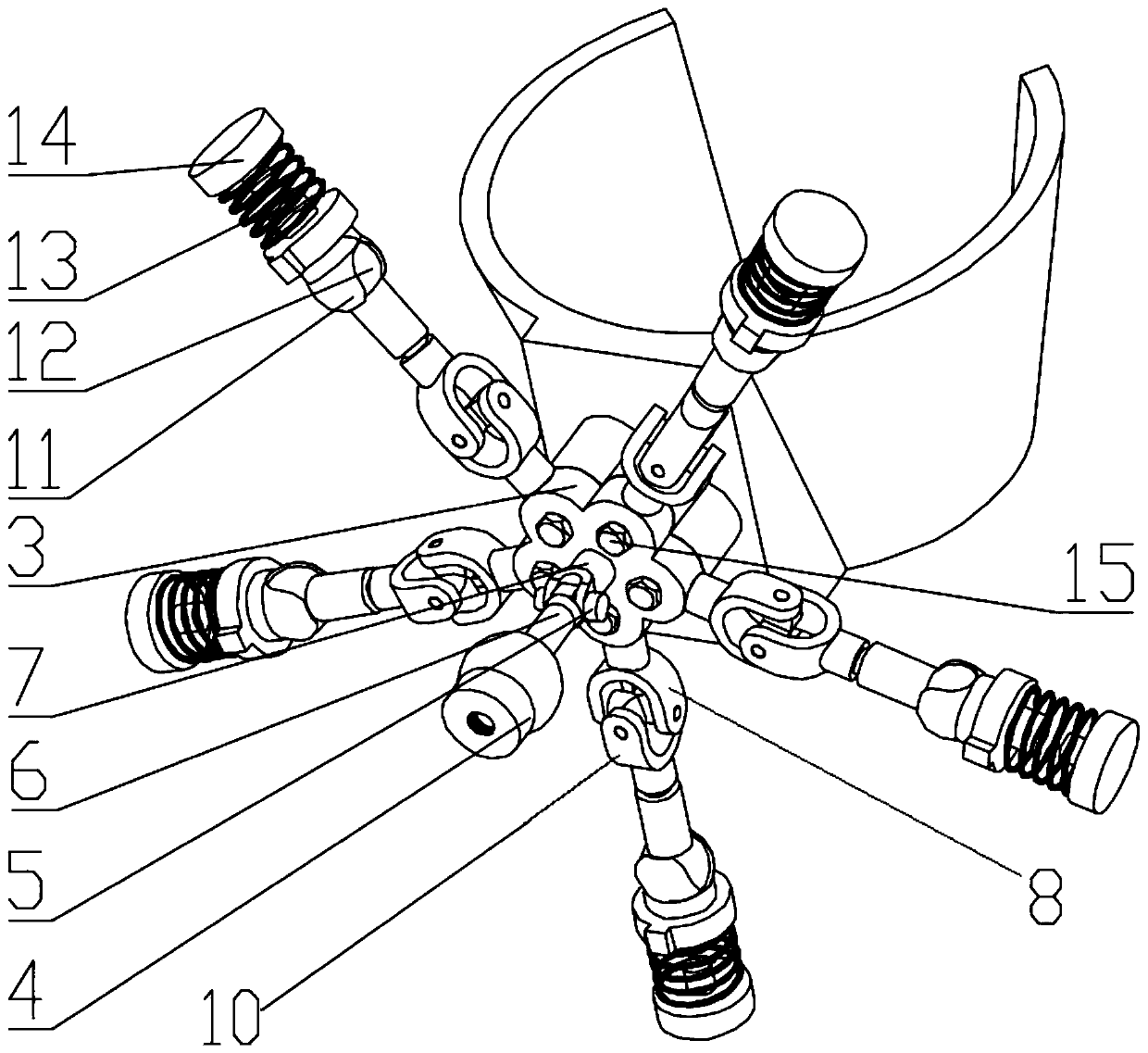

Skull surgery robot system and method

ActiveCN112998855AGuaranteed accuracyIncreased rotational freedomComputer-aided planning/modellingSurgical manipulatorsMilling cutterRectangular coordinates

The invention belongs to the technical field of medical instruments, and particularly relates to a skull surgery robot system and method. In order to solve the problem that in the prior art, line drawing and marking need to be carried out firstly in a skull surgery, and then a clinical surgery needs to be carried out, the invention provides the skull surgery robot system. According to the skull model marking device and method, the posture adjusting module is controlled to adjust movement of the paintbrush / milling cutter so that the paintbrush / milling cutter can have two movement freedom degrees and two rotation freedom degrees, and meanwhile one movement freedom degree and one rotation freedom degree are added to the skull model, so that the paintbrush / milling cutter marks the skull model fixed to the bearing module based on the cutting route. The instrument can move freely within an effective stroke in a space rectangular coordinate system with x, y and z axes as coordinate axes so as to complete operations such as line drawing and dotting on any point on the outer surface of a skull model, and the axis of a paintbrush / milling cutter points to the center of the skull spherical surface; therefore, the accuracy of the line is ensured.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

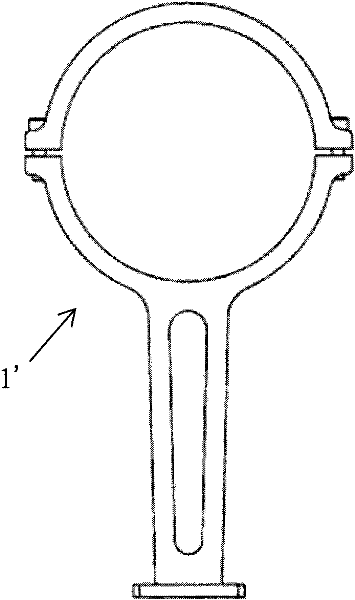

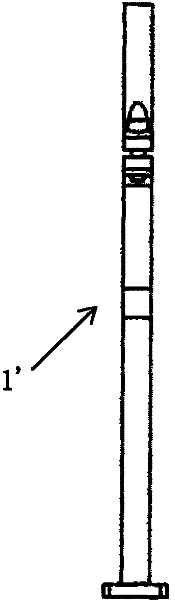

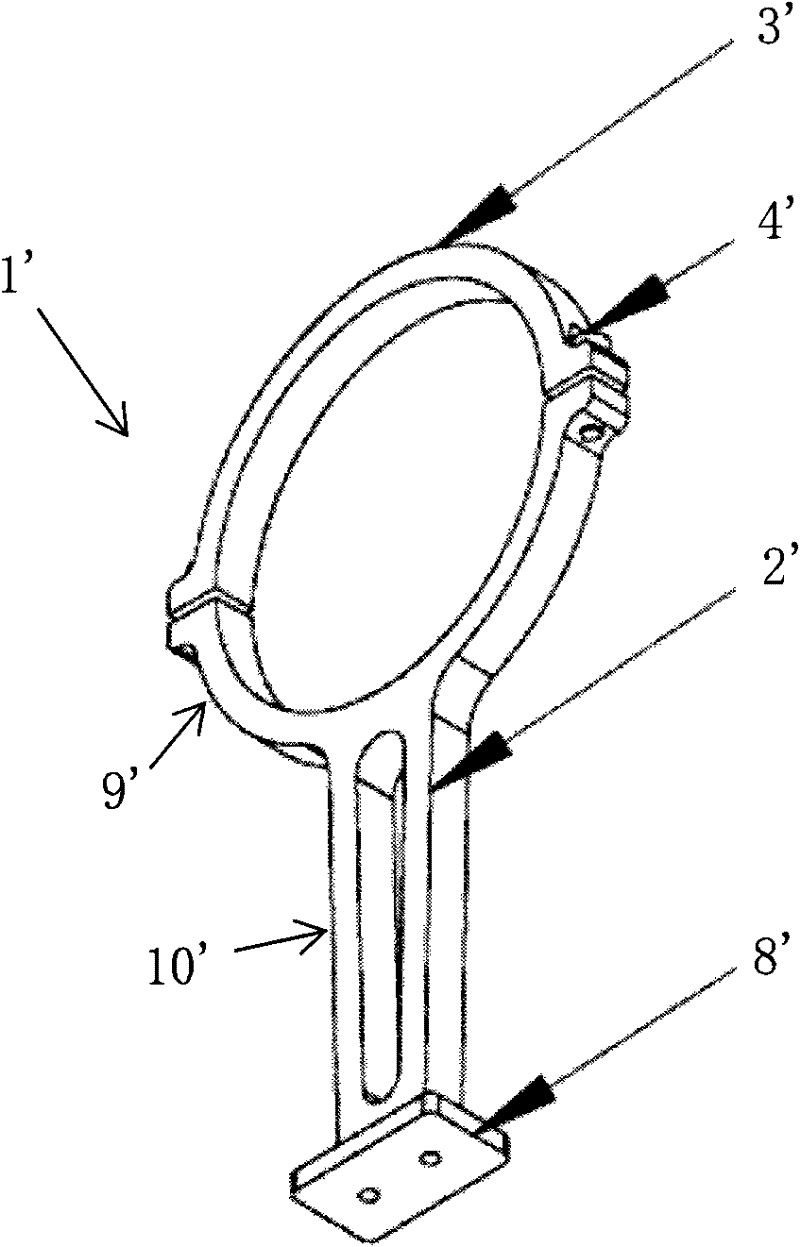

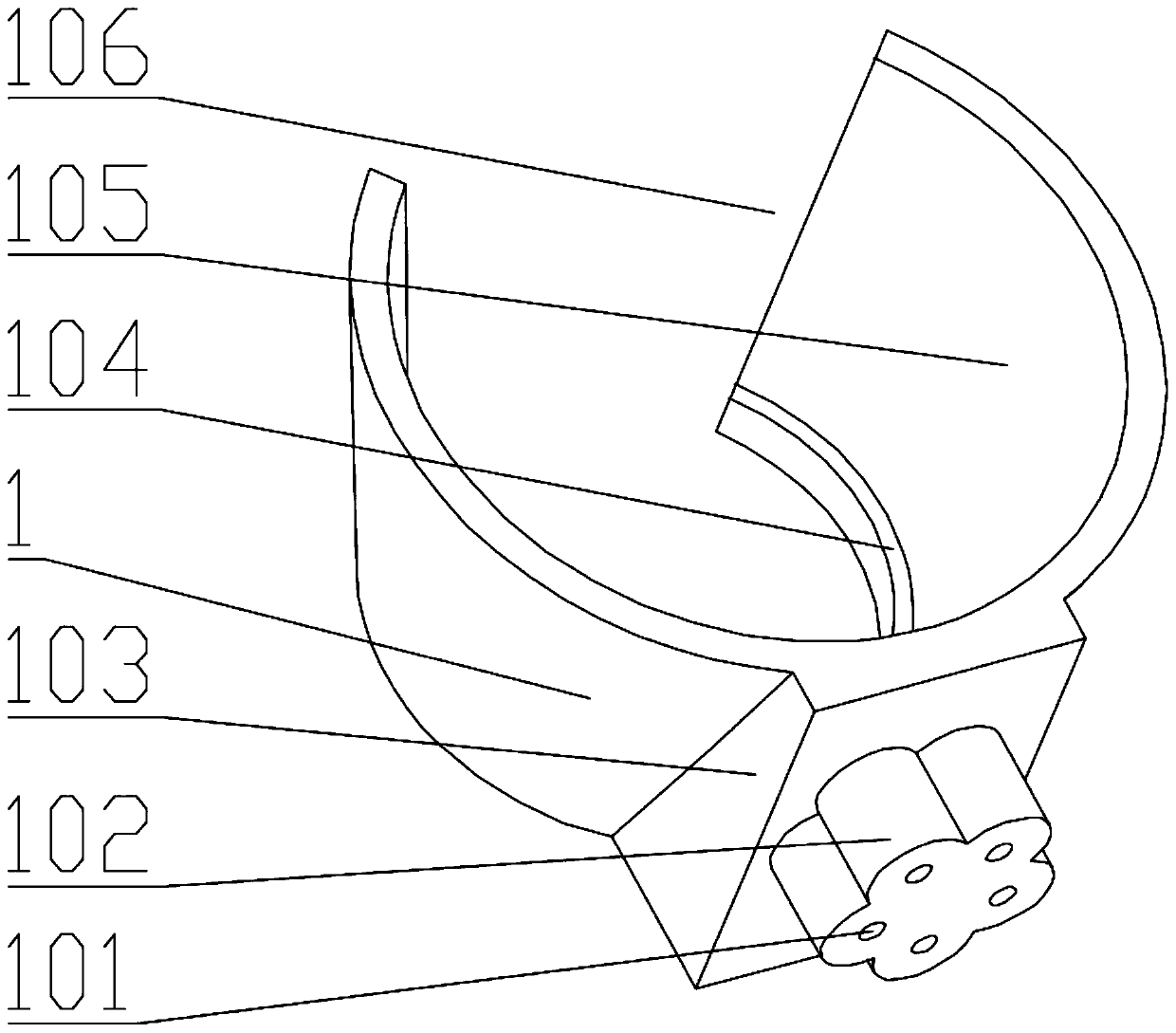

Free rotating and connecting device of hose bag

The invention relates to a free rotating and connecting device (1) of a hose bag. The free rotating and connecting device (1) comprises a semicircular connecting piece (3) and a connecting piece (2) connected with the semicircular connecting piece (3), wherein the connecting piece (2) is provided with a semicircular end part (9) which corresponds to the semicircular connecting piece (3) so as to form a circular ring, a rod part (10) extending from the semicircular end part (9), and a connecting plate (8) connected at the tail end of the rod part (10); the free rotating and connecting device (1) further comprises a ball-shaped free rotating and connecting component (11); the ball-shaped free rotating and connecting component (11) comprises a ball-shaped cavity (17) connected at the connecting plate (8) and a rotating ball connecting rod (5) which is fixed by virtue of the ball-shaped cavity (17) and rotates; and the rotating ball connecting rod (5) is provided with a ball-shaped front end (12) limited in the ball-shaped cavity (17) and a rod body (14) extending out of an opening at the lower end of the ball-shaped cavity (17) from the ball-shaped front end (12). According to the free rotating and connecting device (1), the rotation degree of freedom in a robot and a control circuit is enhanced, the interference is reduced and the service life is prolonged.

Owner:RUIZHONGSY MACHINERY ACCESSORIES SHANGHAI

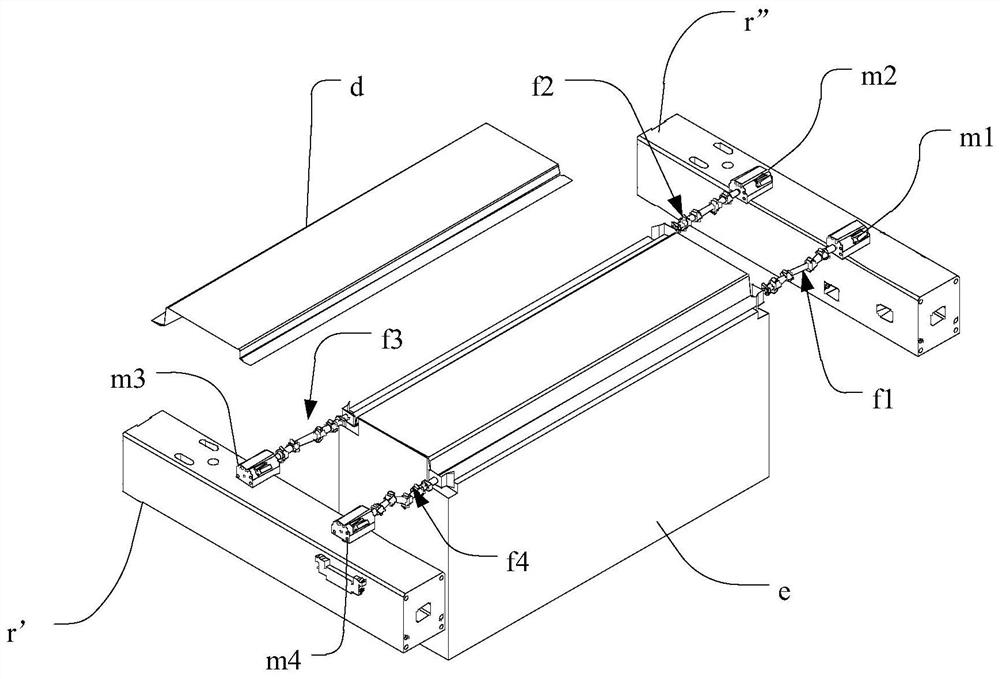

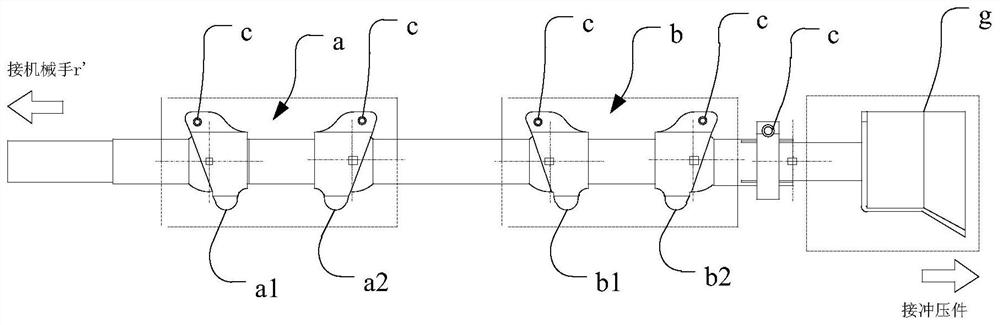

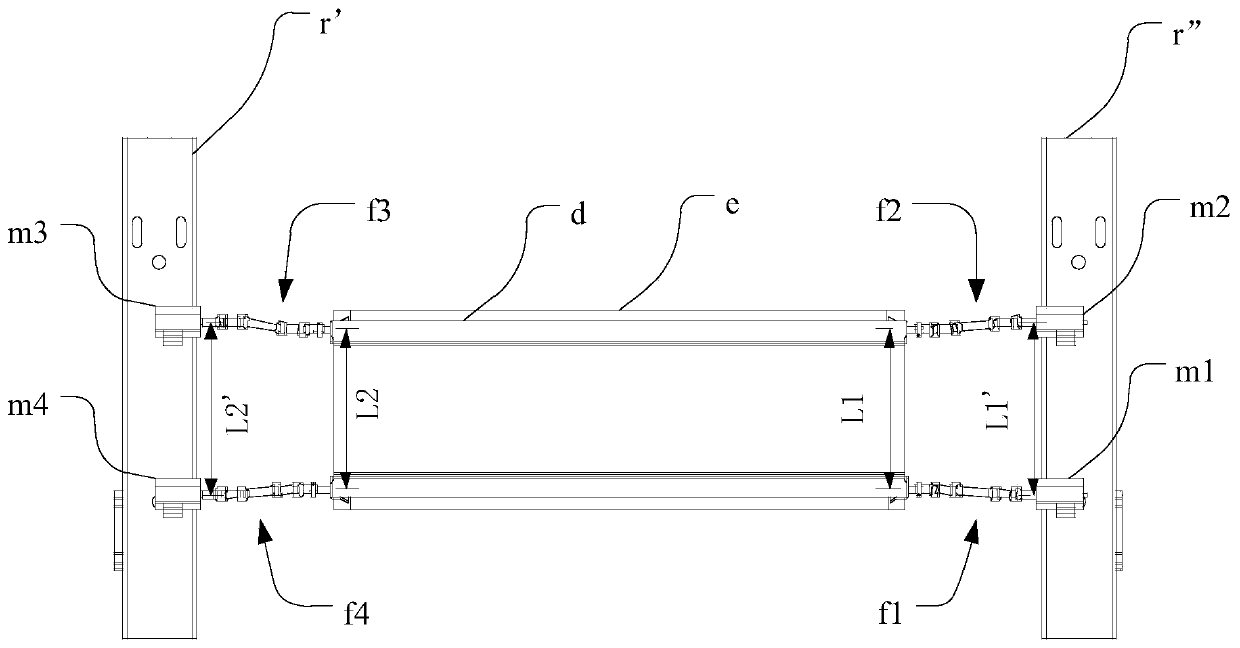

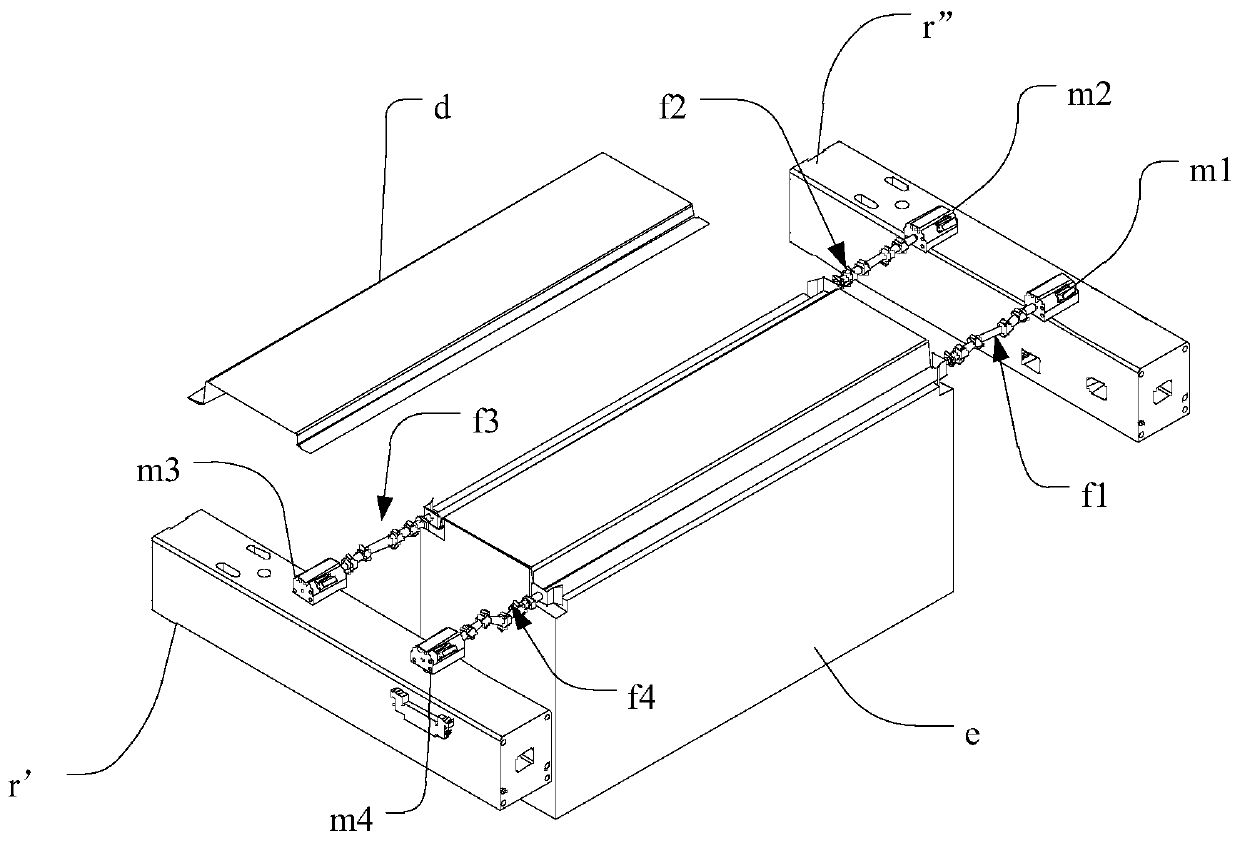

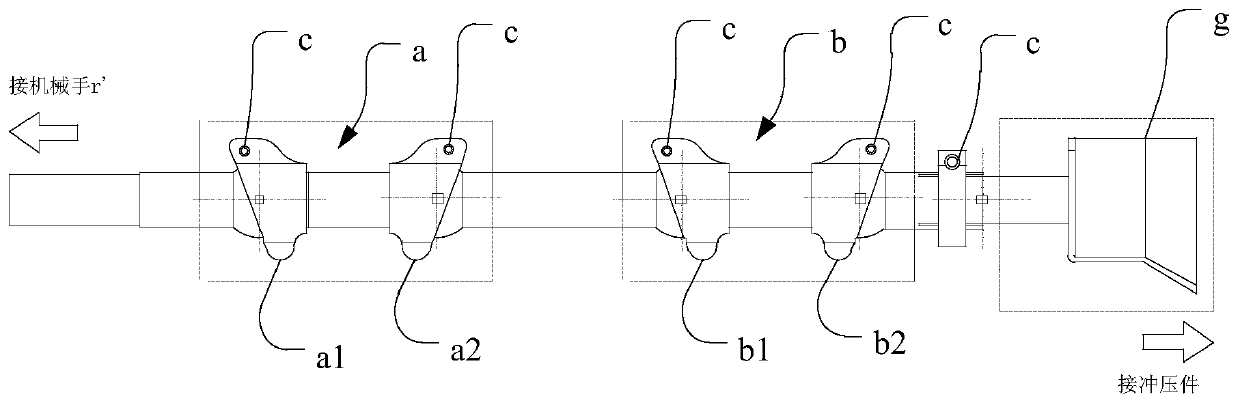

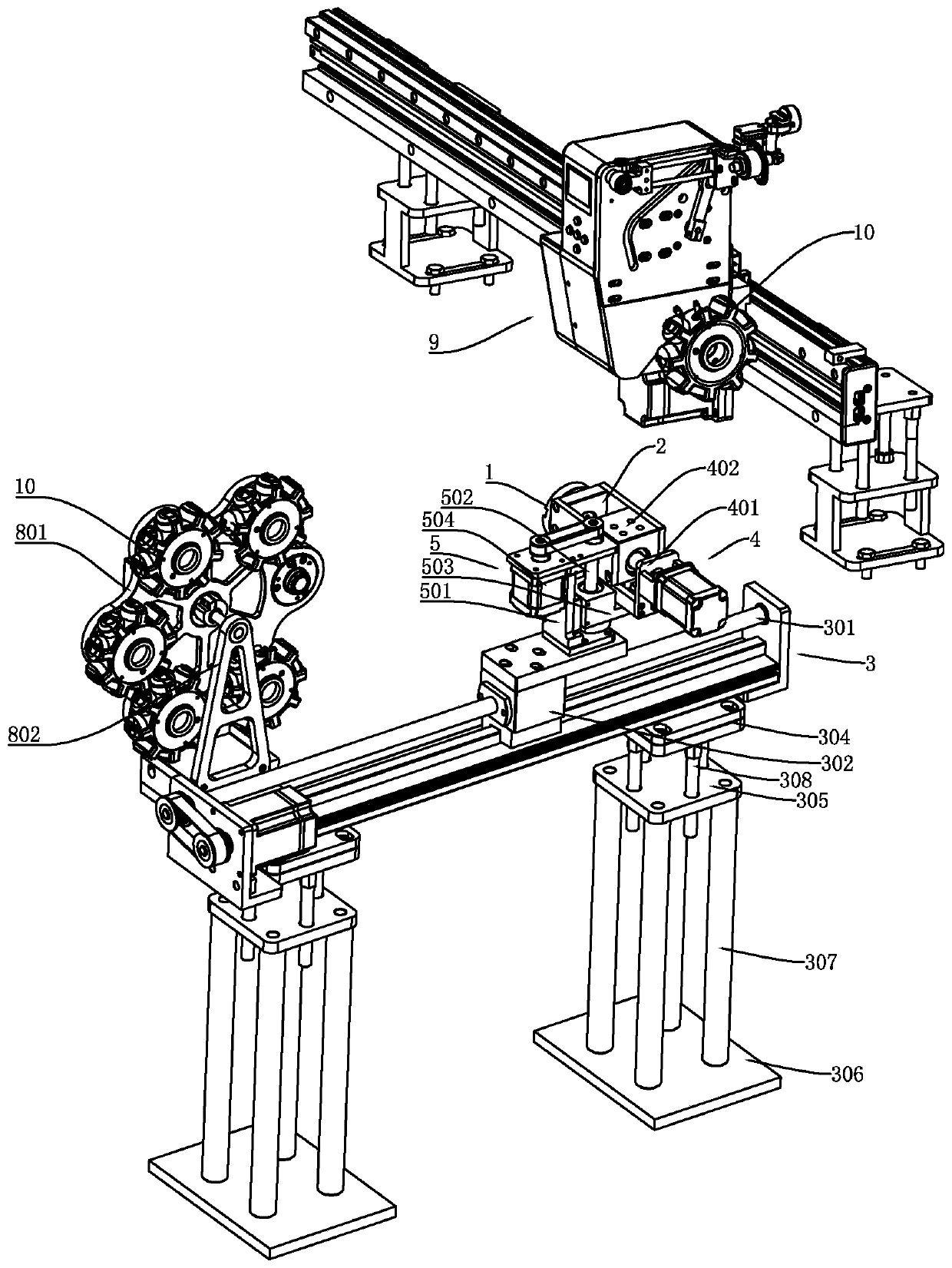

Stamping multi-station conveying system

ActiveCN110238301BIncreased rotational freedomIncreased installation flexibilityMetal-working feeding devicesPositioning devicesRobot handBall joint

The invention relates to a stamping multi-station conveying system, which comprises: a plurality of end pickers, the first ends of the end pickers are used for teaching to stamping parts, each of the end pickers The device includes the first group of ball joint seats and the second group of ball joint seats respectively, the first group of ball joint seats and the second group of ball joint seats respectively include the first ball joint seat and the second ball joint seat, each group of ball joint seats The first spherical joint seat is plugged into the second spherical joint seat in the group, and the first spherical joint seat is rotatable relative to the second spherical joint seat in the group; the number of manipulators is two, and each The manipulators respectively include a manipulator and a mount, the mount is slidably disposed on the corresponding manipulator, and the mount is connected to the second end of a corresponding one of the end pickers. The stamping multi-station conveying system can significantly improve the analysis and planning efficiency of the end effector, and the early analysis and planning results can be directly used for later on-site assembly, thus greatly improving the efficiency of installation and commissioning.

Owner:CH AUTO TECH CORP CO LTD

Mechanical arm clamp capable of automatically adjusting object shapes

InactiveCN112372660AEnsure balanceGuaranteed processing reliabilityGripping headsElectric machineryEngineering

The invention relates to the technical field of robots, and discloses a mechanical arm clamp capable of automatically adjusting object shapes. The mechanical arm clamp comprises a seat body and a clamping mechanism. One end of the seat body is connected with the tail end of a mechanical arm of an external robot or other clamping machines, and the other end of the seat body is fixedly connected with the clamping mechanism. The clamping mechanism comprises a sliding adjusting mechanism, clamping plates and telescopic components. The number of the clamping plates is two, the clamping plates are oppositely arranged, multiple mounting holes are formed in the clamping plates and used for mounting of the telescopic components, and the telescopic components comprise supporting columns, springs andsuction cups. During work, the upper clamping plate and the lower clamping plate are driven to move linearly through the sliding adjusting mechanism, due to the shapes of clamped objects are different, force borne by springs of clamping points are different, and the clamp keeps large-area contact clamping to the different clamped objects through spring deformation and supporting column stretchingand retracting, and therefore the machining reliability is guaranteed. In addition, the seat body is further provided with a first motor, a rotational degree of freedom is added to the clamping mechanism, and clamping is more flexible and convenient.

Owner:GUANGZHOU UNIVERSITY

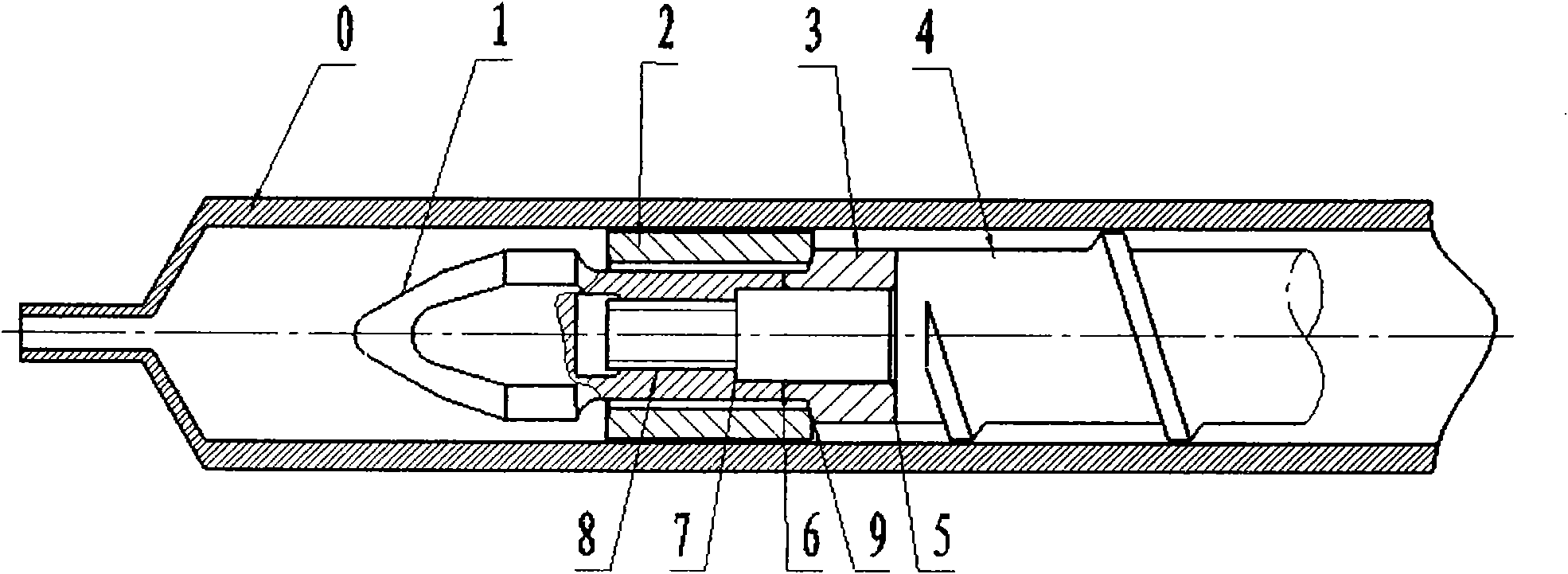

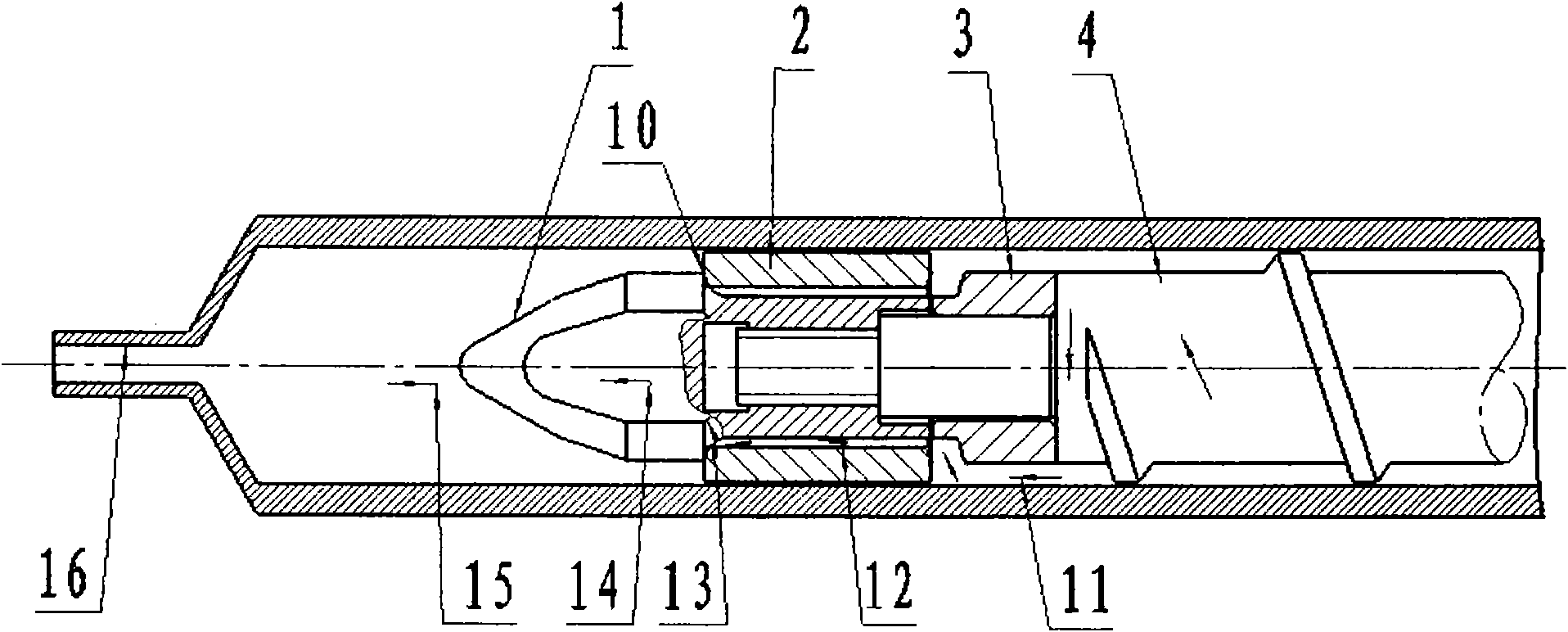

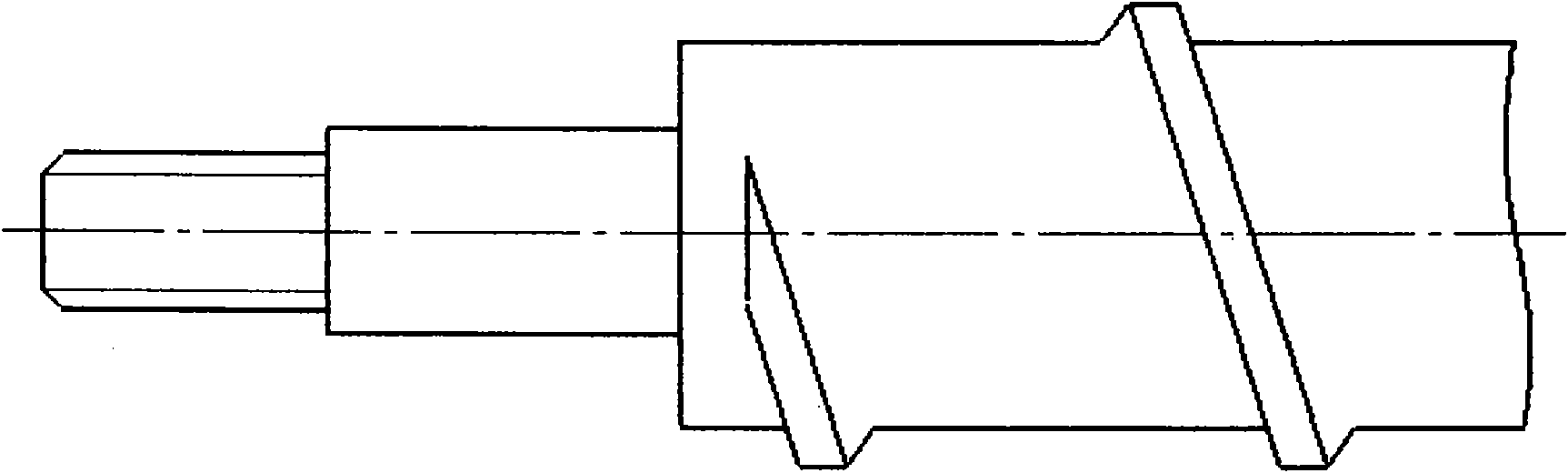

Threaded rod of injection molding machine with reversely connected threaded rod head

The invention relates to a threaded rod of an injection molding machine with a reversely connected threaded rod head, which mainly comprises a threaded rod body, a thrust ring, a check ring and a threaded rod head. The front end of the threaded rod body is provided with a smooth cylinder with a small diameter and a small stud in order, and the stud is matched with an internal threaded hole in the threaded rod head to connect the stud with the threaded rod head. Therefore, the threaded rod has high linearity and concentricity. The thrust ring is sheathed on the smooth cylinder with a small diameter, and the front end surface and the rear end surface of the thrust ring are respectively abutted with the rear end surface of the threaded rod head and the front end surface of the threaded rod. When the stud at the front end of the thread rod is screwed into the internal threaded hole in the threaded rod head by a certain depth, the thrust ring is axially fixed. The thrust ring has different outside diameters according to different requirements for materials and processes so as to generate different backpressure. The annular check ring is installed on a cylinder of the threaded rod head between the thrust ring and the threaded rod head, can rotate freely and can move back and forth. When the rear side surface of the check ring is not fully abutted with the front diagonal side surface of the thrust ring, fusant plasticized in a threaded groove is pressed into a storage section through the clearance, another clearance formed between the cylinder of the threaded rod head and a charging barrel as well as a threaded rod head groove. However, when the rear side surface of the check ring is abutted with the front diagonal side surface of the thrust ring, the fusant in the storage section is prevented from back flowing to the threaded groove, thus playing a role of sealing, and the threaded rod can be injected.

Owner:BEIJING UNIV OF CHEM TECH

Multi-spray-head cooperative biological printing method

ActiveCN110450405AIncreased rotational freedomAvoid duplicationIncreasing energy efficiency3D object support structuresTemperature controlSpray nozzle

The invention discloses a multi-spray-head cooperative biological printing method. The multi-spray-head cooperative biological printing method comprises the following steps: calibrating spray nozzlesof all spray head assemblies to the origin of a world coordinate system, determining the spray head assembly which needs to perform a printing task, and enabling the spray head assemblies to start theprinting task from the origin in sequence; or enabling the spray head assemblies to sequentially perform the printing task, wherein the task path end point of the last spray nozzle assembly is the task path start point of the next spray head assembly; or enabling all spray head assemblies which perform the printing task to perform on the same printing path, and synchronously starting the printingtask from a zero position along the printing task after all spray head assemblies reach the zero position. The multi-spray-head cooperative biological printing method has the advantages that: the spray head assemblies of the system can cooperatively or sequentially work, so that the printing mode is flexible and various; the tip ends of spray nozzles of the spray head assemblies are washed and cleaned, and stable output, in the normal printing task, of materials is guaranteed; and for peripheral type surrounding temperature control and bottom vacuum adsorbing clamping for a working utensil, mass of a forming living body structure is effectively guaranteed, so that the survival rate of a viable tissue is increased.

Owner:ZHEJIANG UNIV

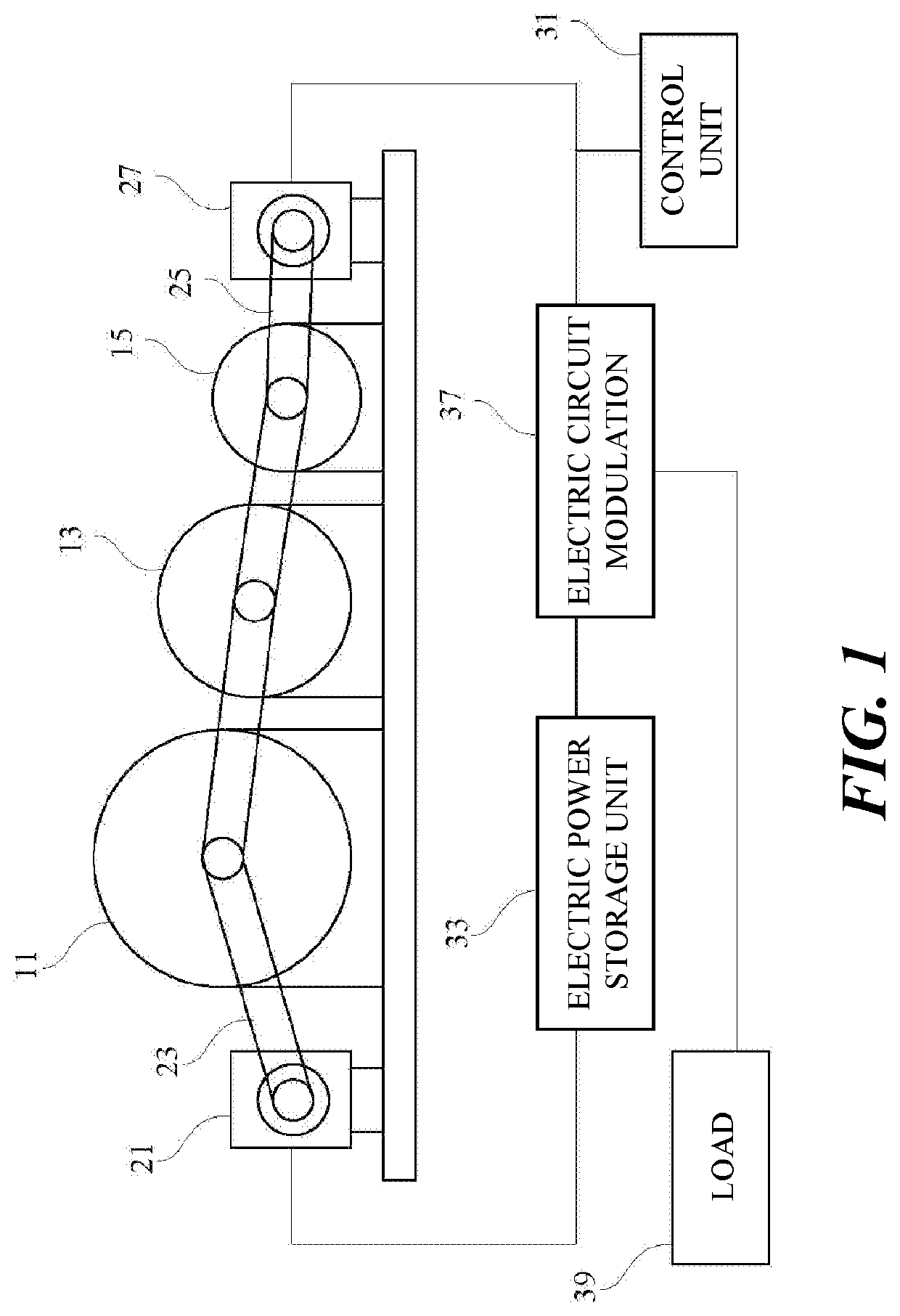

Power generation method and system equipped with energy storage and energy release accommodation mechanism

ActiveUS20220069667A1Improve consumption efficiencyLarge massBatteries circuit arrangementsAc network load balancingControl engineeringProcess engineering

The invention provides a power generation method and a system equipped with energy storage and energy release accommodation mechanism. By using an energy storage and energy release accommodation system arranged in the system, the generator set at an end of the system can immediately supplement energy from an energy storage unit after providing electric energy to a load, so that the output energy will not drop suddenly, while still stably maintaining both the rated energy output and the system operation.

Owner:INFINIFORCE INC

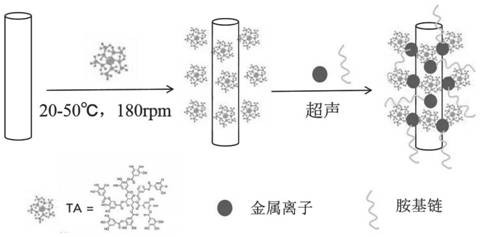

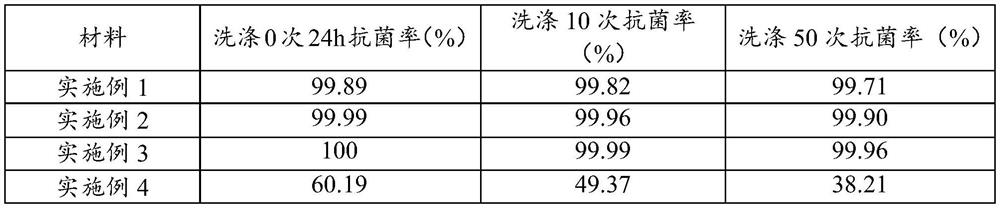

Preparation method of fibrilia antibacterial functional material

ActiveCN113564922AGood flexibilityGrafting is firmPhysical treatmentBiochemical fibre treatmentTannic acidAqueous solution

The invention provides a preparation method of a fibrilia antibacterial functional material. The method comprises the following steps of soaking fibrilia in a tannic acid aqueous solution for a first reaction to obtain pre-modified fibrilia; and carrying out a second reaction on the pre-modified fibrilia, metal ions and organic amine to obtain the fibrilia antibacterial functional material. According to the invention, firstly, tannic acid is grafted on the surface of the fibrilia through hydrogen-bond interaction; after primary grafting of the tannic acid is completed, an aqueous solution of the metal ions and the organic amine is dropwise added under the ultrasonic action for further crosslinking, so that chelating bonds are formed between free phenolic hydroxyl groups of the tannic acid and the metal ions as well as between the metal ions and the organic amine, and the tannic acid is more firmly and uniformly grafted on the surface of the fibrilia; and due to the introduction of the organic amine, the distance between tannic acid and metal ion complexes is increased, uniform and firm grafting on the surface of the fibrilia is realized, and the application environment adaptability of the tannic acid grafted fibrilia is enhanced.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Stamping multi-station transport system

ActiveCN110238301AIncreased rotational freedomIncreased installation flexibilityMetal-working feeding devicesPositioning devicesTransport systemEngineering

The invention relates to a stamping multi-station transport system. The stamping multi-station transport system comprises multiple end pickers and manipulators, wherein one end of each end picker is used for guiding to a stamping part, each end picker comprises a first group of spherical hinged supports and a second group of spherical hinged supports, each group in the first group of the spherical hinged supports and the second group of the spherical hinged supports comprises a first spherical hinged support and a second spherical hinged support, the first spherical hinged support in each group is inserted into the second hinged support in the same group, the first spherical hinged support in each group can rotate relatively to the second hinged support in the same group, the number of the manipulators is two, each manipulator comprises an mechanical arm and an installation seat, the installation seats can be respectively arranged on the corresponding mechanical arms in slidable mode, and each installation seat is connected with a second end of each corresponding end picker. The stamping multi-station transport system can significantly improve analysis and planning efficiency of the end pickers, and early analysis and planning results can be directly used in late field assembly, and therefore installation and debugging efficiency is greatly improved.

Owner:CH AUTO TECH CORP CO LTD

Automatic material change device for bobbin case storage tray

InactiveCN110359196AIncreased rotational freedomEasy to installBobbin-winding devicesAuxillary devicesBobbinDrive shaft

The invention discloses a change device for a bobbin case storage tray. The device structurally comprises a material taking head, a floating mechanism, an adjusting manipulator and a conveying mechanism, a plurality of adjusting arms are sequentially connected to form the adjusting manipulator which at least comprises a horizontal movement adjusting arm of a horizontal movement material taking mechanism and a height adjusting arm for adjusting heights and directions, the material taking head is movably connected with the horizontal movement adjusting arm through the floating mechanism and candeflect relative to the horizontal movement direction of the height adjusting arm under the action of external force, the adjusting manipulator is slidably connected with the conveying mechanism, andthe adjusting manipulator and the conveying mechanism are used for adjusting the spatial position of the material taking head. The bobbin case storage tray on an automatic embroidery machine bobbin case change device can be automatically replaced, butt joint errors in butt joint of the bobbin case storage tray and a drive shaft assembly can be adaptively compensated, and the storage tray can be accurately mounted on the drive shaft assembly for the bobbin case storage tray.

Owner:ZHUJI LIGHT IND TIMES ROBOT TECH CO LTD

Damping mechanism and buffer cylinder type flexible connecting device

PendingCN109774874AGuaranteed validityIncreased rotational freedomFloating buildingsVertical tubeFatigue damage

The invention relates to the field of ocean engineering equipment, in particular to a damping mechanism and a buffer cylinder type flexible connecting device, wherein the damping mechanism comprises across hinge assembly, wherein the cross hinge assembly comprises a near-center hinge support, a cross shaft and a far-center hinge support, which are sequentially connected in a first direction; anda spherical hinge assembly, wherein the spherical hinge assembly comprises a ball head connecting rod and a spherical hinge support with a spherical cavity, a connecting rod part of the ball head connecting rod is fixedly connected with the far-center hinge support, and a ball head part of the ball head connecting rod is hinged in the spherical cavity. According to the invention, the spherical hinge and the cross shaft hinge are both adopted; compared with a prior rigid fixed bracket, the mechanism increases the degree of freedom of rotation, eliminates the alternating bending moment caused byrotation during fixed rigid connection, improves the self-adaptive capacity for random load and impact, greatly reduces the fatigue damage risk and ensures the effectiveness of a vertical pipe.

Owner:CHANGSHA UNIVERSITY

Power-driven roller coaster chassis system

The invention relates to a power-driven roller coaster chassis system. A driving device in linkage steering with a wheel set assembly is used for dispersedly driving a vehicle to realize the synchronous curvature of a driving track and a running track; the climbing and braking capacity of the vehicle is improved, meanwhile, the vehicle body structure can be optimized, the turning radius of the vehicle in the horizontal direction and the vertical direction is reduced, the overall occupied area of equipment is reduced, the space utilization rate is increased, and the equipment competitiveness isenhanced.

Owner:BEIJING SHIBAOLAI AMUSEMENT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com