Threaded rod of injection molding machine with reversely connected threaded rod head

A technology of screw and screw head of injection molding machine, applied in the field of injection molding screw, can solve the problem of low durability of injection molding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

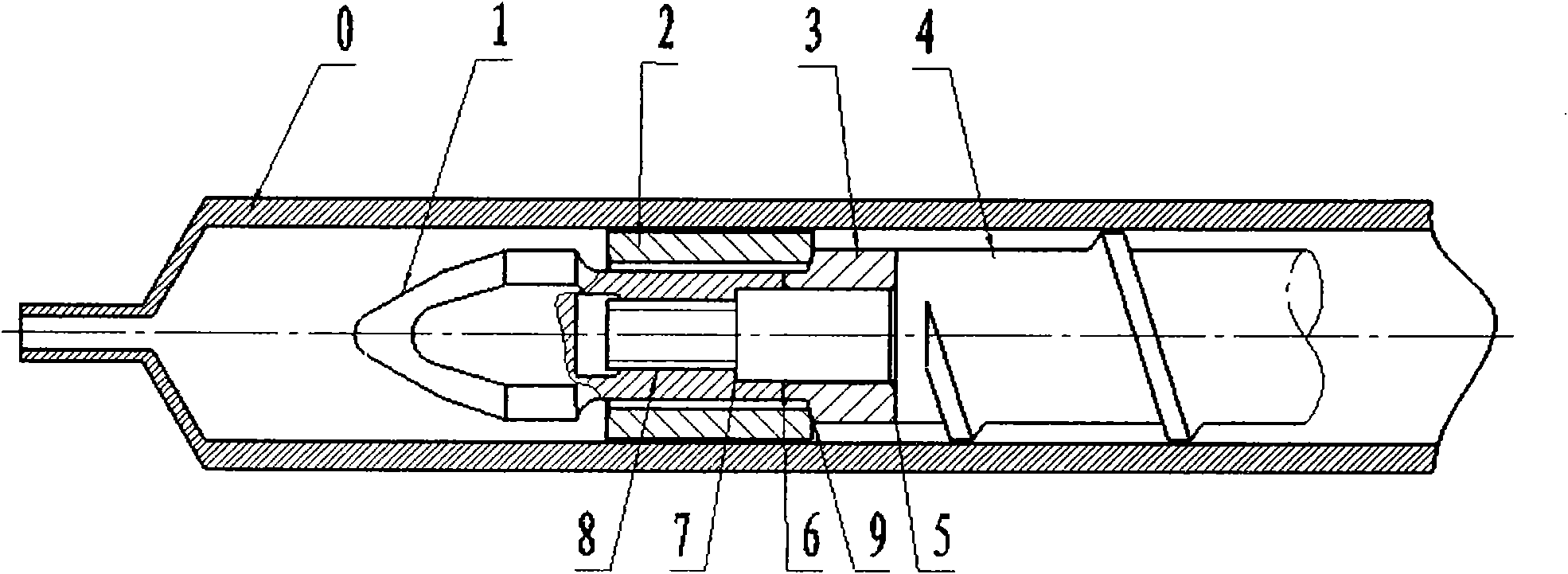

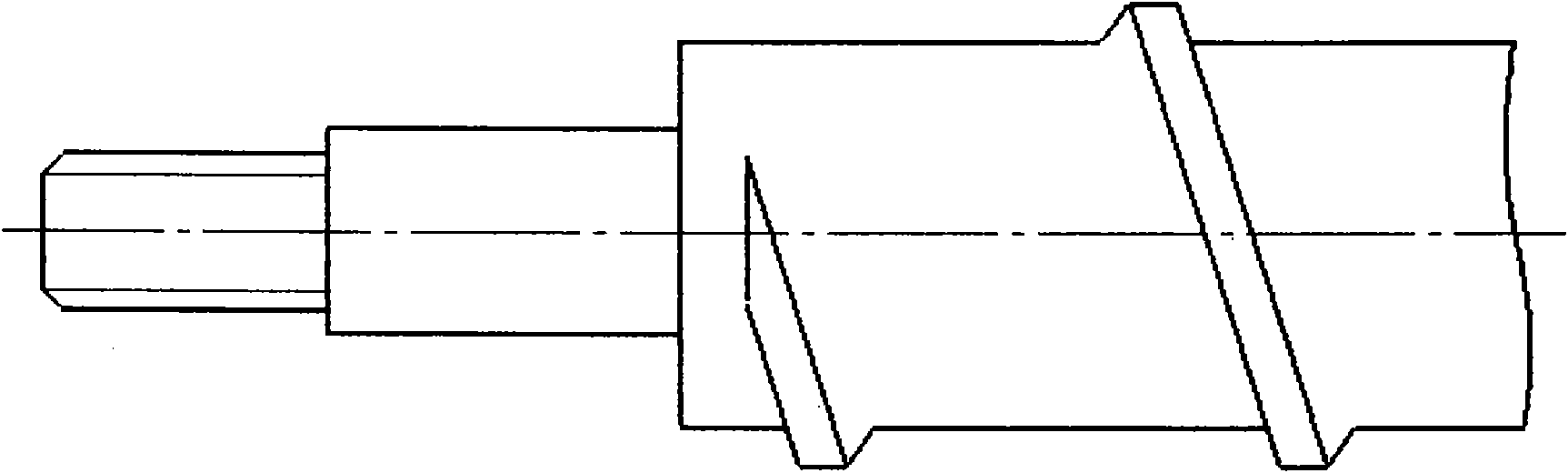

[0018] The injection molding machine screw of the present invention is mainly composed of the following parts: screw head 1 , check ring 2 , thrust ring 3 , and screw body 4 . The front end of the screw body has a section of smooth small-diameter cylinder 6 and a section of stud 8 in turn, and 7 is a stepped surface, and the thrust ring and the screw body are positioned on the contact surface 5 . The external screw thread 8 of the stud matches the internal screw hole of the screw head to connect the two parts, which can have higher straightness and coaxiality.

[0019] Such as figure 1 As shown, when the screw of the injection molding machine injects the material forward. The non-return ring and the thrust ring are closed at the contact surface 9. Since the material is sealed in the storage section in the barrel 0, the screw moves forward, the nozzle 16 is opened, and the material is injected into the mold through the flow channel.

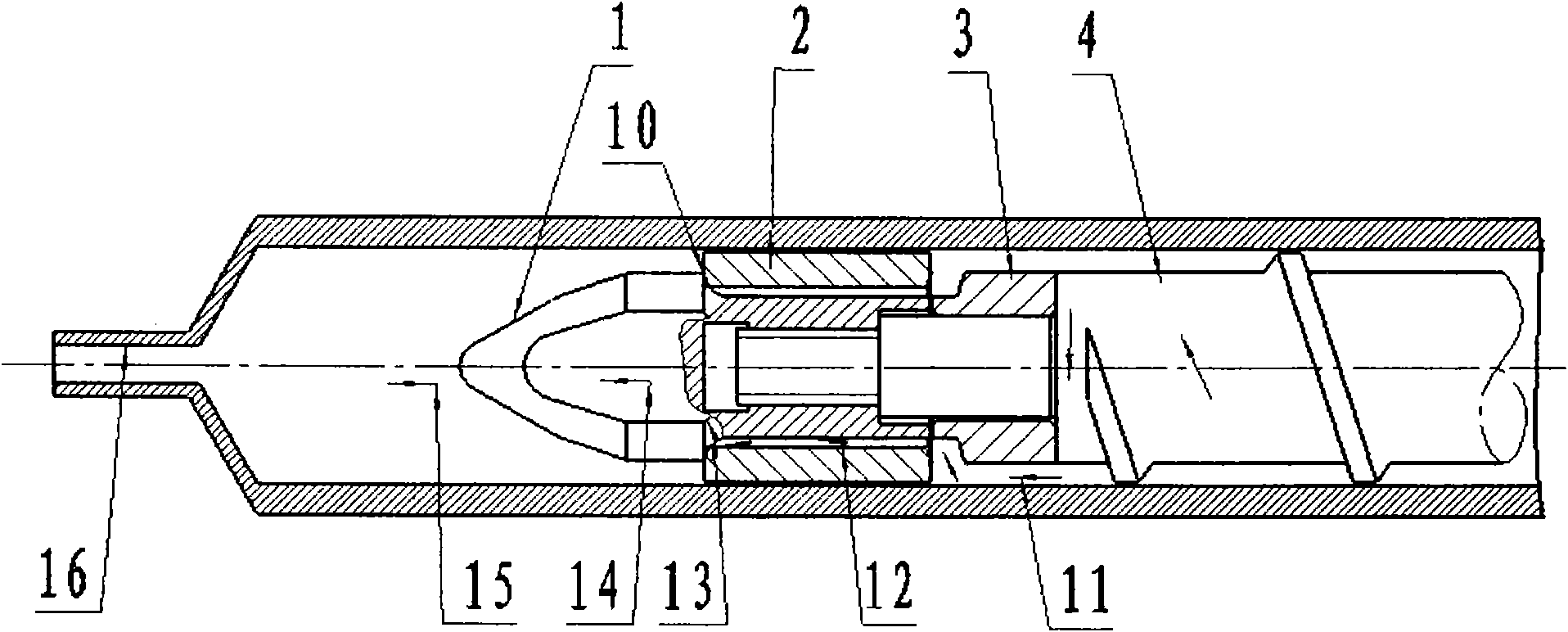

[0020] Such as figure 2 As shown, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com