Insert-assembling type multi-section rotating shaft structure

A shaft structure and plug-in technology, which is applied in the field of plug-in multi-section shaft structure, can solve problems such as insufficient smoothness of movement, limitation of pivot rotation freedom, increased complexity of assembly and processing, etc., to achieve smooth opening and closing Movement, the effect of improving the degree of freedom of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The novelty and other characteristics of the present invention will become clearer with the detailed description of the preferred embodiments in the accompanying drawings.

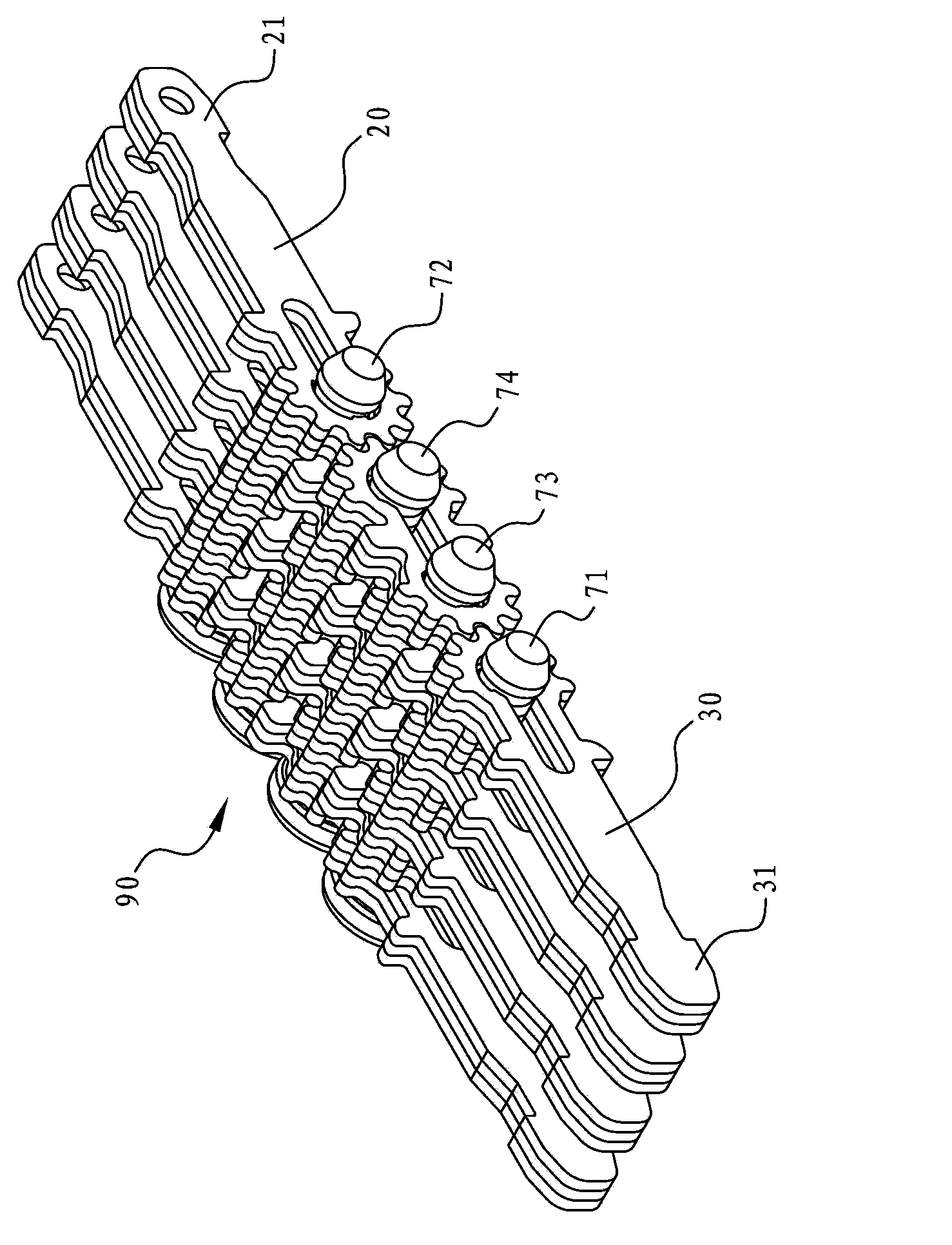

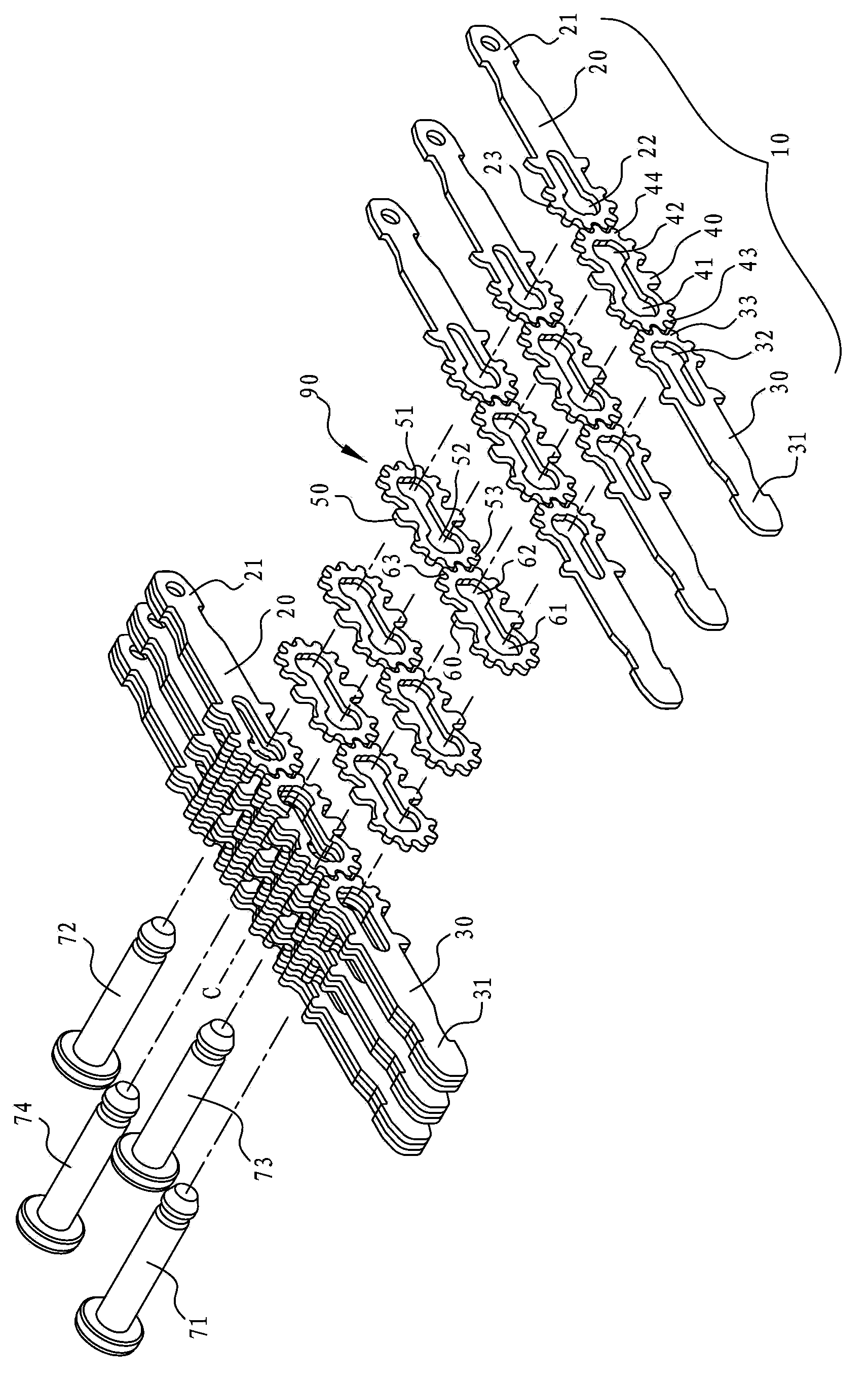

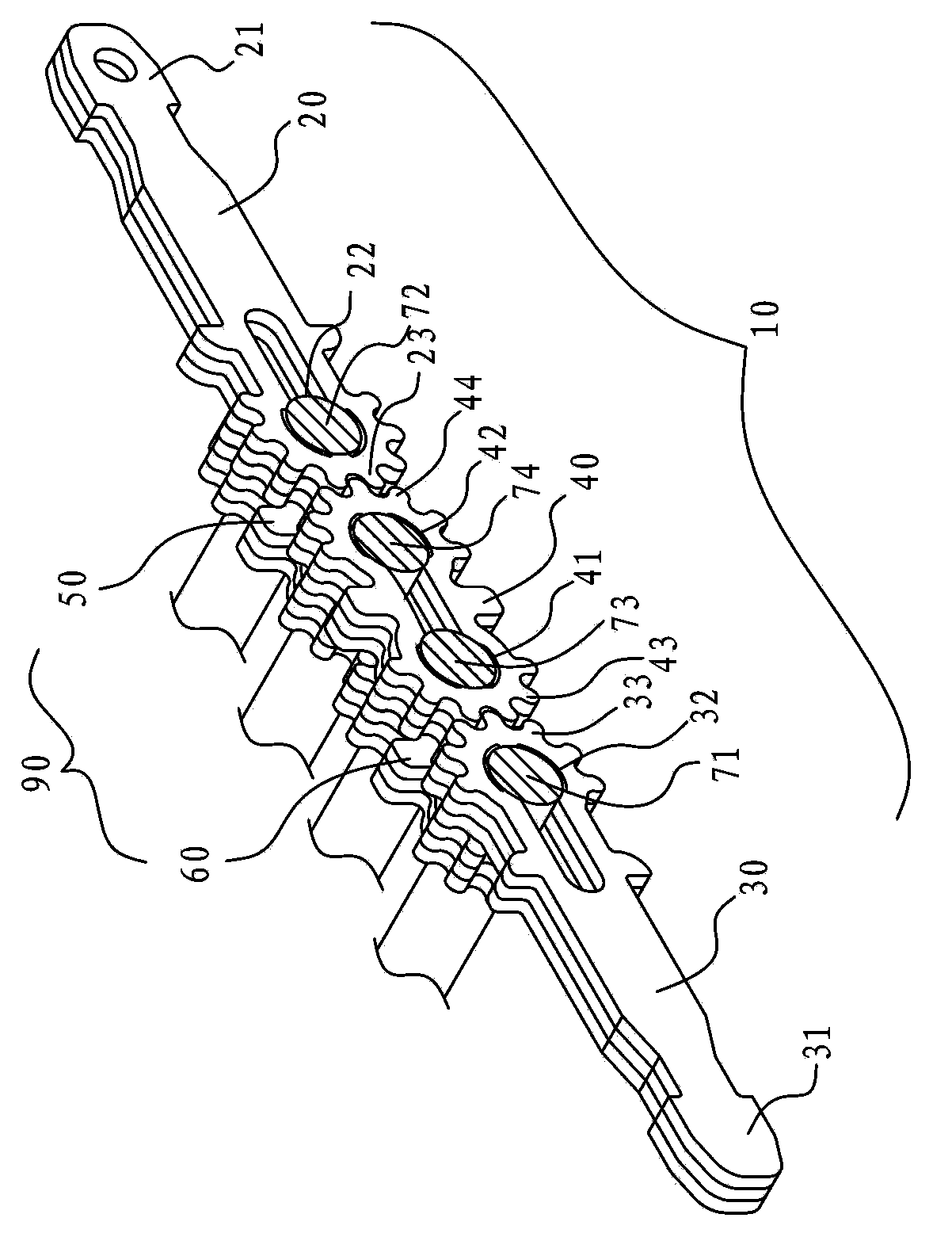

[0038] Such as Figure 1 to Figure 3 As shown, the present invention consists of most active joint groups 10 and follow-up joint groups 90 (refer to image 3 ) jointly and merged with a plurality of shaft pins to form a multi-section shaft structure.

[0039] In order to facilitate the description of the relationship between components, in the following related descriptions, such as figure 2 In the illustrated centerline C, the direction toward the centerline C will be described as "inwardly", and the direction away from the centerline C will be described as "outwardly".

[0040]The active joint group 10 includes at least two opposite first joint plates 20, a second joint plate 30 and an intermediate moving plate group 40, the two opposite first joint plates 20 and the second joint plate 30, Clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com