Multi-spray-head cooperative biological printing method

A bioprinting, multi-nozzle technology, applied in the field of 3D bioprinting, can solve the problems of long printing time, low efficiency, and limiting the ability to print complex organs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

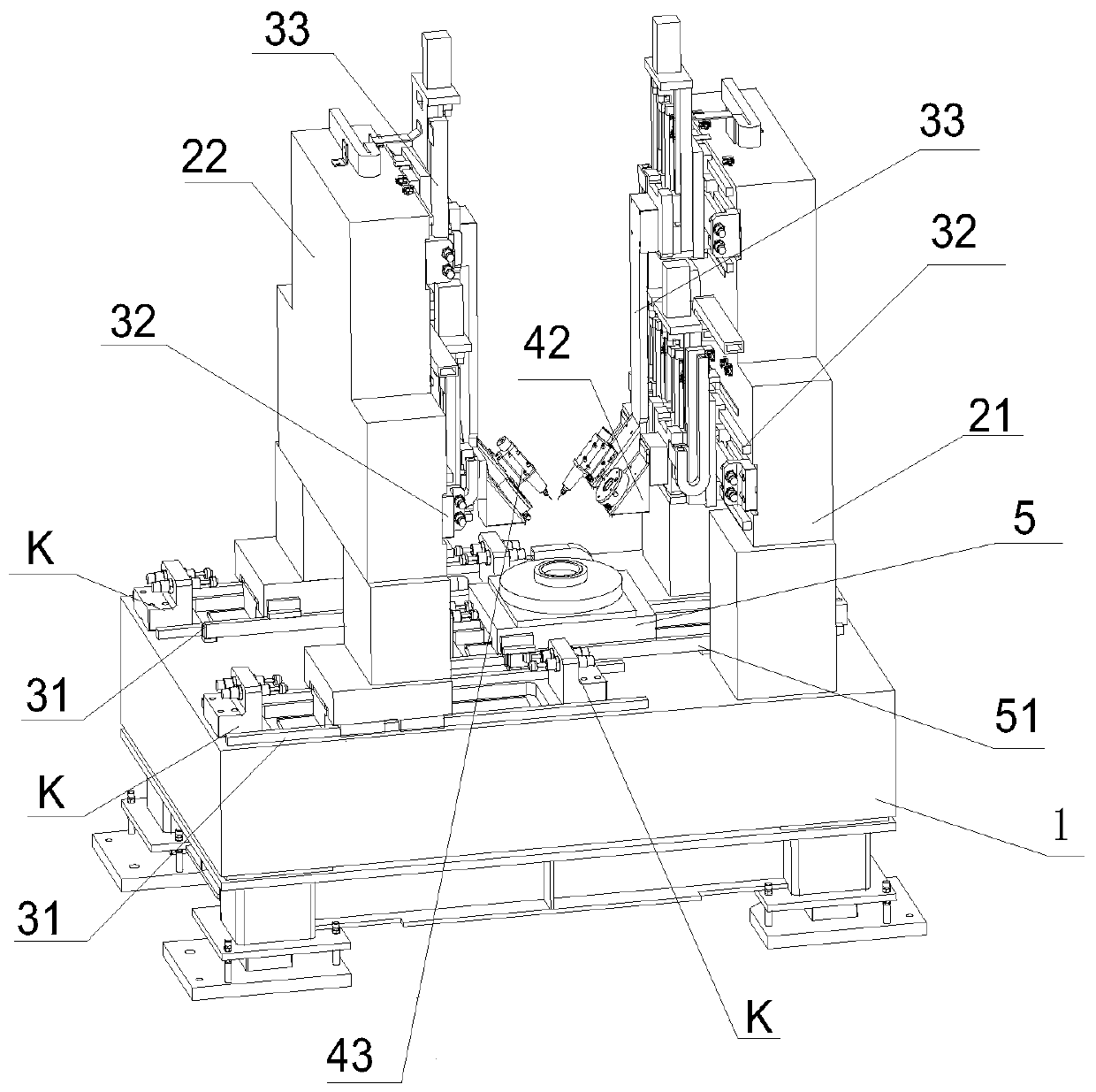

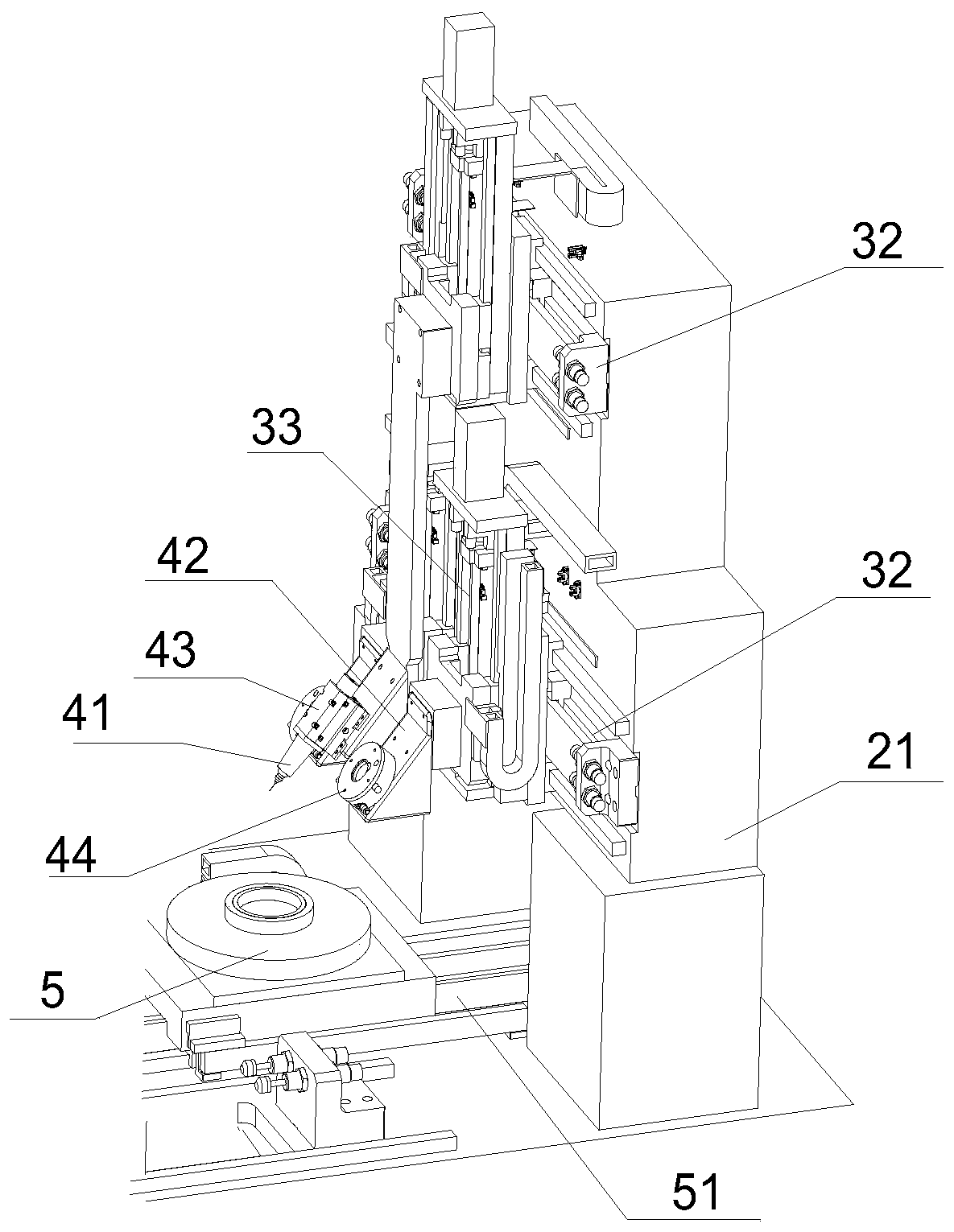

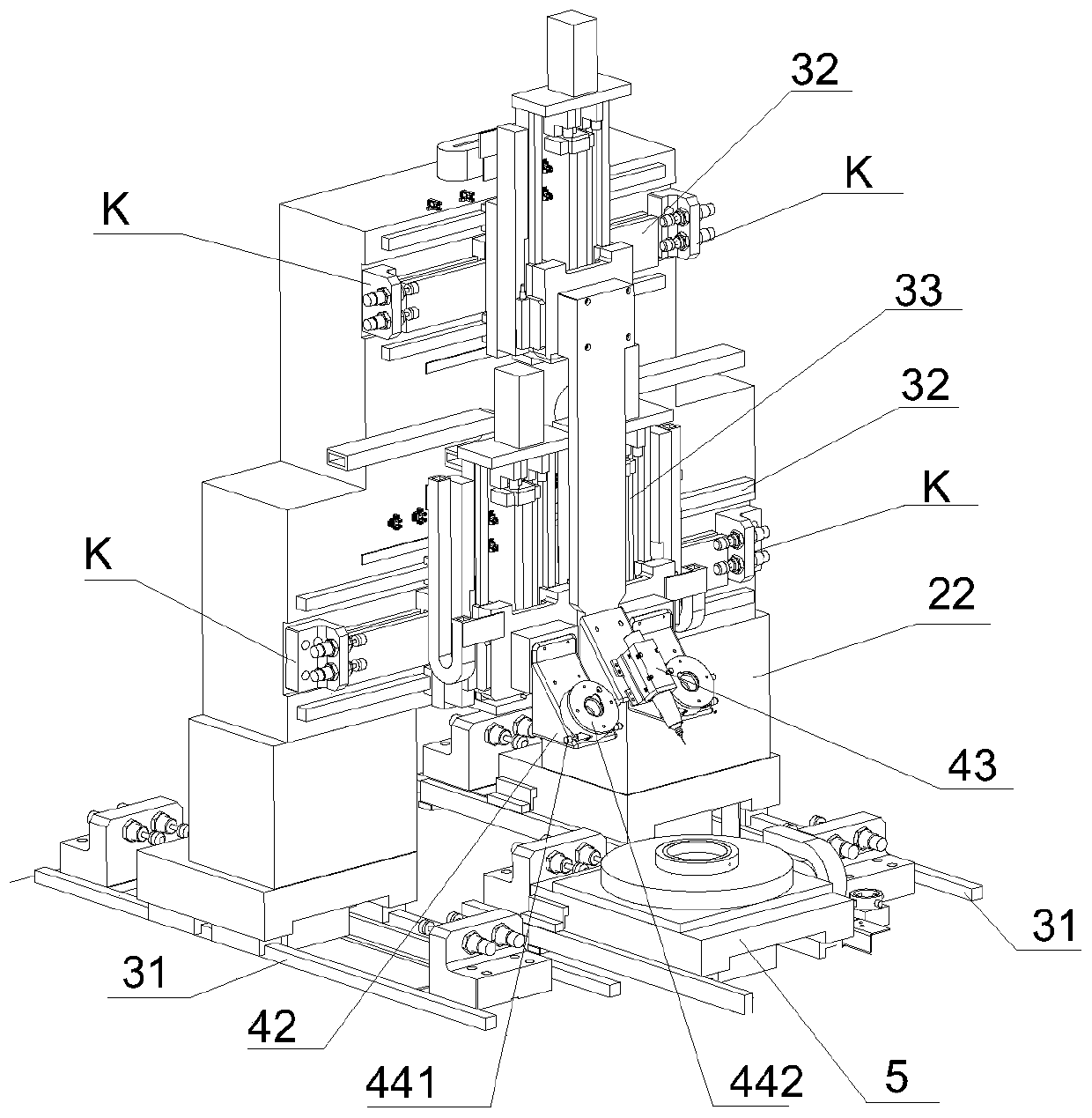

[0084] In conjunction with the accompanying drawings, the structure and working process of the present invention will be described in detail.

[0085] Multi-nozzle bio 3D printing system

[0086] like figure 1 As shown, the multi-nozzle biological 3D printing system of the present invention includes an extruded nozzle assembly and a stage 5, the nozzle assembly has its own nozzle 45, a storage tank 41 and a temperature control module 43; the nozzle assembly is driven along three axes A three-axis translation mechanism that translates to (X-axis 31, Y-axis 32, and Z-axis 33). The three-axis translation mechanism includes a X-axis 31-direction translation unit, a Y-axis 32-direction translation unit, and a Z-axis 33-direction translation unit. The assembly is installed on the Z-axis 33-direction translation unit. The nozzle can move at any point on the XOY plane, and can be raised and lowered along the Z axis 33; the nozzle assembly has independent functions of material stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com