Patents

Literature

67 results about "Backward bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In economics, a backward-bending supply curve of labour, or backward-bending labour supply curve, is a graphical device showing a situation in which as real (inflation-corrected) wages increase beyond a certain level, people will substitute leisure (non-paid time) ...

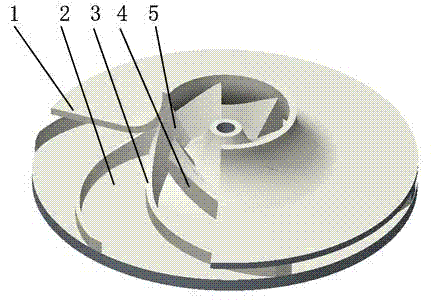

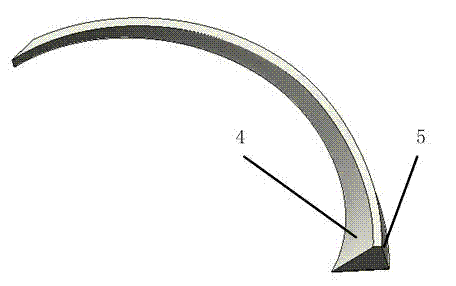

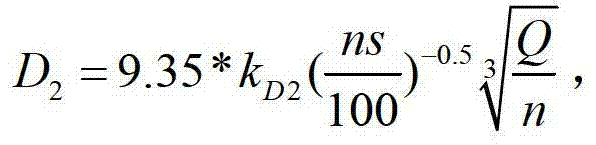

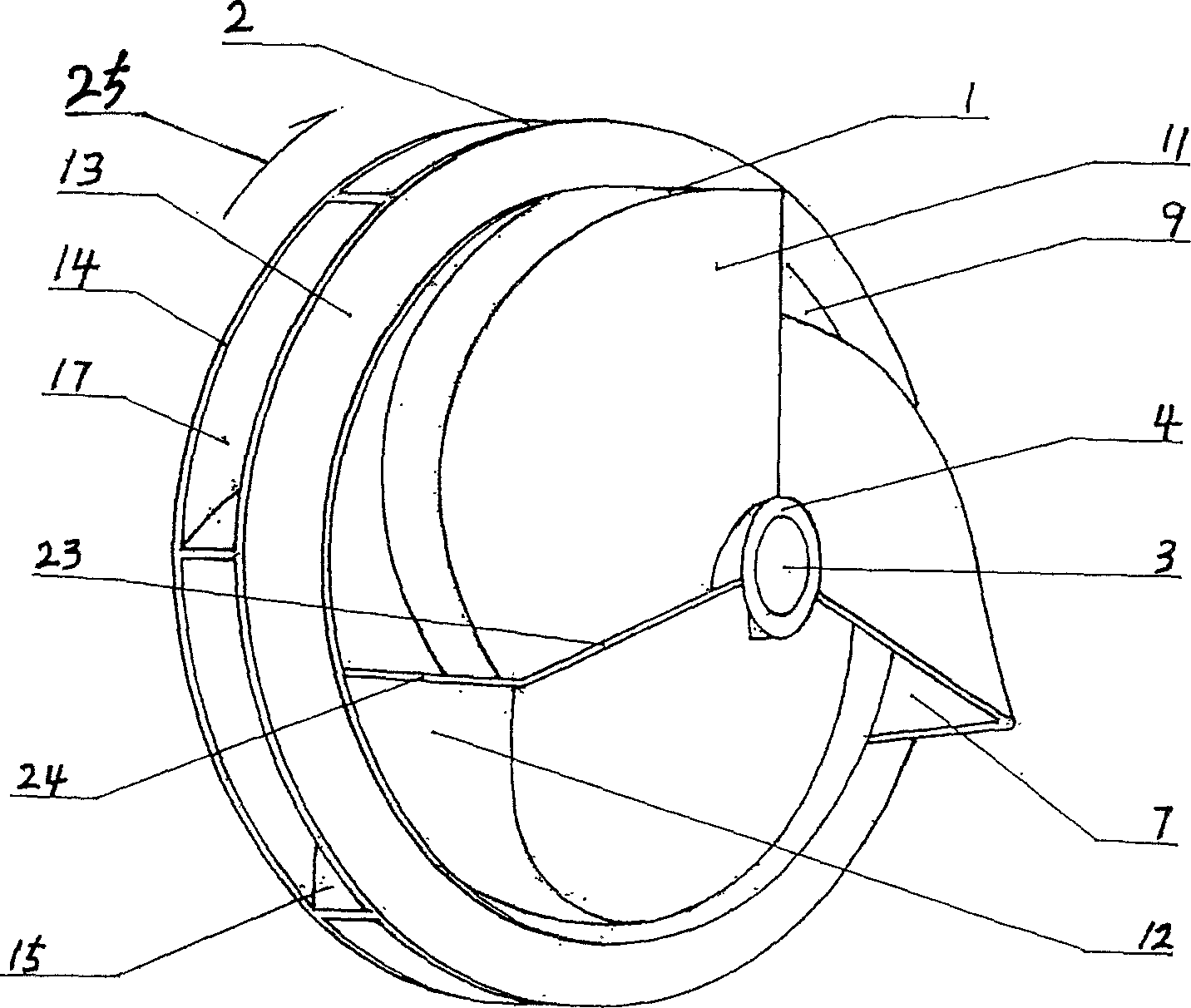

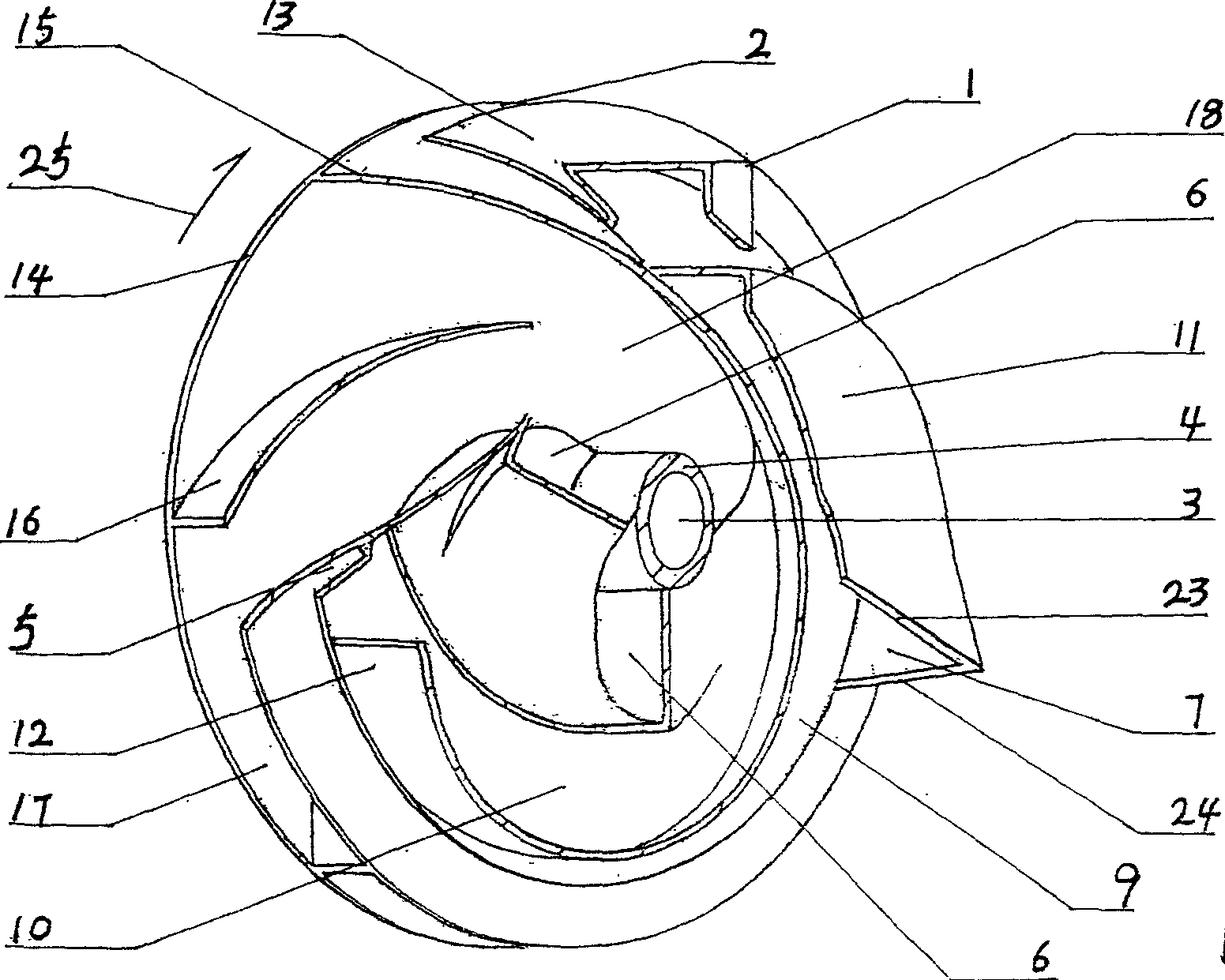

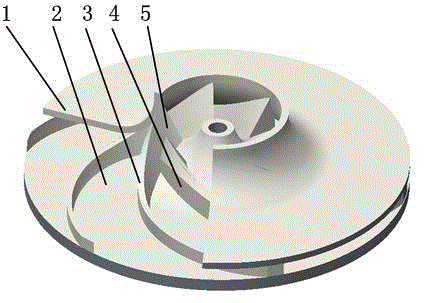

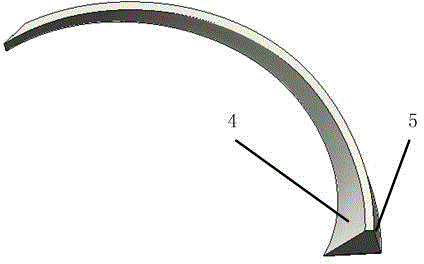

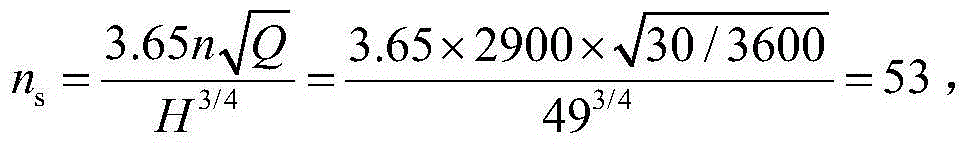

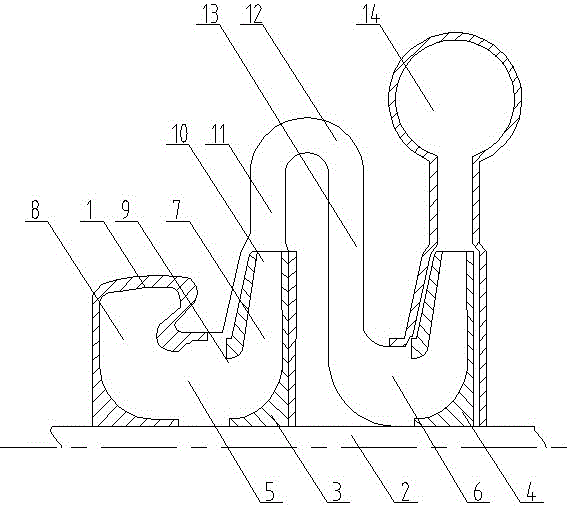

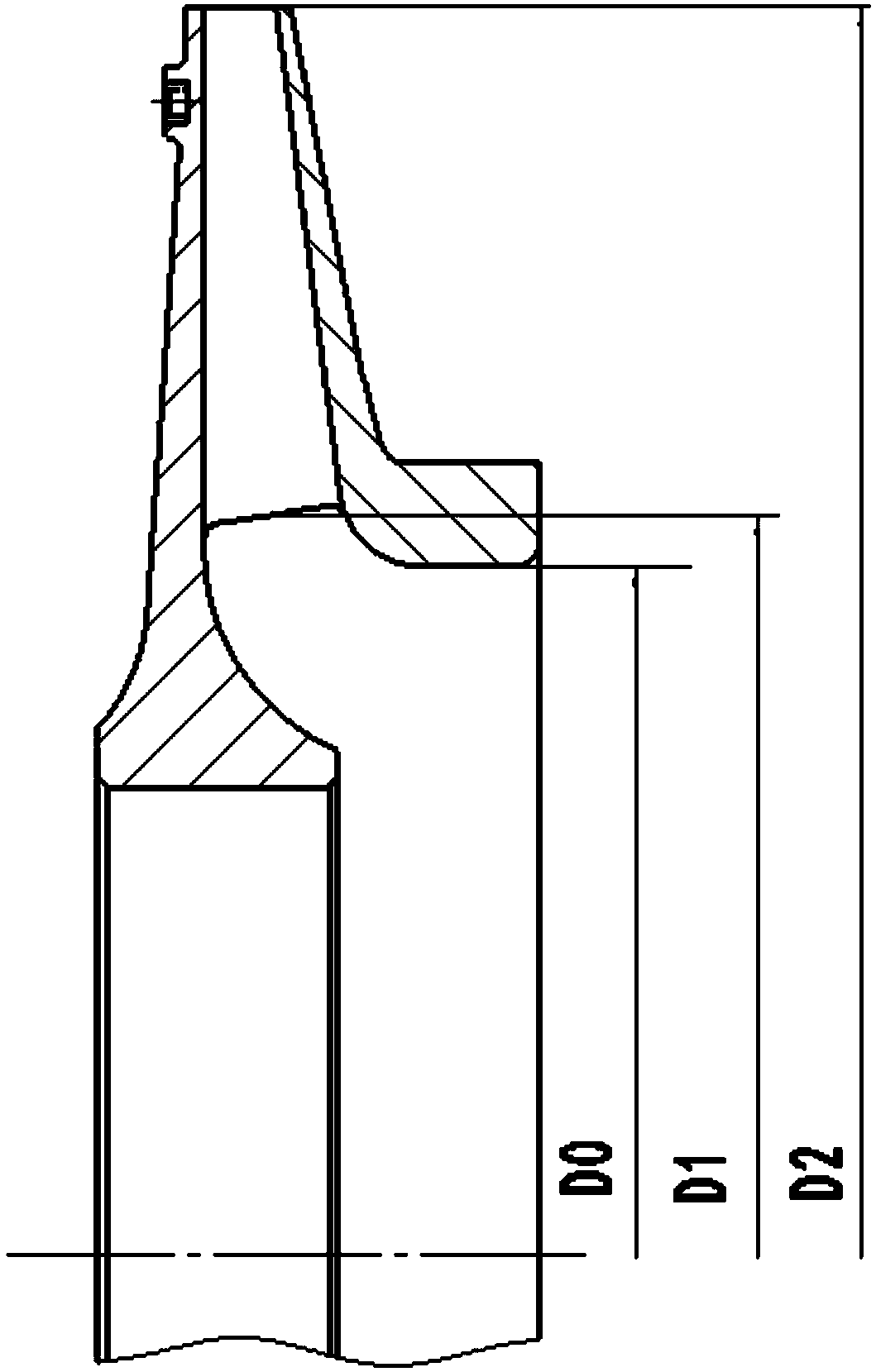

Low-specific-speed impeller and design method for blade thereof

InactiveCN103291653AReduce the cross-sectional areaSatisfy the no-overload characteristicPump componentsPumpsImpellerBackward bending

The invention discloses a low-specific-speed impeller and a design method for a blade of the low-specific-speed impeller. Both a front cover plate and a rear cover plate are of disc structures. The blade is designed according to the method that a column and twisting are combined, namely, a working face (4) or a back face (5) adopts a form of a backward bending column blade and the other side adopts a backward bending blade twisting mode, and therefore the blade accords with the law of fluid motion, reduces hydraulic loss, and improves efficiency of a low-specific-speed centrifuging pump. The thickness of the inlet edge, close to the front cover plate, of the blade is 2-3mm, the thickness of the inlet edge, close to the rear cover plate, of the blade is 5-7mm, and therefore sand mould casting lifting precision is improved, inlet flow passages can be partially blocked, and therefore blade inlet excluding coefficient is reduced, and the non-overload characteristic of the low-specific-speed centrifuging pump is improved. The low-specific-speed impeller and the design method for the blade of the low-specific-speed impeller can be applied to the field of efficient non-overload low-specific-speed impeller designing.

Owner:JIANGSU UNIV

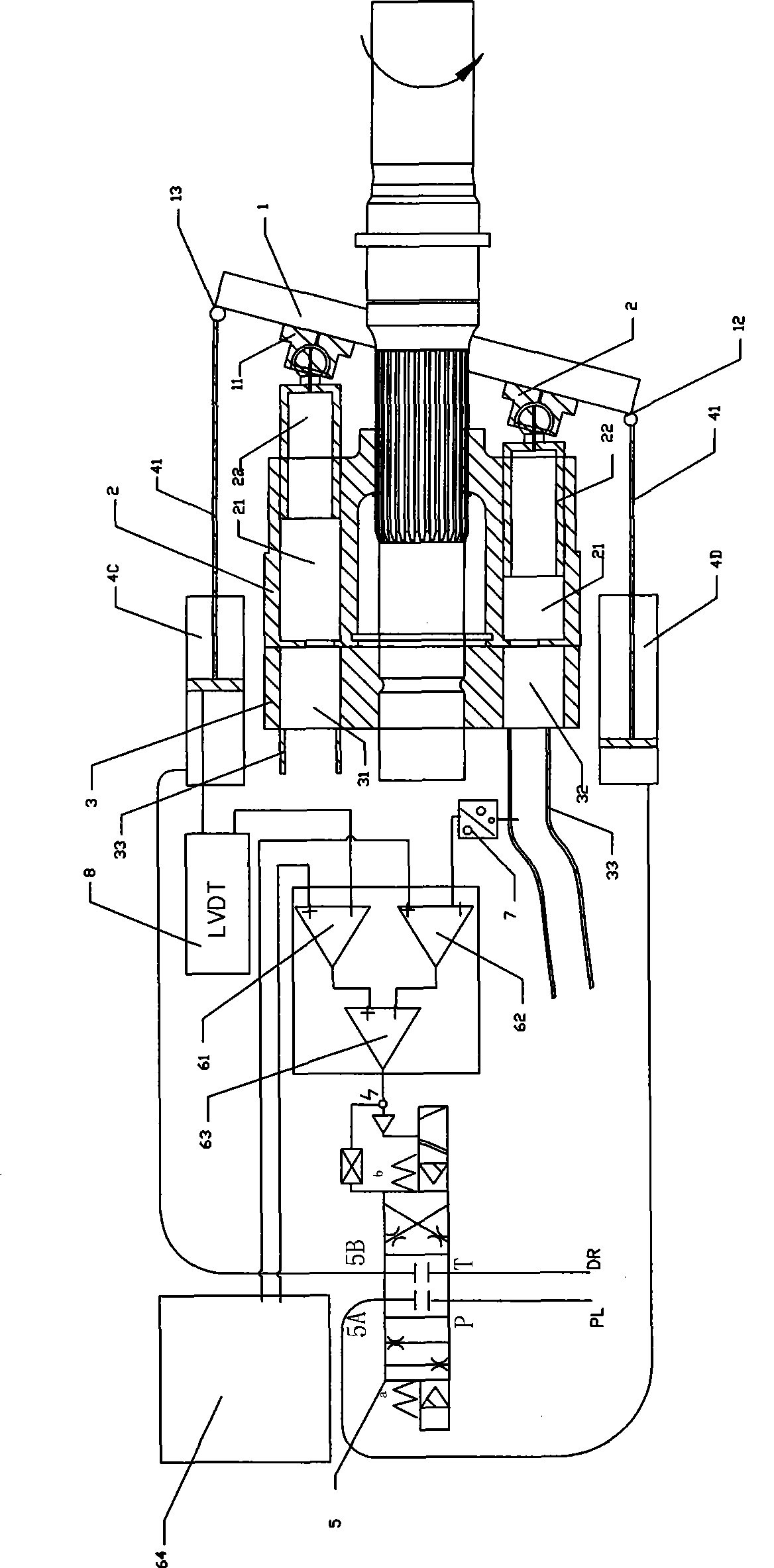

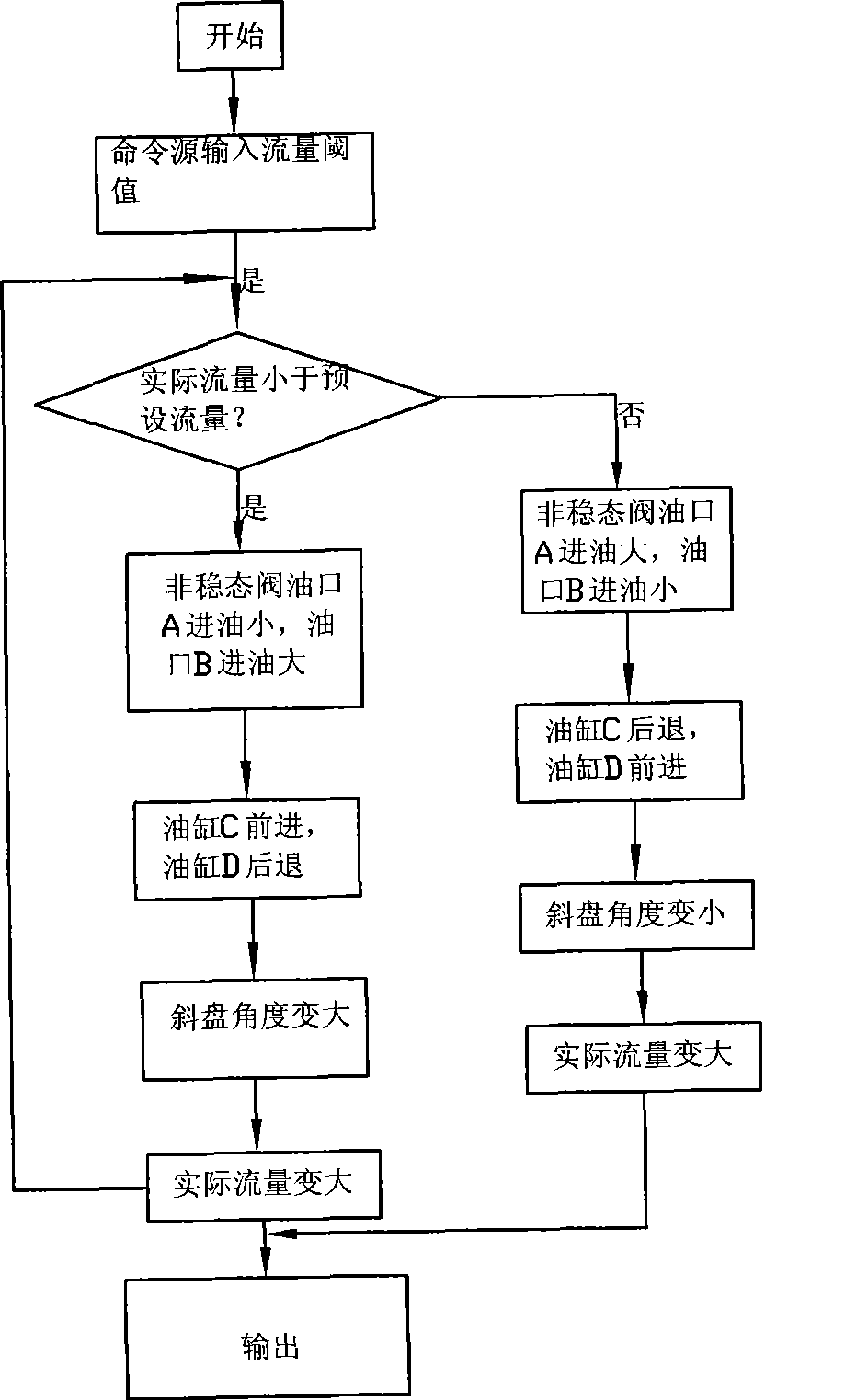

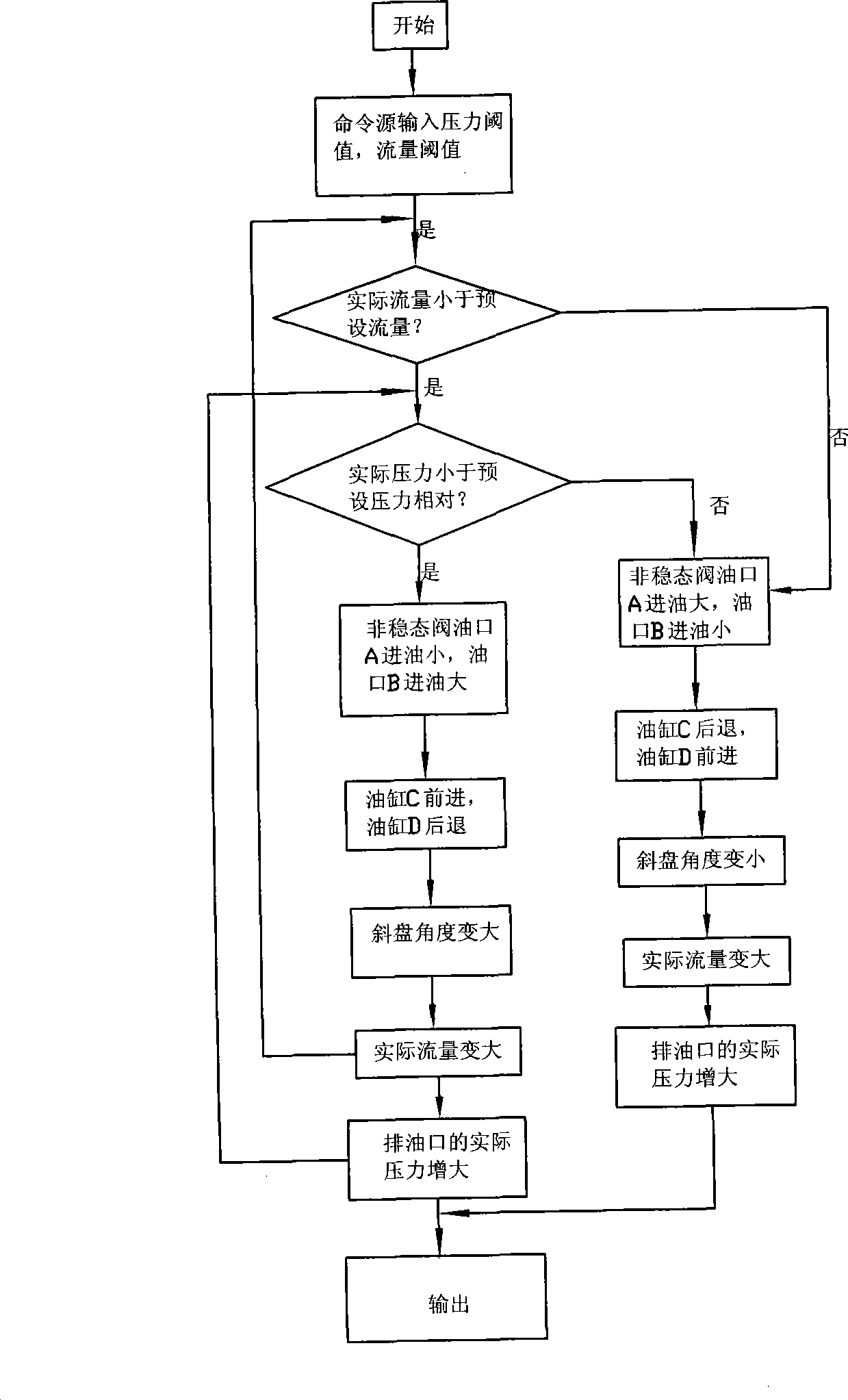

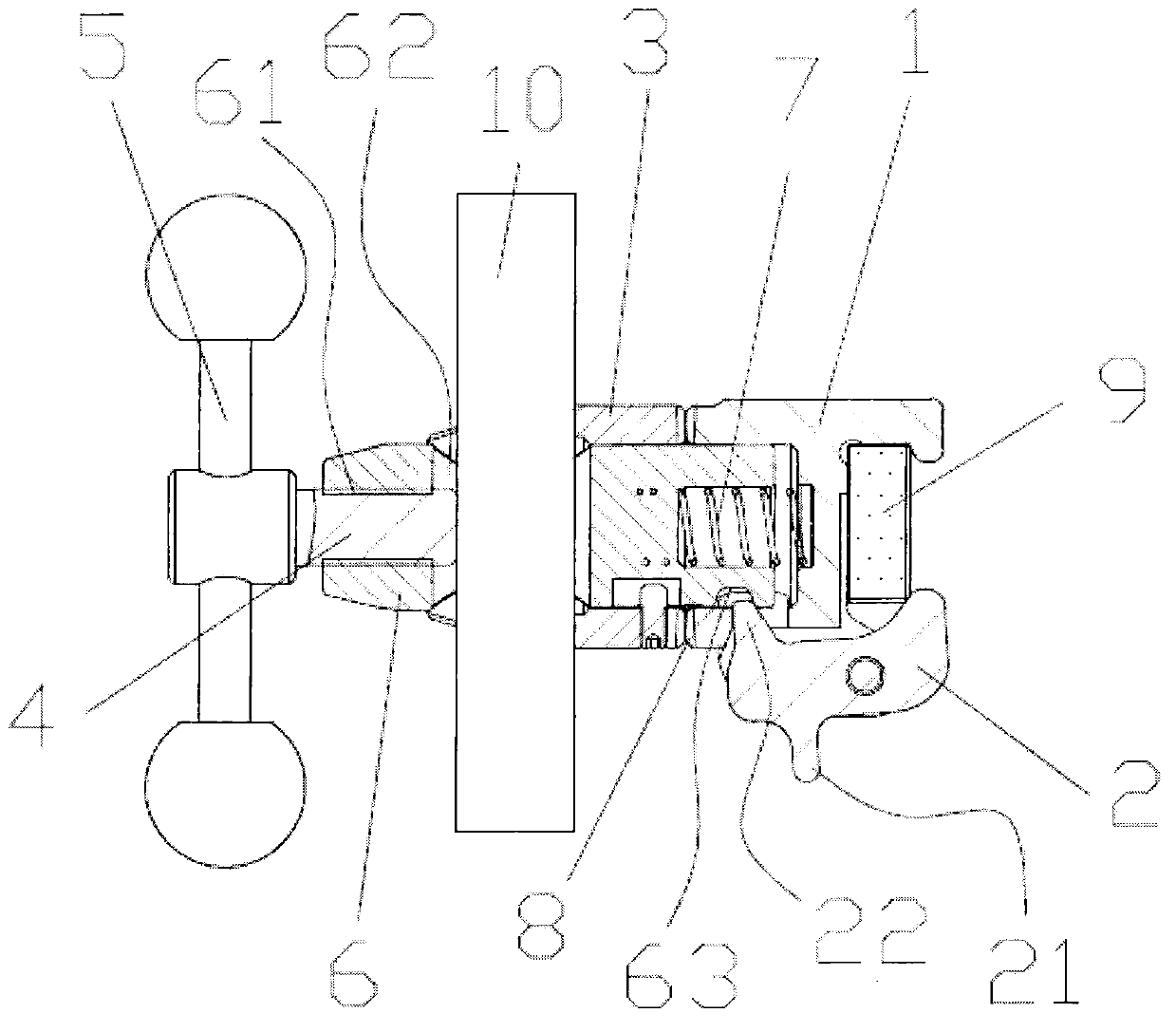

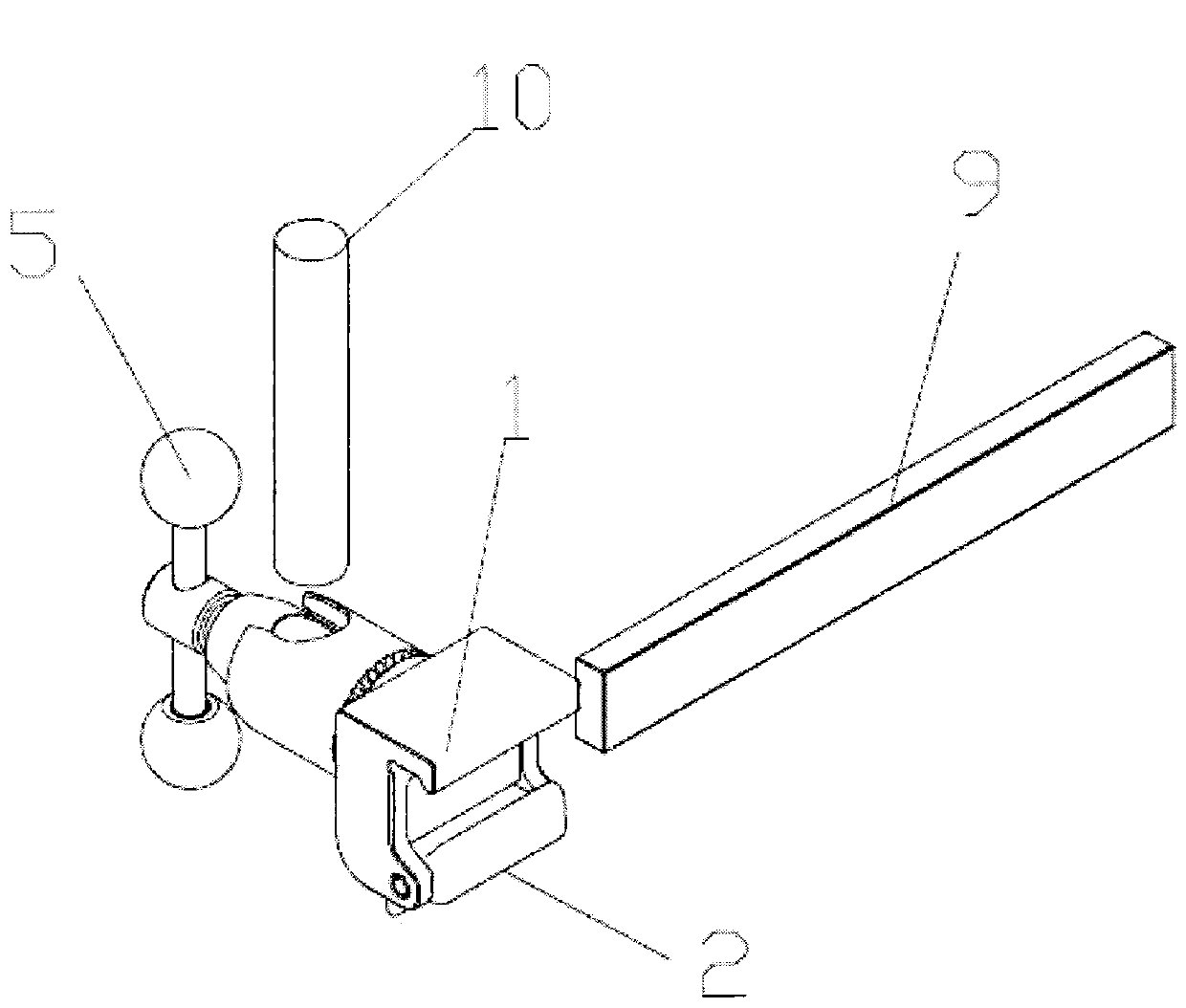

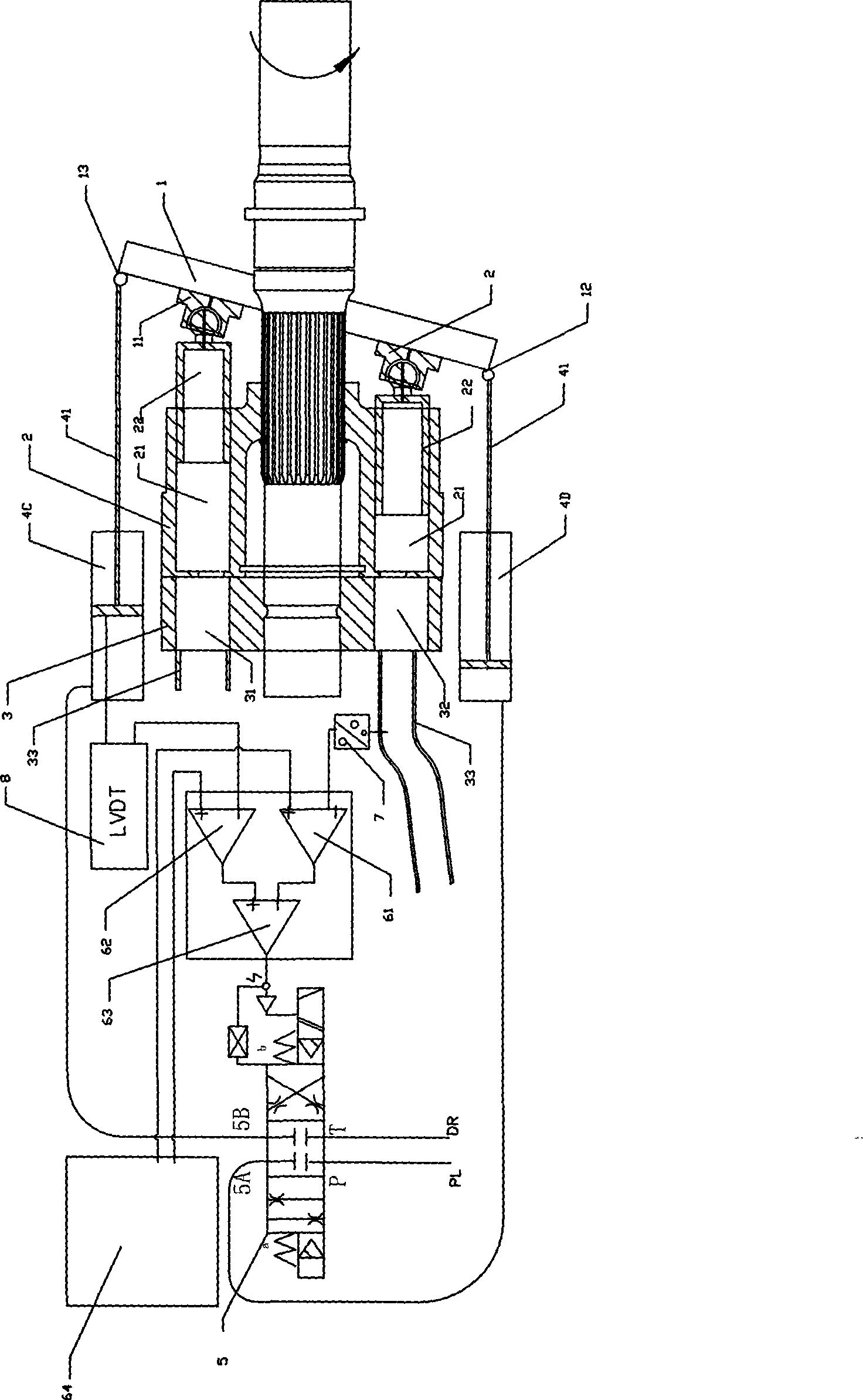

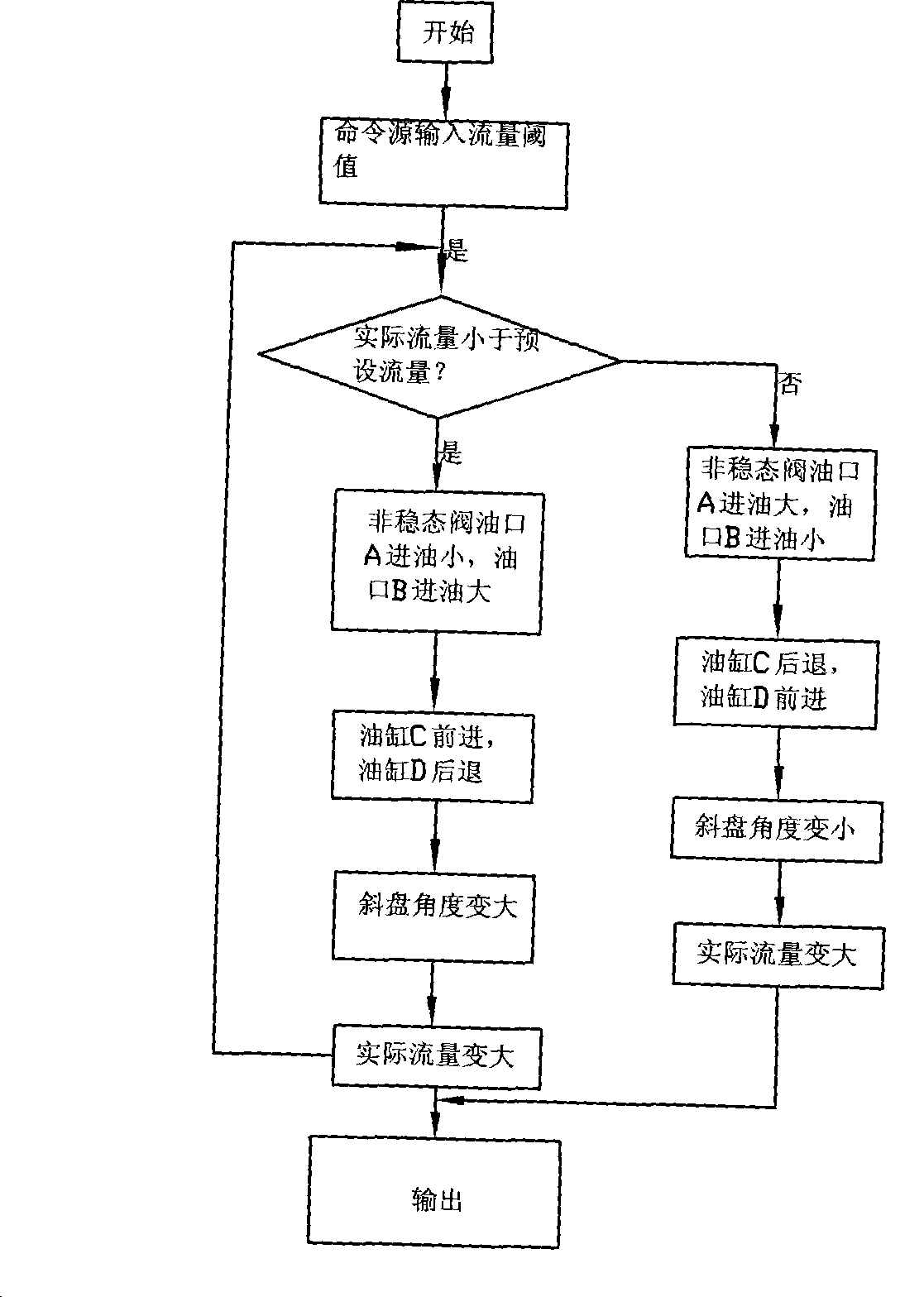

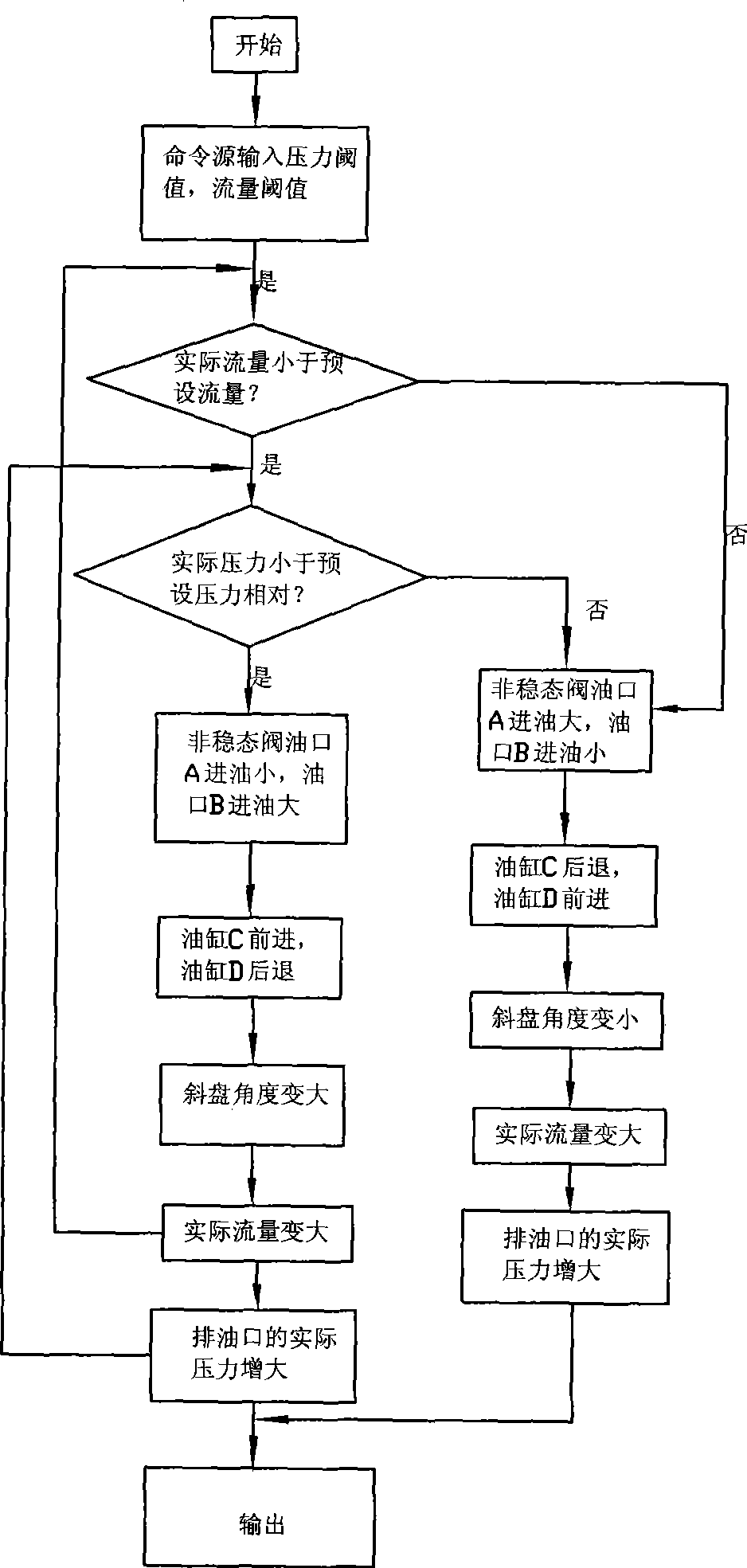

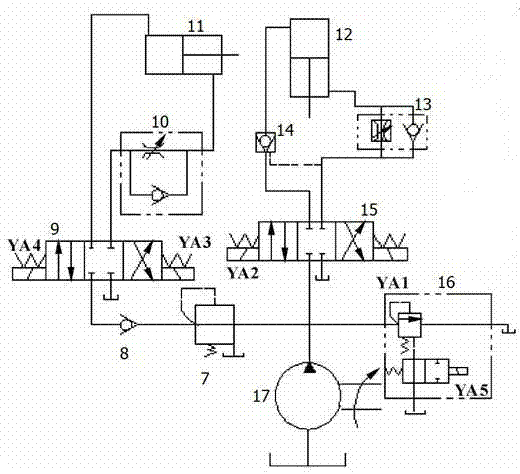

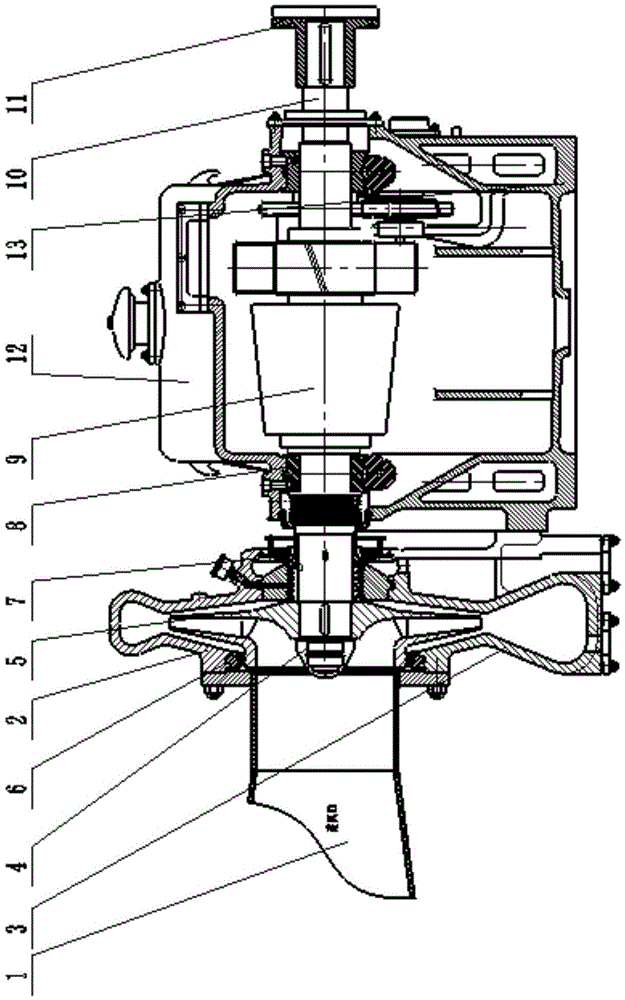

Axial plunger type variable capacity pump

InactiveCN101372941AIntelligent adjustmentAdjustment is quick and precisePositive displacement pump componentsPump controlAudio power amplifierEngineering

The invention relates to an axial plunger-type variable pump which comprises a swash plate, a slipper, a plunger, a plunger cylinder body and a fuel distributor. A forward tipping part and a backward bending part of the swash plate are respectively connected with a push rod of a push action cylinder; the inner cavities of two push action cylinders are respectively communicated with two output ports of an unsteady valve; the unsteady valve is controlled by a controller; the controller comprises a first comparator, an amplifier and a threshold command source; and the amplifier is connected with a second comparator. The invention has the advantages that the accurate change of delivery capacity of the variable pump can be perceived; the angle of the swash plate is rapidly controlled; and the energy consumption is low, and the efficiency is high.

Owner:UNION PLASTIC HANGZHOU MACHINERY +2

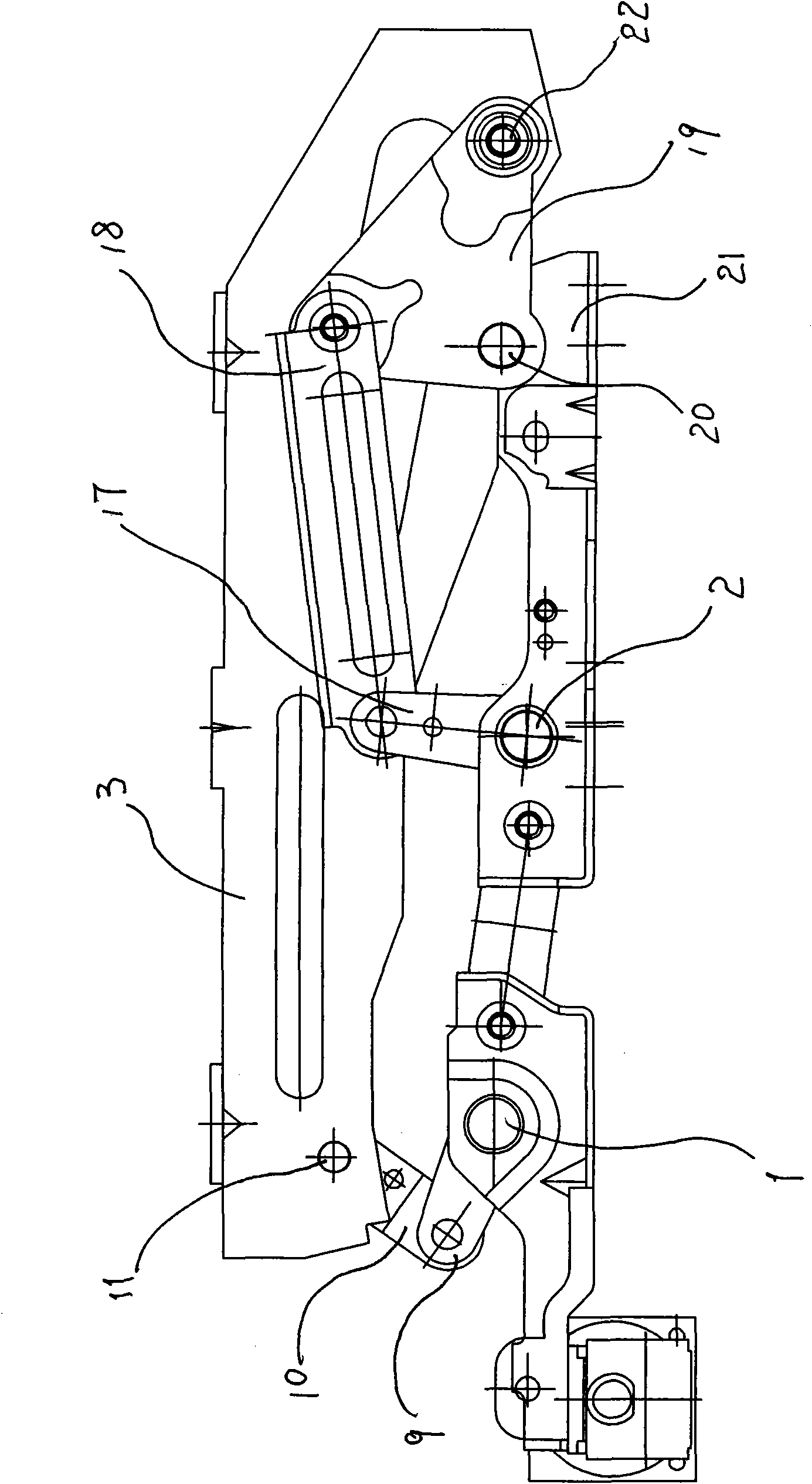

Quick assembly-and-disassembly clamp holder

InactiveCN103126847ARealize automatic snapFast loadingOperating tablesBackward bendingMechanical engineering

The invention discloses a quick assembly-and-disassembly clamp holder which comprises a fixed block, a rotating clamp block, a lock gear sleeve, a knob and a knob handle, a lock bar is further arranged in the lock gear sleeve, inner threads for installing the knob are arranged on the front portion of the lock bar, a through hole is formed in the middle of the lock bar and penetrates up and down, the back portion of the lock bar and the fixed block are connected through a pressure spring, a groove is formed in the lower portion of the back of the lock rod, a protrusive part is arranged on the lower side of the rotating clamp block, a backward bending part is arranged on the upper side of the back of the rotating clamp block and can penetrate through the groove, top blocks are further arranged among the lower portion of the groove, the rotating clamp block and the lock gear sleeve. The quick assembly-and-disassembly clamp holder is simple in structure and convenient to operate, only one step is needed to achieve simultaneous clamp and disassembly of a side track and an accessory clamp rod of an operation bed, and the quick assembly-and-disassembly clamp holder has very good practical value.

Owner:WARRENWELL HIGH TECH

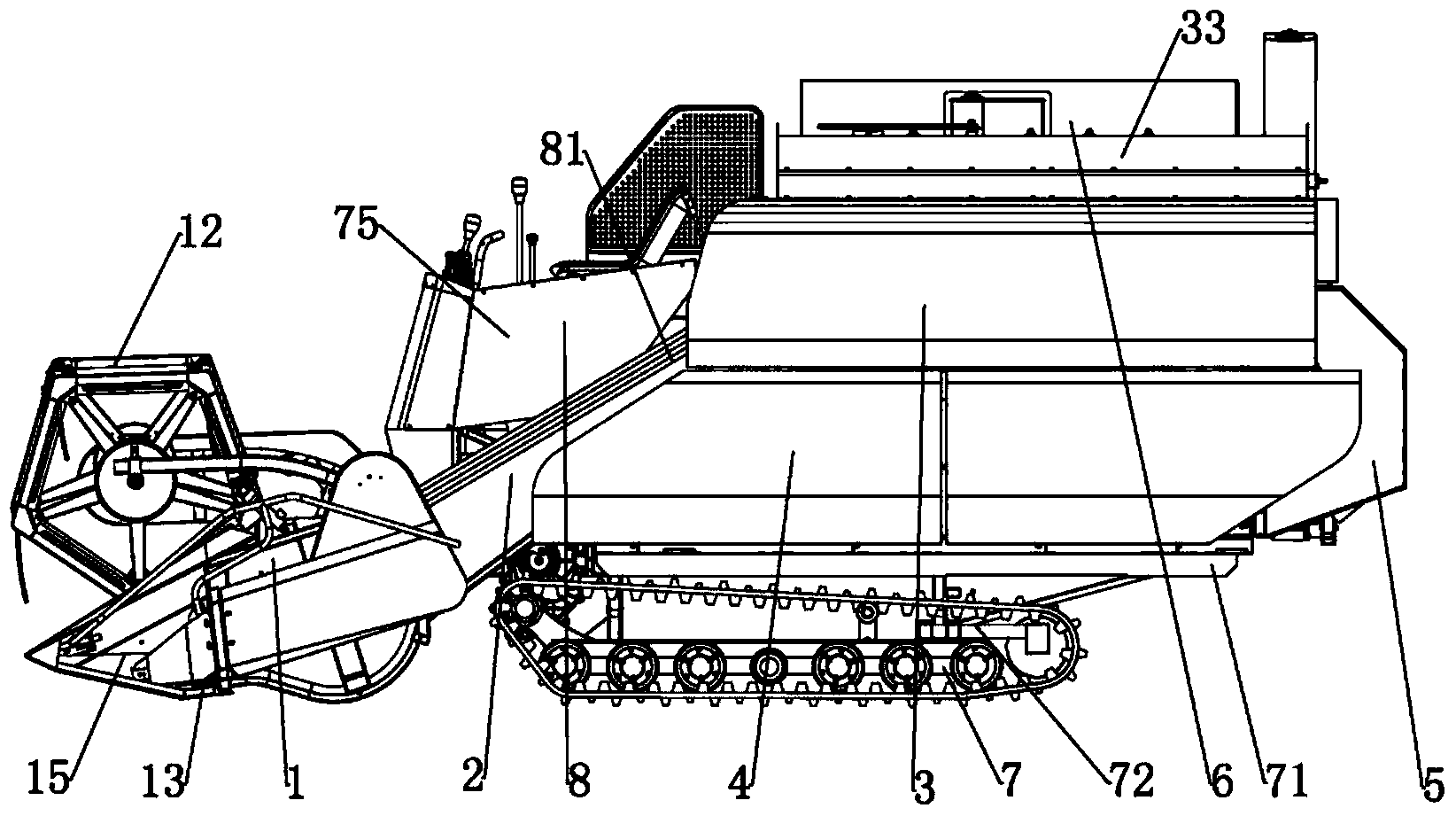

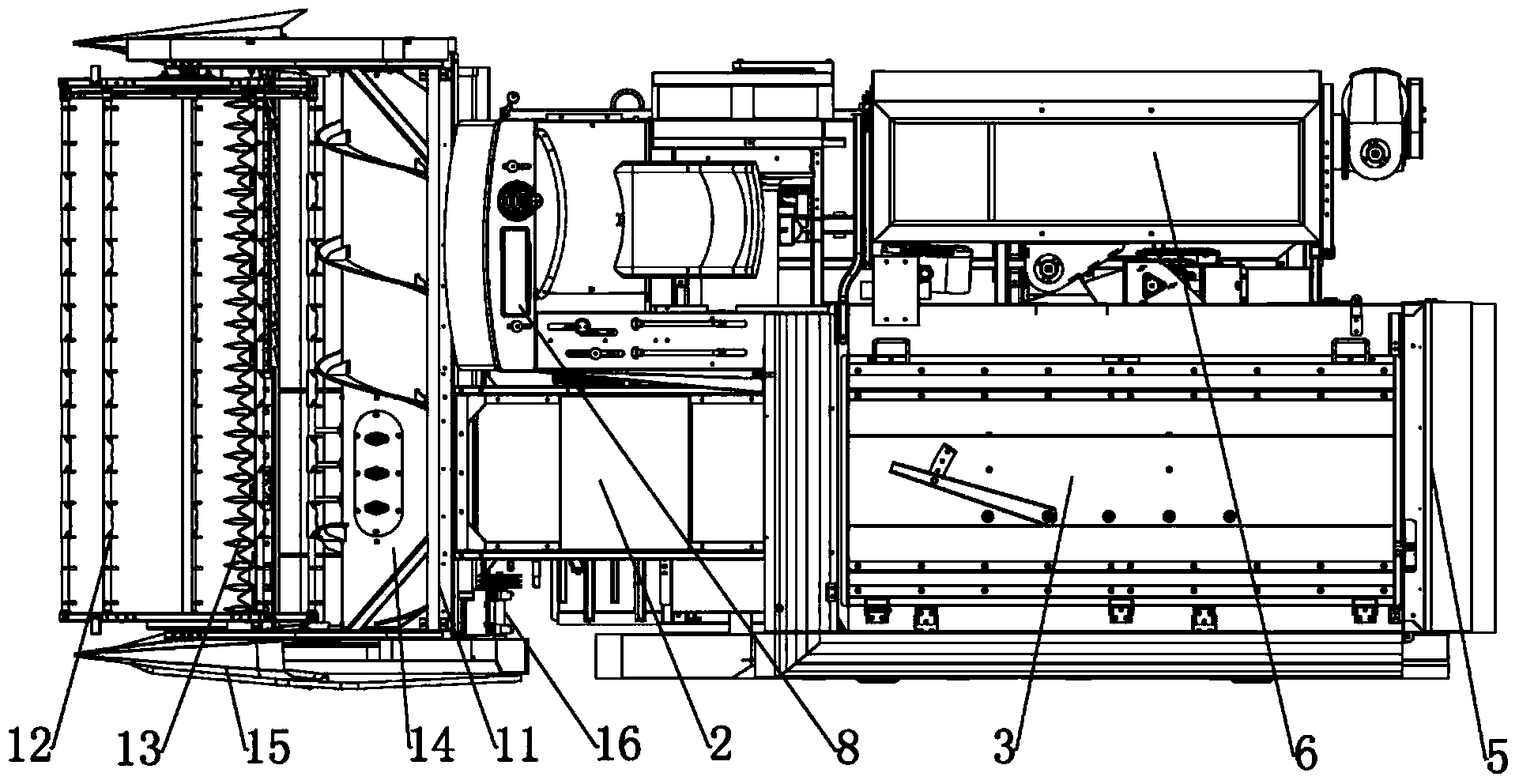

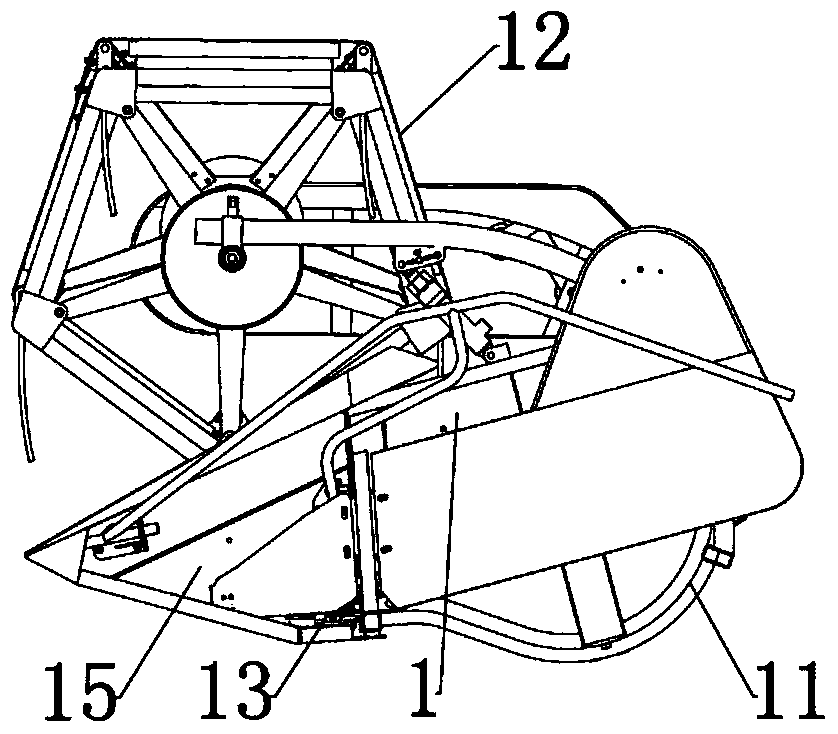

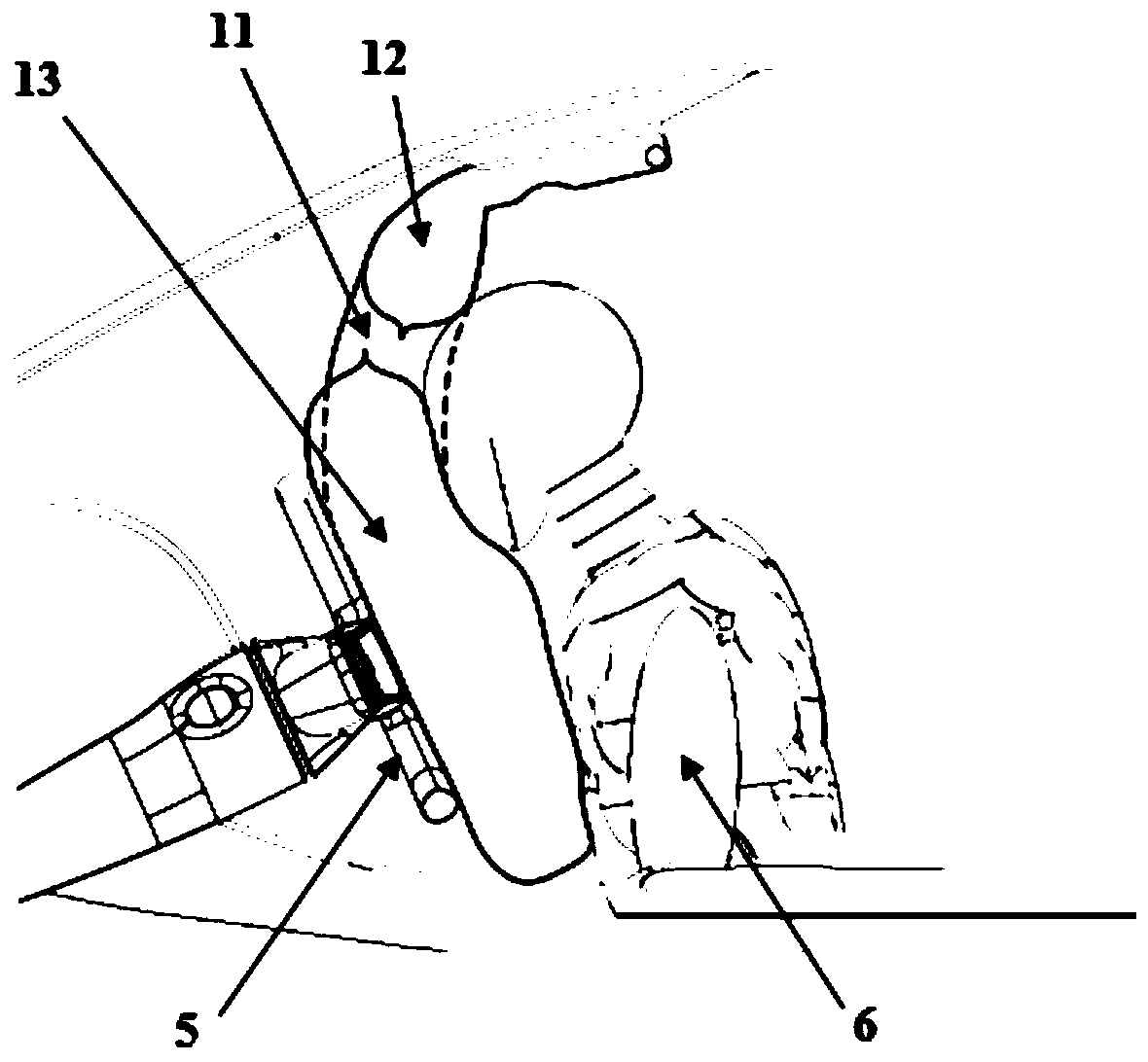

Bridge of combine harvester and combine harvester with bridge

The invention relates to a bridge of a combine harvester. The bridge comprises a front operation tower, a driving cab seat, and a side operation tower, wherein the front operation tower is positioned at the front side of the driving cab seat, a space S with a small upper part and a large lower part is spaced between the front operation tower and the driving cab seat, the side operation tower is positioned at the left side of the driving cab seat, and the front end of the side operation tower is in contact with the back side of the front operation tower. The invention also relates to the combine harvester. The bridge has the advantages that the space S formed between the front operation tower and the driving cab seat is in a right-angle trapezoid shape, so the requirement of ergonomics is met, and a larger space is provided for feet of an operator; a clutch is arranged at one side of the left side surface, opposite to the getting-off side, of the driving cab seat, so the working and the temporary stop of the machine are more conveniently and rapidly controlled; a stop switch is arranged on a front console, and is positioned within the line of sight of the operator, so the operator can more easily and quickly find the stop switch and quickly pull up the stop switch, and the safety is improved; the front end of the handle of the clutch forms a certain tilting angle, so the operator can timely and accurately pull up the clutch; a handrail of the console is provided with a circular pipe with patterns, so the operator can hold the handrail conveniently, and the danger of backward tilting of the operator is effectively avoided by the backward bending of the upper part.

Owner:XINGGUANG AGRI MACHINERY

Bucket screw centrifugal vane of fan and application method of said vane in fluid delivering thereof

The invention comprises integrated axial front and back stages. The front stage fan bucket impeller has a bucket-shape forward bended rectangular main runner screw-coiling round the hub. The back stage helical centrifugal impeller has a main centrifugal runner and a branch backward bended rectangular centrifugal runner. The forward bended runner of the front stage is in communication with the backward bended runner of the back stage to form an integrated impeller.

Owner:QINHUANGDAO SONGHE COMPOSITE MATERIALS DEV

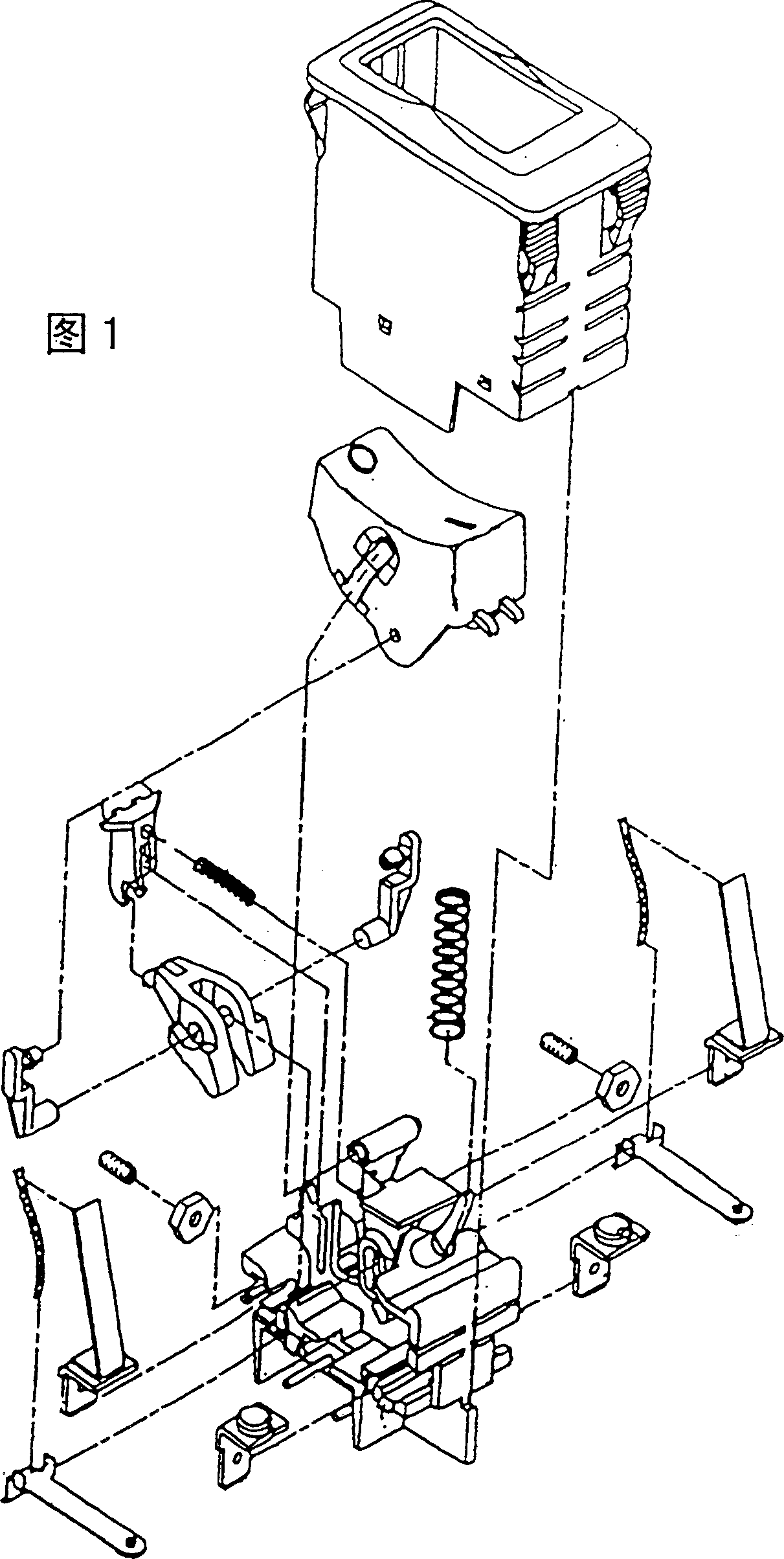

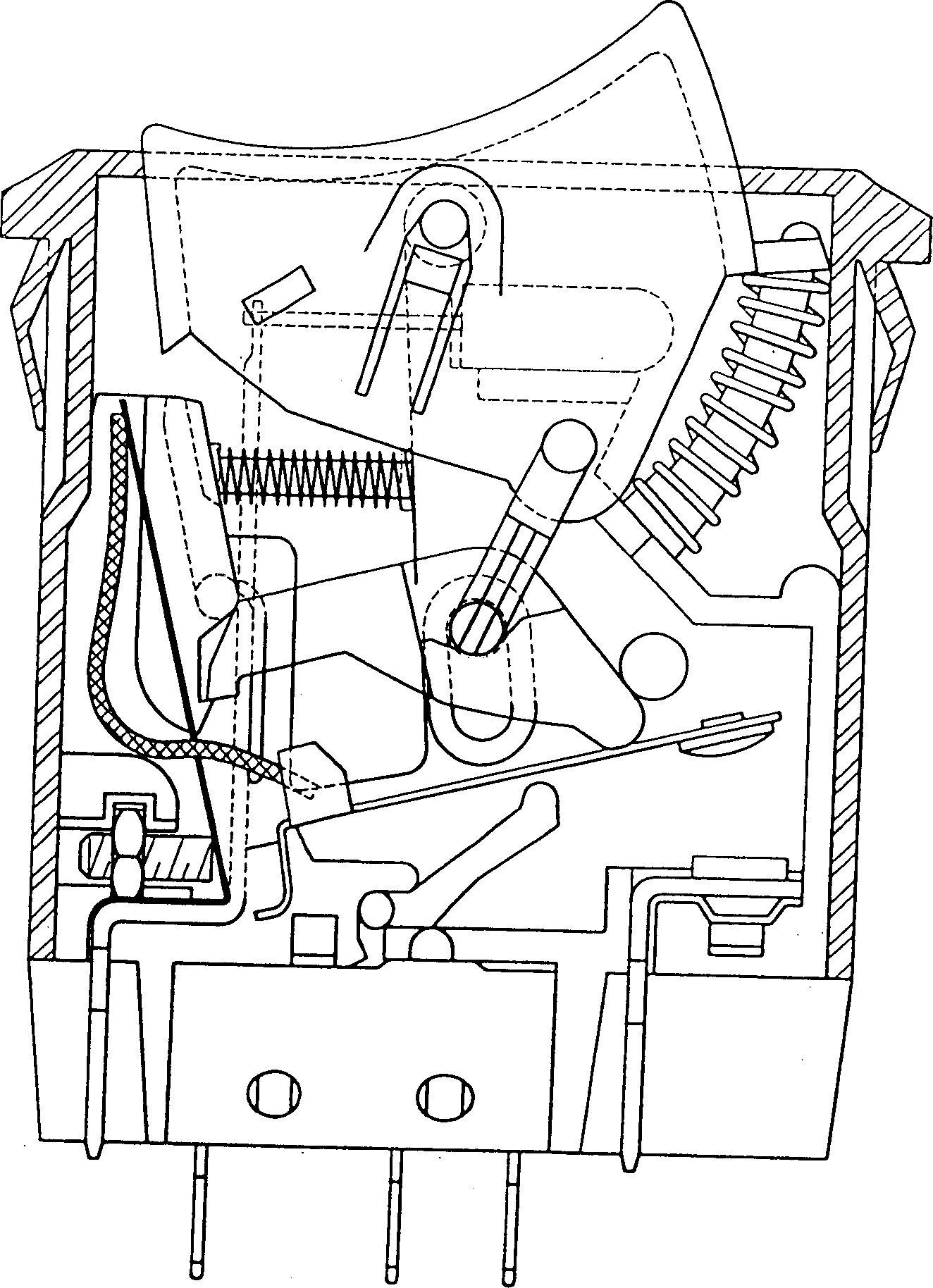

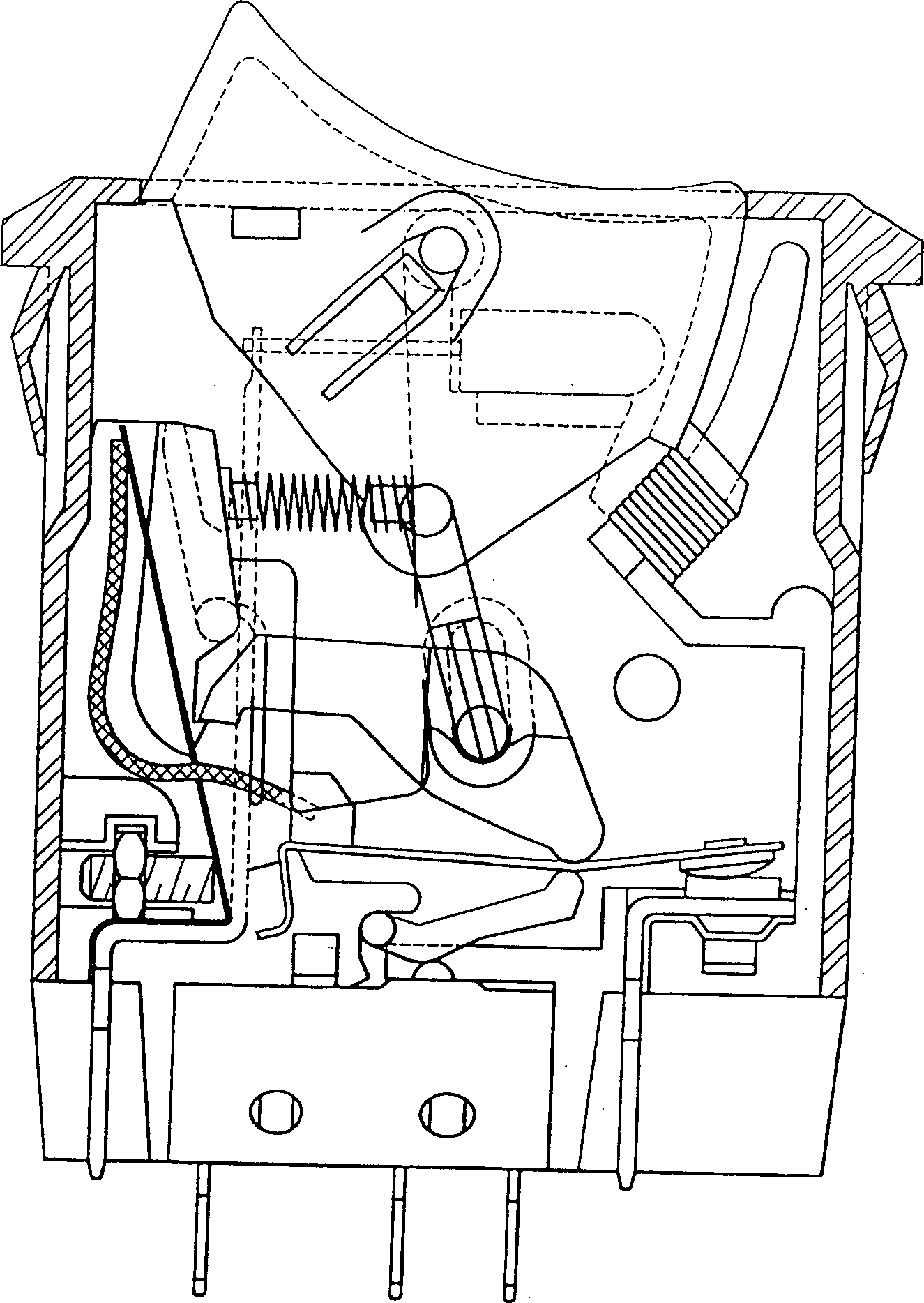

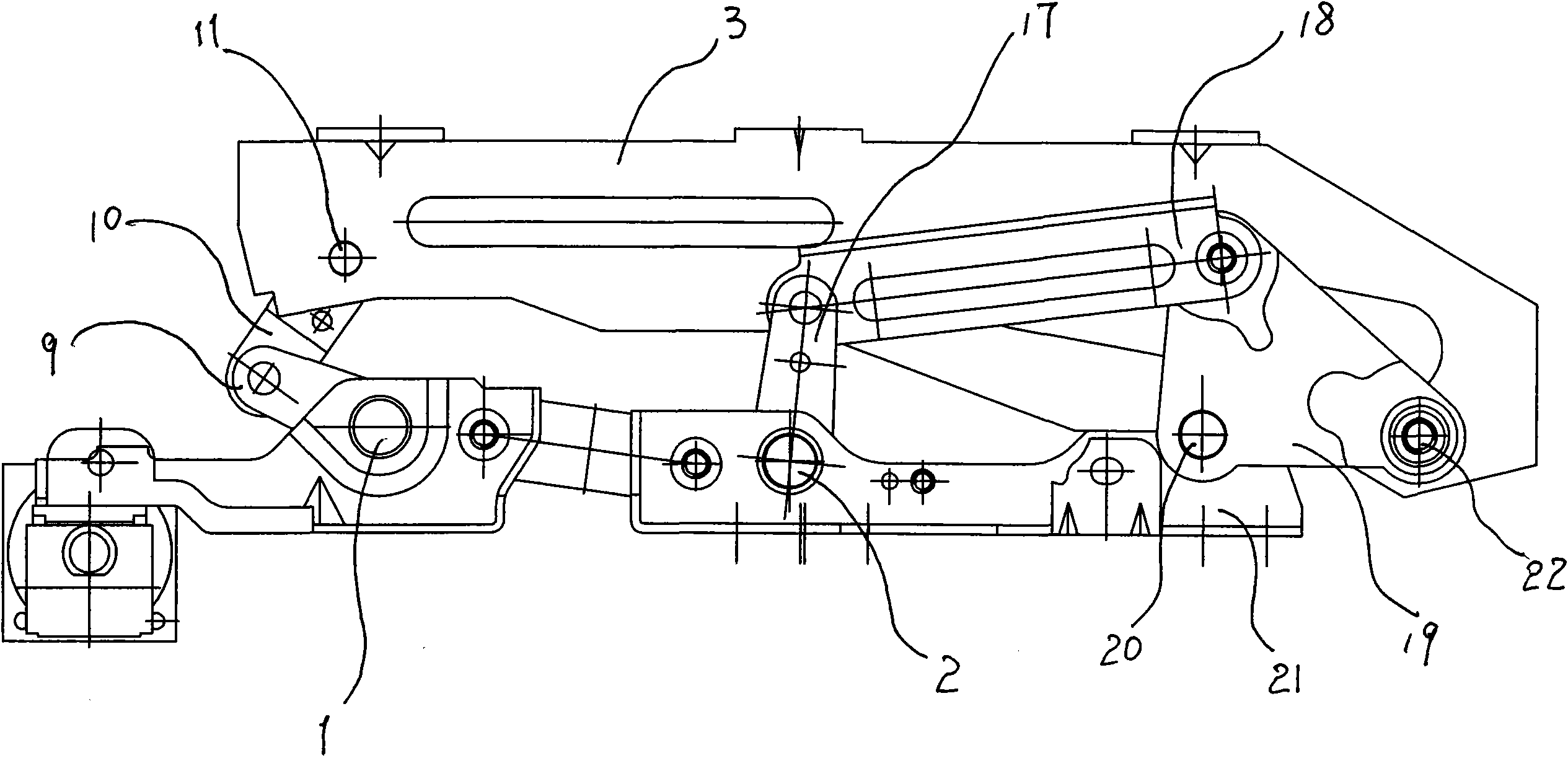

Safety switch trip linking structure

The present invention relates to a safety switch tripping coupled structure. It is characterized by that said invention utilizes the key-pressing operation to couple positioning bar and implement synchronous action, and the mutual coupling action between the positioning bar, ring gradient path and positioning coupling piece can be formed into a cyclic positioning relationship, and the positioning coupling piece can be used to directly push and pull the contact piece to form the switch power-on or power-off. When the current is overloaded under the condition of power-on, the backward bending bounce of the heated and deformed contact piece is said conducting circuit can be used to make the circuit be powered off.

Owner:游聪谋

Axial plunger type variable capacity pump

InactiveCN101372942AIntelligent adjustmentAdjustment is quick and precisePositive displacement pump componentsPump controlAudio power amplifierEnergy expenditure

The invention relates to an axial plunger-type variable pump which comprises a swash plate, a slipper, a plunger, a plunger cylinder body and a fuel distributor. A forward tipping part and a backward bending part of the swash plate are respectively connected with a push rod of a push action cylinder; the inner cavities of two push action cylinders are respectively communicated with two output ports of an unsteady valve; the unsteady valve is controlled by a controller; the controller comprises a first comparator, an amplifier and a threshold command source; and the amplifier is connected with a second comparator. The invention has the advantages that the accurate change of delivery capacity of the variable pump can be perceived; the angle of the swash plate is rapidly controlled; and the energy consumption is low, and the efficiency is high.

Owner:UNION PLASTIC HANGZHOU MACHINERY +2

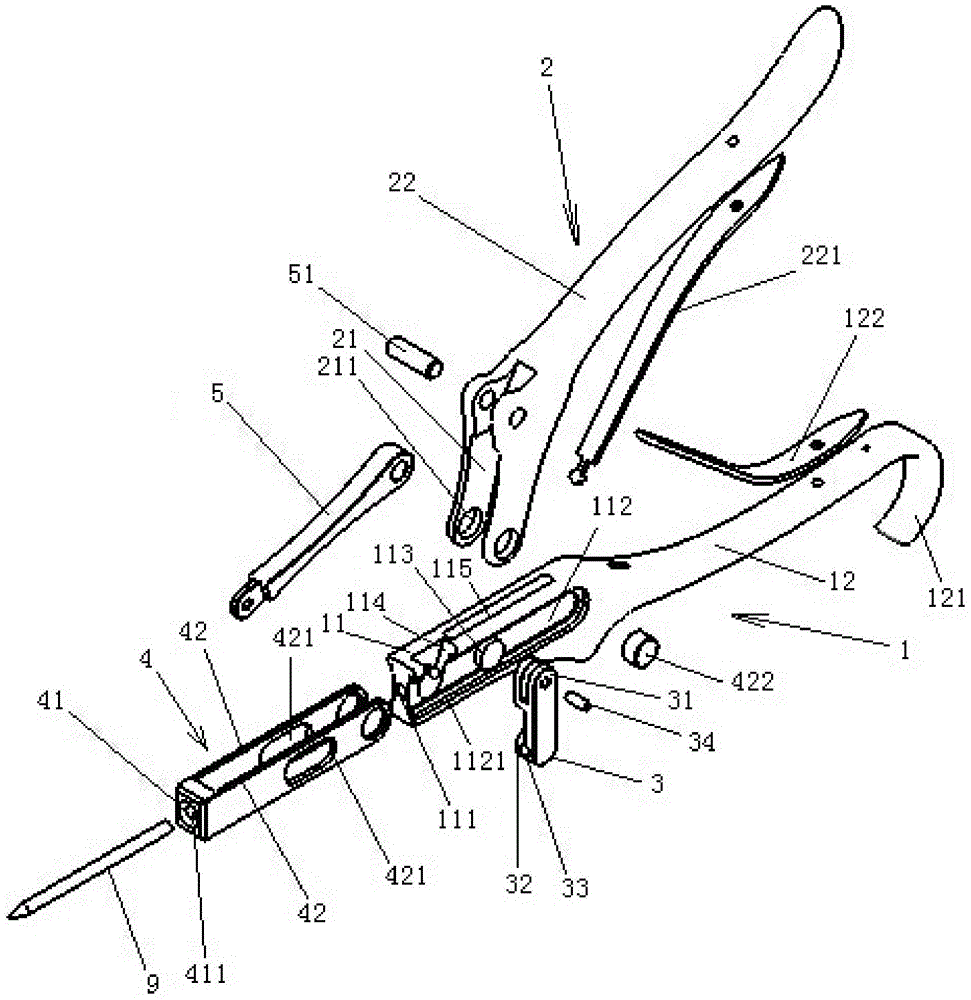

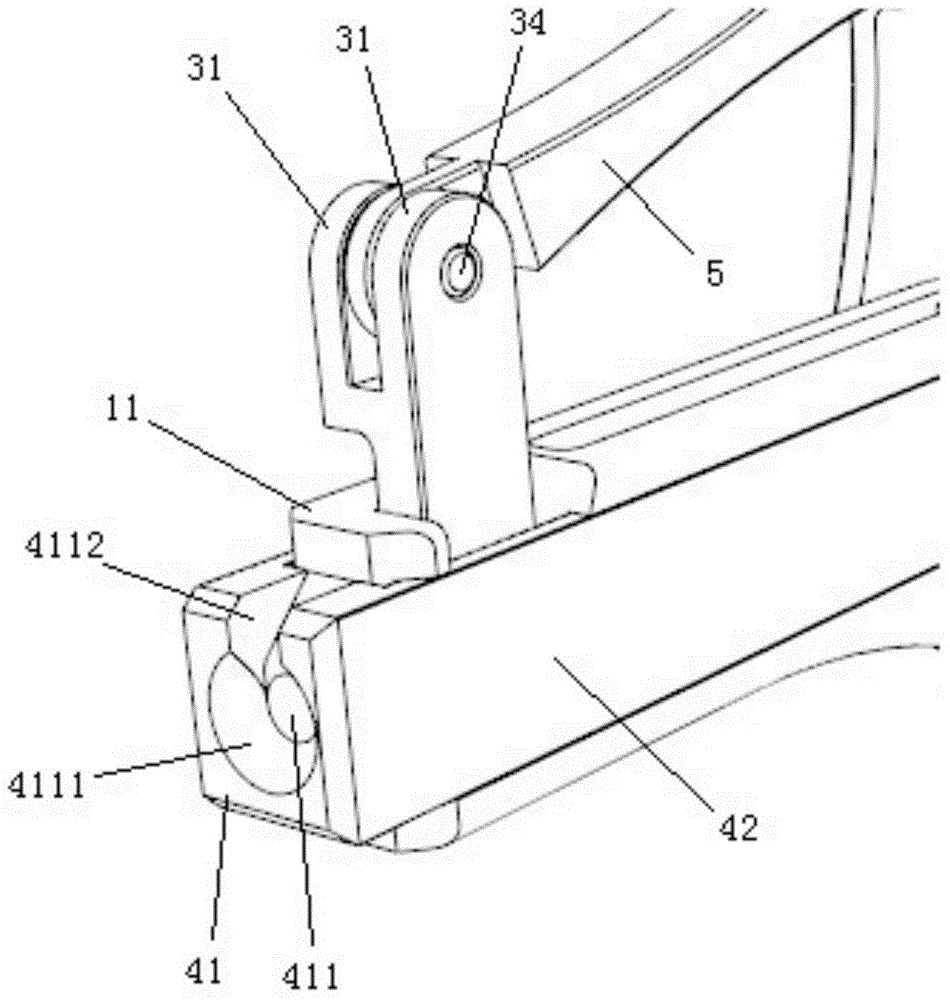

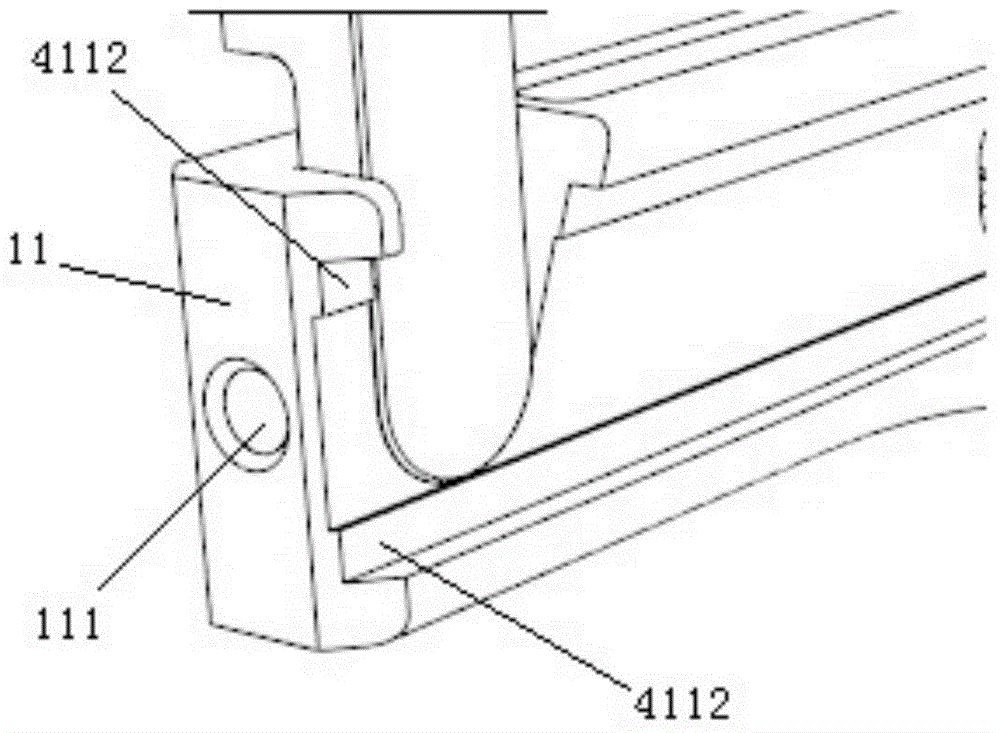

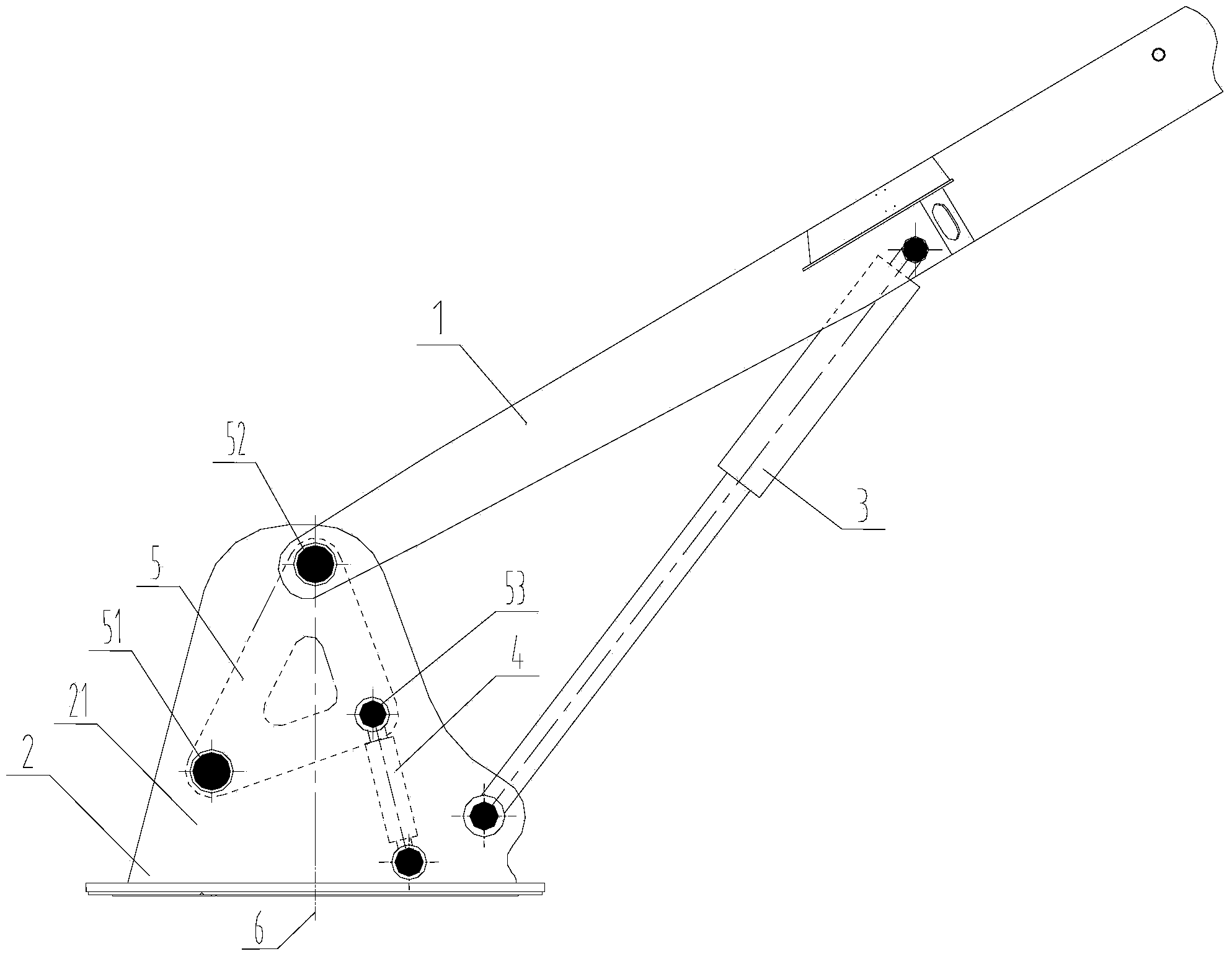

Nail pulling device

ActiveCN105520779APull out nails to save effortNot easy to remove nailsOsteosynthesis devicesSlide plateBackward bending

The invention provides a nail pulling device. The nail pulling device is characterized in that a first pliers body is provided with a slide groove part and a first pliers handle formed at the rear end of the first pliers body, a longitudinal via hole is formed in the middle of the slide groove part, opposite slide grooves are formed in two sides of the slide groove part, each slide groove is provided with a limit protruding block, and a locking groove is formed in the front portion of the slide groove part; a locking block is rotatably arranged in the locking groove, the lower end of the locking block is accommodated in the locking groove and provided with a locking hole corresponding to the via hole, and the upper end of the locking block is exposed out of the locking groove; a slide part is provided with an end plate and two slide plates, the end plate is provided with an end hole corresponding to the via hole, the two slide plates are respectively slidably clamped with the two slide grooves and respectively provided with long holes corresponding to the two limit protruding blocks; a second pliers body is provided with two connecting plates, the rear ends of the connecting plates are connected and extend in a backward bending manner to form a second pliers handle, and the front ends of the two connecting plates are rotatably connected to the rear ends of the two slide plates; two ends of a connecting rod are respectively rotatably connected to the middles of the two connecting plates and the upper end of the locking block. The nail pulling device is labor saving in nail pulling and firm in nail clamping.

Owner:BEIJING NATON TECH GRP CO LTD

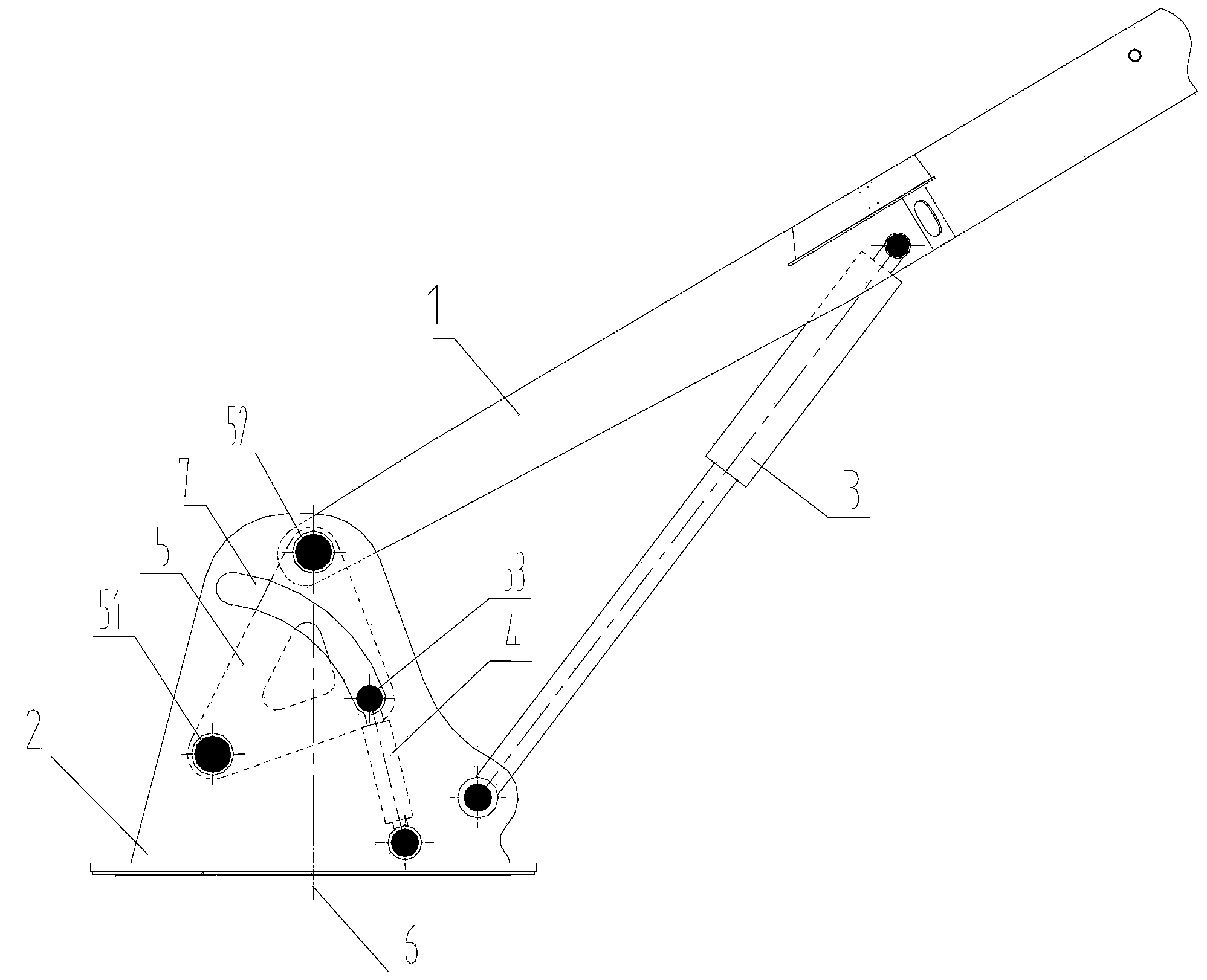

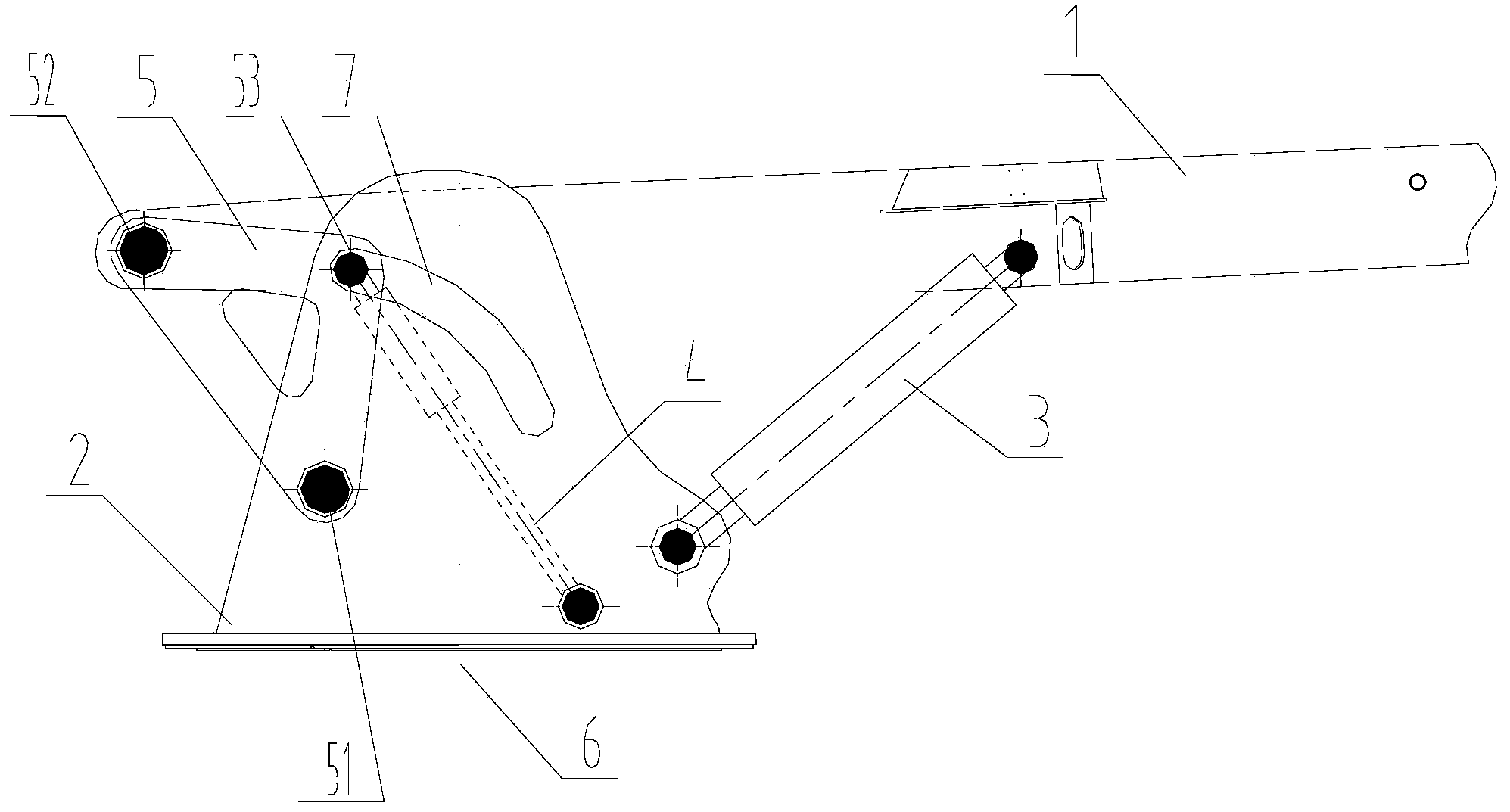

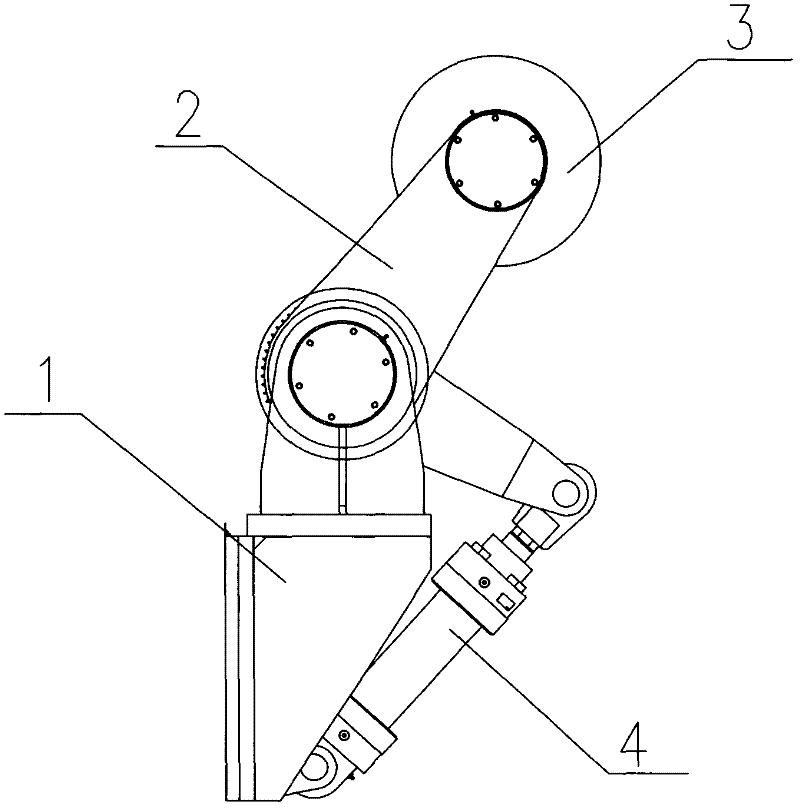

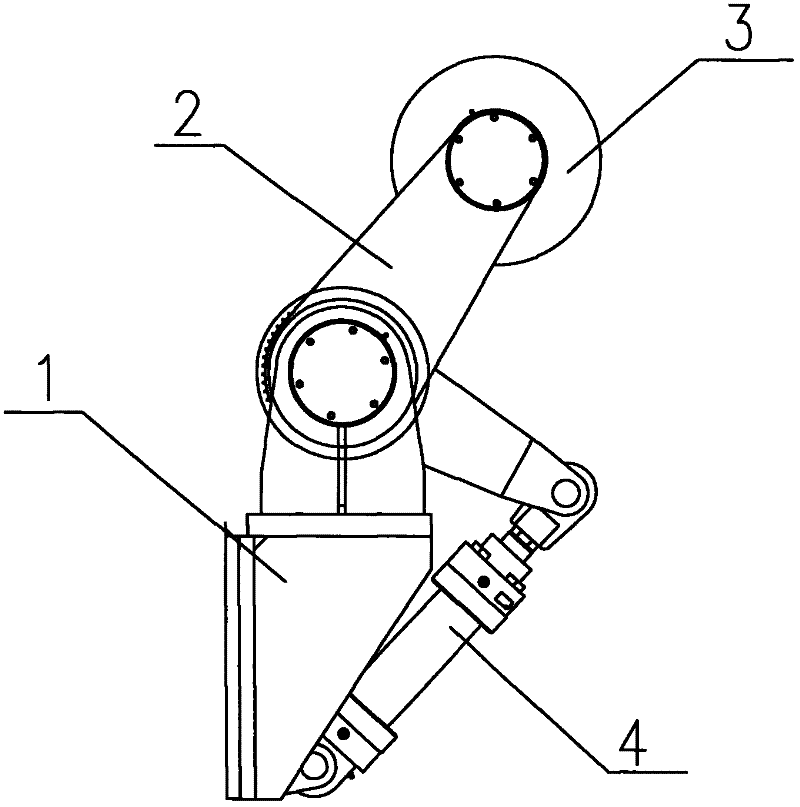

Concrete pump truck and arm frame connecting mechanism thereof

ActiveCN103526942AReduce security risksIncrease layout spaceBuilding material handlingEngineeringStructural type

The invention discloses a concrete pump truck and an arm frame connecting mechanism of the concrete pump truck. The arm frame connecting mechanism comprises a first extensible oil cylinder, a rotating platform and an arm frame hinged to the rotating platform, wherein the two ends of the first extensible oil cylinder are hinged to the rotating platform and the arm frame respectively. The arm frame connecting mechanism further comprises a connecting rod and an extensible mechanism, wherein a first hinge point and a second hinge point are arranged on the connecting rod, the first hinge point is hinged to the rotating platform, the second hinge point is hinged to the arm frame, one end of the extensible mechanism is hinged to the connecting rod, the other end of the extensible mechanism is hinged to the rotating platform, and the extensible mechanism is used for driving the second hinge point to rotate around the first hinge point. Due to the fact that the hinge point of the arm frame and the connecting rod can move, the rotating platform can achieve switching of two structural types, namely, the alignment non-backward bending structural type and the backward bending eccentric structural type, the large long bridge ratio of the arm frame connecting mechanism can be achieved, it can also be ensured that force is well exerted on the rotating platform, and potential safety hazards are reduced.

Owner:SANY AUTOMOBILE MFG CO LTD

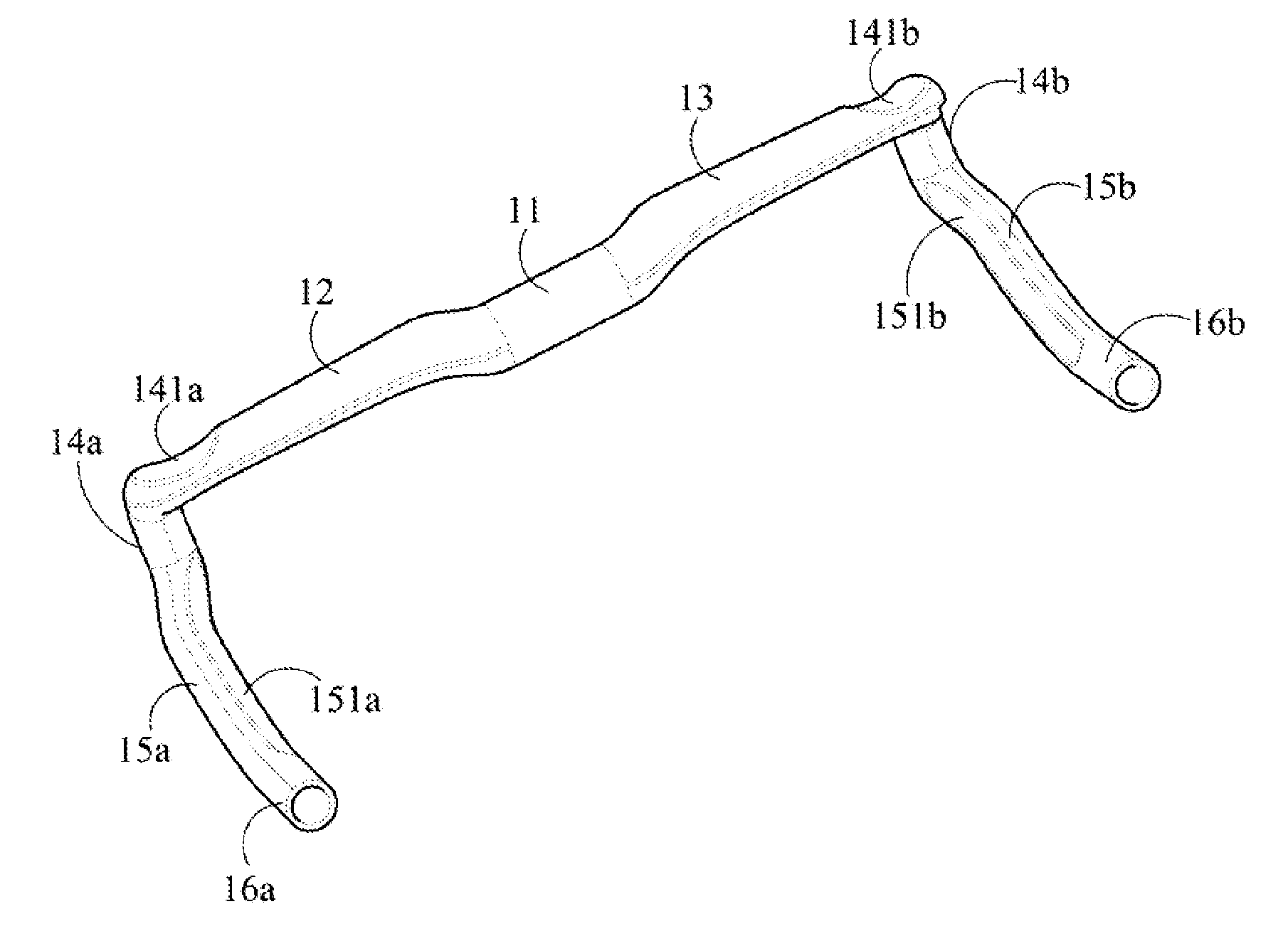

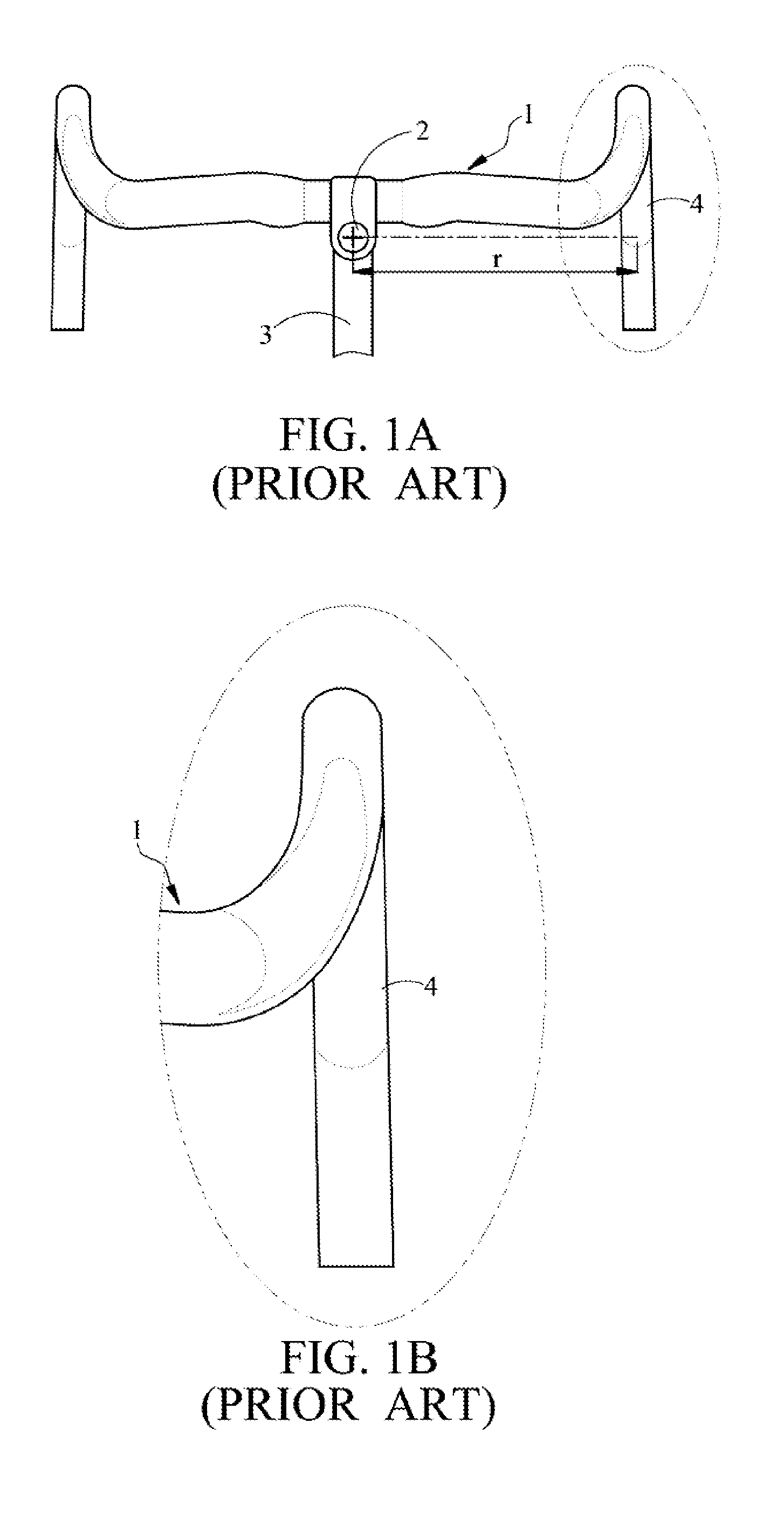

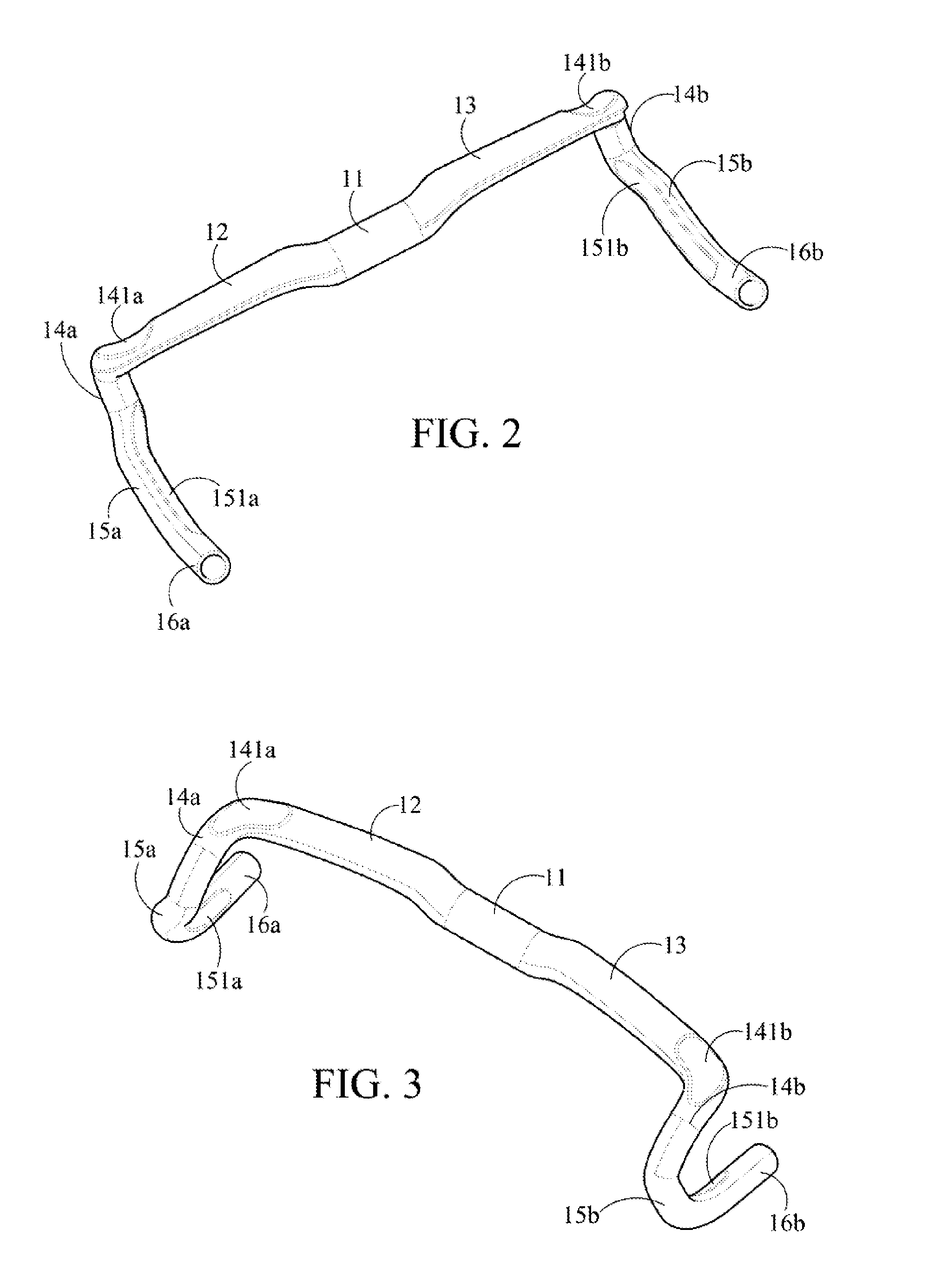

Bicycle handlebar

InactiveUS20150128756A1Avoiding hand sweatingAvoid excessive amplitudeMechanical apparatusSteering deviceEngineeringBackward bending

Owner:TIEN HSIN INDS

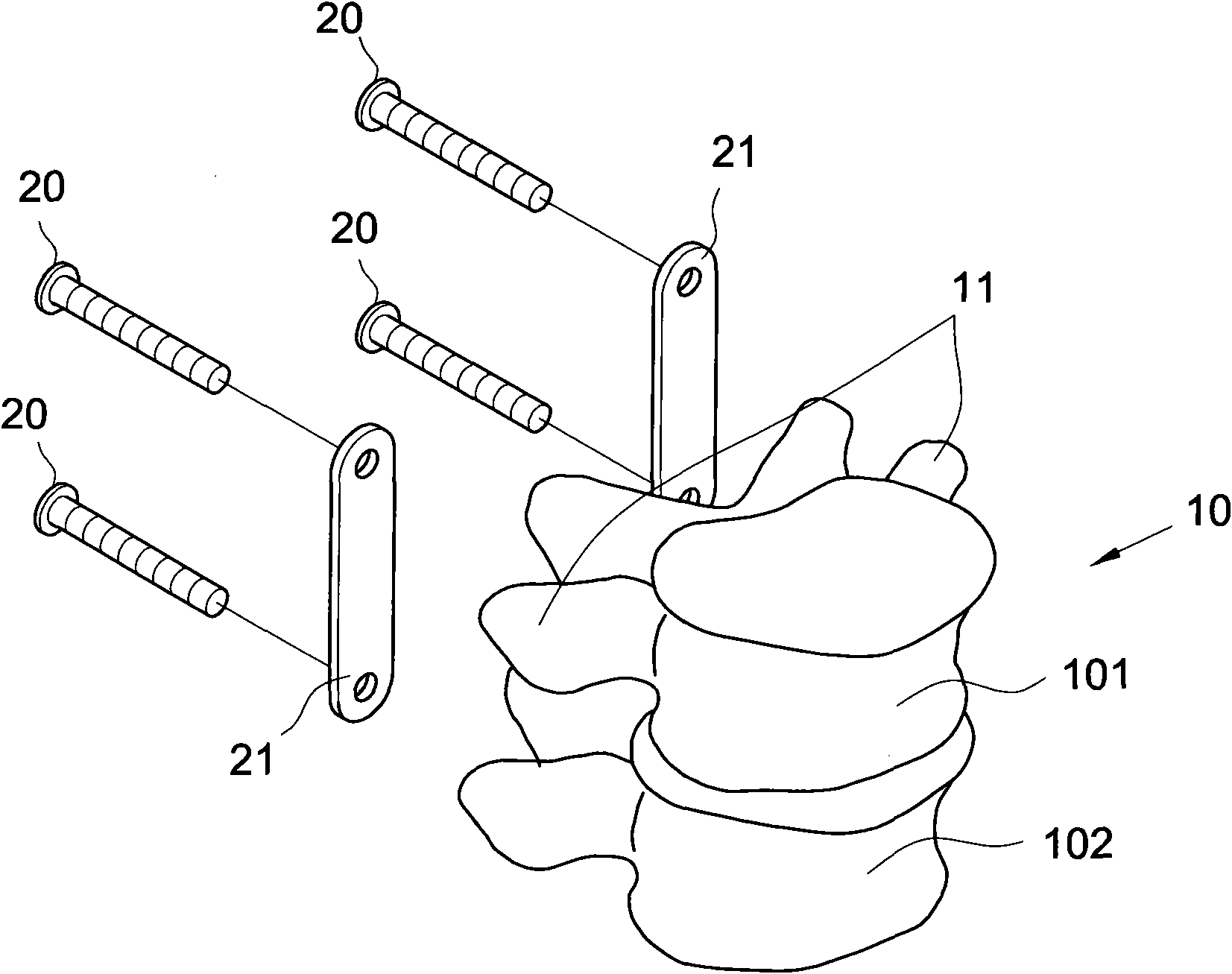

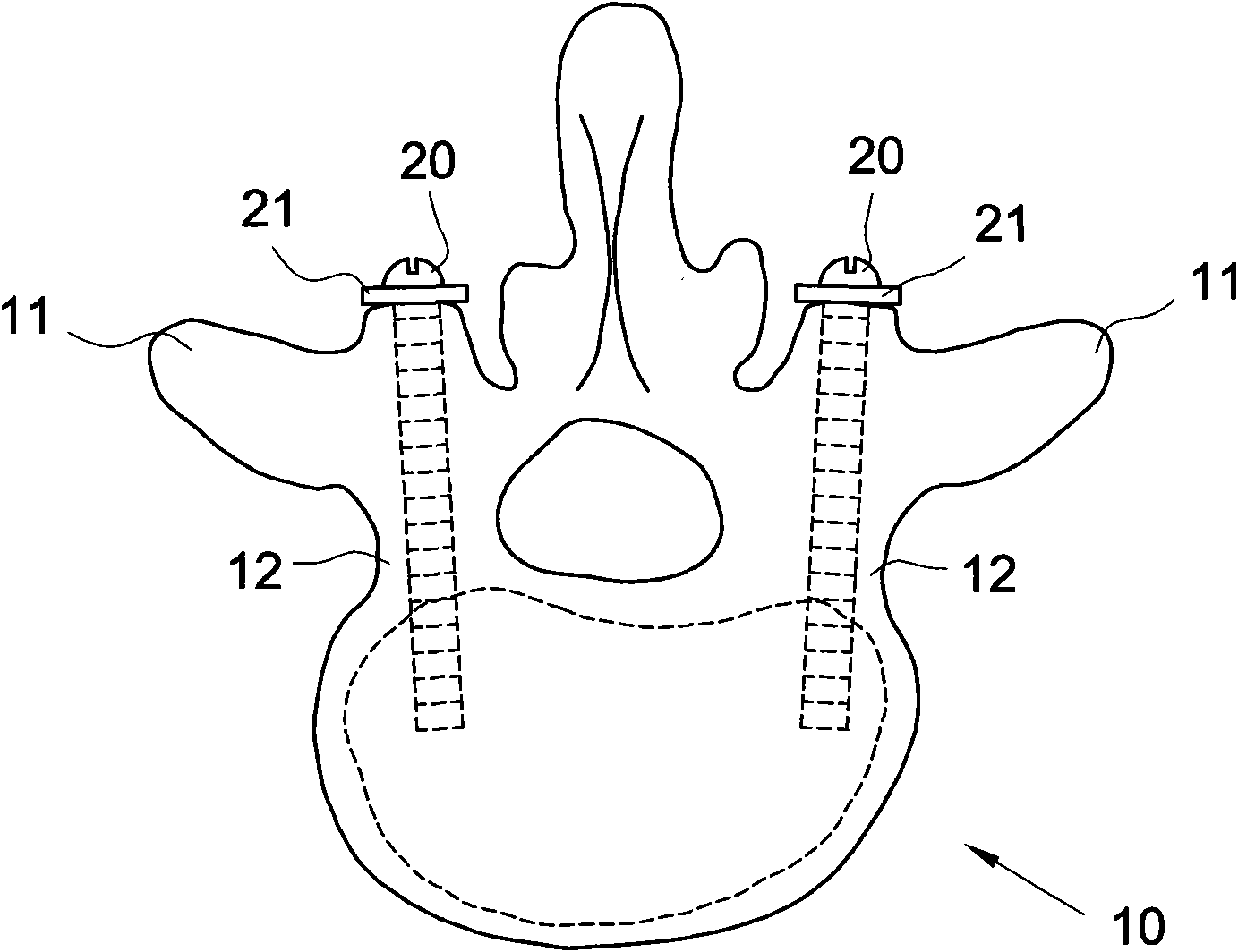

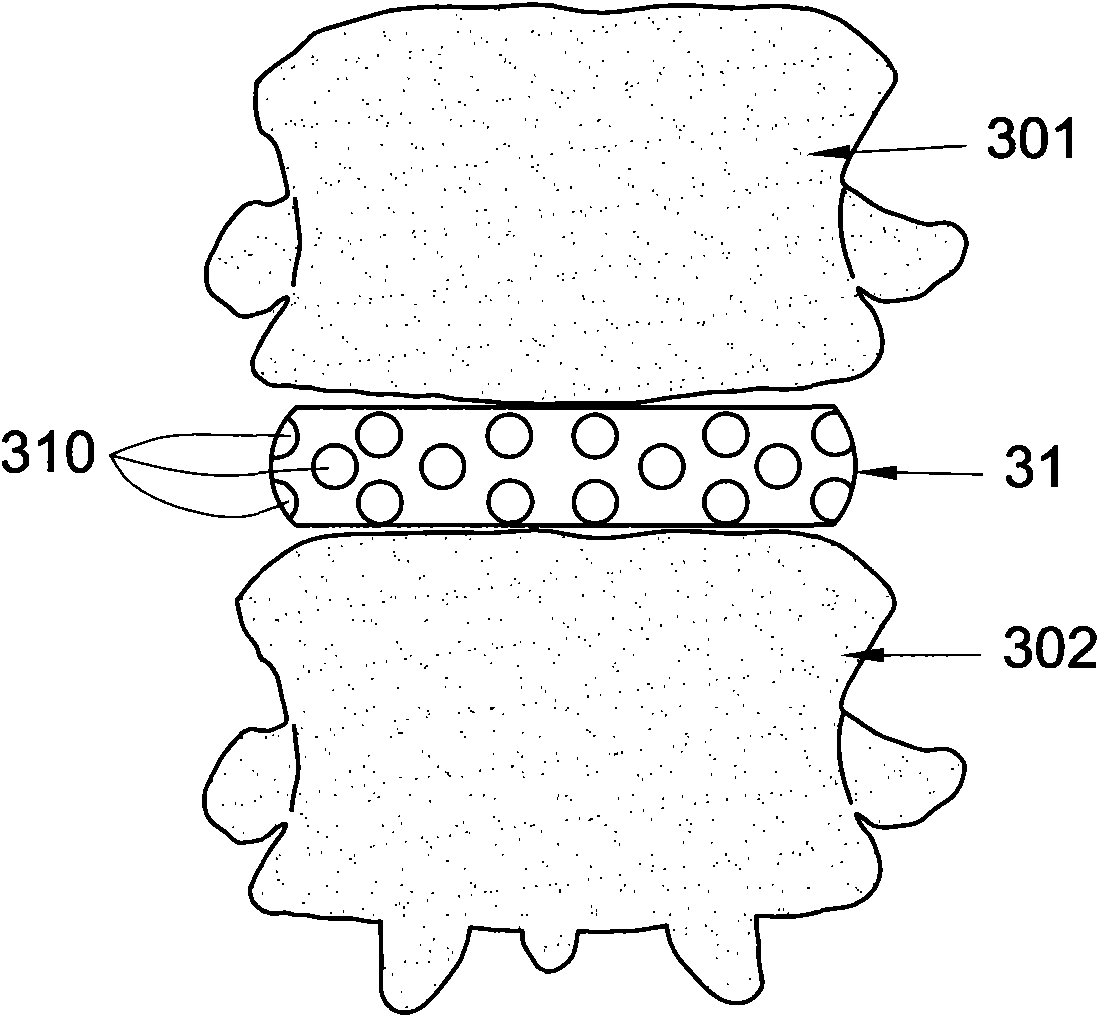

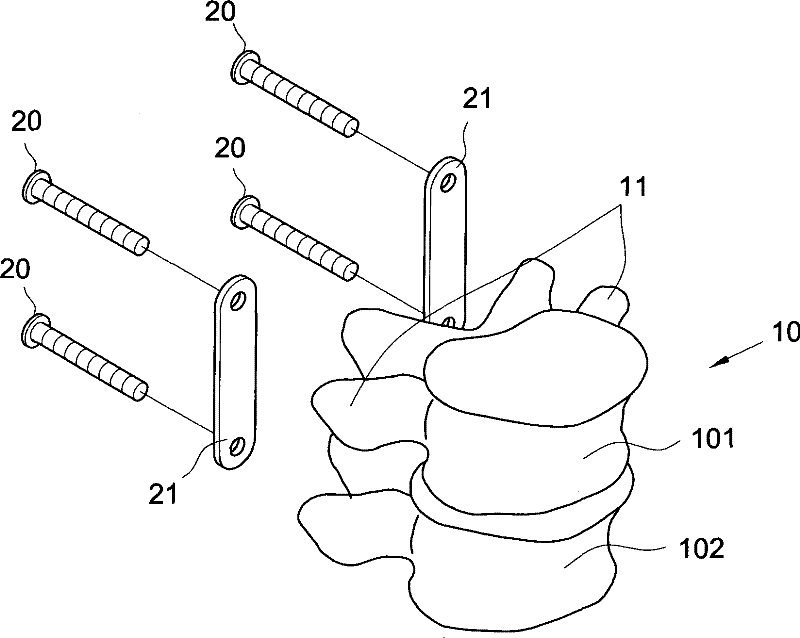

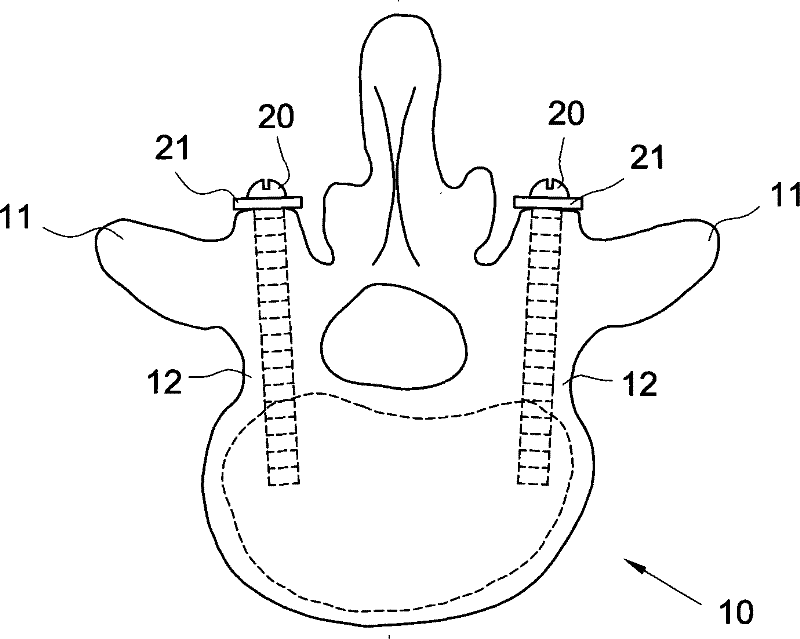

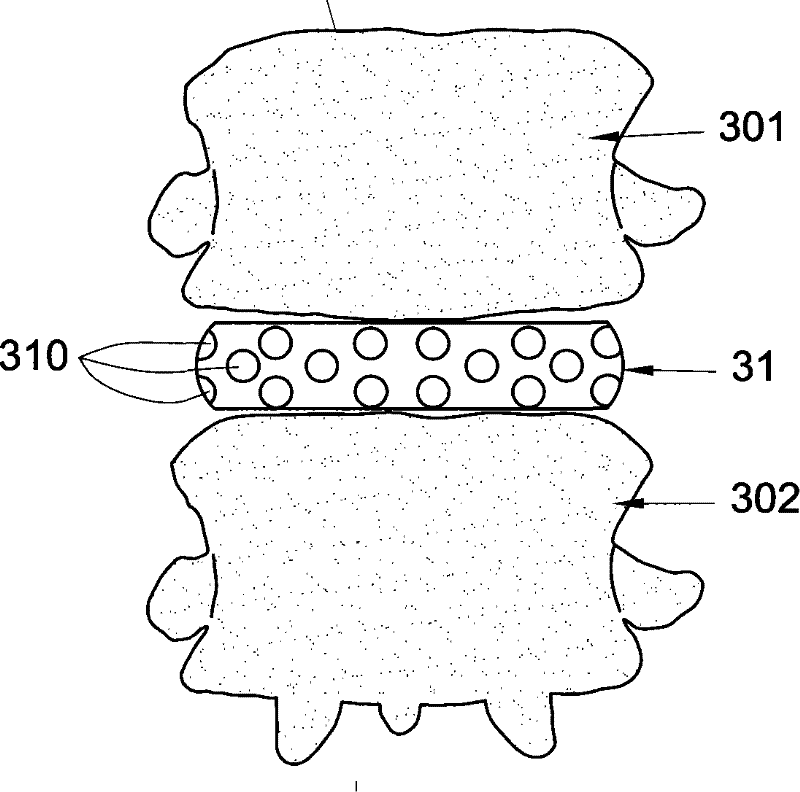

Fixing device for neutralizing actions between two vertebral bodies

The invention discloses a fixing device for neutralizing actions between two vertebral bodies, in particular a fixing device for neutralizing or countervailing actions between two adjacent vertebral bodies. The fixing device is a plate-shaped body, one side of the plate-shaped body is provided with a nail part, and the fixing device is embedded into two corresponding vertebral bodies and intervertebral discs by the nail part. When necessary, the fixing device also can be matched with a support assembly, such as a metal cage, and embedded into the intervertebral discs of the two corresponding vertebral bodies. Therefore, the fixing device can effectively control actions between the two vertebral bodies, such as forward bending, backward bending, left and right incline, left and right turn, and the like, and enable an autogenous bone embedded between the two adjacent vertebral bodies not to generate the problem of non-union or psuedarthrosis because of actions between the vertebral bodies before completely inosculated with the vertebral bodies.

Owner:A SPINE ASIA

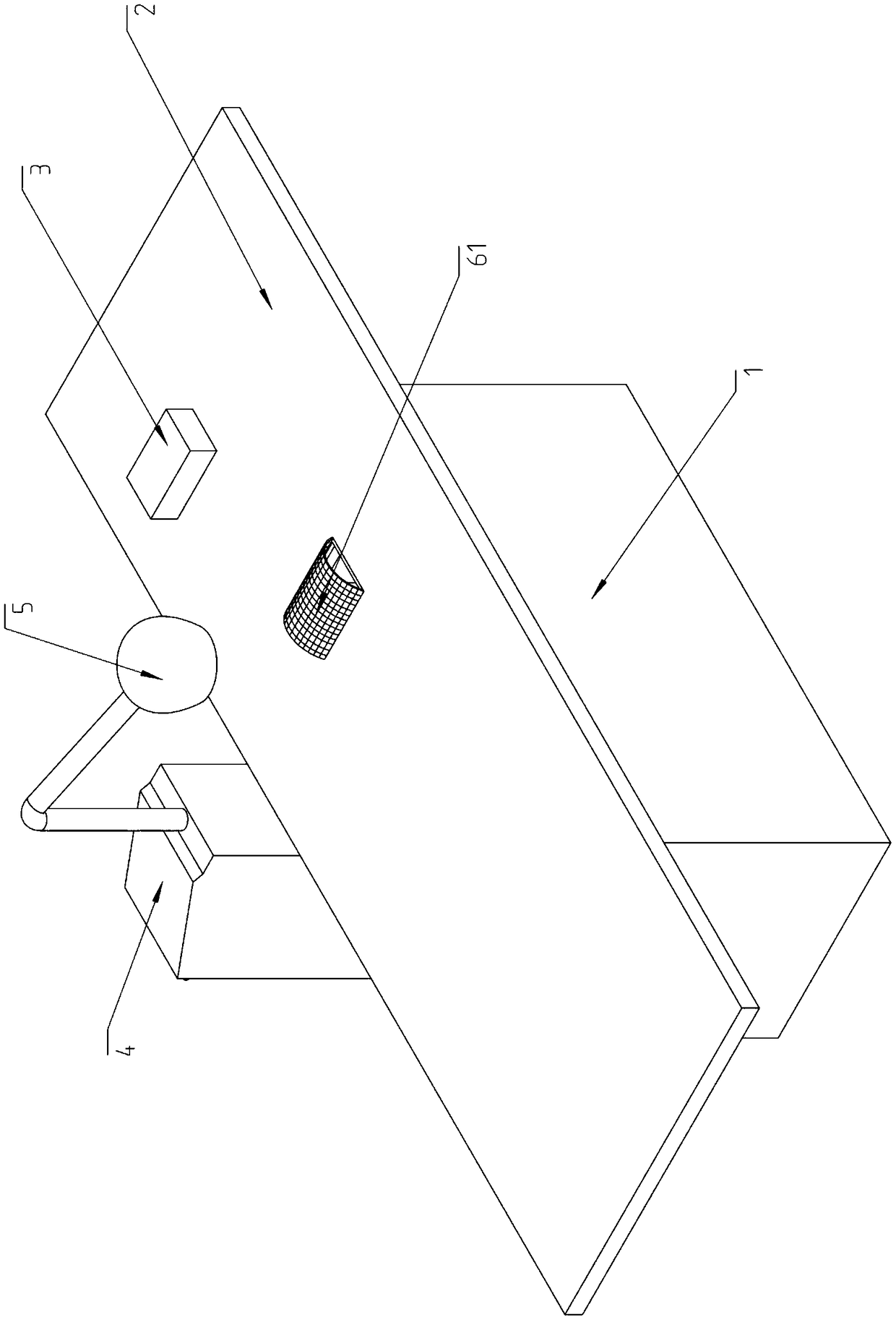

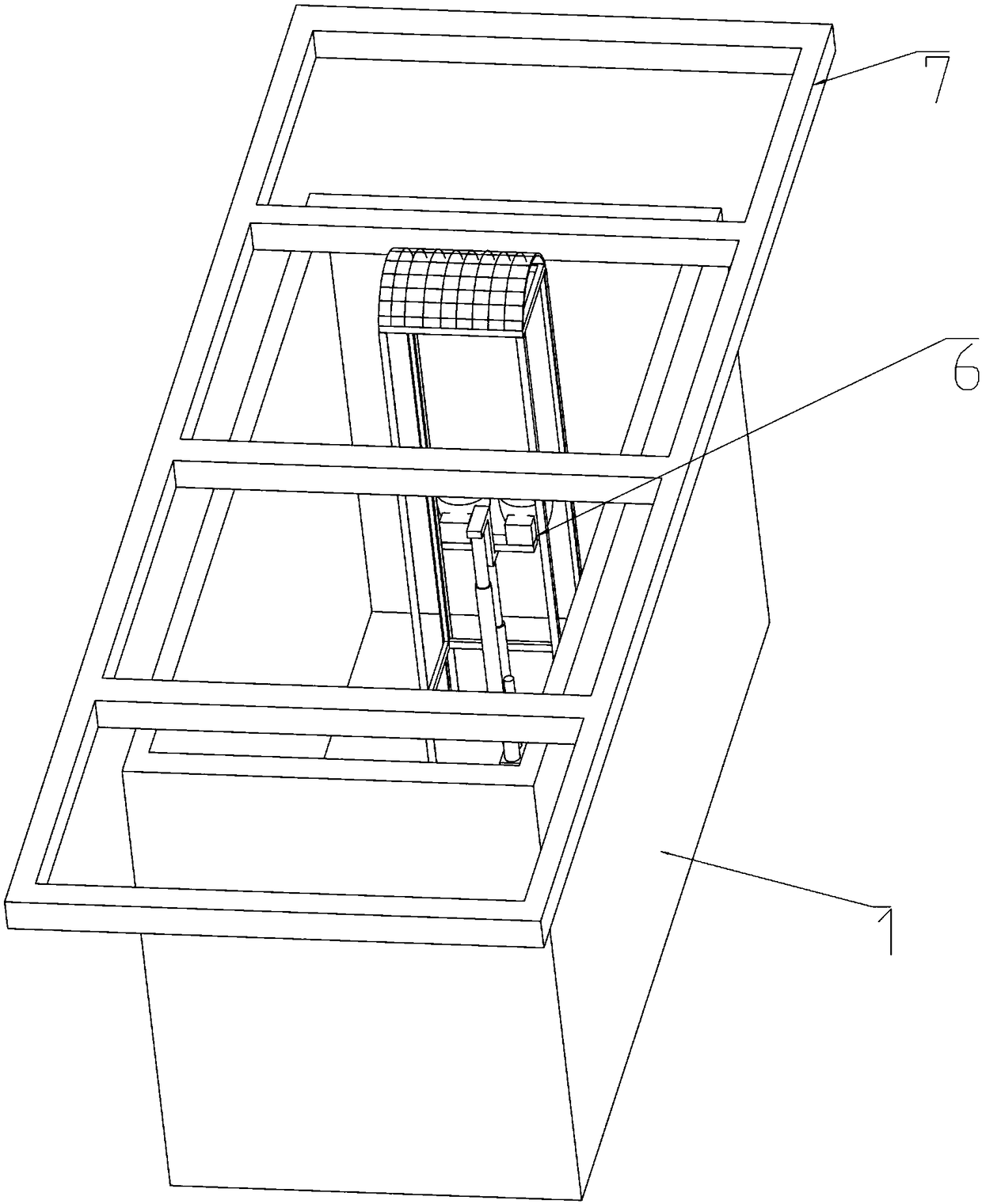

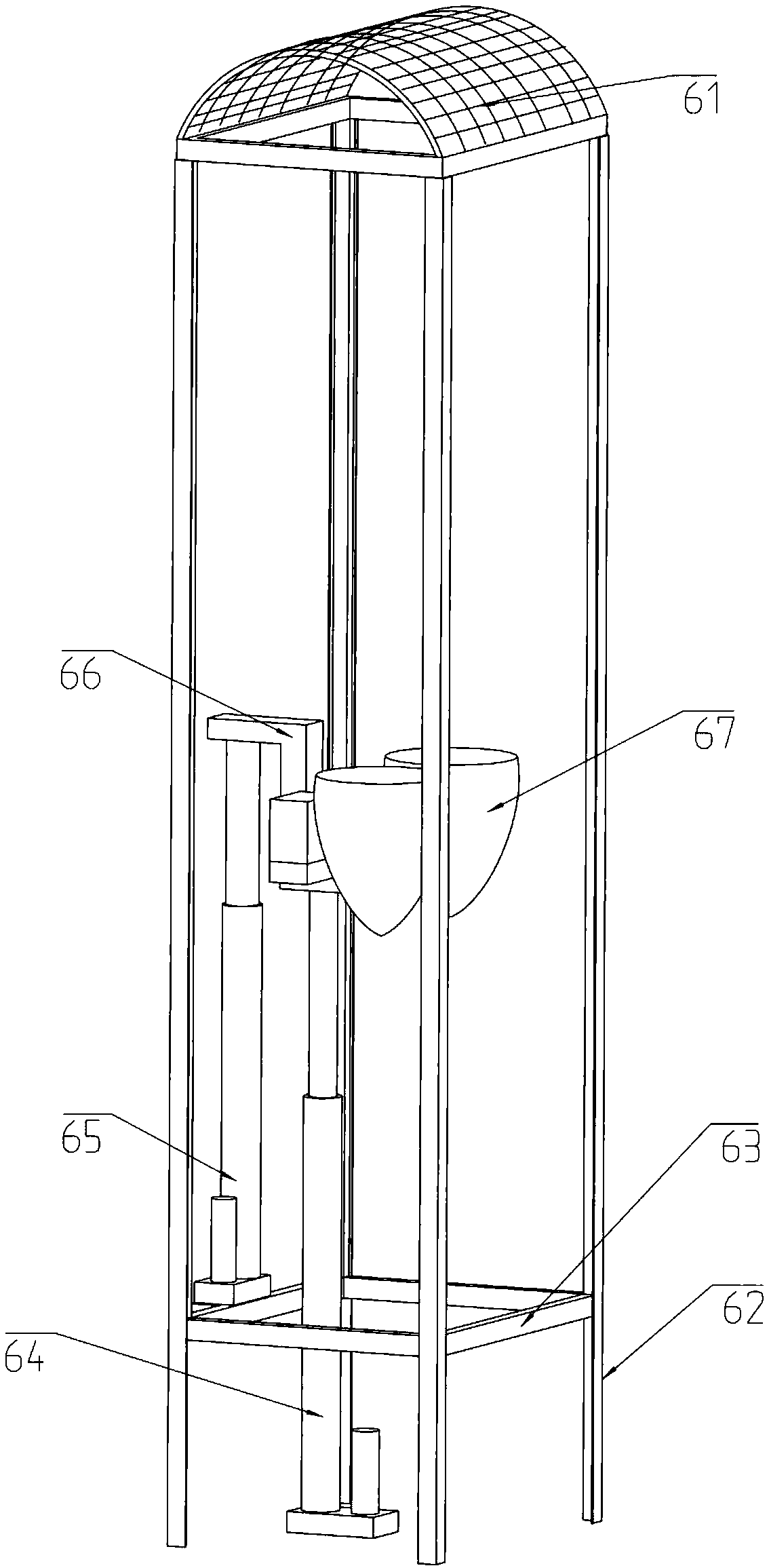

A novel lumbar vertebral physiotherapy and rehabilitation therapeutic apparatus

PendingCN109199792APrecision therapyRhythm SynchronizationChiropractic devicesLight therapyIntervertebral spacePassive movements

A lumbar vertebra physiotherapy rehabilitation therapeutic apparatus disclosed in the invention mainly includes a bed body, Finger-pulse modulate thunder-fire moxibustion therapeutic instrument, a table board is arranged above that bed body through a table board support, a thunder-fire moxibustion instrument modulate by finger pulse is arranged beside that bed body, a synergistic lif device is arranged in that inn part of the bed, a synergistic lif device is supported by four lif rails, a lif bracket is arranged in that lif rail, the top of the lifting bracket is connected with a lumbar lifting cover, the bottom side of the lifting bracket is connected with a cooperative telescopic rod, the top of the cooperative telescopic rod is fixedly connected with the bottom telescopic rod through the connecting bracket, the bottom of the bottom telescopic rod is fixed on the bed body, and an internal infrared radiation lamp holder is symmetrically installed on the platform of the connecting bracket. The invention adopts double telescopic rods, which can freely adjust the height; Finger-pulse modulated thunder-fire moxibustion instrument is used to simulate traditional moxibustion in all directions. A lumbar spur, a backward bend traction, a decompression of that lumbar disc along with the sector open of the intervertebral space, backward bend passive movement, strain of the lumbar muscle, and promotion of blood circulation have tremendous application potential in the lumbar spur, backbend traction, and lumbar disc decompression.

Owner:HANGZHOU DALISHEN MEDICAL DEVICE

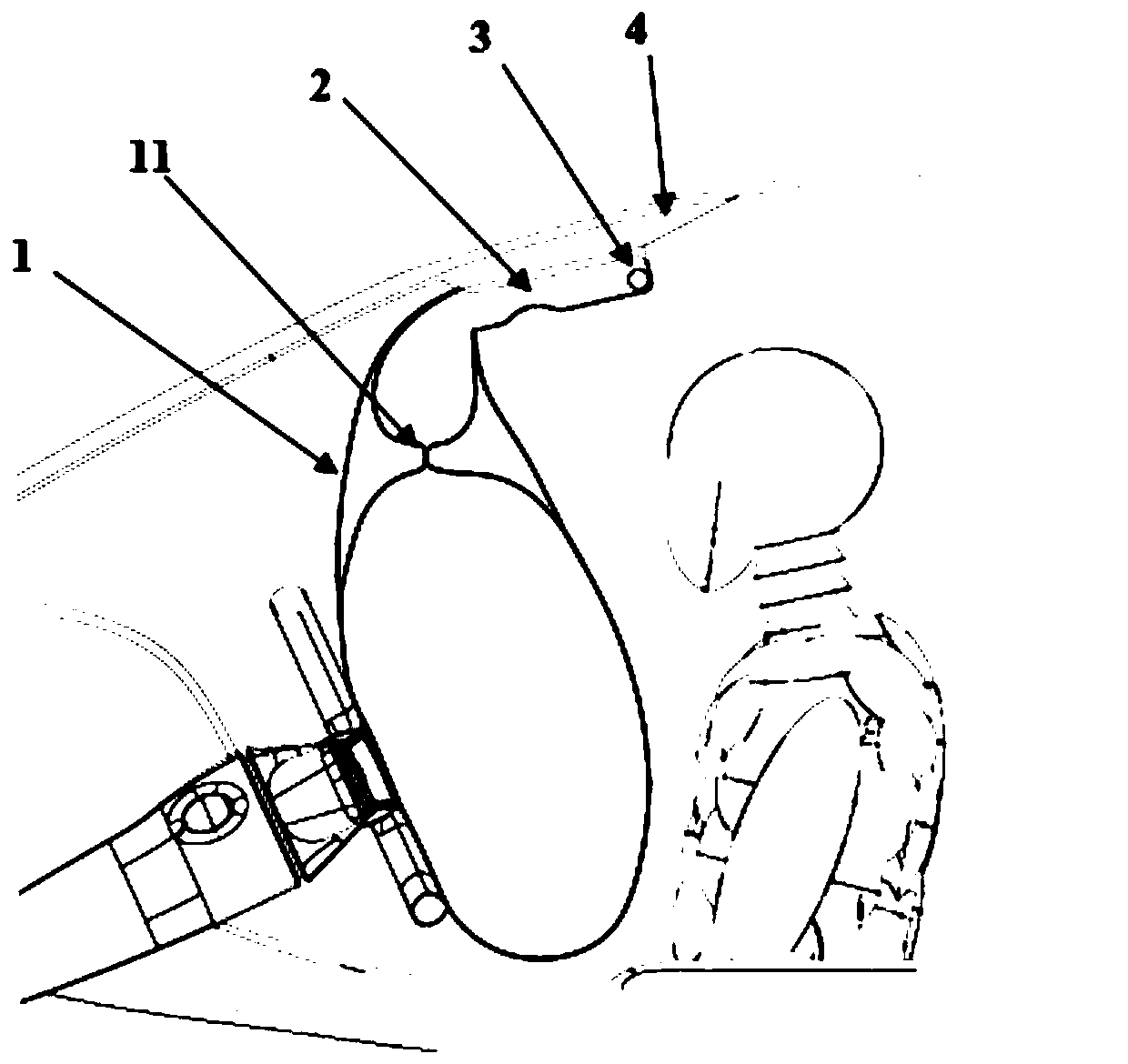

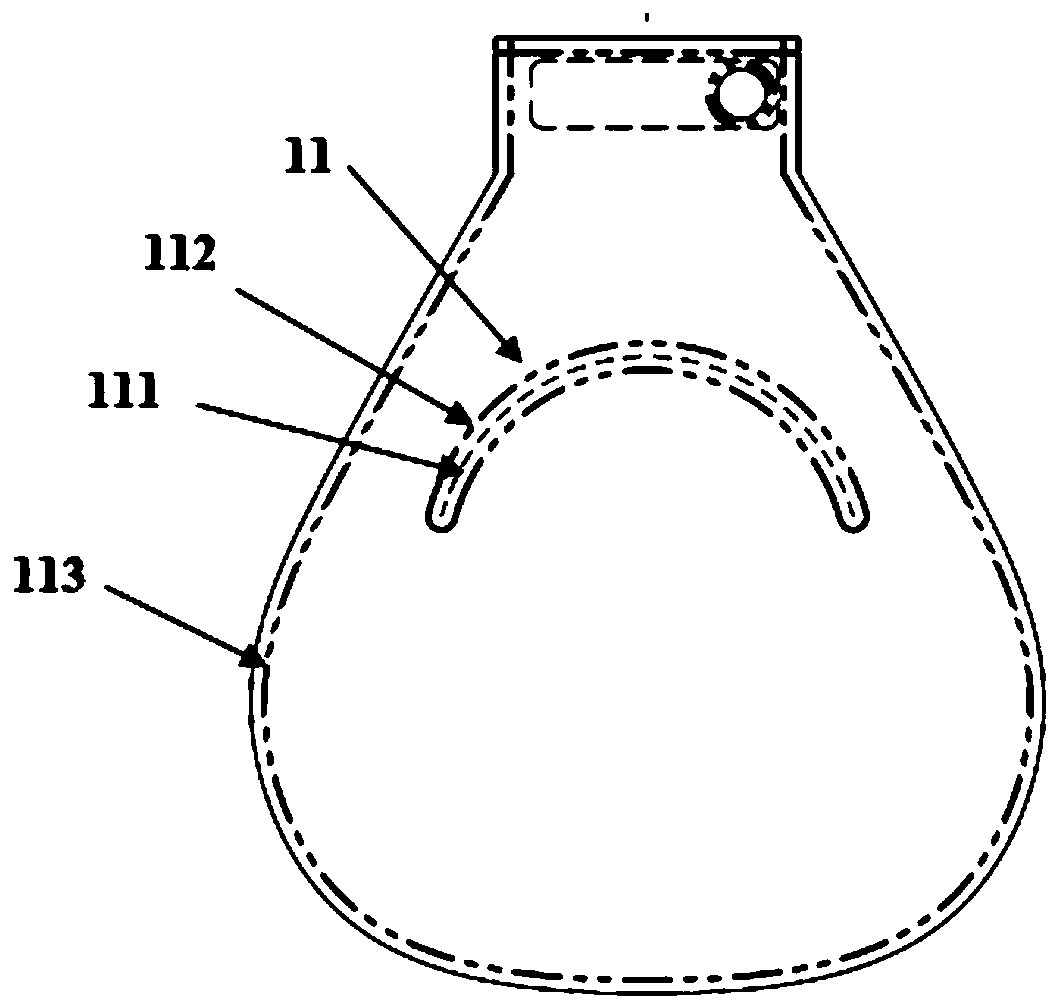

Top-mounted gasbag

PendingCN109774646AReduced Risk of Neck InjuriesLow costPedestrian/occupant safety arrangementEngineeringNeck injury

The invention relates to the technical field of passive safety devices, in particular to a top-mounted gasbag. The gasbag comprises a gasbag body, a gas generator and a shell, wherein the upper middlepart of the gasbag body is provided with a separable part, the separable part divides the gasbag body into an upper gasbag cavity and a lower gasbag cavity, the two sides of the separable part are provided with gas guide parts, and the upper gasbag cavity and the lower gasbag cavity are communicated by the gas guide parts. Compared with the prior art, the gasbag has the advantages that a top-mounted gasbag structure is designed, the separable part is arranged at the upper middle part of the gasbag body, and when a driver moves towards the gasbag filled with gas and squeezes the gasbag, the portion, close to the head of the driver, of the gasbag is compressed more easily, so that the risk of neck injuries caused by excessive backward bending of the neck of the driver is reduced; moreover,the gasbag adopts a simple design for cutting and sewing pieces and is simple in structure, low in cost and easy to popularize.

Owner:SHANGHAI LINGANG JOYSON SAFETY SYST CO LTD +1

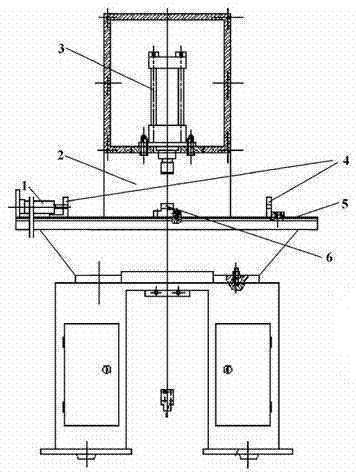

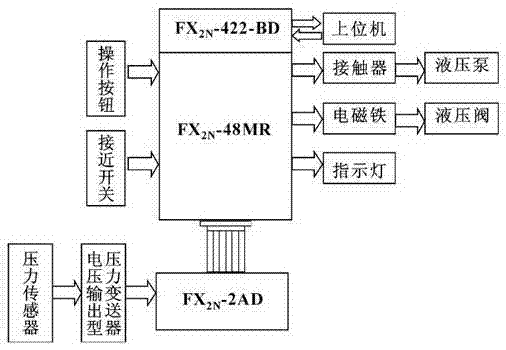

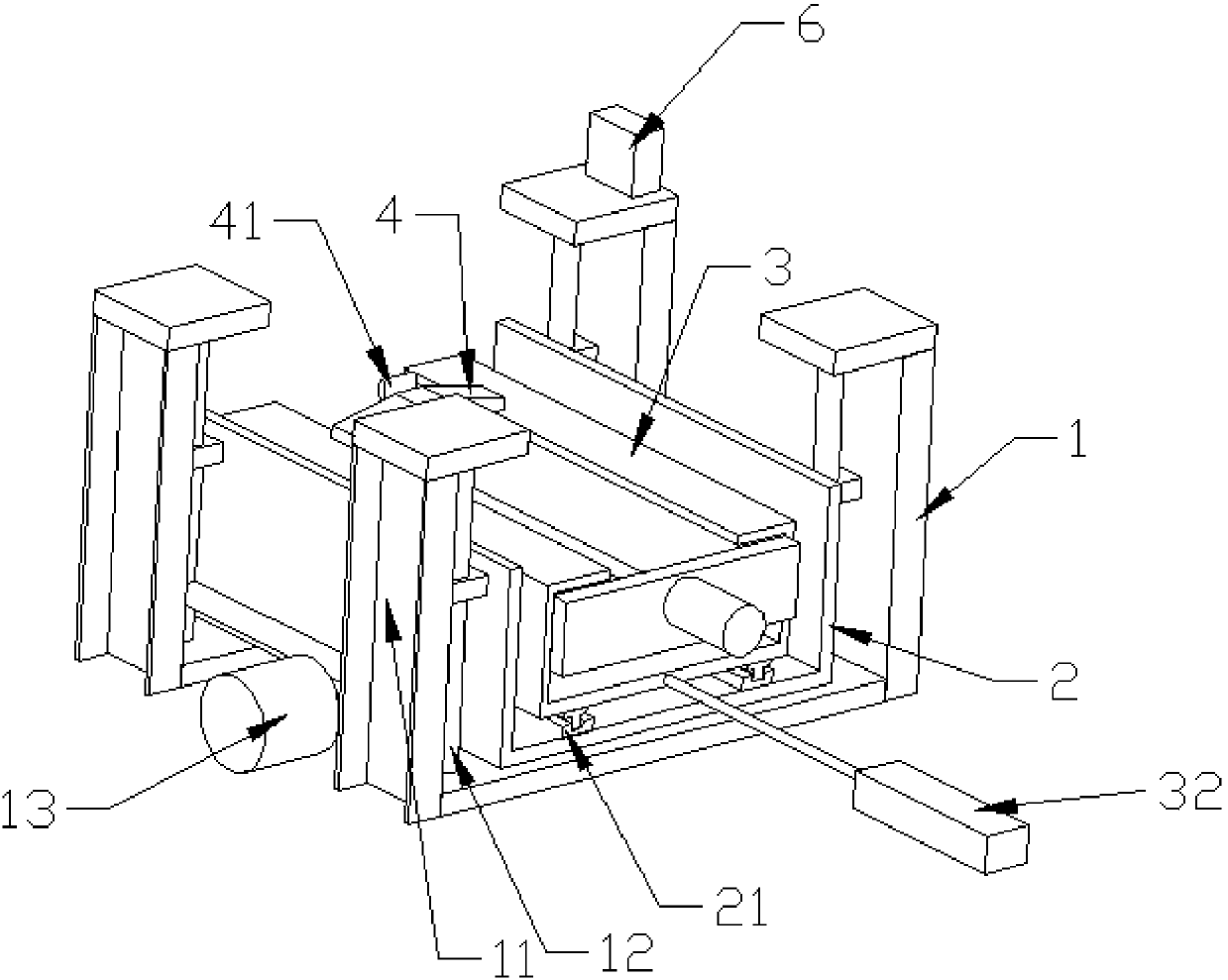

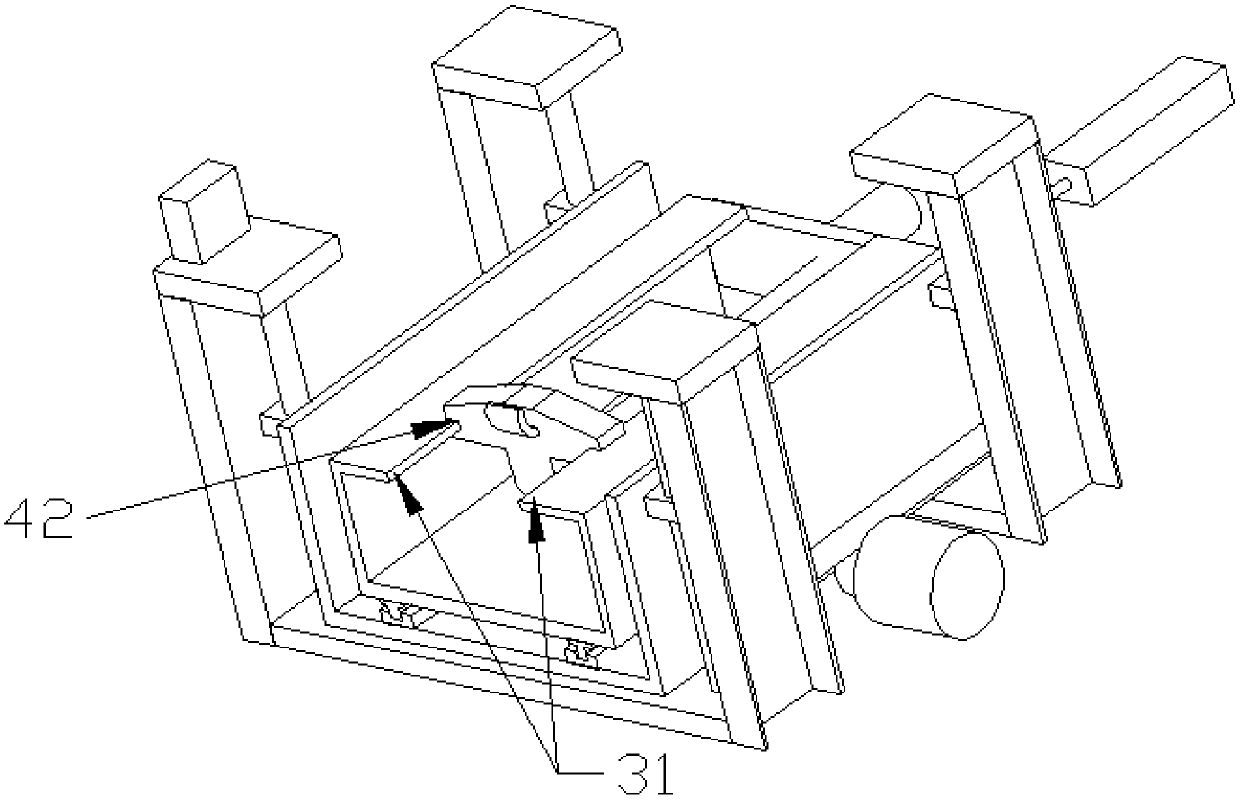

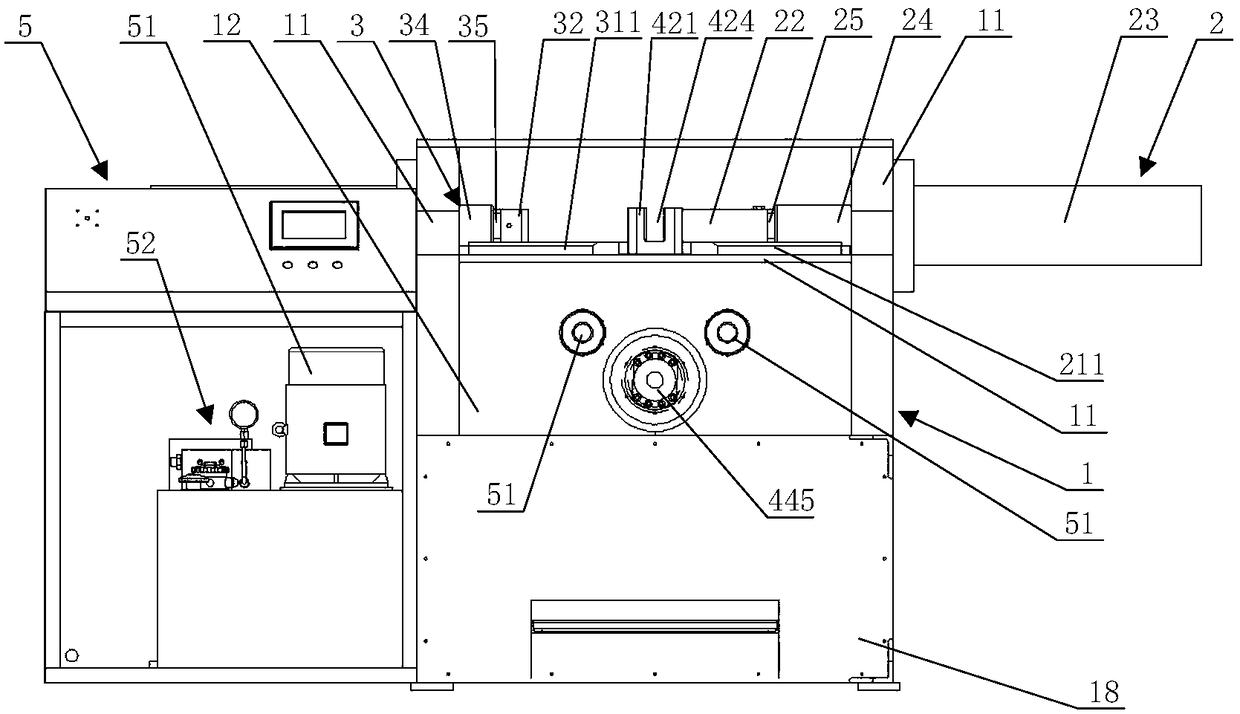

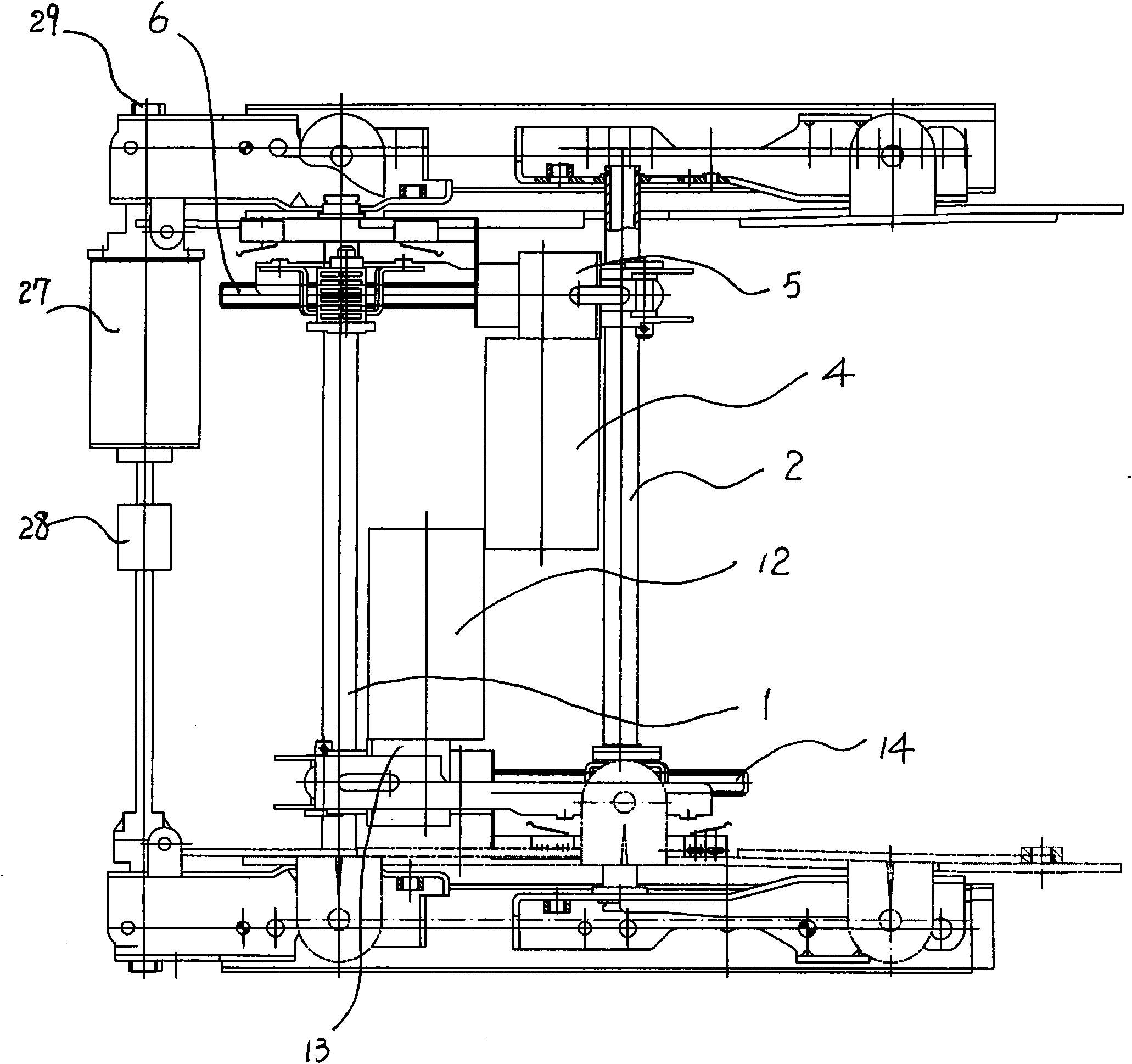

Shaft type part straightening machine

InactiveCN106862313AHigh technical contentImprove machining accuracyMetal working apparatusHydraulic cylinderPulp and paper industry

A straightening machine for shaft parts, the straightening machine is a single cantilever type, mainly composed of a frame, a workbench, two V-shaped support blocks, a pressure sensor, a straightening hydraulic cylinder, and a hydraulic pressure switch for adjusting the distance between the V-shaped blocks. Cylinder composition. The straightening machine achieves the purpose of straightening by reverse bending and gradually reducing the bending deflection. The straightening machine integrates machinery, hydraulic pressure, detection technology and PLC control technology, which improves the technical content and processing accuracy of the product.

Owner:申久祝

Rolling mill auxiliary jig

ActiveCN107583956AFully contactedReduce labor intensityMetal rolling stand detailsMetal rolling arrangementsEngineeringUltimate tensile strength

The invention provides a rolling mill auxiliary jig, and belongs to the field of rolling mill roller assembling and disassembling devices. The rolling mill auxiliary jig comprises an assembling and disassembling head which can do up-down vertical movement and front-back horizontal movement. The assembling and disassembling head comprises an upward and backward bend at the front end and a plane structure. The bend is matched with a to-be-assembled / disassembled rolling mill roller. The plane structure is located below the bend, and the rolling mill roller can be conveniently ejected when assembled. The rolling mill roller can be mechanically assembled and disassembled, labor intensity is reduced, and safety and work efficiency are improved.

Owner:TIANJIN YU RUN DE METAL PROD

Fixing device for neutralizing actions between two vertebral bodies

ActiveCN101564317BEasy to controlReduce stress loadInternal osteosythesisFastenersNon unionIntervertebral disc

The invention discloses a fixing device for neutralizing actions between two vertebral bodies, in particular a fixing device for neutralizing or countervailing actions between two adjacent vertebral bodies. The fixing device is a plate-shaped body, one side of the plate-shaped body is provided with a nail part, and the fixing device is embedded into two corresponding vertebral bodies and intervertebral discs by the nail part. When necessary, the fixing device also can be matched with a support assembly, such as a metal cage, and embedded into the intervertebral discs of the two corresponding vertebral bodies. Therefore, the fixing device can effectively control actions between the two vertebral bodies, such as forward bending, backward bending, left and right incline, left and right turn,and the like, and enable an autogenous bone embedded between the two adjacent vertebral bodies not to generate the problem of non-union or psuedarthrosis because of actions between the vertebral bodies before completely inosculated with the vertebral bodies.

Owner:A SPINE ASIA

Centrifugal supercharger

InactiveCN105626554AStable and safe mechanical transmissionExtend your lifePump componentsRadial flow pumpsImpellerEngineering

A centrifugal supercharger comprises a power input shaft, a large gear, a small gear shaft, a shaft sleeve, an impeller, an exhaust wheel, a bearing, a coupler, a volute casing and the like. The centrifugal supercharger is characterized in that the large gear is mounted on the power input shaft and is engaged with the small gear shaft through inclined teeth, and through an inclined gear, mechanical transmission will be more stable and safer; the impeller, the exhaust wheel, the shaft sleeve, a shaft head nut and other parts are mounted on the small gear shaft to form a main component of the centrifugal supercharger, and the main component is a rotor of the centrifugal supercharger; and the exhaust wheel is arranged on the outer side of a sealing device at the contact position of the impeller and the volute casing of the supercharger. A casting structure is adopted in a machine shell, and an X-shaped structural manner is adopted in an upper volute casing body and a lower volute casing body; a stainless steel closed type impeller is adopted as the impeller, a blade manner of a backward bending structure is adopted in blades, the blades are alternative in length, and the number of the blades is 11; and according to the centrifugal supercharger, the working efficiency is greatly improved, the manufacturing and maintaining cost is greatly reduced, the service life of the supercharger is greatly prolonged, and the centrifugal supercharger is unanimously praised.

Owner:北京斯特透平机械有限公司

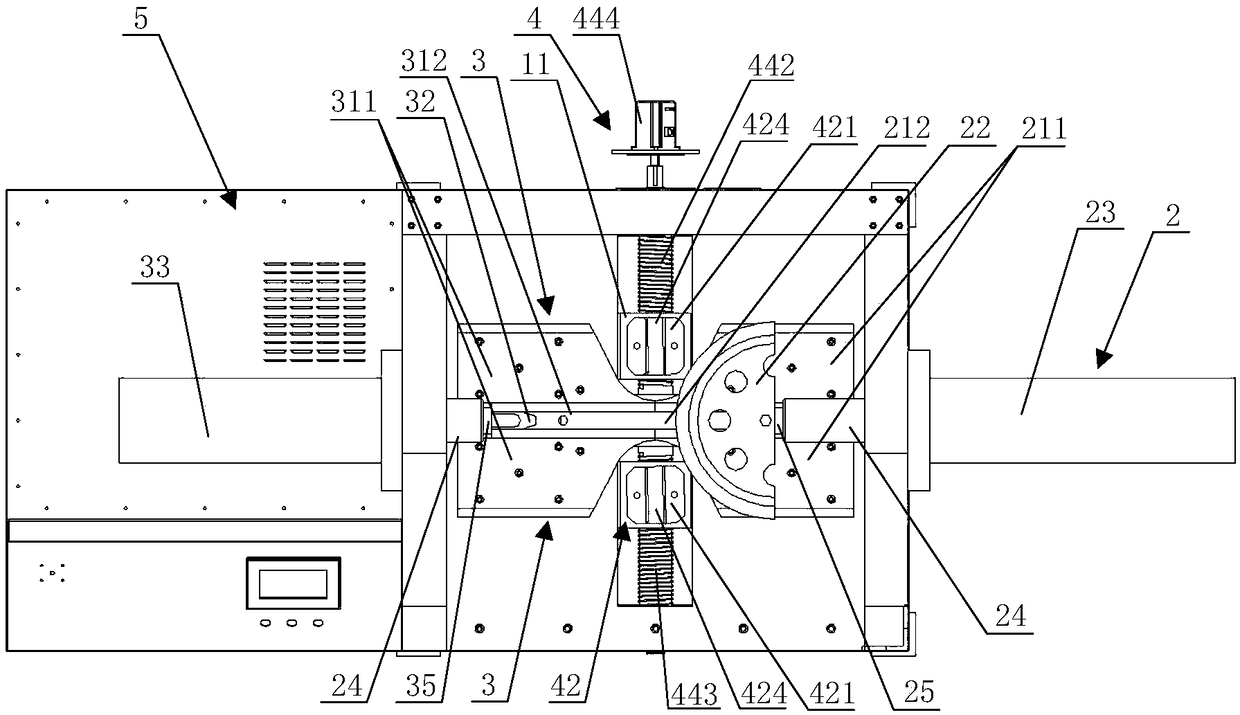

Bending test system

PendingCN108645716ARealization of secondary bendingAchieving positive bendingMaterial strength using steady bending forcesTest sampleEngineering

The invention provides a bending test system. The system comprises a worktable, a first bending mechanism, a second bending mechanism, a clamping device and a power device, wherein the clamping deviceis connected with the worktable and is used for clamping a test sample; the first bending mechanism and the second bending mechanism are respectively arranged on the two sides of the clamping deviceso as to bend the test samples in the different directions; the power device is connected with the first bending mechanism and the second bending mechanism so as to drive alternating motion of the first bending mechanism and the second bending mechanism. According to the bending test system disclosed by the invention, manual intervention is not needed, and through arrangement of the first bendingmechanism and the second bending mechanism arranged on the two sides of the clamping device and the power device for driving alternating motion of the first bending mechanism and the second bending mechanism, forward bending and backward bending of the test samples can be realized, the problem of larger errors of test results of the test sample after secondary clamping is avoided, the bending quality is ensured, the working efficiency is improved, and the bending test system is convenient and quick.

Owner:天津泰格瑞祥仪器设备有限公司

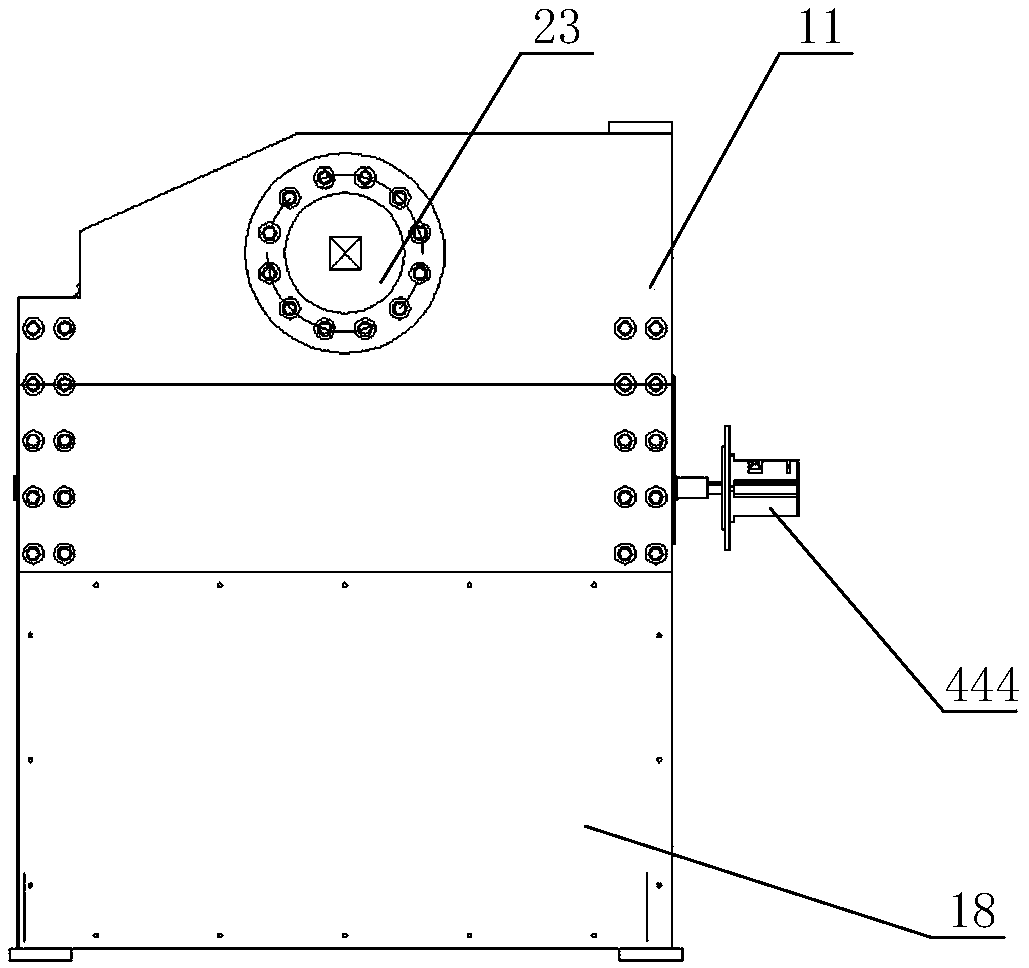

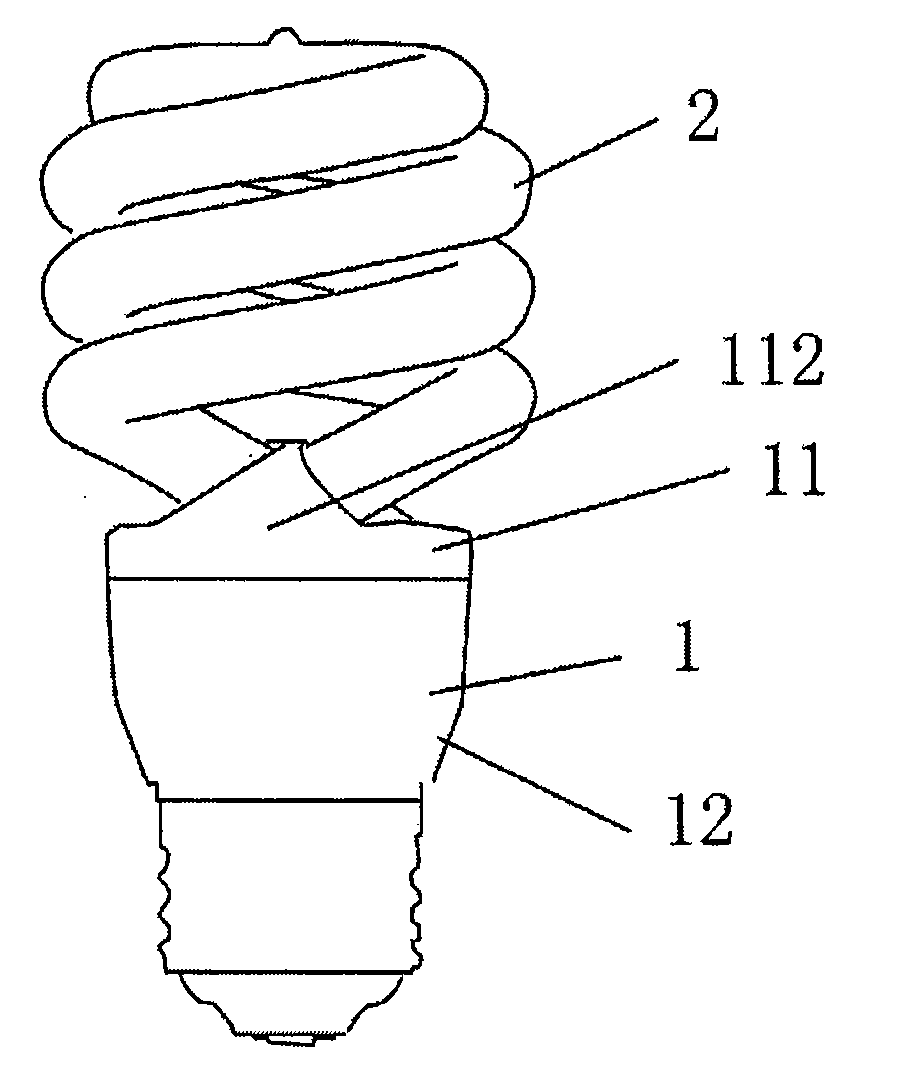

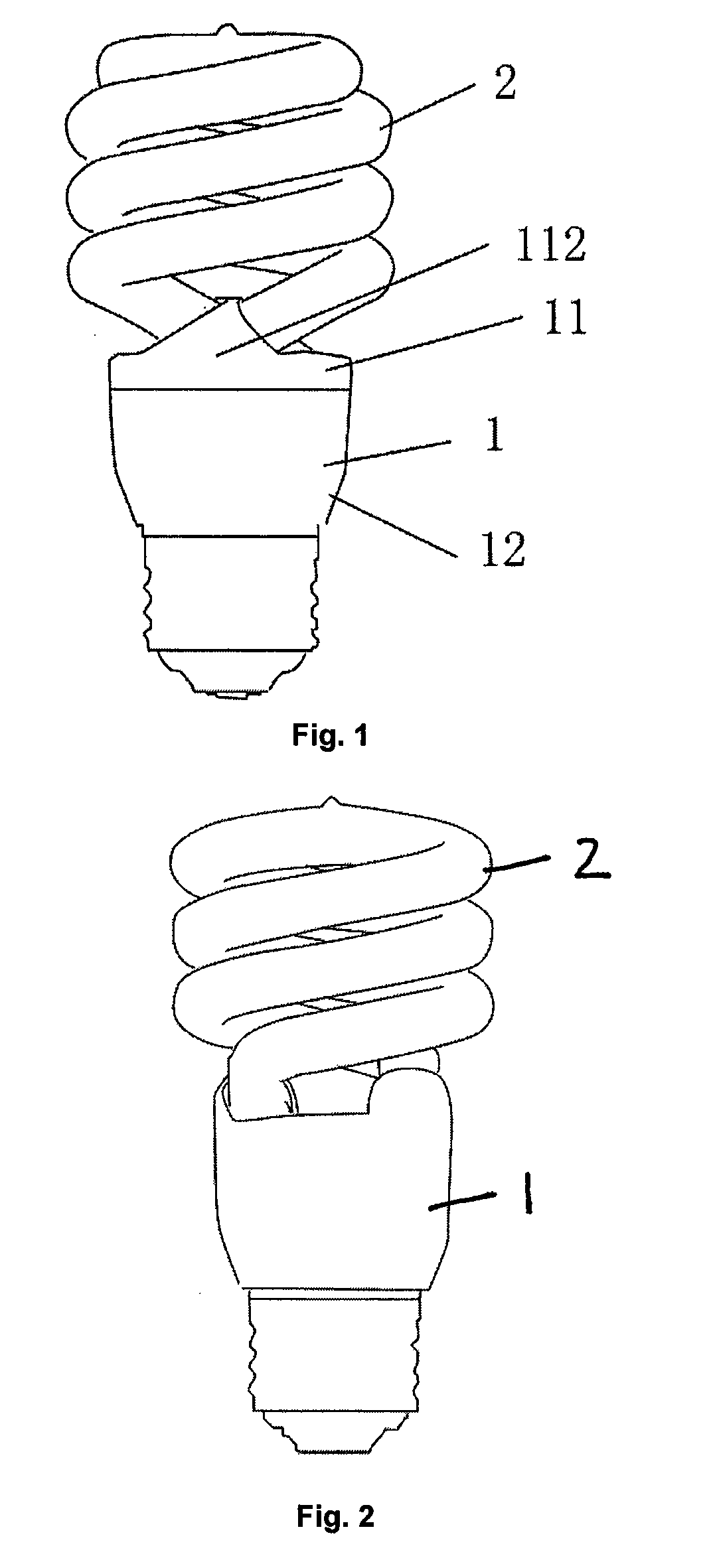

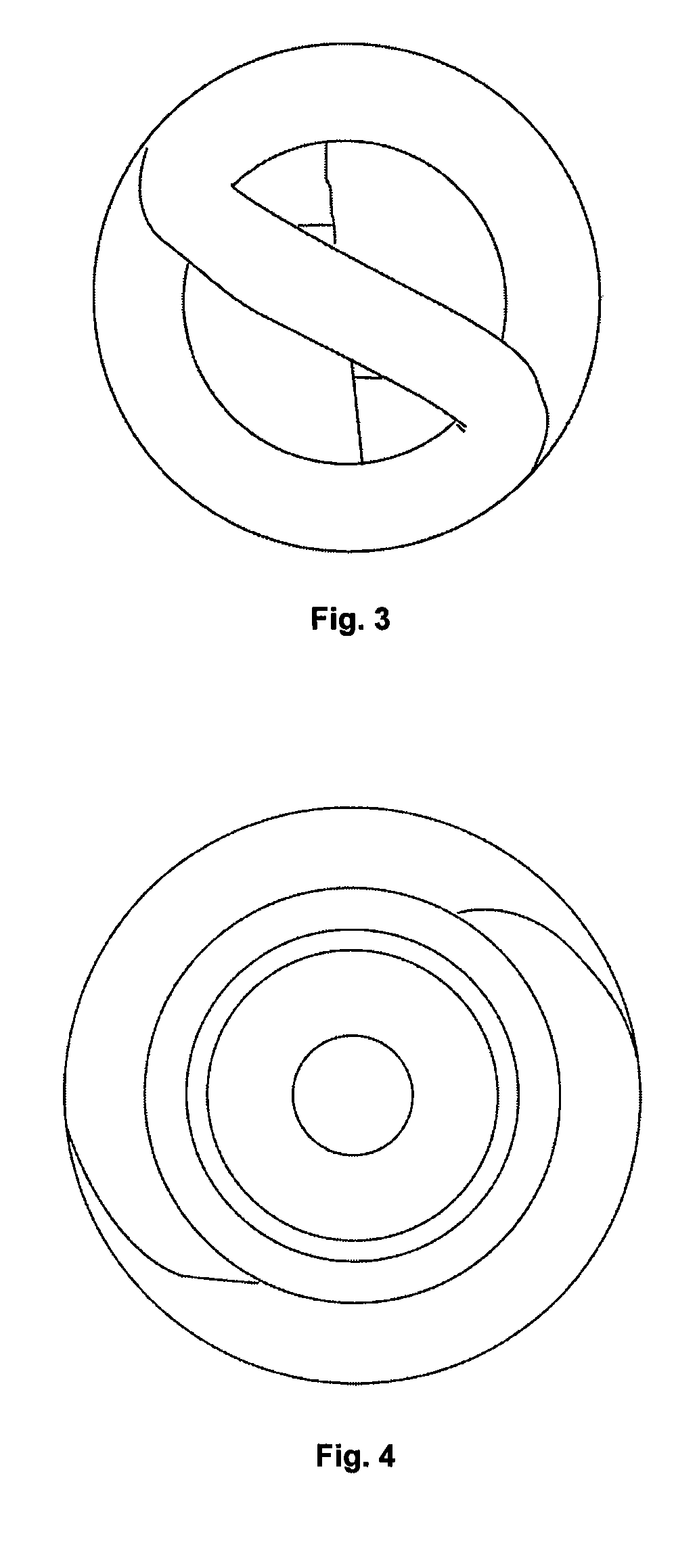

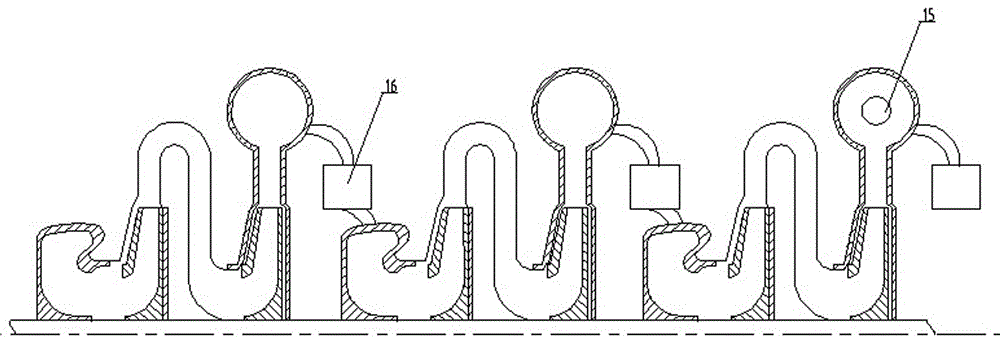

Semi-full helical luminous electronic energy-saving lamp

InactiveUS20080265741A1Improve quality consistencySolve the lack of spaceDischarge tube luminescnet screensLamp detailsInterface pointEngineering

A semi-full helical luminous electronic energy-saving tube and an electronic energy-saving lamp using the tube are disclosed. The structure at the connection between the end of tube and the enclosure is a straight section. An inward bend of the straight section is achieved via an interface point between the straight section and the helical portion of the tube. The interface point includes a sharp, V-shaped 180° backward bend. By making use of the sharp inward bend, a sufficient space is left for the enclosure process.

Owner:CRYSTAL GREEN LIGHTING

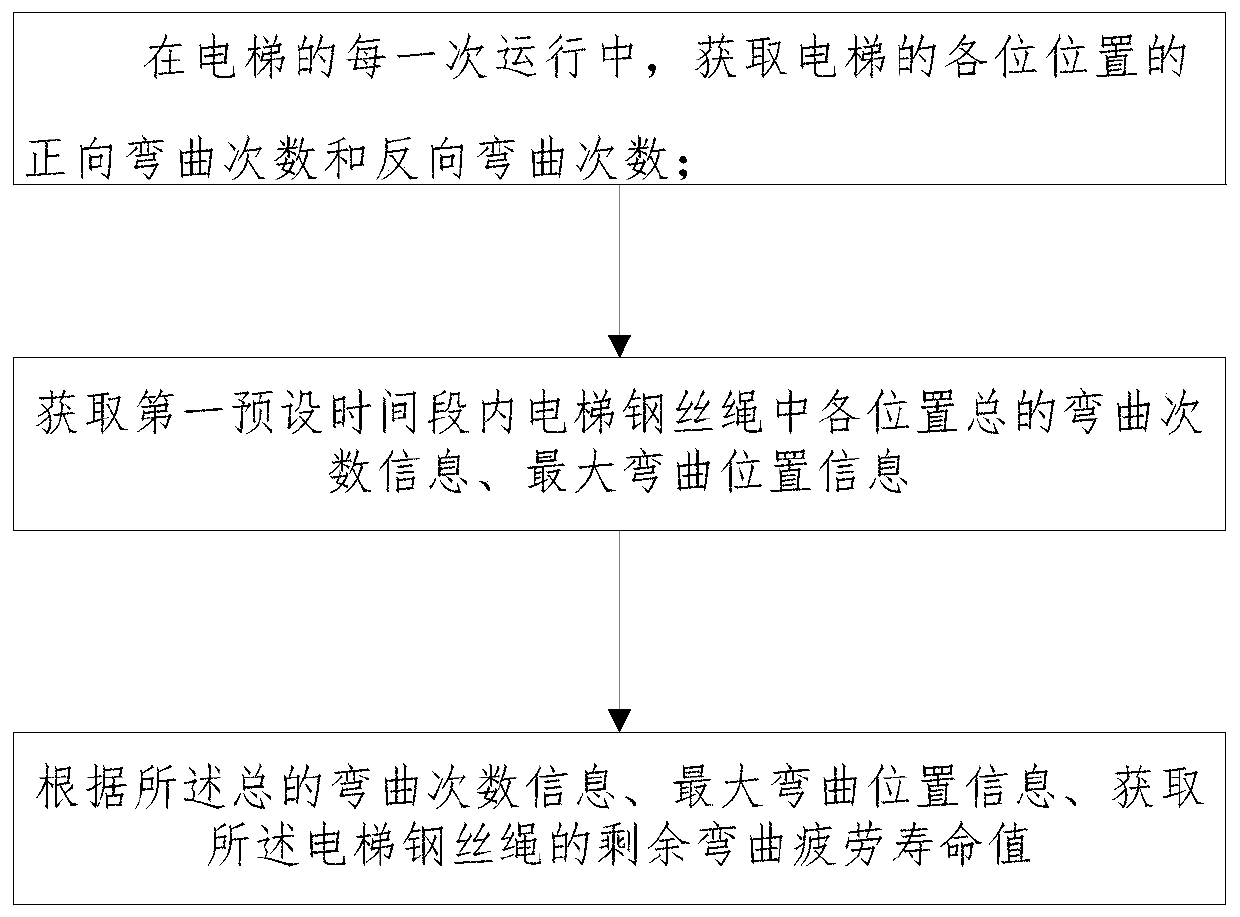

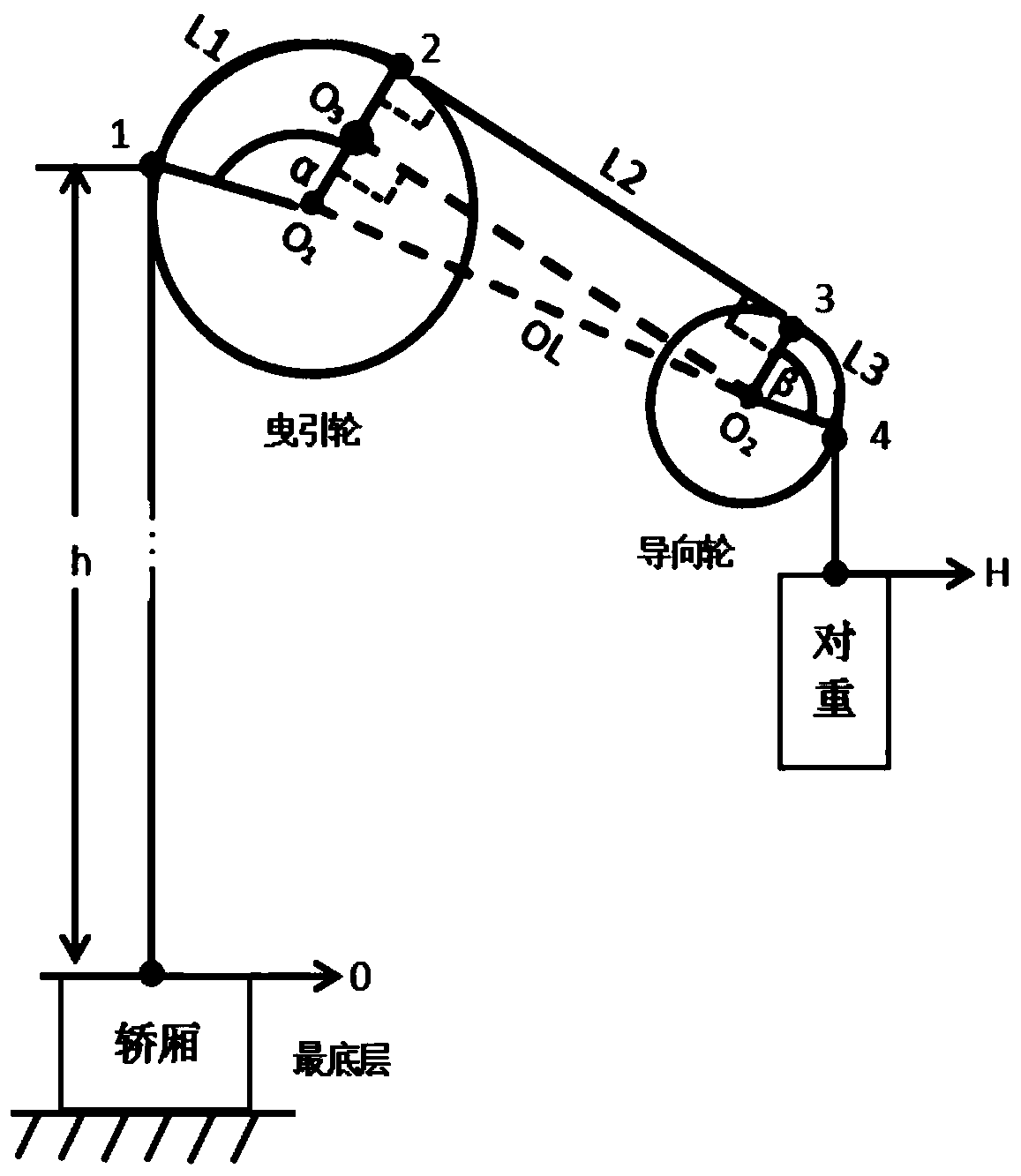

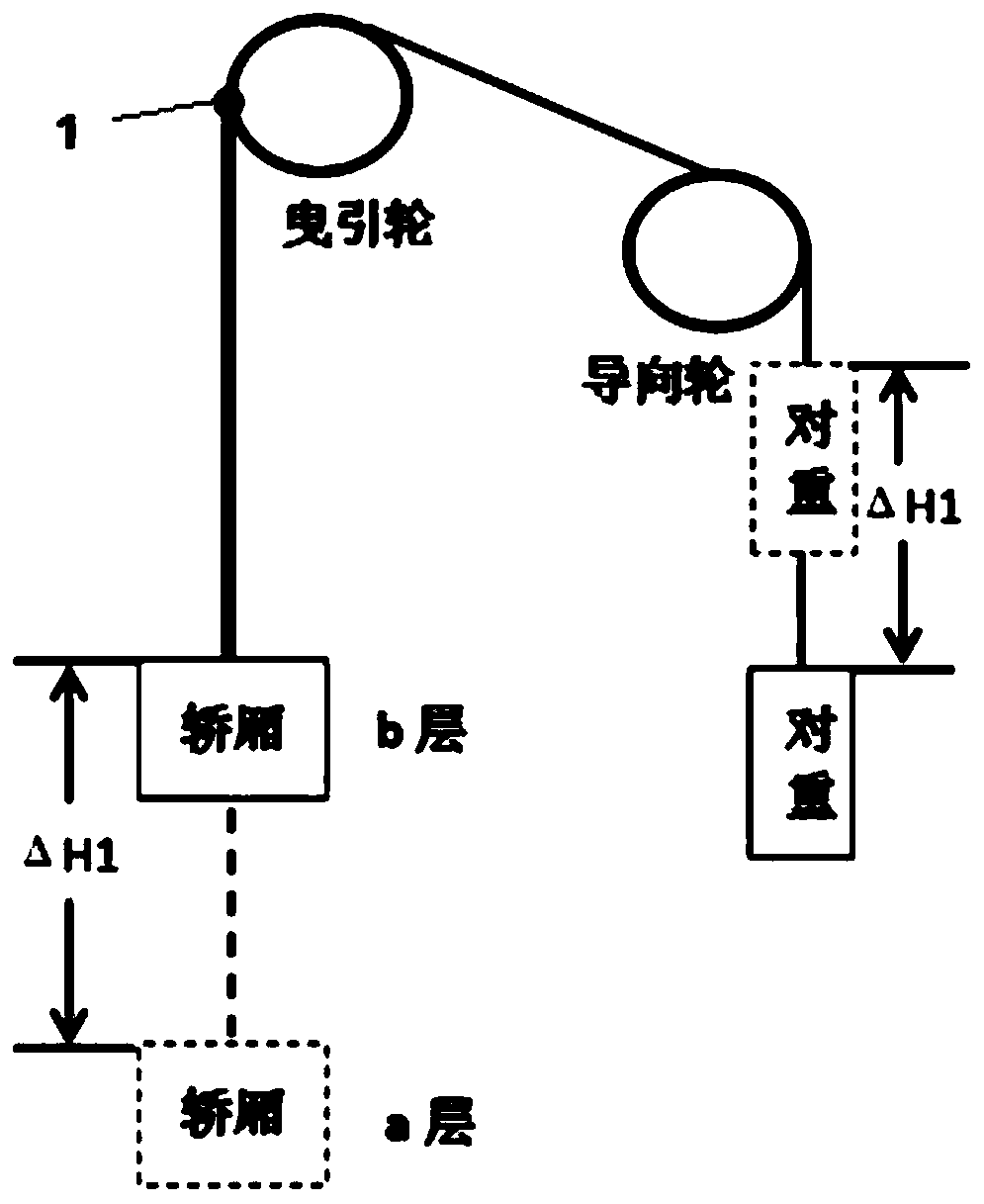

Elevator safety inspection method based on number of bending times of elevator rope

The invention relates to an elevator rope inspection method. The method comprises the following steps of, during each operation of an elevator, obtaining the number of forward bending times and the number of backward bending times of each position of the elevator based on the information about the number of destination floors received by an elevator control board and the basic information of the elevator; obtaining the information about the total number of bending times of each position and the information about the maximum bending position in the elevator rope during a first preset time period; and obtaining a remaining bending fatigue life value of the elevator rope according to the information about the total number of bending times and the information about the maximum bending position. The elevator rope inspection method provided by the invention can obtain the accurate number of bending times of the steel wire rope, and send out alarm signals according to the total number of bending times, so that the maintenance personnel can perform maintenance on the elevator according to the alarm signals, thereby improving the work efficiency.

Owner:NORTHEASTERN UNIV

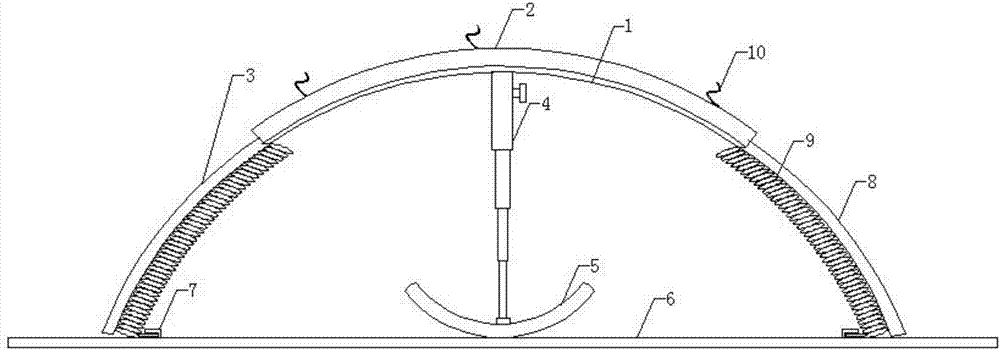

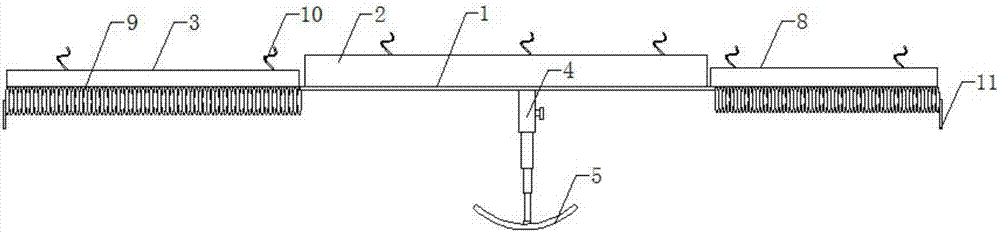

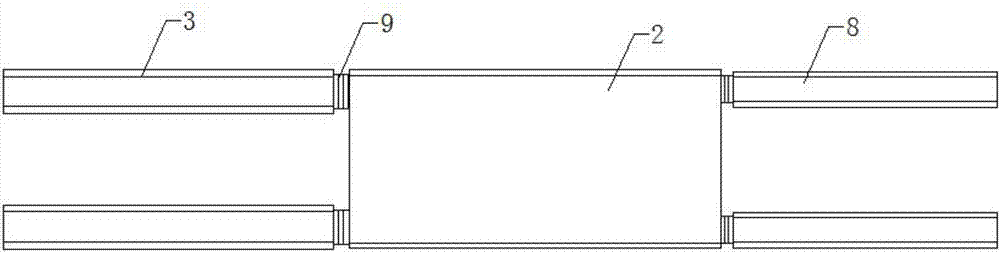

Martial art waist backward bending training stand

The invention discloses a martial art waist backward bending training stand. The training stand comprises an elastic plate and a bottom plate, a waist supporting and protecting plate is arranged on the top of the elastic plate, the bottom of the waist supporting and protecting plate is fixedly adhered to the top of the elastic plate through an adhesive, two leg supporting and protecting plates are disposed at one end of the elastic plate, two arm supporting and protecting plates are arranged at the other end of the elastic plate, elastic hoses are arranged at the bottoms of the leg supporting and protecting plates and the bottoms of the arm supporting and protecting plates, the elastic hoses are fixedly connected with the leg supporting and protecting plates and the arm supporting and protecting plates through a plurality of tying belts, an L-shaped protrusion is welded to one end of each elastic hose, the other end of each elastic hose is fixedly connected to the elastic plate through a bolt, and a telescopic rod is arranged at the bottom of the elastic plate. A safe and reliable sports device is provided for trainees, the psychological fear of beginners is overcome during training, the confidence of the trainees is enhanced, and the class teaching effect is improved.

Owner:宿州学院

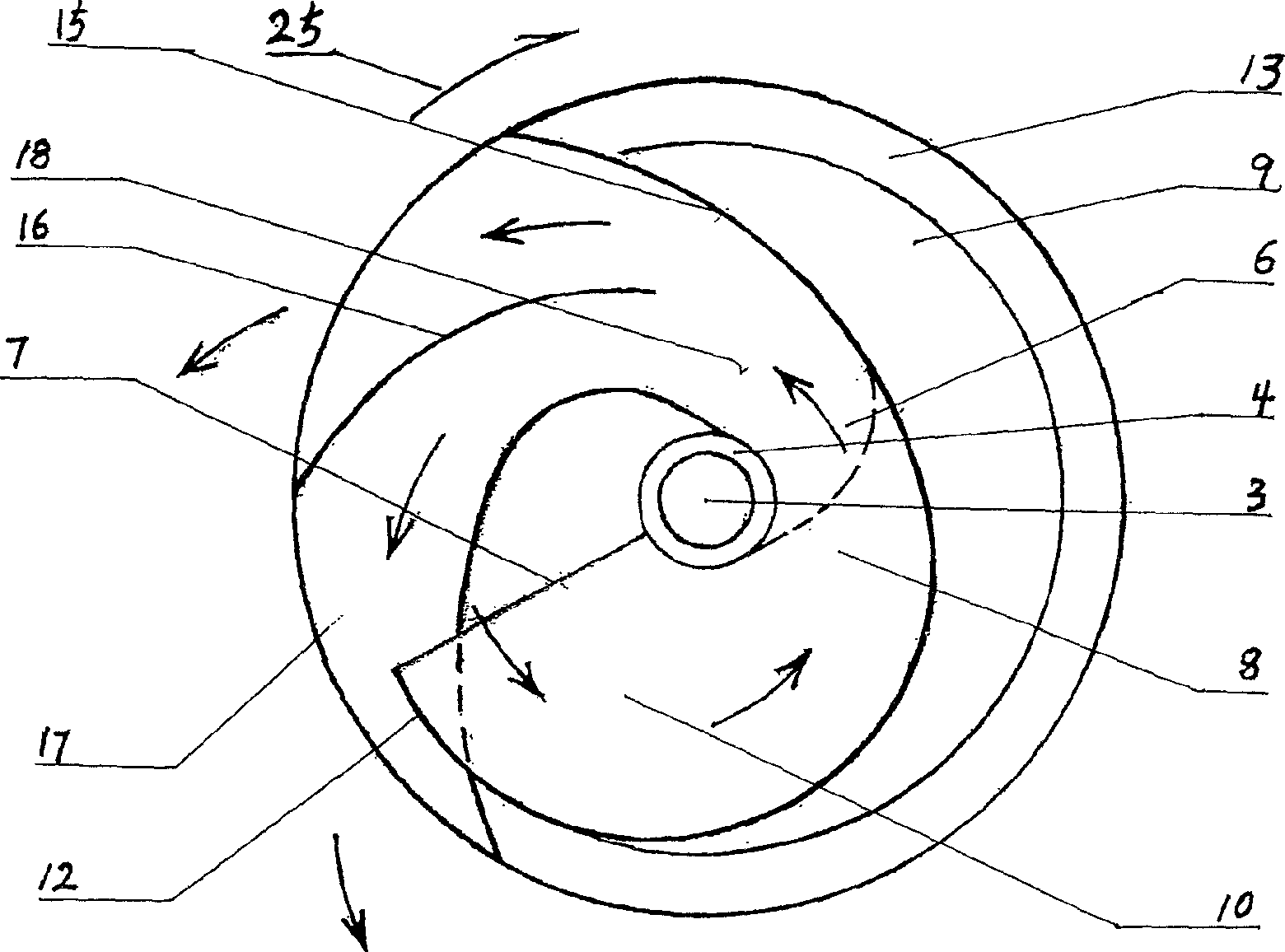

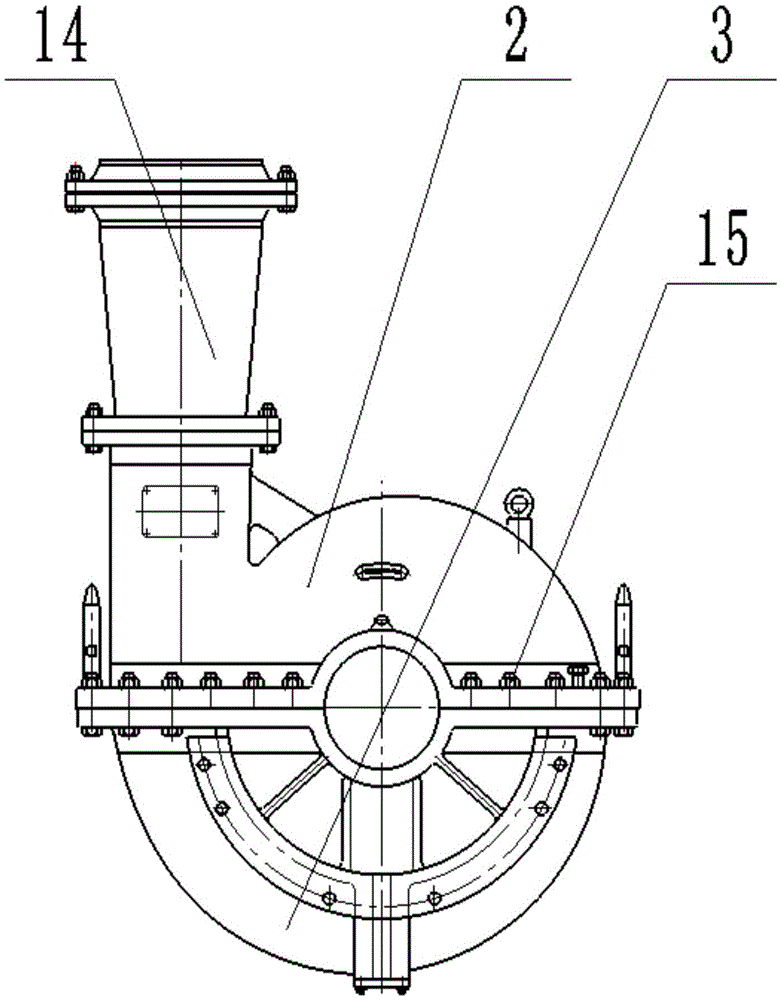

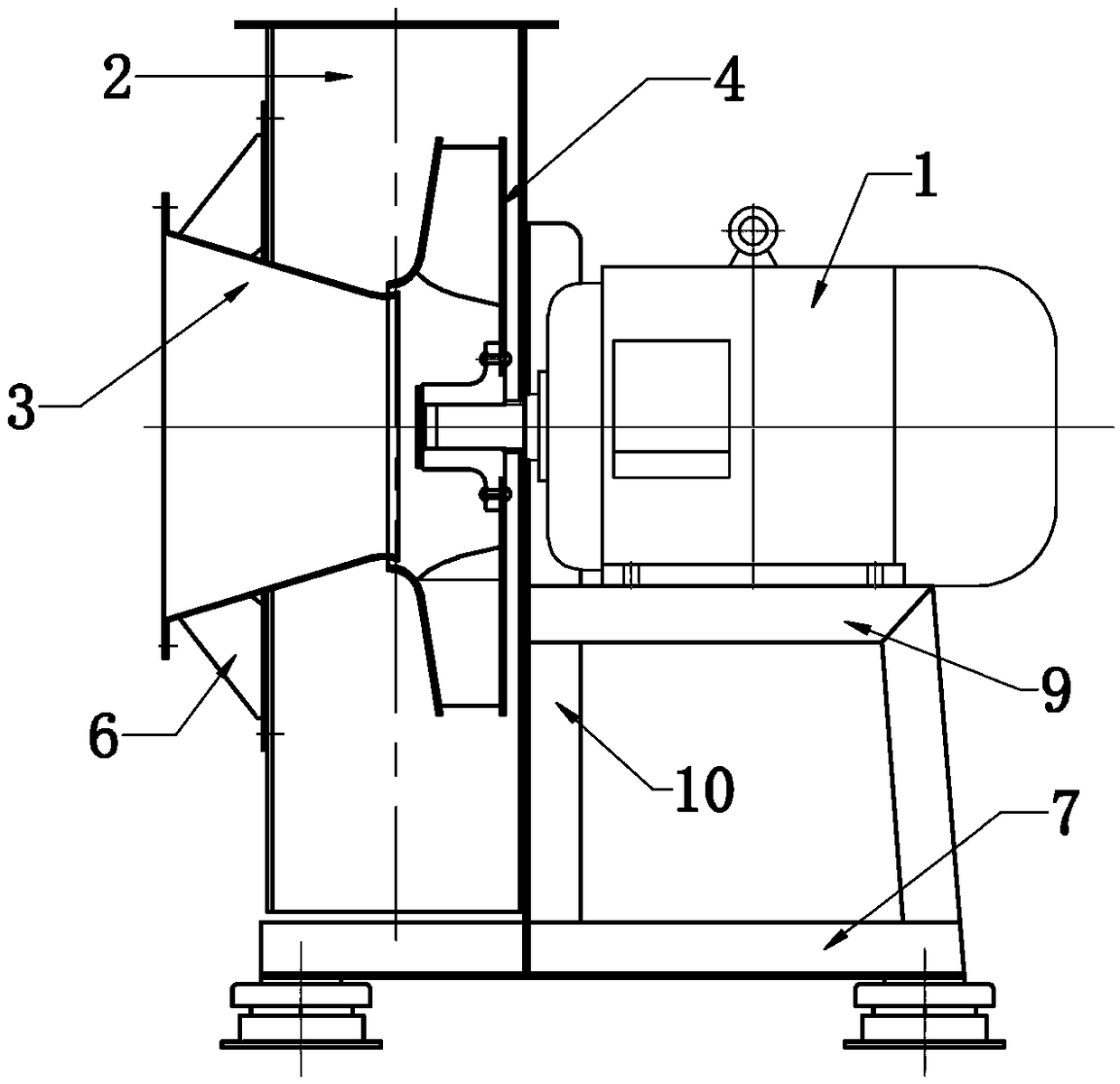

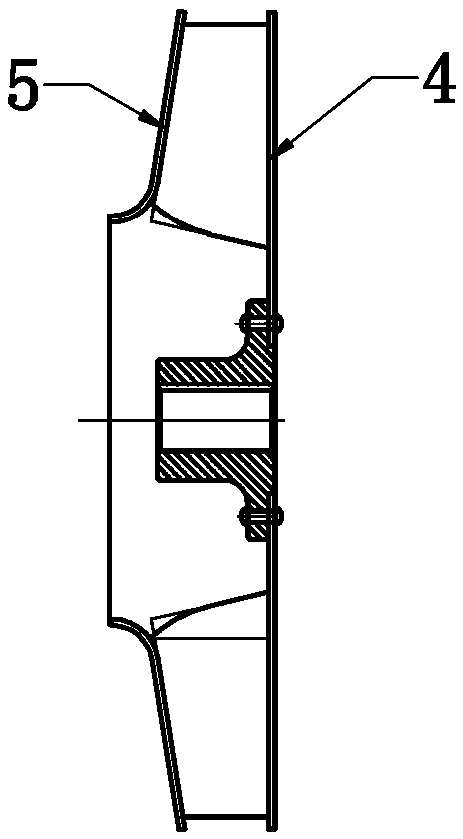

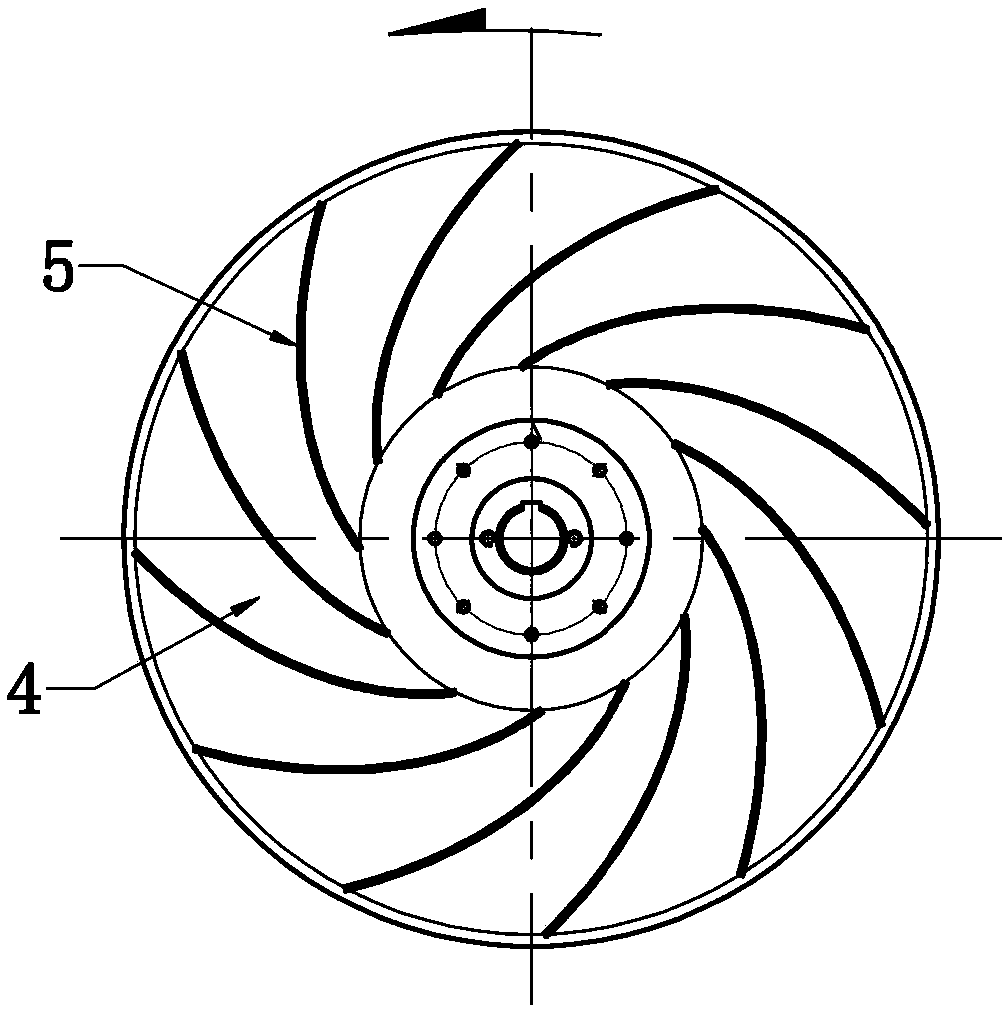

Single-suction single-stage centrifugal fan with high pressure and low flow

PendingCN109441848AImprove efficiencyMeet energy consumption requirementsPump componentsPump installationsImpellerSingle stage

The invention discloses a single-suction single-stage centrifugal fan with high pressure and low flow. The single-suction single-stage centrifugal fan comprises a driving motor, a machine shell and anair inlet ring, wherein a main shaft of the driving motor is provided with an impeller, the air inlet ring is fixedly mounted on the front side of the machine shell and extends into the machine shell, and the machine shell is arranged of a volute-shaped structure. Backward bending type blades are arranged on the end surface of the impeller, and the center of the impeller forms a circular cavity.The air inlet ring is of a cone structure with a large outer side opening and a small inner side opening, and the air inlet ring directly faces the center of the impeller and extends into the circularcavity. Each of the blades has an angle inclined from the periphery towards the center of the impeller as viewed from the side end faces, and the inner ends of the blades each have an arc angle extending outward from the center of the impeller. After adopting the structure, the design requirements of airtightness are satisfied, flow losses are reduced, and the efficiency of the impeller is greatly improved; and the structure design is compact, the size is small, a production material is saved, the requirements for energy consumption of the fan are met, the energy saving space is larger, and the overall structural strength and operational stability are further improved.

Owner:ZHENJIANG DANTU DISTRICT FOOD FACTORY

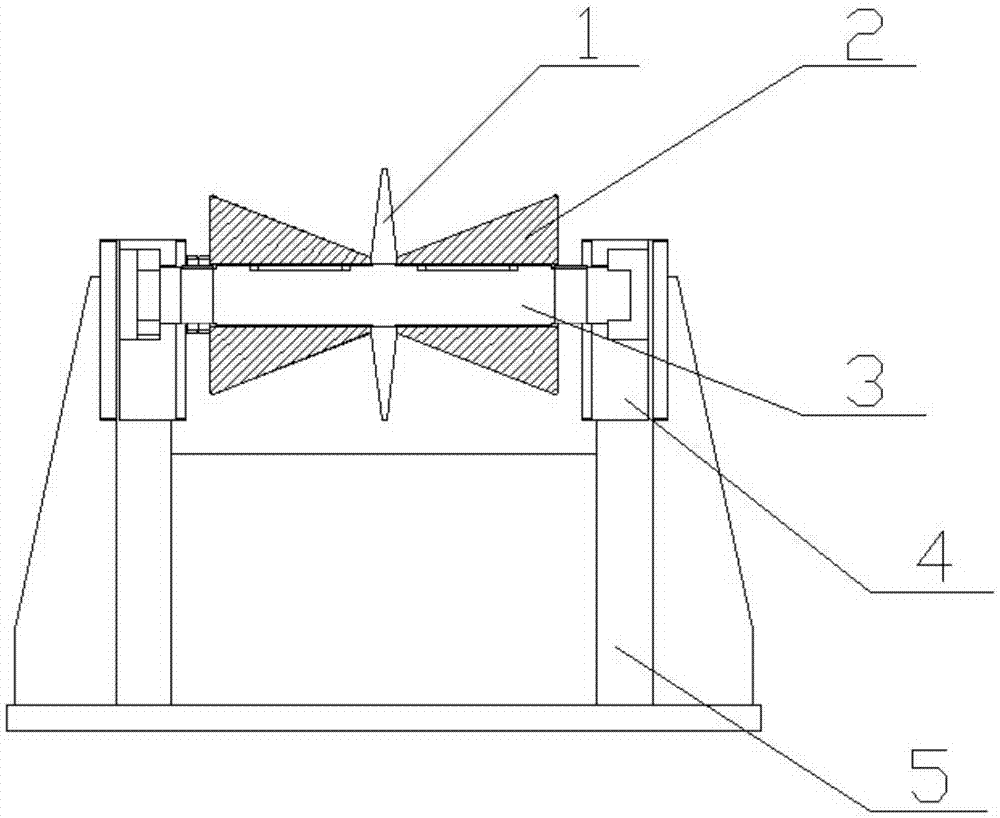

Manufacture method for guiding carrier roller in guide roller used for backward bending machine

ActiveCN105436836AStable center of gravityHigh conveying precisionMetal-working feeding devicesPositioning devicesEngineeringHigh pressure

The invention discloses a manufacture method for guiding carrier rollers in a guide roller used for a backward bending machine, belongs to the field of backward bending machines and solves the problem of low quality due to unstable transmission when a high pressure resistant steel pipe with a big caliber and a big wall thickness is processed in the prior art. The device comprises guiding carrier rollers, a rolling shaft, a rolling shaft seat and a guide roller frame, wherein the guiding carrier rollers are installed on the rolling shaft; the rolling shaft is installed on the rolling shaft seat; the rolling shaft seat is installed on the guide roller frame; the two guiding carrier rollers are of circular truncated cone shapes; the two guiding carrier rollers of the circular truncated cone shapes are installed on the rolling shaft in a way that the upper bottom surfaces of the two guiding carrier rollers are opposite; a guide pulley is arranged between the two guiding carrier rollers of the circular truncated cone shapes and is of a disk shape, and the center position is thicker than the edge position. The device can accurately capture the center of gravity of a steel pipe to be processed, the openings of the steel pipes are always kept on the same straight line, steel pipe conveying stability is greatly improved, and steel pipe processing quality is improved.

Owner:安徽五洋机床制造有限公司

A low specific speed impeller and its blade design method

InactiveCN103291653BReduce the cross-sectional areaSatisfy the no-overload characteristicPump componentsPumpsImpellerEngineering

The invention discloses a low-specific-speed impeller and a design method for a blade of the low-specific-speed impeller. Both a front cover plate and a rear cover plate are of disc structures. The blade is designed according to the method that a column and twisting are combined, namely, a working face (4) or a back face (5) adopts a form of a backward bending column blade and the other side adopts a backward bending blade twisting mode, and therefore the blade accords with the law of fluid motion, reduces hydraulic loss, and improves efficiency of a low-specific-speed centrifuging pump. The thickness of the inlet edge, close to the front cover plate, of the blade is 2-3mm, the thickness of the inlet edge, close to the rear cover plate, of the blade is 5-7mm, and therefore sand mould casting lifting precision is improved, inlet flow passages can be partially blocked, and therefore blade inlet excluding coefficient is reduced, and the non-overload characteristic of the low-specific-speed centrifuging pump is improved. The low-specific-speed impeller and the design method for the blade of the low-specific-speed impeller can be applied to the field of efficient non-overload low-specific-speed impeller designing.

Owner:JIANGSU UNIV

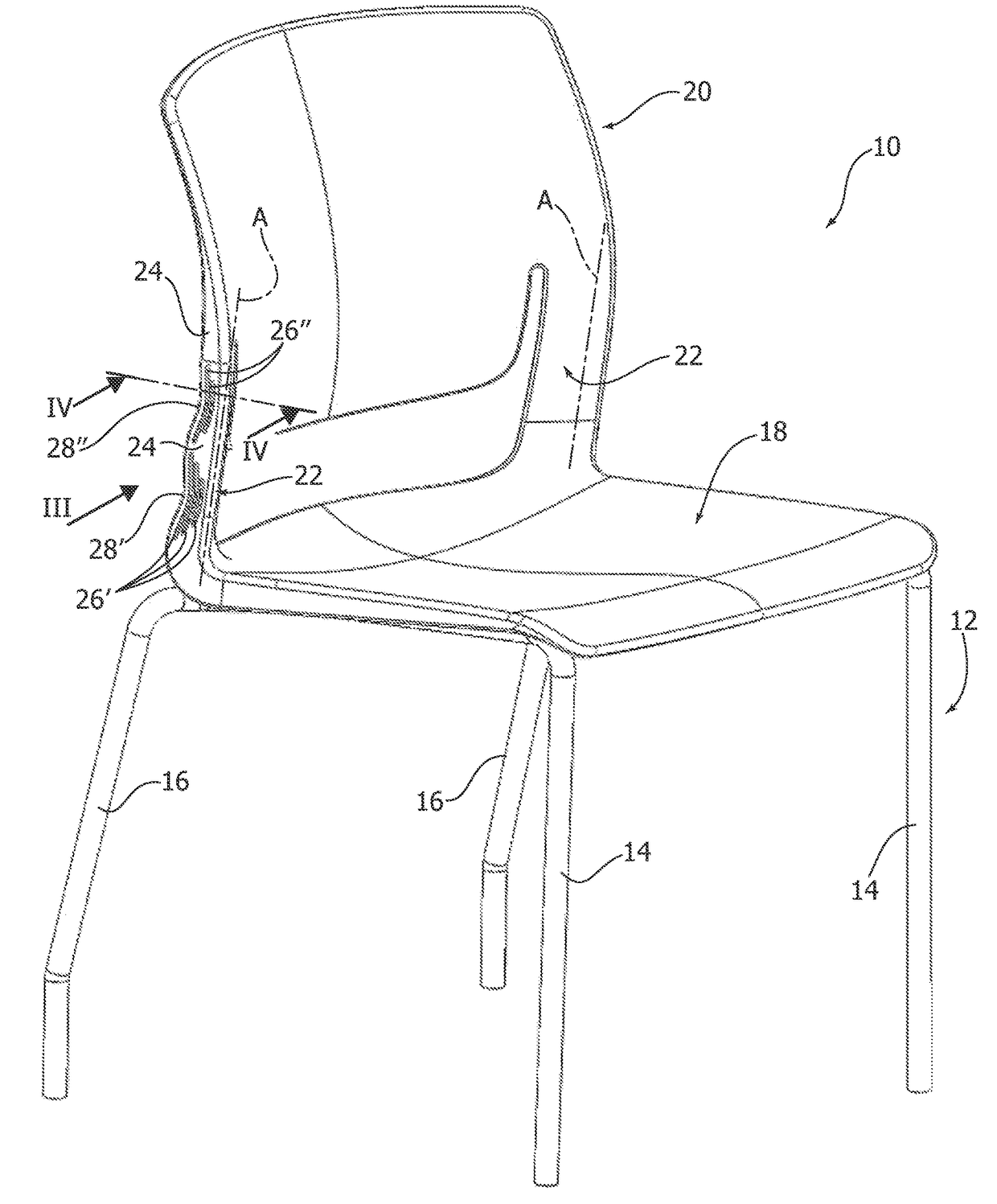

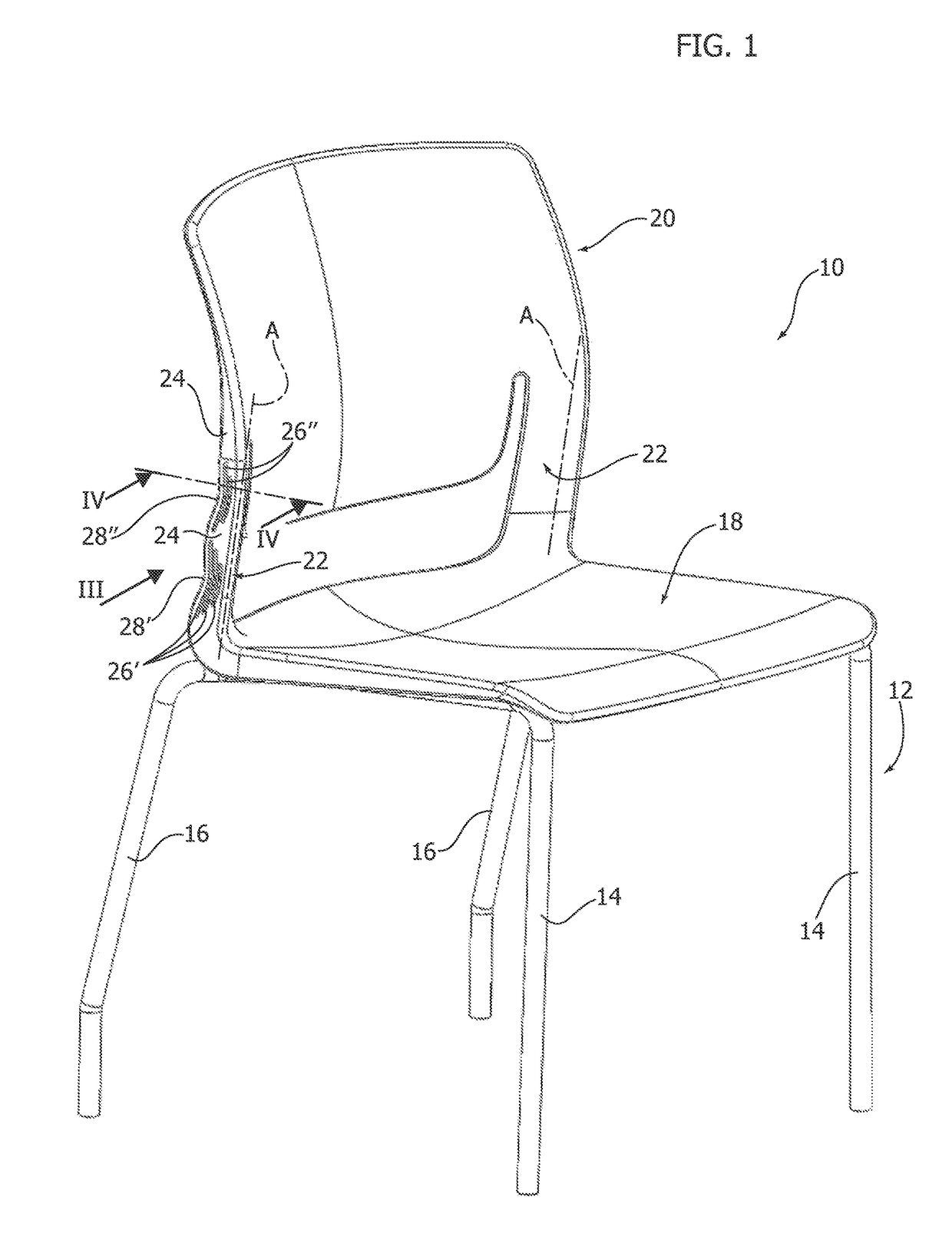

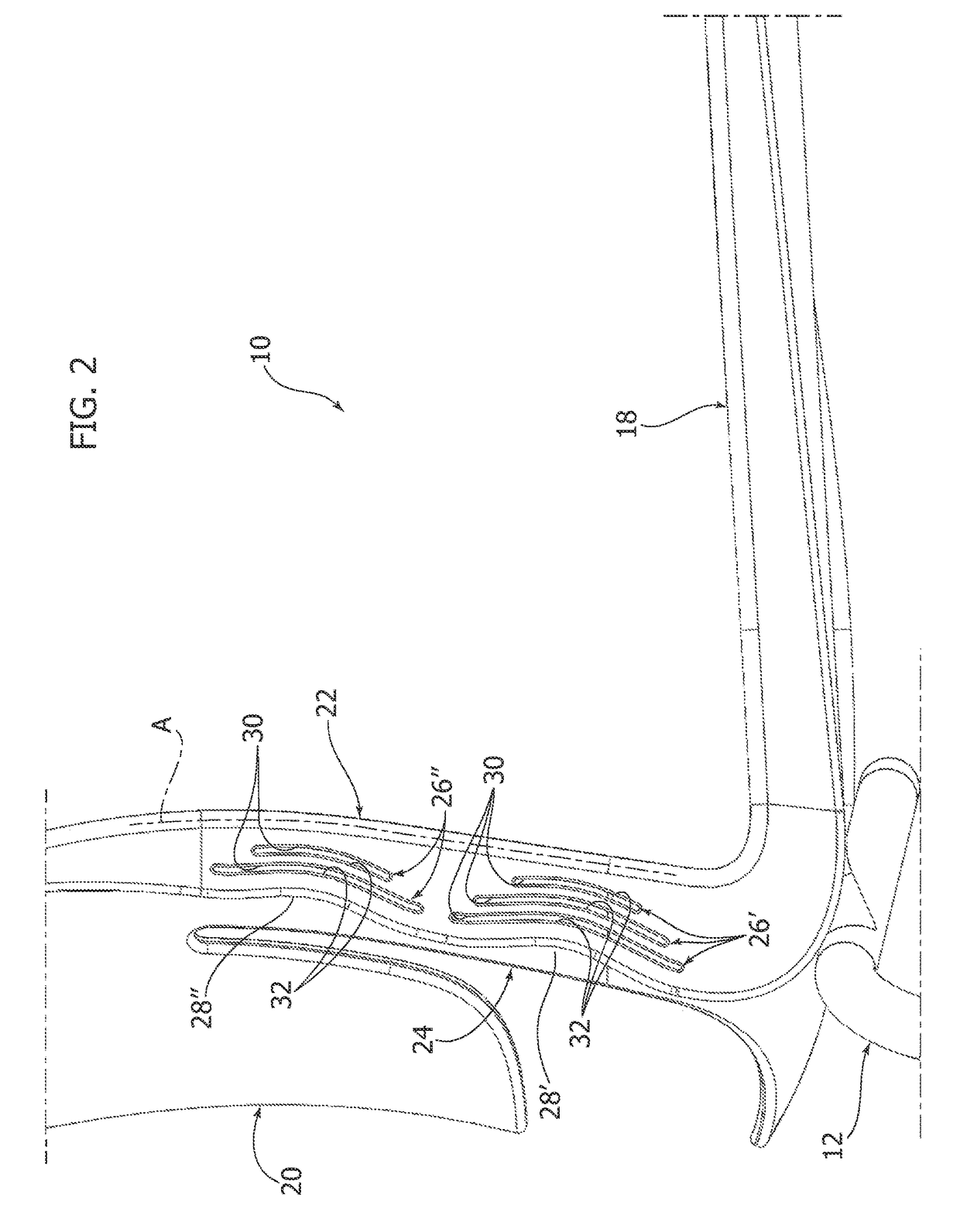

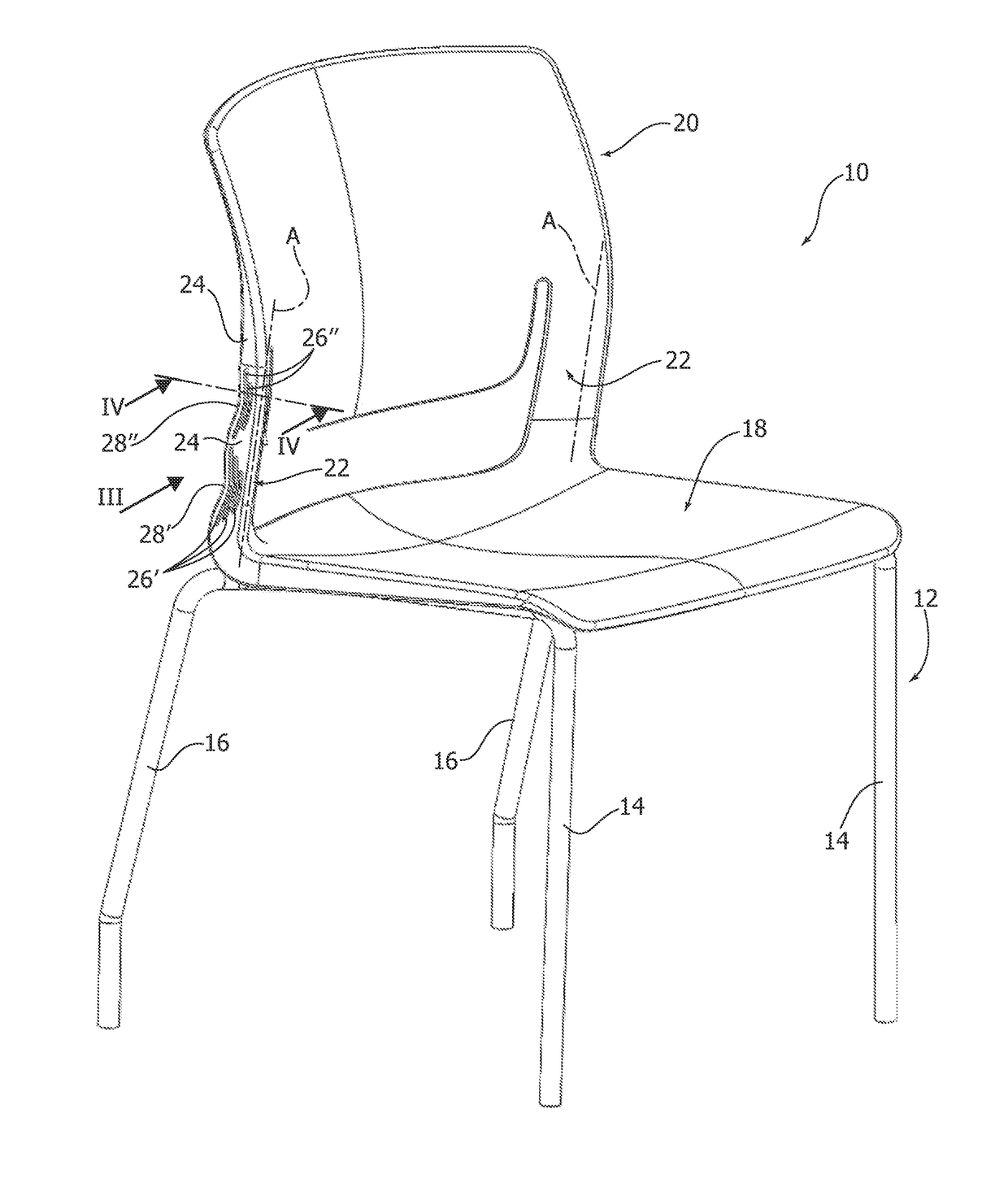

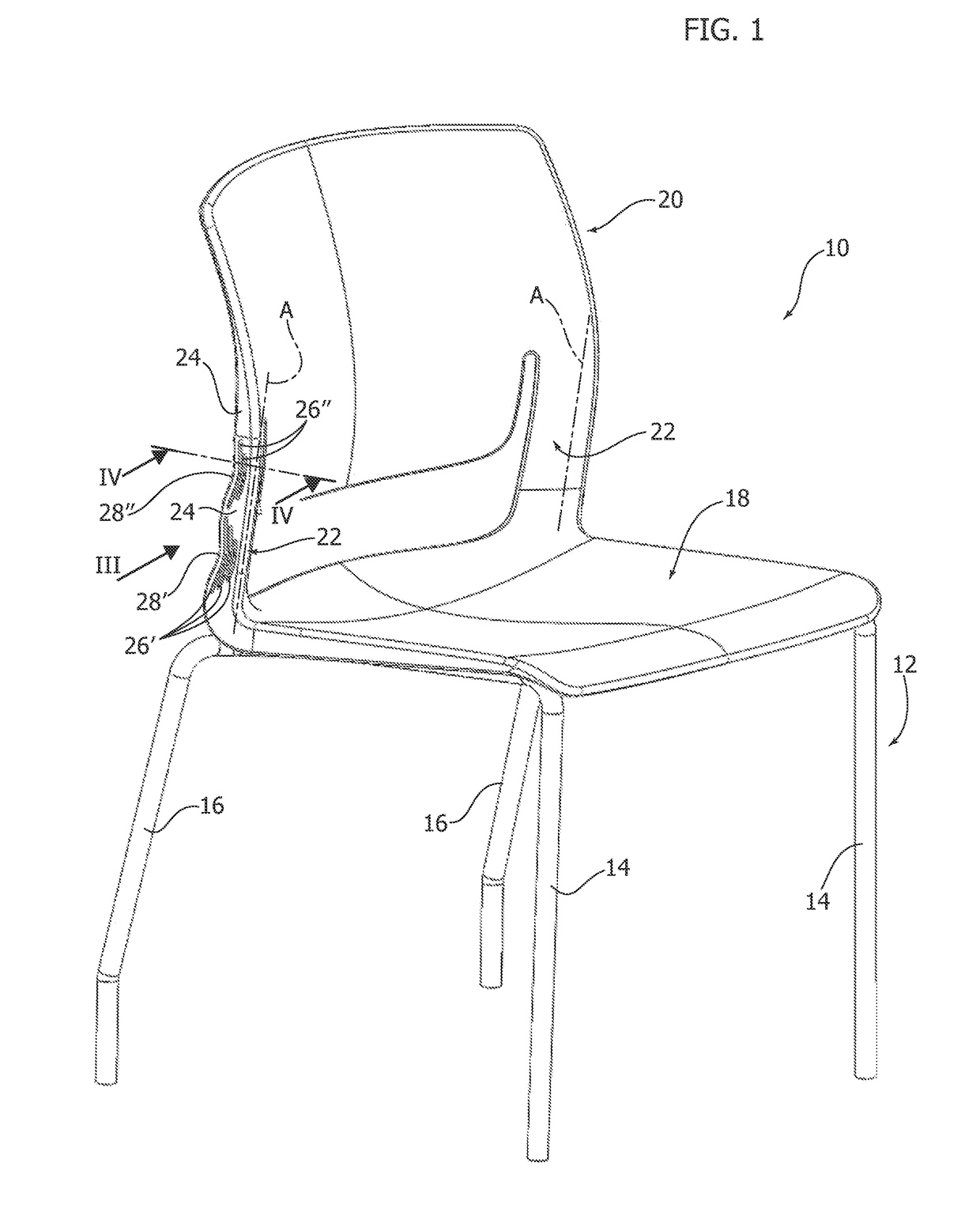

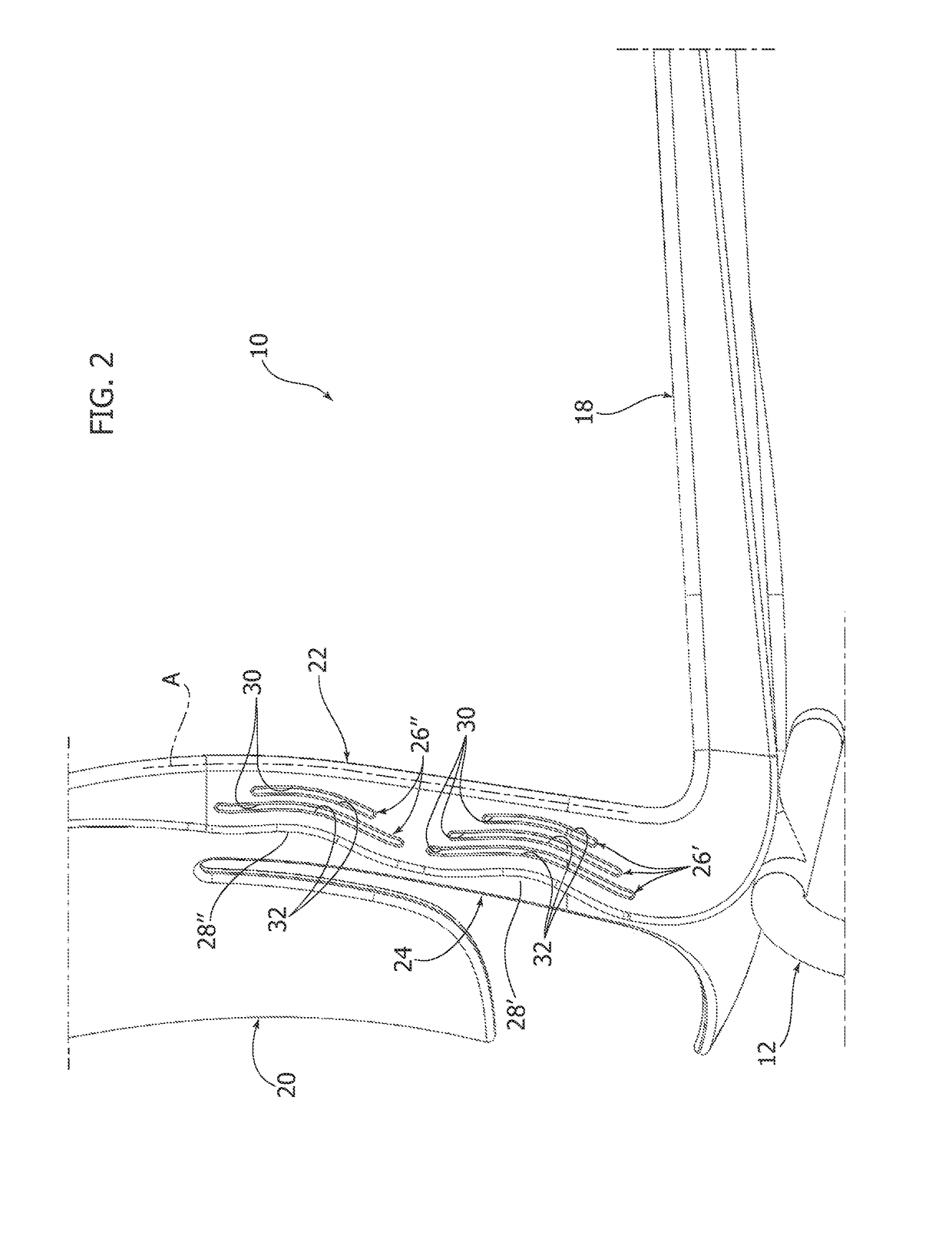

Chair with a tilting backrest

A chair comprising: a support structure, a seat fixed to the support structure, and a backrest connected to the seat by means of at least one upright of plastic material, wherein said at least one upright is elastically deformable to allow a movement of the backrest between a rest position and a tilted position, wherein said at least one upright is provided with at least one vertical rib having at least one localized bending zone wherein at least one through-cut is formed, which allows bending of the vertical rib, and wherein said at least one through-cut has a first and a second stop surface that come into mutual contact in the backwards inclined position of the backrest to stop the backward bending of the upright, wherein said at least one through-cut has the shape of a closed arched slot, which extends generally along a vertical axis of said upright.

Owner:PRO CORD SPA

Seam enlarging mechanism for pre-backward bending processing

The invention relates to a seam enlarging mechanism for pre-backward bending processing. The mechanism which comprises a bearer is characterized in that: a support which is arranged on the bearer is provided with a rolling wheel; the support which has an L shape is pivoted to the bearer, the rolling wheel is arranged on the upper end of the L-shaped support, and an oil cylinder which is arranged on the lower end of the L-shaped support is pivoted to the bearer; the seam enlarging mechanism which is adopted is convenient for a pipe barrel to enter the backward processing and not be locked; and the L-shaped support which can rotate is adopted and the bottom of the L-shaped support is provided with the oil cylinder, so the telescoping of the oil cylinder is convenient for adjusting the up and down movement of the rolling wheel, thereby the width of a required seam is adjusted.

Owner:SUZHOU WEIDA WELDING & CUTTING TECH

Chair with a tilting backrest

A chair comprising: a support structure, a seat fixed to the support structure, and a backrest connected to the seat by means of at least one upright of plastic material, wherein said at least one upright is elastically deformable to allow a movement of the backrest between a rest position and a tilted position, wherein said at least one upright is provided with at least one vertical rib having at least one localized bending zone wherein at least one through-cut is formed, which allows bending of the vertical rib, and wherein said at least one through-cut has a first and a second stop surface that come into mutual contact in the backwards inclined position of the backrest to stop the backward bending of the upright, wherein said at least one through-cut has the shape of a closed arched slot, which extends generally along a vertical axis of said upright.

Owner:PRO CORD SPA

Seat frame mechanism capable of adjusting sitting posture

The invention relates to a seat frame mechanism capable of adjusting a sitting posture. The mechanism comprises a front shaft, a rear shaft and a movable plate, wherein a forward-bending motor is connected with a lead screw through a forward-bending speed reducer; the lead screw is matched with a nut which is hinged at one end of a rocker; the other end of the rocker and a front downward prop bar are both fixed on the front shaft; the front downward prop bar is hinged with a front upward prop bar which is hinged with one end of the movable plate through a front rotating shaft; the transmission manner of a backward-bending motor is similar to that of the forward-bending motor; a rear prop bar of the backward-bending motor is hinged with a rear connecting rod which is hinged with a triangular swing rod; the triangular swing rod is hinged on a support through a hinge shaft; and the other end of the movable plate is hinged on the triangular swing rod through a rear rotating shaft. The mechanism overcomes the defect that the sitting posture cannot be adjusted as required in the prior art, realizes the functions of leaning forwards, bending backwards, lifting and horizontally moving of seat frames through the design, improves the use comfort, has the advantages of compact structure, convenient posture adjusting and stable operation, and can greatly improve the overall massaging property of a massage chair when combined with the massage chair.

Owner:ZHEJIANG HAOZHONGHAO HEALTH PROD

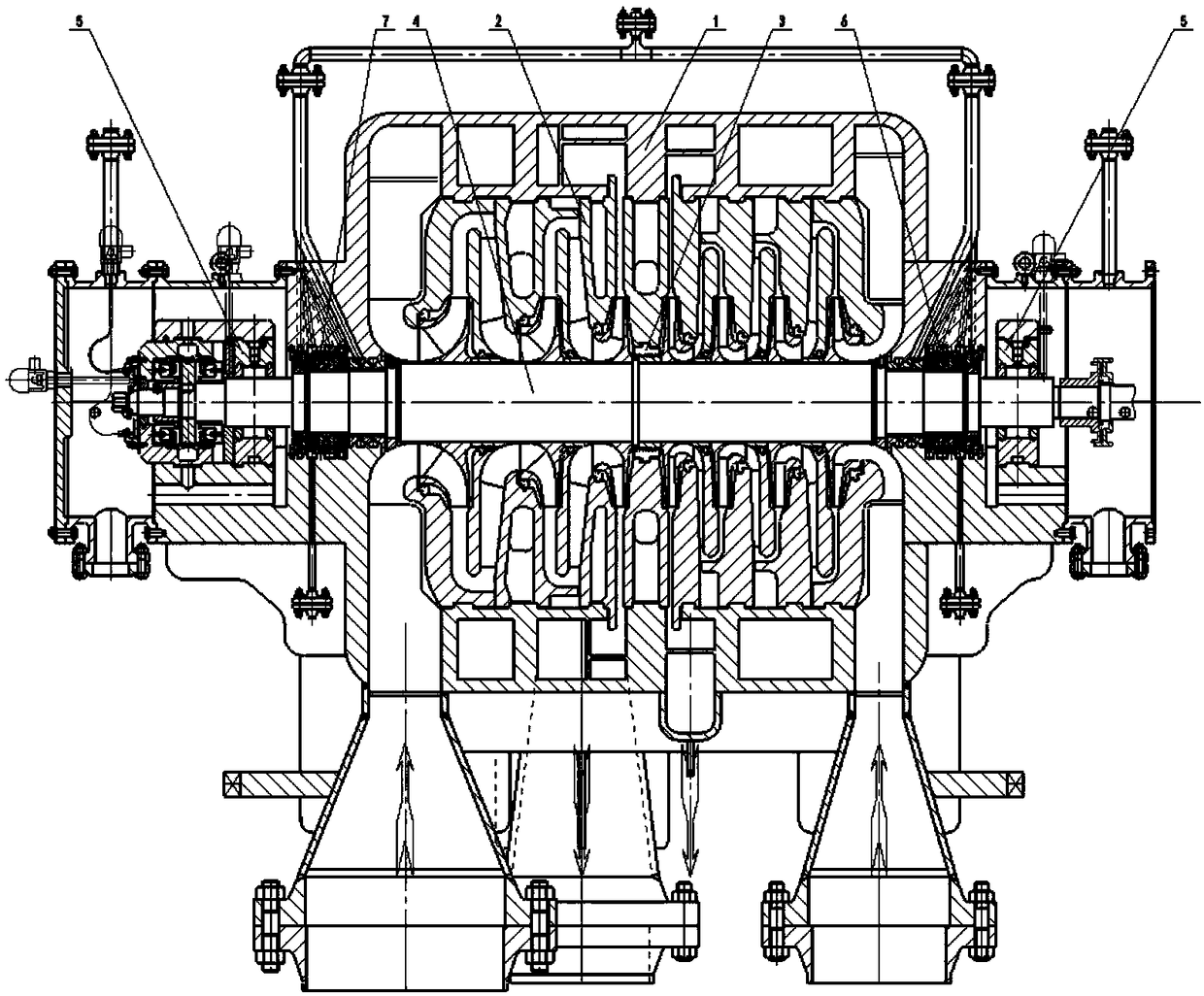

VPSA large-capacity centrifugal vacuum pump

PendingCN106593899ARelieve pressureIncrease pressurePump componentsRadial flow pumpsEngineeringCyclic compression

The invention relates to a VPSA large-capacity centrifugal vacuum pump. A backward bending type three dimensional impeller and a vaneless diffuser are adopted in each stage of the VPSA large-capacity centrifugal vacuum pump, a cooler is installed between every two sections, a cooler is installed on the outlet of the last section, and three coolers exist. An air inlet chamber and an air outlet spiral chamber are installed in every section, and three air inlet chambers and three air outlet spiral chambers exist. The air inlet chambers are double bracing radial air inlet chambers, and the air outlet spiral chambers are circular symmetrical spiral chambers. When the VPSA large-capacity centrifugal vacuum pump works, air is sucked through the air inlet chambers and rotates at high speed with the first-stage impeller; under the effect of centrifugal force, the kinetic energy and the static energy of the air are increased and threw out through passageways among vanes in the radial direction, and enter the first-stage diffuser with a gradually enlarged passageway area; the kinetic energy of the air is reduced and conversed into the static energy, the pressure of the air is increased, and then the air passes through a first-stage bending way and a return device and enters the second stage to be compressed continuously. Cyclic compression is conducted in sequence, after the last compression is completed, and the air is collected through a spiral shell and discharged through an exhaust pipe. As the exhausting process is conducted continuously, the mass flow rate is continuously reduced, inlet pressure is continuously reduced, the vacuum degree is continuously improved, and until the next cycle period, a unit is under the operating process with continuous changeable working conditions.

Owner:JIANGSU ASIA PACIFIC IND PUMP TECH DEV CO LTD

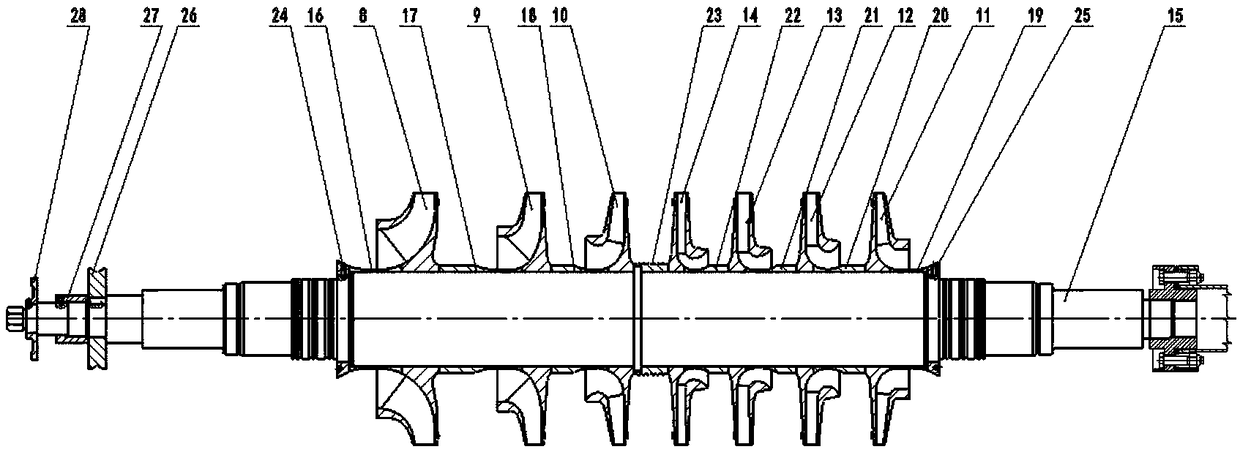

Centrifugal compressor for butadiene C4 deep processing device

The invention provides a centrifugal compressor for a butadiene C4 deep processing device. The centrifugal compressor is mainly composed of a stator group (comprising a machine shell, an isolation plate, a balance disc seal, an opening ring seal, an end cover and the like), a rotor group (including a main shaft, impellers, a spacer bush, a balance disc and the like), a bearing group (including a supporting bearing and a thrust bearing), a dry gas seal and the like, and is characterized in that (1) the compressor is provided with two sections of inlets / outlets and adopts a horizontal subdivision structure; (2) the compressor is provided with seven or eight impellers and the diameter of the impellers is phi520mm; all the impellers adopt backward bending blade type impellers; (3) matching andfixing each grade of separation plate and a seam allowance on the machine shell; (4) the supporting bearing adopts a tilting pad bearing; two sides of the main shaft adopt same structures at two sides and the thrust bearing is a Kinsbury type; (5) the balance disc is mounted at one side with high pressure and is used for balancing an axial force. The compressor provided by the invention is especially suitable for being applied to a butadiene C4 deep processing technology and very considerable economic benefits can be obtained.

Owner:SHENYANG SITE MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com