Centrifugal supercharger

A supercharger, centrifugal technology, applied in the field of superchargers, to achieve the effect of improving product life, stable and safe mechanical transmission, and improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

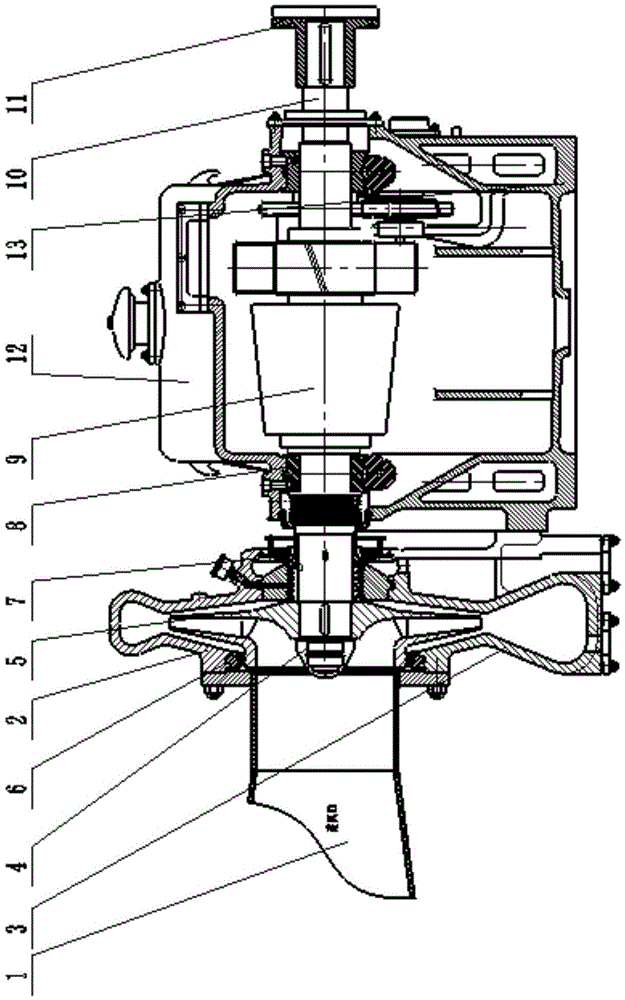

[0017] Hereinafter, the centrifugal supercharger of the present invention will be further described in detail with reference to the drawings and specific embodiments.

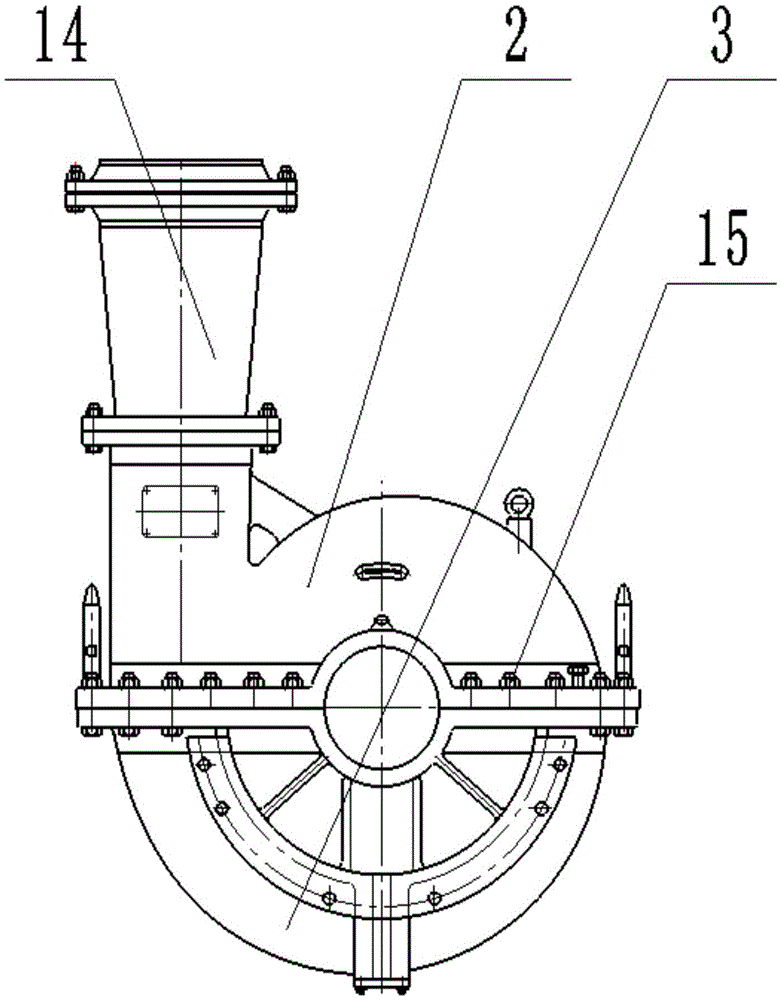

[0018] figure 1 It is a front cross-sectional view of the centrifugal supercharger of the present invention, as shown in the figure. The centrifugal supercharger includes the air inlet cylinder 1, the upper volute 2, the lower volute 3, the shaft end nut 4, the impeller 5, the sealing assembly 6, the exhaust wheel 7, the bearing 8, the pinion shaft 9, and the power input shaft 10. , Coupling 11, upper machine cover 12, lower machine base 13. The impeller 5 and the exhaust wheel 7 are installed on the pinion shaft, the impeller is fixed by the shaft end nut 4, the installed pinion shaft is placed on the lower frame with bearing support, and the power input shaft 10 passes through a large gear and a small gear. The gear shaft is combined, and the upper machine cover and the lower machine base are installed.

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com