Bucket screw centrifugal vane of fan and application method of said vane in fluid delivering thereof

A technology of centrifugal impeller and bucket screw, which is applied to the centrifugal impeller of turbofan bucket screw and the application field of the impeller in fluid transportation, and can solve the problems of advanced design of impeller without substantial breakthrough, need of diffuser reflux device, insufficient improvement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to understand the above-mentioned features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific application examples.

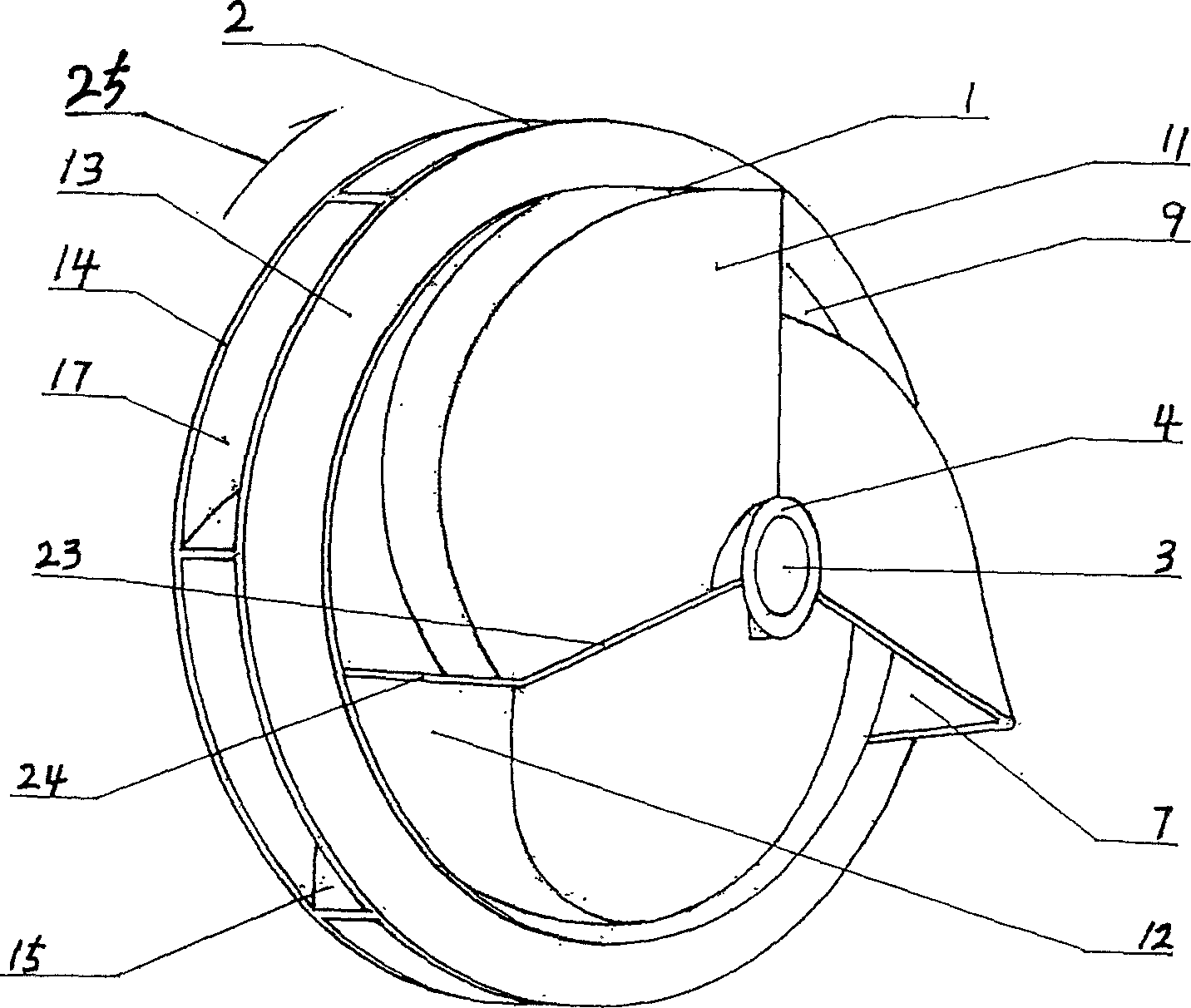

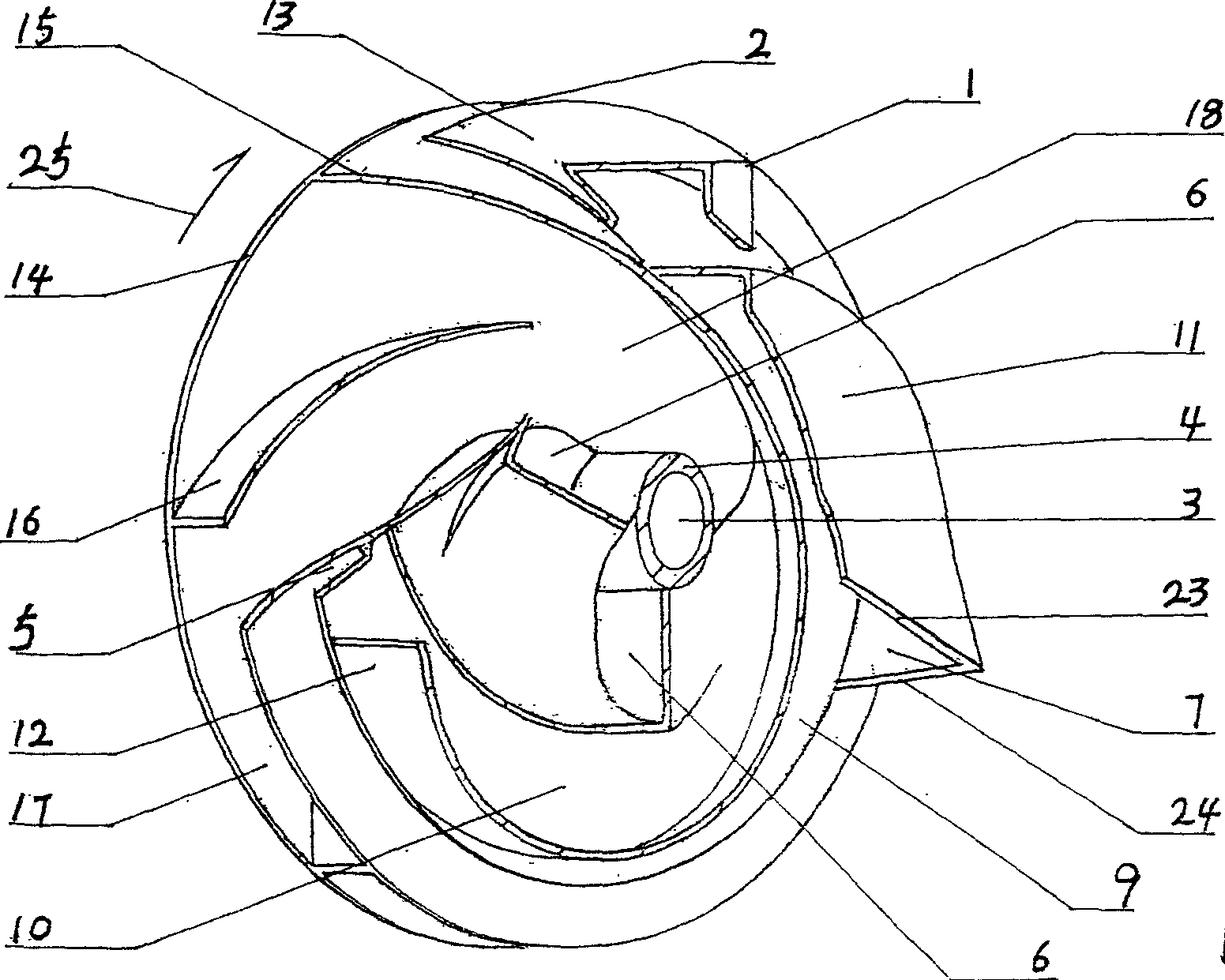

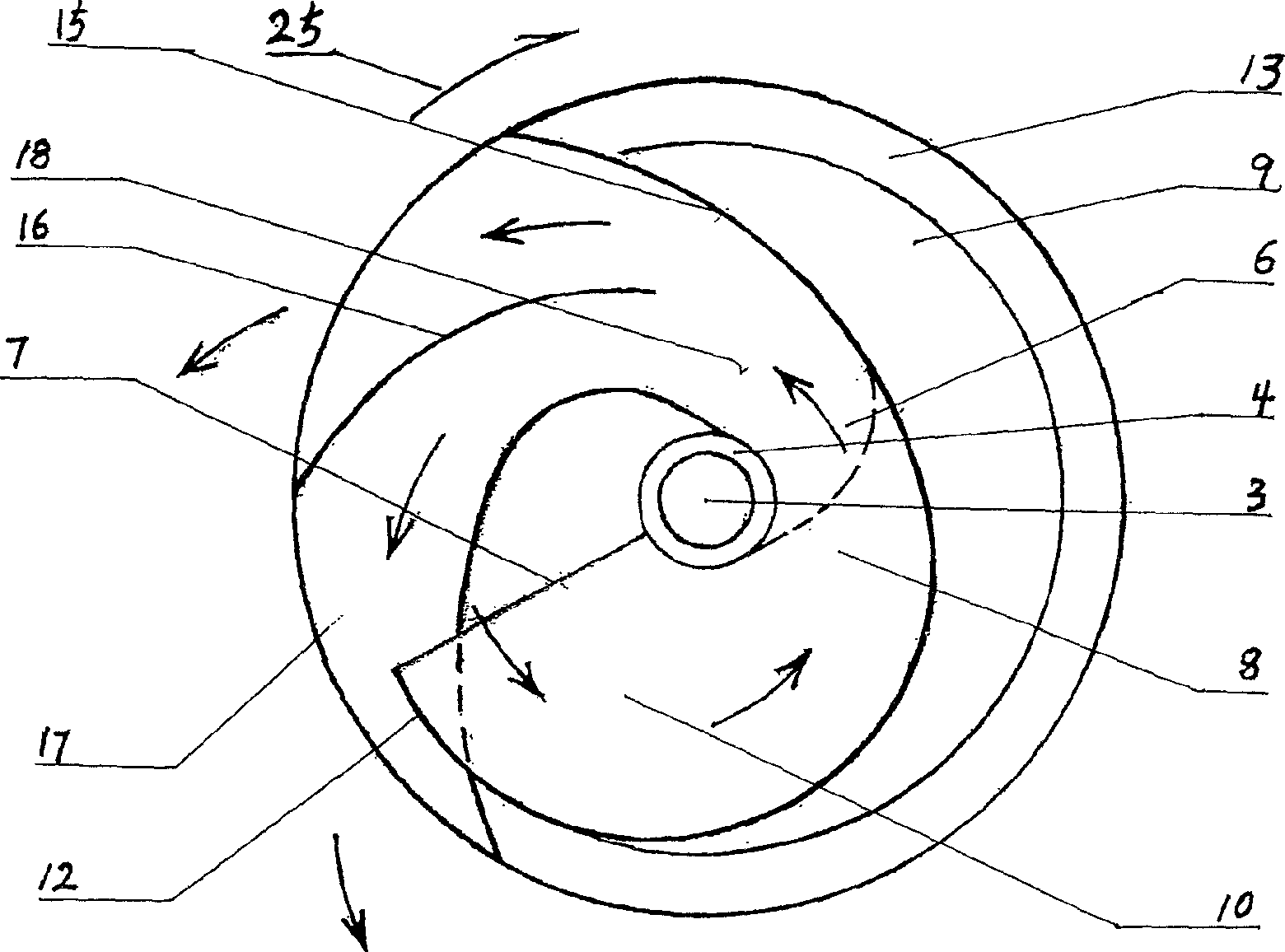

[0038] In the embodiment, there are three main channels and a turbofan bucket spiral centrifugal impeller with an isolation sealing groove.

[0039]The turbofan bucket spiral centrifugal impeller consists of the impeller as a whole; the front and rear stages are each in the shape of a flat cylinder in the axial direction, and the center of the axial circular surface; the power shaft hole and hub that run through the central axis of the front and rear two stages, and the front stage turbofan bucket The impeller: three axial turbofan blades uniformly arranged on the outer peripheral surface of the hub at constant intervals and three radial scroll blades uniformly arranged on the axial peripheral surface of the rear disc with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com