Axial plunger type variable capacity pump

A plunger type, variable displacement pump technology, applied in the field of variable displacement pumps, can solve the problems of large energy consumption, slow return speed, slow righting speed of swash plate, etc., and achieve reasonable force application, rapid adjustment and fast response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

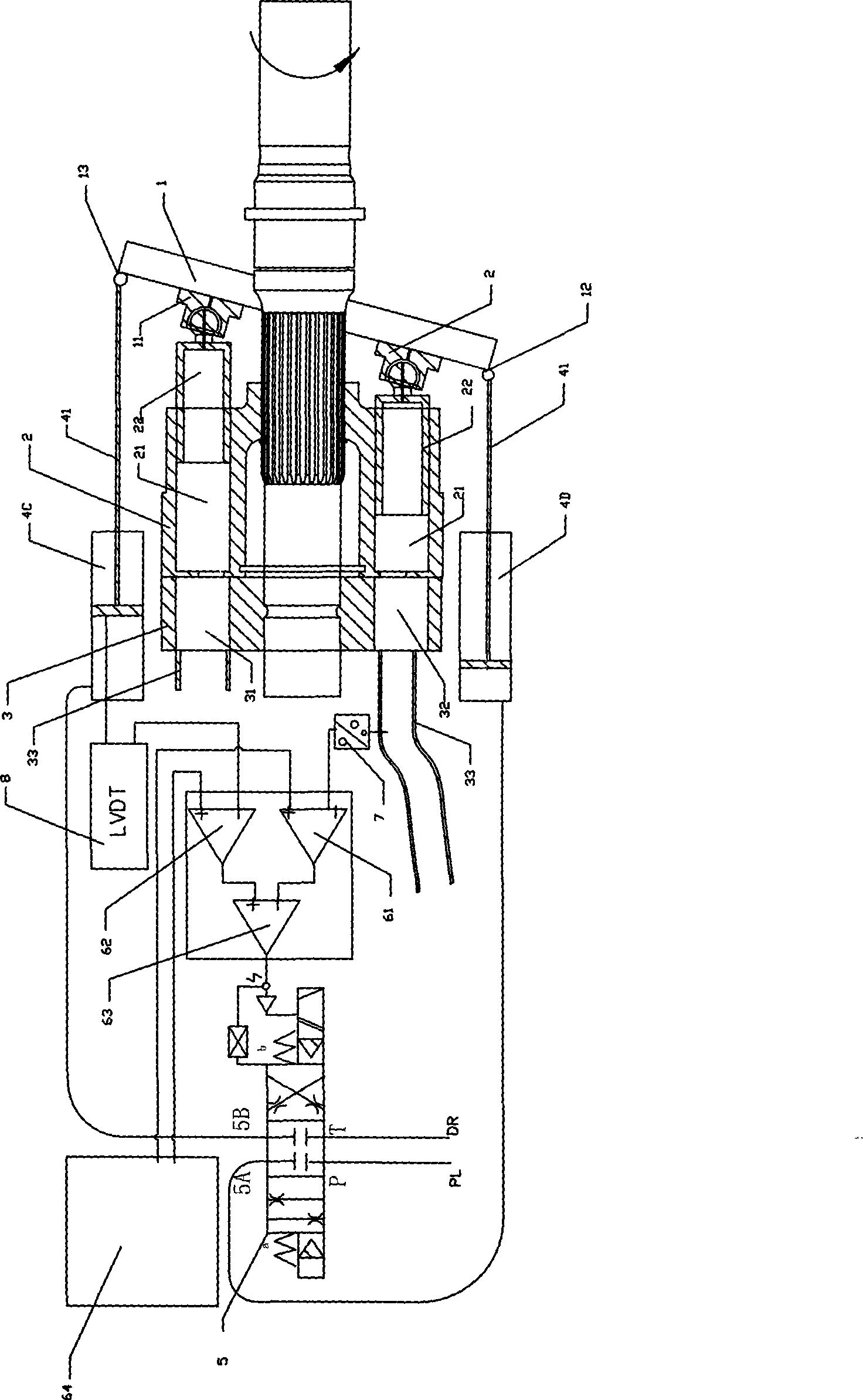

[0041] refer to figure 1 , figure 2 :

[0042] The axial piston type variable displacement pump described in the present invention includes:

[0043] The swash plate 1 hinged on the swash plate seat in a manner that can change the relative inclination angle;

[0044] A rotatable plunger cylinder 2, the cylinder 2 is arranged with an axial plunger hole 21 along the circumferential direction; the front part of the plunger hole 21 is provided with a plunger 22, and the plunger 22 The front end of the swash plate is connected to a sliding shoe 11 that can slide on the surface of the swash plate 1 in the form of a ball joint;

[0045] The rear part of the plunger cylinder 2 is connected to an oil distribution pan 3, and the oil suction port 31 and the oil discharge port 32 are arranged on the oil distribution pan 3, and the oil suction port 31 and the oil discharge port 32 are connected to the The rear part of the plunger hole 21; the oil suction port 31 and the oil discharge ...

Embodiment 2

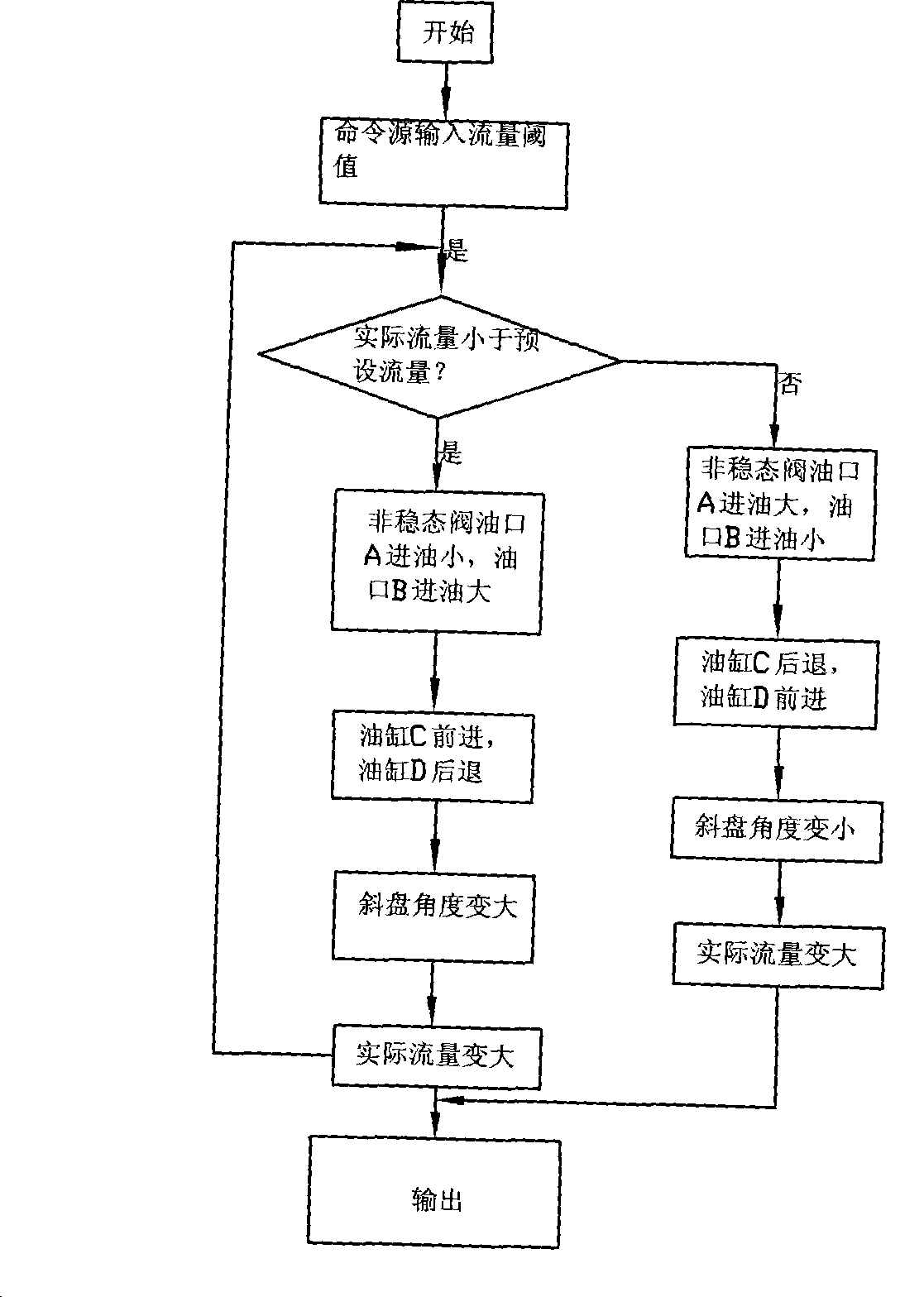

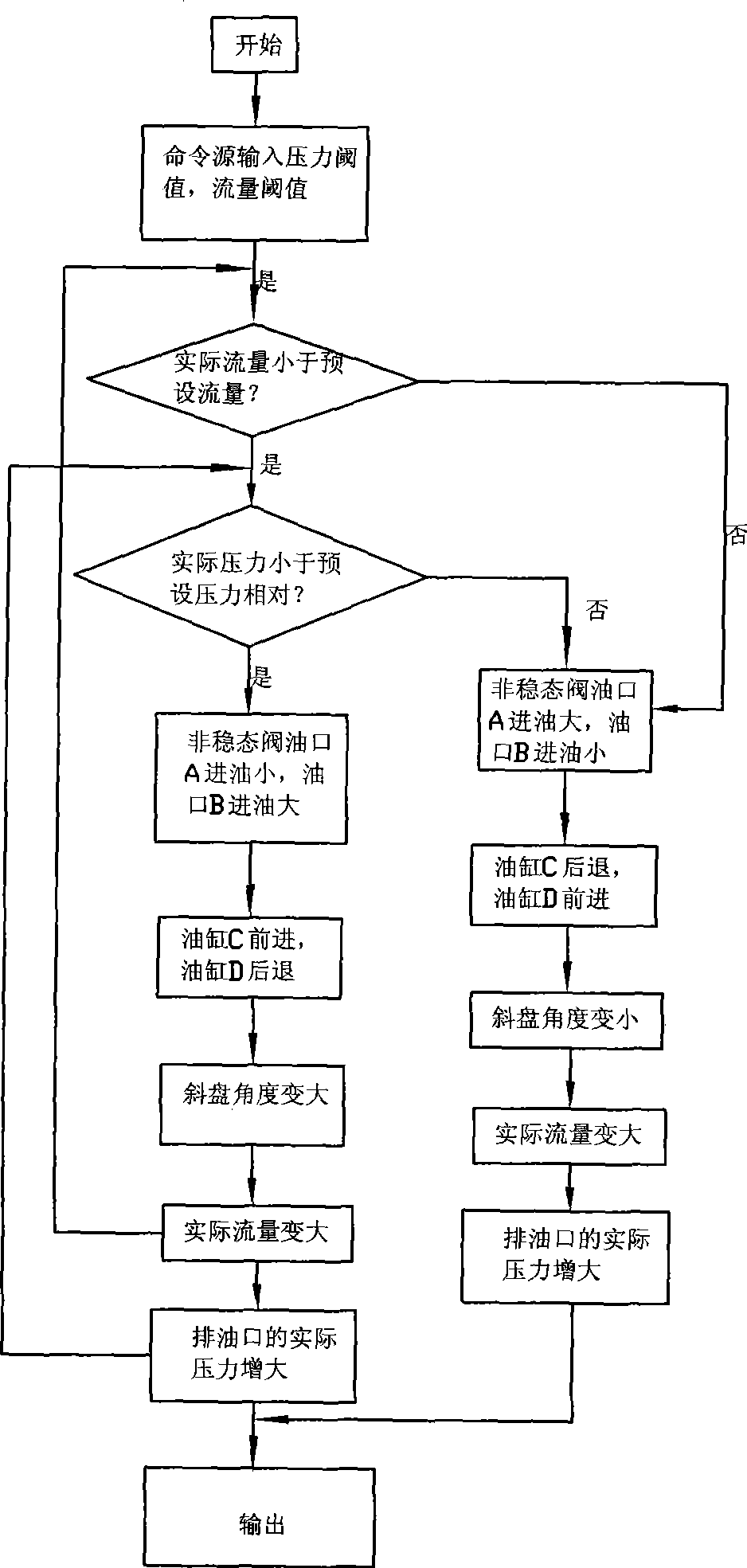

[0060] refer to figure 1 , image 3 :

[0061] The difference between embodiment two and embodiment one is:

[0062] The negative input terminal of the amplifier 63 is connected to the second comparator 62, and the positive and negative input terminals of the second comparator 62 are respectively connected to the threshold value command source 64 and a device for measuring the tilt displacement of the swash plate 1. Displacement sensor 8, the threshold command source 64 outputs the flow threshold set according to user needs, the displacement sensor 8 outputs a displacement signal corresponding to the actual flow, and the second comparator 62 outputs the flow threshold and the actual flow comparison results.

[0063] The controller is provided with a mode selection module, and the mode selection module controls the amplifier 63 to select a pressure mode or a flow mode or a flow-pressure mode to control the unsteady valve;

[0064] The amplifier 63 selects the flow-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com