Elevator safety inspection method based on number of bending times of elevator rope

A technology of bending times and wire ropes, used in elevators, transportation and packaging, etc., can solve problems such as low work efficiency of staff, wire fatigue, and decreased toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

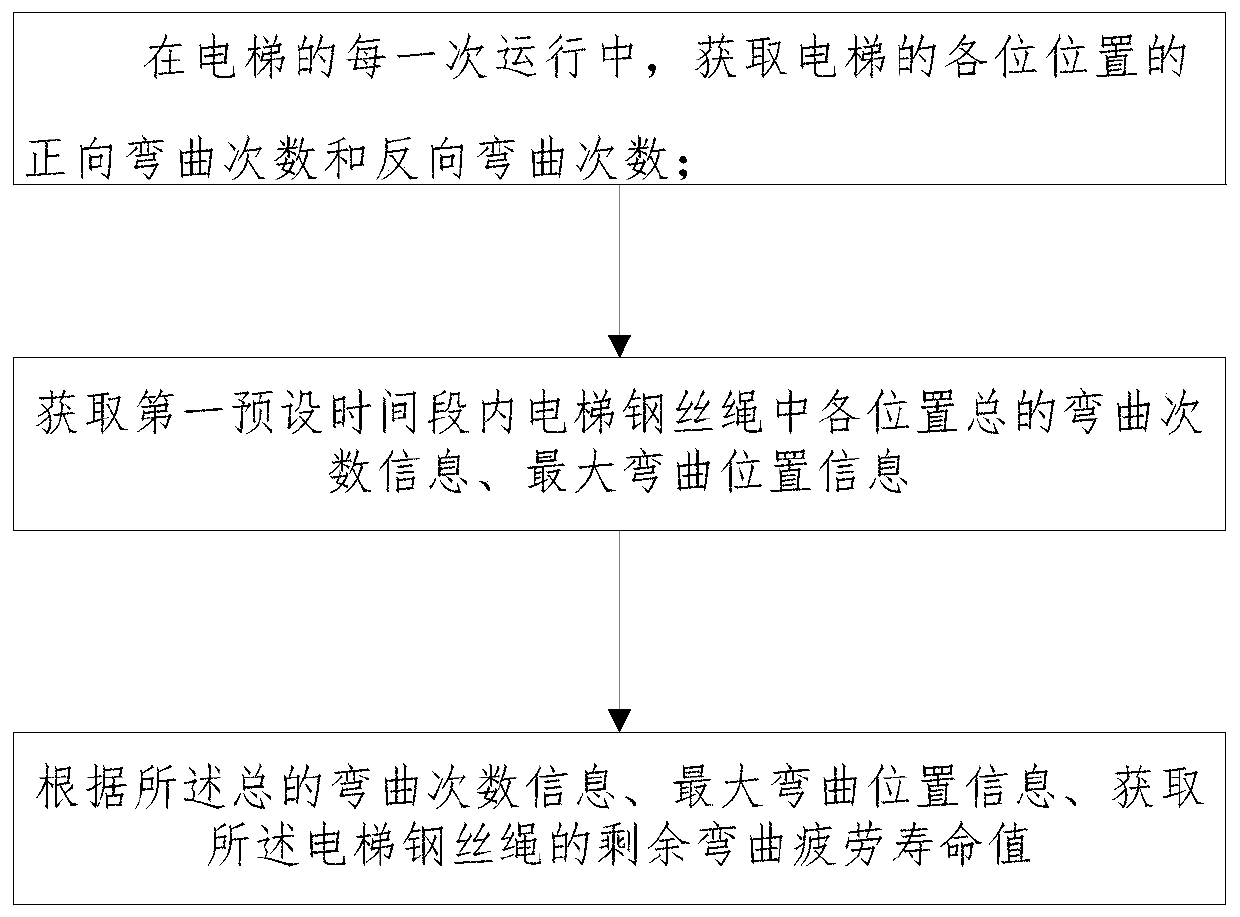

[0118] Step 1. In each operation of the elevator, based on the information on the number of destination floors received by the elevator control board and the basic information of the elevator, obtain the number of forward bending times and the number of reverse bending times at each position of the elevator.

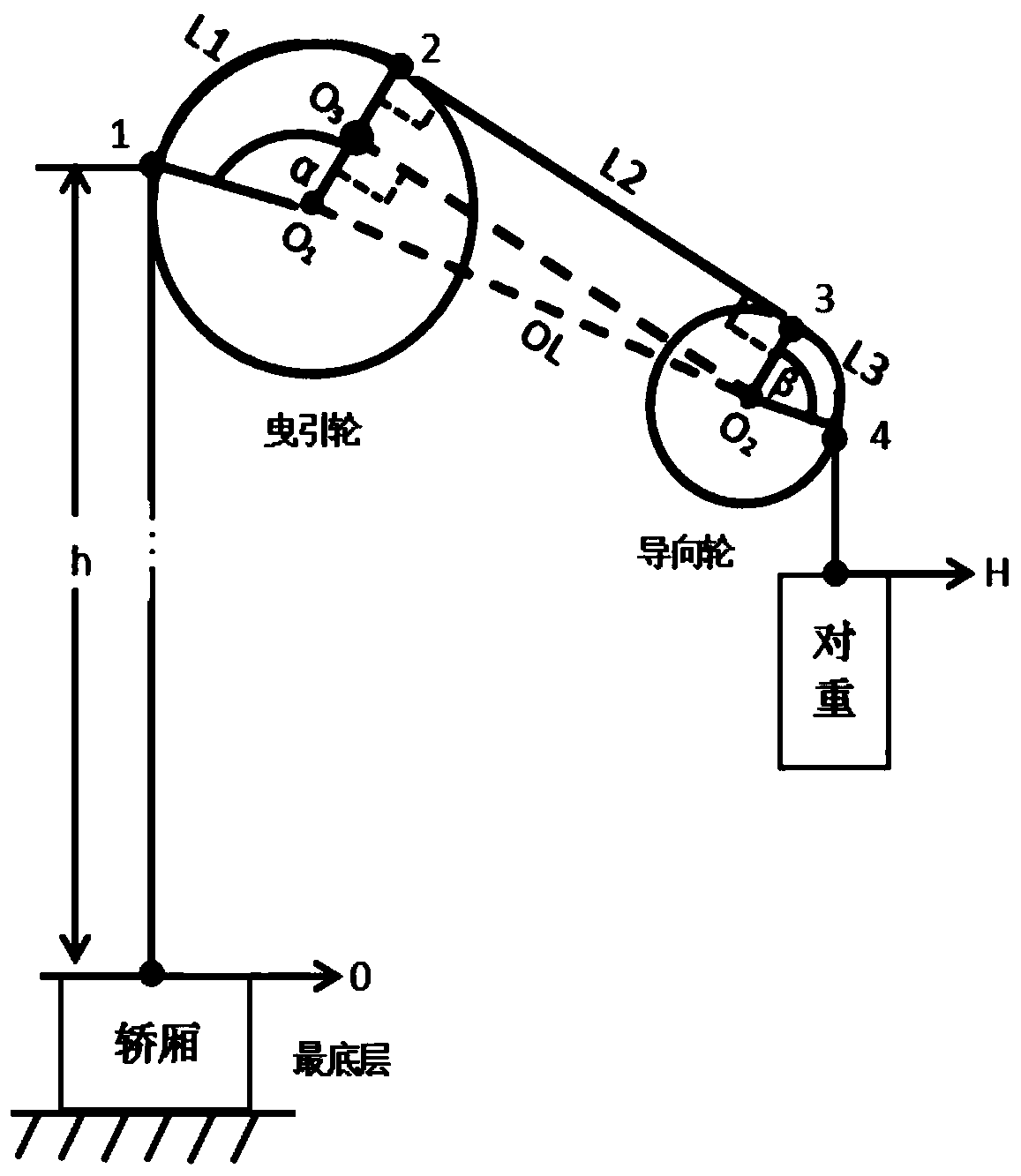

[0119] Please refer to the attached figure 2 As shown, in this embodiment, based on the basic information of the elevator, the length L1 of the steel wire rope wound on the traction sheave during elevator operation is obtained according to the formula (a); where L1 is the first contact geometric tangent point 1 between the steel wire rope and the traction sheave The length of the wire rope from the position to the second geometric tangent point 2 of the wire rope and the traction sheave;

[0120] Formula (a):

[0121]

[0122] Where α: indicates the wrap angle between the wire rope and the traction sheave;

[0123] D1: Indicates the diameter of the traction sheave....

Embodiment 2

[0179] The present embodiment is as shown in Table 1 with reference to the elevator parameters of a certain business building.

[0180] Table 1 The main parameters of the example elevator

[0181]

[0182] Q1: In this implementation, the diameters of the traction wheel and the guide wheel are 400 mm and 380 mm (mm), and the wrap angles are α=150° and β=120°. The distance between the two wheels is 2 meters. Get the following length parameters:

[0183]

[0184]

[0185]

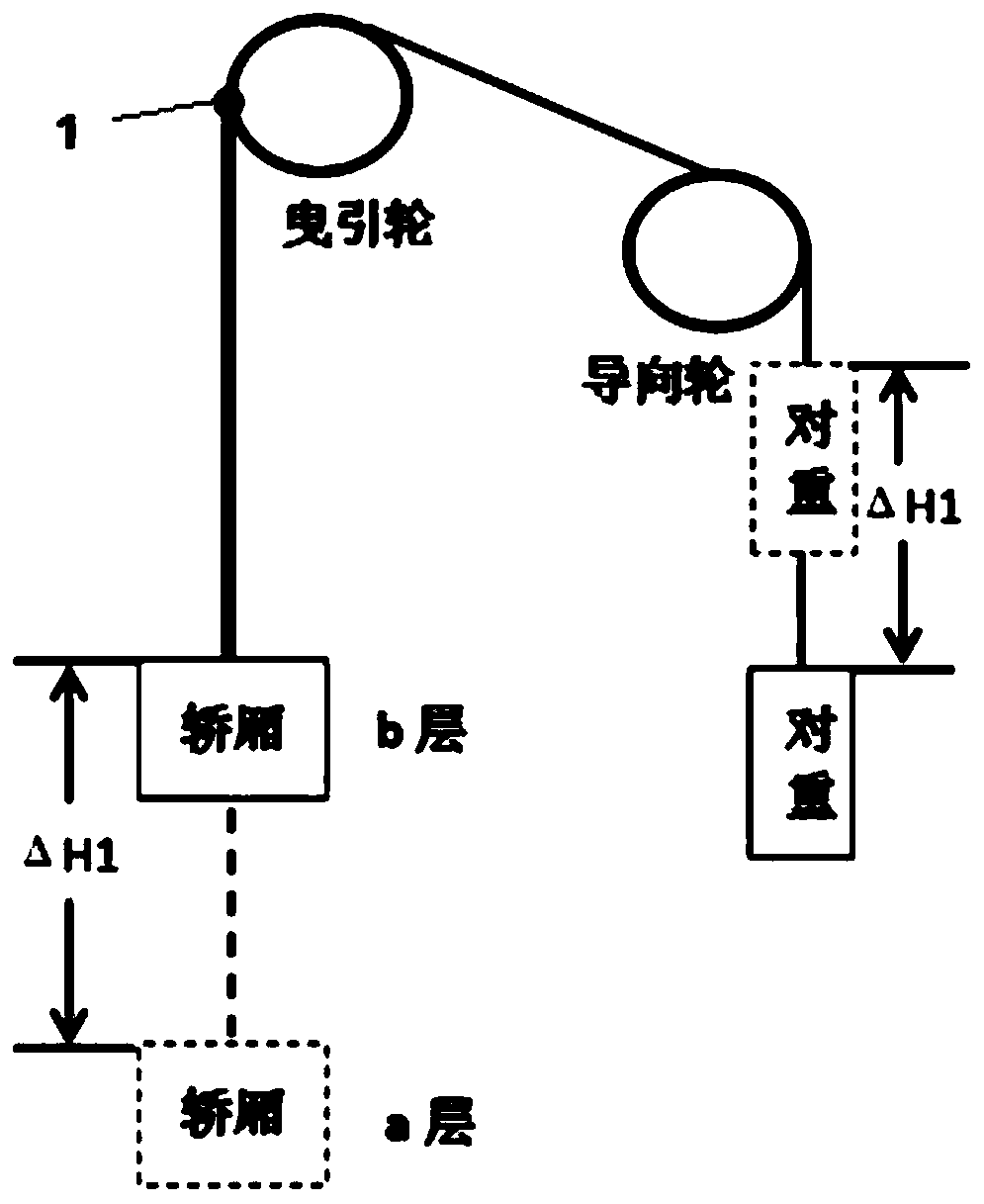

[0186] In this embodiment, it is assumed that the current elevator is in the i-th ascending operation process since the elevator was installed and put into use, and the initial floor number of the elevator is 7 floors, then a i for 7. Assuming that the destination floor of the elevator is 15 floors, then b i for 15. It can be calculated that the length of the moving wire rope during the elevator’s ascent process is ΔHi=3×|15-7|=24m, the initial number of layers corresponds to the coordinate po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com