Patents

Literature

64 results about "Cyclic compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

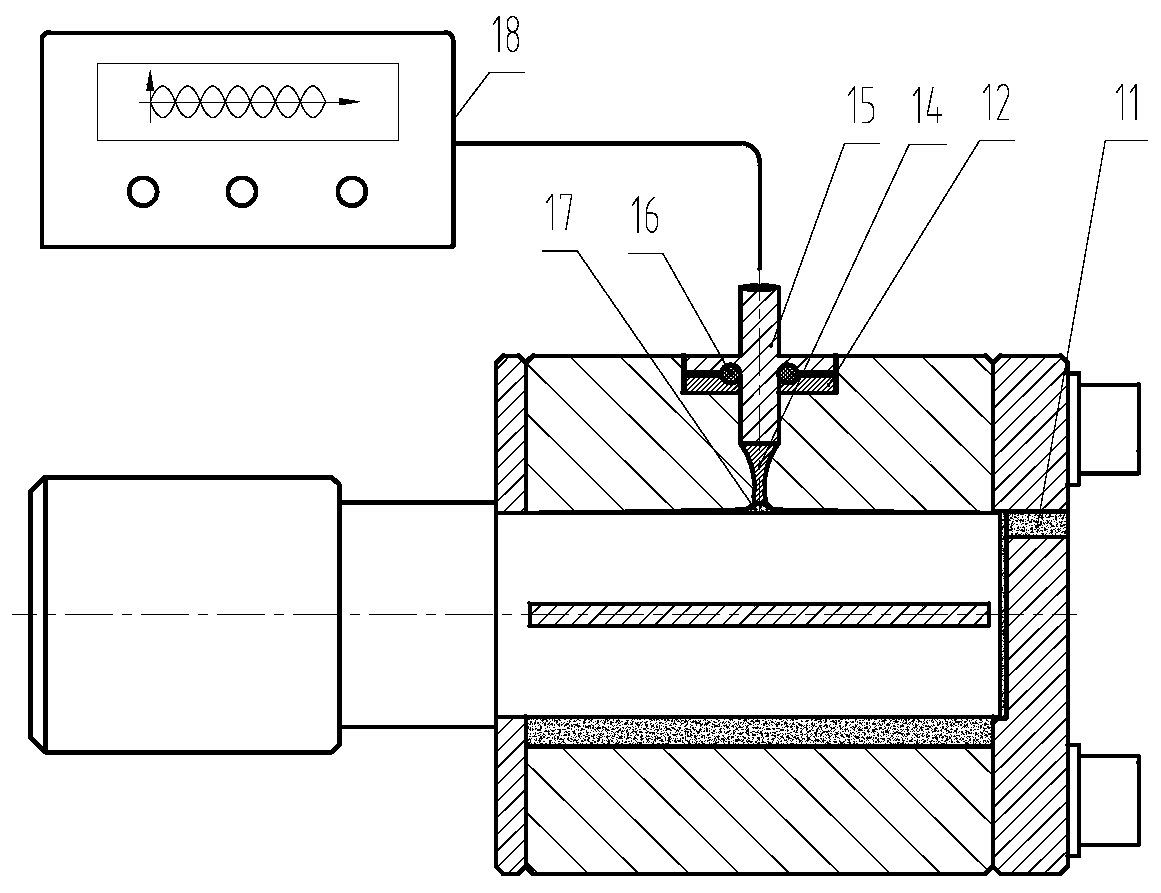

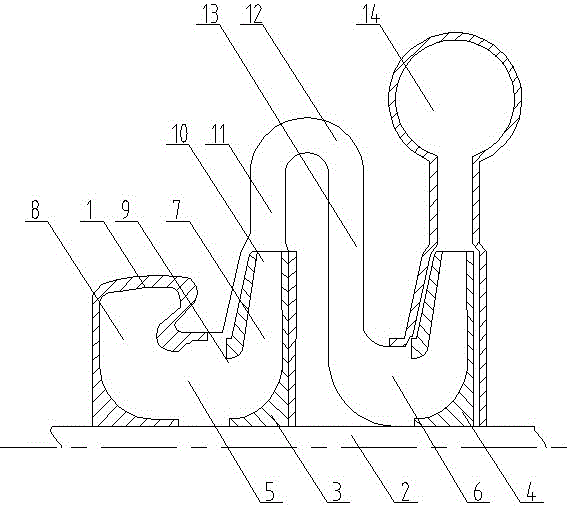

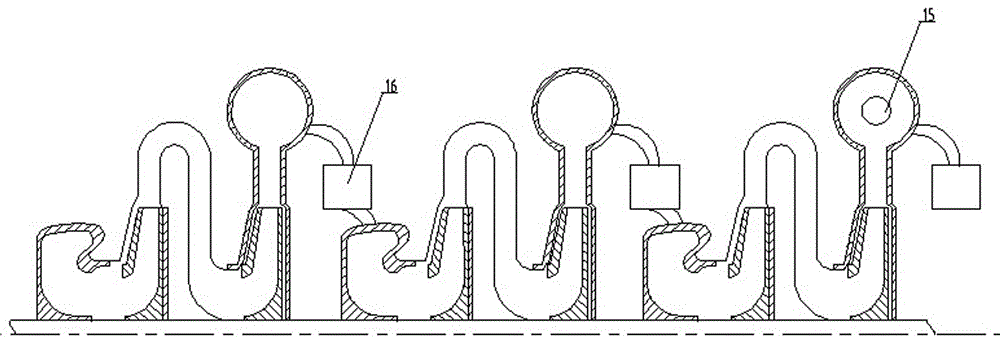

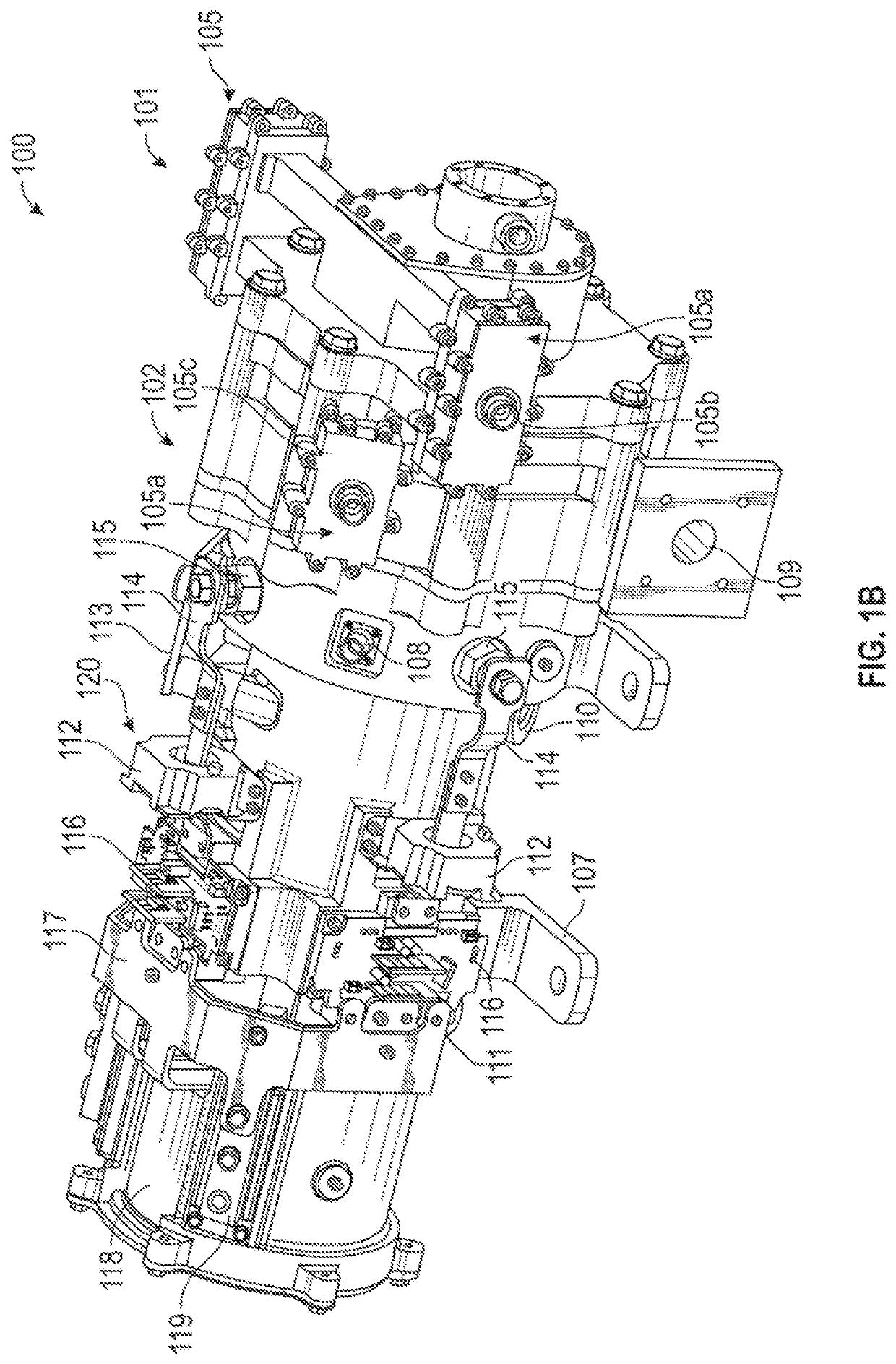

Testing device for vertical cyclic compression-lateral swing shearing dynamic loading

InactiveCN104749055AEvenly distributedUniform stressMaterial strength using repeated/pulsating forcesCyclic compressionActuator

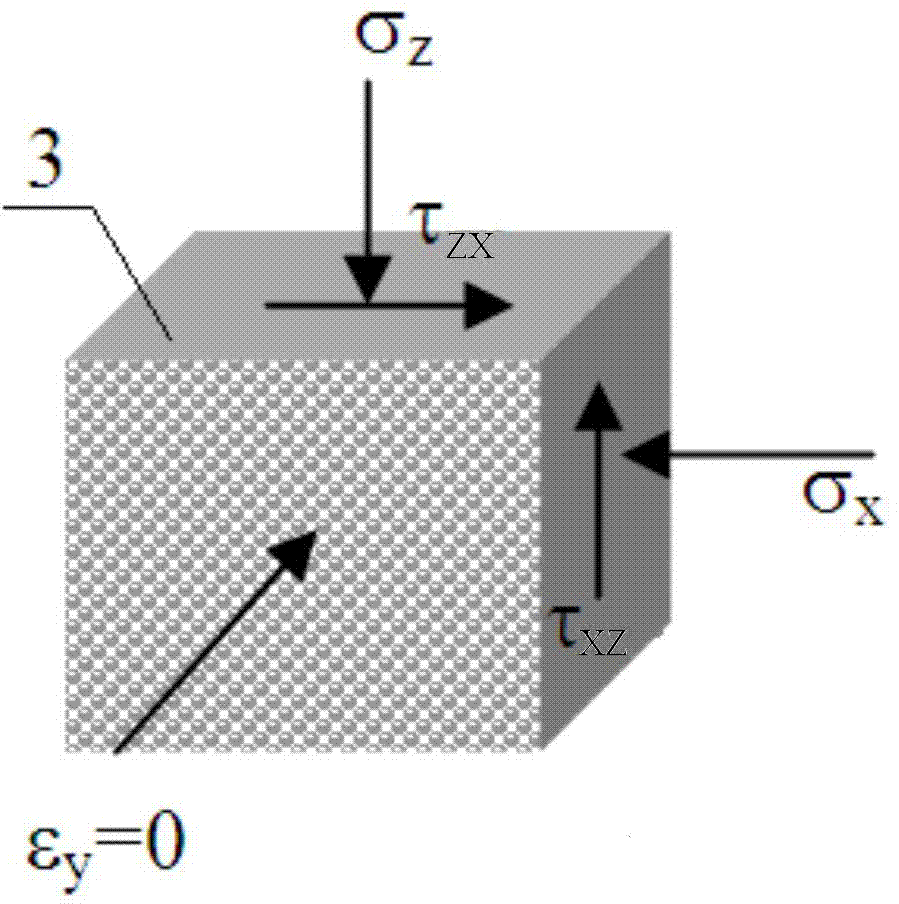

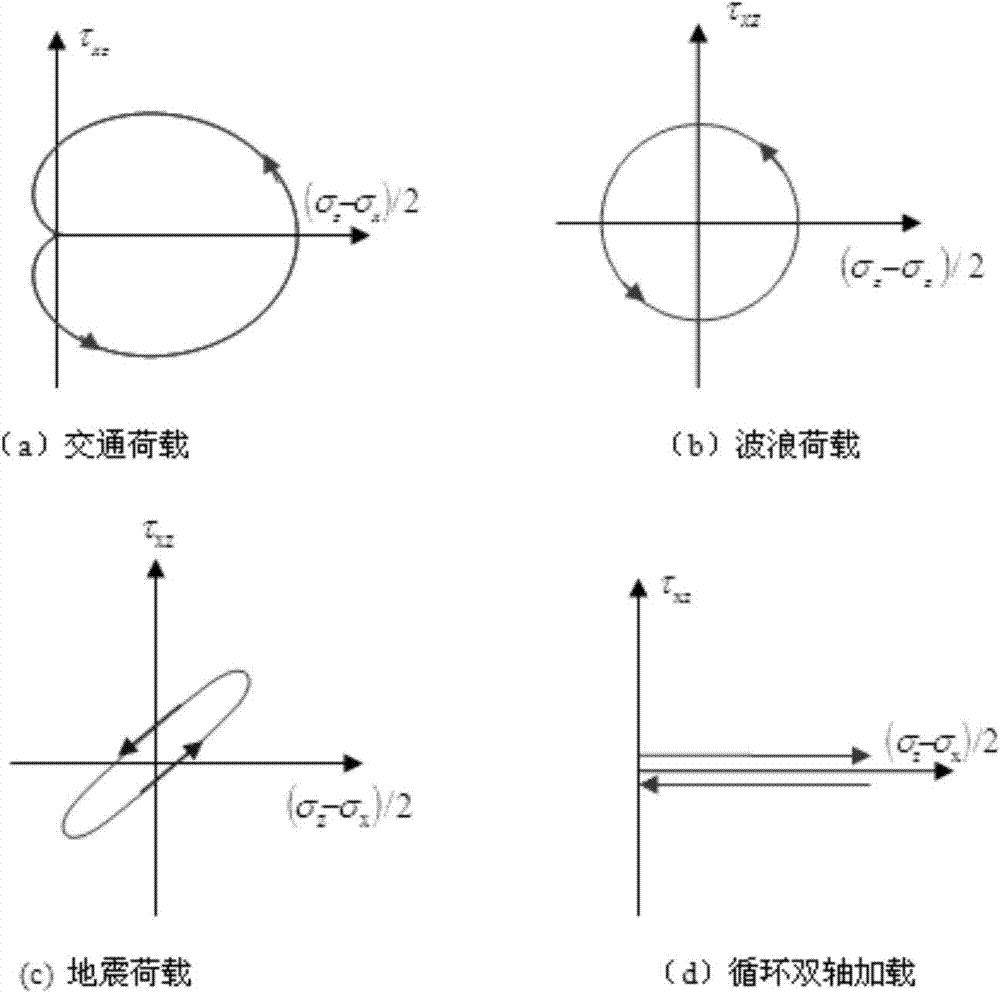

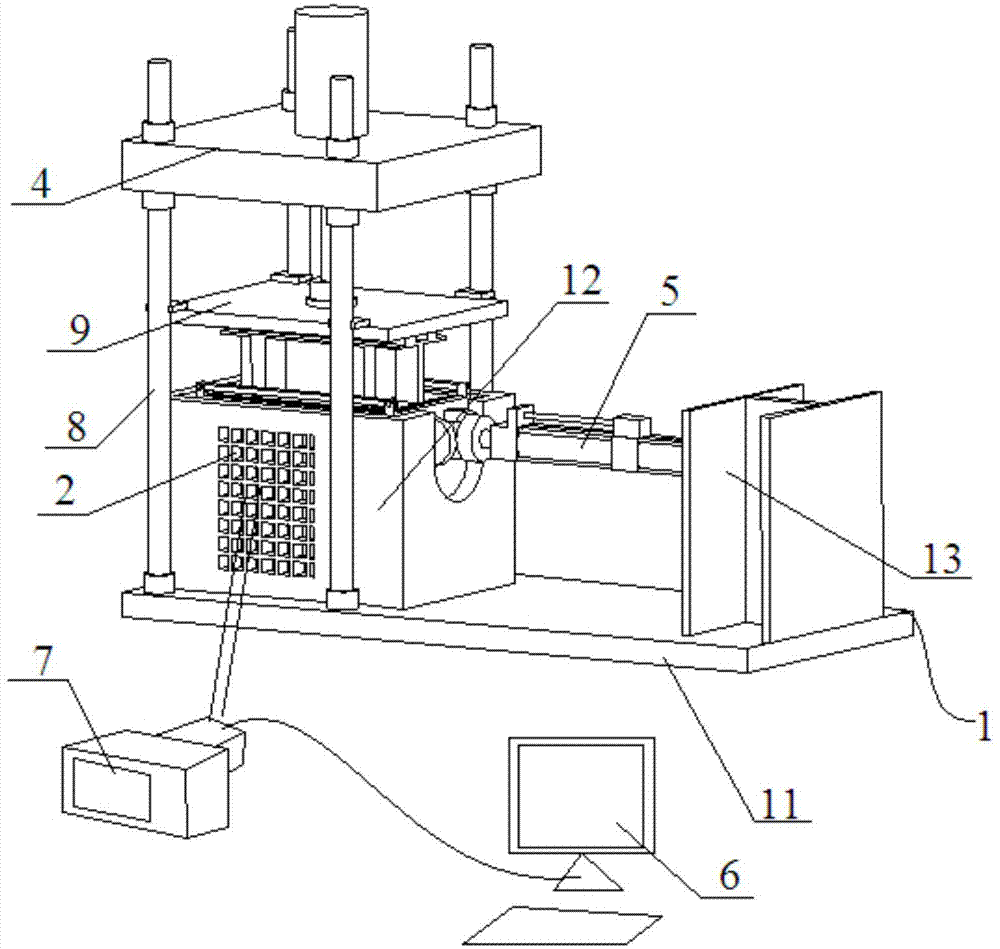

The invention relates to a testing device for vertical cyclic compression-lateral swing shearing dynamic loading. The testing device comprises a peripheral frame, a model case arranged in the peripheral frame, a loading unit for loading the model case and a data acquisition unit for acquiring testing data of a soil test sample in the model case, wherein the soil test sample fills the model case; the loading unit comprises a vertical dynamic load actuator which applies a vertical dynamic load, a lateral swing dynamic load actuator which applies a lateral swing horizontal shearing dynamic load and a lateral pressure loading unit which controls a confining stationary load of the model case. Compared with the prior art, the device provided by the invention can independently apply a horizontal rotating cyclic dynamic load to realize cyclic shearing dynamic load, and can be independently loaded or coupled with the vertical cyclic dynamic load. Moreover, the device is simple in structure, easy to assemble and detach and simple and convenient to operate in the experimental process.

Owner:TONGJI UNIV

Carbon nanotube/polypyrrole composite sponge and preparation method thereof

ActiveCN103450682AWith cyclic compression stabilityQuality content controllableMaterial nanotechnologyElectrolysis componentsPolypyrroleCyclic compression

The invention relates to carbon nanotube / polypyrrole composite sponge and a preparation method thereof, belonging to the field of the synthesis and application of carbon nanocomposites. The carbon nanotube / polypyrrole composite sponge is formed through stacking and winding composite tubes with microcosmic core-shell structures and has a porous structure, wherein each composite tube consists of a carbon nanotube and a uniform-thickness polypyrrole layer coated outside the carbon nanotube. The mass content of polypyrrole in the composite sponge is controllable; the composite sponge has good elasticity, good cyclic compression stability and excellent electrochemical properties; the carbon nanotube / polypyrrole composite sponge is prepared by the method which combines a chemical vapor deposition method, an adsorption composite method and an electrochemical polymerization method; the preparation method has ingenious conception and is simple and easy in operation.

Owner:TSINGHUA UNIV

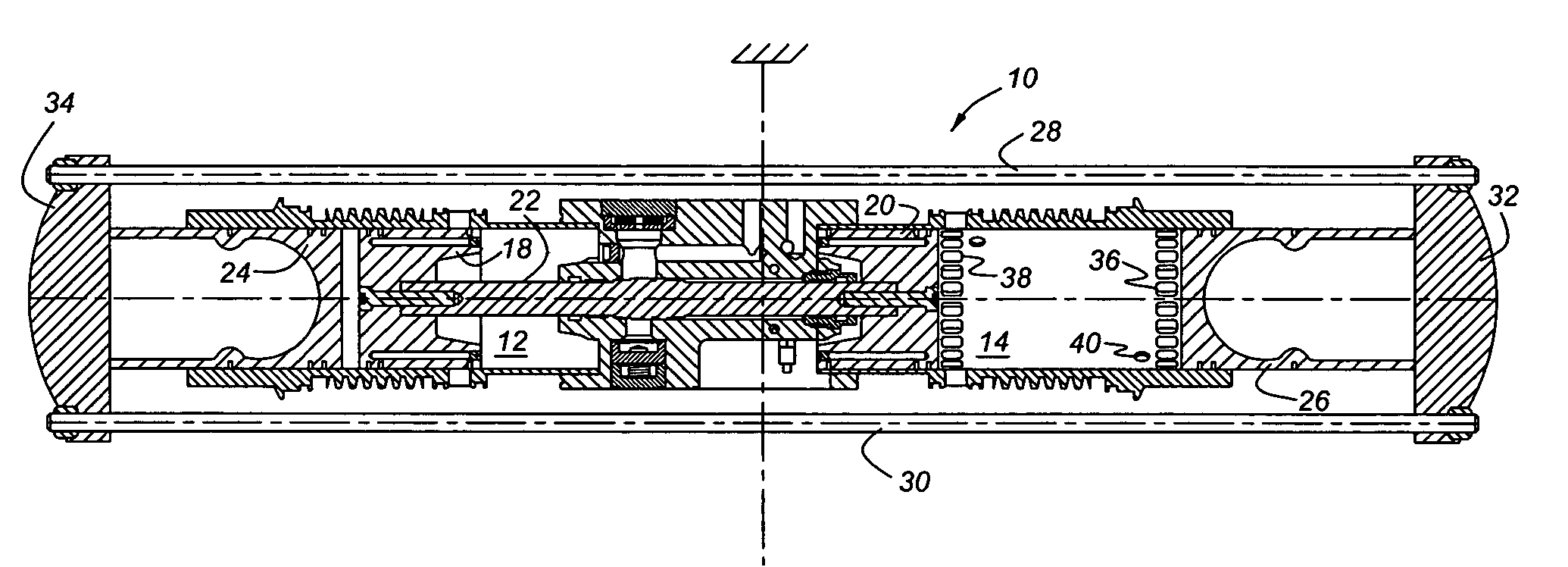

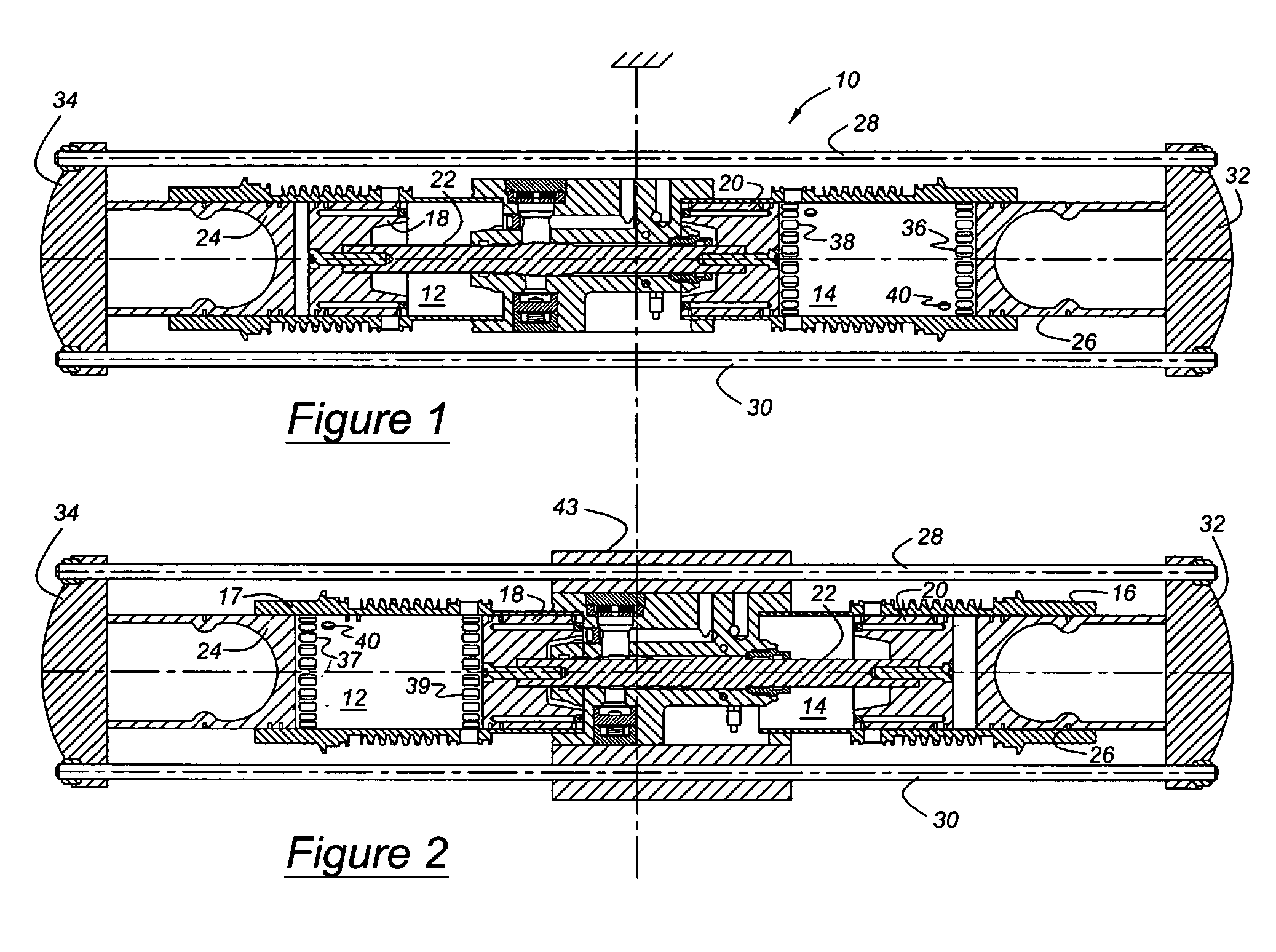

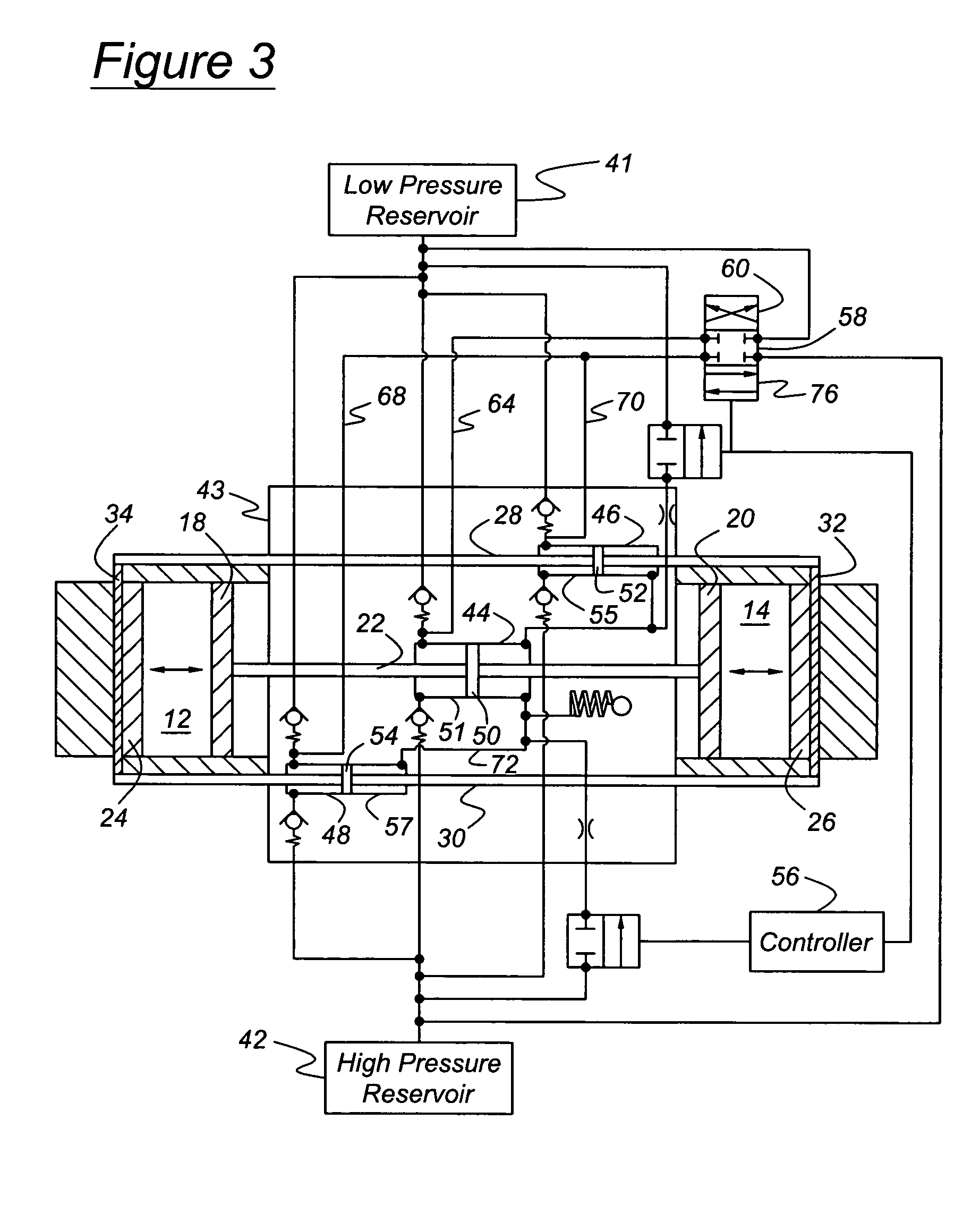

Starting a compression ignition free piston internal combustion engine having multiple cylinders

InactiveUS6983724B2Increase kinetic energyIncrease pressureFree piston enginesCyclic compressionMaximum pressure

A method for starting a free piston, internal combustion engine includes supplying an air charge to a space in a combustion cylinder, and reciprocating the piston in the cylinder so that the maximum pressure of the air charge in the space cyclically increases. Air and fuel are cyclically admitting to the cylinder to produce an air-fuel mixture, and spark ignition is used to produce cyclic combustion of the air-fuel mixture. The air-fuel ratio of the mixture is increasing when a maximum pressure in the cylinder occurs within a predetermined period following a TDC position of the piston. Spark ignition is discontinued, and cyclic compression ignition (HCCI) of the air-fuel mixture occurs.

Owner:FORD GLOBAL TECH LLC

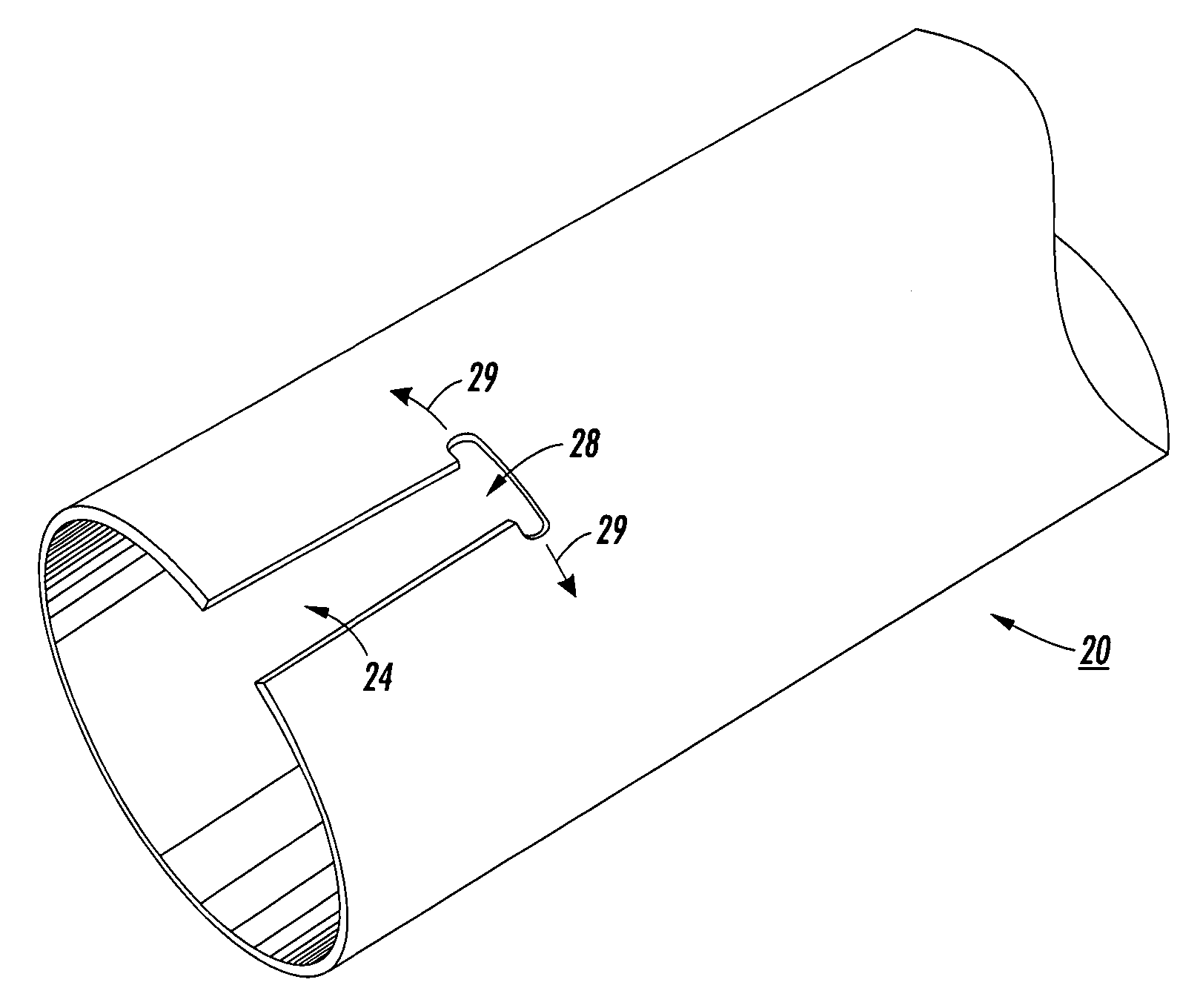

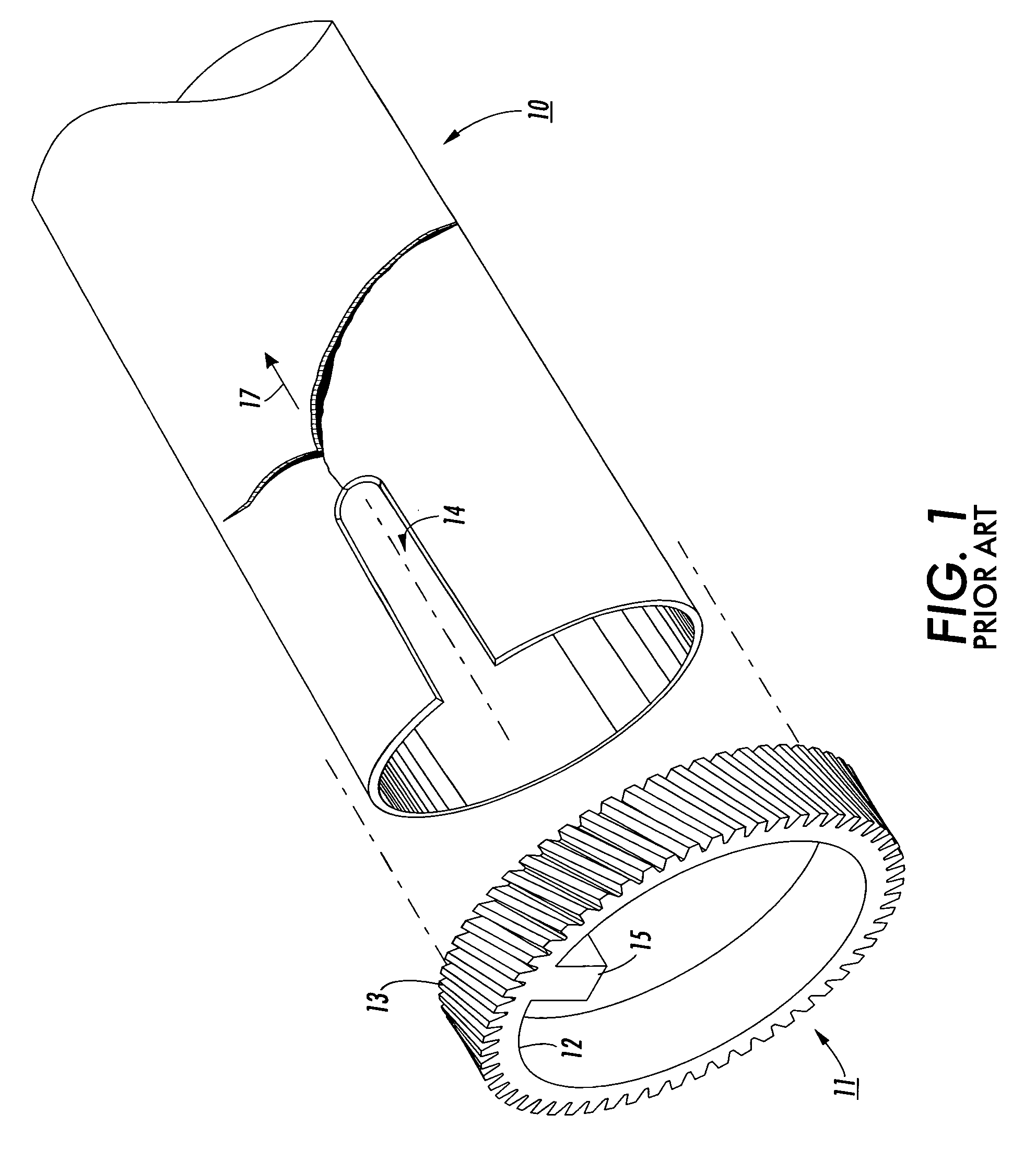

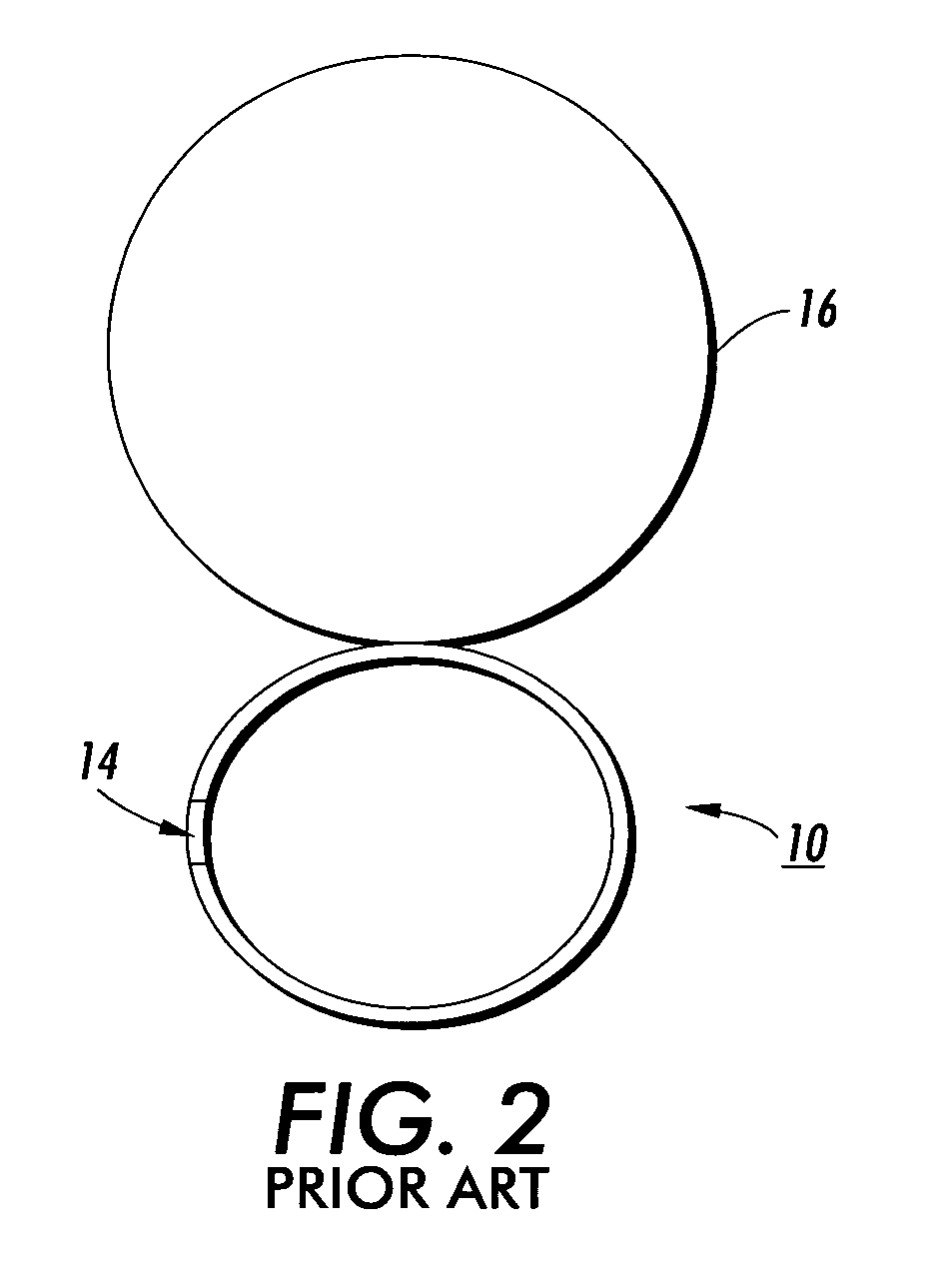

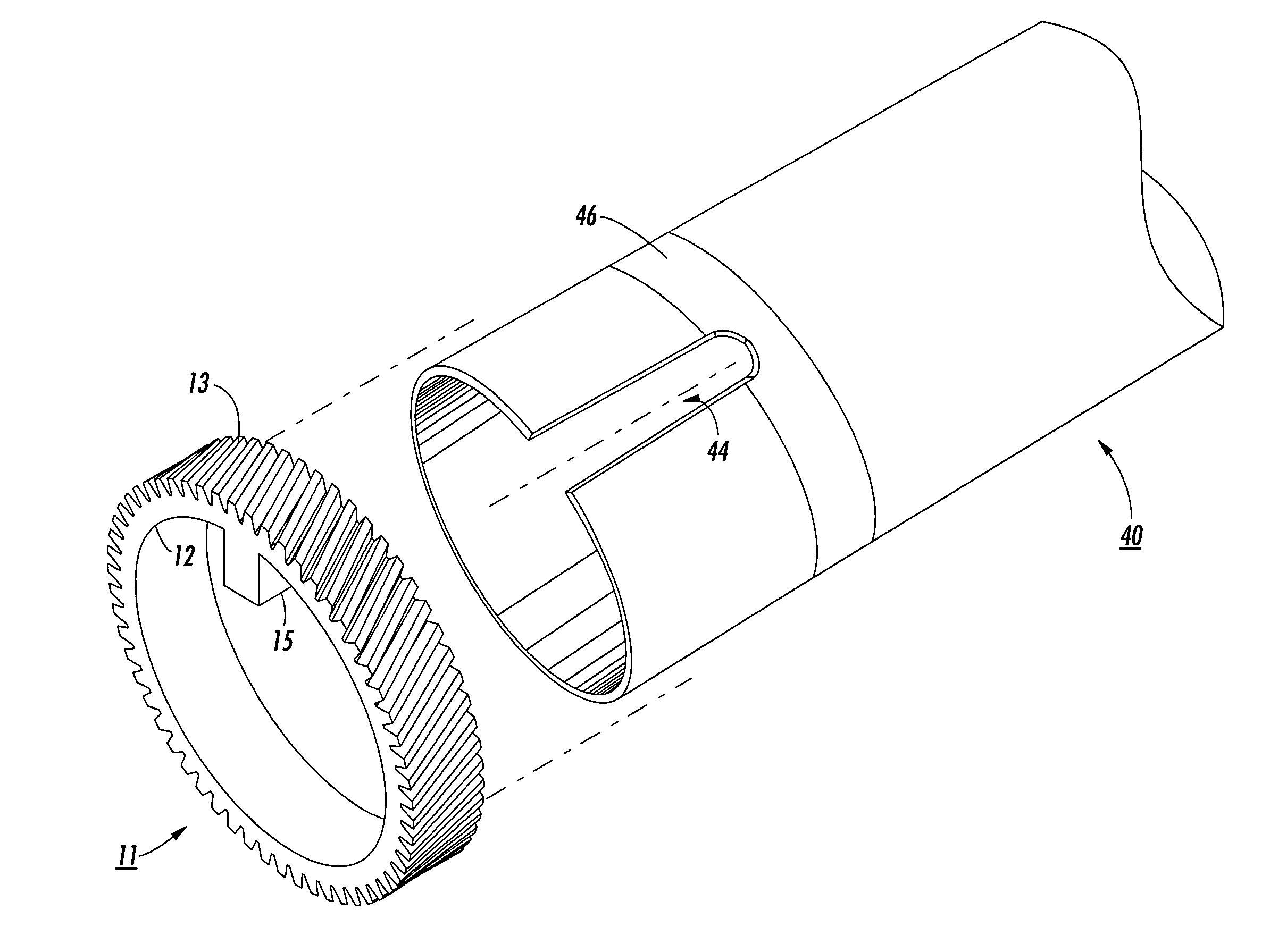

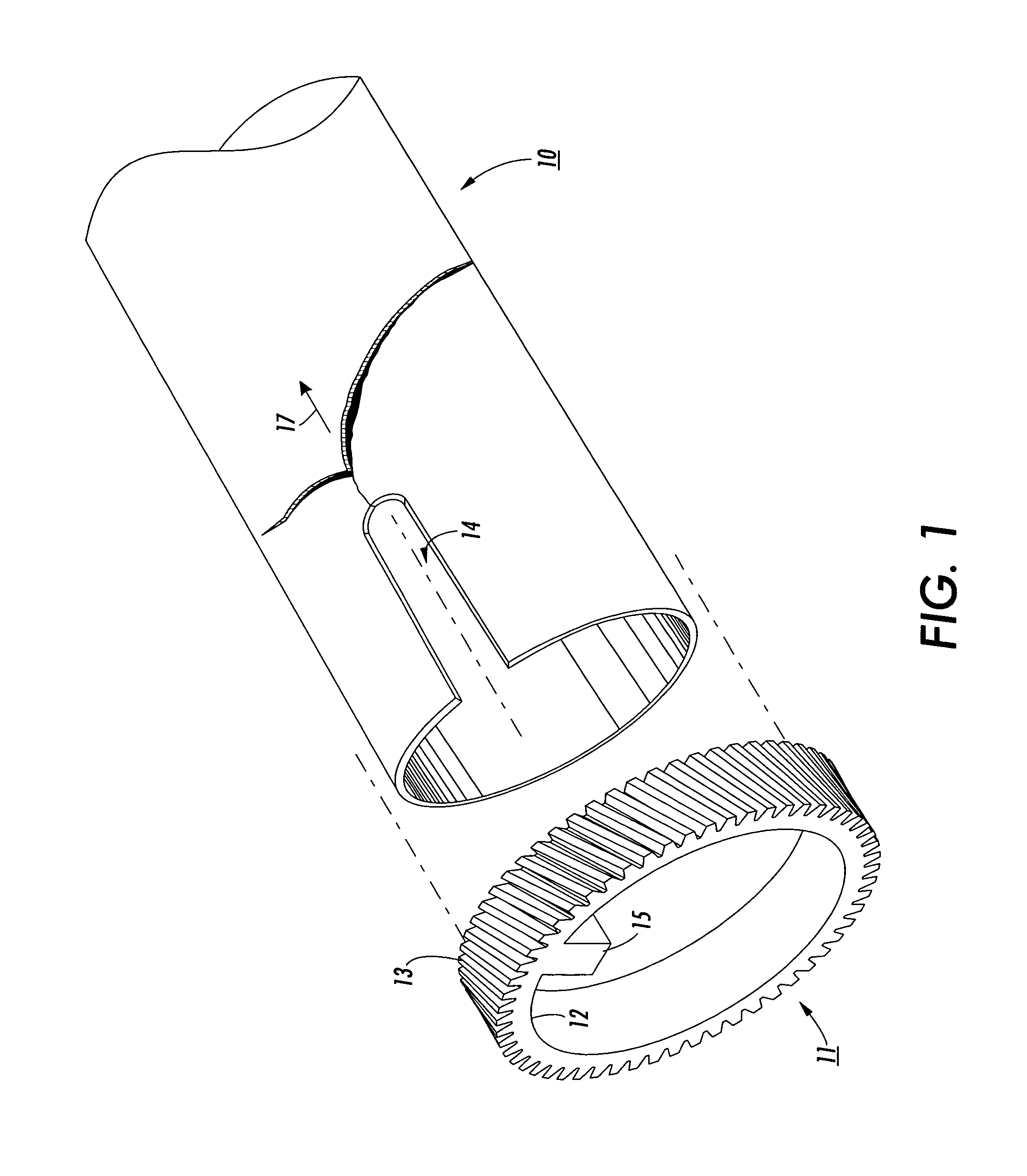

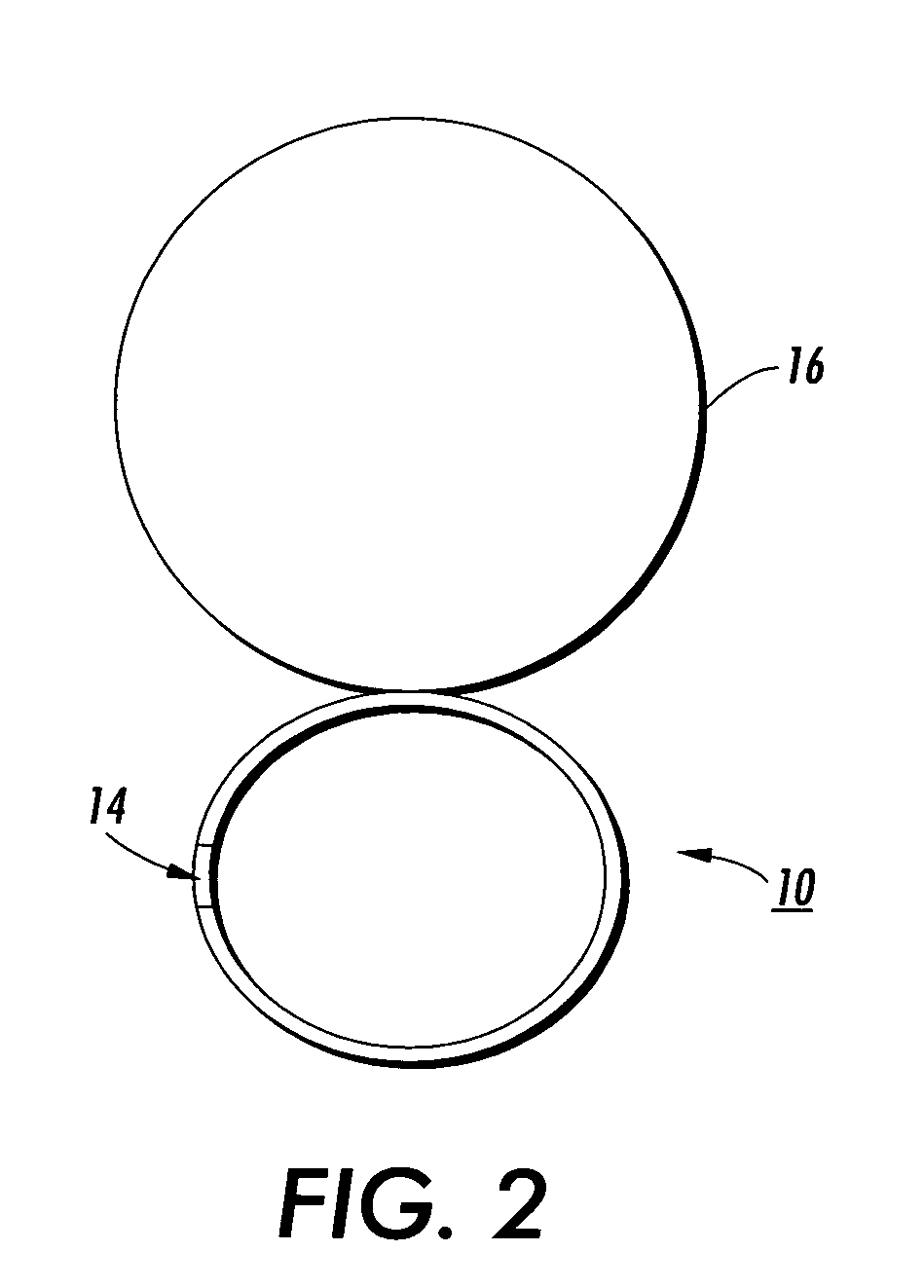

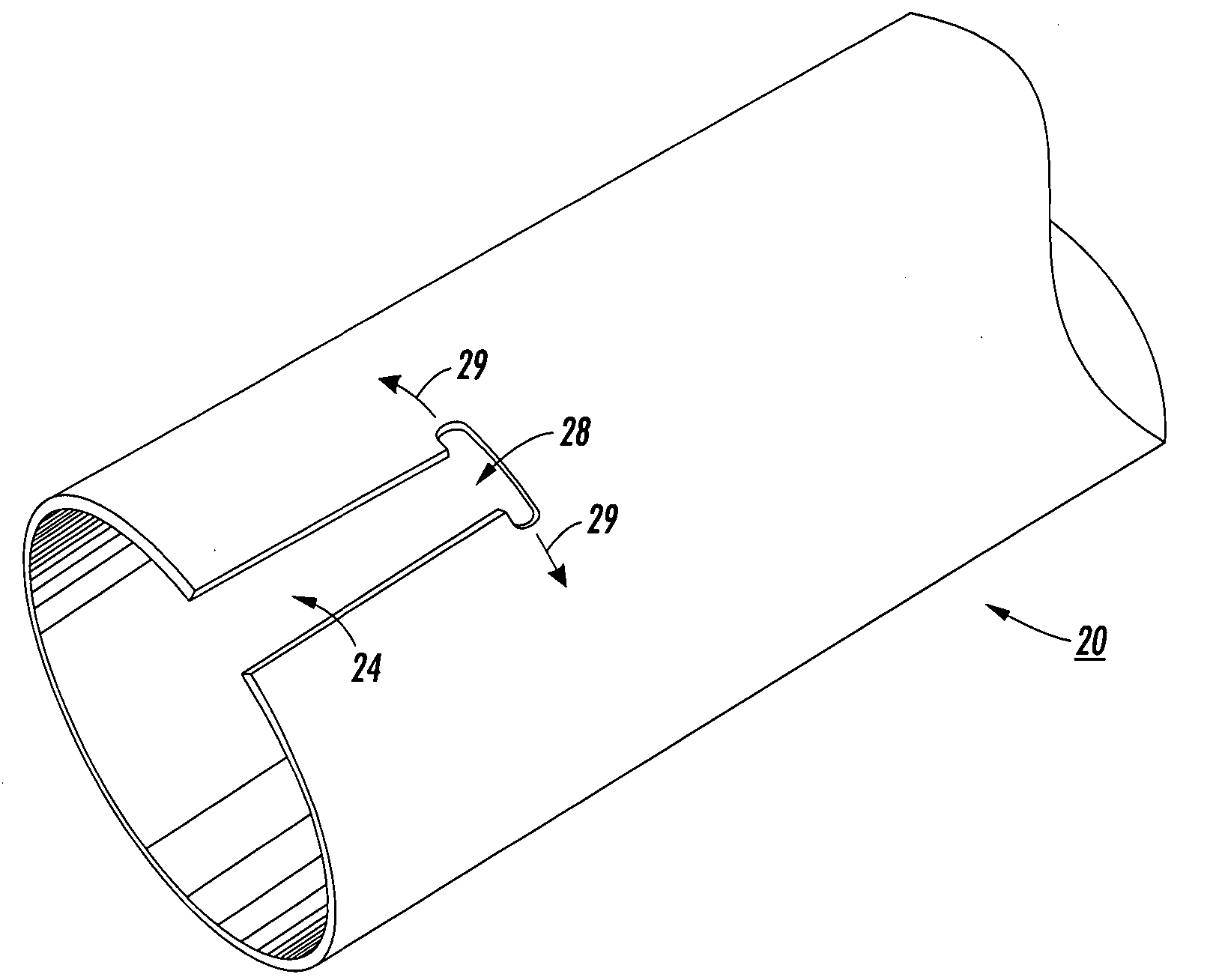

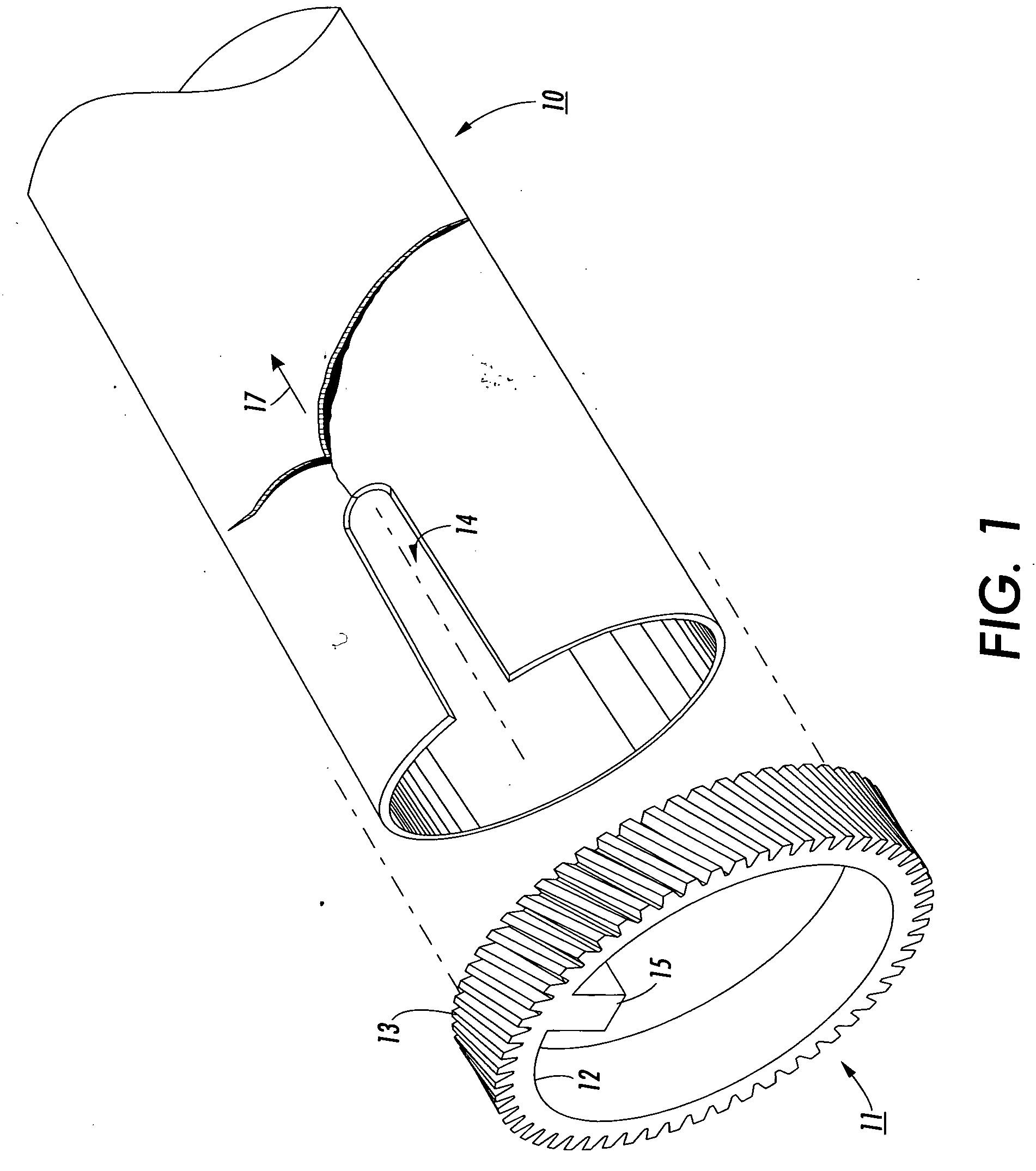

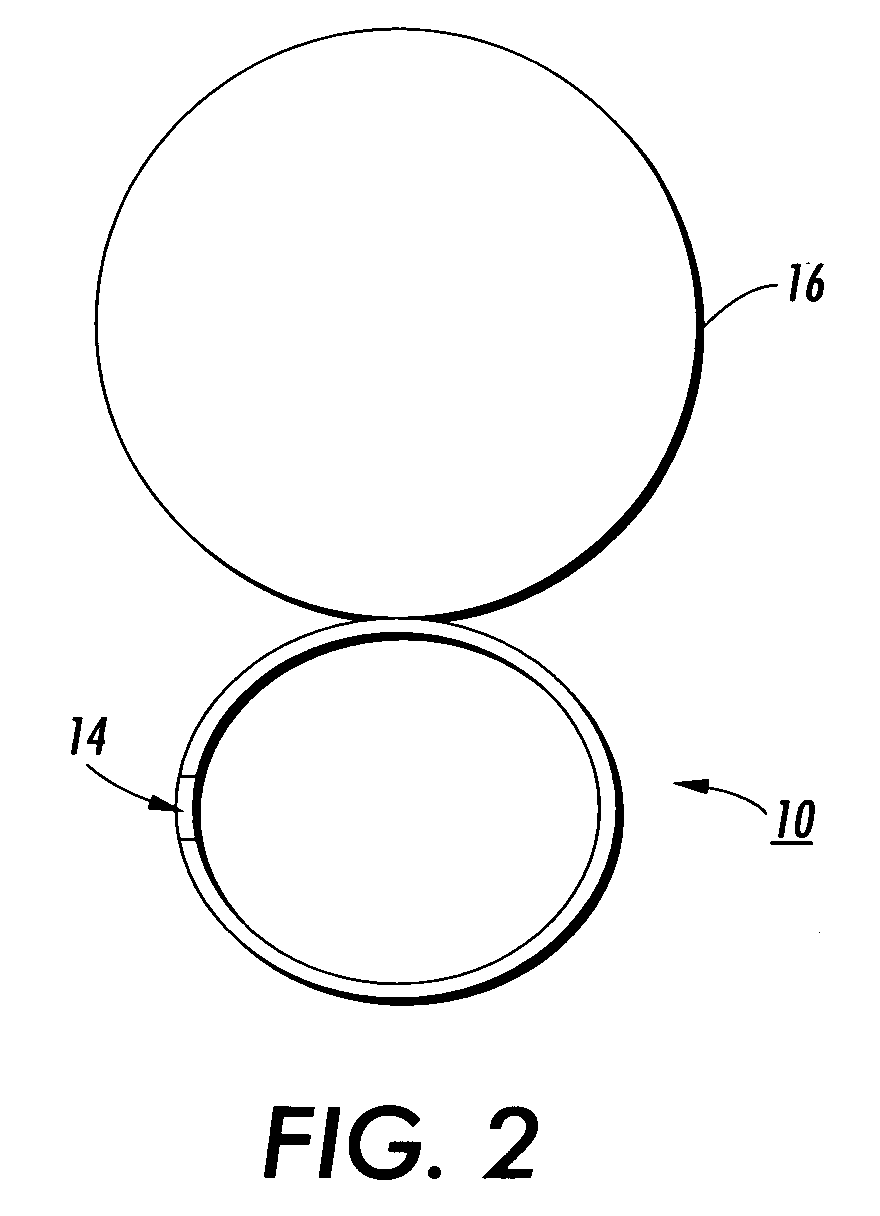

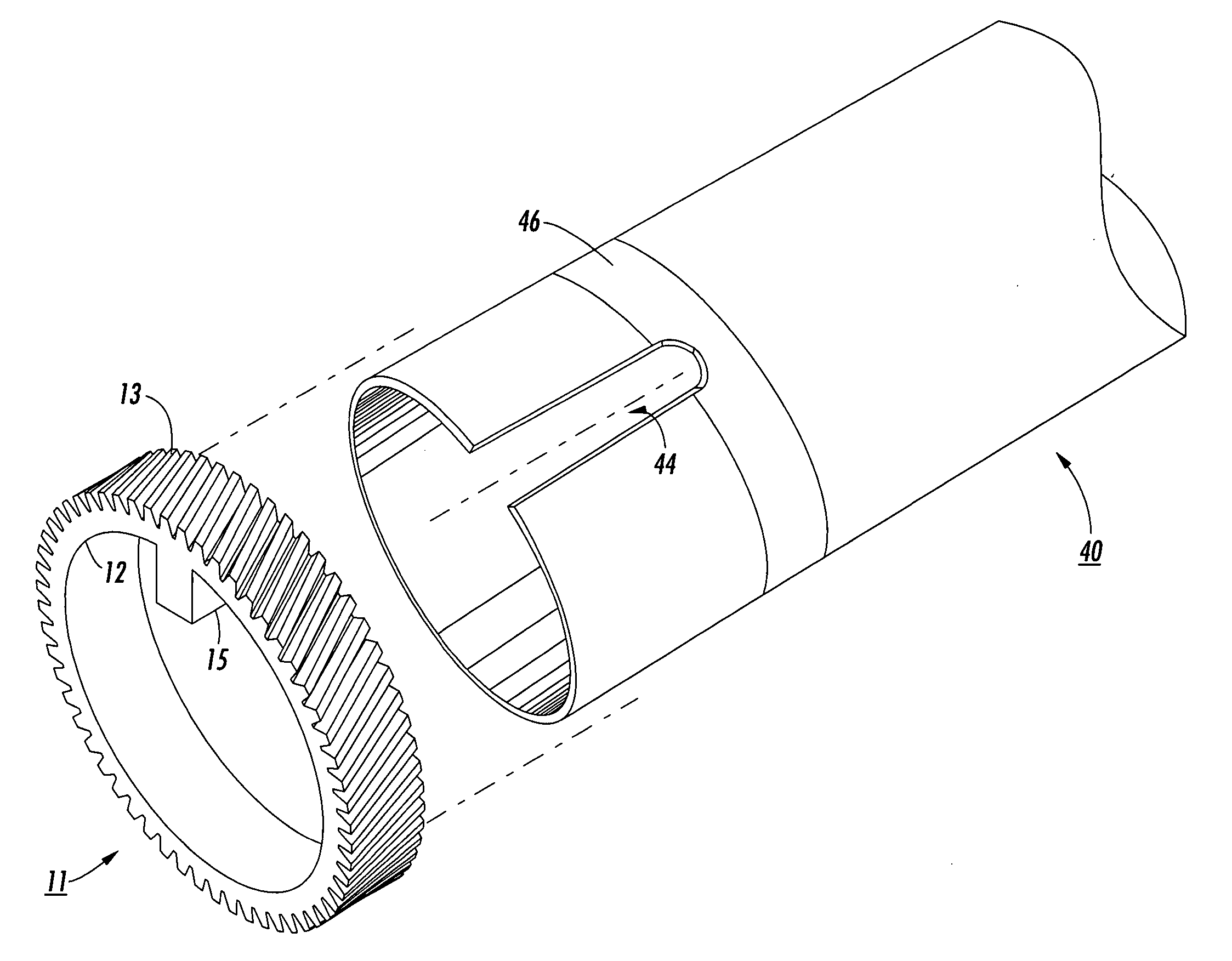

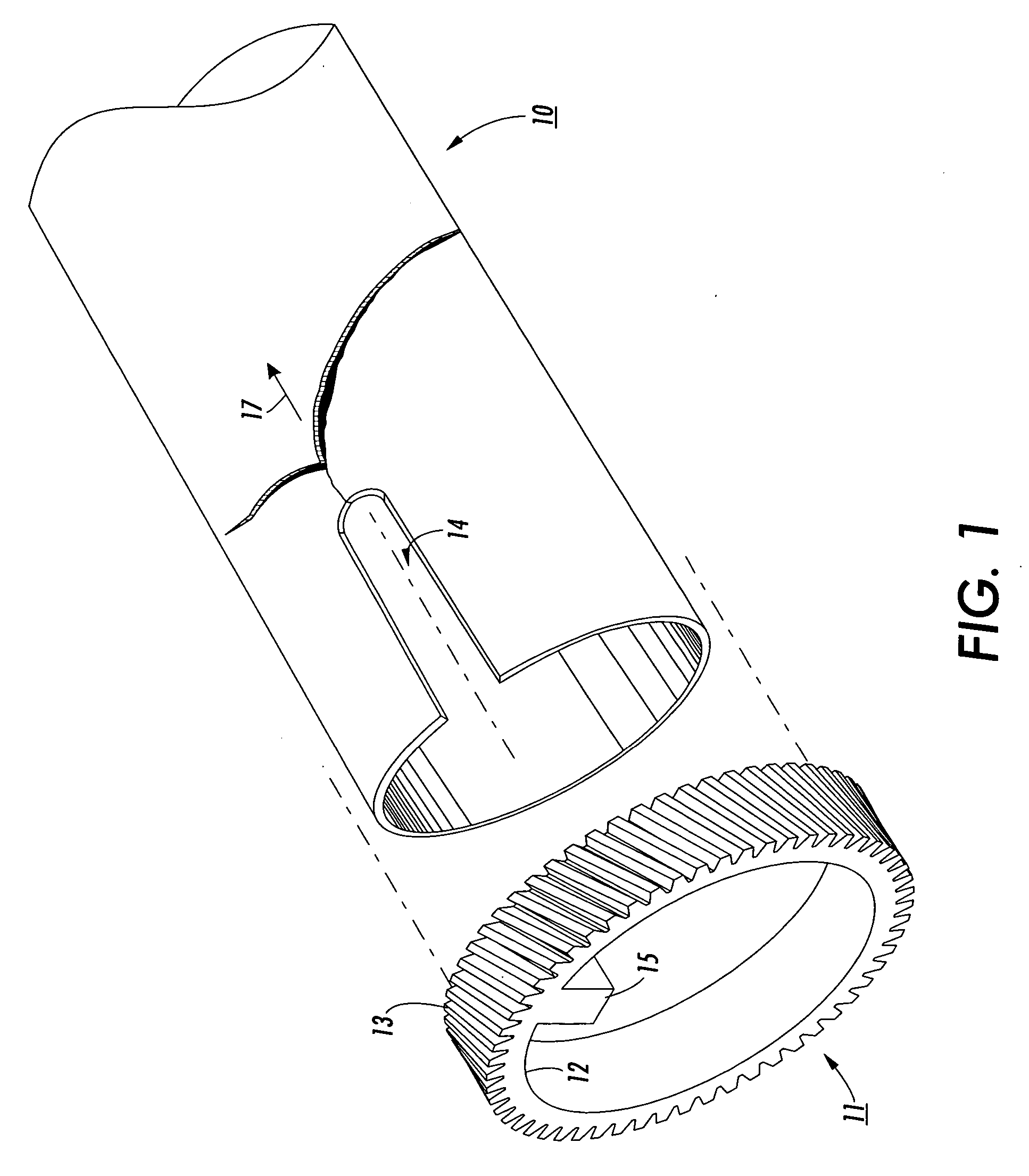

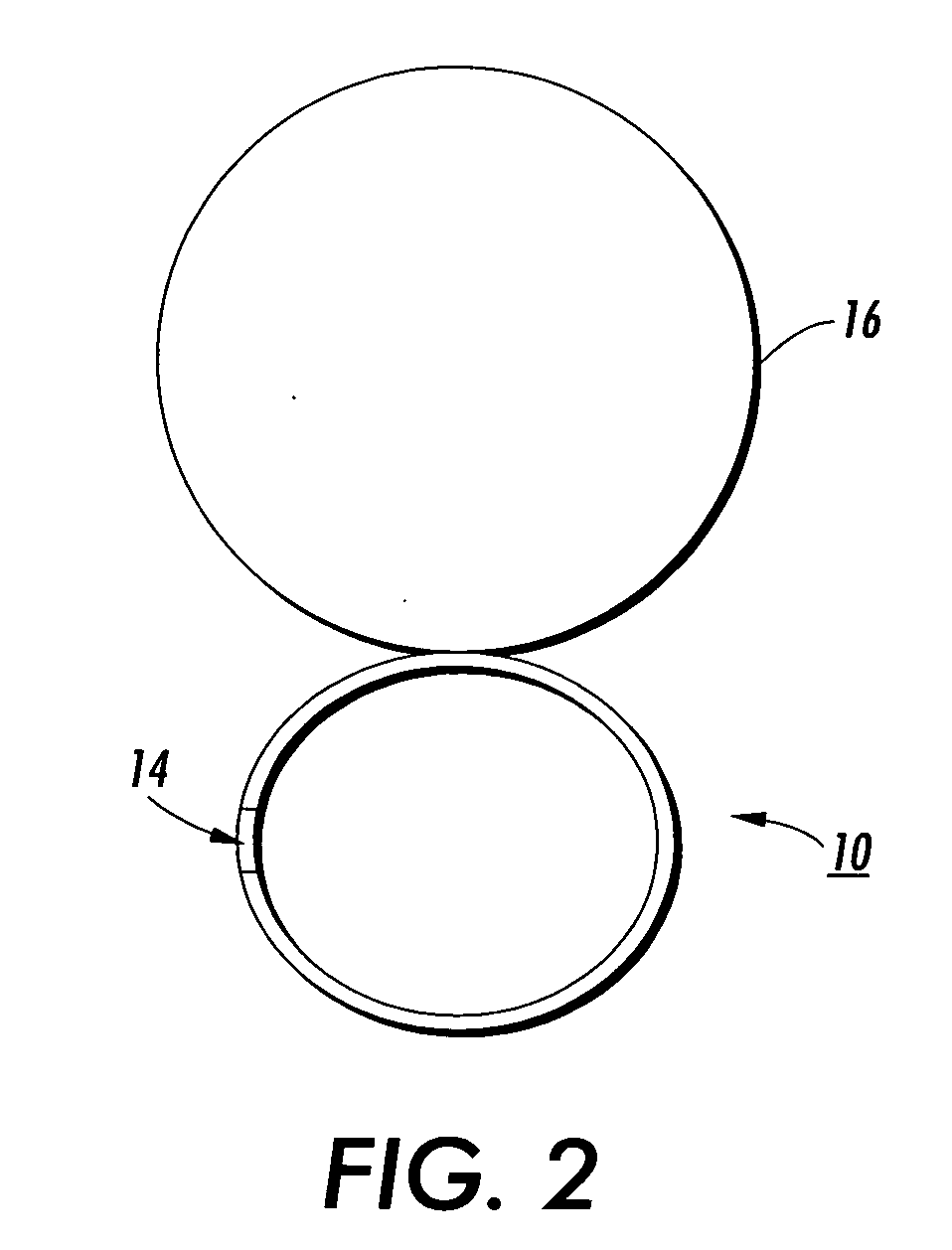

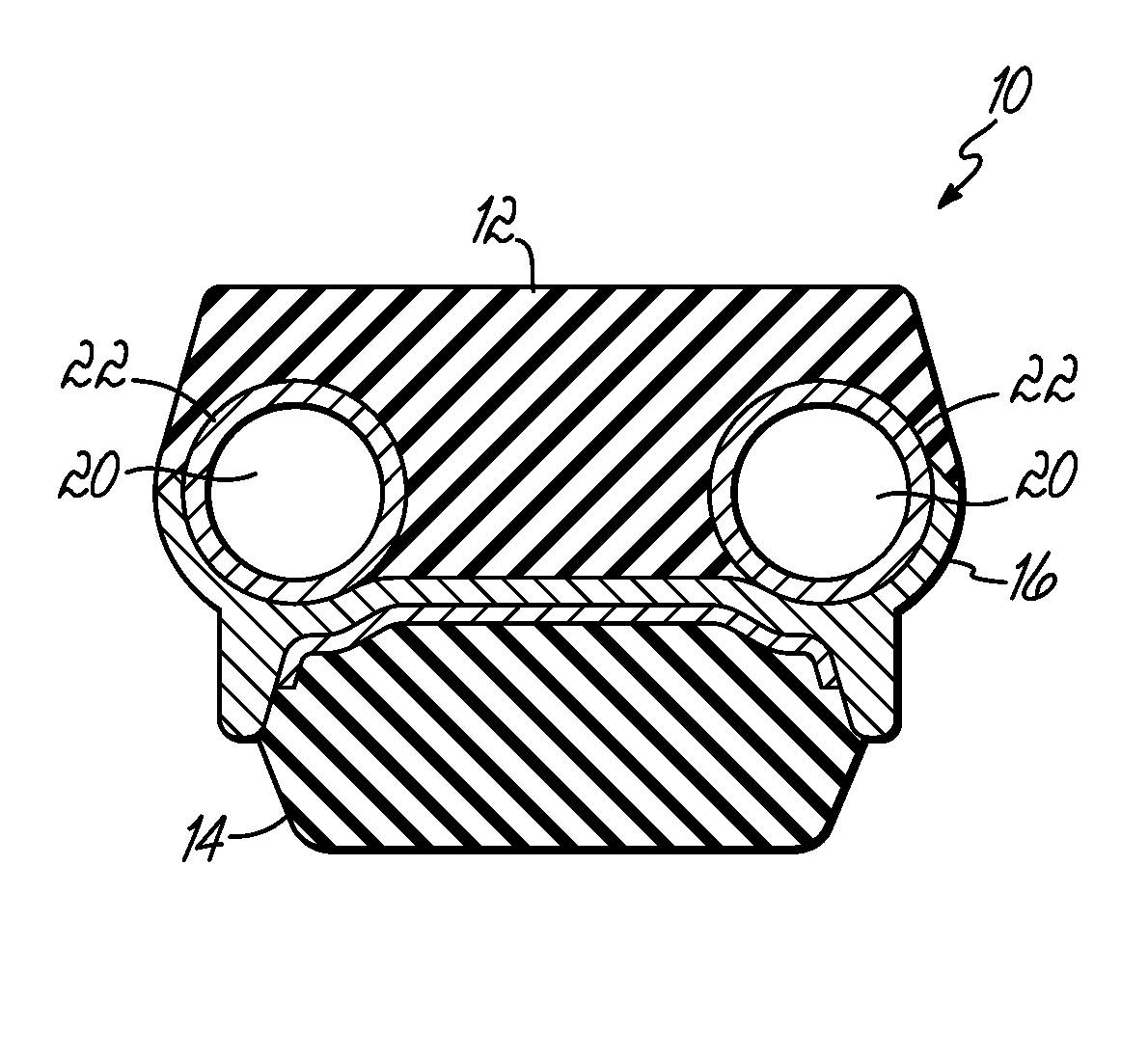

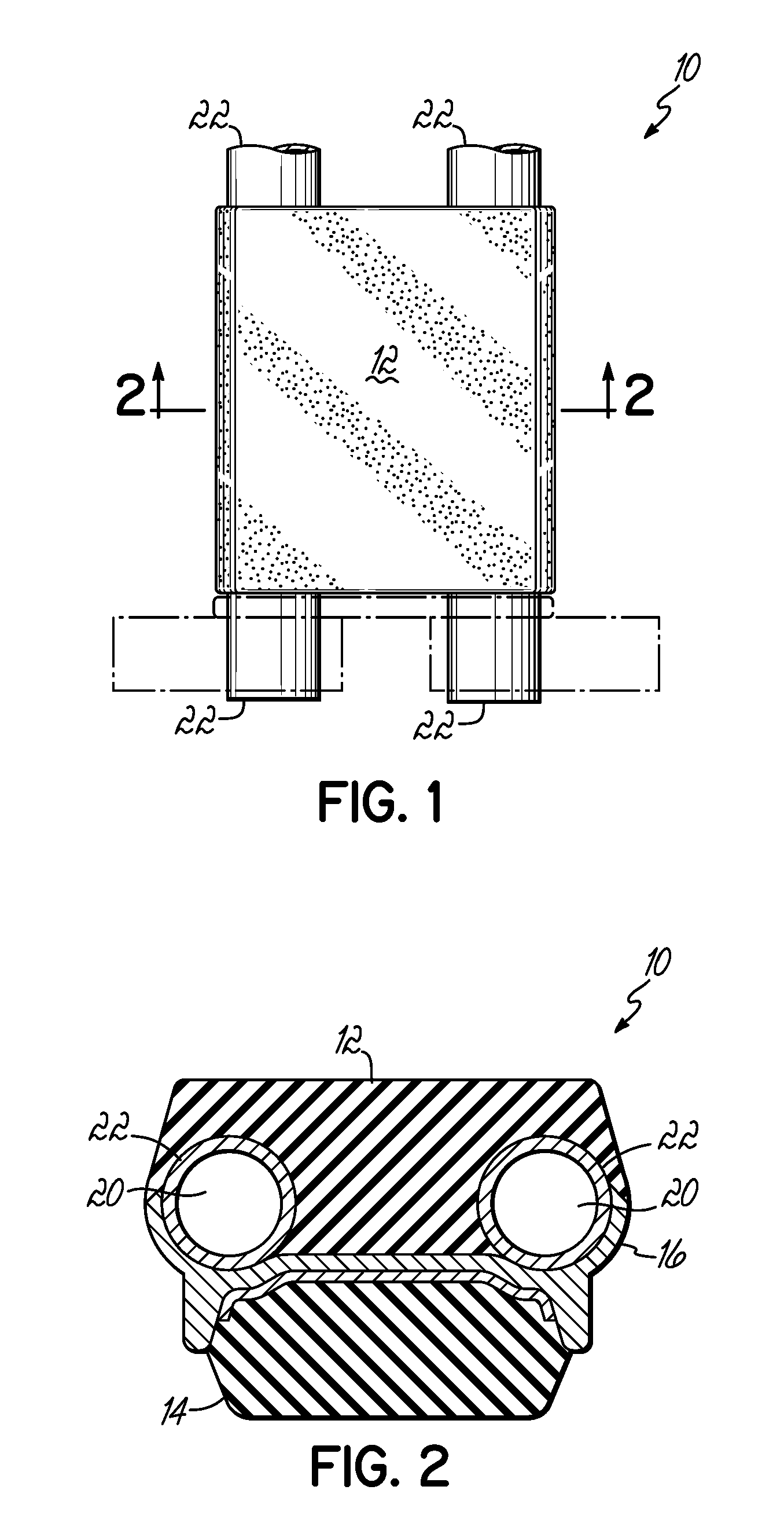

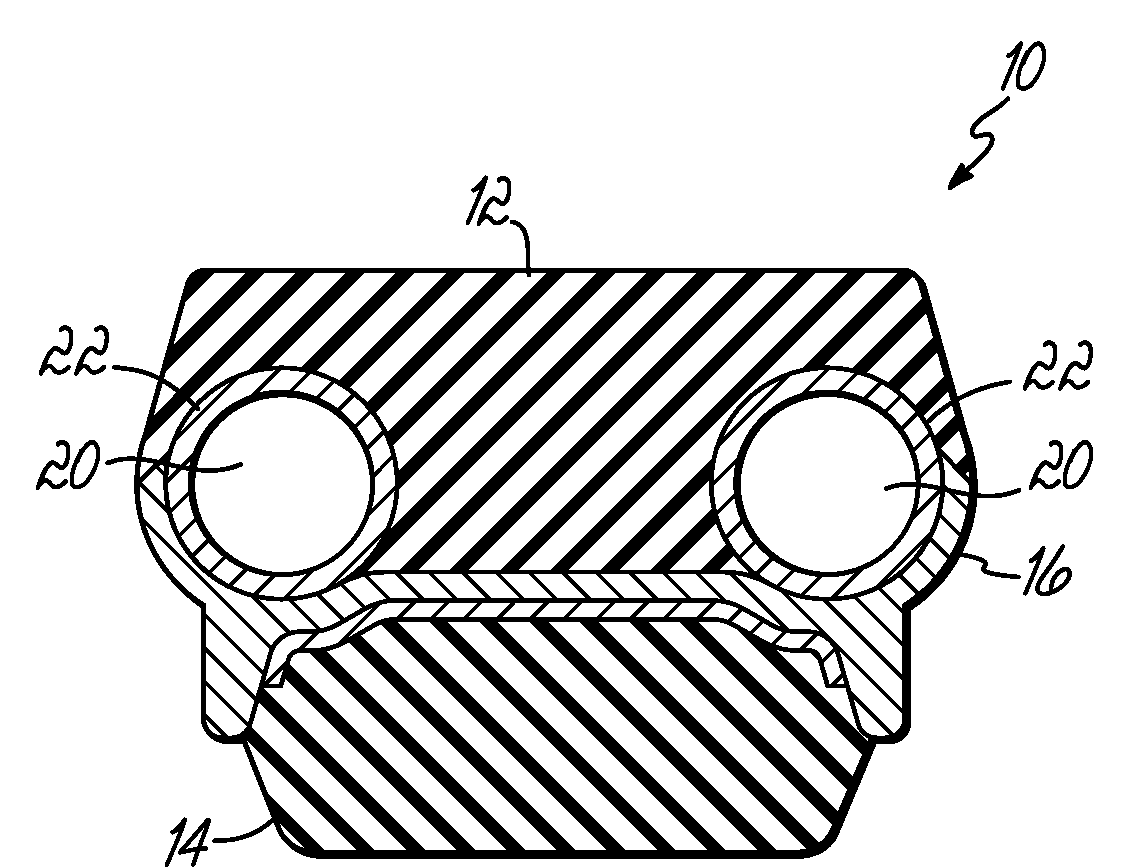

Thin walled fuser roll with stress redirected from axial to radial direction

A thin-walled fuser roll core cylinder assembly permitting fast warm-up times and improved energy efficiency wherein cracking of the thin walls of the core cylinder due to cyclic compression is prevented by redirecting axial stress at the terminus of an axial keyway to a radial direction. The keyway is for coupling the core cylinder to a drive gear. Use of such a thin-walled fuser roll in an imaging system and a process of fusing toner onto a copy substrate using the thin-walled fuser core.

Owner:XEROX CORP

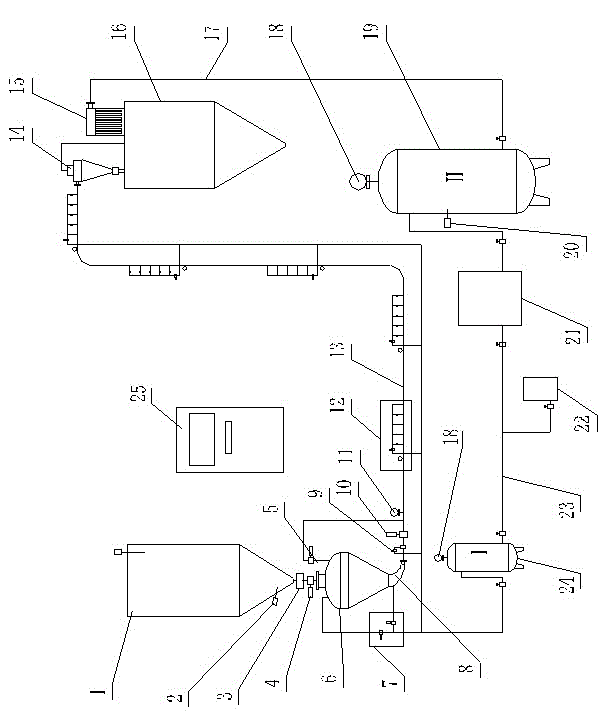

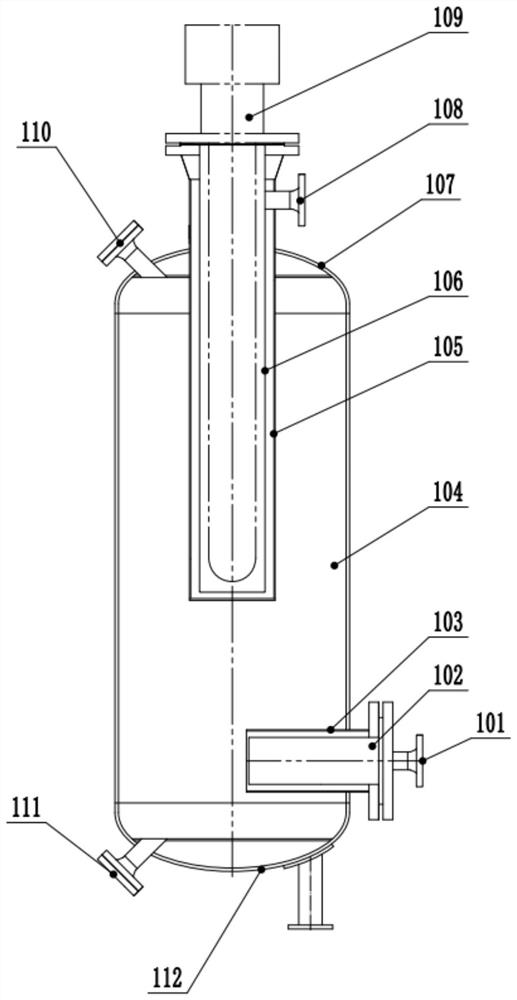

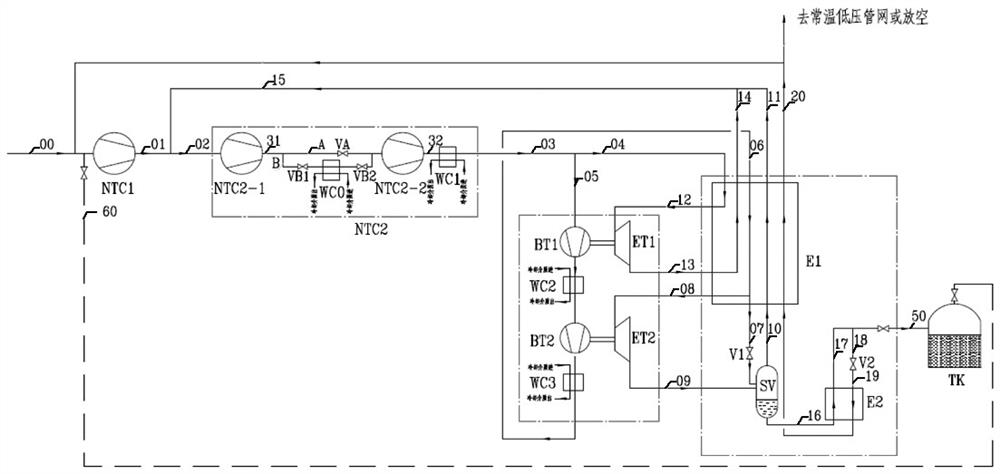

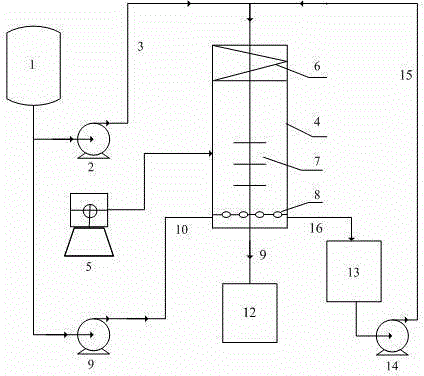

Lead powder and nitrogen gas closed-cycle static-pressure dense-phase sectional boosting pneumatic conveying system

InactiveCN104401736AReduce in quantityReduce maintenanceBulk conveyorsCyclic compressionNitrogen gas

The invention discloses a lead powder and nitrogen gas closed-cycle static-pressure dense-phase sectional boosting pneumatic conveying system. The system comprises a lead powder storage bin (1), a lead powder discharging device (3), a pneumatic feed valve (4), a transmitting bin pump (6), a lead powder conveying main gas source valve group (7), a discharge fluidization device (8), a bin pump discharge port boosting device (9), a pneumatic discharge valve (10), a dust conveying pipeline internal pressure sensor (11), a sectional external booster (12) with a pressure sensor, a dust conveying pipeline (13), a gas-solid separation device (14), an ultrafiltration device (15), a lead powder bin (16), a nitrogen gas return pipeline (17), a nitrogen gas storage tank II (19), a nitrogen gas recycling compression system device (21), a high-pressure nitrogen gas pipeline (23), a nitrogen gas storage tank I (24) and a system control device (25) which are sequentially connected. According to the system, the equipment quantity and the equipment maintenance load can be reduced, and the occupational risks of lead powder conveying in a lead-acid storage battery production process can be effectively eliminated or reduced.

Owner:WUXI HONGQI DUST COLLECTOR EQUIP

Thin walled fuser roll with strengthened keyway

A thin-walled fuser roll core cylinder assembly permitting fast warm-up times and improved energy efficiency wherein cracking of the thin walls due to cyclic compression is prevented by strengthening the thin walls proximate to the end region where the core cylinder is engaged by the drive gear. Use of such a thin-walled fuser roll in an imaging system and a process of fusing toner onto a copy substrate using the thin-walled fuser core.

Owner:XEROX CORP

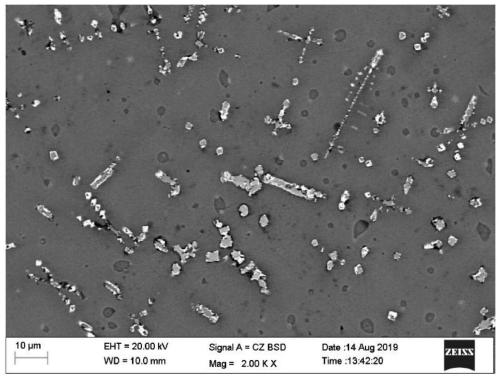

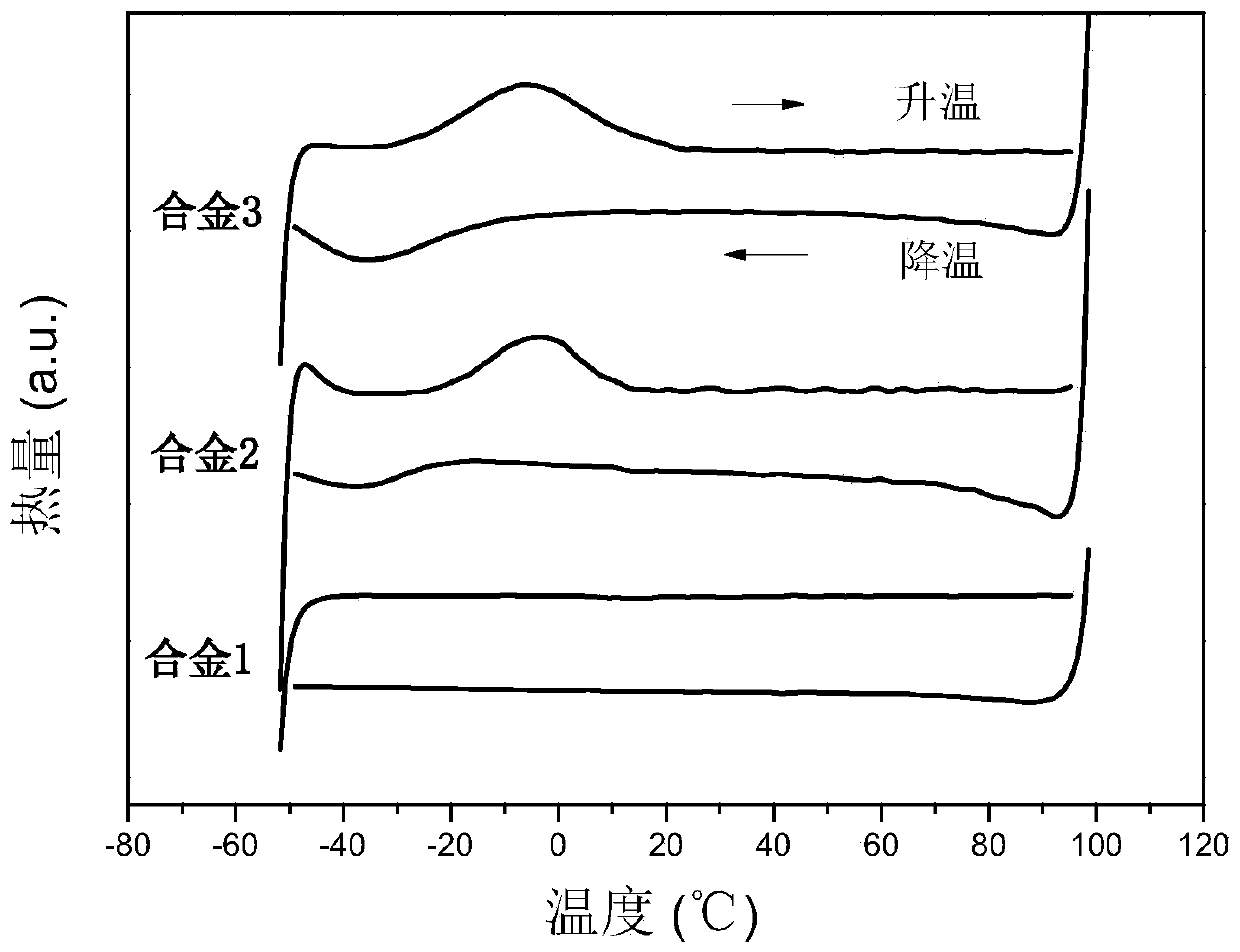

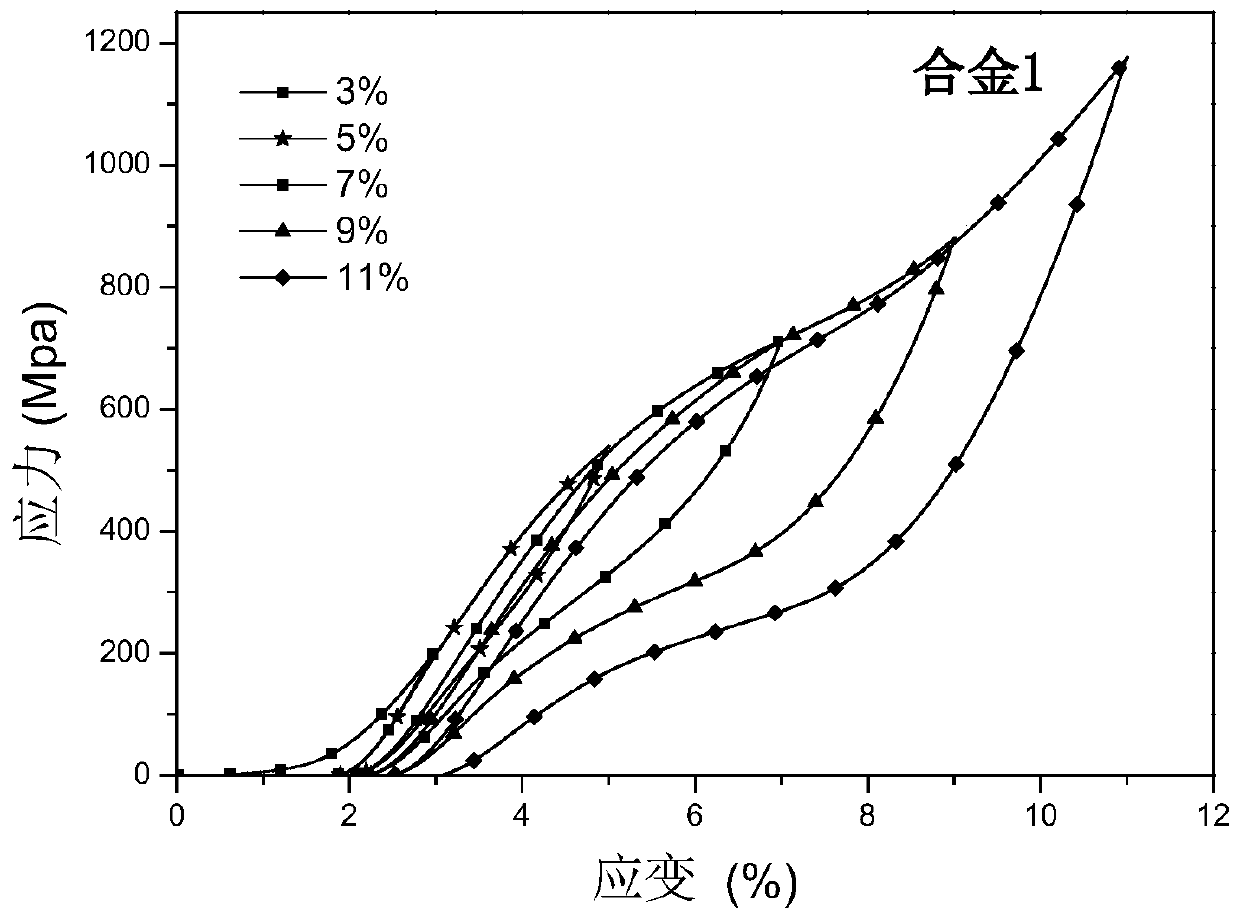

Low-temperature hyperelastic Ti-Ni-Cu-Y-Hf shape memory alloy and preparation method thereof

The invention relates to a low-temperature hyperelastic Ti-Ni-Cu-Y-Hf shape memory alloy and a preparation method thereof. The alloy is prepared from the following chemical components including, by atomic percent, 39%-47% of Ti, 42%-46% of Ni, 4%-8% of Cu, 0.5%-1.5% of Y and 2%-10% of Hf. The alloy is prepared by the following method of putting the raw materials including the Ti, the Ni, the Cu, the Y and the Hf in a vacuum arc melting furnace according to the component proportion, and repeatedly melting to obtain an alloy ingot; cutting the alloy ingot into a required shape, placing the alloyingot in a heat treatment furnace, filling argon, and performing homogenization treatment; rapidly putting the homogenized alloy ingot into an ice-water mixture, and carrying out quenching treatmentso as to obtain a solid solution state Ti-Ni-Cu-Y-Hf shape memory alloy; and cutting the solid solution state alloy into rod-shaped samples, and carrying out cyclic compression memory training to obtain the rod-shaped shape memory alloy with the higher recovery rate and superelasticity. The preparation method is low in cost, simple in process and easy to operate, and the prepared shape memory alloy has high recoverable strain and good low-temperature superelasticity and has potential application value.

Owner:CHINA THREE GORGES UNIV

Thin walled fuser roll with stress redirected from axial to radial direction

InactiveUS20050129433A1Energy efficiencyFaster warm up timeElectrographic process apparatusCyclic compressionMechanical engineering

A thin-walled fuser roll core cylinder assembly permitting fast warm-up times and improved energy efficiency wherein cracking of the thin walls of the core cylinder due to cyclic compression is prevented by redirecting axial stress at the terminus of an axial keyway to a radial direction. The keyway is for coupling the core cylinder to a drive gear. Use of such a thin-walled fuser roll in an imaging system and a process of fusing toner onto a copy substrate using the thin-walled fuser core.

Owner:XEROX CORP

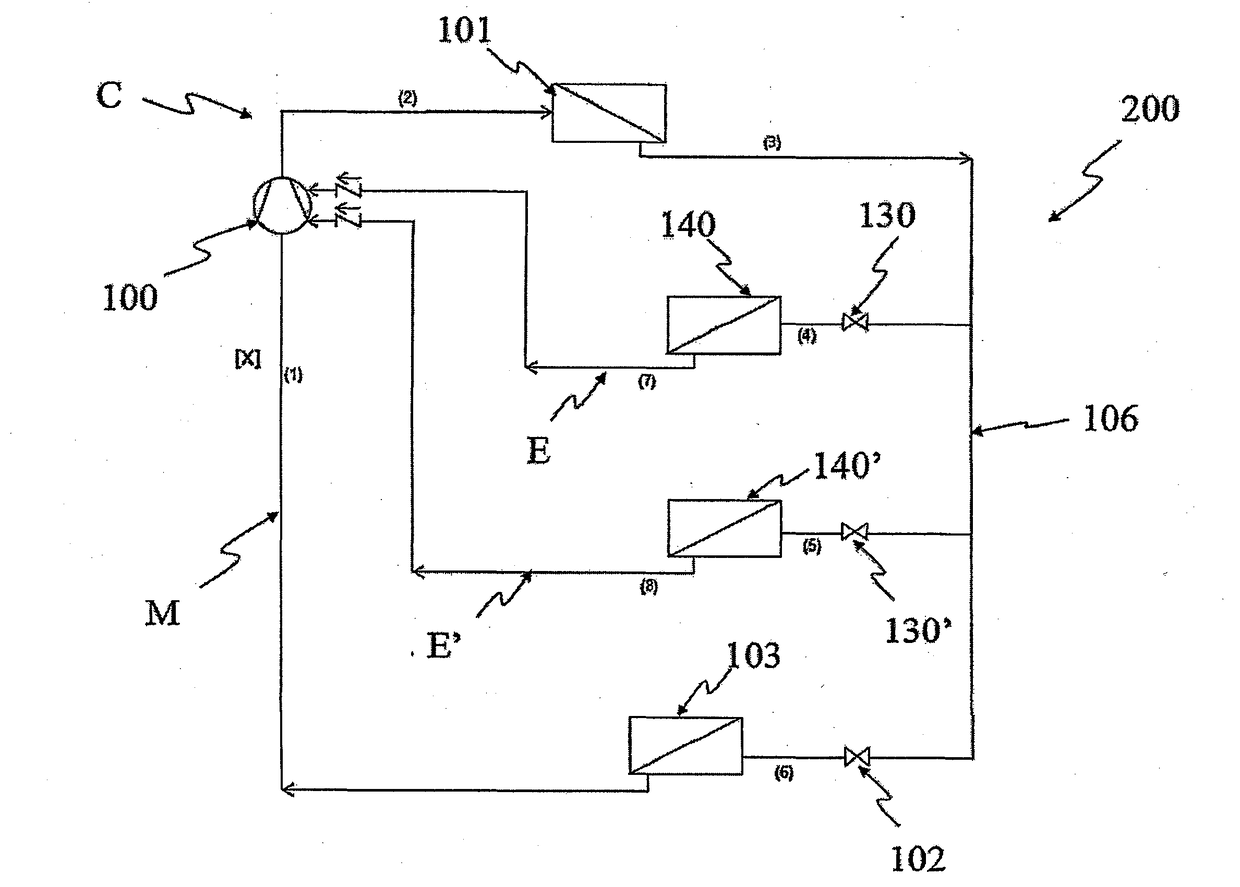

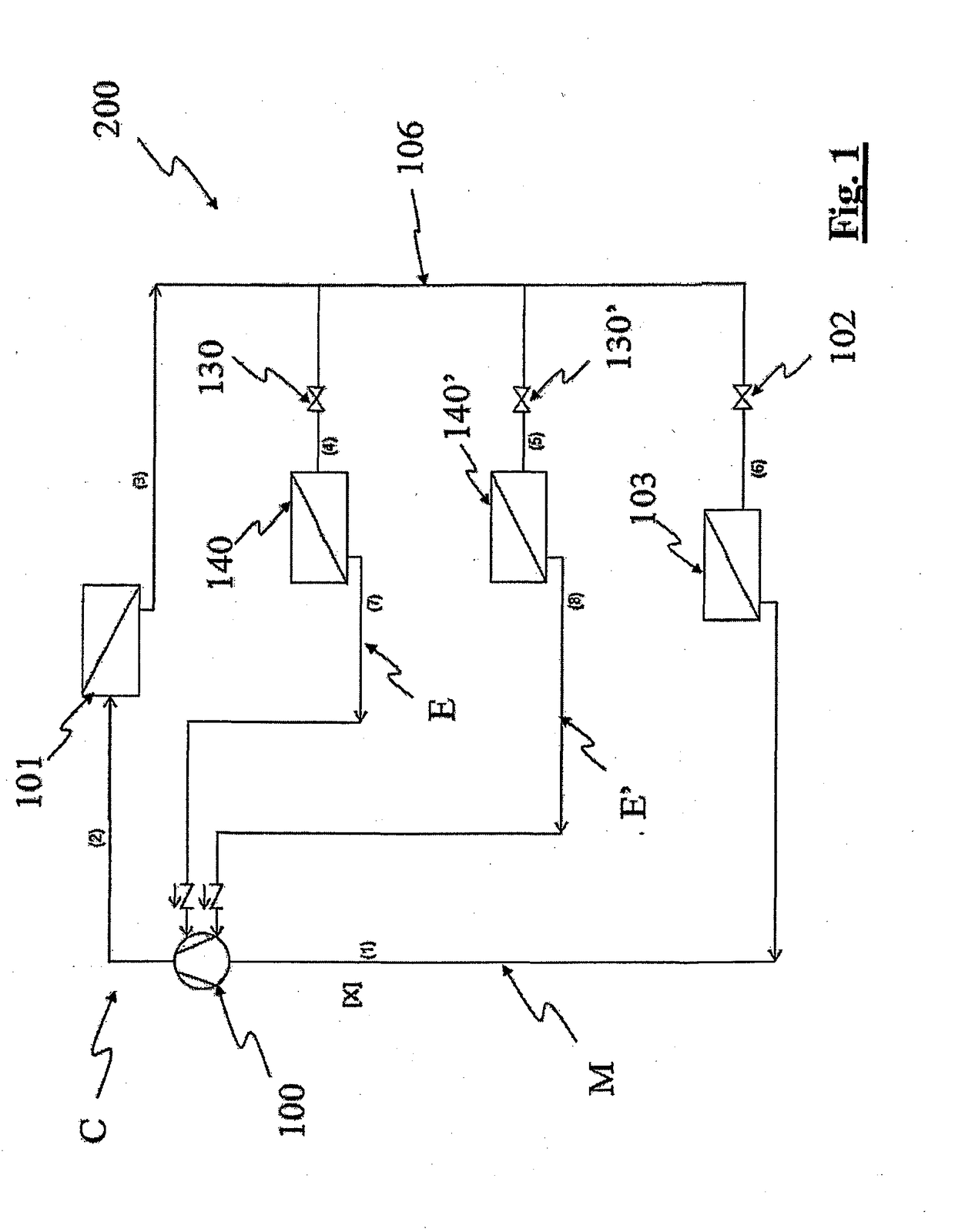

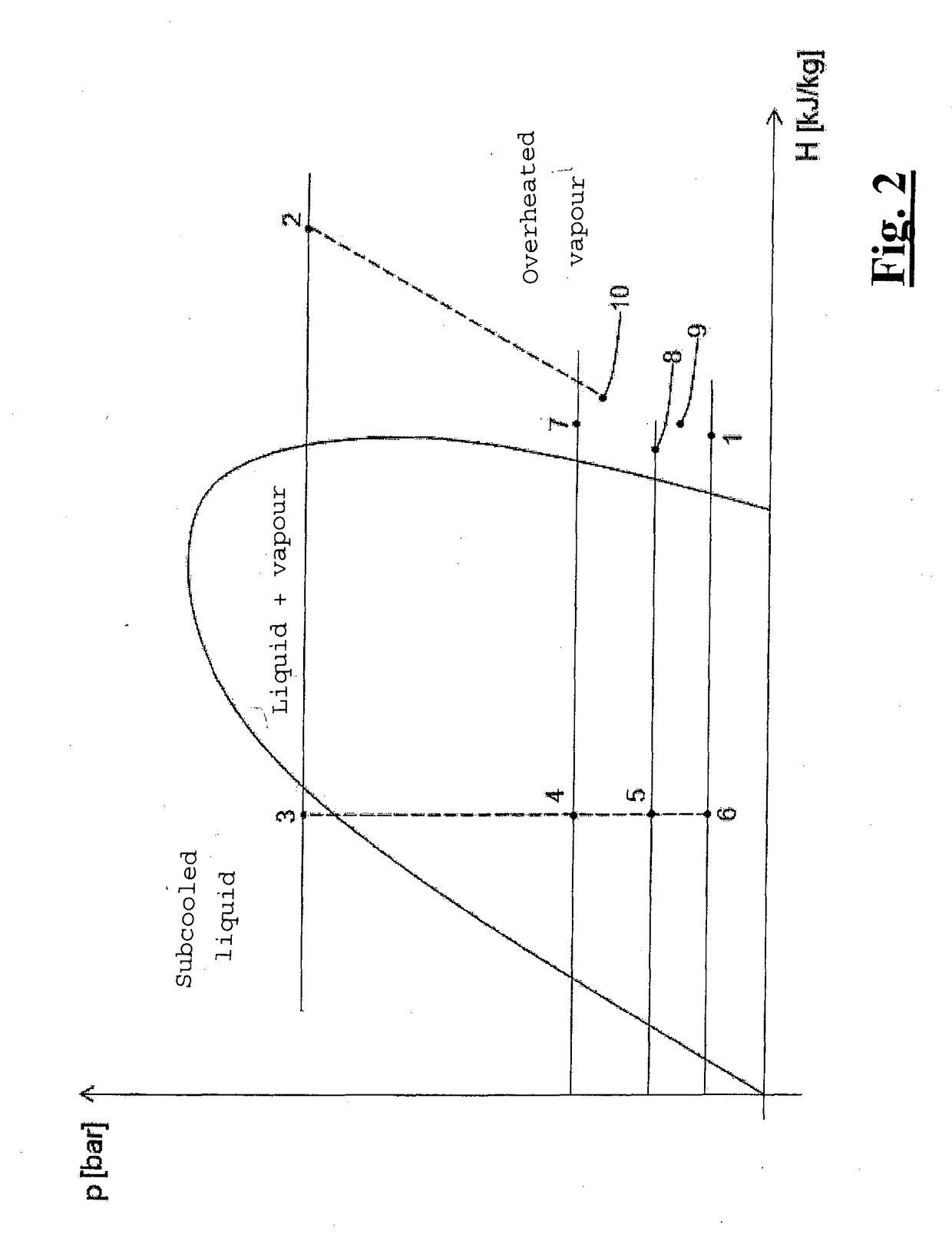

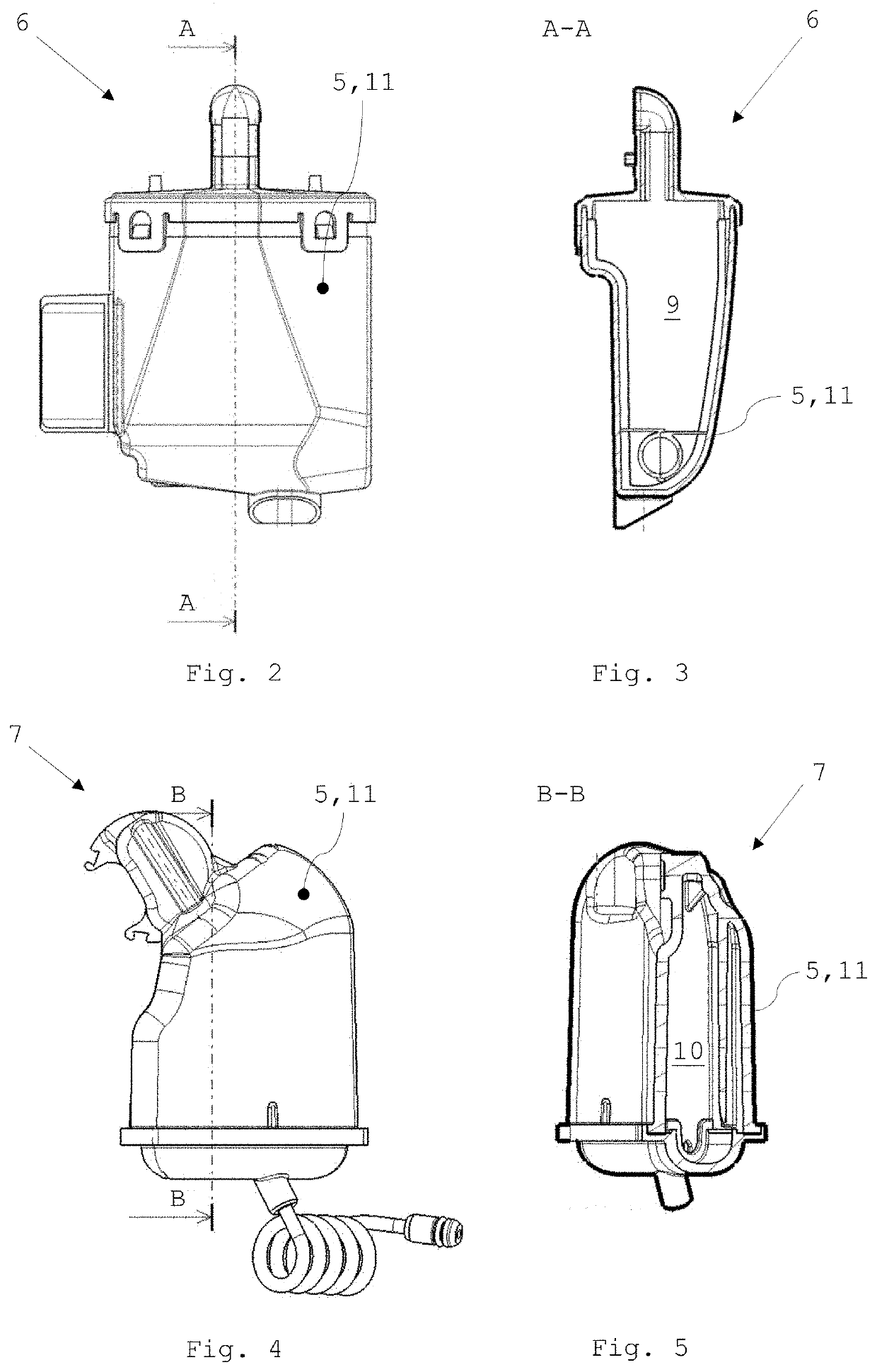

Reciprocating compressor for a cooling device

InactiveUS20180258922A1Inhibition biasAvoiding excessive lossCompressorPositive displacement pump componentsMain branchTop dead center

A reciprocating compressor for a cooling device provided with a closed circuit (C) having a main branch (M), in which a first flow rate (X) of circulating coolant enters in the compressor, and a first economizer branch, or secondary branch (E), in which a second flow rate (X1) of coolant circulates under a pressure different from the pressure of the first flow rate (X) of coolant, the compressor being provided with a cylinder and a piston reciprocatingly moving in the cylinder, between a top dead center (S) and a bottom dead center (I), and having a suction duct for the entrance of the first flow rate of coolant, and a port obtained in the wall of the cylinder for the entrance of the second flow rate of coolant, in such a way that the piston exposes at least in part the first inlet port, at least during its inlet stroke, and covers the port at least during its compression stroke, wherein the first inlet port has a slit shape with the main dimension substantially transverse to the axis (A) of the cylinder.

Owner:ANGELANTONI TEST TECH

Thin walled fuser roll with strengthened keyway

InactiveUS20050129435A1Improve energy efficiencyFaster warm up timeElectrographic process apparatusCyclic compressionMechanical engineering

A thin-walled fuser roll core cylinder assembly permitting fast warm-up times and improved energy efficiency wherein cracking of the thin walls due to cyclic compression is prevented by strengthening the thin walls proximate to the end region where the core cylinder is engaged by the drive gear. Use of such a thin-walled fuser roll in an imaging system and a process of fusing toner onto a copy substrate using the thin-walled fuser core.

Owner:XEROX CORP

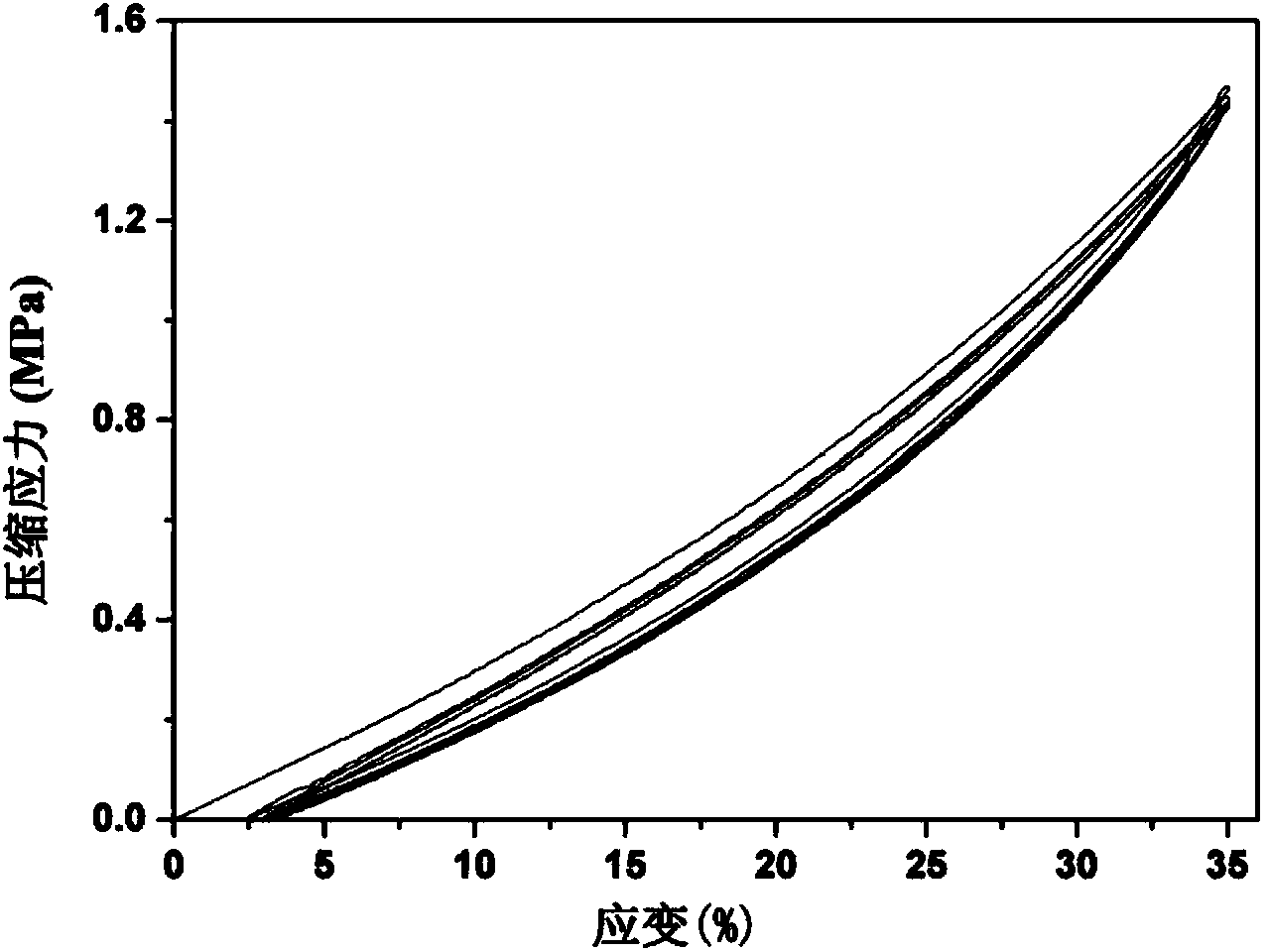

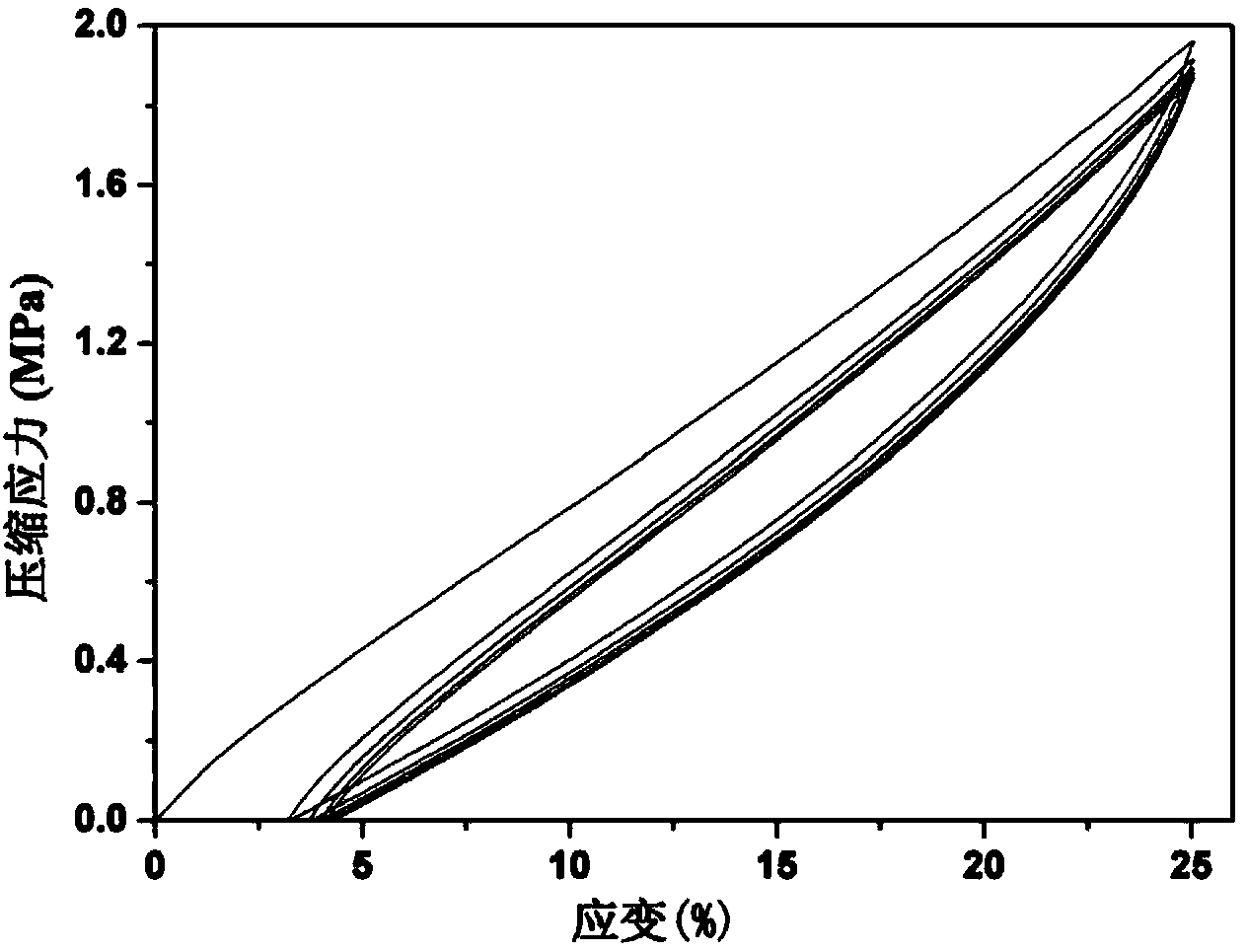

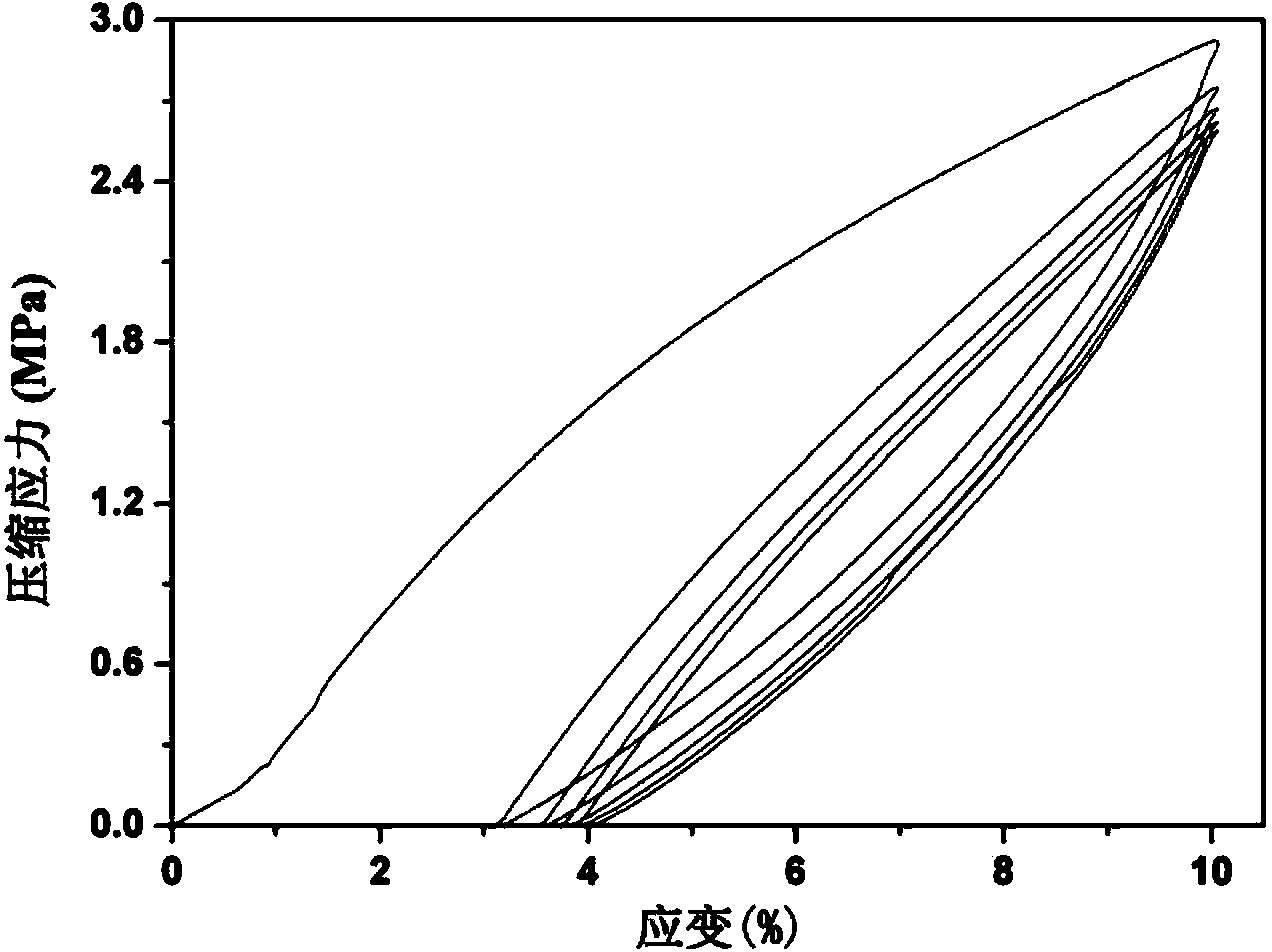

Characterization method for compression stress softening and transient-persistent deformation of elastic body

InactiveCN103776709AMaterial strength using repeated/pulsating forcesResidual strainClassical mechanics

The invention relates to a characterization method for the compression stress softening and transient-persistent deformation of an elastic body and provides an effective method for evaluating the stress softening and transient-persistent deformation of the elastic body under circular compression. A quantitative characterization method comprises the following steps: (a) carrying out single-shaft circular compression test on a columnar sample on a universal tensile test machine, and repeatedly and continuously compressing and releasing the sample at the same speed, so as to acquire a circular compression stress-strain curve; (b) reading the compression stress when the sample is compressed to a specific compression strain each time from the circular compression stress-strain curve, thus acquiring quantitative stress softening data under a circular compression mode; (c) calculating an instant height H1 of the sample according to the residual strain when the stress is reduced to 0 in each compression period on the circular compression stress-strain curve and recording transient compression deformation as K, wherein the initial height of the columnar sample is h0, the height of the columnar sample is hs when the sample is compressed to reach a stipulated compression strain, and a calculation formula is shown in the specification.

Owner:QINGDAO UNIV OF SCI & TECH

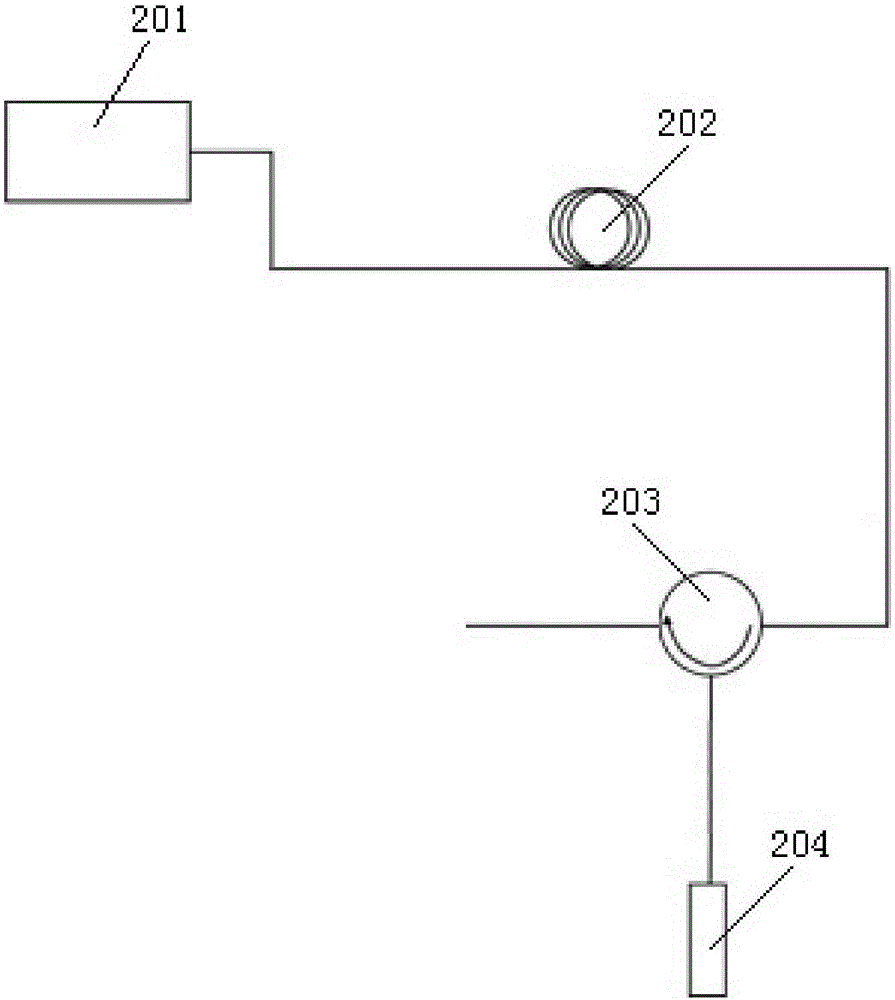

Wavelength-tunable narrow linewidth laser based on graphene Bragg grating

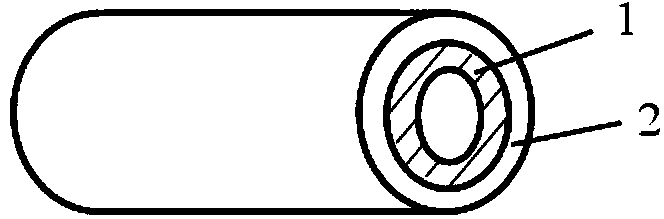

InactiveCN106654833AAdjust the center wavelengthHigh precisionActive medium shape and constructionGratingRefractive index

The invention provides a wavelength-tunable narrow linewidth laser based on a graphene Bragg grating. The wavelength-tunable narrow linewidth laser comprises the graphene Bragg grating, wherein the graphene Bragg grating comprises a fiber core, cladding and a graphene layer which covers the cladding in sequence from inside to outside. The thickness of the cladding is regulated to cover the cladding with the graphene layer, the light intensity of pump light transmitted to the fiber core is regulated to regulate the modulation refractive index of the graphene Bragg grating, the regulation of the central wavelength of the graphene Bragg grating is realized, so that the weave length of a laser signal returned and output by the graphene Bragg grating can be regulated, and the laser signal subjected to wavelength regulation can be subjected to further linewidth cyclic compression on the basis of a Rayleigh optical fiber. Through the laser, the central wavelength of the graphene Bragg grating can be regulated, the accuracy and the response time of the regulation of the central wavelength of the graphene Bragg grating are improved, and in addition, a laser signal with ultra-narrow linewidth can be obtained on the basis of the Rayleigh optical fiber.

Owner:CHONGQING UNIV

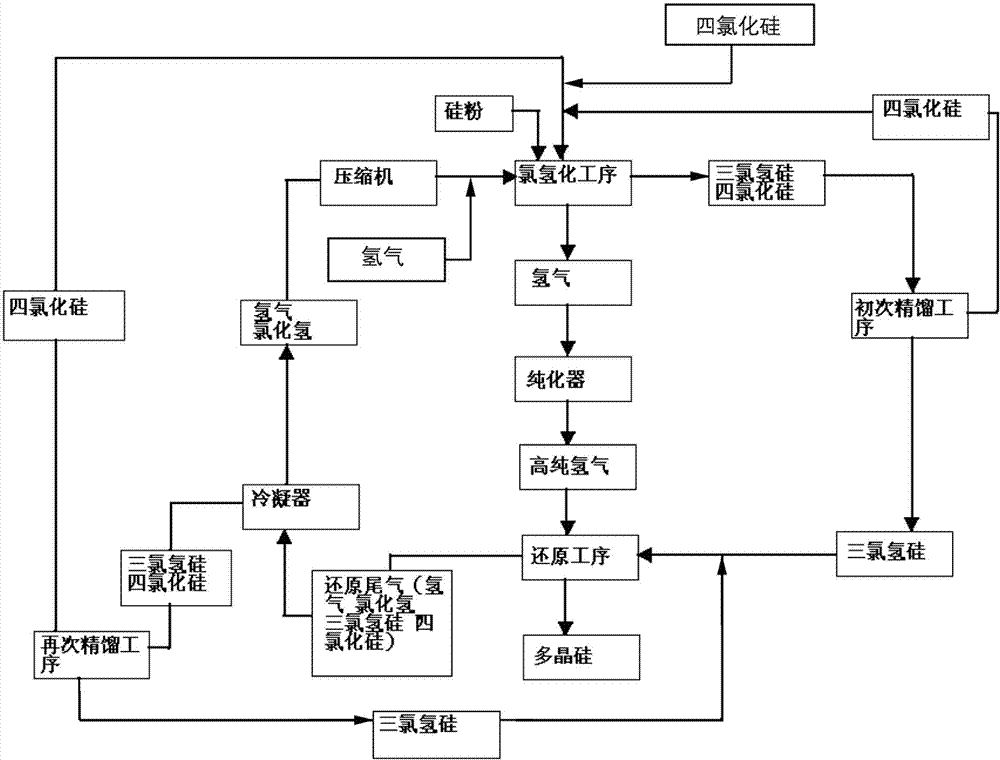

Polycrystalline silicon production process

The invention provides a polycrystalline silicon production process capable of simplifying process, reducing energy consumption and saving production cost. A chlorine hydride technique is used to substitute a synthetic process and a cold hydrogenation process in a traditional production system. A condenser and a purifier are used in the invention to substitute a dry recovery system in a traditional production system. A general circulation established between a hydrochlorination process and a reduction process can utilize hydrogen produced in the reduction as a supplementary gas for hydrochlorination, so that the operation cost is reduced. As the hydrochlorination and hydrogen reduction general circulation are realized, only a set of hydrogen compressor needs to be configured after the condenser, so as to save energy; and because of the one-stage compression, the number of one-time configured compressors and standby machines thereof is greatly reduced, thereby reducing one-time investment and operating costs by more than 10%.

Owner:巴彦淖尔聚光硅业有限公司

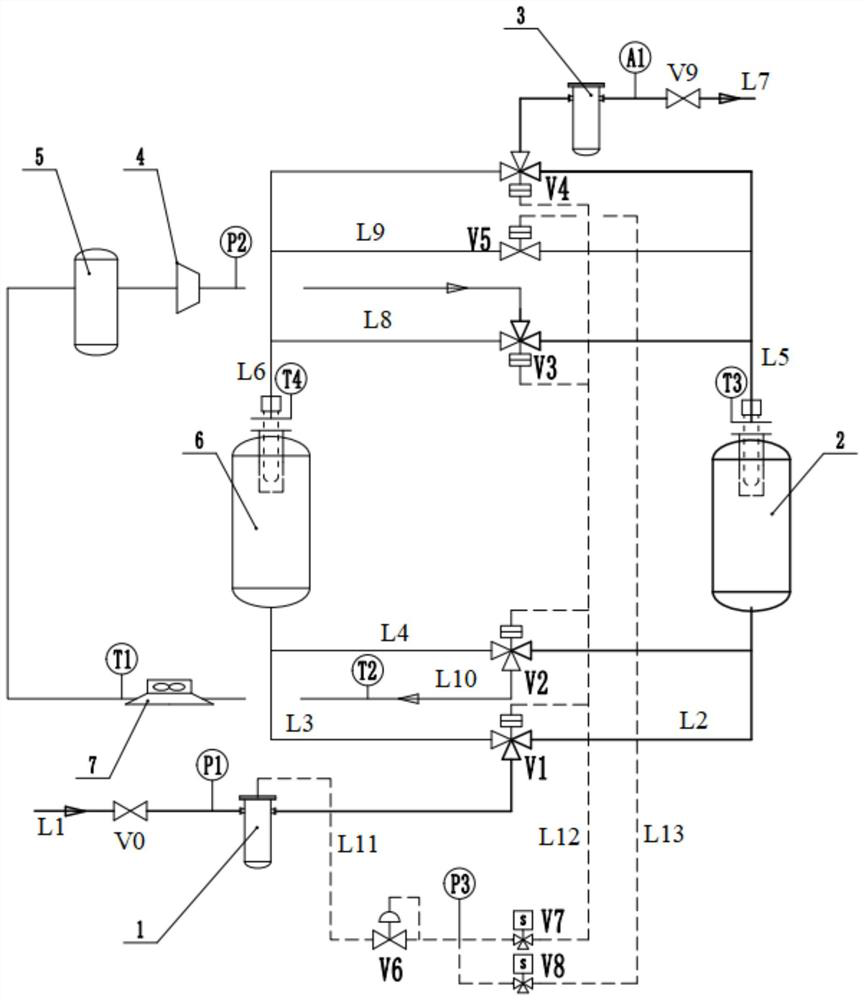

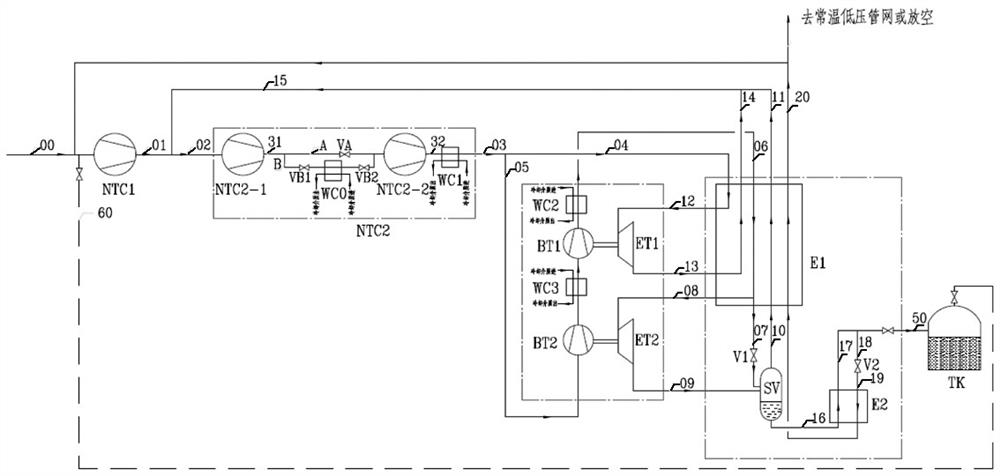

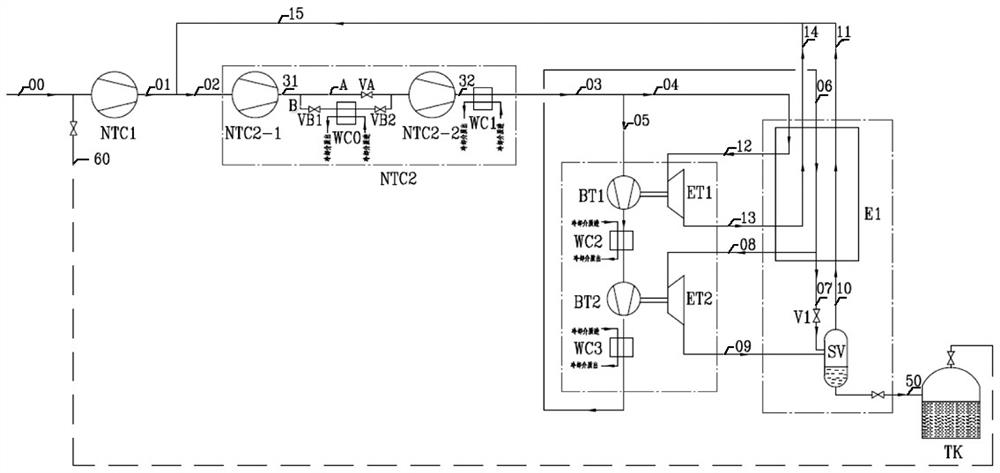

Natural gas heating and regeneration integrated dehydration device and method

PendingCN114231327ASatisfy the function of zero emissionMeet the requirements of transportationGas treatmentDispersed particle filtrationAir compressionVapor–liquid separator

The invention relates to a natural gas heating and regeneration integrated dehydration device and method, the device comprises an inlet filter (1), a first dehydration tower (2), a second dehydration tower (6), an outlet filter (3), a circulating compressor (4), a gas-liquid separator (5) and a cooler (7), and the first dehydration tower (2) and the second dehydration tower (6) are switched for adsorption and regeneration. According to the device disclosed by the invention, the heater and the drying tower are designed in a built-in manner, the inlet and the outlet of the tower adopt a filter element form and can be randomly disassembled, assembled and replaced, the structure meets a larger flow area, the device does not need an additional instrument air compression system, air filtered at the inlet can meet instrument air source conditions, energy consumption is avoided, and the gas quality is clean.

Owner:XINDI ENERGY ENG TECH

Preparing method of fine-grain large-size magnesium alloy profile

The invention provides a preparing method of a fine-grain large-size magnesium alloy profile. The method sequentially includes the steps of performing homogenization heat treatment on a magnesium alloy ingot blank, performing upsetting, three times of cyclic compressing and rolling, putting the magnesium alloy ingot blank back into a furnace for heat preserving, performing upsetting, four times ofcyclic compressing and rolling, putting the magnesium alloy ingot blank back into the furnace for heat preserving, performing upsetting, five times of cyclic compressing and rolling, putting the magnesium alloy ingot blank back into the furnace for heat preserving, performing upsetting, six times of cyclic compressing and rolling, putting the magnesium alloy ingot blank back into the furnace forheat preserving, performing extruding by means of residual heat, and performing quenching at an extrusion outlet through an annular nozzle to obtain the magnesium alloy profile. By means of the method, the blank can be effectively prevented from cracking in the preparing process, the edge temperature and deformability of the blank can be improved, complete static recrystallization can happen to magnesium alloy, more importantly, grains of the magnesium alloy profile can be refined, and the preparing method is particularly suitable for preparing the large-size magnesium alloy profile.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

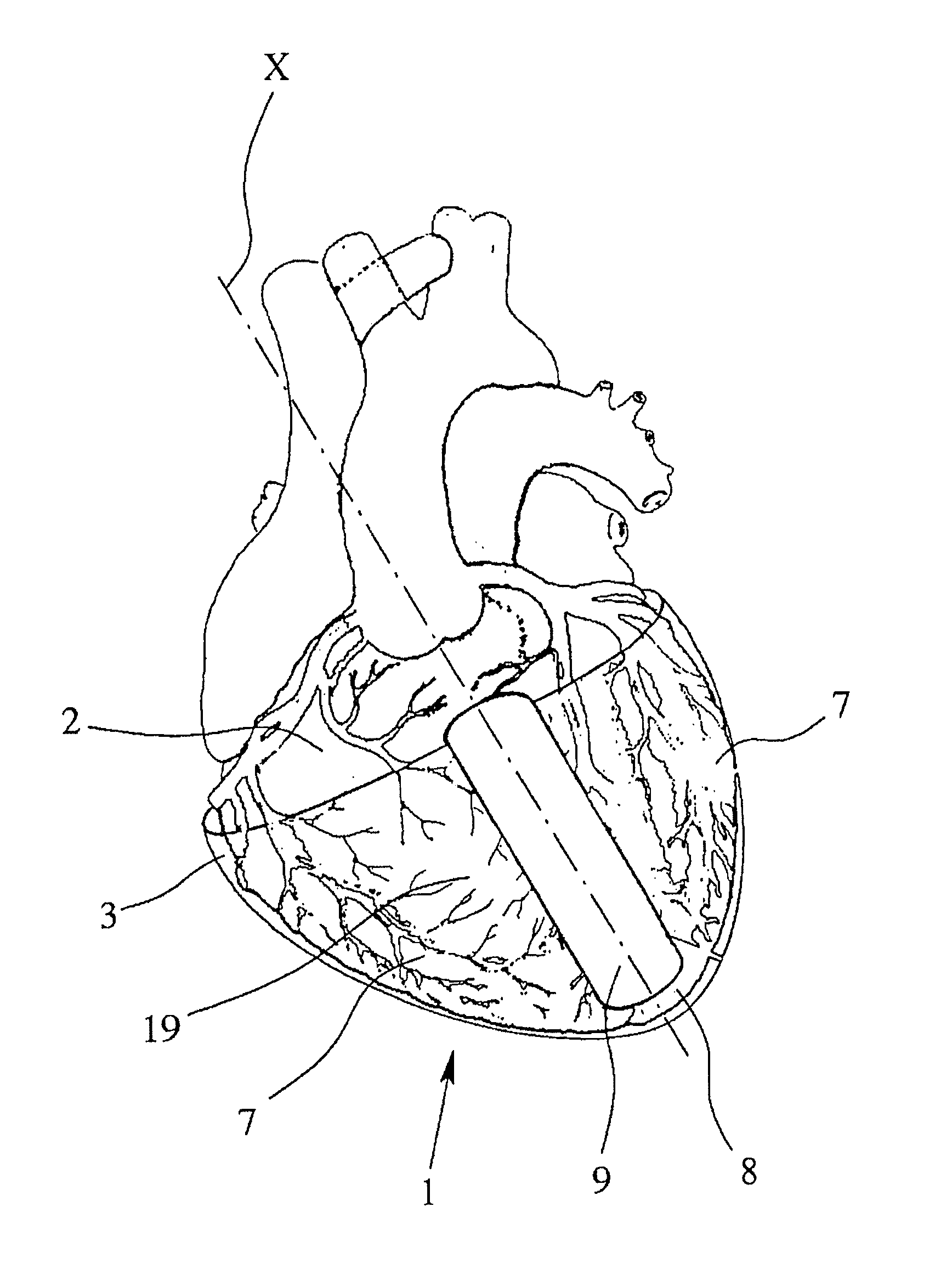

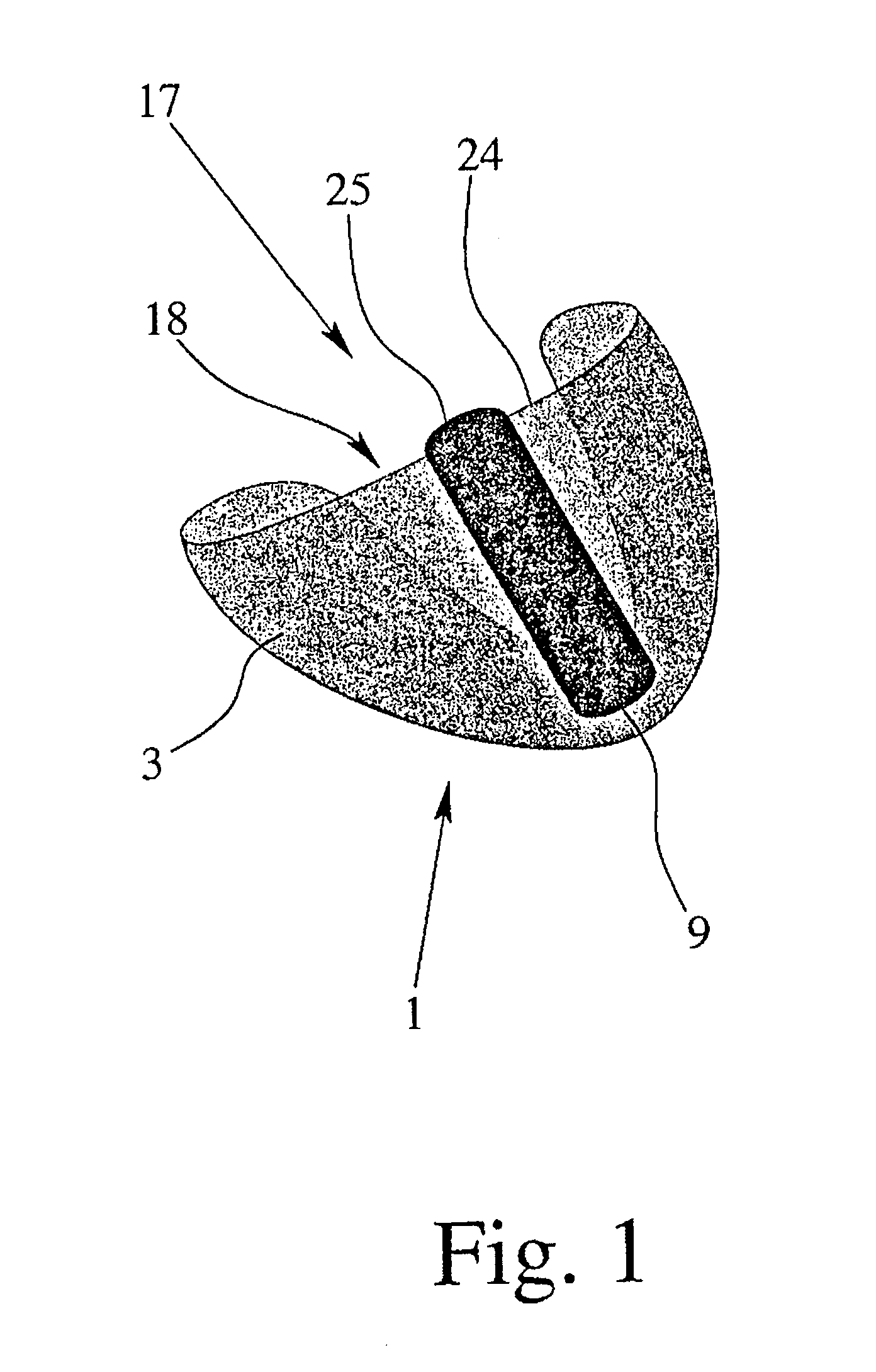

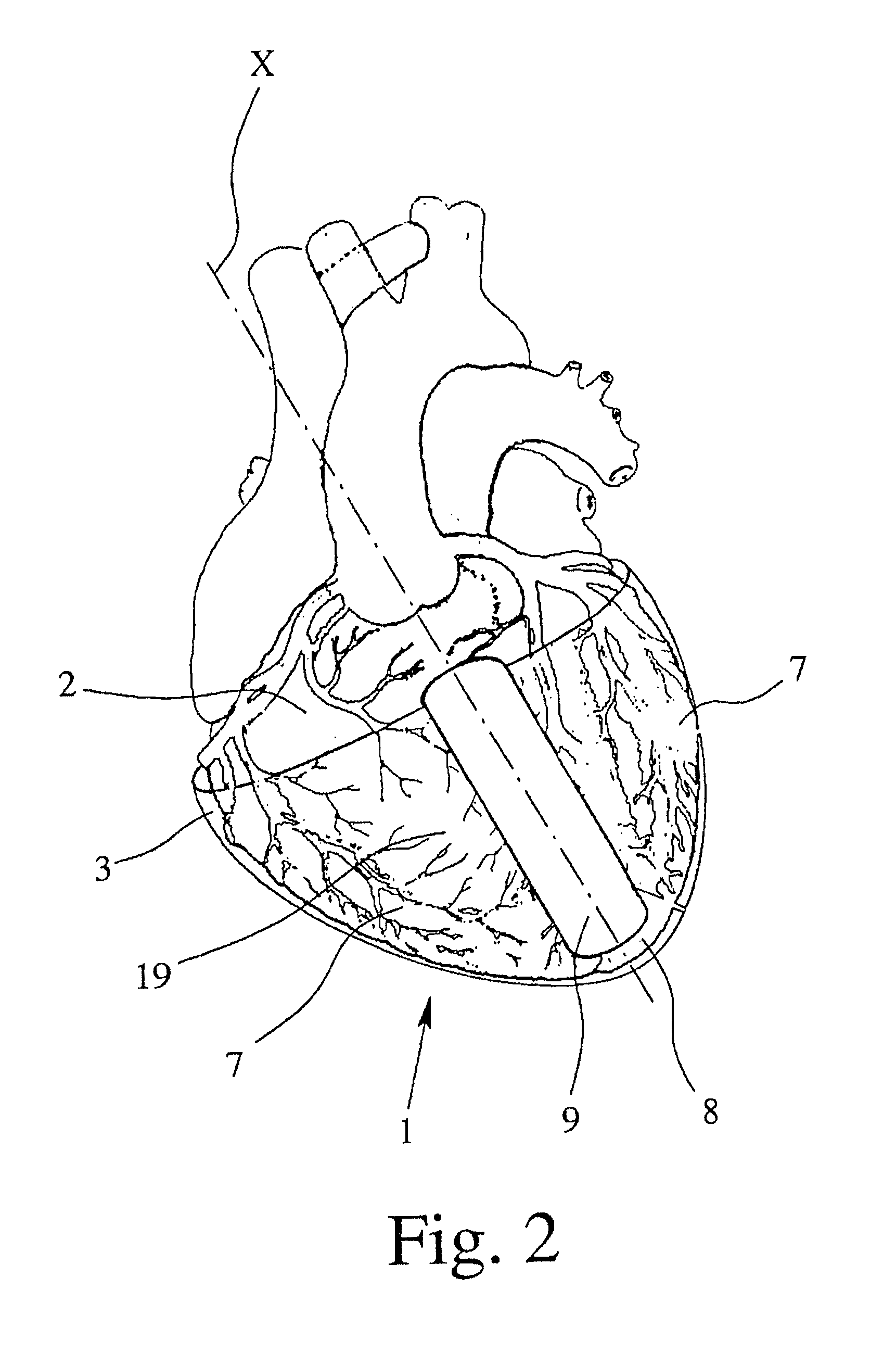

Device and system for assisting and/or taking over the pumping function of the heart

InactiveUS20110098806A1Without risk of damageEasy to introduceIntravenous devicesBlood pumpCyclic compressionBiomedical engineering

A device for assisting and / or taking over the pumping function of the heart, with a multilayer sheathing part configured for compressing the heart at least in certain sections, wherein the sheathing part has at least one stabilization layer for shaping the sheathing part and at least one inner extensible augmentation layer, and wherein at least one cavity is formed between the stabilization layer and the augmentation layer, the cavity being inflatable and deflatable by a fluid, for cyclic compression of the heart. Provision is made for the stabilization layer to be inflatable with a fluid, at least in certain sections, in order to convert the sheathing part from a coiled and / or collapsed insertion state of the device in the body into an arched functional state, wherein the heart, in the functional state of the sheathing part, is at least partially sheathed and / or encompassed.

Owner:PPA TECH GMBH

Device for recycling cold energy of low-temperature nitrogen and using method of device

PendingCN113758148AReduce energy consumptionLow cooling recovery efficiencySolidificationLiquefactionEnergy recoveryCyclic compression

The invention discloses a device for recycling cold energy of low-temperature nitrogen and a using method of the device. The device comprises a compression system, an expansion refrigeration system and a heat exchange system which communicate through pipelines and valves, the compression system is composed of a raw material compressor suitable for low-temperature gas and a circulating compressor suitable for low-temperature gas. The compressor is used for compressing low-temperature nitrogen. The expansion refrigeration system is composed of one or more turbo expanders and provides a cold source for the device. The heat exchange system is composed of one or more sets of heat exchangers and used for heat exchange of nitrogen liquefaction. The three systems are highly coupled, can adapt to the raw material low-temperature nitrogen under different temperature conditions, are wide in application range, and can greatly improve the cold energy recovery efficiency of the low-temperature nitrogen and reduce the energy consumption of liquid nitrogen products.

Owner:HANGZHOU HANGYANG

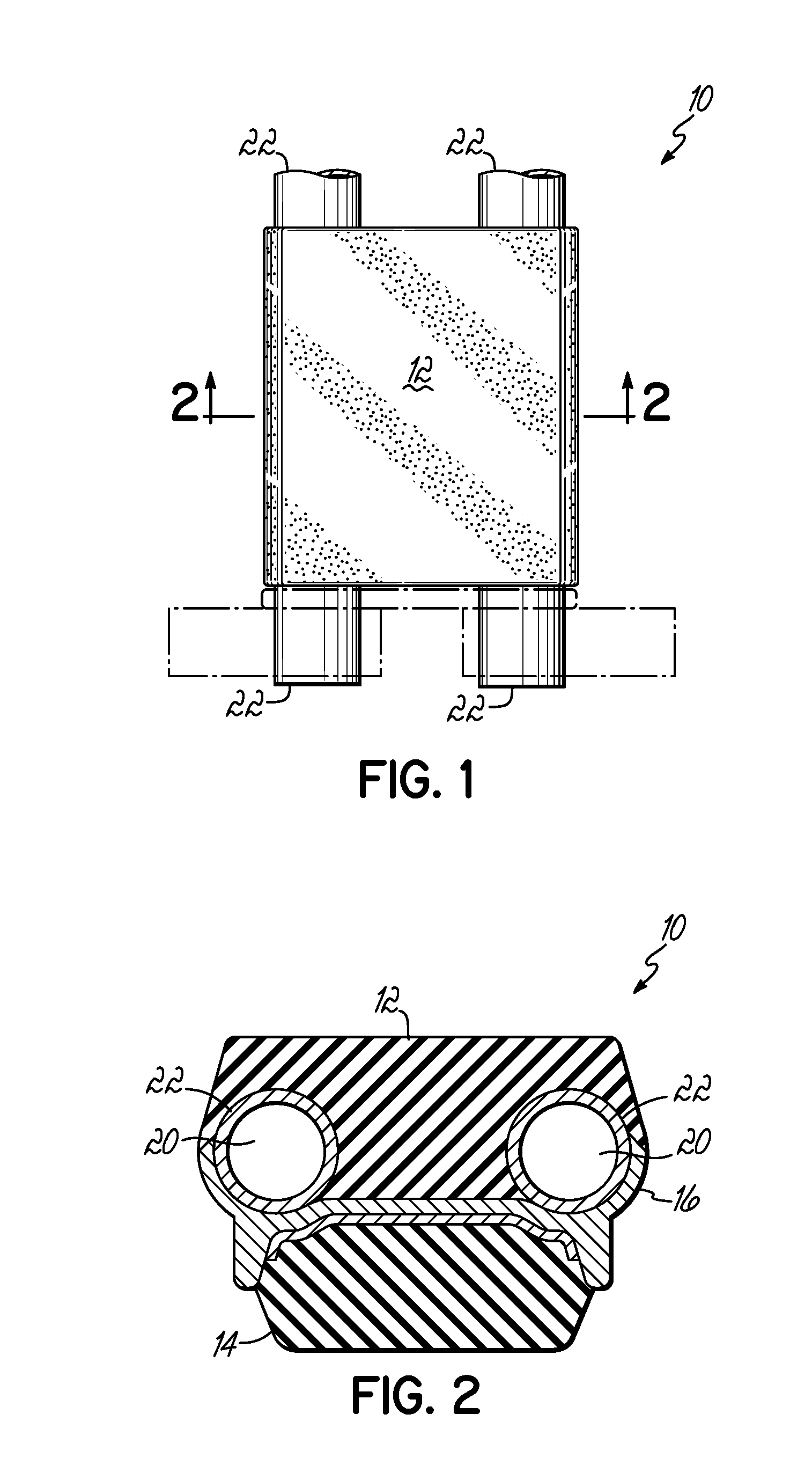

Track segment with EP(D)M rubber based backer and method of making

InactiveUS7901016B2Improve heat resistanceGood cut/tear strengthEndless track vehiclesEngineeringCyclic compression

Owner:VEYANCE TECH

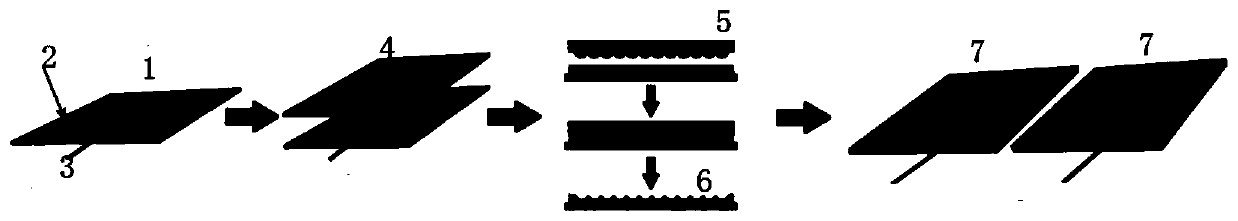

Method for dilute acid pretreatment of plant straws by microwave-cyclic compression percolation

ActiveCN103060481AImprove reaction efficiencyReduce concentrationBiofuelsGlucose productionPhysical chemistryEngineering

The invention discloses a method for dilute acid pretreatment of plant straws by microwave-cyclic compression percolation. The method comprises: first conducting standing infiltration on straw particles with a dilute acid solution, then loading the straw particles into a cylindrical reactor, performing fed-batch of the dilute acid solution to the reactor, and at the same time, applying the action of microwave and compressing the straw particles, and discharging the liquid in the reactor; after solid-liquid separation, re-injecting the acid solution and dispersing the straw particles uniformly; carrying out fed-batch of the filtrate obtained from the separation to the reactor, and at the same time, applying the action of microwave and compressing the straw particles, and discharging the liquid in the reactor; and repeating the operations till the end of the reaction. By infiltrating the straw particles in the acid solution in advance and adopting a filtrate cyclic compression mode, the method provided in the invention reduces the concentration and dosage of the acid solution, increases the reaction product concentration, and enhances the reaction speed simultaneously.

Owner:CHINA PETROLEUM & CHEM CORP +1

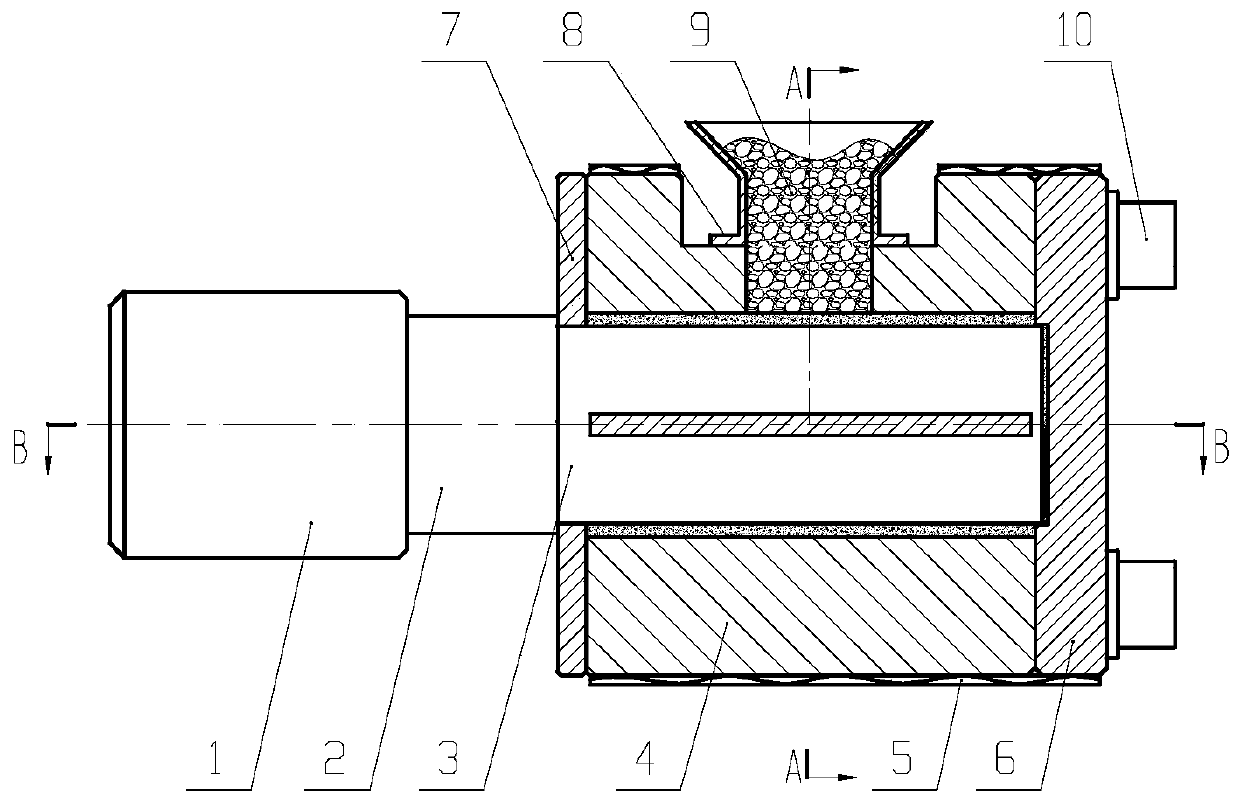

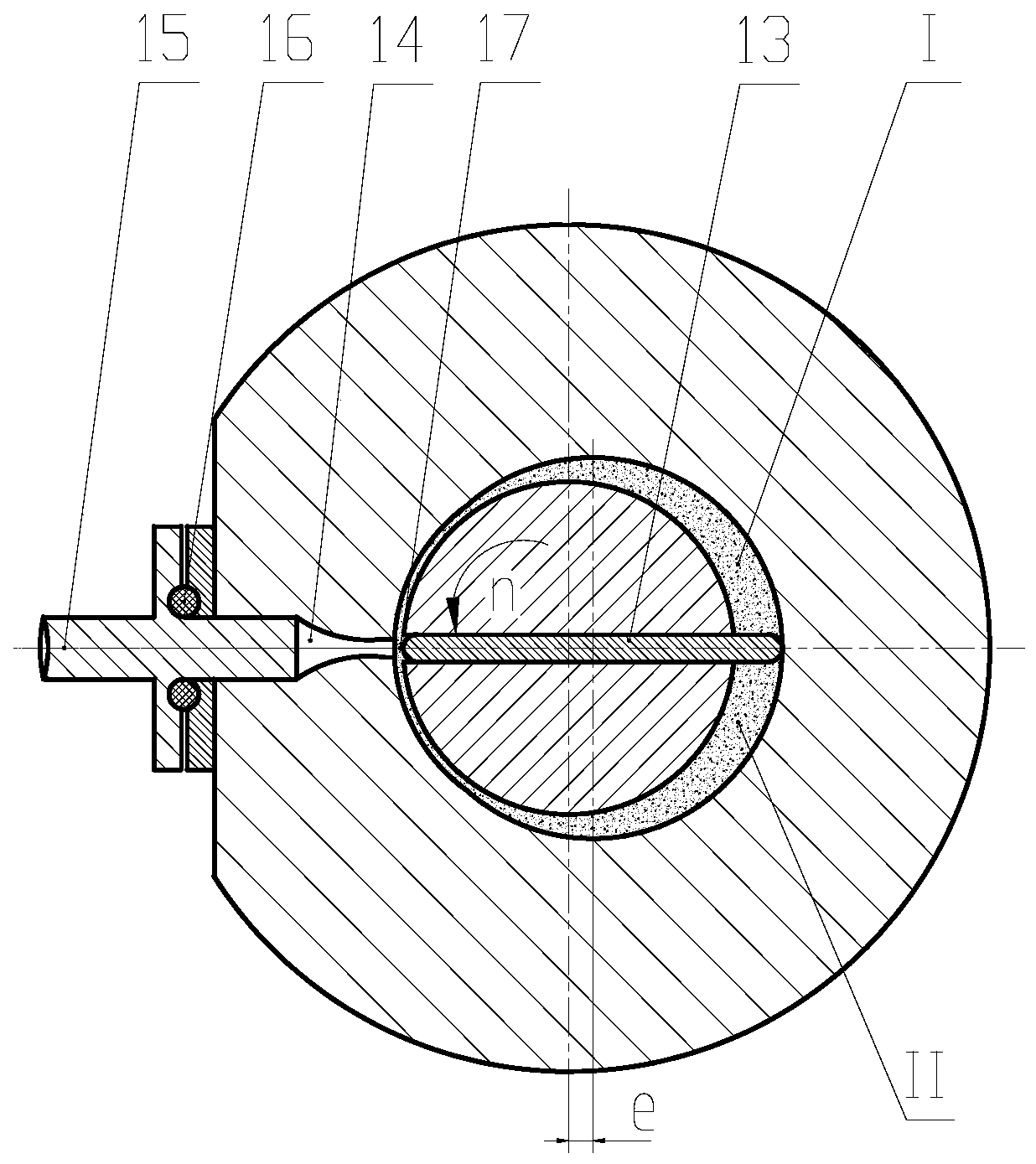

Method and device for synergistically preparing ultrahigh-viscosity polymer blend

The invention discloses a method and device for synergistically preparing an ultrahigh-viscosity polymer blend. According to the method, a material flows in circularly compressed and expanding modes during periodical change of the size, and is under the size tensile stress effect in the direction consistent with the flowing direction, ultrasonic vibration is superposed in the direction perpendicular to the flowing direction through an ultrasonic device arranged at a through hole of an eccentric stator, and polymer material mixing under the synergistic effect of the vibration shear stress and the size tensile stress is achieved. A rectangular through groove is radially formed in a rotor shaft of the device, a sliding plate is placed in the radial rectangular through groove of the rotor shaft, a volume enclosure space is divided into two periodical change parts by the sliding plate, and the two parts communicate through a passing groove; a vibration transmission rod is connected with anultrasonic generator; and the vibration transmission rod is mounted in the through hole of the eccentric stator through a flange plate and a flange. The processes of mass transfer and heat transfer inthe mixing process are reinforced, and the characteristics that a mixing device is simple in structure, high in mixing efficiency, good in mixing property and capable of being automatically cleaned are achieved.

Owner:SOUTH CHINA UNIV OF TECH +1

Track segment with ep(d)m rubber based backer and method of making

InactiveUS20090102280A1Improve heat resistanceGood cut/tear strengthEndless track vehiclesPolymer scienceEthylene-propylene-diene-monomer

The present invention is directed generally to track segments for track vehicles and, more specifically, to a track segment having an ethylene propylene diene monomer (EP(D)M) rubber based backer, and a method of making. In one embodiment, the track segment includes an EP(D)M rubber based backer including a rubber compound having 100 phr EP(D)M rubber wherein the diene component is optionally present, a peroxide curing agent, and one or more acrylic and / or methacrylic coagents. The track segment further includes a track pad and a track body. The track pad and backer cooperate with the track body to define the track segment for use in a track for a track vehicle. The EP(D)M rubber based compound provides a desirable balance of low heat build-up under heavy dynamic cyclic compression conditions, and also has a desirable load carrying capability, high heat resistance, and good cut / tear strength in hot climates.

Owner:VEYANCE TECH

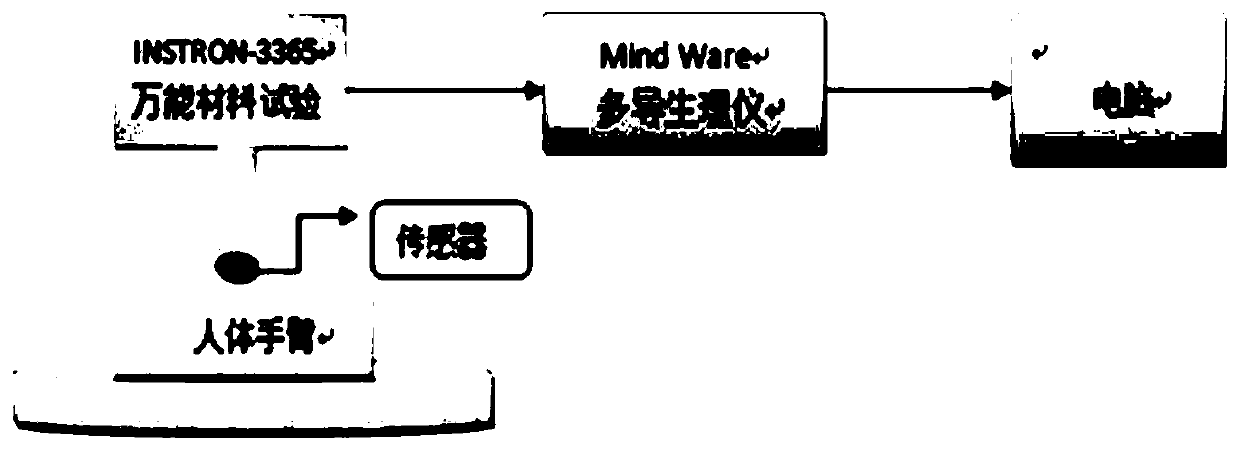

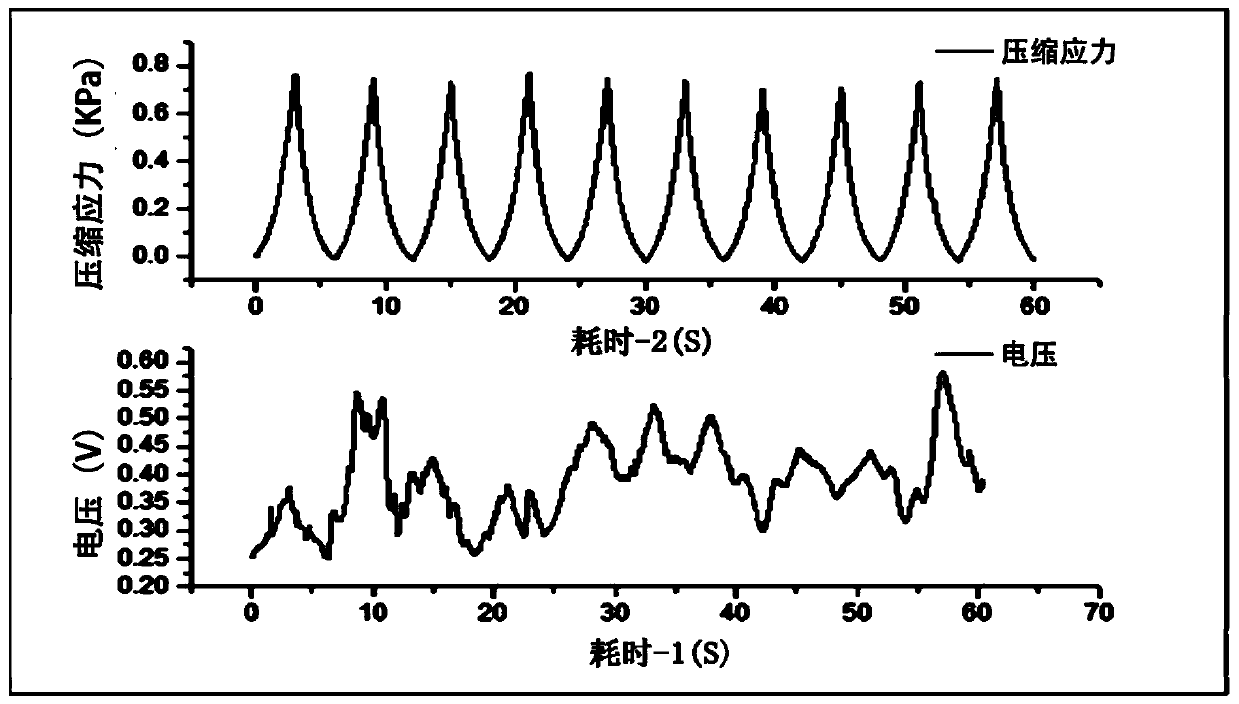

Skin touch sensor and manufacturing method thereof

PendingCN110530558ADisadvantages of changing only for large pressure measurementsForce measurementMaterials testingCyclic compression

The invention discloses a skin touch sensor. The skin touch sensor comprises a flexible base layer and a conductive composite material layer, wherein a plurality of groove structures are arranged on the conductive composite material layer; and the skin touch sensor is characterized in that the relevant coefficient of voltage and pressure of the skin touch sensor is formed by steps of placing sensors on the skin on the inner side of a human arm, then connecting the sensors with a Mind Ware multi-guide physiological instrument, next carrying out repeated cyclic compression experiment data collection on the sensors with different sizes through a universal material testing machine INSTRON, and then carrying out data fitting. The invention further discloses a preparation method of the skin touch sensor. The skin touch pressure sensor provided by the invention has the beneficial effects of being combined with any textiles to prepare the skin touch pressure sensor capable of measuring the small pressure, so that the defect that the skin touch sensor is only suitable for high pressure measurement is overcome; and in addition, the skin touch sensor can be directly worn and directly attachedto skin of the surface of a human body, and can be used for testing the pressure borne by the human body in static or dynamic states.

Owner:MINJIANG UNIV

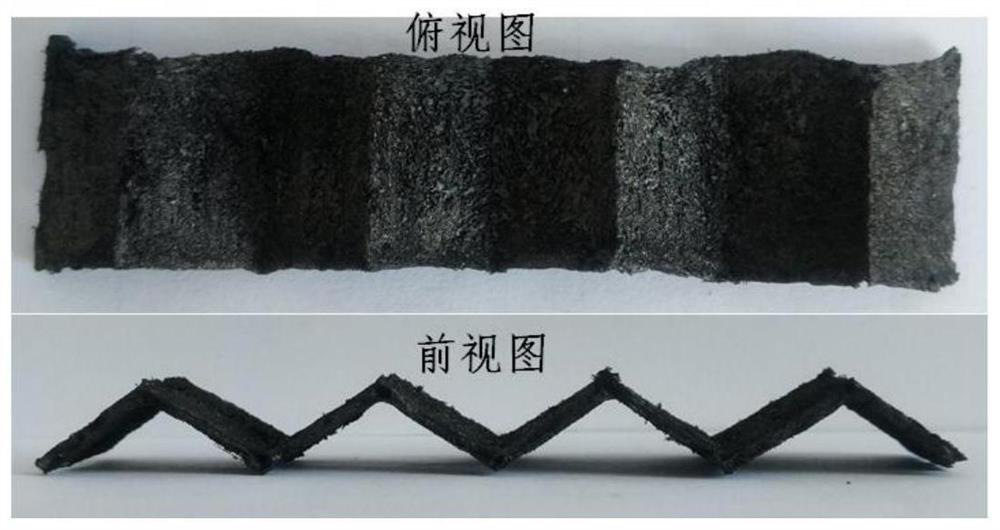

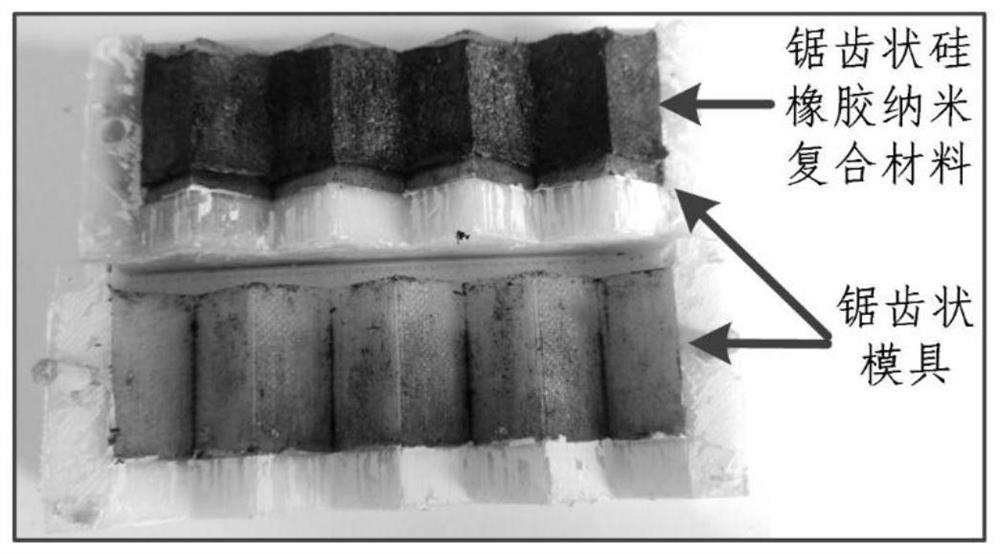

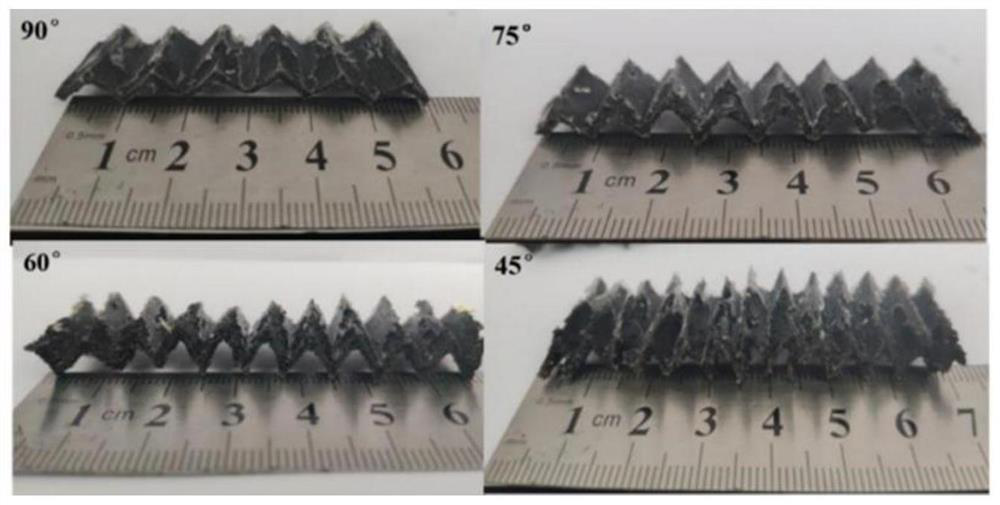

Sawtooth-shaped conductive silicone rubber nano composite material as well as preparation method and application thereof

ActiveCN114854199AOvercome the defect of simplification of macroscopic shapeImprove electromagnetic shielding performanceAdditive manufacturing apparatusMagnetic/electric field screeningRubber materialCyclic compression

The invention discloses a zigzag conductive silicone rubber nano composite material as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly, constructing a three-dimensional continuous conductive aerogel network in a zigzag mold by using a high-conductivity carbon nanomaterial; and filling the gel network with a silicone rubber prepolymer, and curing / demolding to form the flexible zigzag conductive silicone rubber material with a specific included angle. The composite material can show excellent conductivity under the condition of extremely low filler content (less than or equal to 5.0 wt%). Besides, under the condition that the content of the conductive filler is kept fixed, the electromagnetic shielding effectiveness value of the material can be effectively adjusted by simply adjusting and controlling the included angle (15-120 degrees) of the zigzag material, for example, the electromagnetic shielding effectiveness under the X wave band (8.2-12.4 GHz) can be controllably adjusted within the range of 31.0-48.3 dB. Meanwhile, the macroscopic zigzag structure also has excellent angle stability, and the angle of the zigzag structure is not obviously changed after 1000 times of cyclic compression-tensile tests.

Owner:QINGDAO UNIV OF SCI & TECH

VPSA large-capacity centrifugal vacuum pump

PendingCN106593899ARelieve pressureIncrease pressurePump componentsRadial flow pumpsEngineeringCyclic compression

The invention relates to a VPSA large-capacity centrifugal vacuum pump. A backward bending type three dimensional impeller and a vaneless diffuser are adopted in each stage of the VPSA large-capacity centrifugal vacuum pump, a cooler is installed between every two sections, a cooler is installed on the outlet of the last section, and three coolers exist. An air inlet chamber and an air outlet spiral chamber are installed in every section, and three air inlet chambers and three air outlet spiral chambers exist. The air inlet chambers are double bracing radial air inlet chambers, and the air outlet spiral chambers are circular symmetrical spiral chambers. When the VPSA large-capacity centrifugal vacuum pump works, air is sucked through the air inlet chambers and rotates at high speed with the first-stage impeller; under the effect of centrifugal force, the kinetic energy and the static energy of the air are increased and threw out through passageways among vanes in the radial direction, and enter the first-stage diffuser with a gradually enlarged passageway area; the kinetic energy of the air is reduced and conversed into the static energy, the pressure of the air is increased, and then the air passes through a first-stage bending way and a return device and enters the second stage to be compressed continuously. Cyclic compression is conducted in sequence, after the last compression is completed, and the air is collected through a spiral shell and discharged through an exhaust pipe. As the exhausting process is conducted continuously, the mass flow rate is continuously reduced, inlet pressure is continuously reduced, the vacuum degree is continuously improved, and until the next cycle period, a unit is under the operating process with continuous changeable working conditions.

Owner:JIANGSU ASIA PACIFIC IND PUMP TECH DEV CO LTD

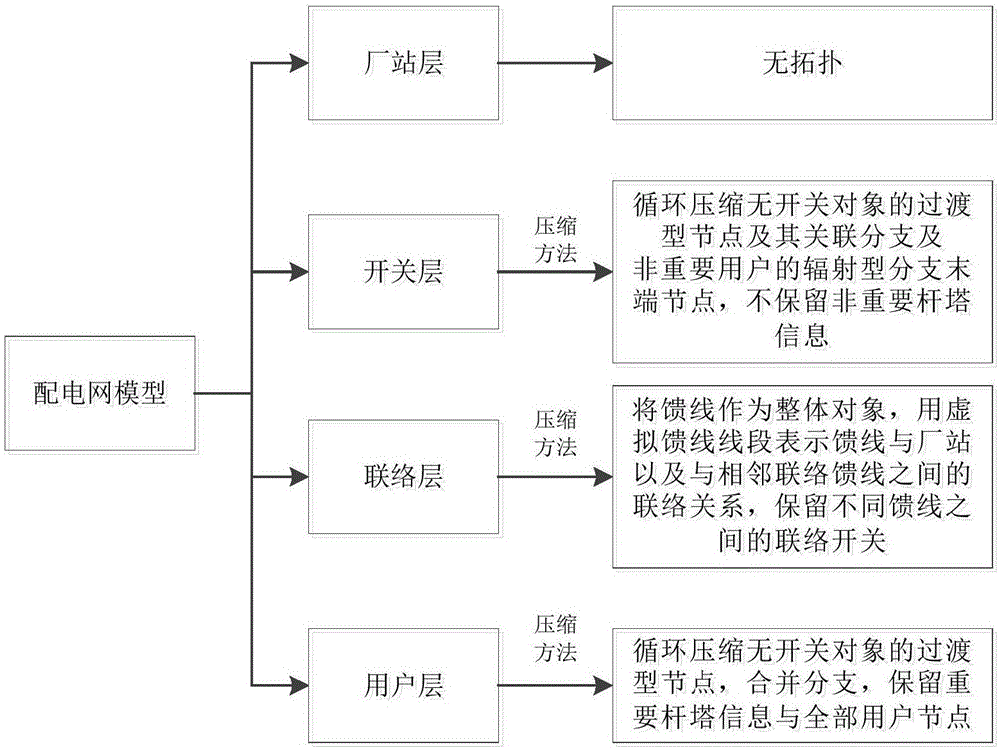

Hierarchical abstraction and compression method for distribution network model

InactiveCN105022892AMeet scheduling decision requirementsImprove retrieval efficiencySpecial data processing applicationsCyclic compressionTower

The invention discloses a hierarchical abstraction and compression method for a distribution network model. The distribution network model is abstractly divided into four layers: a plant station layer, a switch layer, a connectivity layer and a user layer, wherein the connectivity layer, the switch layer and the user layer are obtained according to a compression algorithm, the compression rule of which is as follows: the connectivity layer: a feeder line is a whole object which is compressed to a segment and connectivity switches among different feeder lines are retained; the switch layer: a transitional branch without a switch object is compressed and the tail end of a radiation pattern branch of a non-important user is compressed, and no pole and tower information is retained, and cyclic compression is carried out; and the user layer: a transitional branch without a switch object is compressed, important pole and tower information and user nodes are retained, and cyclic compression is carried out. According to the method disclosed by the invention, the topological attributes of a multi-sided hierarchical model and a GIS detailed model of the distribution network are fully consistent, thereby better blending the requirement of macro and micro decision-making views required by a power distribution operation decision on corresponding abstraction model of the distribution network.

Owner:STATE GRID CHONGQING ELECTRIC POWER +1

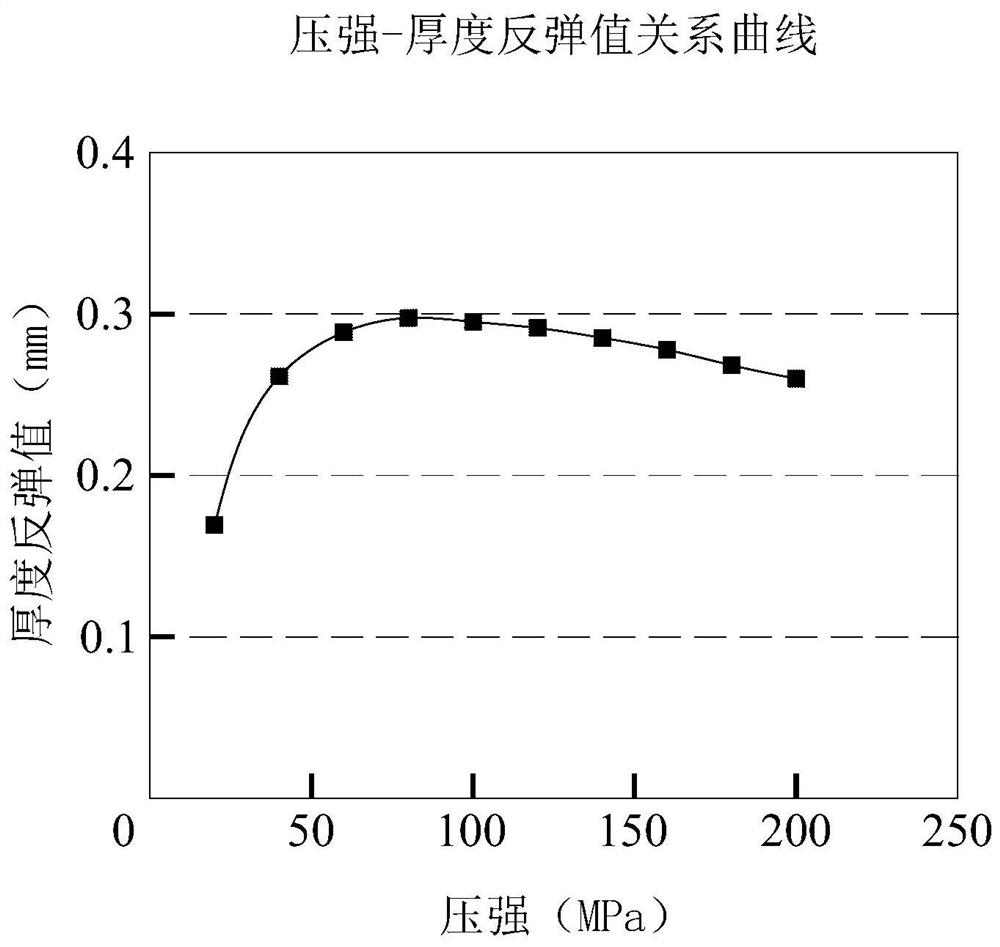

Method for evaluating crushing strength of powder particles

PendingCN114136817AAvoid safety hazardsAvoid breakingMaterial strength using repeated/pulsating forcesMaterial resistanceCyclic compressionUltimate tensile strength

The invention discloses a method for evaluating the crushing strength of powder particles, which comprises the following steps of: compacting a powder sample of battery cell material particles, performing a continuous pressurization-pressure relief cyclic compression experiment on the powder sample, measuring thickness rebound values of the powder sample when different pressures are applied, drawing a pressure-thickness rebound value relation curve of the powder sample, and calculating the crushing strength of the powder particles according to the pressure-thickness rebound value relation curve. And taking the highest point of the curve as a pressure critical point for crushing the powder sample. According to the method, a pressurization-pressure relief circulation experiment is carried out on a powder sample of battery cell material particles at increasing pressure, the pressure intensity applied each time and the thickness of the powder sample are recorded, a pressure intensity-thickness rebound value relation curve is calculated and drawn, and the pressure intensity critical point of crushing of the powder sample can be judged through the highest point of the curve, so that the crushing accuracy of the powder sample is improved. Therefore, the maximum bearing pressure of the powder is known, and the hardness performance of the material is represented.

Owner:元能科技(厦门)有限公司

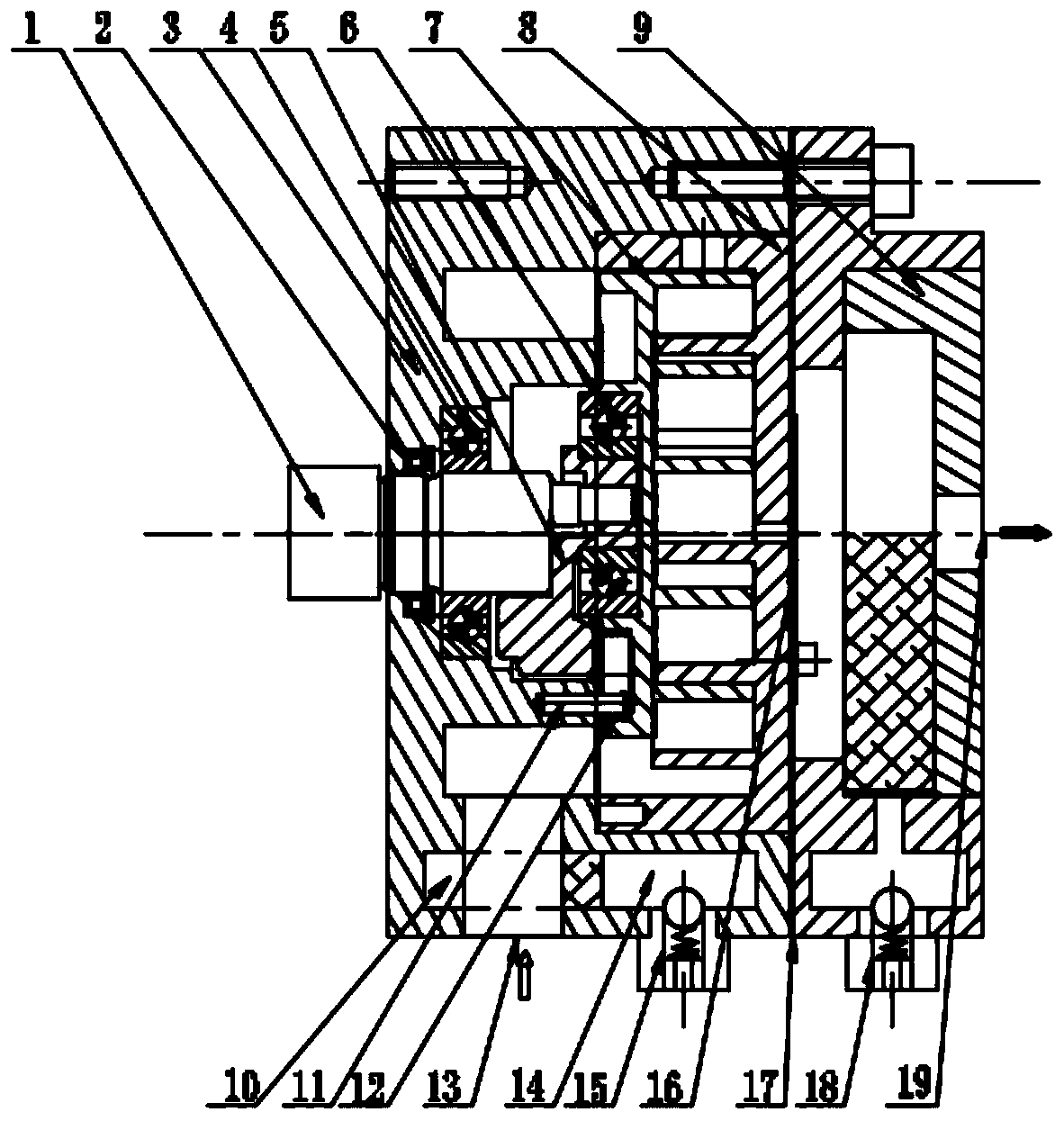

Hydrogen circulation compression pump

ActiveCN110905807AAvoid enteringPrevent leakageSealing arrangement for pumpsRotary piston pumpsDrive shaftCompression Pump

The invention discloses a hydrogen circulation compression pump. The hydrogen circulation compression pump comprises a shell body, a driving shaft, a moving scroll plate and a static scroll plate, wherein the driving shaft, the moving scroll plate and the static scroll plate are installed on the shell body, the driving scroll plate is driven by the driving shaft to rotate relative to the static scroll plate, a working cavity with a gradually changing volume is formed, an opened accommodation cavity is formed in the shell body, the moving scroll plate and the static scroll plate are located inthe accommodation cavity, the driving shaft penetrates through the shell body, and then is connected with the moving scroll plate, a main bearing is arranged between the driving shaft and the shell body, a moving plate bearing is arranged between the driving shaft and the moving scroll plate, the main bearing and the moving plate bearing are both ceramic bearings without lubrication, a hydrogen inlet, a hydrogen exhaust port and a water removing device are further arranged on the shell body, the hydrogen inlet, the working cavity and the hydrogen exhaust port sequentially communicate with oneanother, the water removing device comprises two water absorbing layers, the first water absorbing layer is located between the hydrogen inlet and the working cavity, and the second water absorbing layer is located between the hydrogen exhaust port and the working cavity. According to the hydrogen circulation compression pump, the situations that impurities such as lubricating oil enter the working cavity and hydrogen is leaked are mainly avoided; and the water removing device is arranged, and the quality of the hydrogen is improved.

Owner:博致新源(北京)科技有限公司

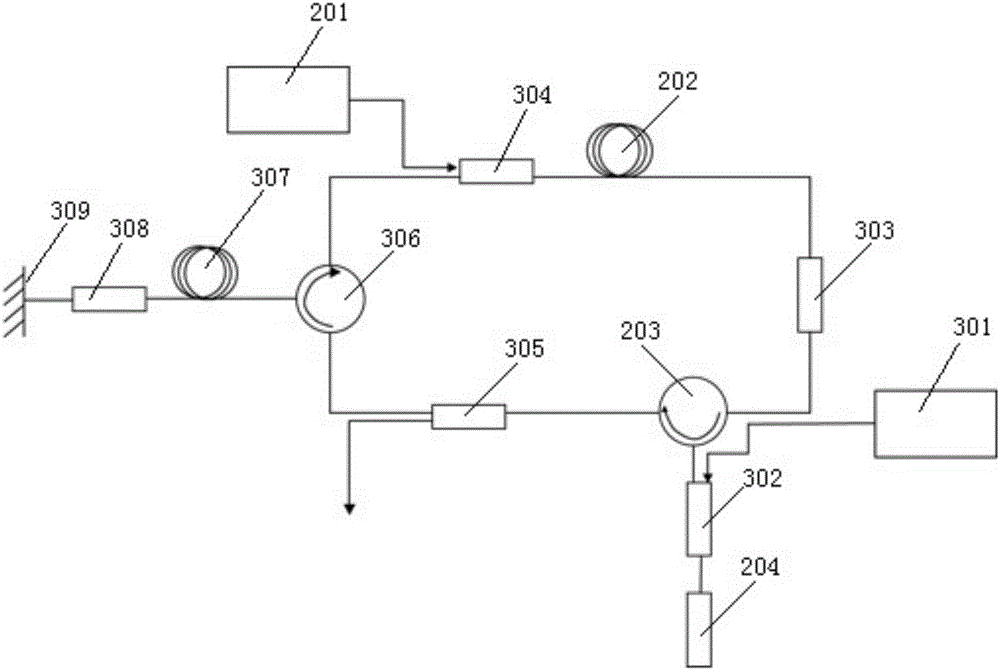

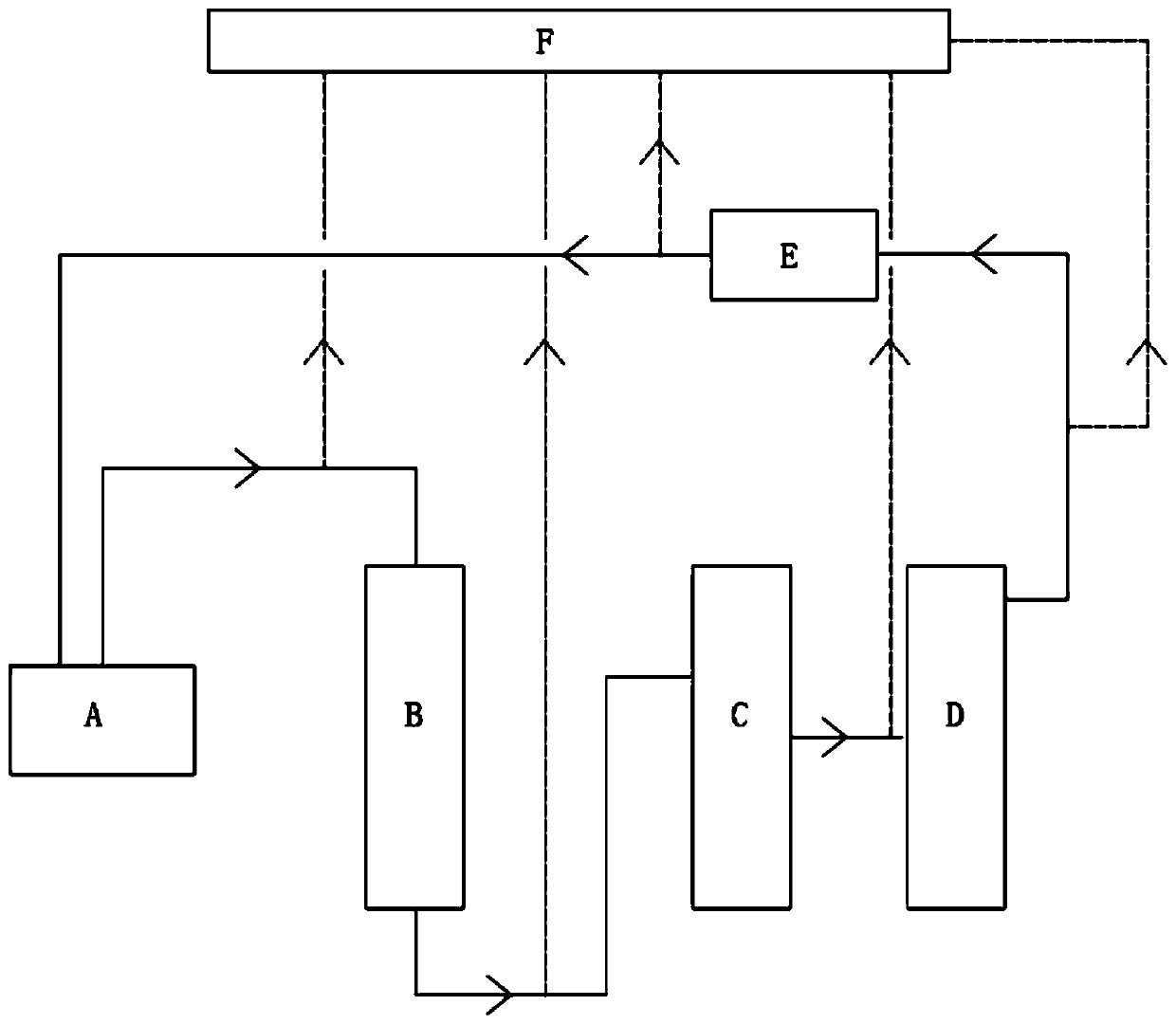

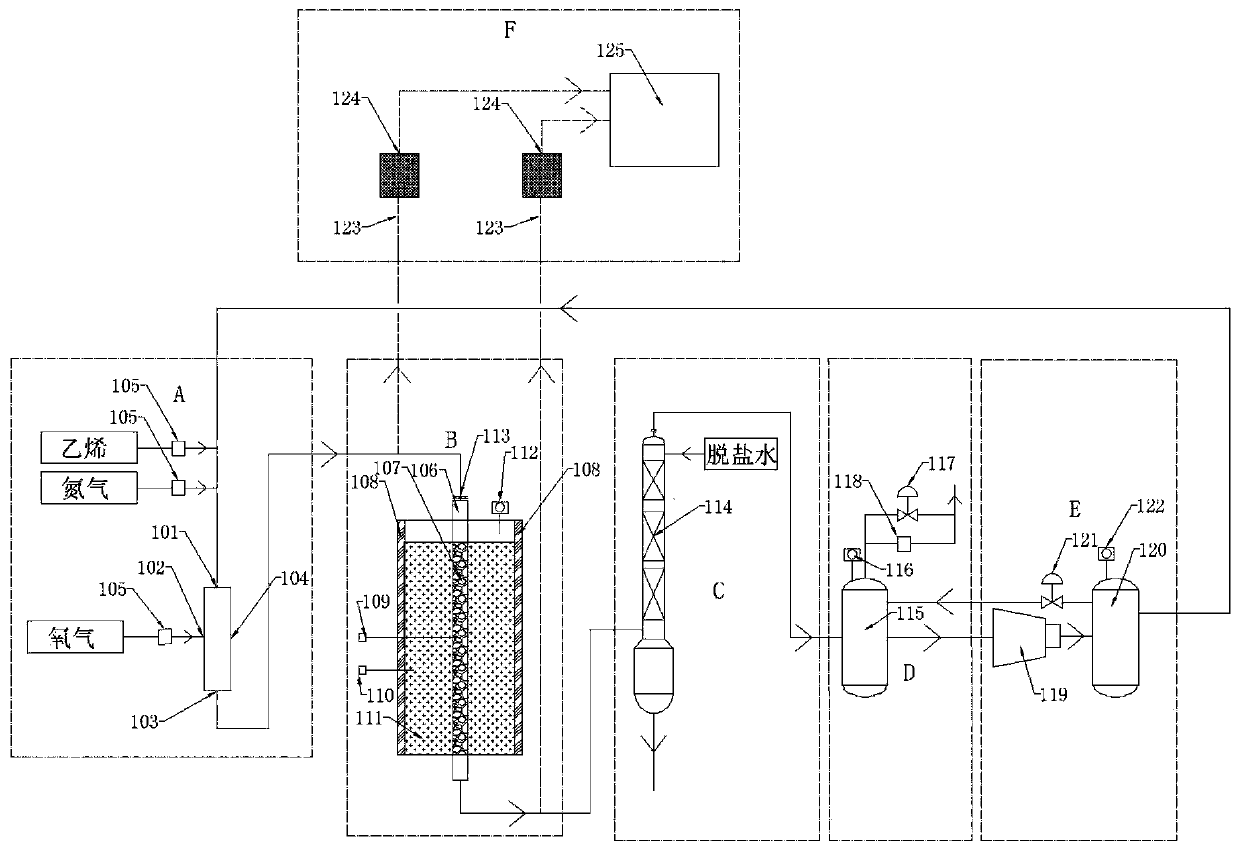

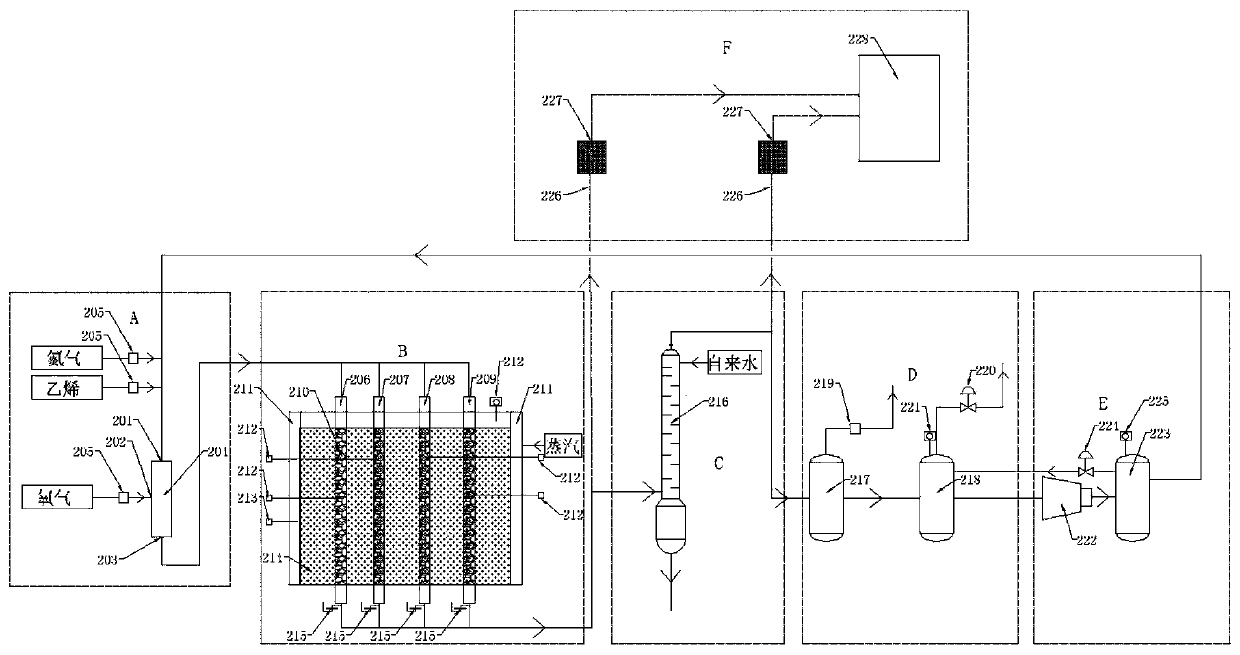

Pilot test device for evaluating performance of low-carbon hydrocarbon oxidation catalyst

PendingCN110873777AAccurate and stable evaluationStable pressure and flowChemical analysis using catalysisPtru catalystOxocarbon

The invention provides a pilot test device for evaluating the performance of a low-carbon hydrocarbon oxidation catalyst. The device comprises a raw material preparation system, a reaction system, anabsorption system, a lean recycle gas component regulation and control system, a cyclic compression system and an online analysis system, wherein the raw material preparation system, the reaction system, the absorption system, the lean recycle gas component regulation and control system and the cyclic compression system are connected in sequence and are combined into a closed loop. By adopting thetest device, the problem that an existing pilot test device for the performance of the low-carbon hydrocarbon oxidation catalyst in the gas circulation type process cannot effectively adjust accumulated COx carbon oxides in recycle gas while ensuring the process conditions such as device pressure flow and the like are stable is well solved, the accurate and stable evaluation of the catalyst is achieved, and an important guarantee is provided for the catalyst sample from a small test to industrialization.

Owner:兰州金润宏成新材料科技有限公司

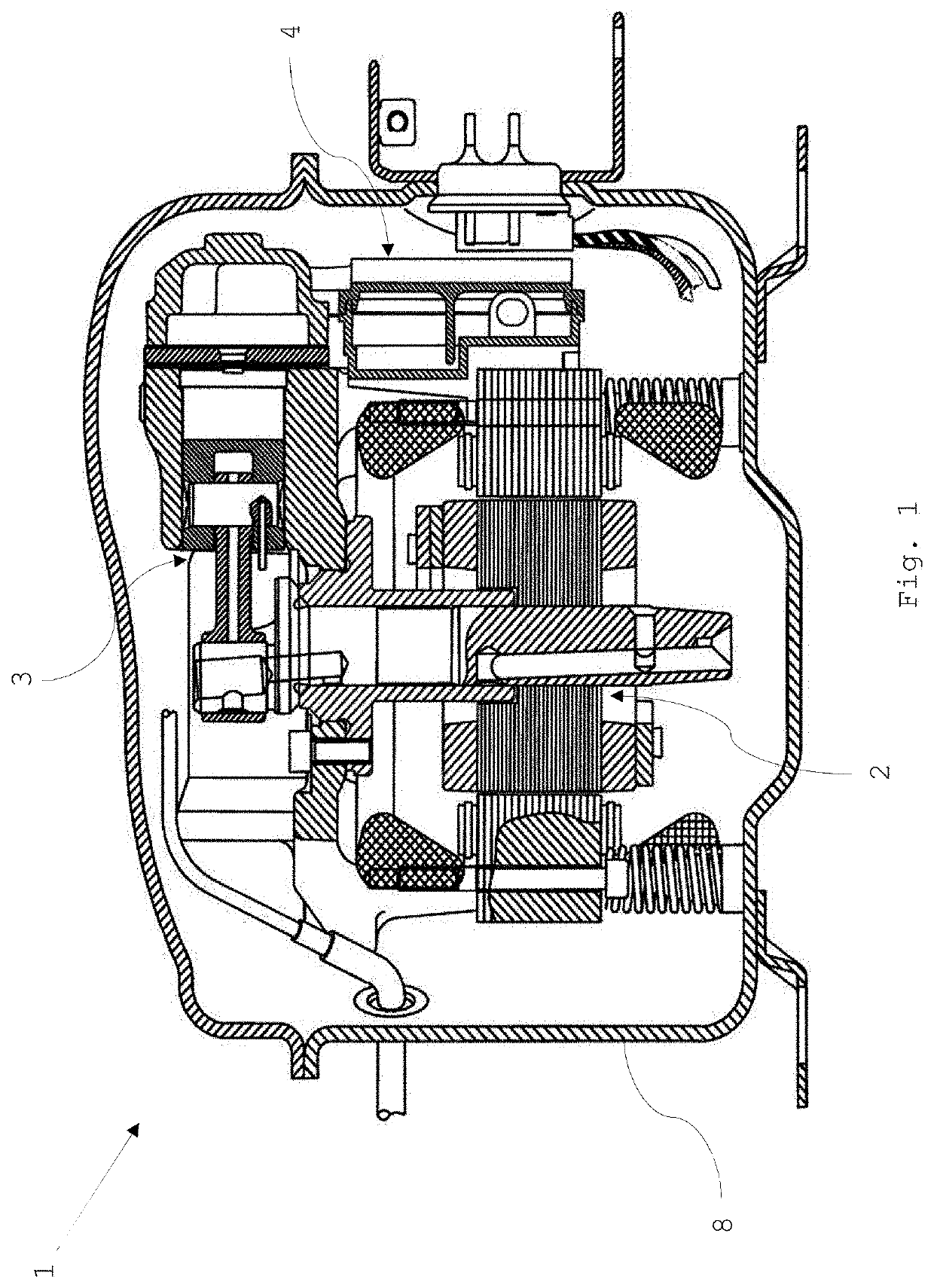

Refrigerant compressor

InactiveUS20200102945A1Improve efficiencyLow absorption ratePositive displacement pump componentsEngine componentsElectric driveCyclic compression

Refrigerant compressor includes an electrical drive unit, a piston / cylinder unit which can be driven by the drive unit for the cyclical compression of refrigerant, and at least one sound-damping unit made of a thermoplastic, through which sound-damping unit refrigerant can flow and which sound-damping unit includes at least one damping chamber. The at least one sound-damping unit is connected to the piston / cylinder unit in order to enable an exchange of refrigerant between the sound-damping unit and piston / cylinder unit. The at least one sound-damping unit includes at least in sections a functional surface. The functional surface is embodied such that an emissivity of a section of the sound-damping unit includes the functional surface is less than 0.7. The at least one sound-damping unit or at least one of the sound-damping units is embodied as a discharge muffler arranged downstream of the piston / cylinder unit in the direction of flow.

Owner:SECOP AUSTRIA

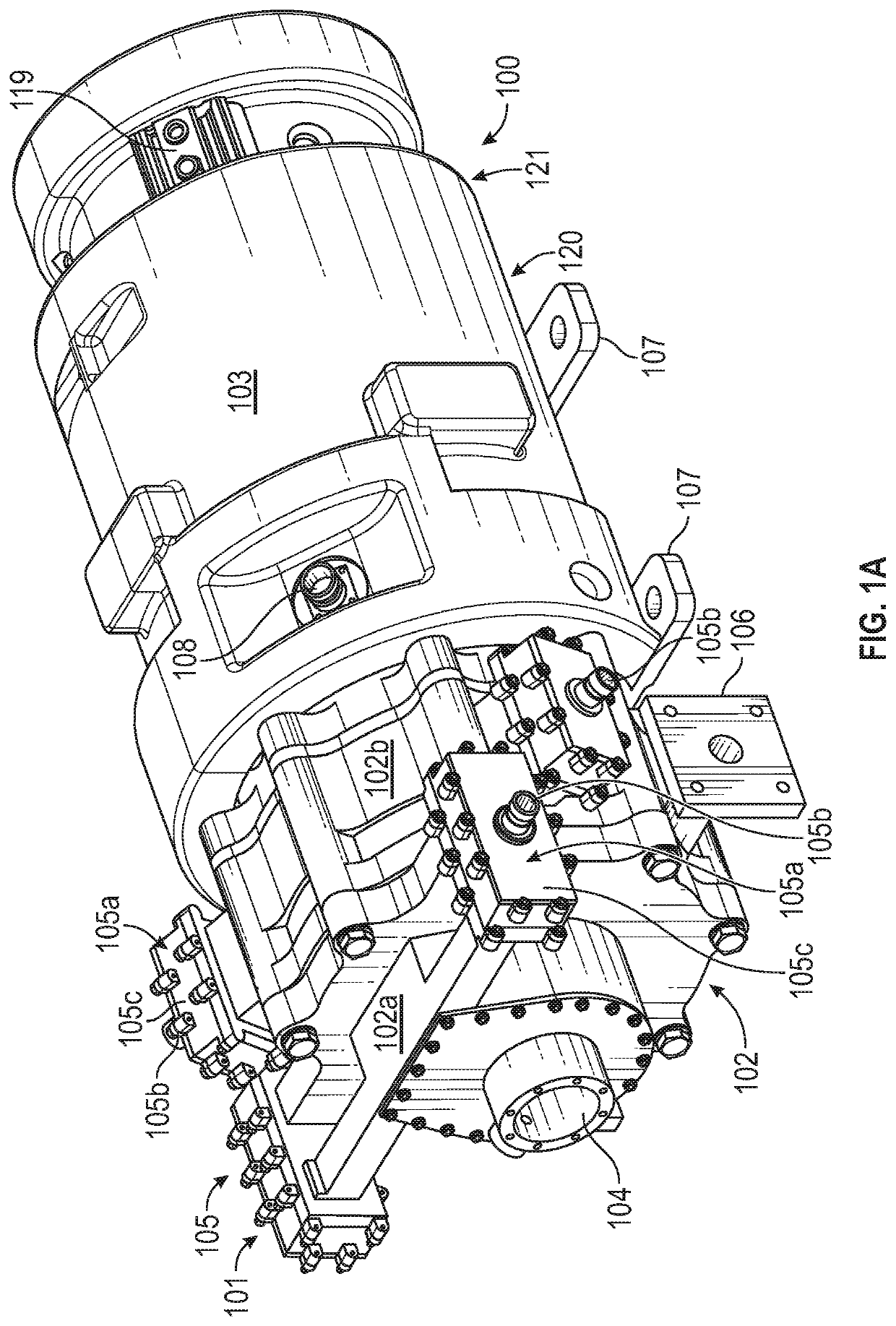

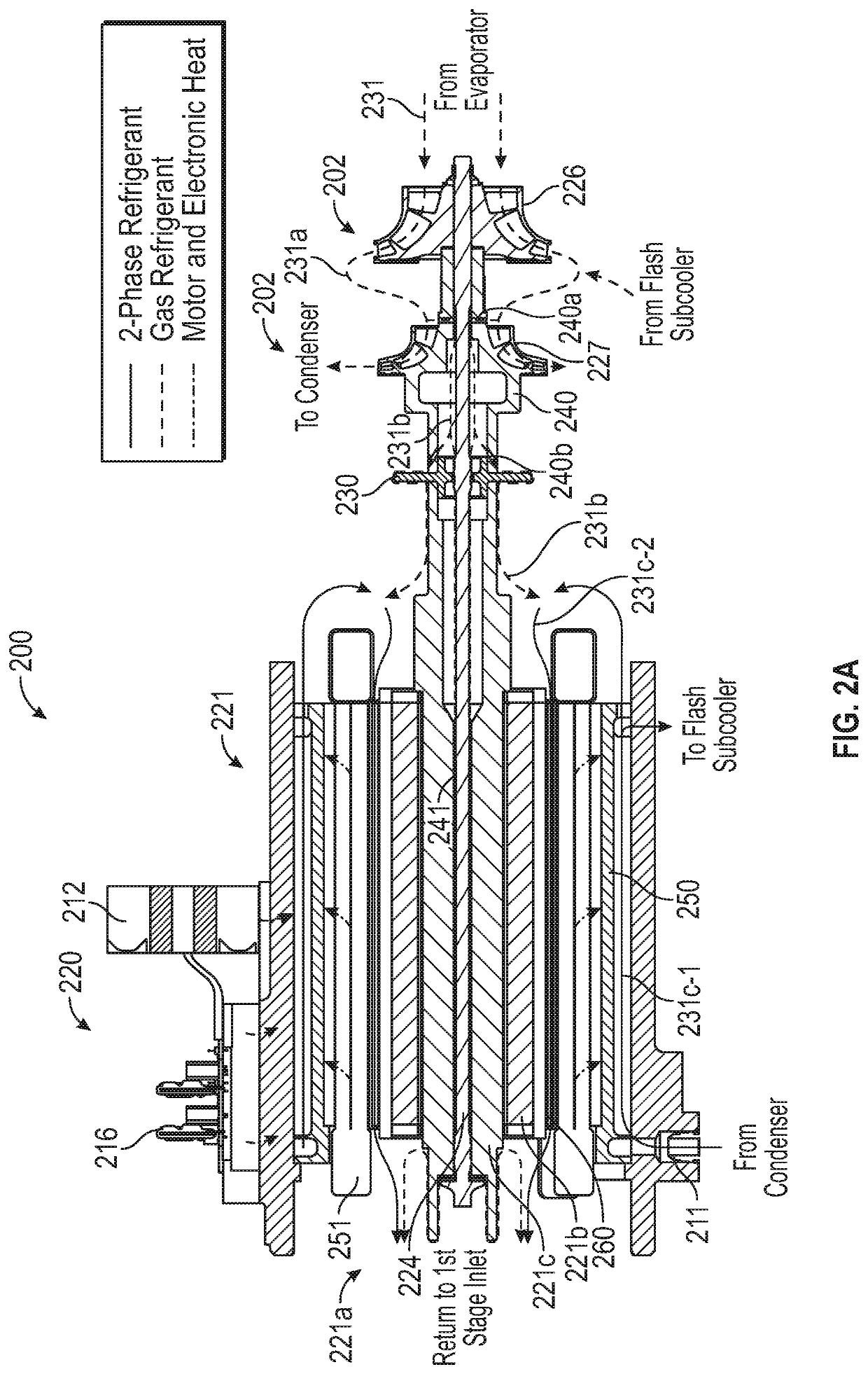

Multistage compressor having interstage refrigerant path split between first portion flowing to end of shaft and second portion following around thrust bearing disc

A vapor cycle compressor includes a motor section and a compression section operatively engaged with the motor section. A refrigerant path is in the motor section and in the compression section. The refrigerant path includes: a compression refrigerant path, for a single phase compression refrigerant, in the compression section; an inner rotor shaft refrigerant path, for a single phase inner rotor shaft refrigerant, in the compression section and in the motor section; and a stator refrigerant path, for a two phase stator refrigerant, in the motor section.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com