Method for evaluating crushing strength of powder particles

A technology of crushing strength and powder particles, which is applied in the field of battery material characteristic detection, can solve the problems of high cost and complicated operation, and achieve the effect of low cost, simple process and reduced R&D cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

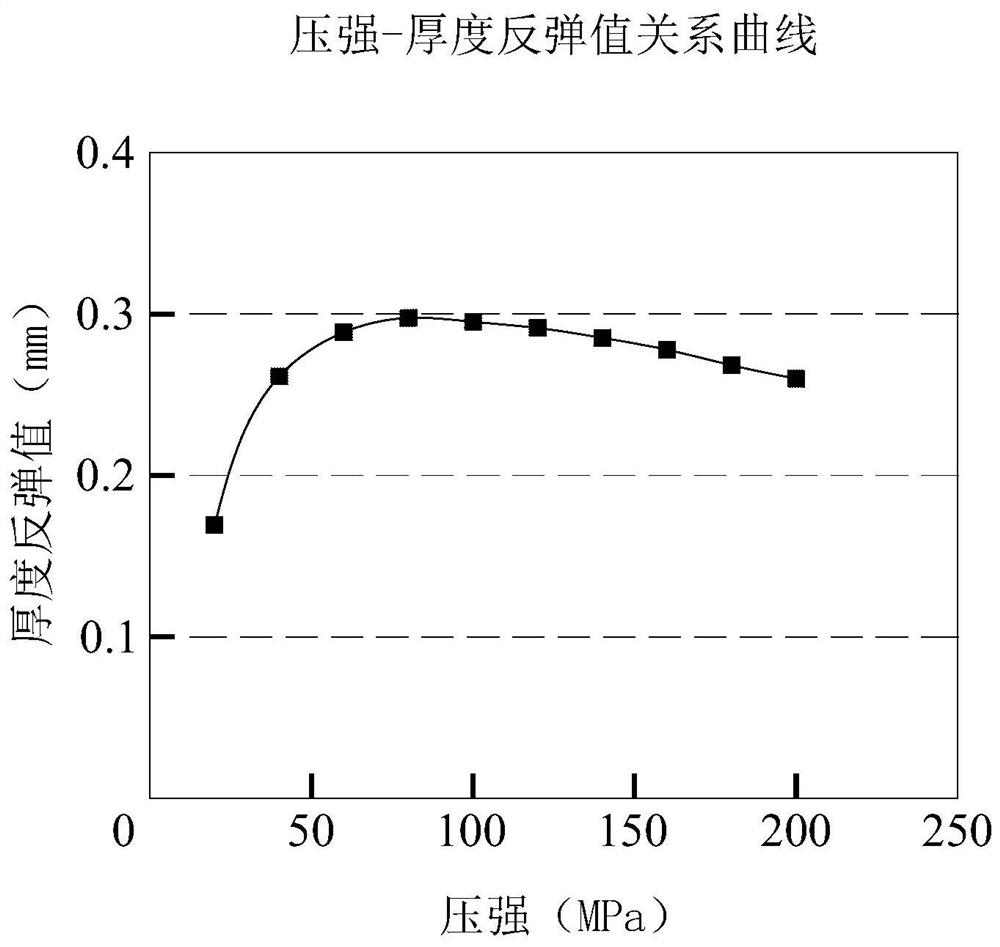

[0017] The invention is a method for evaluating the crushing strength of powder particles. After the powder sample of the cell material particles is vibrated, the powder sample is subjected to a continuous pressurization-depressurization cycle compression experiment, and the thickness of the powder sample is measured when different pressures are applied. Rebound value, draw the pressure-thickness rebound value relationship curve of the powder sample, and take the highest point of the curve as the critical point of pressure for the powder sample to break.

[0018] The present invention uses compaction density meter and powder resistance meter during concrete implementation, comprises the following steps:

[0019] Step 1. Take the powder sample of the cell material particles and pour it into the jig (laying thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com