Polycrystalline silicon production process

A production process, polysilicon technology, applied in the direction of silicon, etc., can solve the problems of complex equipment and process flow, energy consumption reduction, etc., and achieve the effect of reducing operating costs, reducing one-time investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

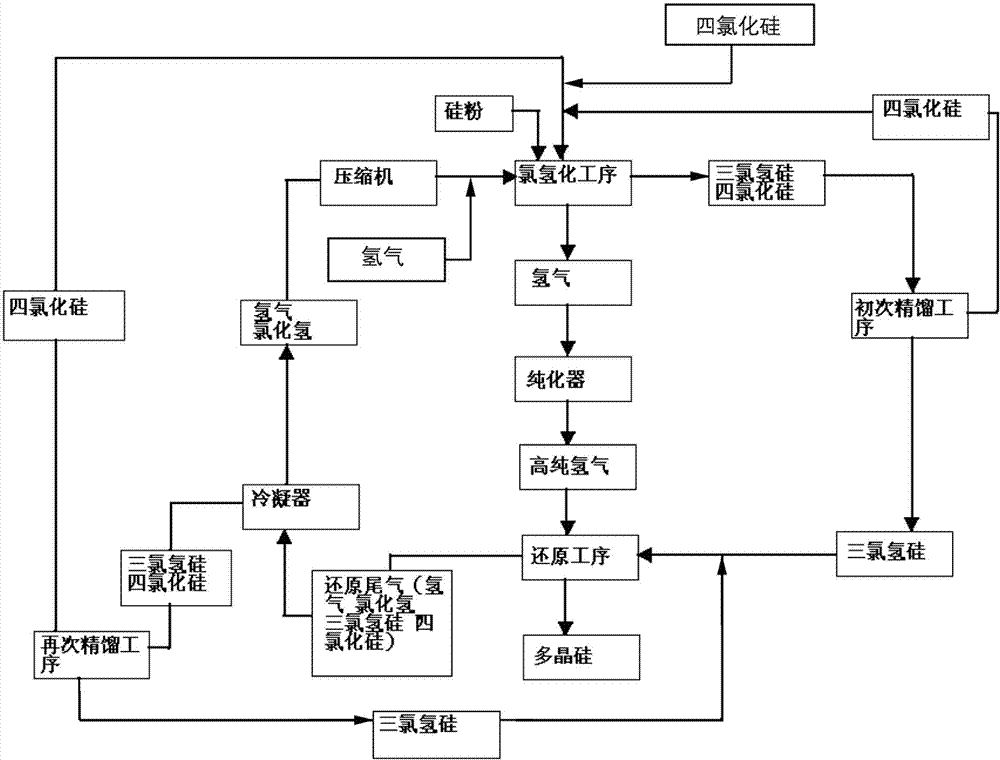

[0031] Such as figure 1 As shown, in the polysilicon production process of the present invention, industrial silicon powder reacts with silicon tetrachloride and hydrogen in the reactor in the hydrochlorination process to generate hydrogen and mixed chlorosilanes of trichlorosilane and silicon tetrachloride, which are passed through low temperature Condensation Condensate trichlorosilane and silicon tetrachloride, hydrogen is sent to the purifier, and the condensed mixed chlorosilane of trichlorosilane and silicon tetrachloride is sent to the primary rectification process, and the working pressure of the purifier is 1.5Mpa ;

[0032] The trichlorosilane and silicon tetrachloride mixed chlorosilanes from the hydrochlorination process are separated in the primary rectification process to remove high and low boilers, and the silicon tetrachloride is sent to the hydrochlorination process for recycling. The purity produced by the primary rectification is 99.99% The above high-...

Embodiment 2

[0038] Such as figure 1 As shown, in the polysilicon production process of the present invention, industrial silicon powder reacts with silicon tetrachloride and hydrogen in the reactor in the hydrochlorination process to generate hydrogen and mixed chlorosilanes of trichlorosilane and silicon tetrachloride, which are passed through low temperature Condensation Condensate trichlorosilane and silicon tetrachloride, send hydrogen to the purifier, and send the mixed chlorosilane of trichlorosilane and silicon tetrachloride to the primary rectification process, and the working pressure of the purifier is 2.0Mpa ;

[0039]The trichlorosilane and silicon tetrachloride mixed chlorosilanes from the hydrochlorination process are separated in the primary rectification process to remove high and low boilers, and the silicon tetrachloride is sent to the hydrochlorination process for recycling. The purity produced by the primary rectification is 99.99% The above high-purity trichlorosilan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com