Device for recycling cold energy of low-temperature nitrogen and using method of device

A cold energy recovery and low temperature technology, which is applied in refrigeration and liquefaction, cold treatment separation, solidification, etc., can solve the problems that cannot be popularized and applied on a large scale, and achieve the effect of reducing cost and site size, wide load operation range, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

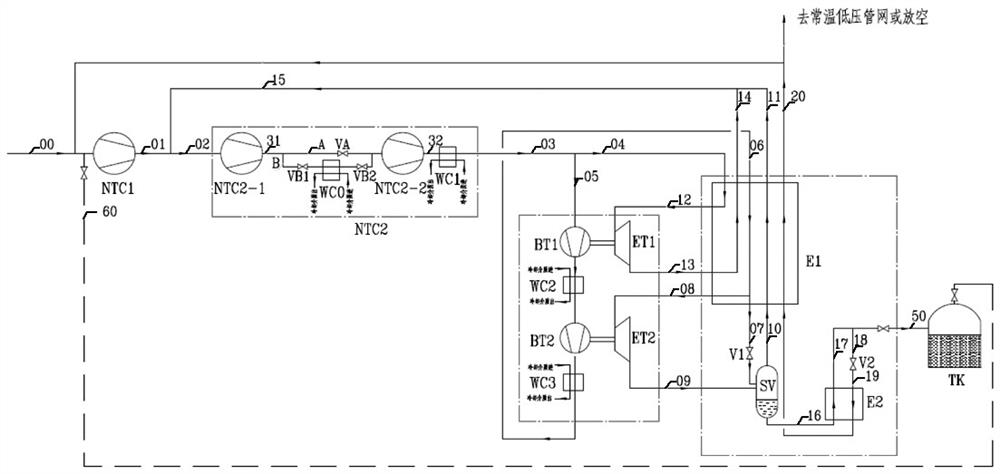

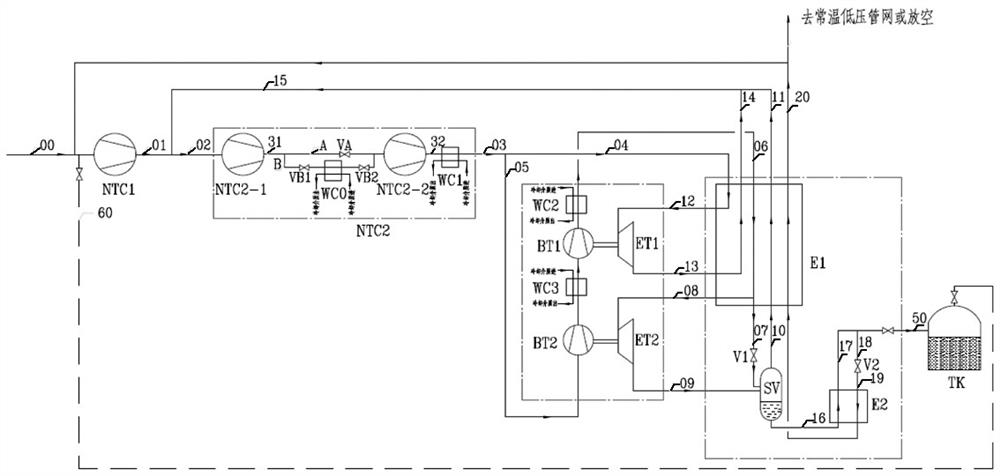

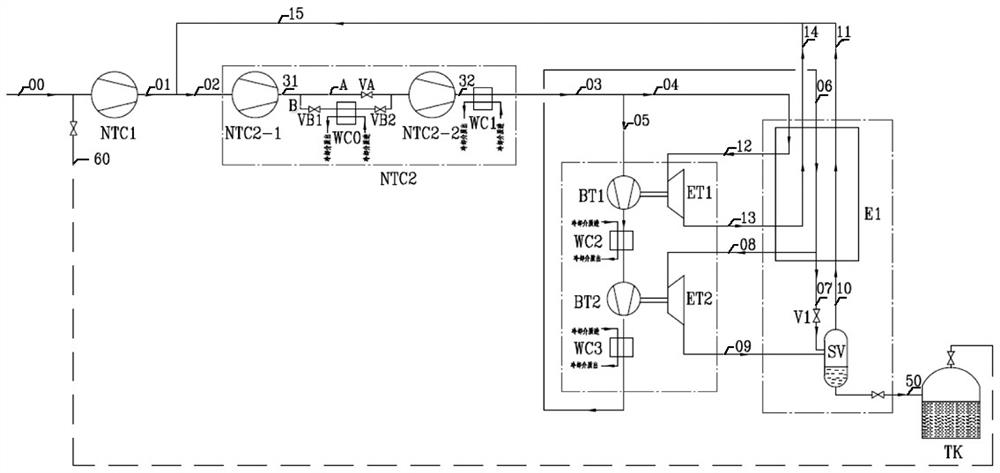

[0045] exist figure 1 In the embodiment, the raw material is clean and dry and the nitrogen 00 with a temperature of about 110K is compressed to about 0.52MPaA by the raw material low-temperature compressor NTC1 connected in series with two impellers, and the temperature of the nitrogen 01 is raised to about 219K, and then directly enters the TC2 of the circulating compressor NTC2 The -1 stage is compressed to about 1.1MPaA, the outlet temperature of the compressed thirty-first gas 31 is about 313K, and then directly enters the TC2-2 stage of the circulating compressor NTC2 through the A channel and is compressed to about 3.0MPaA, and the temperature rises To around 388K. The compressed thirty-second gas 32 is subcooled to 313K by the aftercooler WC1 and the third gas 03 is divided into two streams: the fourth gas 04 and the fifth gas 05 . The fourth gas 04 enters the heat exchanger E1 and cools down in the heat exchanger E1. After cooling to about 290K, it is extracted from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com