Reciprocating compressor for a cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Referring particularly to such figures, with numeral 100 is denoted the reciprocating compressor according to the invention.

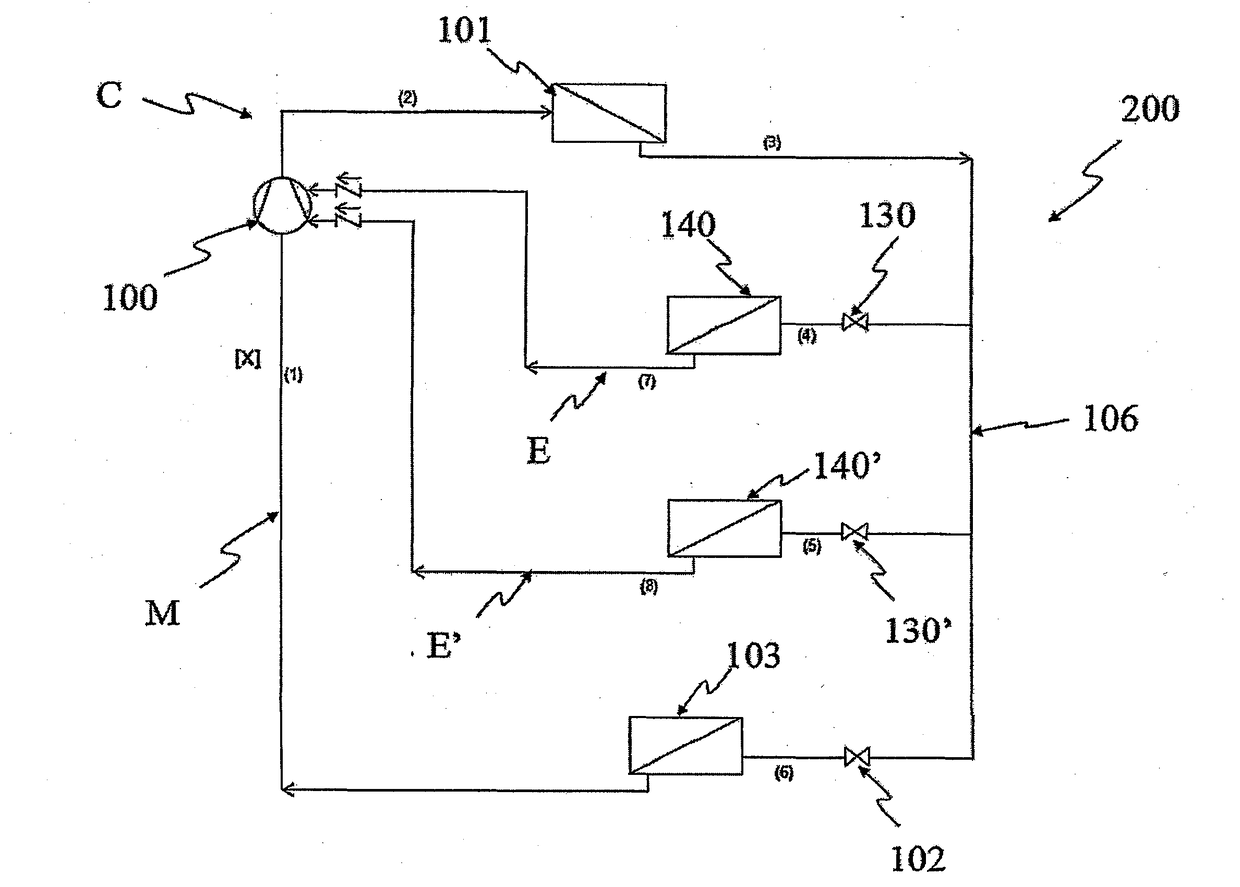

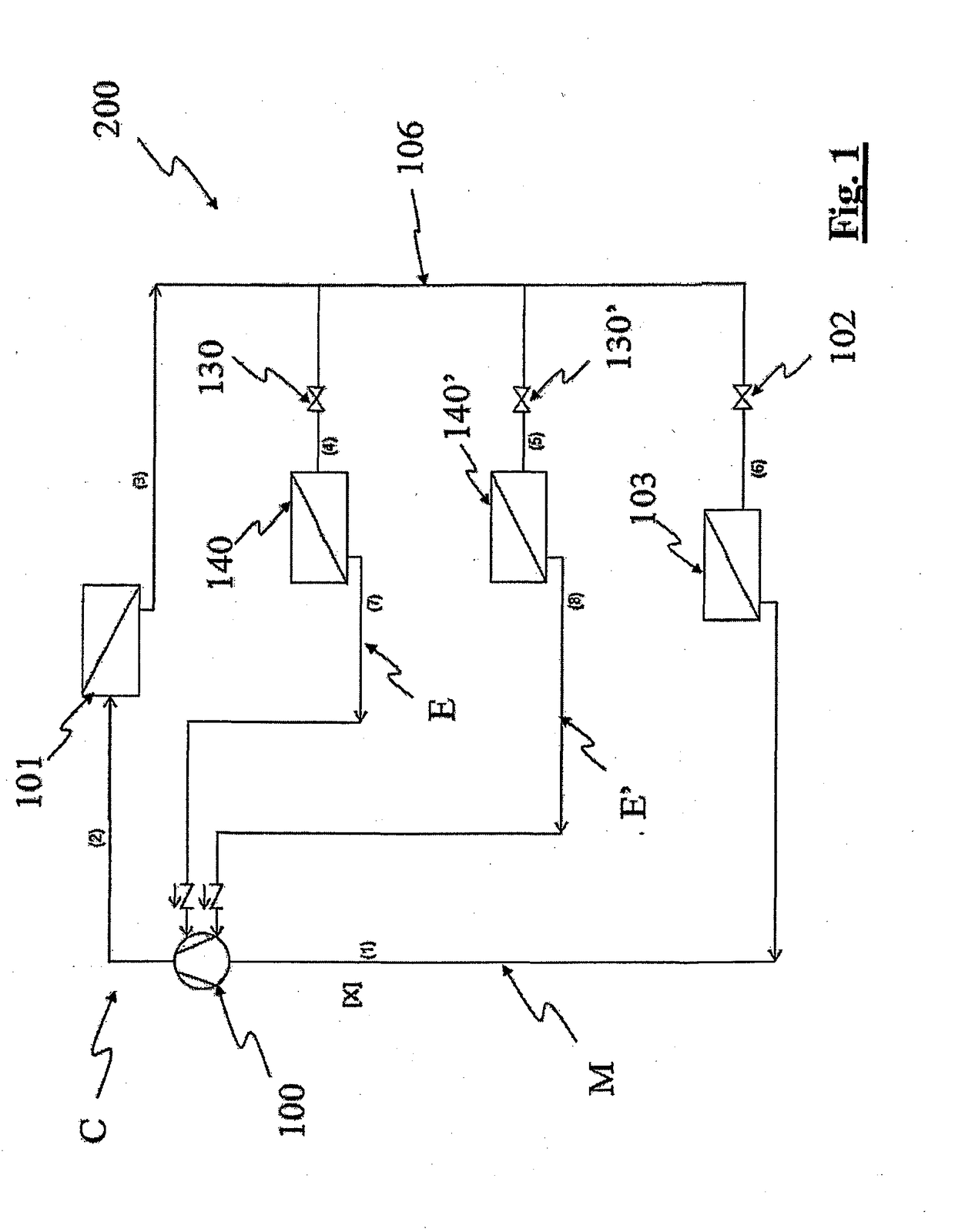

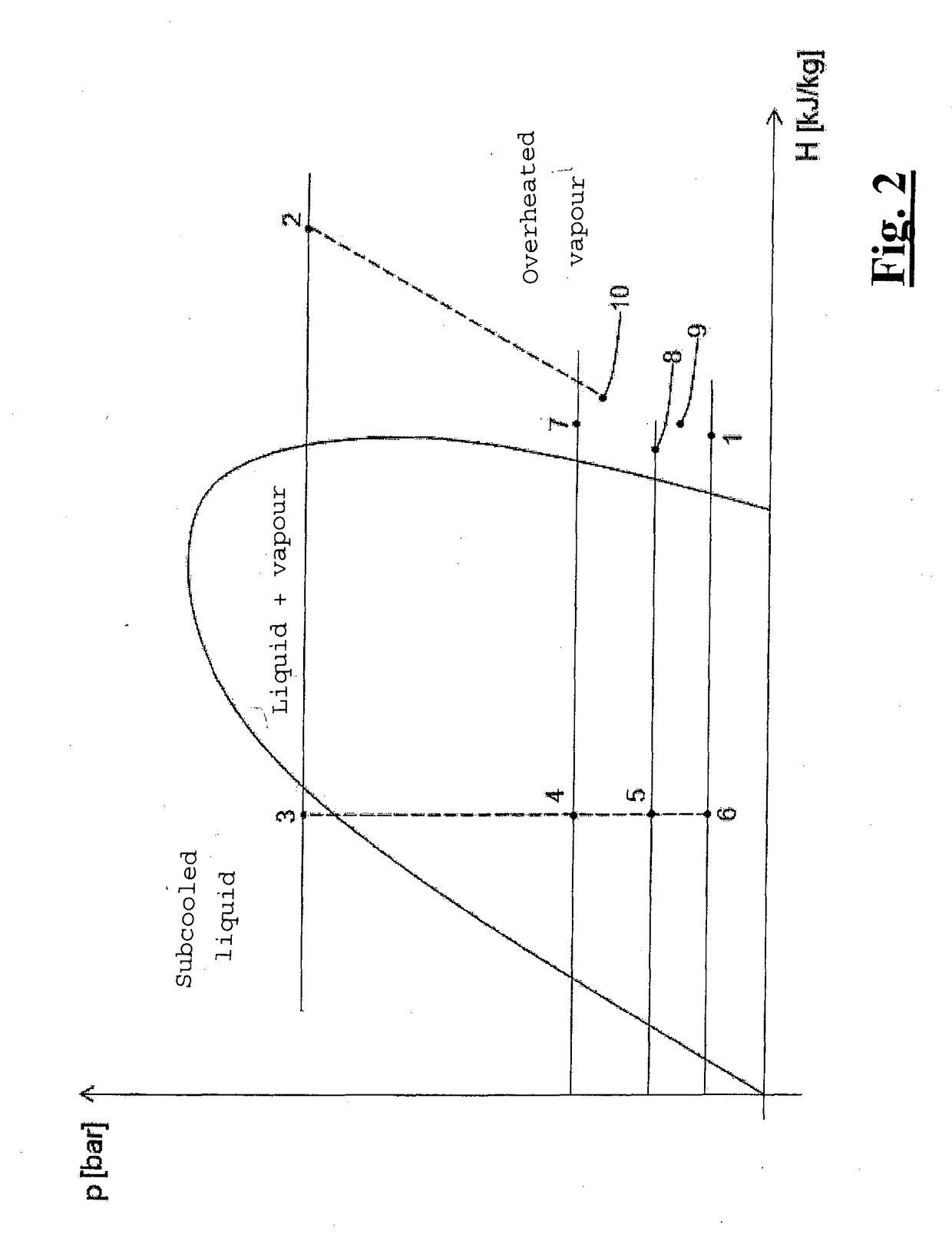

[0025]In FIG. 1 the scheme of a cooling device 200 provided with a reciprocating compressor 100 according to the invention provided with a cylinder 110 and a piston 111 reciprocatingly moving in the cylinder 110, between a top dead centre S (see FIG. 3d) and a bottom dead centre I (see FIG. 3c), is shown. In particular, the refrigeration device 200 comprises a closed circuit C in which a certain flow rate of coolant is circulating. Such a closed circuit C comprises, in its turn, a main branch M, in which a first flow rate X of coolant is circulating and enters the compressor 100 through a suction duct 109, a first secondary branch E and a second secondary branch E′. In such a first secondary branch E a second flow rate X1 of coolant circulates, whereas in the additional secondary branch E′ an additional flow rate X2 of coolant circulates. The sum of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com