Method for dilute acid pretreatment of plant straws by microwave-cyclic compression percolation

A plant straw and pretreatment technology, applied in the direction of biofuel, sugar production, food science, etc., to achieve the effect of reducing further degradation, fast heating speed, and uniform heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

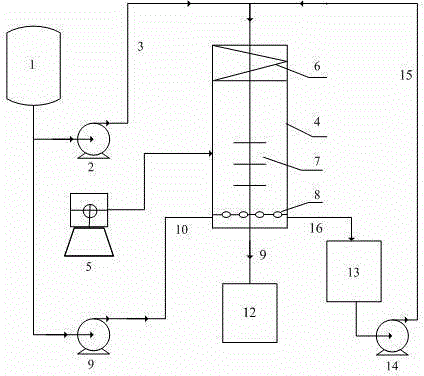

Method used

Image

Examples

Embodiment 1

[0035] (1) Crush the corn stalks into 10-20mm particles. Take 200g of straw particles and measure 400mL of prepared 0.5% (w / w) dilute sulfuric acid solution, which contains 0.1mol / L Fe 2 (SO 4 ) 3 , Slowly pour dilute sulfuric acid into a plastic bucket with corn stalks, stir repeatedly until the solid and liquid are evenly mixed, then seal it and let it soak at room temperature for 24 hours.

[0036] (2) Add the soaked corn stalks into the reactor, and feed 0.2% (w / w) dilute sulfuric acid at a rate of 80mL / min, which contains 0.08mol / L Fe 2 (SO 4 ) 3 , start the elastic compressor and the microwave generator at the same time, the microwave power is 1000w / (kg dry straw), the mode of action is to act on the microwave for 3min every 2min, the reaction temperature is controlled at 180°C, and the reaction pressure is 12atm.

[0037] (3) After the liquid in the reactor is separated from the solid, pump fresh acid into the reactor to submerge the solid. The concentration of the...

Embodiment 2

[0041] (1) Crush the corn stalks into 10-20mm particles. Take 200g of straw granules, measure 400mL of prepared 0.5% (w / w) dilute sulfuric acid, which contains 0.1mol / L Fe 2 (SO 4 ) 3 , Slowly pour dilute sulfuric acid into a plastic bucket with corn stalks, stir repeatedly until the solid and liquid are evenly mixed, then seal and soak at room temperature for 24 hours.

[0042] (2) Add the soaked corn stalks into the reactor, and feed 0.2% (w / w) dilute sulfuric acid at a rate of 120mL / min, which contains 0.08mol / L Fe 2 (SO 4 ) 3 , start the elastic compressor and the microwave generator at the same time, the microwave power is 2000 watts / (kg dry straw), the mode of action is to act on the microwave for 3 minutes every 2 minutes, the reaction temperature is controlled at 180 ° C, and the reaction pressure is 12 atm.

[0043] (3) After the liquid in the reactor is separated from the solid, pump fresh acid into the reactor to submerge the solid. The concentration of the fre...

Embodiment 3

[0047] (1) Take 200g of corn stalks with a particle size of 10-20mm, and measure 400mL of prepared 0.5% (w / w) dilute sulfuric acid, which contains 0.1mol / L Fe 2 (SO 4 ) 3 , Slowly pour dilute sulfuric acid into a plastic bucket with corn stalks, stir repeatedly until the solid and liquid are evenly mixed, then seal and soak at room temperature for 24 hours.

[0048] (2) Add the soaked corn stalks into the reactor, and feed 0.2% (w / w) dilute sulfuric acid solution at a rate of 160mL / min, which contains 0.08mol / L Fe 2 (SO 4 ) 3 , start the elastic compressor and the microwave generator at the same time, the microwave power is 3000 watts / (kg dry straw), the action mode is to act on the microwave for 3 minutes every 2 minutes, the reaction temperature is controlled at 180°C, and the reaction pressure is 12atm.

[0049] (3) After the liquid in the reactor is separated from the solid, pump fresh acid into the reactor to submerge the solid. The concentration of the fresh acid is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com