Pilot test device for evaluating performance of low-carbon hydrocarbon oxidation catalyst

A technology of oxidation catalyst and test device, which is applied in the direction of using catalysis for chemical analysis, etc., can solve the problems of unrealistic supporting decarburization separation unit, inability to realize accurate and stable carbon oxides in device evaluation data, and non-disclosure, etc., to achieve accurate and The effect of stable evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

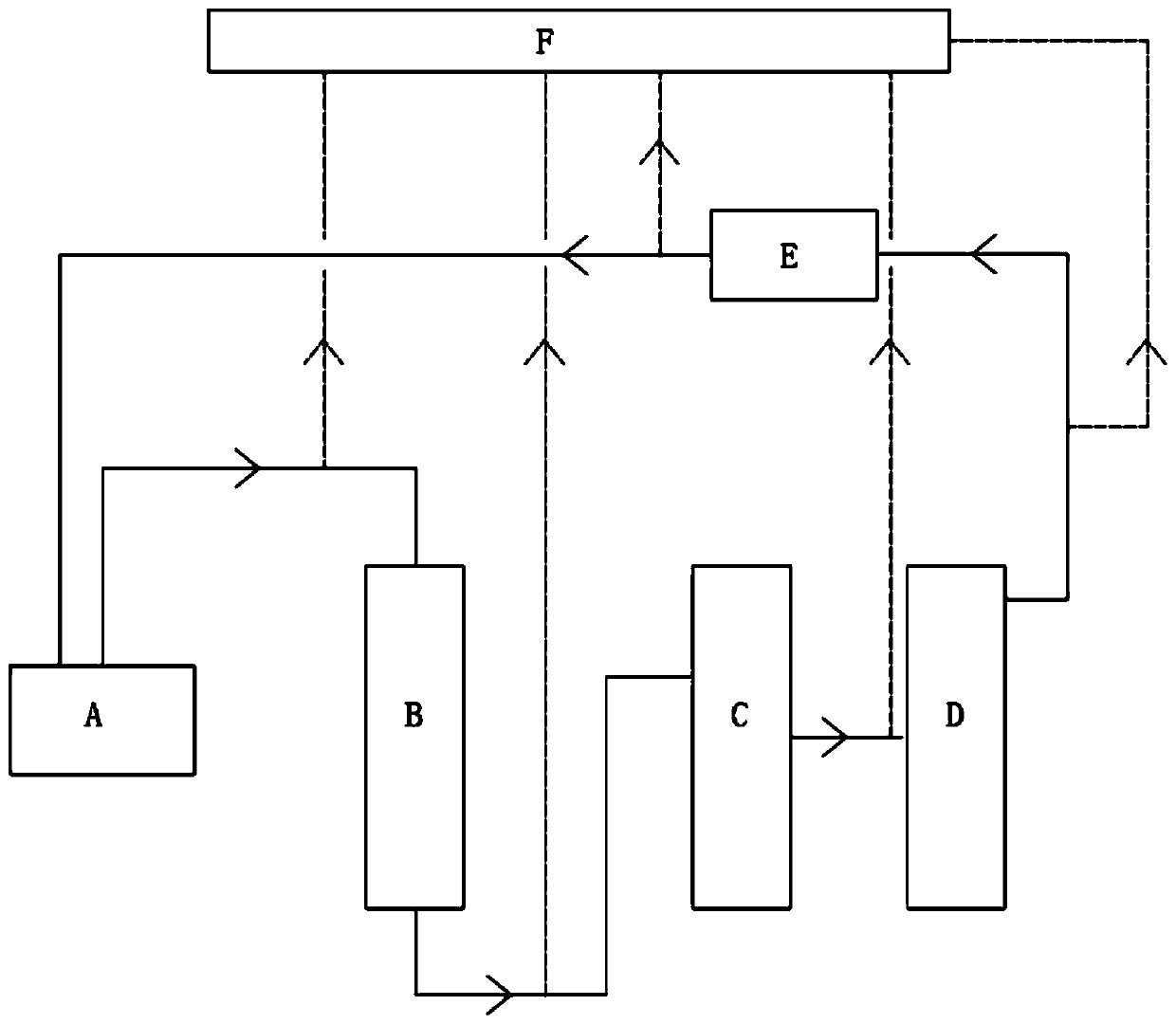

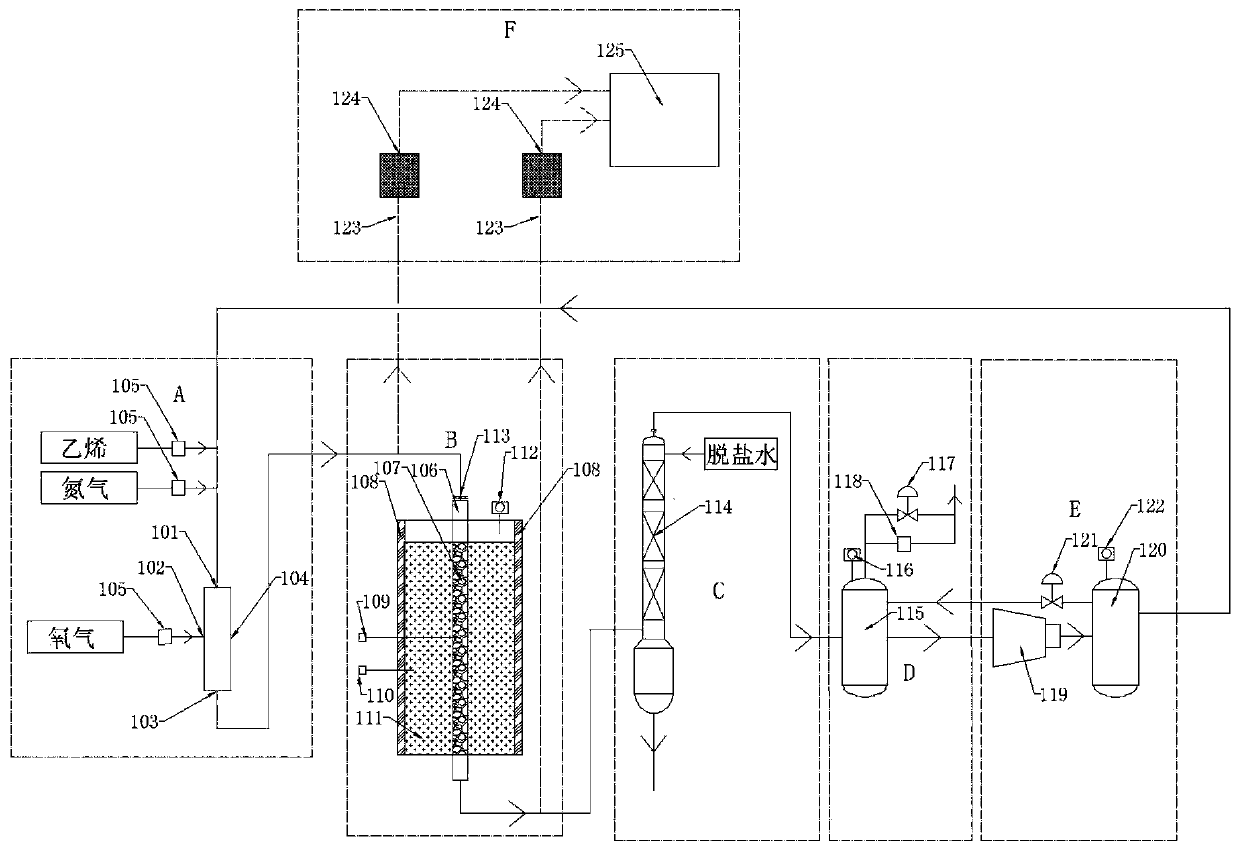

[0136] A pilot test device for evaluating the performance of ethylene oxide to ethylene oxide catalyst, the device includes a raw material configuration system A, a reaction system B, an absorption system C, a lean cycle gas component control system D, a cycle compression System E and online analysis system F:

[0137] like figure 2 As shown, the raw material configuration system A includes a mixer 104 for raw material configuration, and the mixer 104 has three interfaces, the first interface 101 is used to connect with the raw material gas pipeline and the circulating compression system E respectively, and the second interface 102 is used for It is connected with the oxidant pipeline, and the third interface 103 is used to connect to the reaction system B. During the mixing process, ethylene and nitrogen enter the mixer 104 through the feed gas pipeline, and oxygen enters the mixer 104 through the oxidant pipeline, and they are mixed in the mixer 104 . Each raw material is...

Embodiment 2

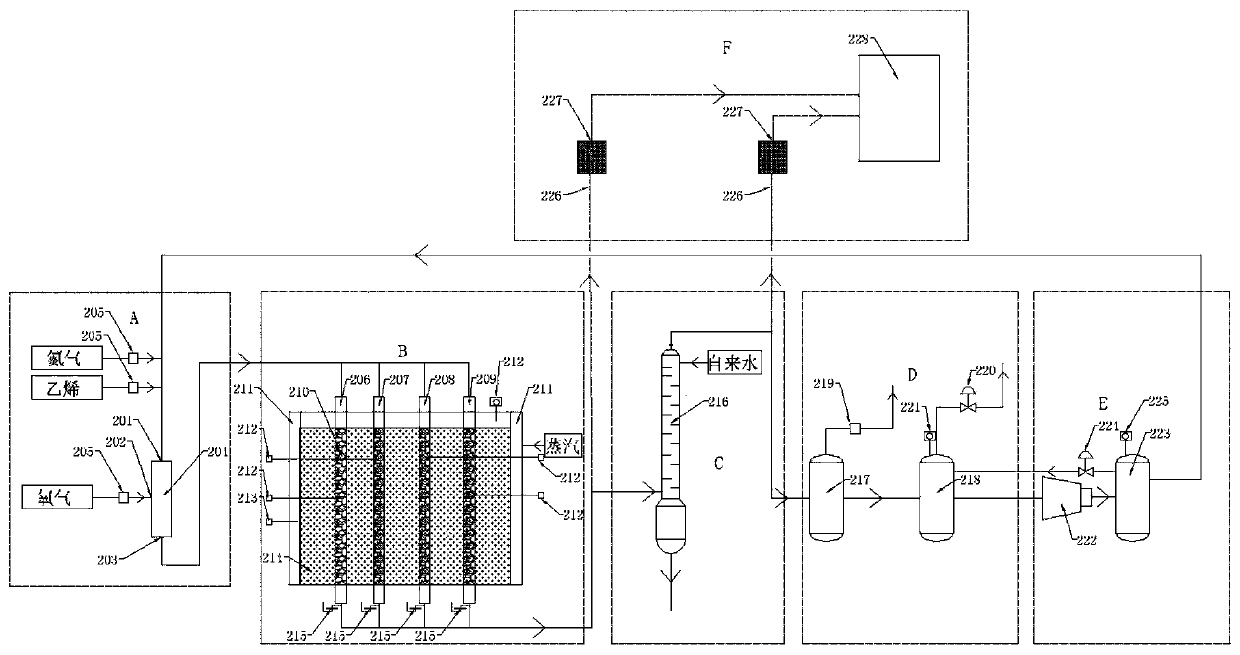

[0148] A pilot test device for evaluating the performance of ethylene oxide to ethylene oxide catalyst, the device includes a raw material configuration system A, a reaction system B, an absorption system C, a lean cycle gas component control system D, a cycle compression System E and online analysis system F:

[0149] like image 3 As shown, the raw material configuration system A includes a mixer 204 for raw material configuration, and the mixer 204 has three interfaces, the first interface 201 is used to connect with the raw material gas pipeline and the circulating compression system E respectively, and the second interface 202 is used for It is connected with the oxidant pipeline, and the third interface 203 is used to connect to the reaction system B. During the mixing process, ethylene and nitrogen enter the mixer 204 through the feed gas pipeline, oxygen enters the mixer 204 through the oxidant pipeline, and they are mixed in the mixer 204 . Each raw material is unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Equivalent diameter | aaaaa | aaaaa |

| Equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com