Low-nitrogen combustion transformation method and system for medium-grade kiln

A low-nitrogen combustion and kiln technology, used in furnaces, furnace components, furnace control devices, etc., can solve difficult to control the combustion temperature of mixed gas, poor control of nitrogen oxide emissions, and reduce the heating performance of mid-range kilns, etc. problems, to achieve the effect of improving service life, ensuring stable combustion and stable flue gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

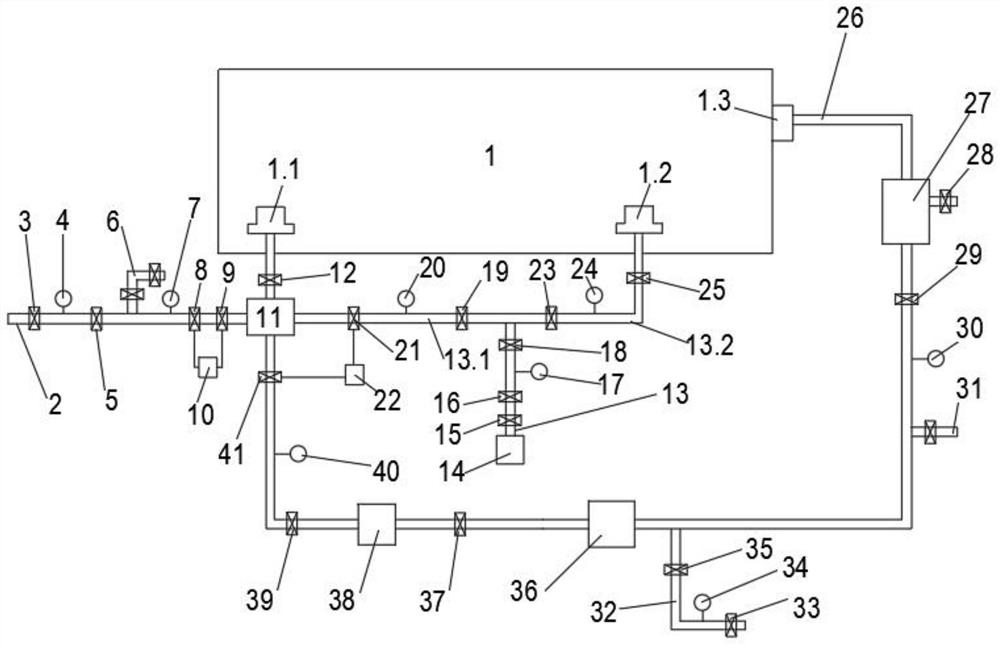

Image

Examples

Embodiment 1

[0056] In this example, a mid-range kiln is transformed from "coal to gas", the original coal-burning device is removed, and the gas-burning device is installed. The specific transformation method is as follows:

[0057] A low-nitrogen combustion modification method for a mid-range kiln, comprising the following steps:

[0058] step 1:

[0059] Remove the original coal-burning device of the mid-range kiln;

[0060] Step 2:

[0061] Renovate the mid-range kiln, set the first middle gas inlet and the middle gas inlet in the mid-range kiln, set up a mixer at the first middle gas inlet, and connect to the natural gas pipeline, air pipeline and flue gas circulation pipeline;

[0062] Step 3:

[0063] The air pipe is connected to the gas inlet in the middle to supplement the combustion oxygen inside the mid-range kiln;

[0064] Step 4:

[0065] Set the pressure-stabilizing release pipeline, safety cut-off valve, pressure switch, pressure gauge and solenoid valve on the natural ...

Embodiment 2

[0095] In this example, a mid-range kiln is transformed from "coal to gas", the original coal-burning device is removed, and the gas-burning device is installed. The specific transformation method is as follows:

[0096] A low-nitrogen combustion modification method for a mid-range kiln, comprising the following steps:

[0097] step 1:

[0098] Remove the original coal-burning device of the mid-range kiln;

[0099] Step 2:

[0100] Renovate the mid-range kiln, set the first middle gas inlet and the middle gas inlet in the mid-range kiln, set up a mixer at the first middle gas inlet, and connect to the natural gas pipeline, air pipeline and flue gas circulation pipeline;

[0101] Step 3:

[0102] The air pipe is connected to the gas inlet in the middle to supplement the combustion oxygen inside the mid-range kiln;

[0103] Step 4:

[0104] Set the pressure-stabilizing release pipeline, safety cut-off valve, pressure switch, pressure gauge and solenoid valve on the natural ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com