Method and device for synergistically preparing ultrahigh-viscosity polymer blend

A technology of polymers and blends, which is applied in the field of preparation of polymer blends, can solve the problems of low mixing efficiency of mixing equipment and inability to effectively mix ultra-high-viscosity polymer systems, and achieve simple structure, reduced labor intensity, The effect of fast interface update

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

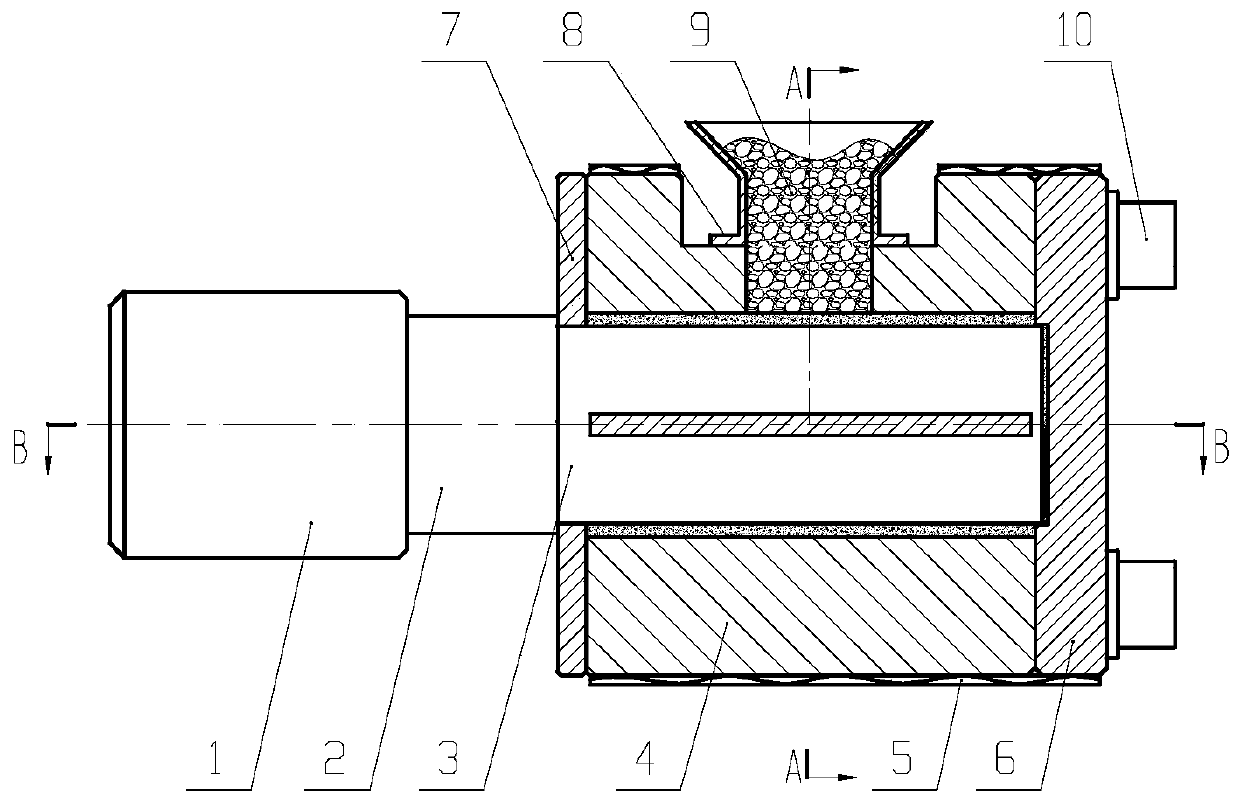

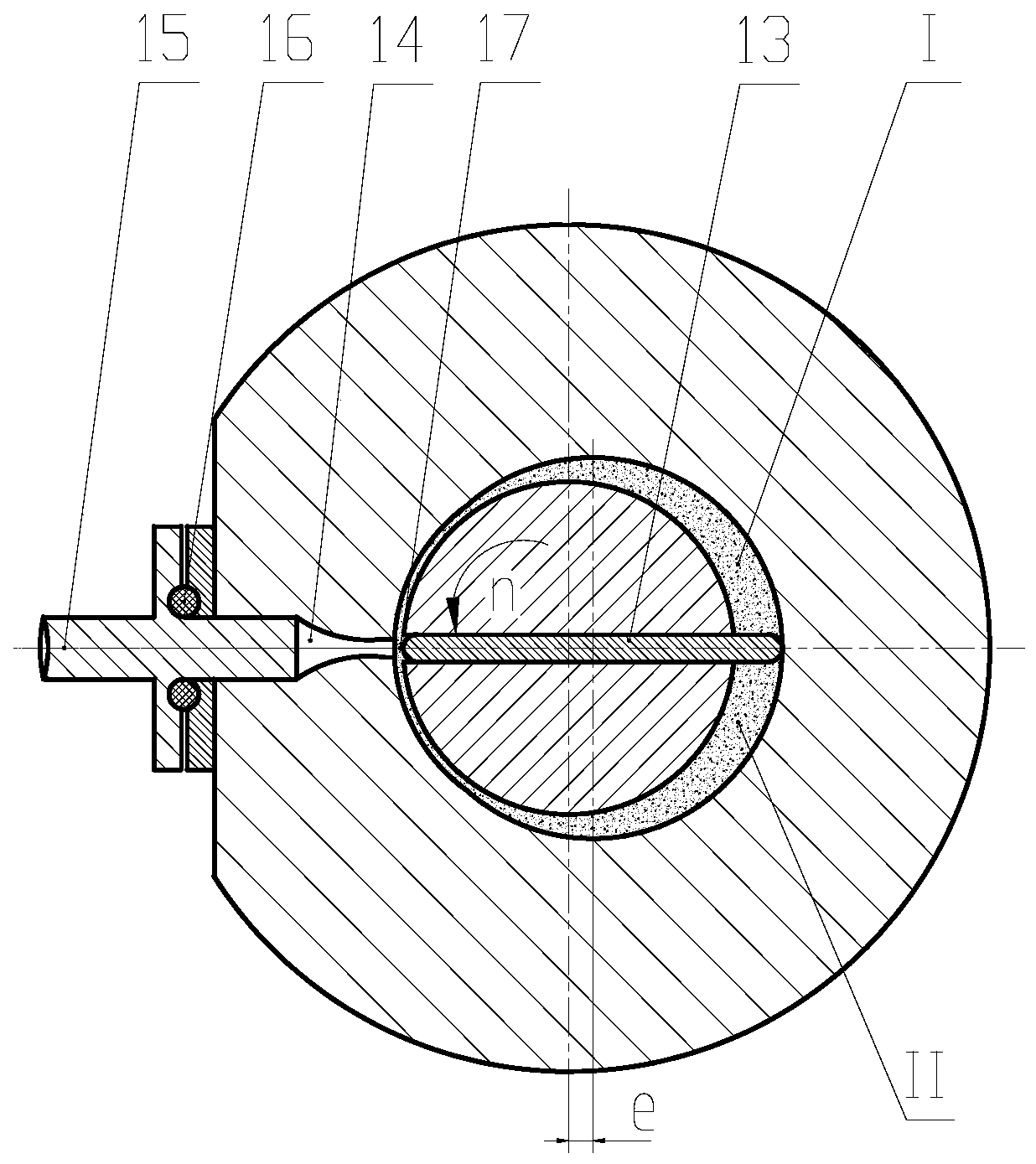

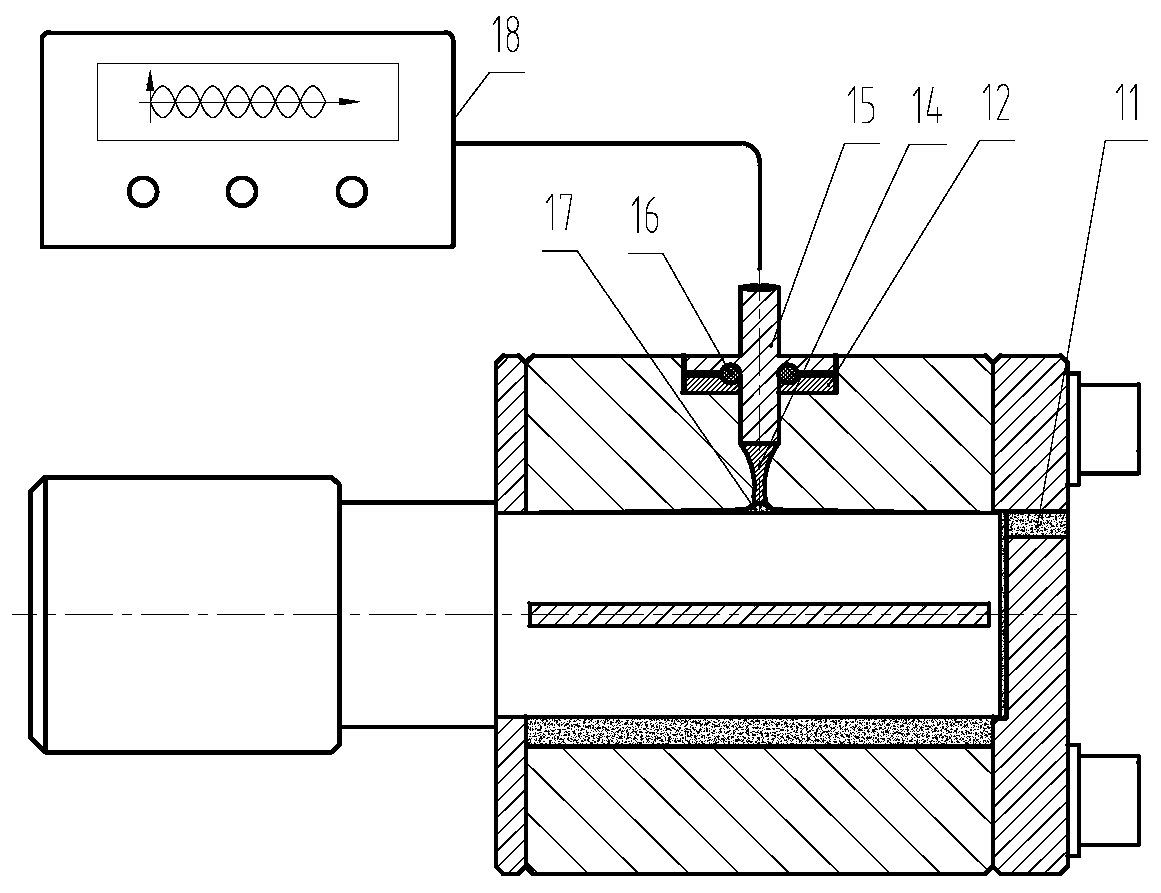

[0038] like Figure 1-Figure 4 As shown, a device for synergistically preparing ultra-high viscosity polymer blends is mainly composed of a driving motor 1, a gearbox 2, a rotor shaft 3, an eccentric stator 4, a heater 5, a discharge cover 6, an end cover 7, and a hopper 8. It consists of a slide plate 13, an ultrasonic probe 14 and an ultrasonic generator 18; the drive motor 1 is coaxially installed and connected to the reduction box 2; the end cover 7 and the discharge cover 6 are arranged at both ends of the eccentric stator. The heater 5 is fixed on the outer surface of the eccentric stator 4 by screws. The end cover 7 is fixed on the end cover of the reduction box 2 by screws, the eccentric stator 4 and the discharge cover 6 are fixed on the end cover 7 by screws 10, and the screws 10 are fixed on the end cover through the discharge cover 6 and the eccentric stator 4 at the same time 7; the discharge cover 6 is provided with a discharge hole 11; one end of the rotor shaf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com