Patents

Literature

131 results about "Performance limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

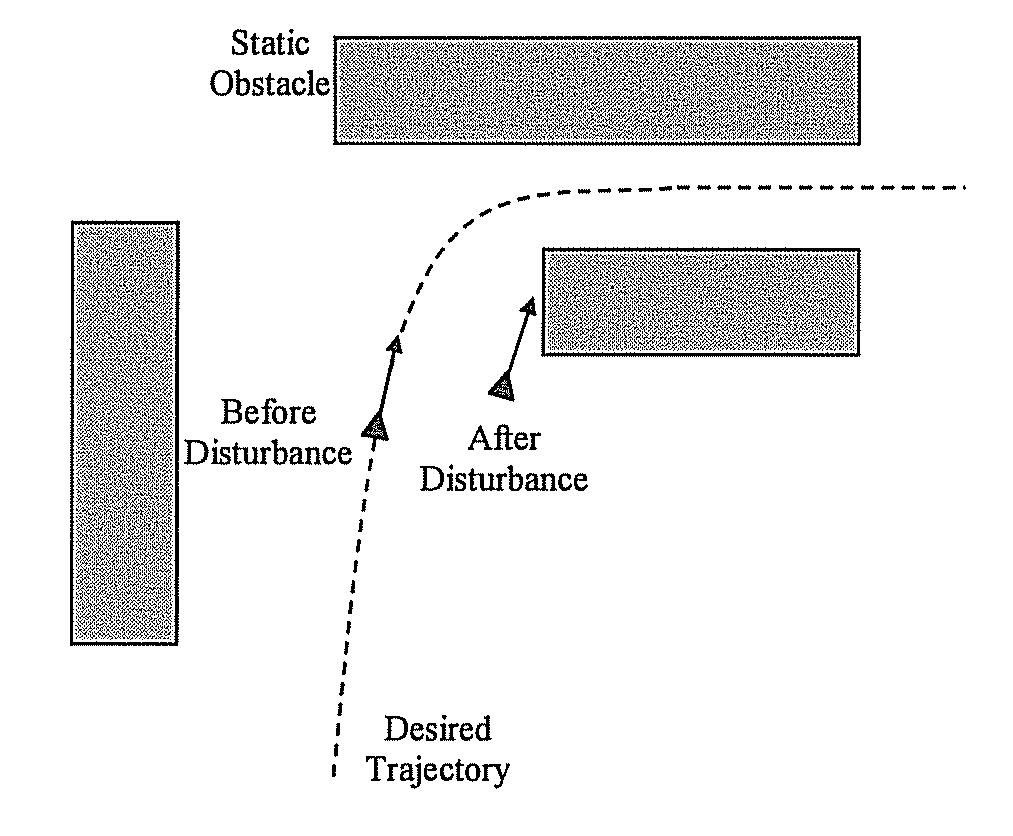

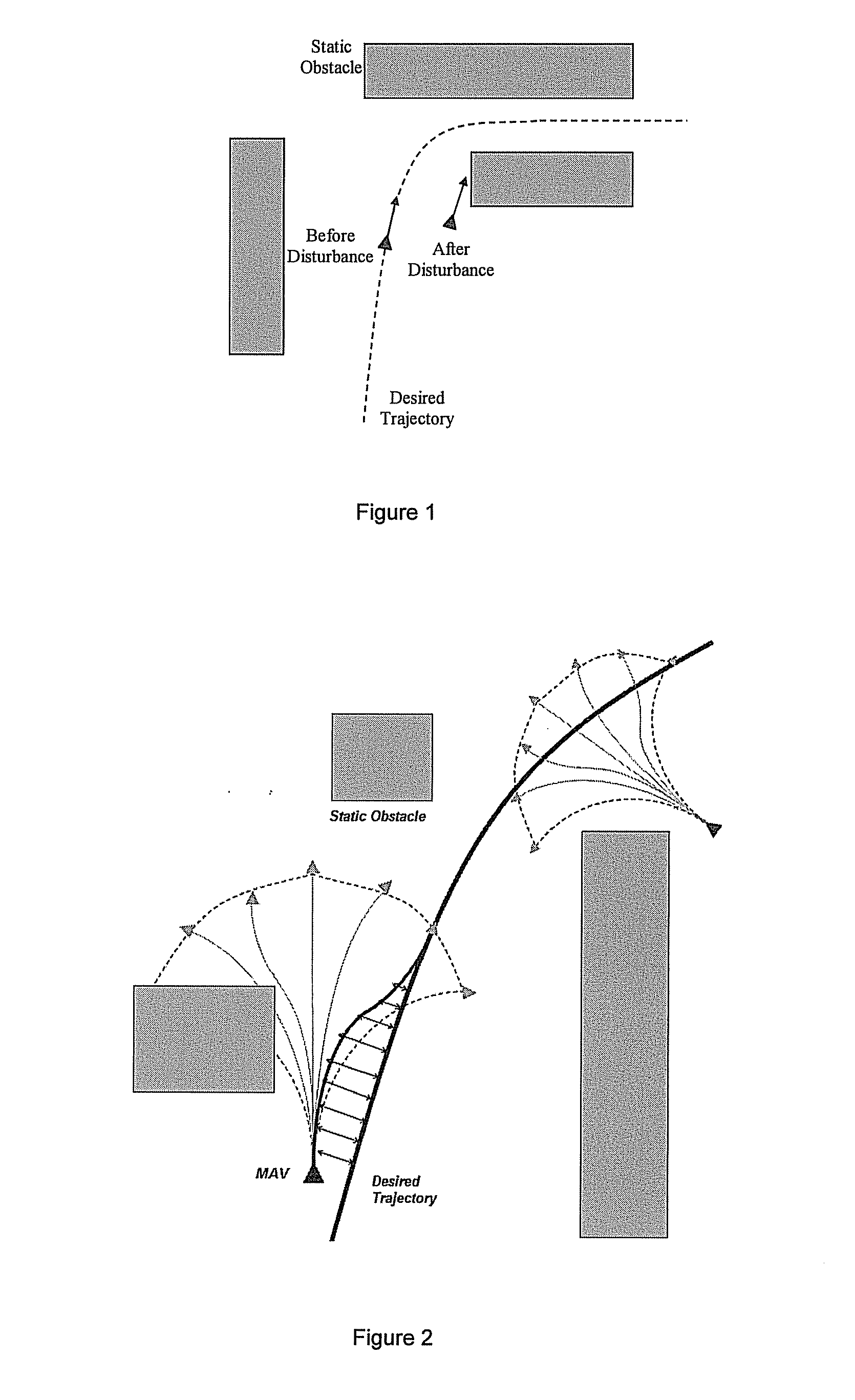

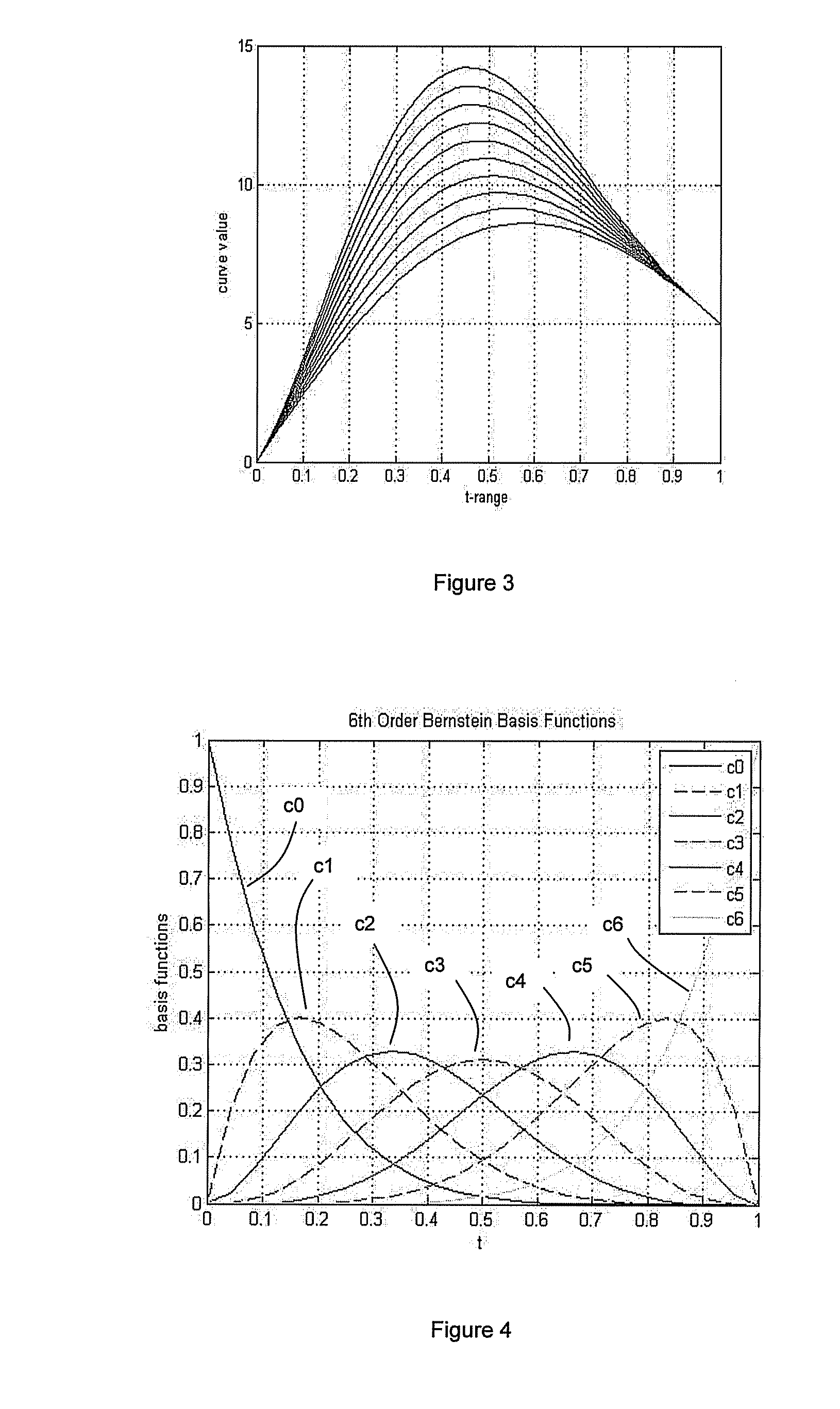

Vehicle Control

InactiveUS20110029235A1Improved vehicle controlAccurate trackingNavigation instrumentsVehicle position/course/altitude controlHorizonPerformance limit

A method of vehicle control, in which a global target trajectory is tracked by successively calculating an optimum local trajectory in 4D output space to approach the global trajectory and observe vehicle performance limits and surrounding obstacle clearance. A receding horizon framework is proposed which successively updates the optimum local trajectory according to the current state of the vehicle. Processing overheads can be kept to a minimum by calculating performance limits offline, and optimisation is simplified by using a cost function approach.

Owner:QINETIQ LTD

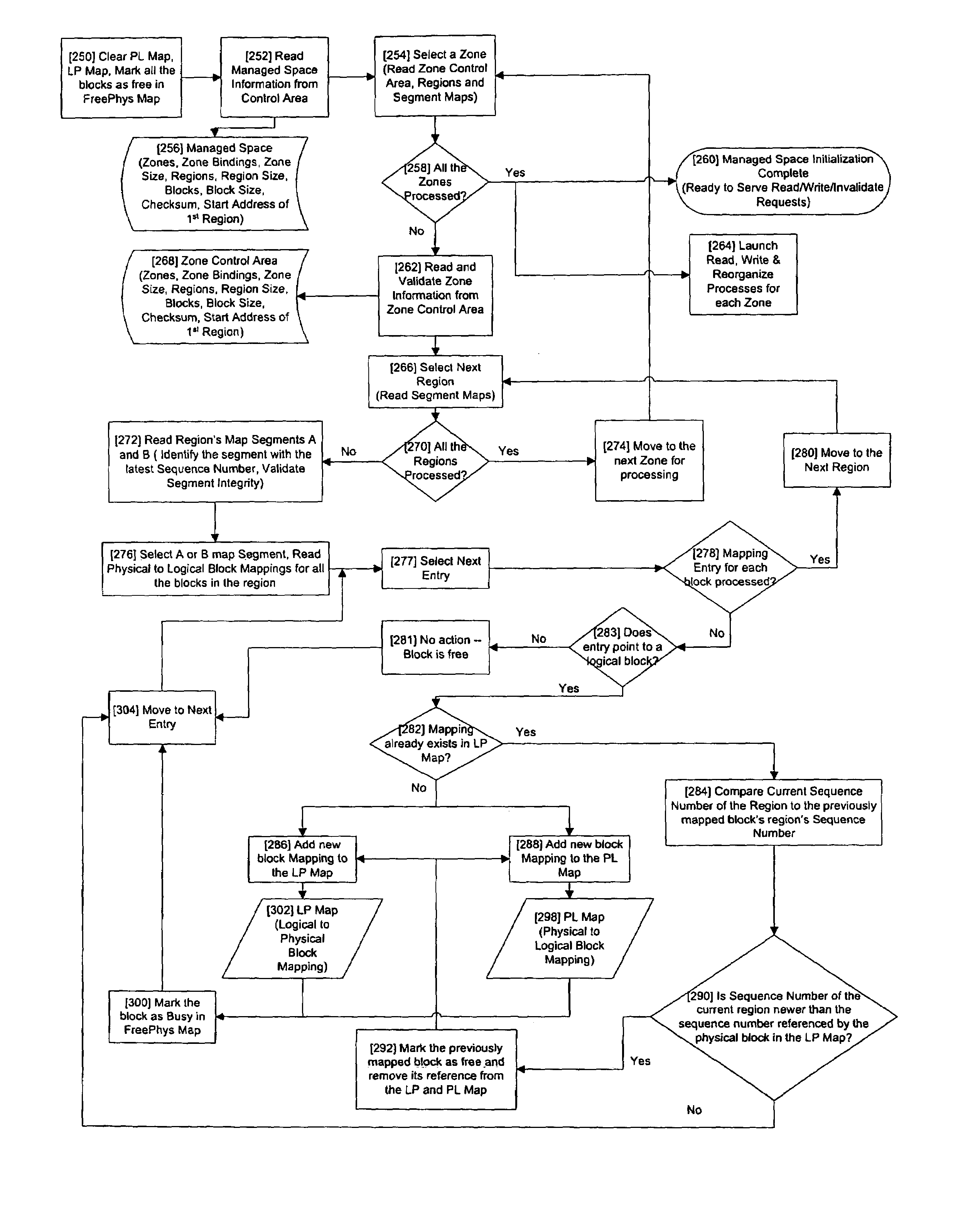

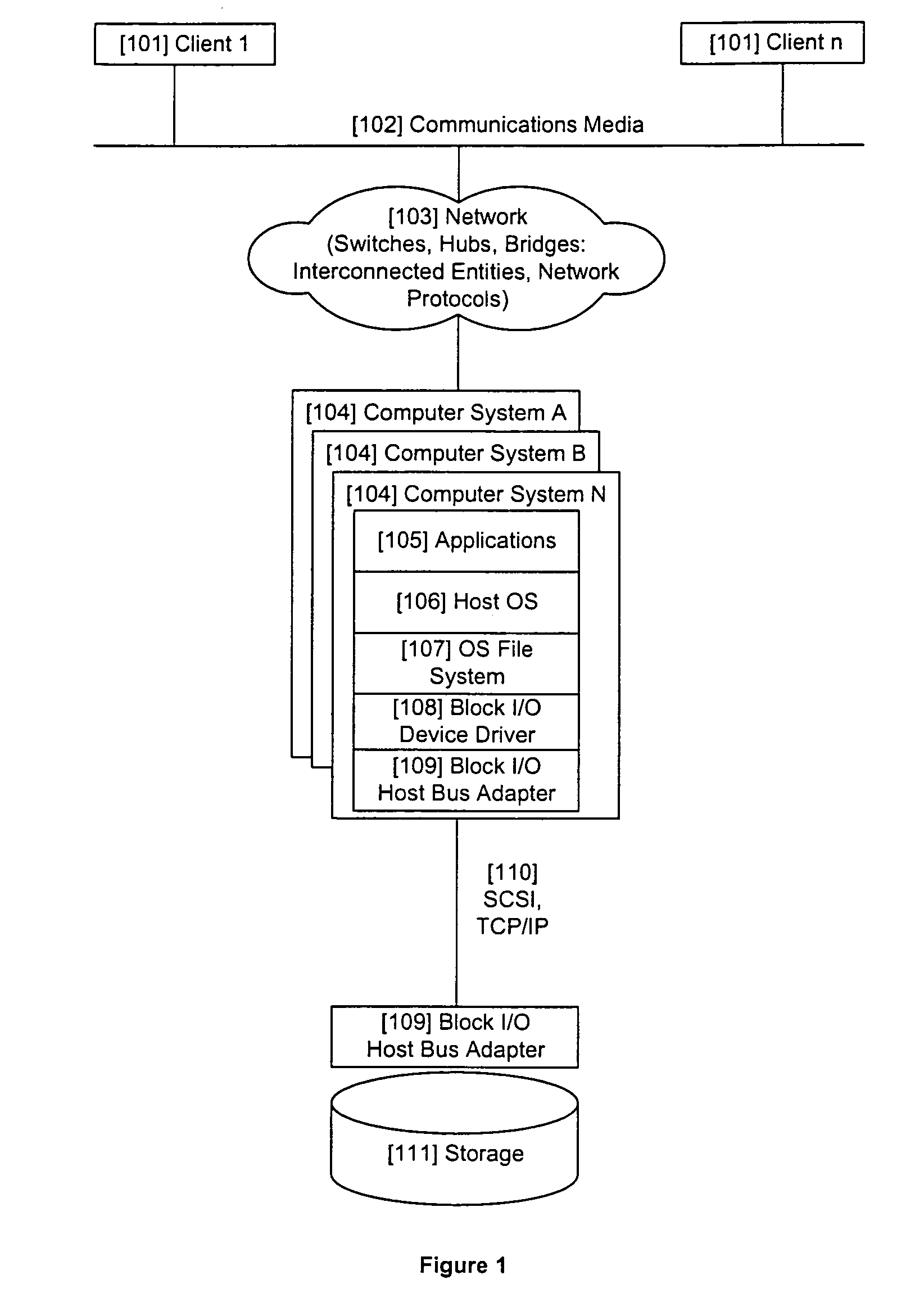

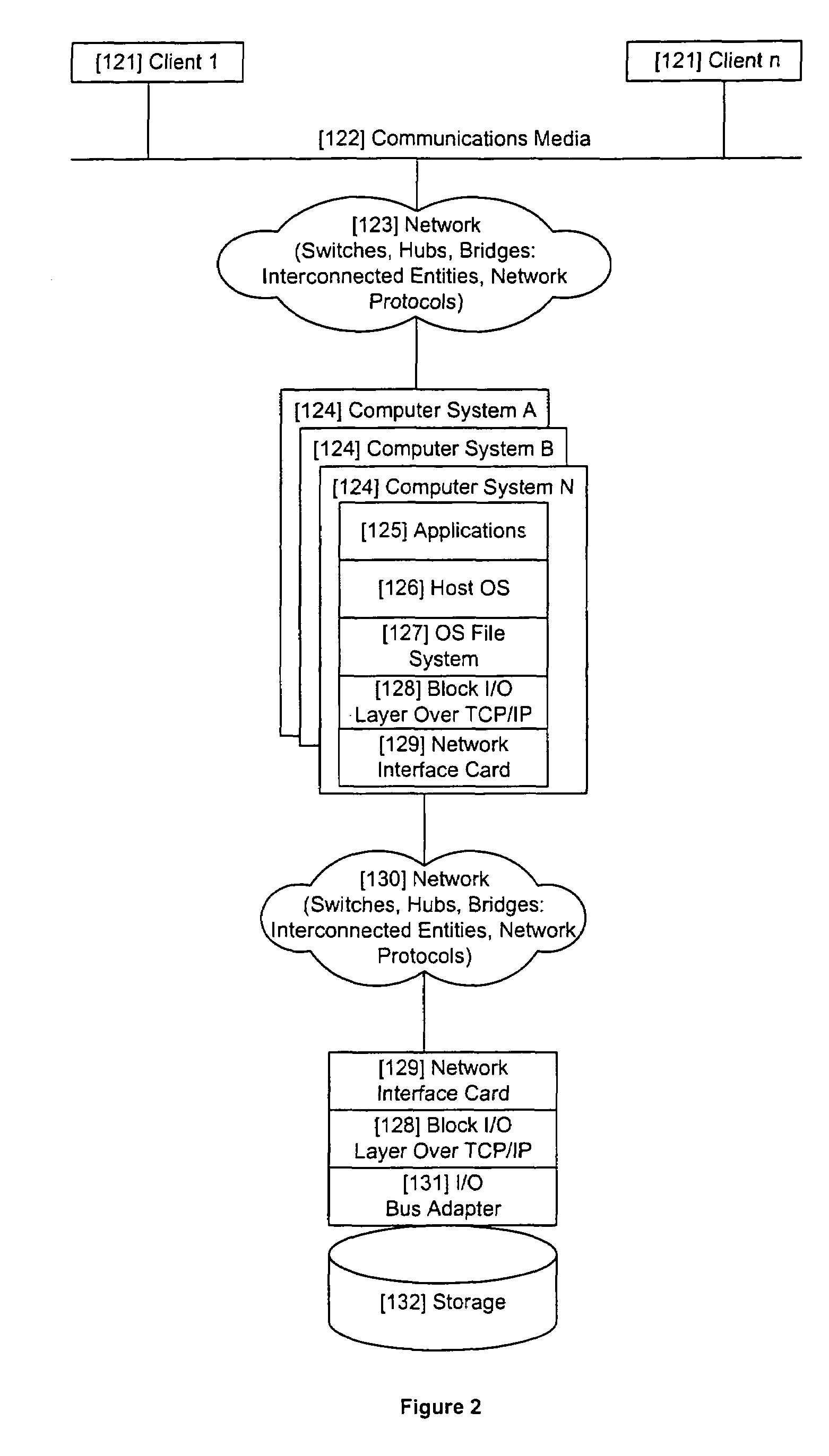

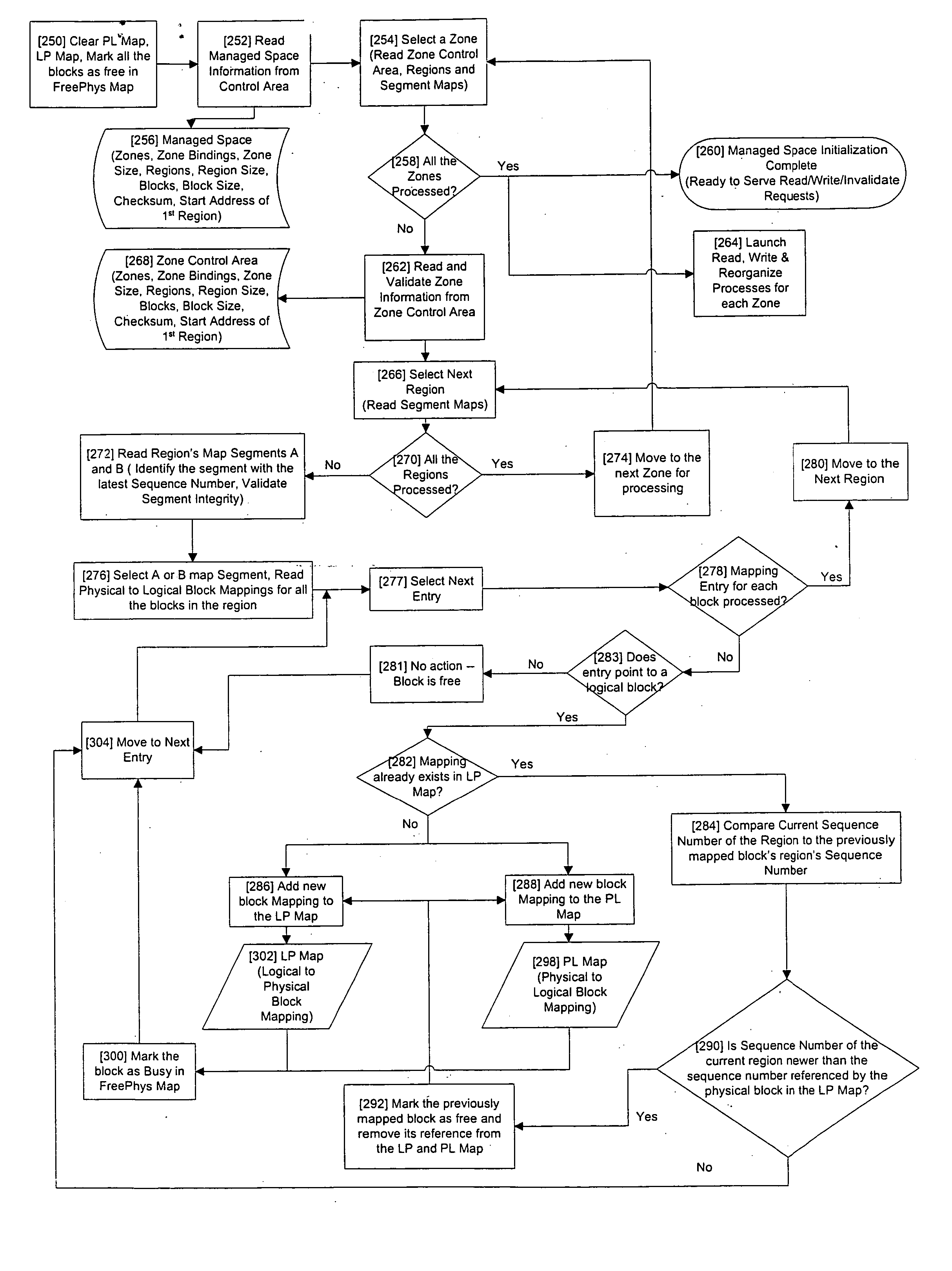

Method and apparatus for improving update performance of non-uniform access time persistent storage media

InactiveUS7328307B2Improve performanceImprove random access performanceInput/output to record carriersMemory adressing/allocation/relocationRAIDAccess time

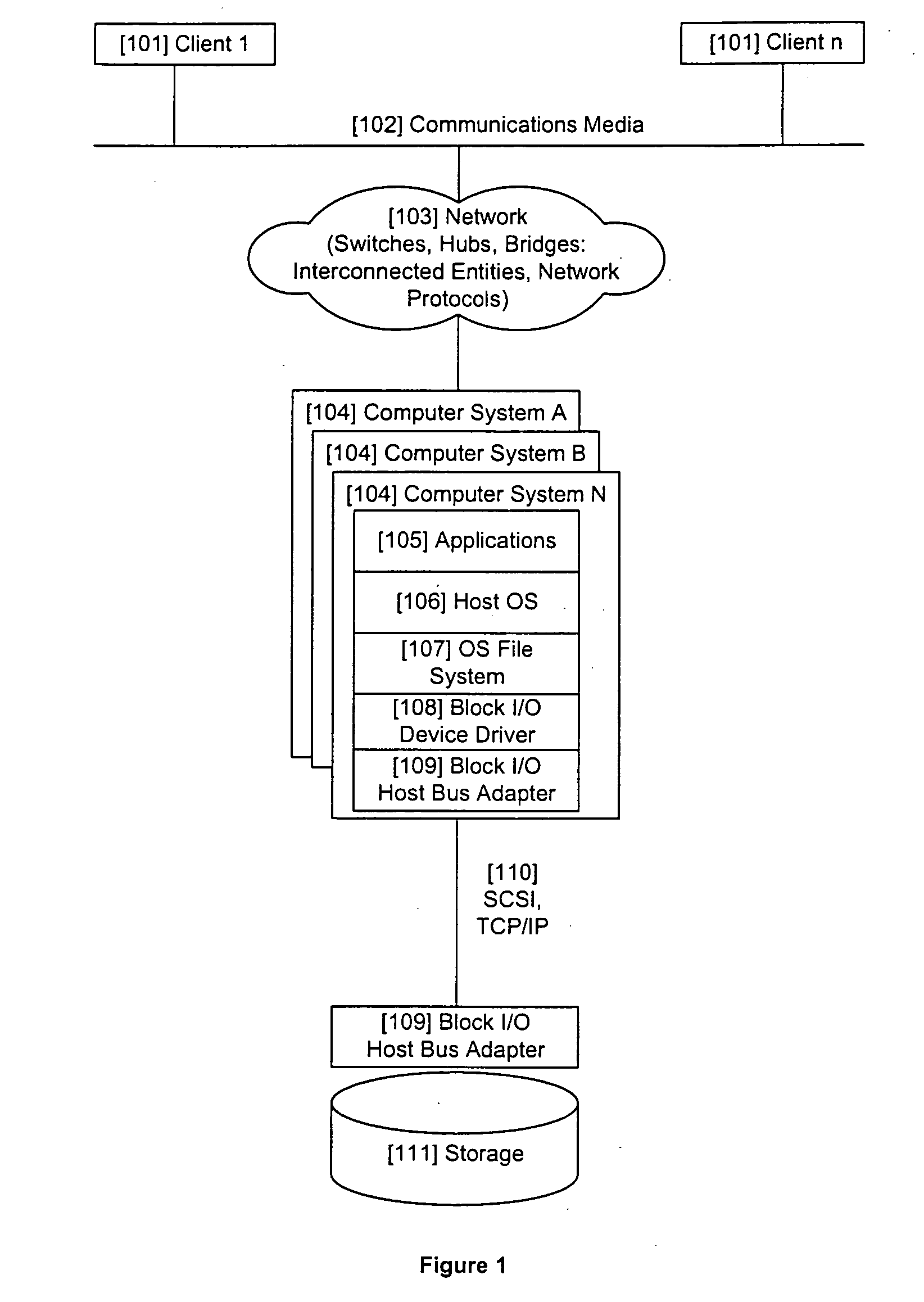

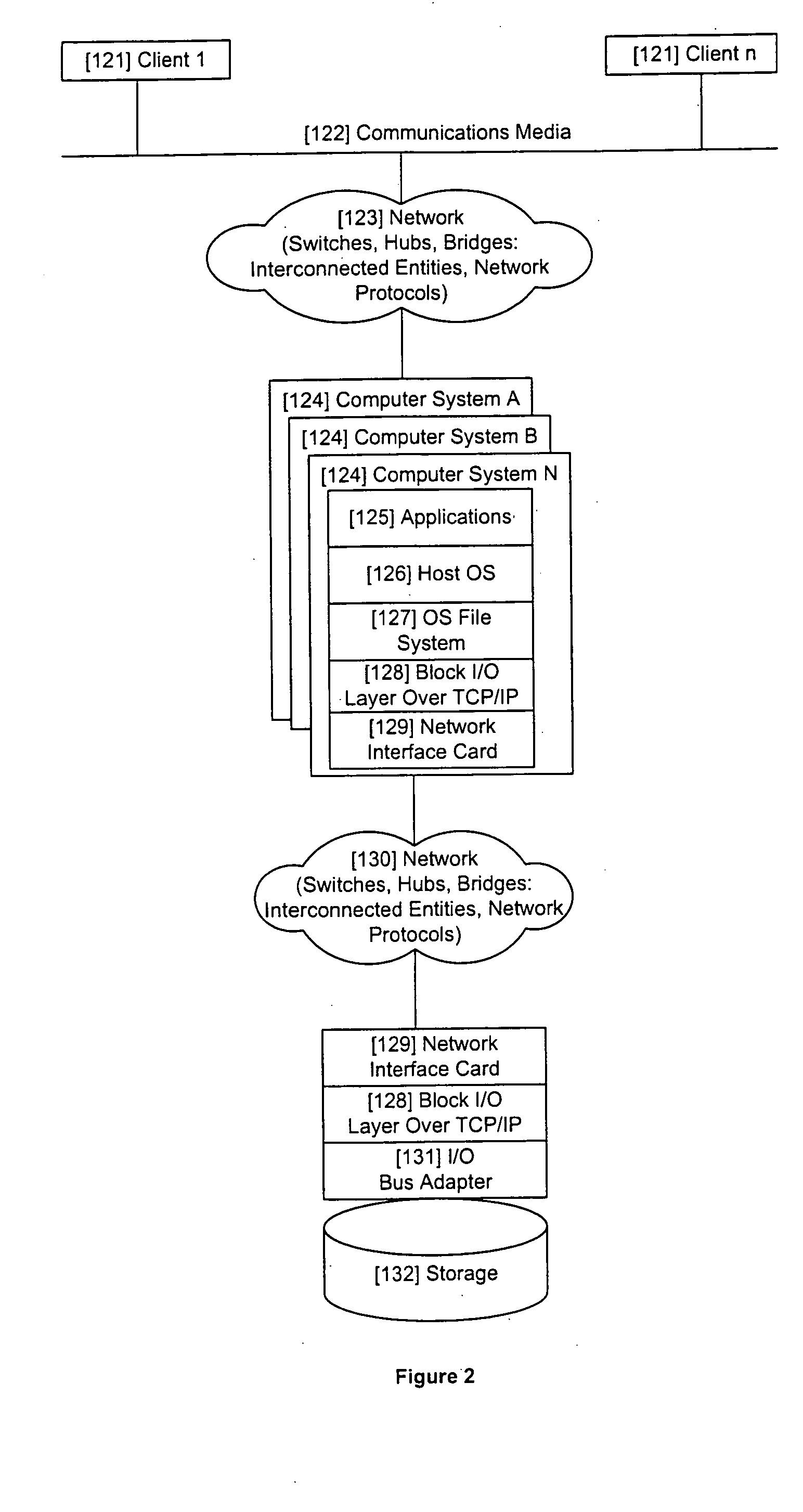

A high volume storage system is described which continuously remaps where data is stored. The remapping is designed so that writing occurs on an optimum speed basis tuned to the storage system being utilized, e.g., the writes occur in substantially sequential disk storage locations to the extent possible. By remapping data on a substantially continuous basis writes advantageously occur nearer the sequential performance limits of the particular drive or devices being utilized. A methodology is described which improves the external performance of a random access storage system, such as a RAID array. The illustrative embodiments introduce a continuous, optimized dynamic reorganization of the storage media that converts concurrent updates from one or more logical volumes to one or more sequential streams, as appropriate to the number of physical devices and channels over which the updates can be dispersed and thereby minimize the number of seek operations necessary on each physical device.

Owner:UNIFIED PATENTS

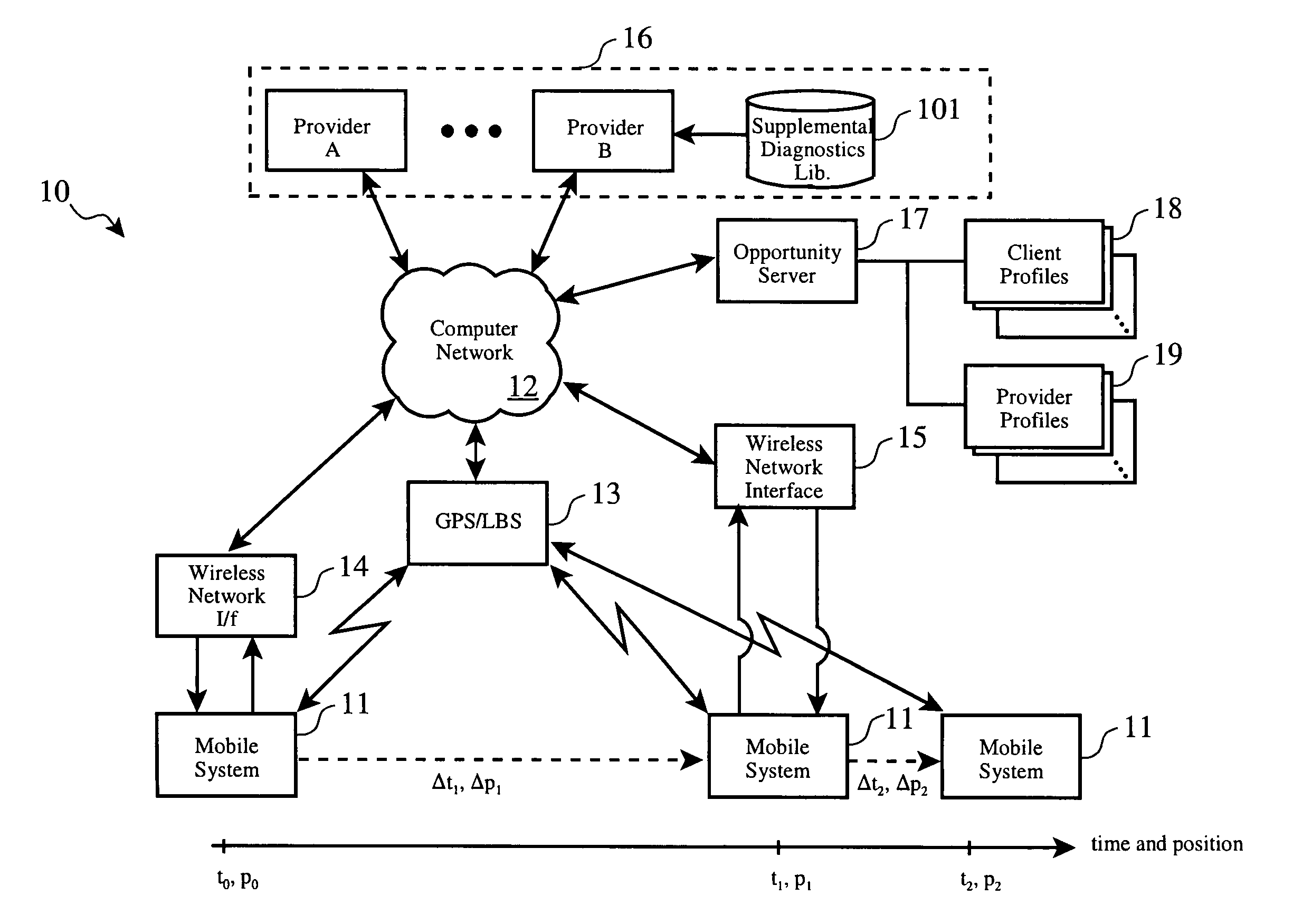

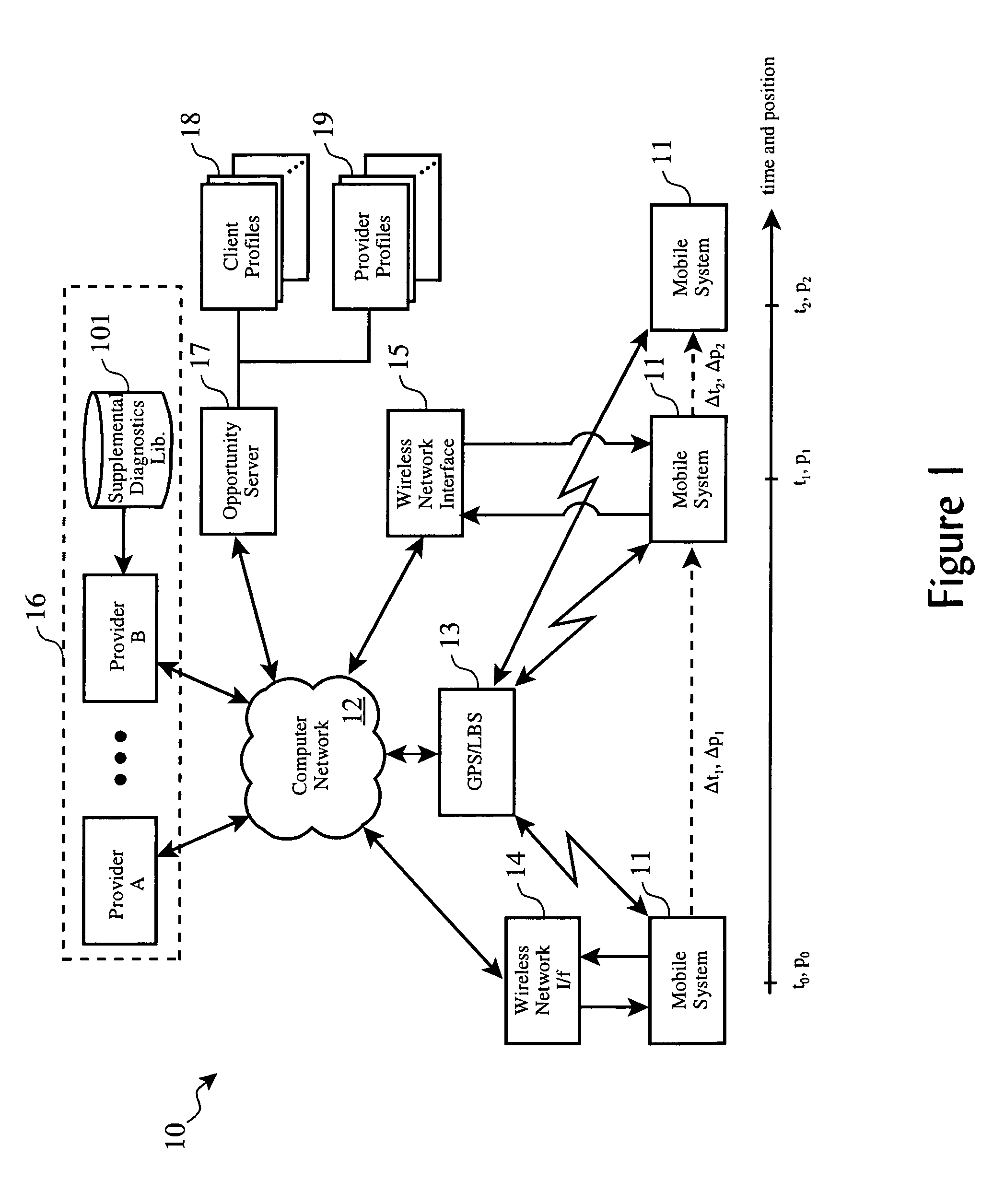

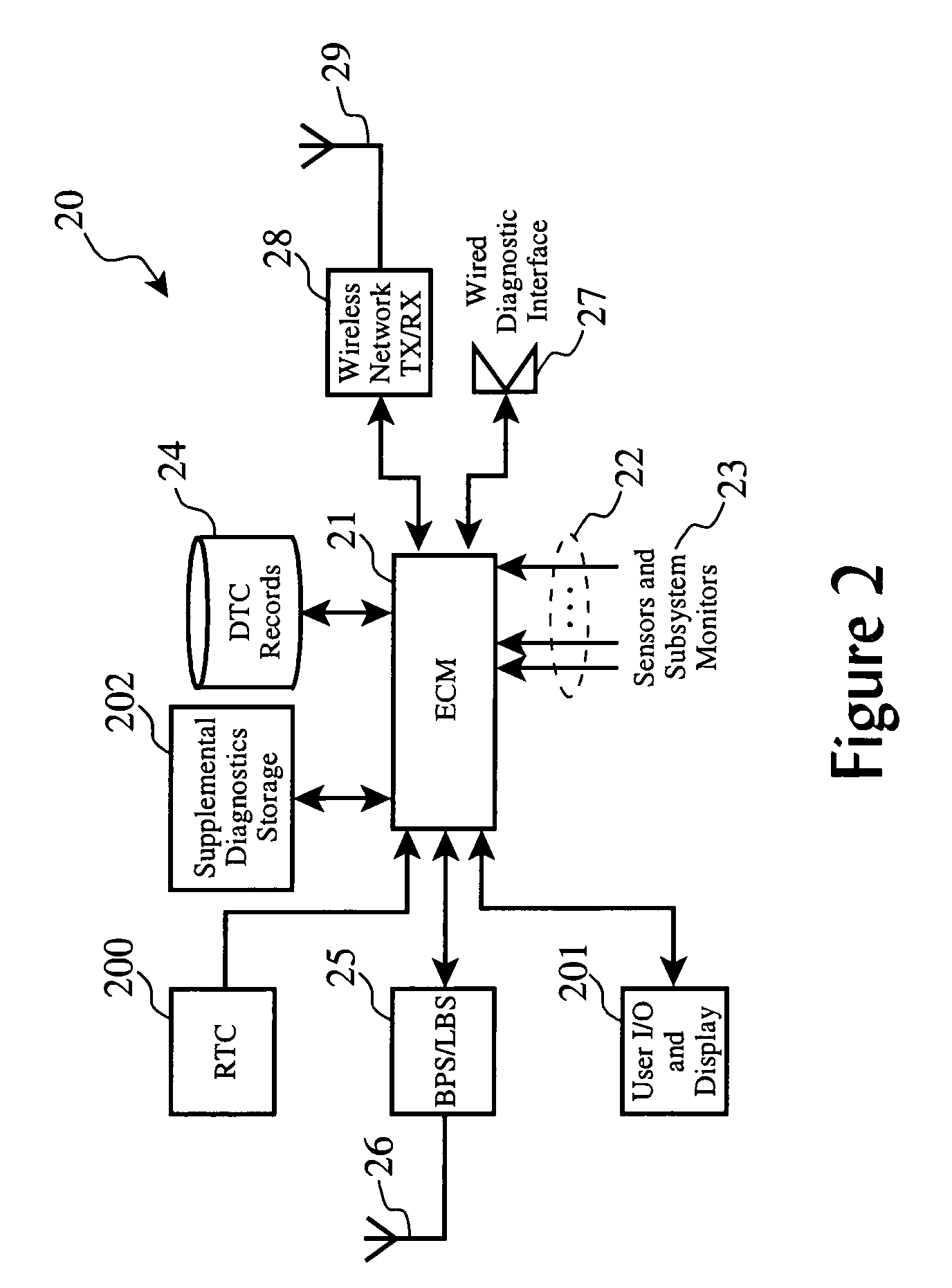

On-demand supplemental diagnostic and service resource planning for mobile systems

Owner:SLINGSHOT IOT LLC

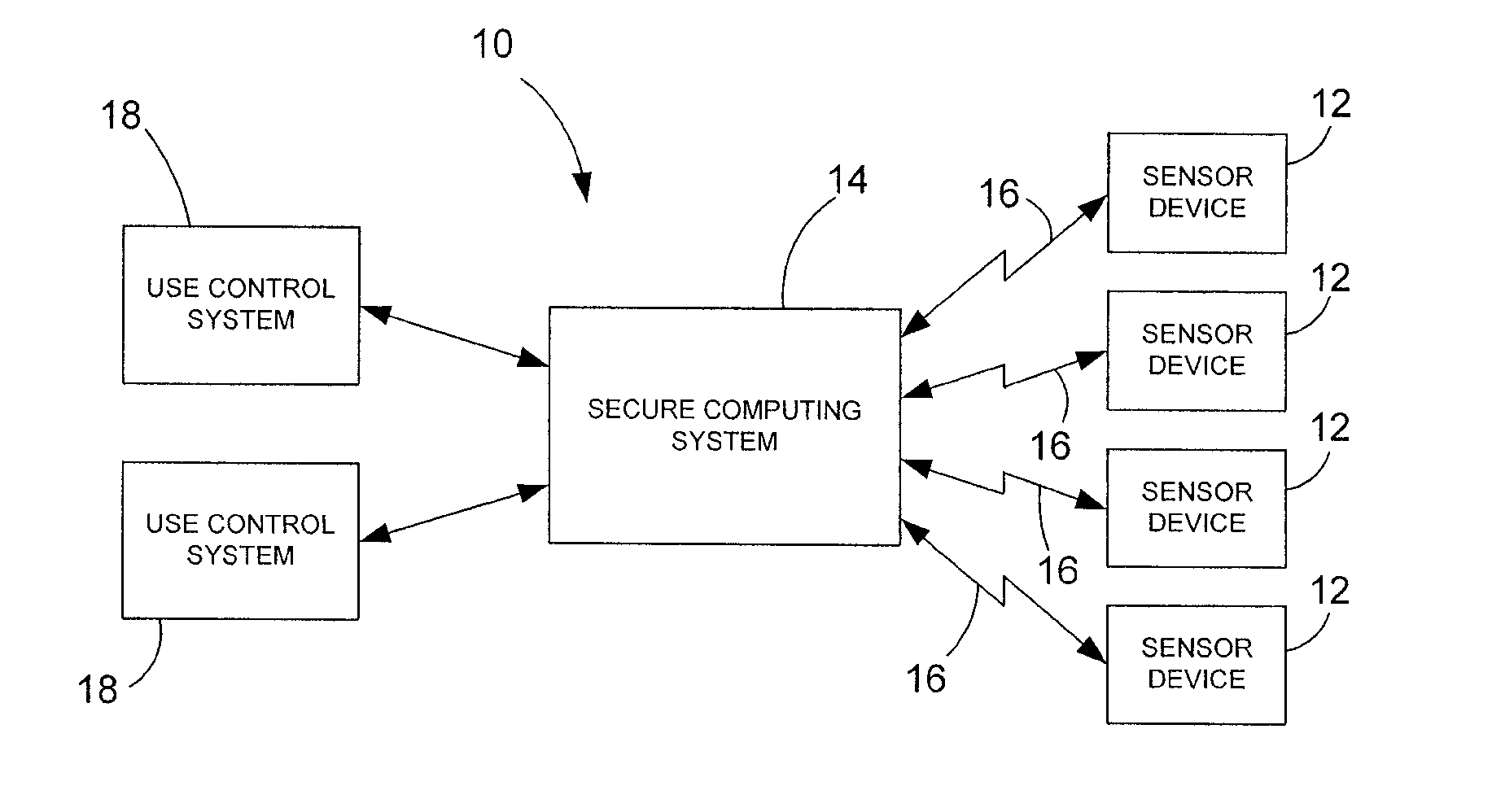

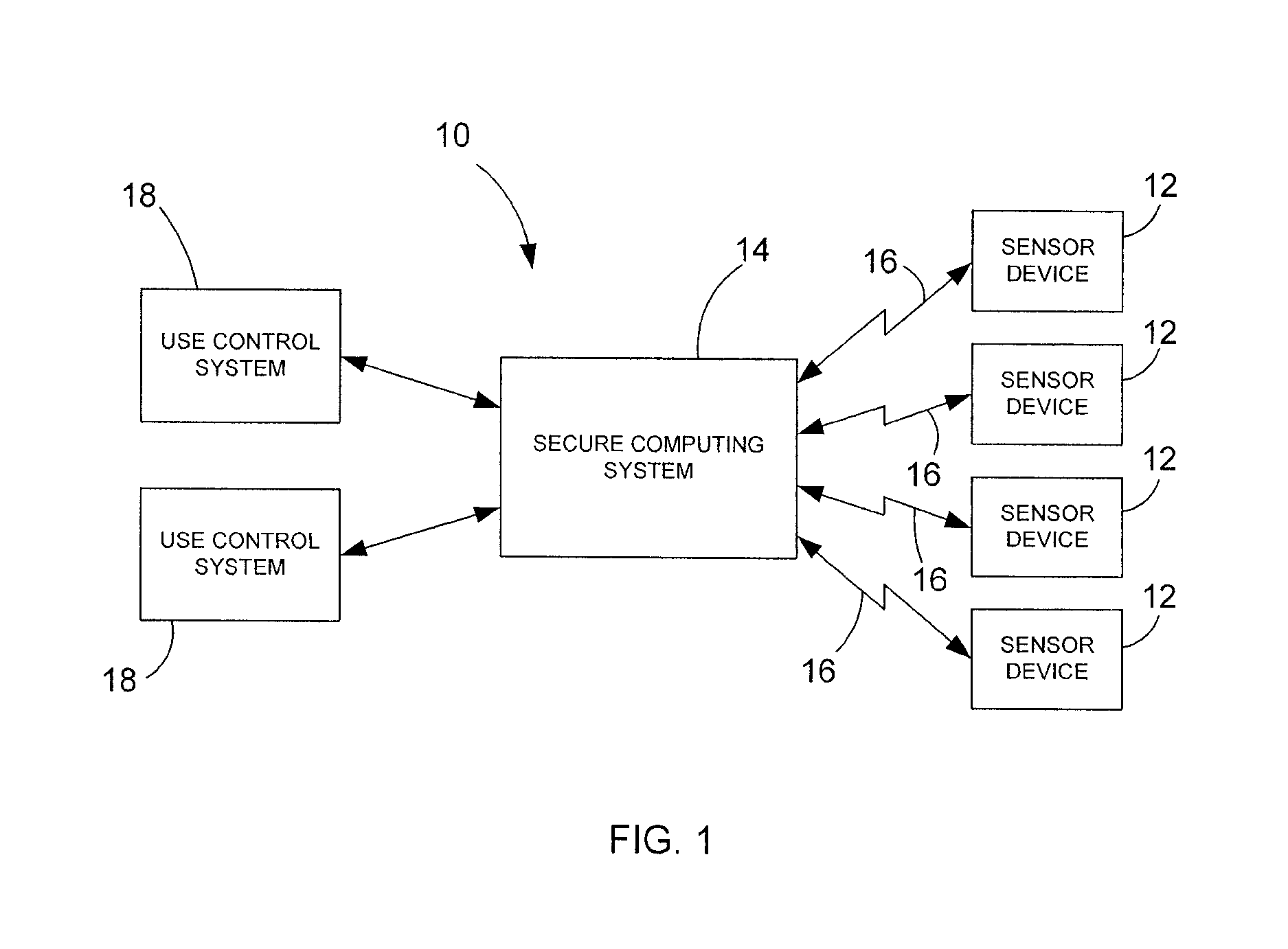

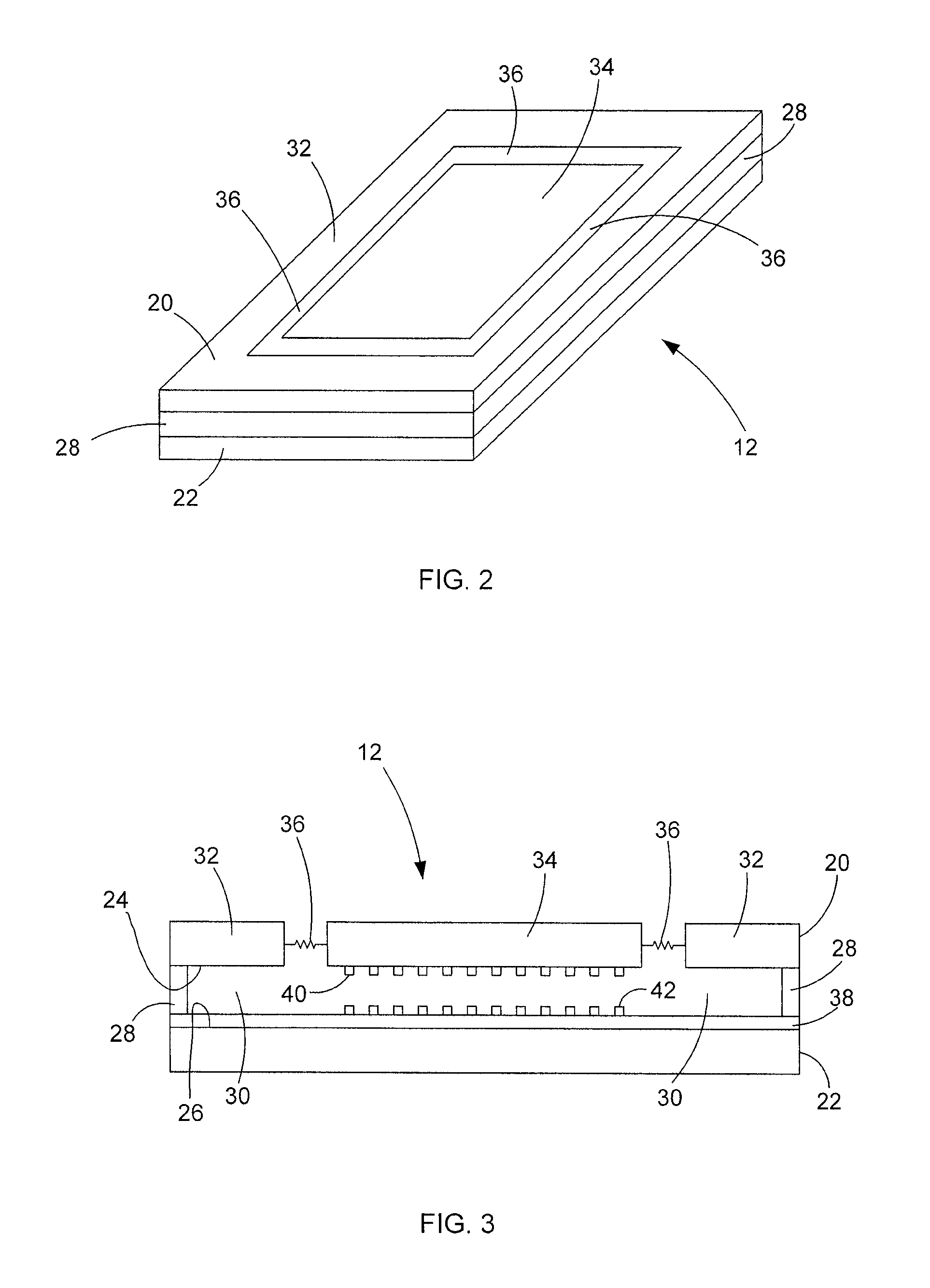

System and method for controlling remote sensors

A system and method for controlling one or more remote sensors includes wirelessly communicating with the sensors, monitoring operation of each one of the sensors, and causing any one of the sensors that is operating in an unauthorized manner to be disabled. In one embodiment, the sensors can include micro-mechanical structure supporting electronic circuitry. The electronic circuitry is capable of monitoring at least one performance parameter of the sensor, comparing the monitored parameter to a preset limit, and disabling the sensor if the preset performance limit is exceeded.

Owner:HEWLETT PACKARD DEV CO LP

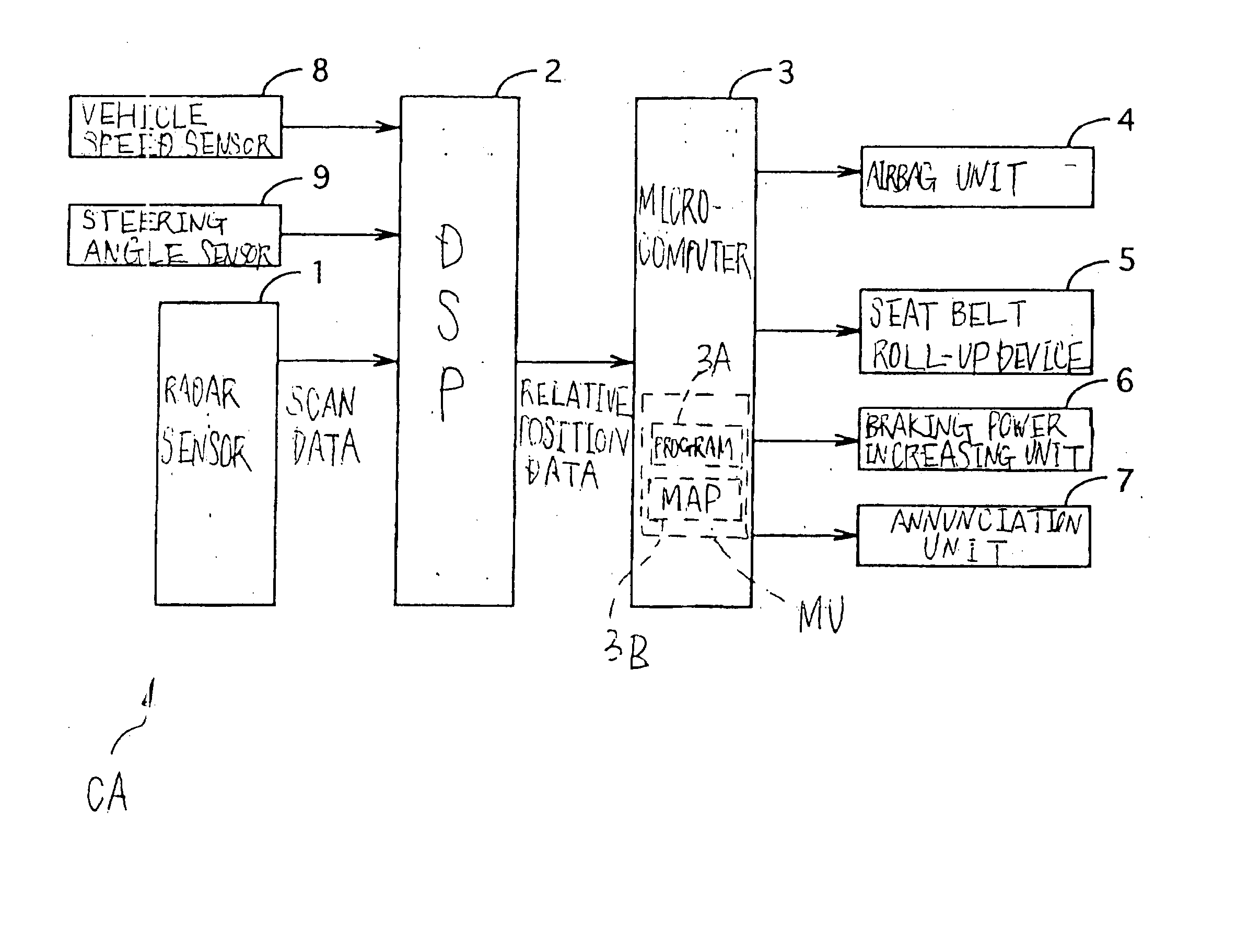

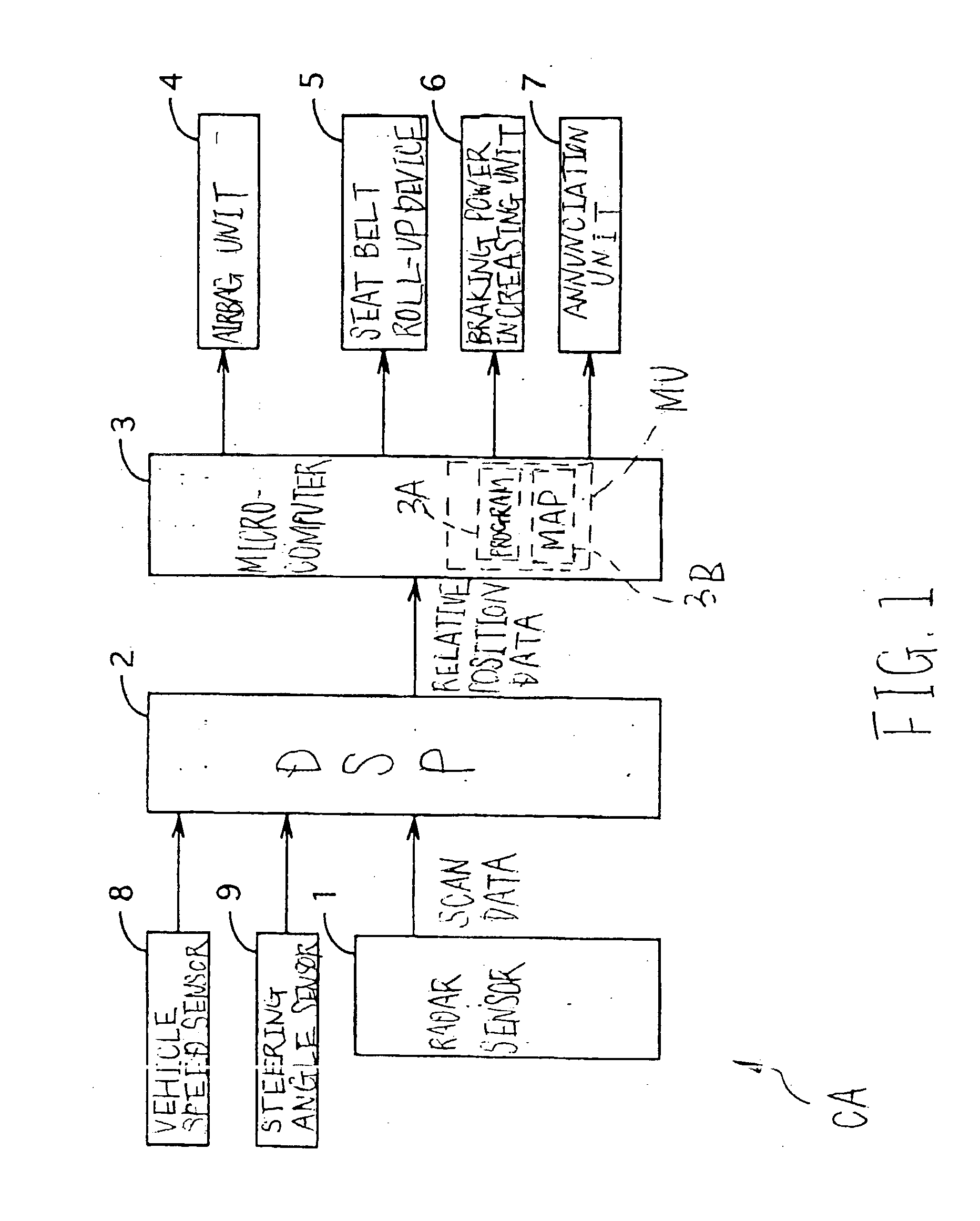

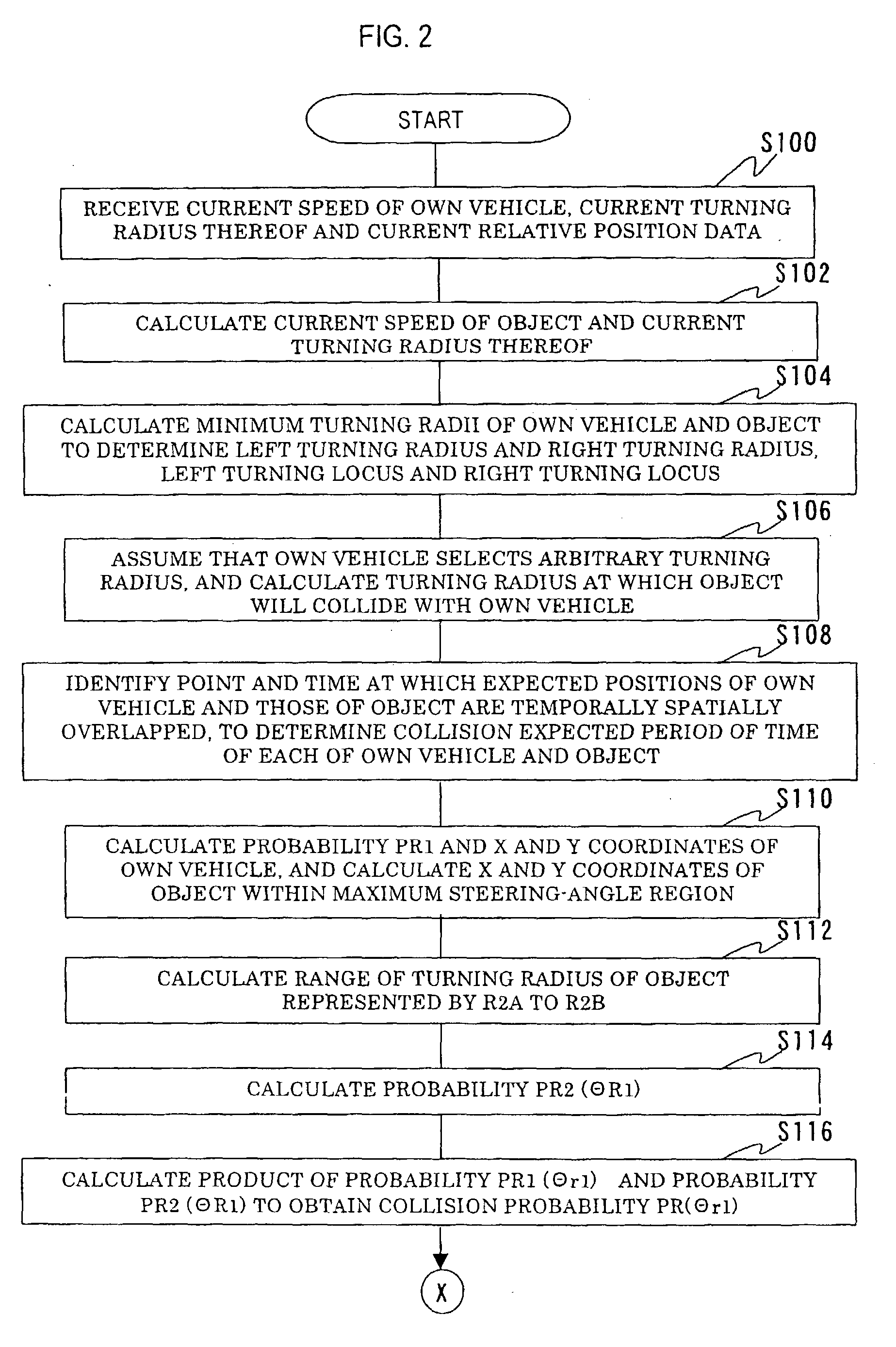

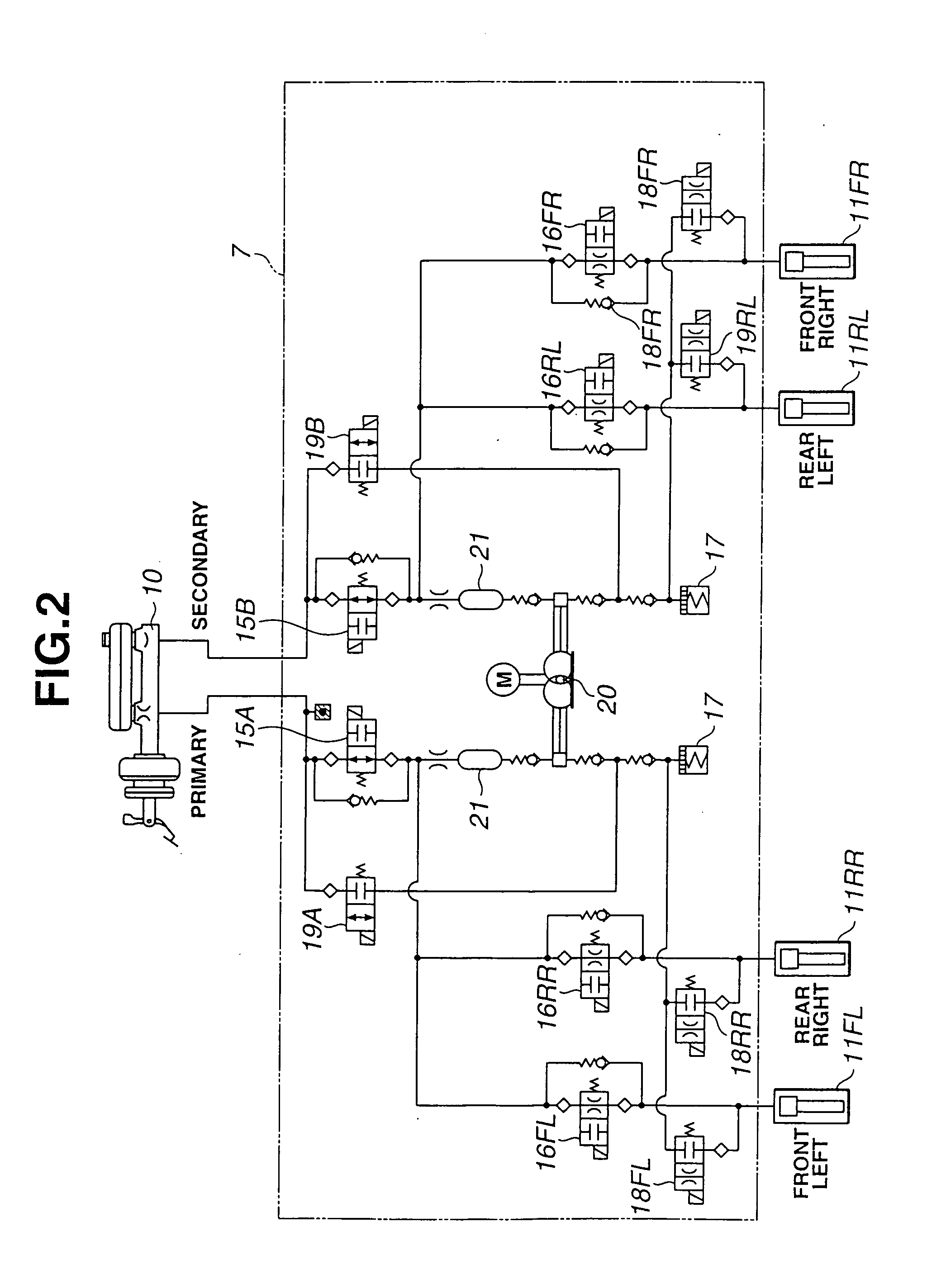

Collision damage reduction system

InactiveUS20030139883A1Reduce harmBelt retractorsDigital data processing detailsMicrocomputerTurn angle

In a collision damage reduction system, a microcomputer obtains a first performance limit data of the own vehicle according to the detected speed thereof by a first detecting unit and a second performance limit data of the object according to the relative position data detected by a first detecting unit, the detected speed of the own vehicle and the detected turning angle thereof by a third detecting unit. The microcomputer calculates a total collision probability representing a probability that the own vehicle and the object will collide with each other on a runnable space according to the first performance limit data, the second performance limit data, the detected speed of the own vehicle and the relative position data. In addition, the microcomputer instructs the operation unit to operate at least one of the first operation and the second operation according to the total collision probability.

Owner:DENSO CORP

Method and apparatus for improving update performance of non-uniform access time persistent storage media

InactiveUS20050210218A1Improve performanceImprove random access performanceInput/output to record carriersMemory adressing/allocation/relocationRAIDAccess time

A high volume storage system is described which continuously remaps where data is stored. The remapping is designed so that writing occurs on an optimum speed basis tuned to the storage system being utilized, e.g., the writes occur in substantially sequential disk storage locations to the extent possible. By remapping data on a substantially continuous basis writes advantageously occur nearer the sequential performance limits of the particular drive or devices being utilized. A methodology is described which improves the external performance of a random access storage system, such as a RAID array. The illustrative embodiments introduce a continuous, optimized dynamic reorganization of the storage media that converts concurrent updates from one or more logical volumes to one or more sequential streams, as appropriate to the number of physical devices and channels over which the updates can be dispersed and thereby minimize the number of seek operations necessary on each physical device.

Owner:UNIFIED PATENTS

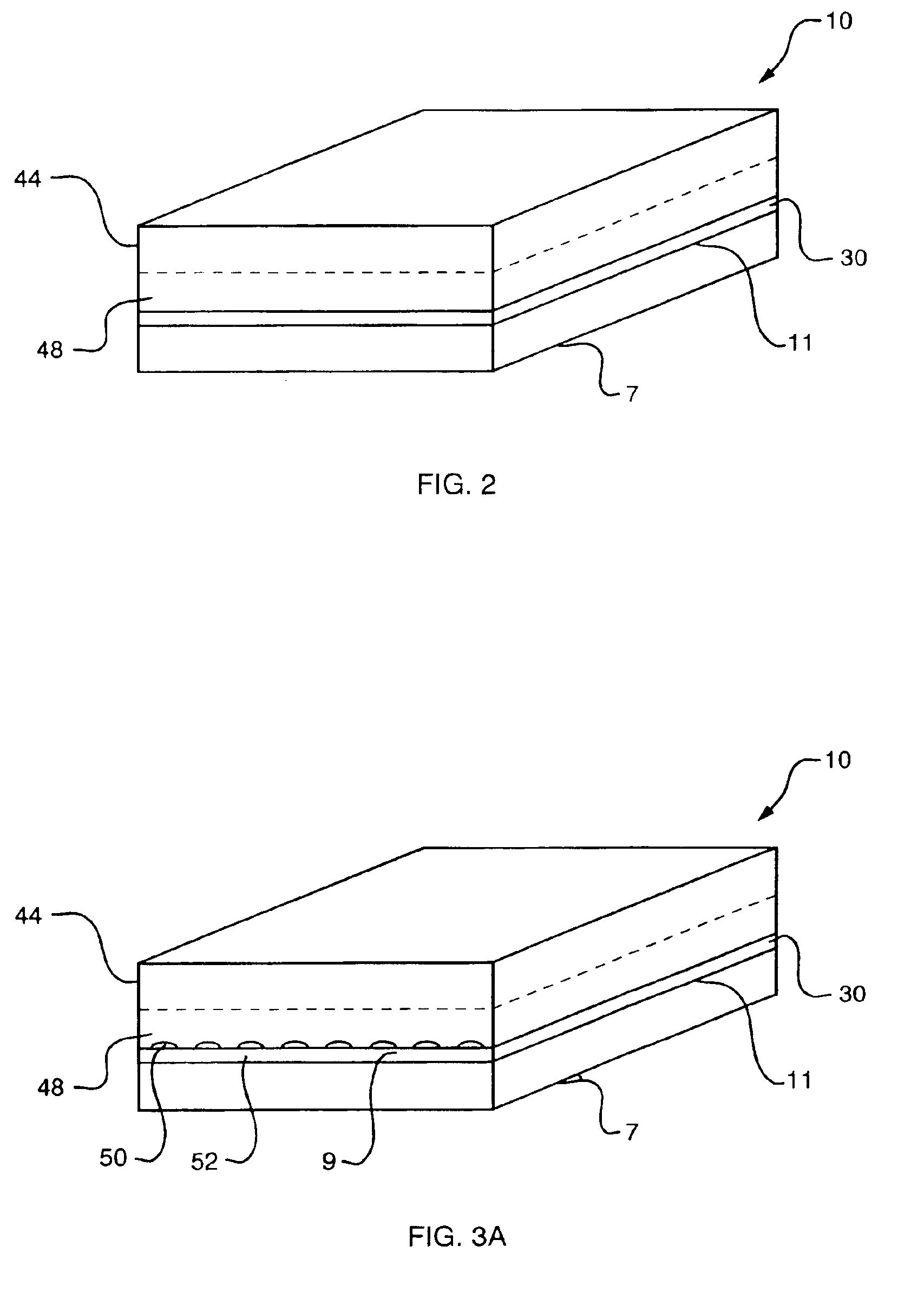

Modified diffusion layer for use in a fuel cell system

InactiveUS6890680B2Improve fuel efficiencyEasy to operateCell electrodesFuel cell auxillariesPreferential flowFuel cells

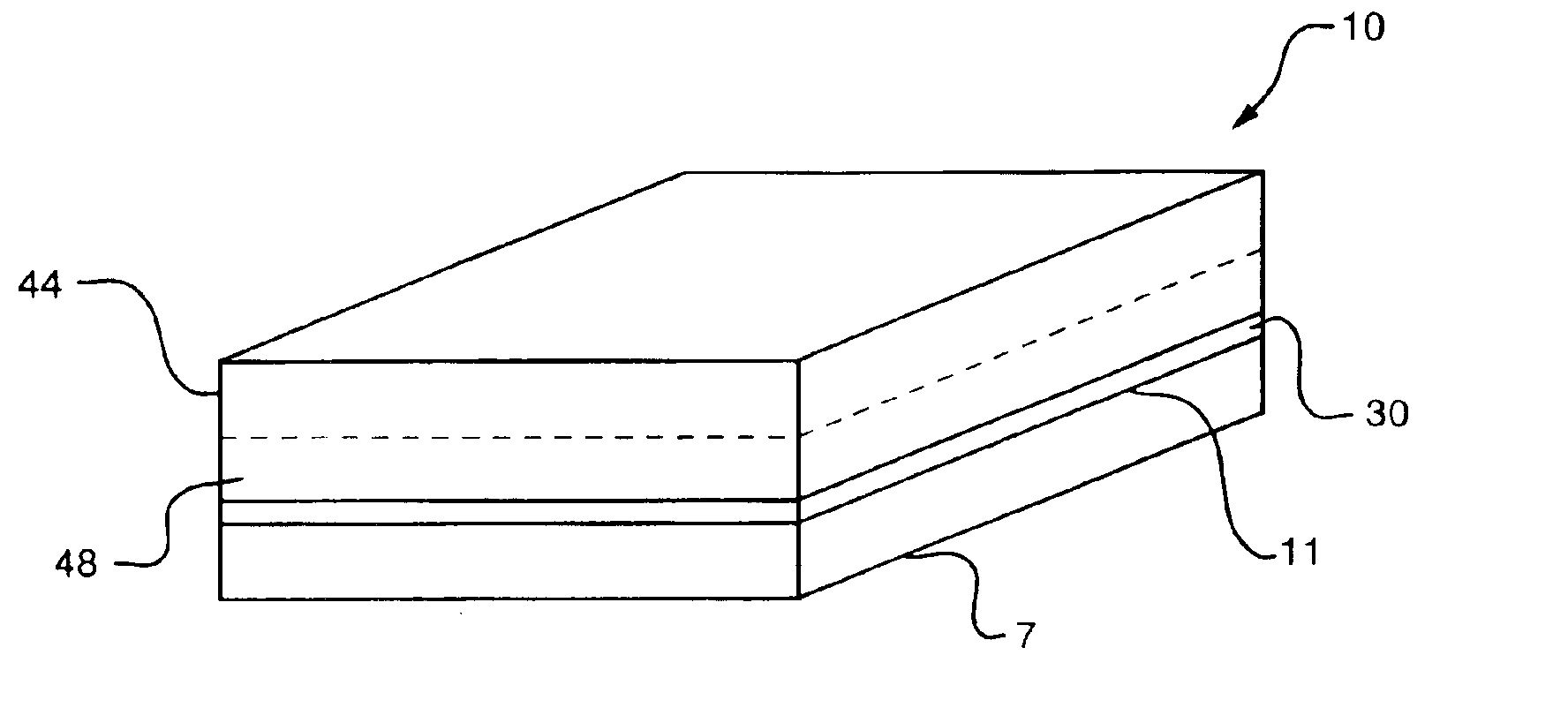

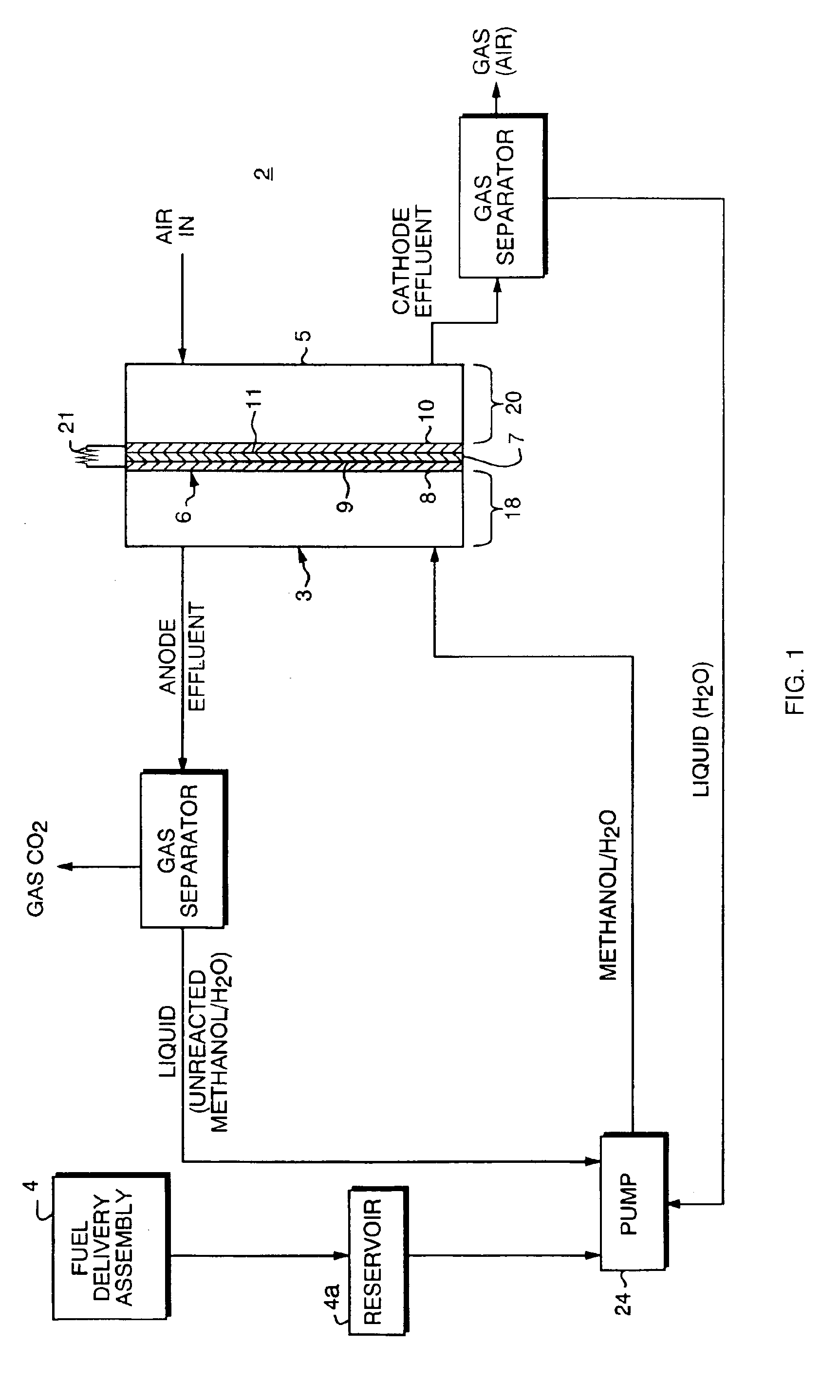

A fuel cell diffusion layer providing a preferential path by which liquid reactants or byproducts may be supplied to or removed from a direct oxidation fuel cell is described. The modified diffusion layer will be typically on the cathode side of the fuel cell and its use is to eliminate or minimize flooding of the cathode diffusion layer area, which is a performance limiting condition in direct methanol fuel cells. In accordance with one embodiment of the invention, the diffusion layer includes a substrate that is coated with a microporous layer. A pattern may be embossed into the diffusion layer, to create preferential flow paths by which water will travel and thereby be removed from the cathode catalyst area. This avoids cathode flooding and avoids build up of potentially destructive pressure by possible cathodic water accumulation. This also provides a means for collecting cathode water for redirection In accordance with another aspect of the invention, the preferential path is established by applying a thicker microporous layer to the carbon cloth or carbon paper and drying it in such a fashion so that when it dries, the surface of the microporous layer cracks to provide the pathways.

Owner:MTI MICROFUEL CELLS

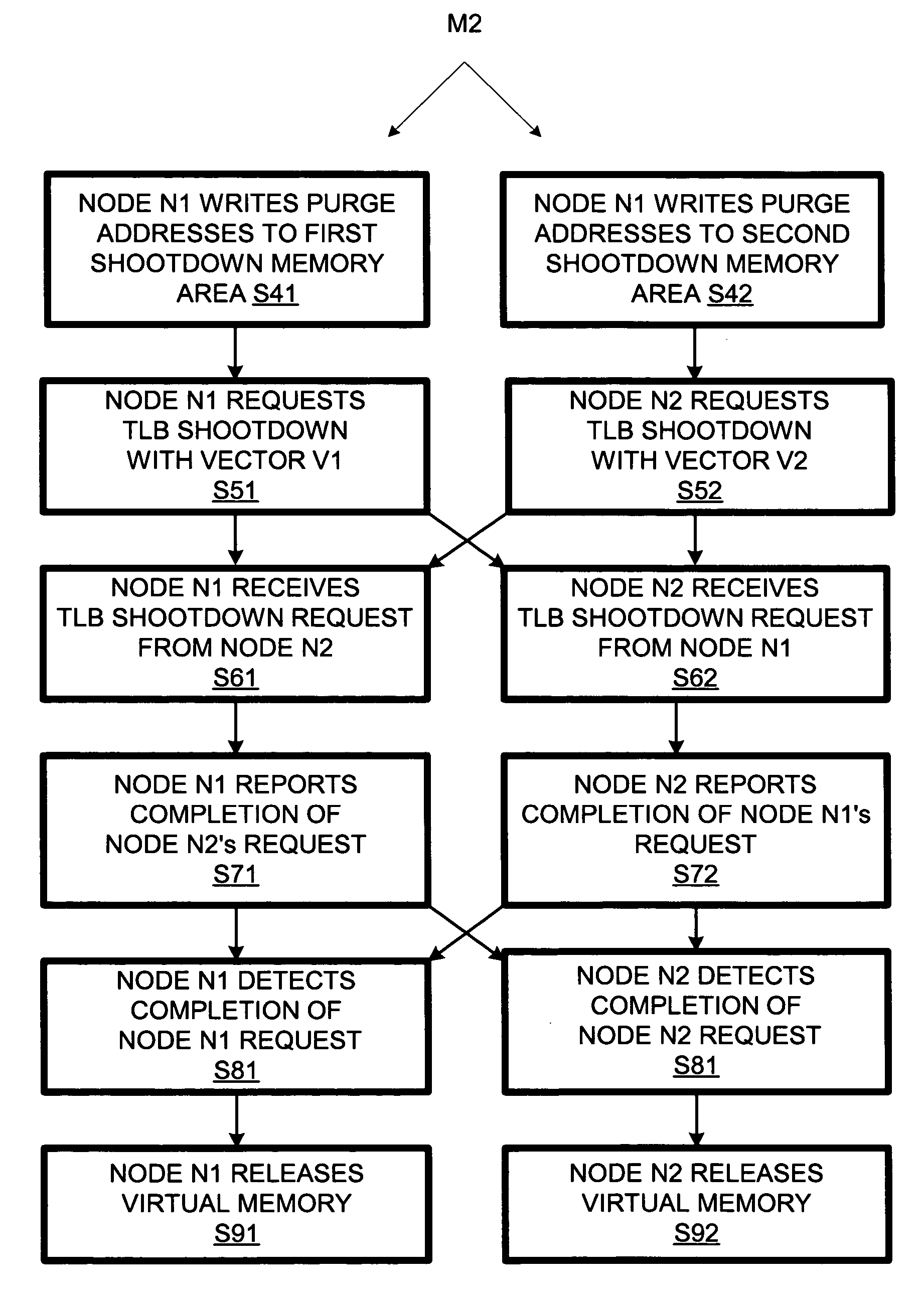

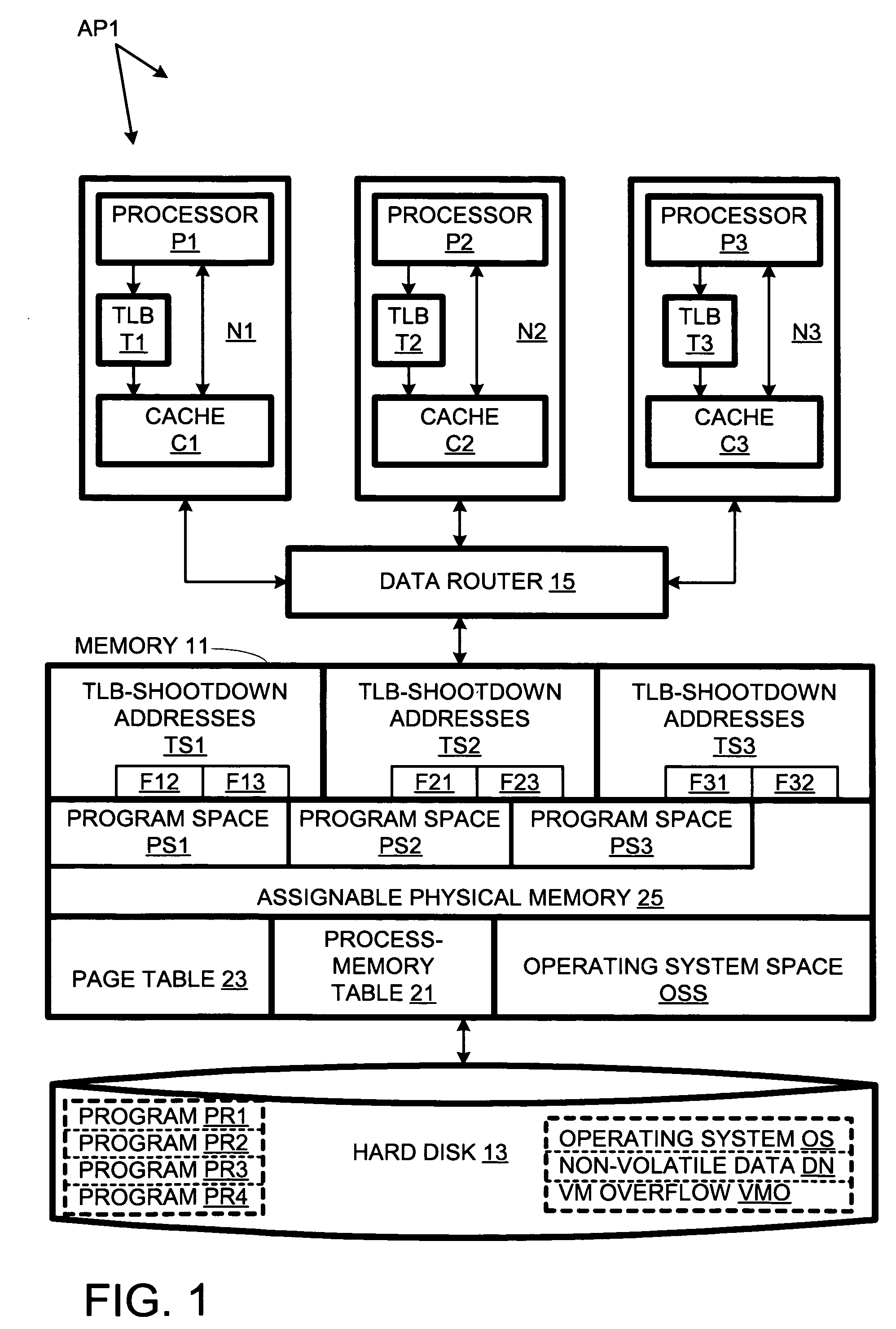

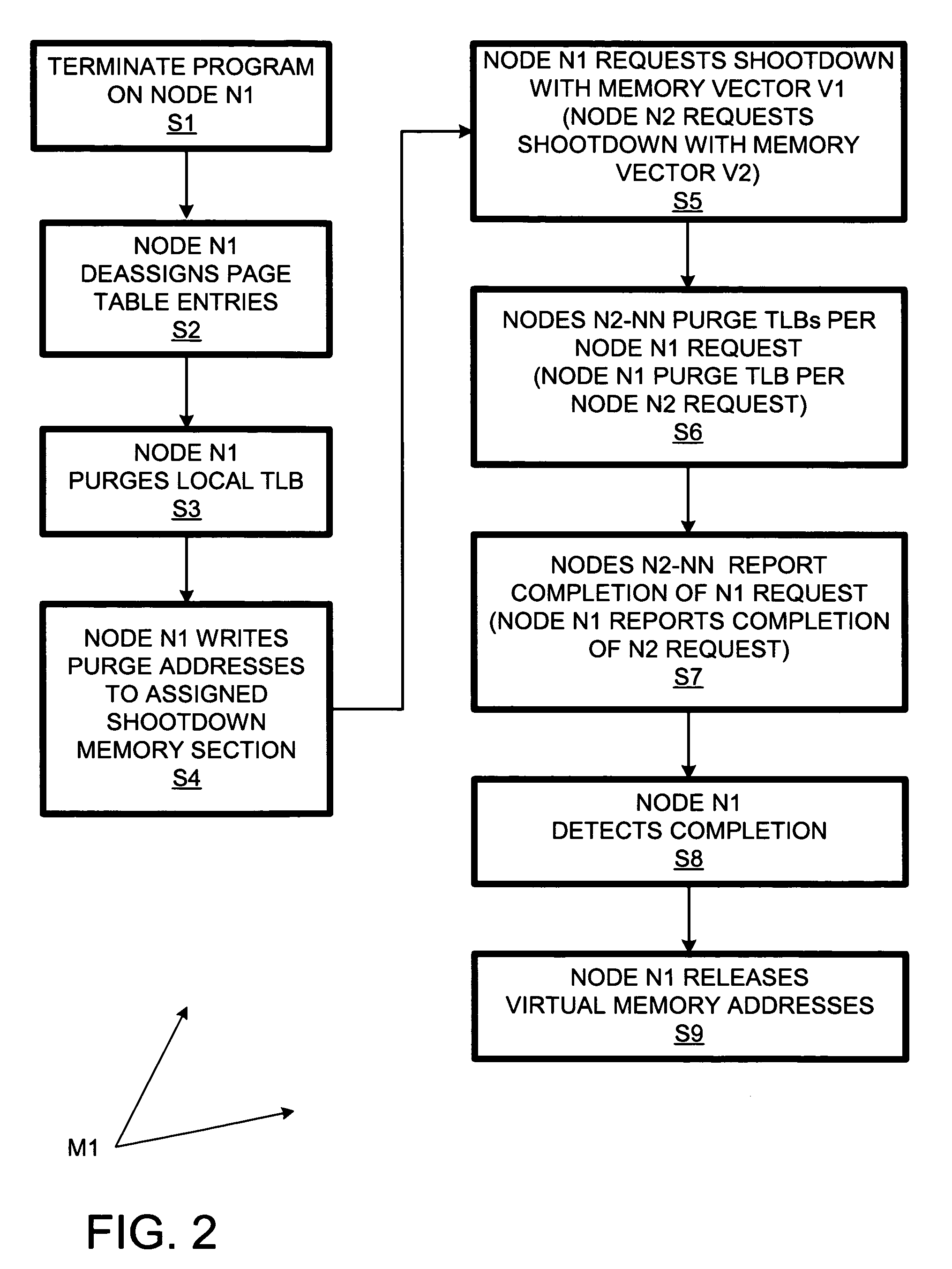

Multiprocessor system having plural memory locations for respectively storing TLB-shootdown data for plural processor nodes

InactiveUS20060026359A1Raise the possibilityMemory architecture accessing/allocationMemory adressing/allocation/relocationExtensibilityMulti processor

The present invention provides a multiprocessor system and method in which plural memory locations are used for storing TLB-shootdown data respectively for plural processors. In contrast to systems in which a single area of memory serves for all processors' TLB-shootdown data, different processors can describe the memory they want to free concurrently. Thus, concurrent TLB-shootdown request are less likely to result in performance-limiting TLB-shootdown contentions that have previously constrained the scaleability of multiprocessor systems.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

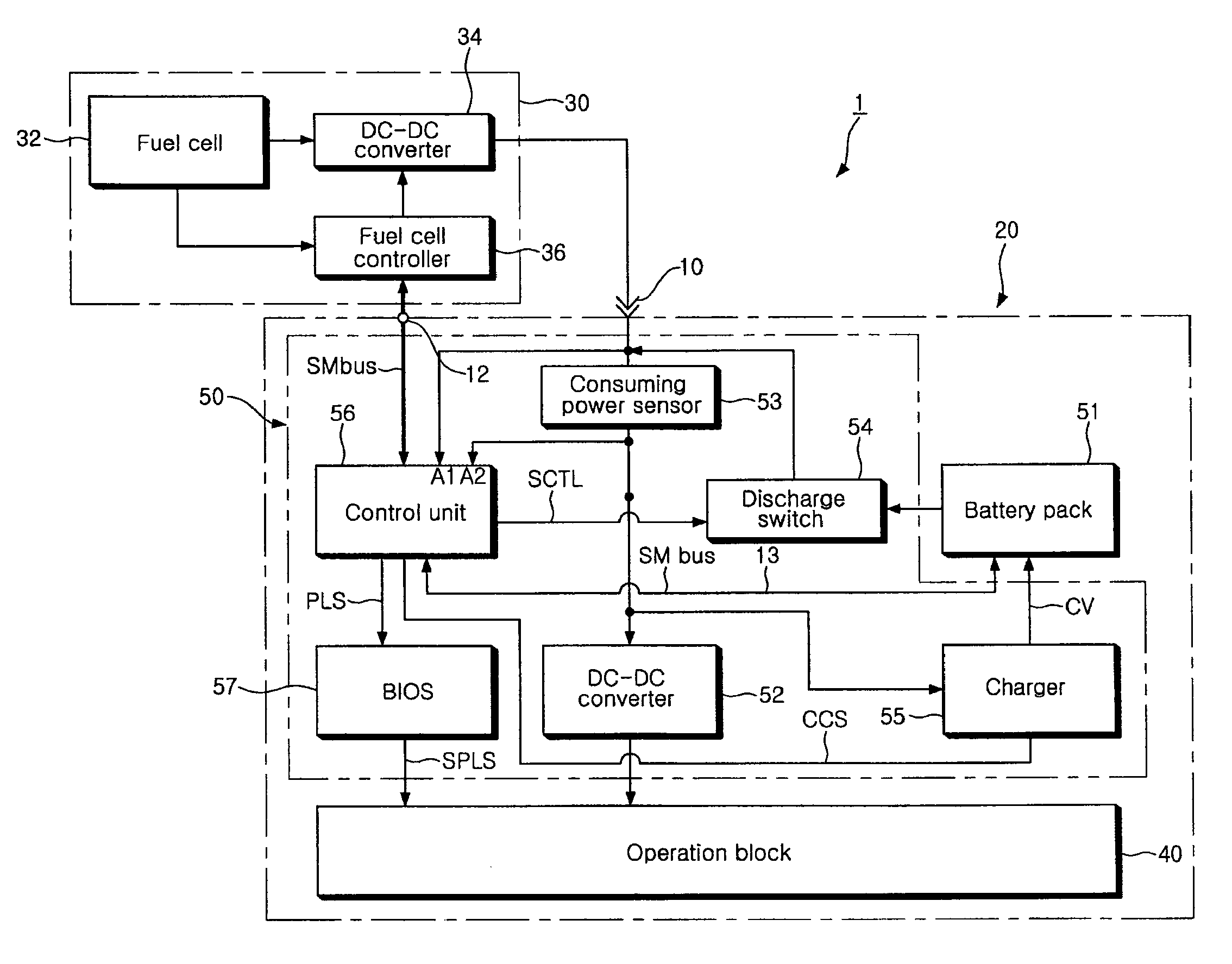

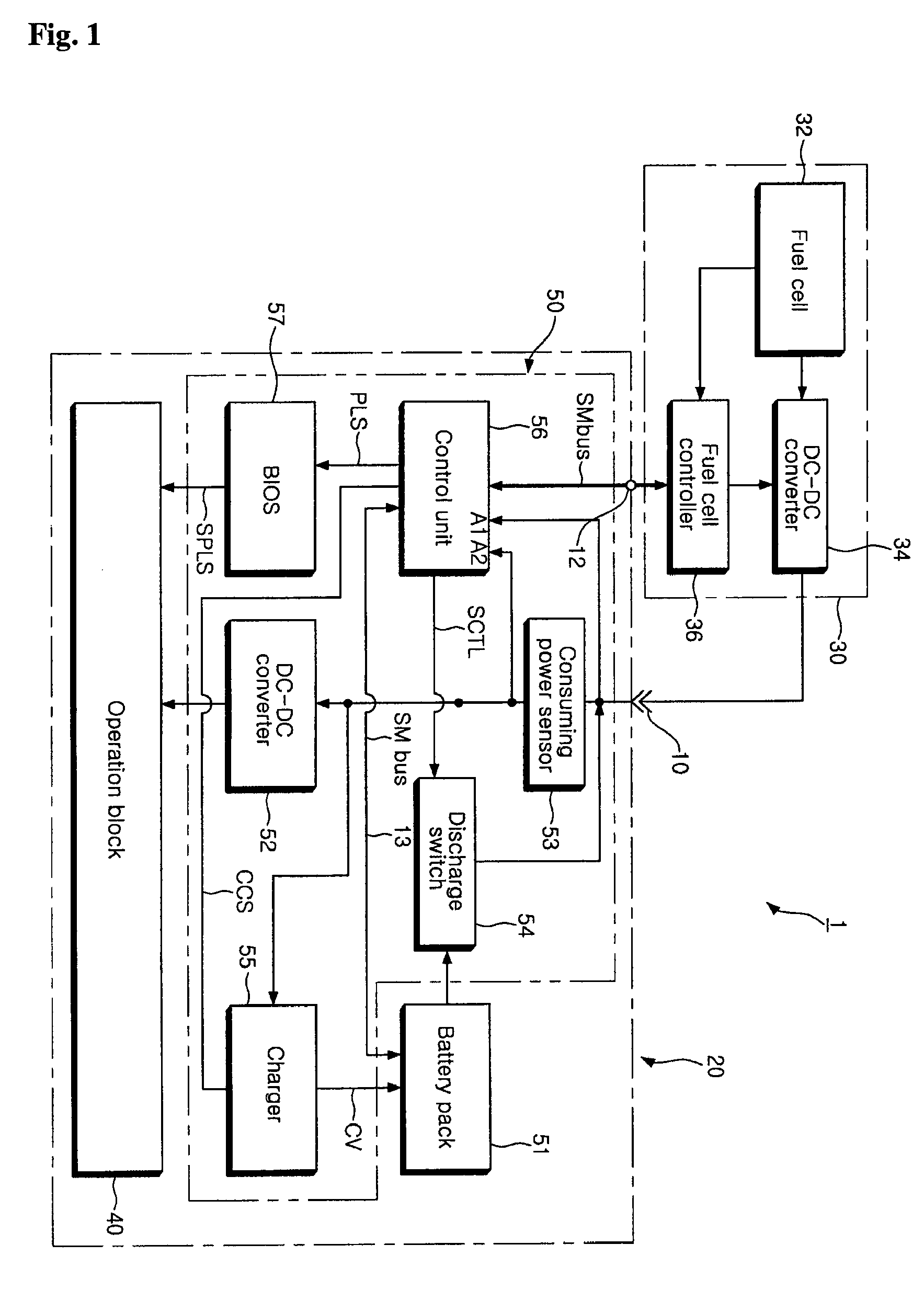

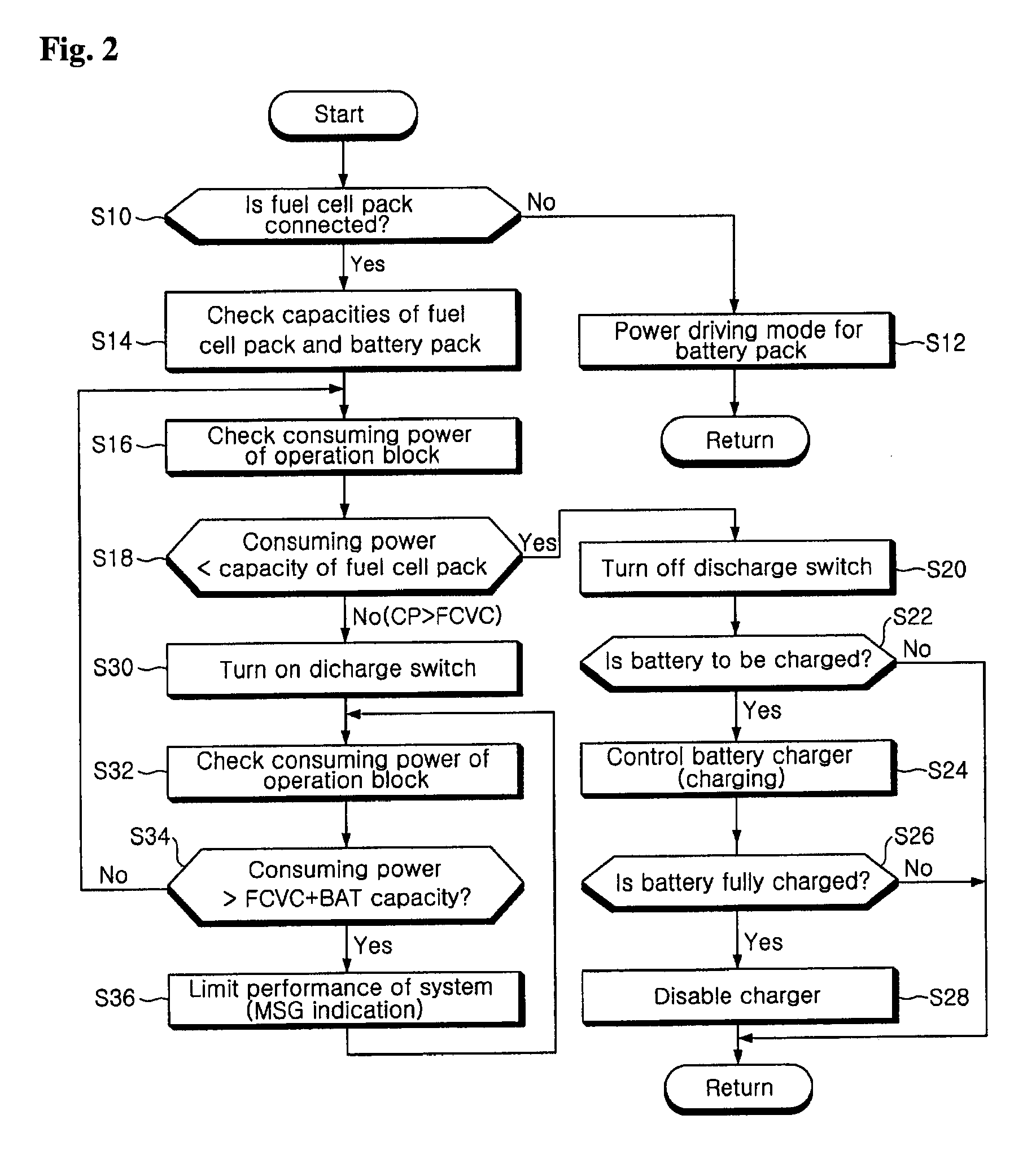

Power management and control in electronic equipment

InactiveUS20070224461A1Efficient supplyBatteries circuit arrangementsDigital data processing detailsFuel cellsElectric power

To manage power of a fuel cell and a battery for an electronic device, an amount of power consumed by an operation module in the electronic device may be sensed. Generated voltage capacity of the fuel cell and remaining capacity of the battery may be acquired. The battery may be charged / discharged based on the sensed amount of consumed power and the generated voltage capacity of the fuel cell. A performance limit signal may be provided to the operation module if the sensed amount of consumed power exceeds a sum of the generated voltage capacity of the fuel cell and the remaining capacity of the battery. The operation module may adjust a frequency of an internal operation clock in response to the performance limit signal.

Owner:LG ELECTRONICS INC

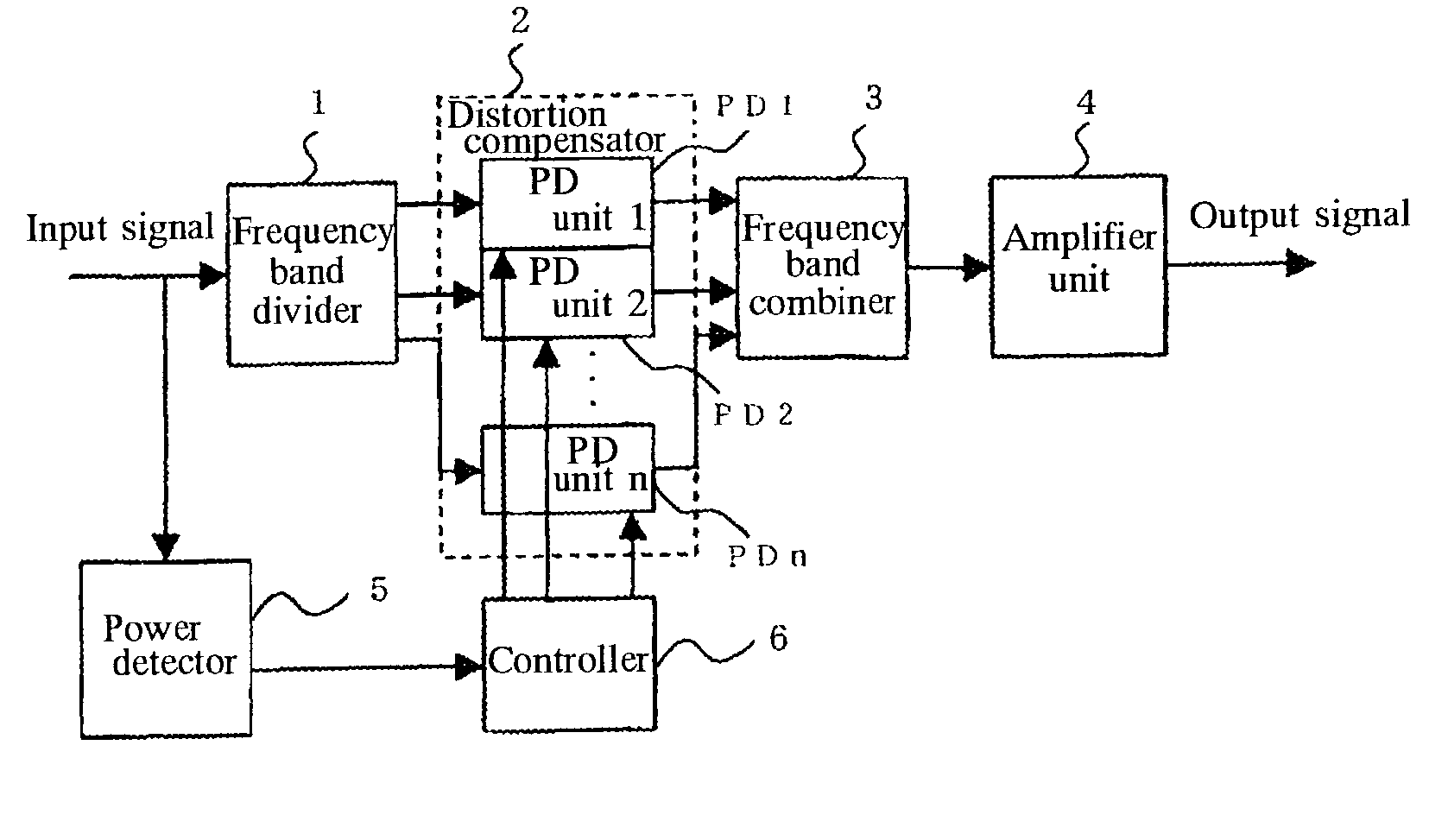

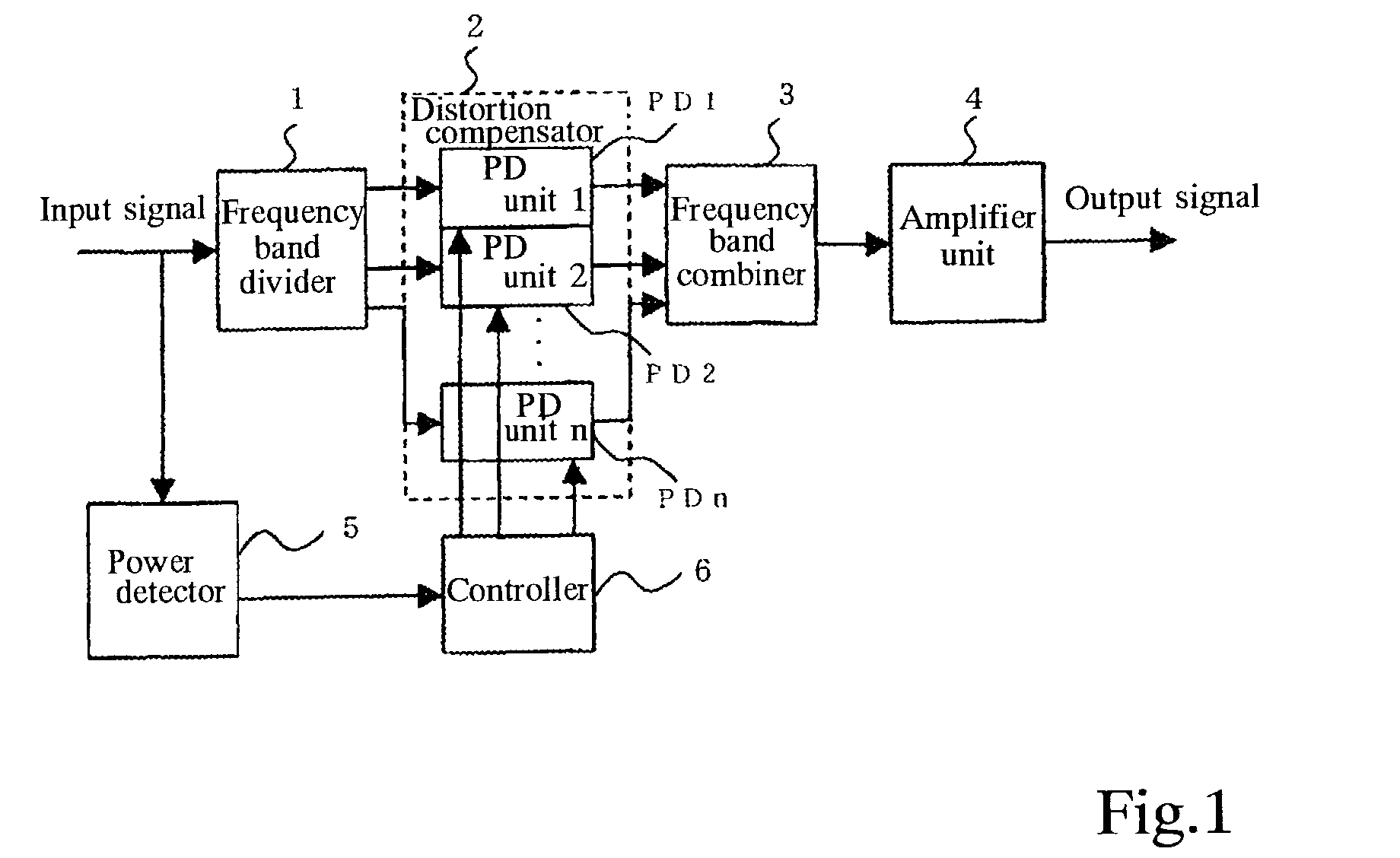

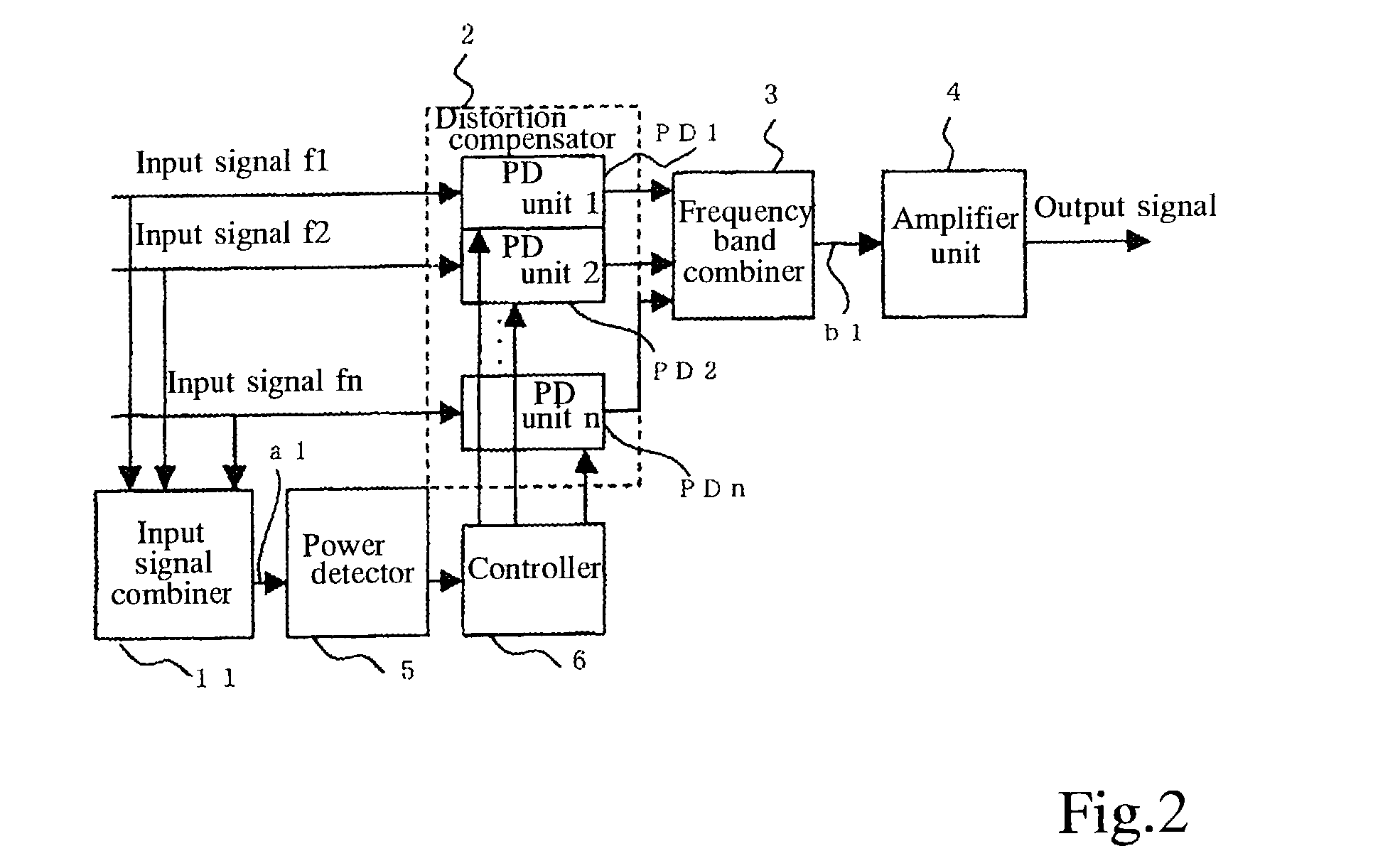

Distortion compensator

InactiveUS7142615B2Reduce the impactCompensation DistortionAmplifier modifications to reduce non-linear distortionModulated-carrier systemsAudio power amplifierMultiple frequency

A distortion compensator for compensating for distortion produced in an amplifier that amplifies a signal includes a signal level detector for detecting a level of a signal to be amplified and a distortion compensator for conducting distortion compensation based on the detection result separately for each frequency band signal of multiple frequency band signals contained in the signal to be amplified. The distortion compensator improves distortion compensation performance by reducing the effect of frequency characteristics that restrict the distortion compensation performance limit.

Owner:KOKUSA ELECTRIC CO LTD

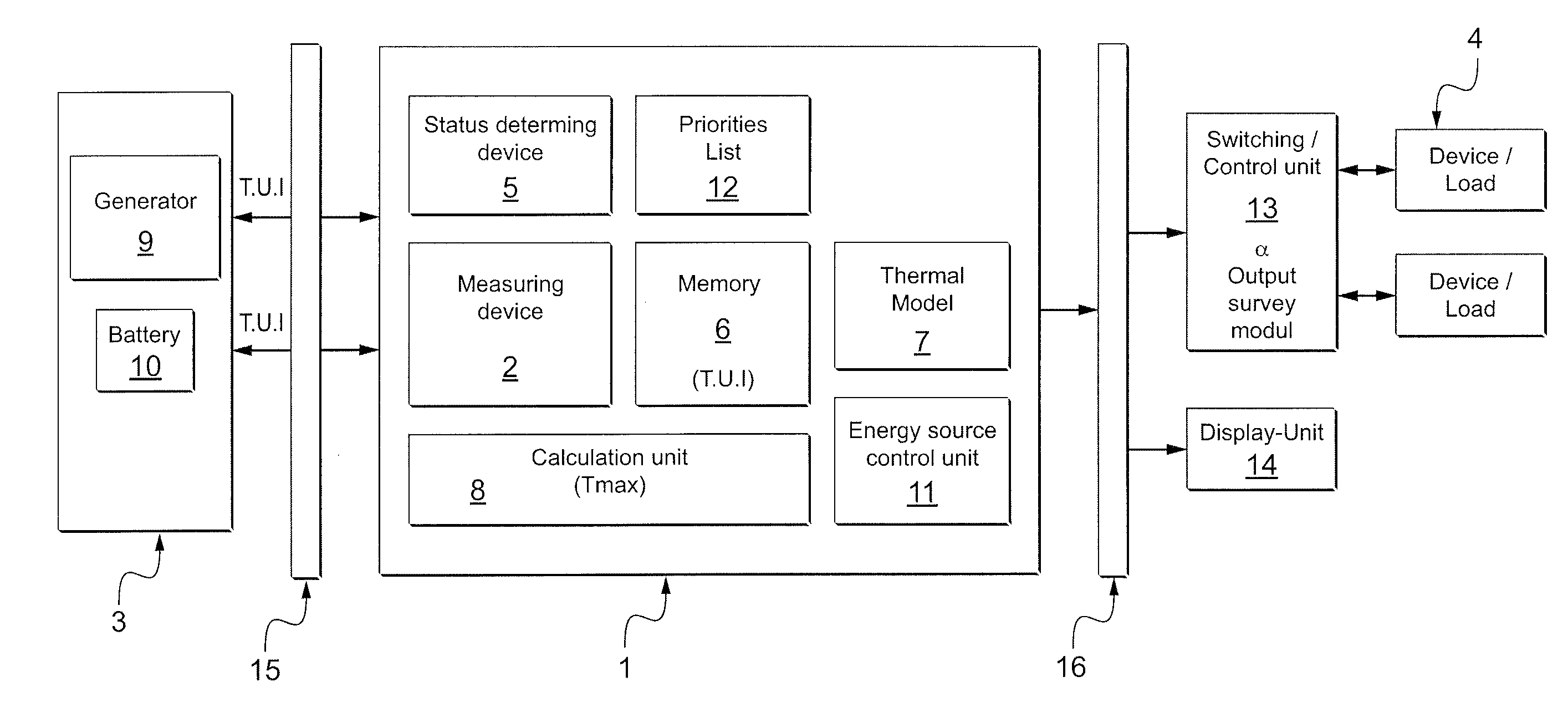

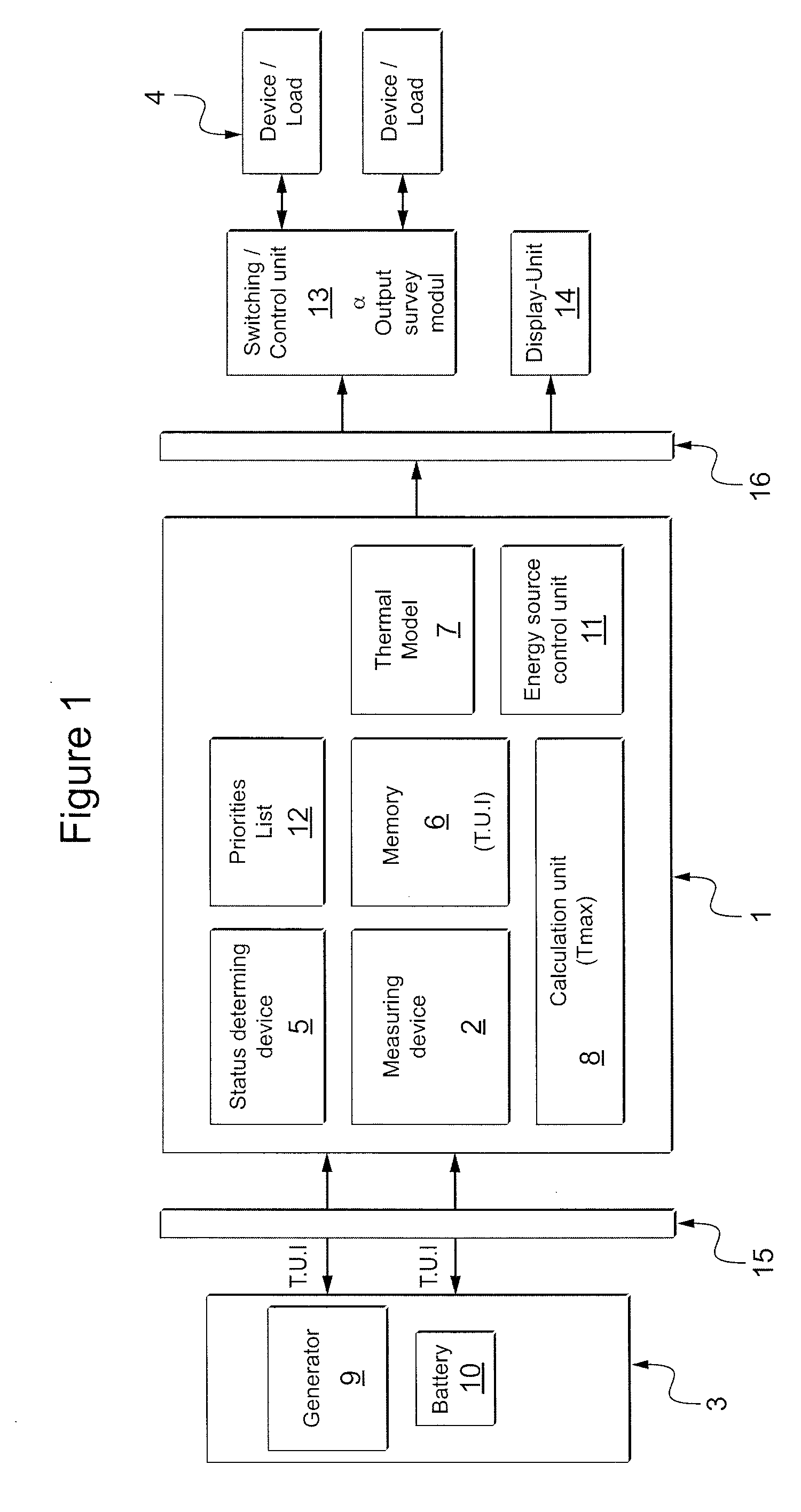

Method and system for an optimized utilization of energy resources of an electrical system

ActiveUS20110190963A1Raise priorityReduce complexitySafety arrangmentsElectric power distributionEngineeringThermal model

A method for optimized utilization of available energy resources / sources (3) of an electrical system such as for a vehicle generator system. The steps include: determining performance parameters LIst (e.g. current I, voltage U, temperature T, power PD (Pverlust), PE (Pwirk), efficiency, etc.) of a preferred energy resource (3); entering performance parameters LIst (current I, voltage U, temperature T, altitude of the vehicle, etc.) of the energy resource (3) into a thermal model (7); comparing a performance parameter LIst of the energy resource (3) with a specified performance limit parameter LSoll at a specified threshold level; determining a value for an energy reservoir ERest of a preferred energy resource (3); and to calculate a remaining time TMax depending on the energy reservoir ERest of a preferred energy resource (3) and using the one or more identified performance parameters LIst to maintain an operational state of the vehicle.

Owner:AIRBUS HELICOPTERS DEUT GMBH

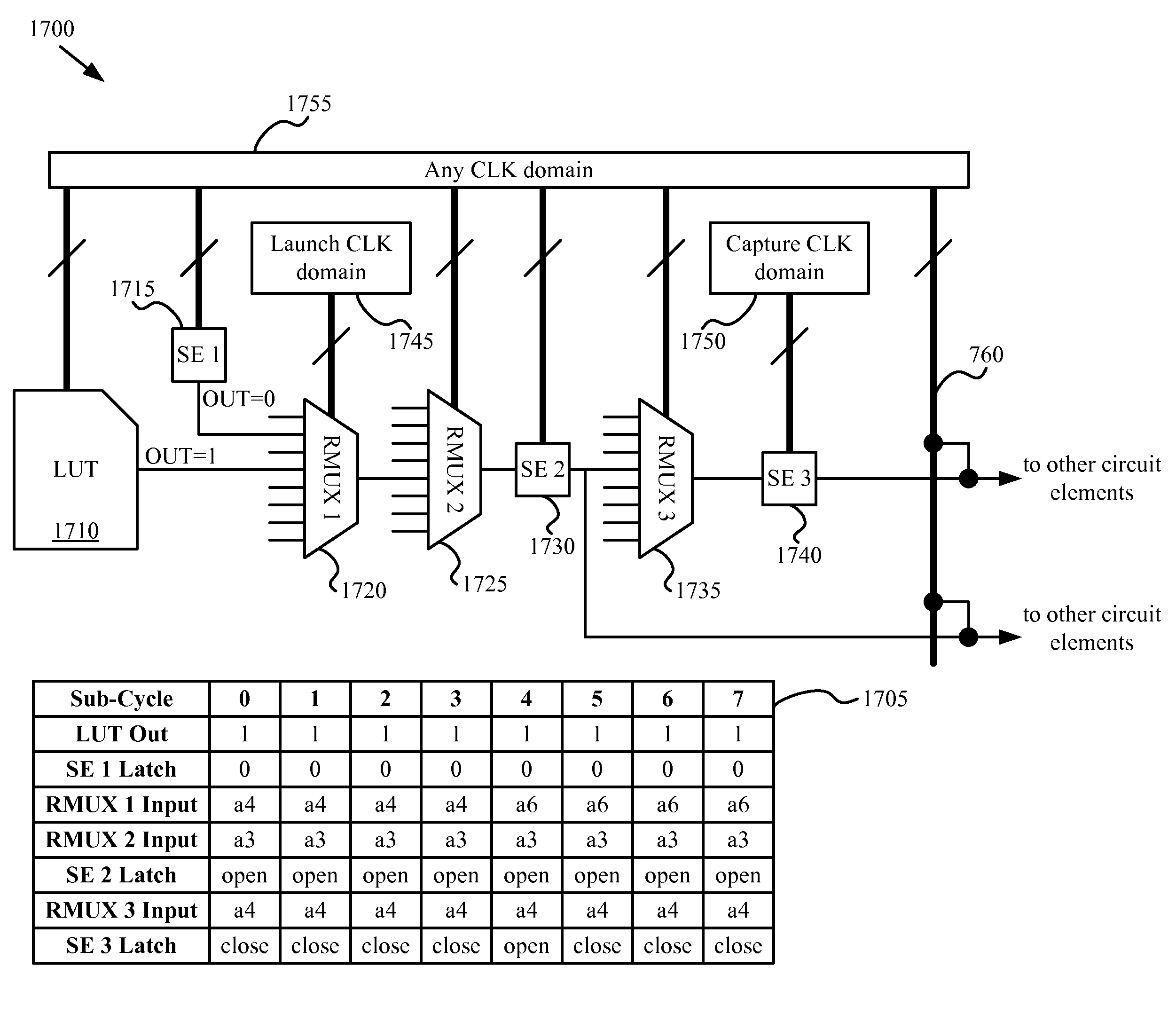

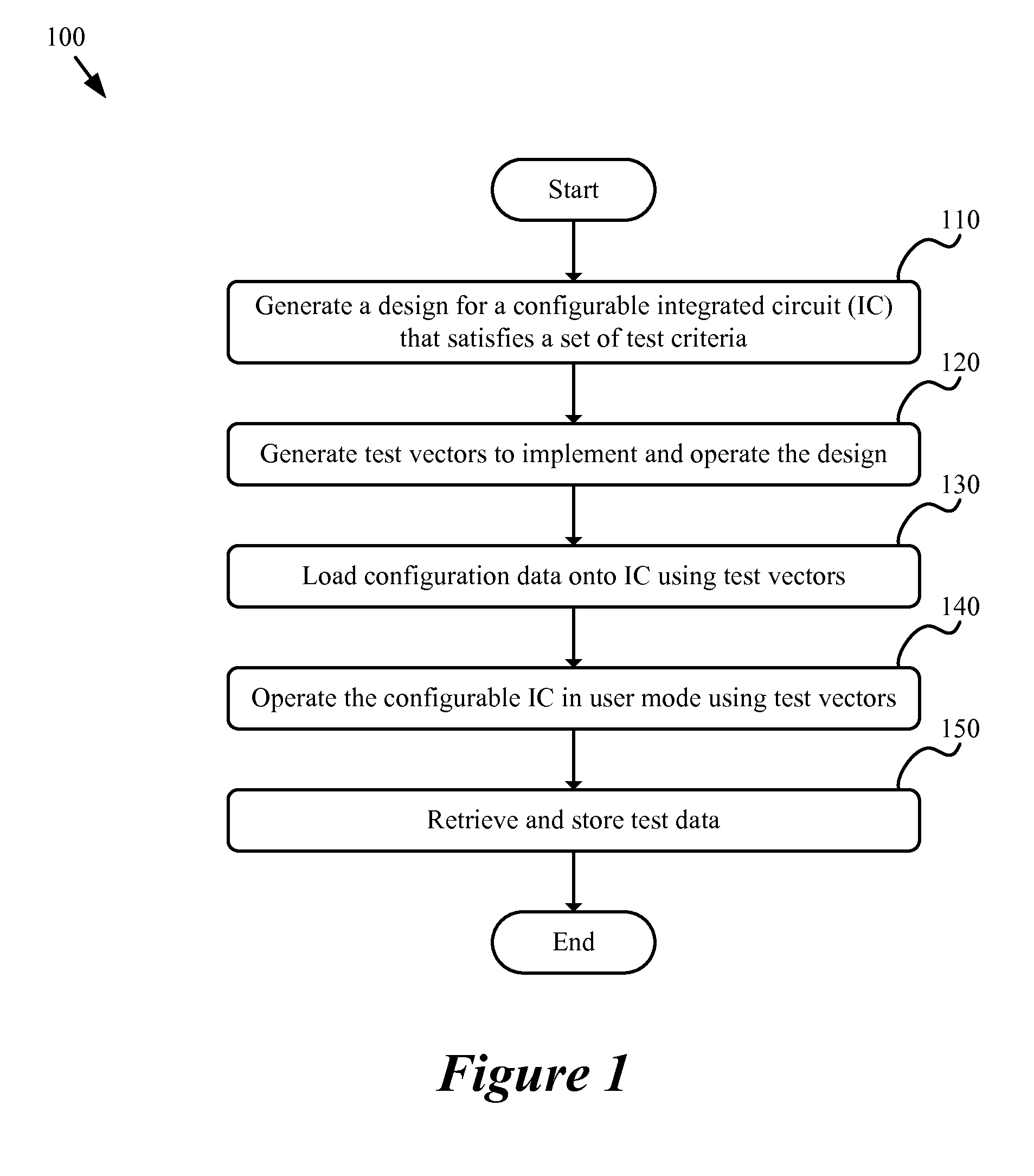

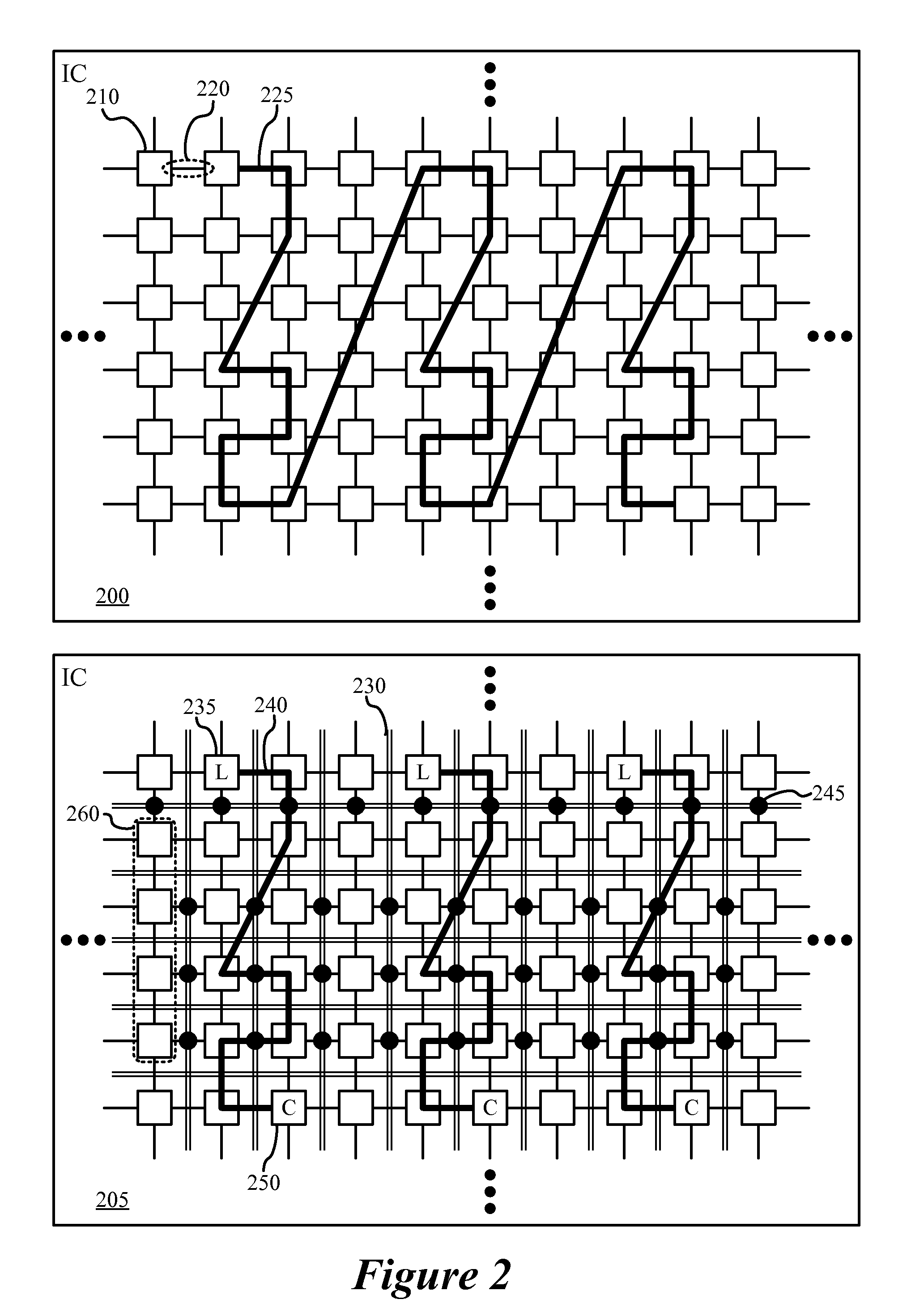

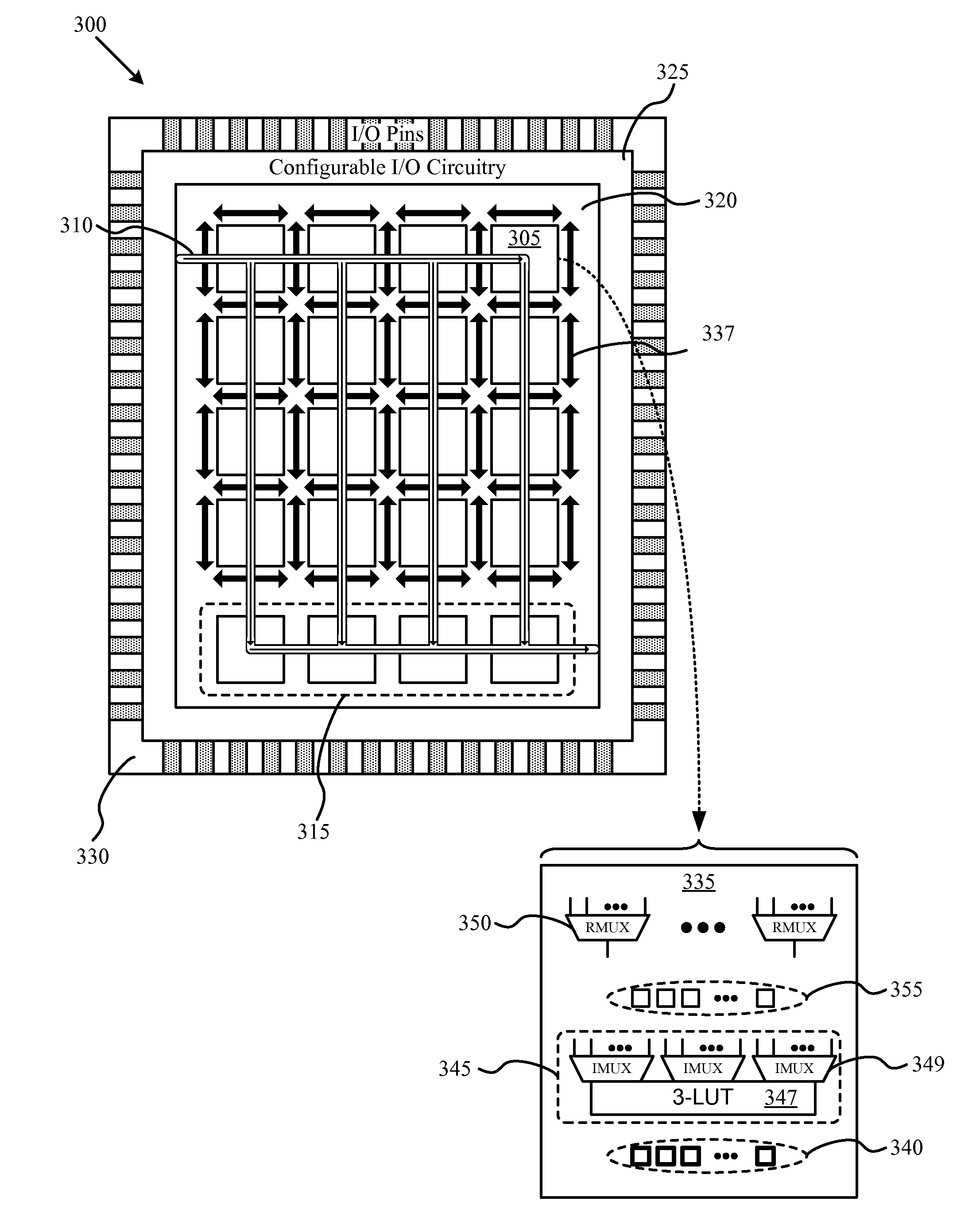

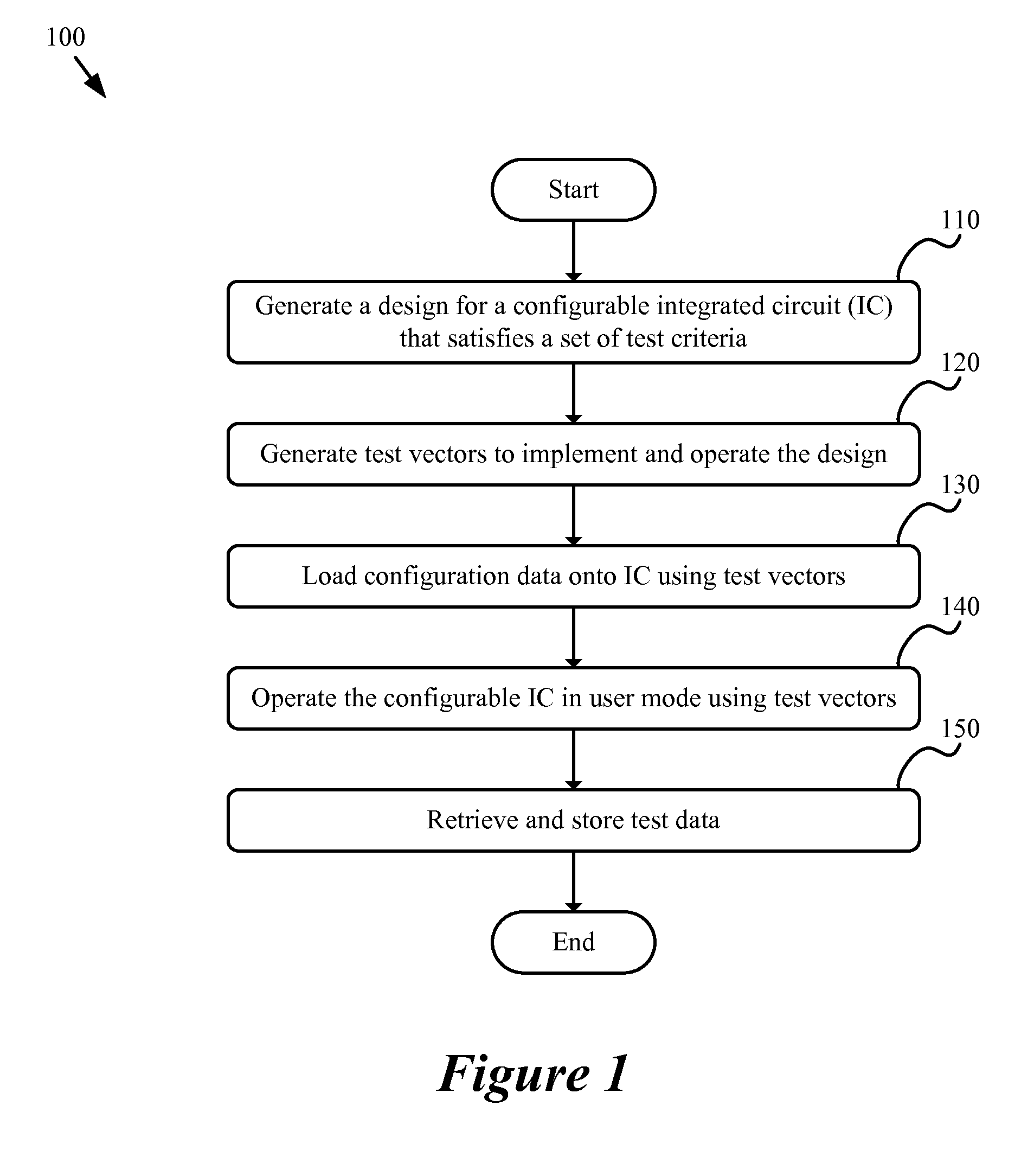

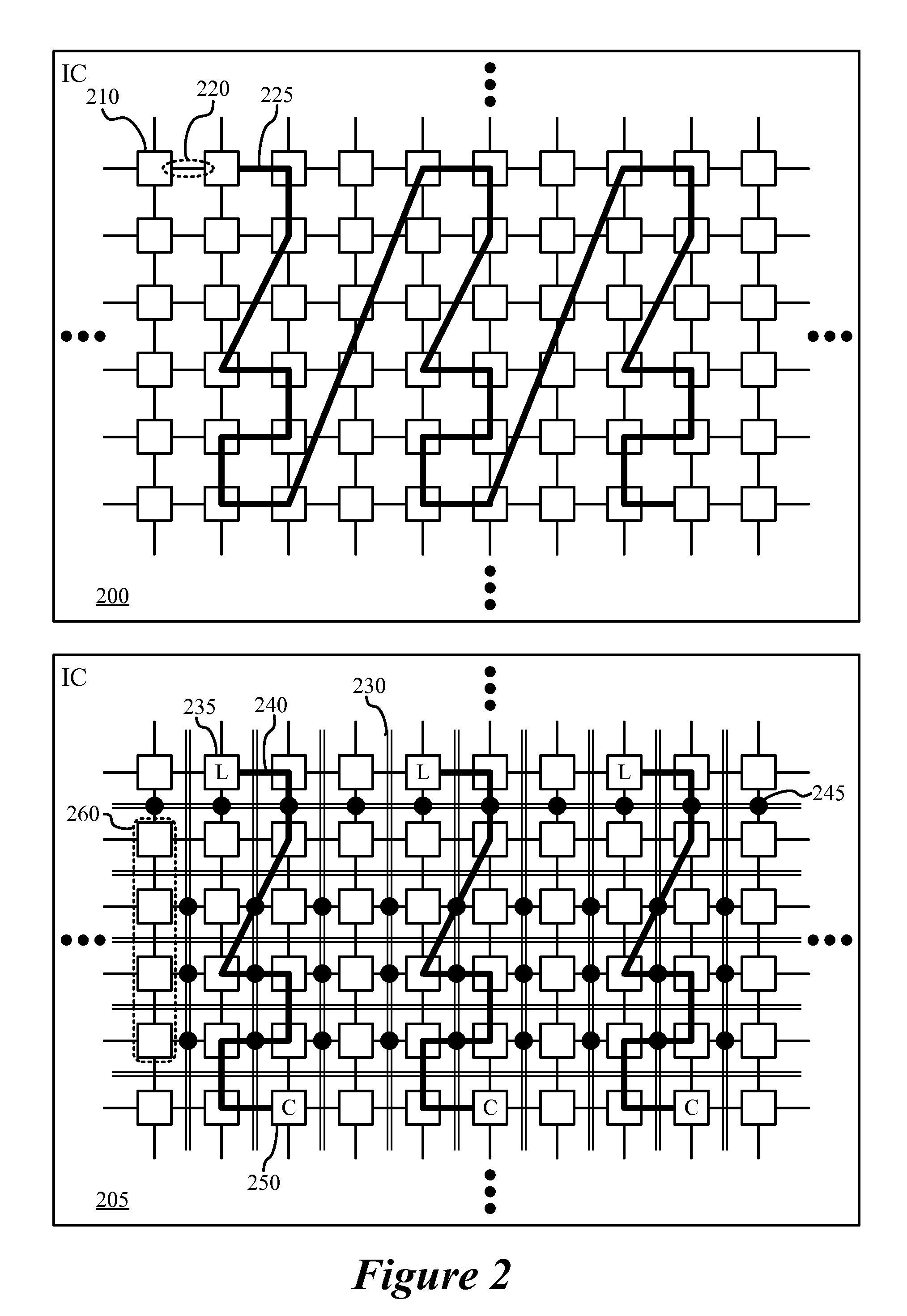

Micro-granular delay testing of configurable ICs

ActiveUS8072234B2Delay in testingEnsure correct executionReliability increasing modificationsFail-safe circuitsComputer hardwarePerformance limit

A method for testing a set of circuitry in an integrated circuit (IC) is described. The IC includes multiple configurable circuits for configurably performing multiple operations. The method configures the IC to operate in a user mode with a set of test paths that satisfies a set of evaluation criteria. Each test path includes a controllable storage element for controllably storing a signal that the storage element receives. The method operates the IC in user mode. The method reads the values stored in the storage elements to determine whether the set of circuitry is operating within specified performance limits.

Owner:ALTERA CORP

Micro-Granular Delay Testing of Configurable ICs

ActiveUS20110068820A1Ensure correct executionReduce minimum testable durationReliability increasing modificationsFail-safe circuitsComputer hardwarePerformance limit

A method for testing a set of circuitry in an integrated circuit (IC) is described. The IC includes multiple configurable circuits for configurably performing multiple operations. The method configures the IC to operate in a user mode with a set of test paths that satisfies a set of evaluation criteria. Each test path includes a controllable storage element for controllably storing a signal that the storage element receives. The method operates the IC in user mode. The method reads the values stored in the storage elements to determine whether the set of circuitry is operating within specified performance limits.

Owner:ALTERA CORP

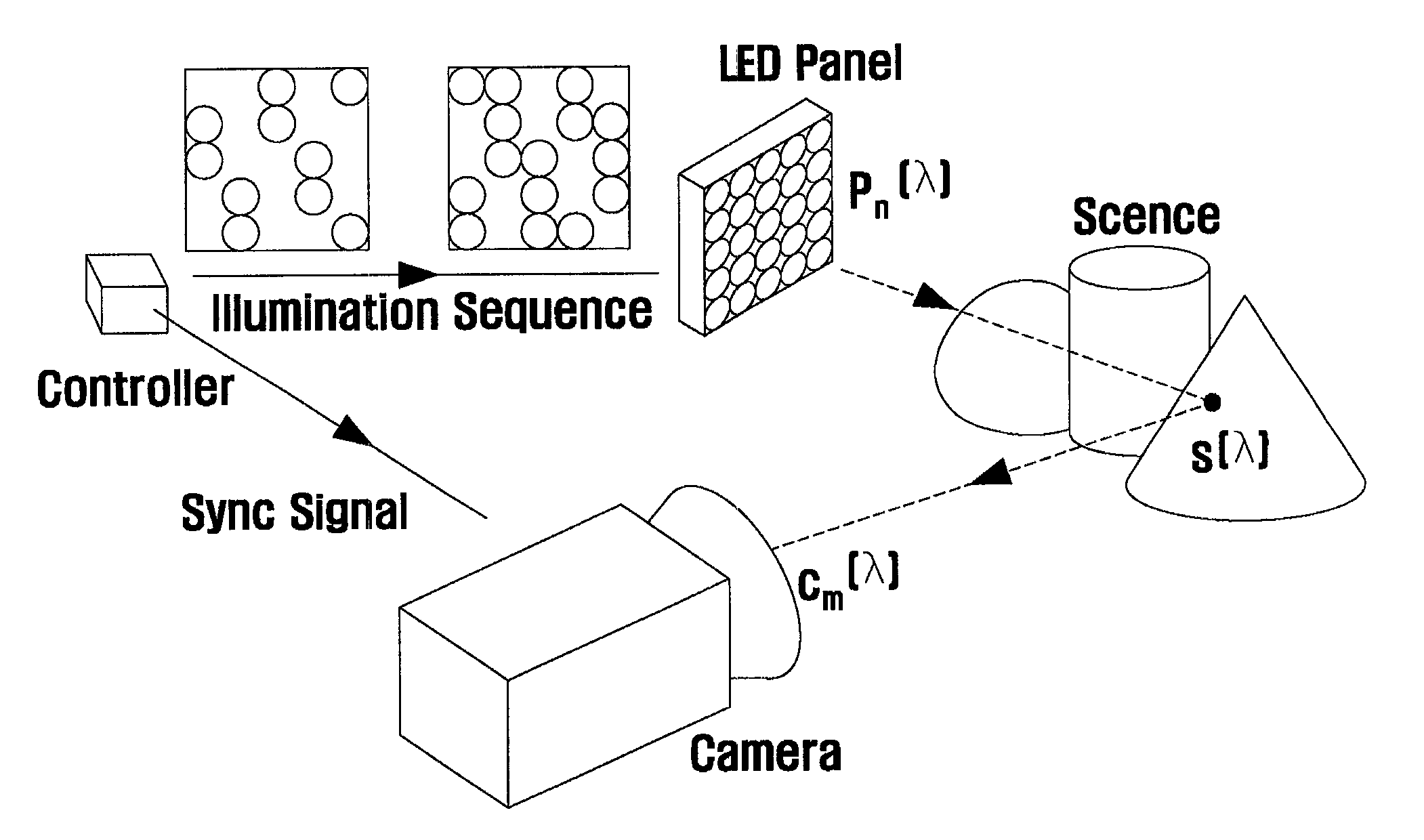

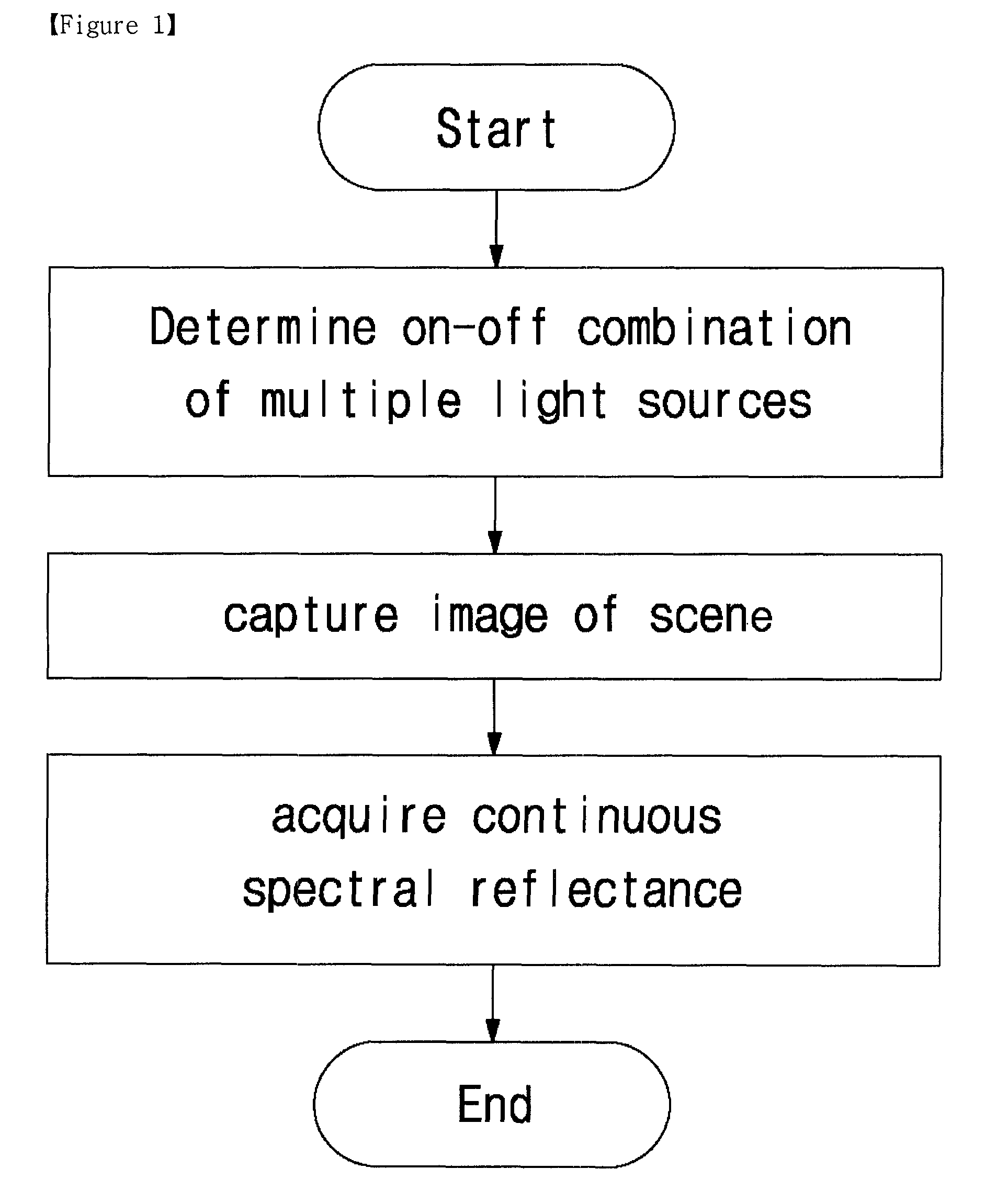

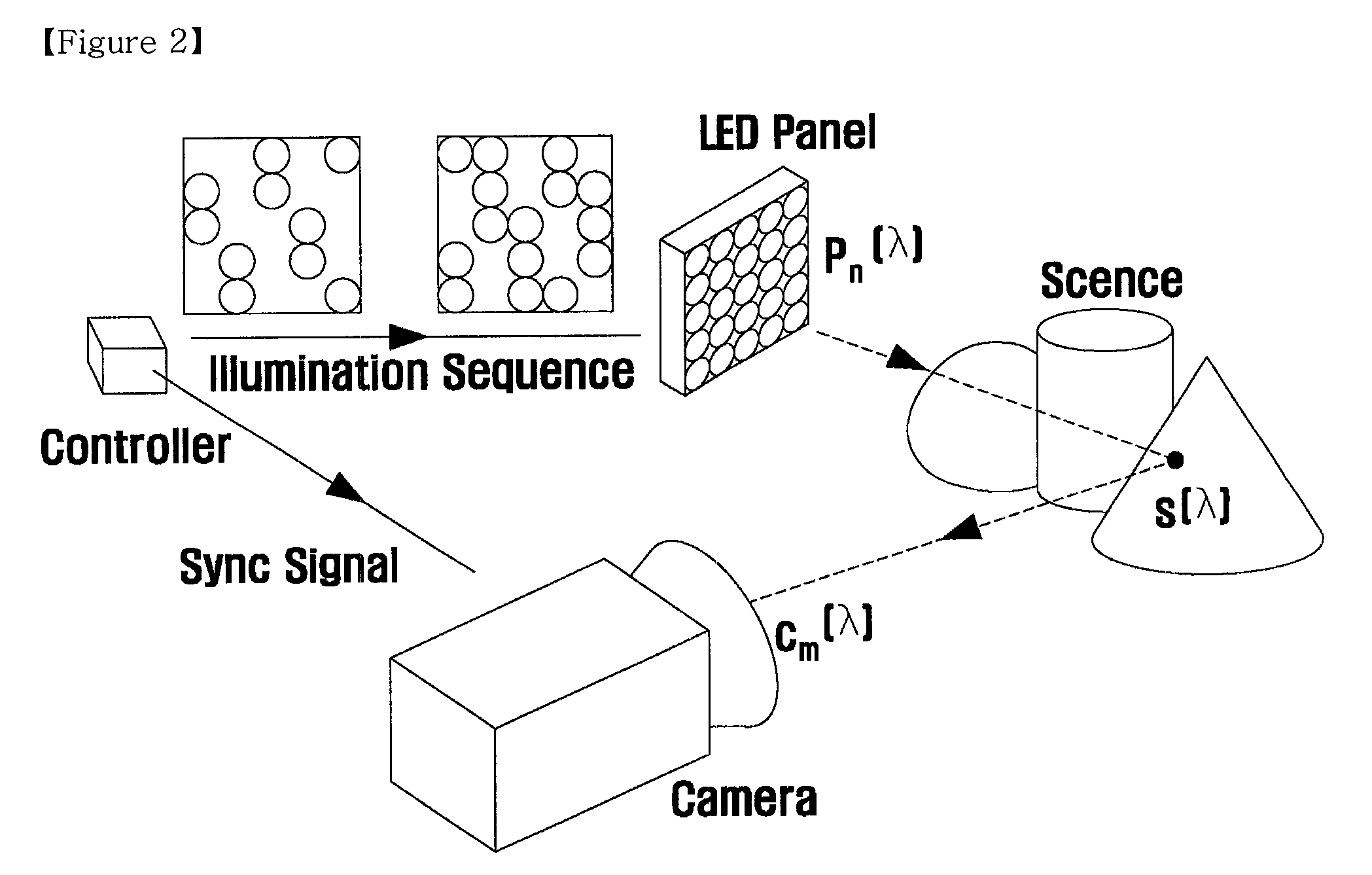

Method of multispectral imaging and an apparatus thereof

InactiveUS8284279B2Minimize the numberControl performanceTelevision system detailsImage analysisMicrocontrollerControl signal

A multispectral imaging method and system is provided. A multispectral imaging method of the present invention includes determining an on-off combination of a plurality of light sources illuminating a scene; illuminating the scene with the light sources according to the on-off combination selected on the basis of a first control signal generated by a microcontroller; capturing an image of the scene by operating a camera on the basis of a second control signal synchronized with the first control signal; determining a plurality of spectral basis functions and weights of the spectral basis functions; and acquiring a continuous spectral reflectance by summing values obtained by multiplying the spectral basis functions and respective weights. The multispectral imaging method of the present invention is practical and efficient in that a continuous spectral reflectance image can be acquired with a minimized number of measurements required for obtaining spectral reflectance. Accordingly, the multispectral imaging method of the present invention can be applied to various fields, such as image reproduction and medical imaging, while overcoming performance limits of the conventional RGB imaging techniques.

Owner:PARK JONG IL +3

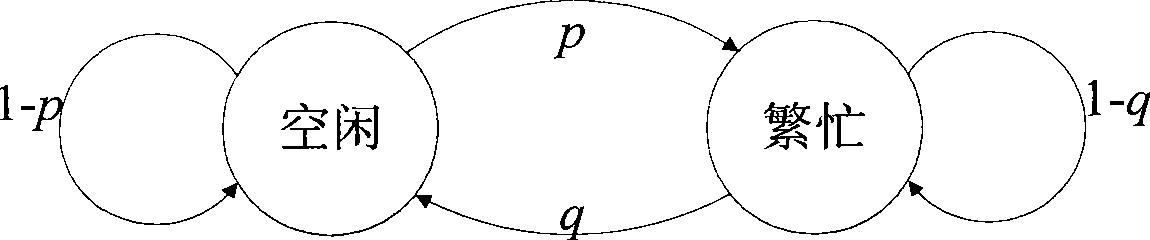

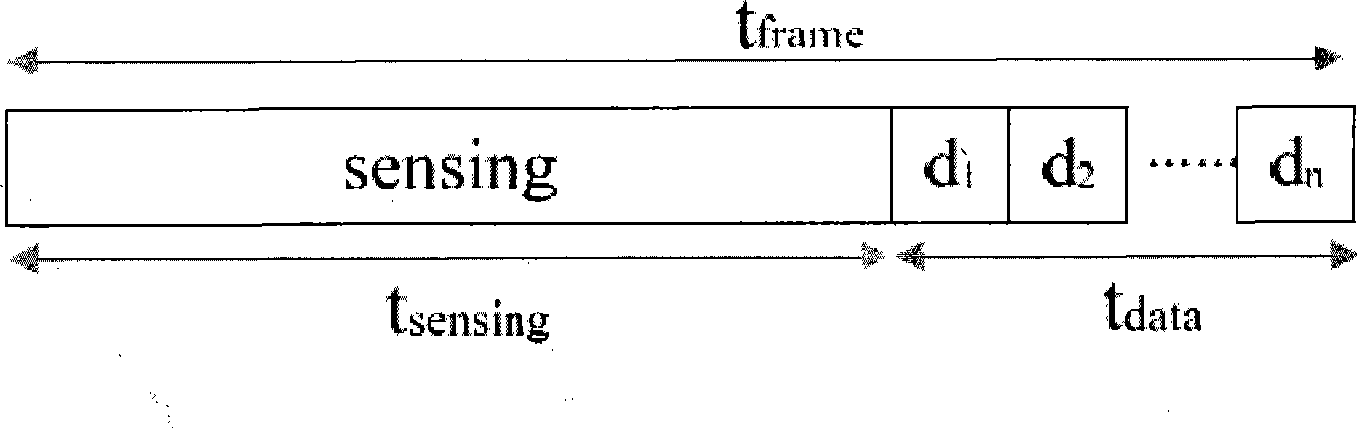

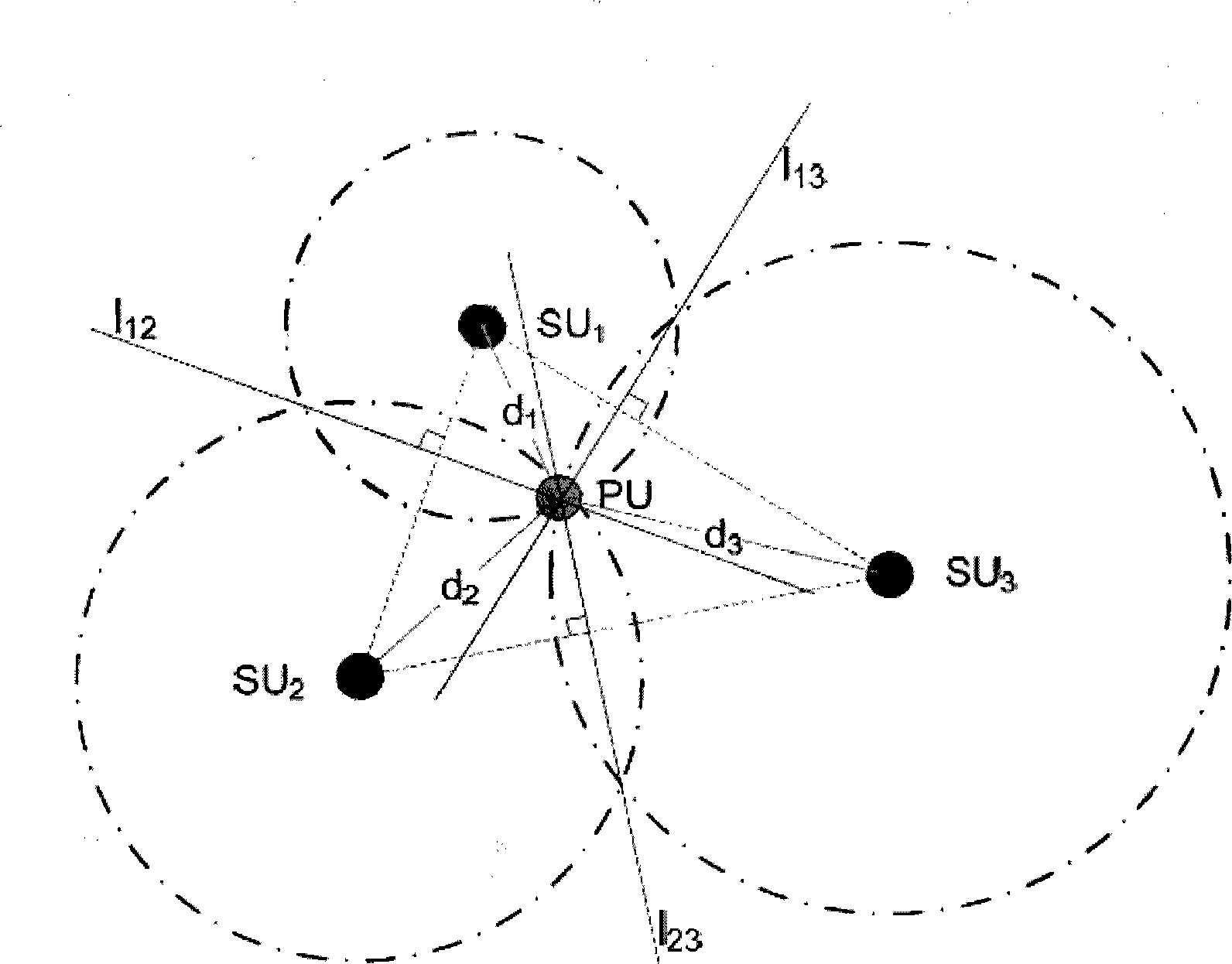

Method for positioning main user in cognition radio network

InactiveCN101419276AImprove detection resultsImprove positioning errorReceivers monitoringPosition fixationRadio networksCognition

The invention provides a method for positioning PU of cognitive radio networks. The method comprises the following steps: acquiring a plurality of detecting results on the PU based on MAC communication protocol through an idle channel capable of perceiving at least three SU of the PU within certain time slot; and based on the plurality of the detecting results in the last step, calculating and determining the position of the PU by an iterative algorithm of weighting least squares. The method has the advantage that the method acquires location algorithm-based positioning precision by utilizing a little information without basing on the location algorithm, and further improves the performance of positioning algorithm by introducing the iterative algorithm of weighting least squares. The deduction of Cramer-Rao theory performance limit and a plurality of imitations prove that the positioning error of the method is extremely similar to Cramer-Rao limit theory performance.

Owner:TSINGHUA UNIV

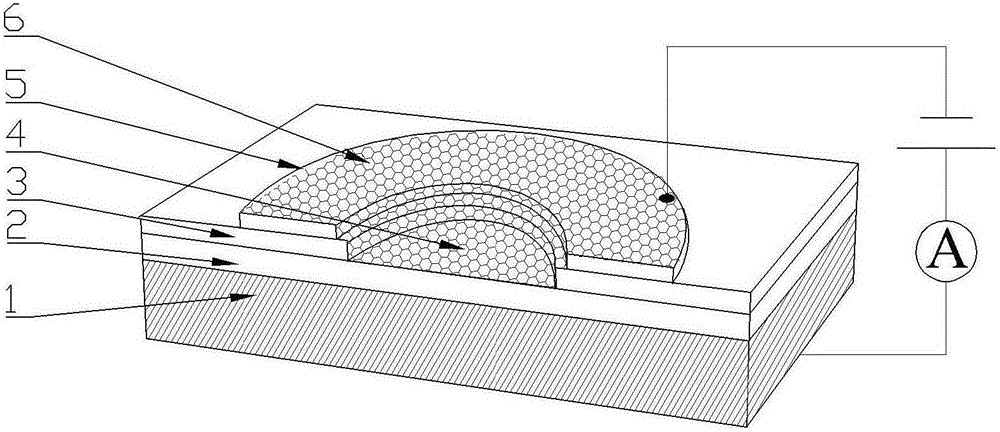

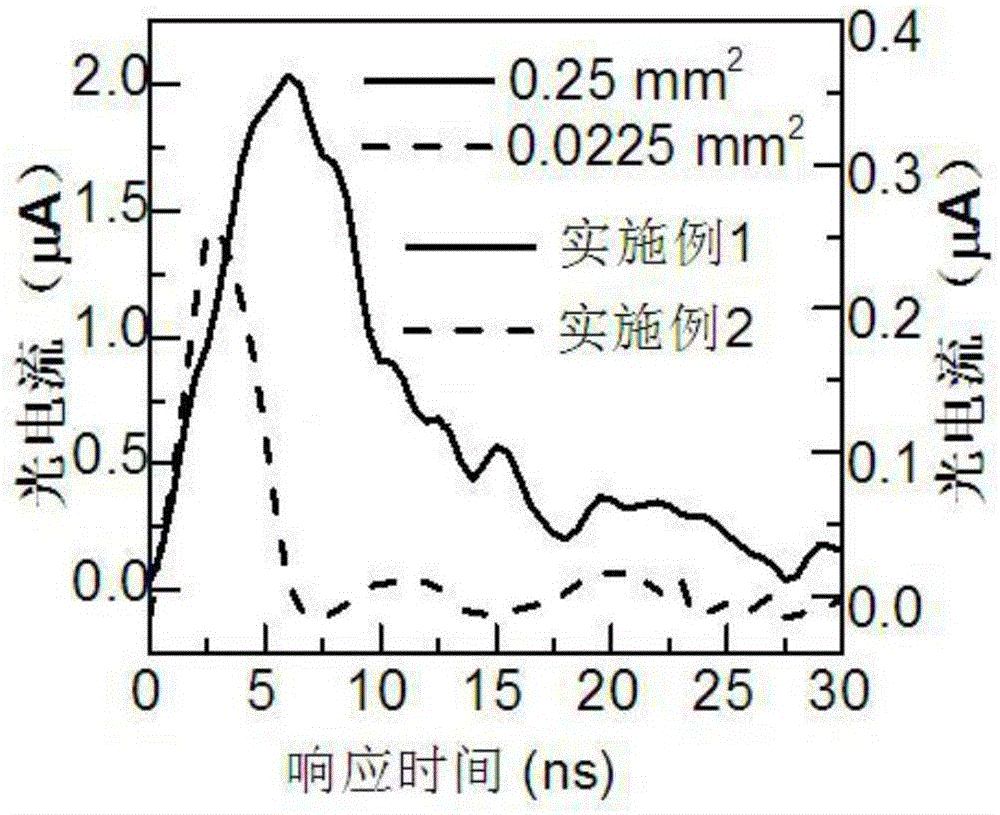

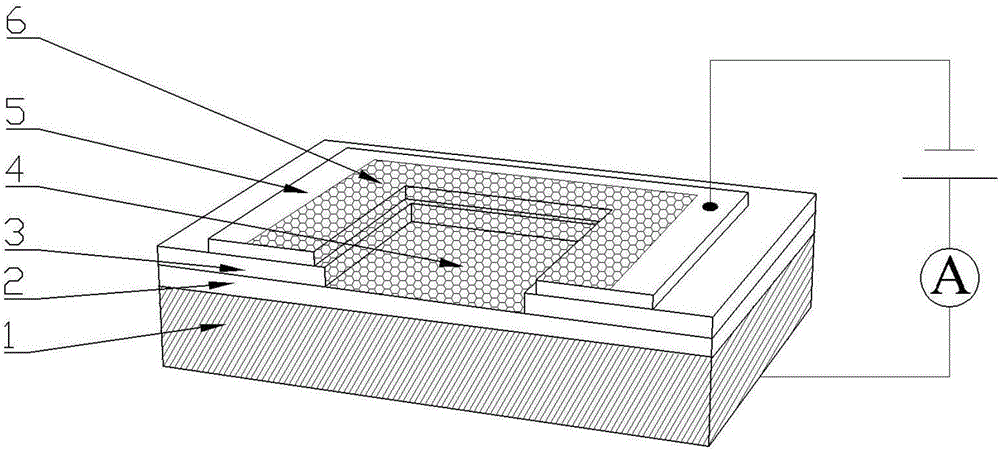

Silicon-based ultraviolet photoelectric detector based on graphene and fabrication method of silicon-based ultraviolet photoelectric detector

InactiveCN106169516AImprove UV ResponsivityImprove response speedFinal product manufactureSemiconductor devicesUltraviolet lightsLight response

The invention discloses a silicon-based ultraviolet photoelectric detector based on graphene. The silicon-based ultraviolet photoelectric detector comprises an epitaxial silicon substrate, an isolation layer, a silicon window, a top electrode and a graphene thin film which are sequentially laminated, and the epitaxial silicon substrate is provided with a heavily-doped layer and a light-doped layer. The fabrication method comprises the following steps of sequentially planting the isolation layer and the top electrode on the epitaxial silicon substrate after the epitaxial silicon substrate is fabricated, etching the silicon window, and moving the graphene thin film in the silicon window and the top electrode for complete fabrication. An ultra-shallow junction design formed by a graphene / silicon structure is used for improving ultraviolet wave band response; the surface recombination is reduced by epitaxial growth of a thin silicon light-doped structure on an upper surface of the heavily-doped bottom layer, the ultraviolet response is effectively improved, the visible light response is suppressed, and the spectral selectivity detection is achieved; and with the adoption of the high-conductivity graphene thin film, extra ultraviolet light is absorbed, and the ultraviolet sensitivity and the response speed can be improved and are approximate to or even exceed a theoretical performance limit of a traditional silicon-based ultraviolet detector.

Owner:杭州紫元科技有限公司

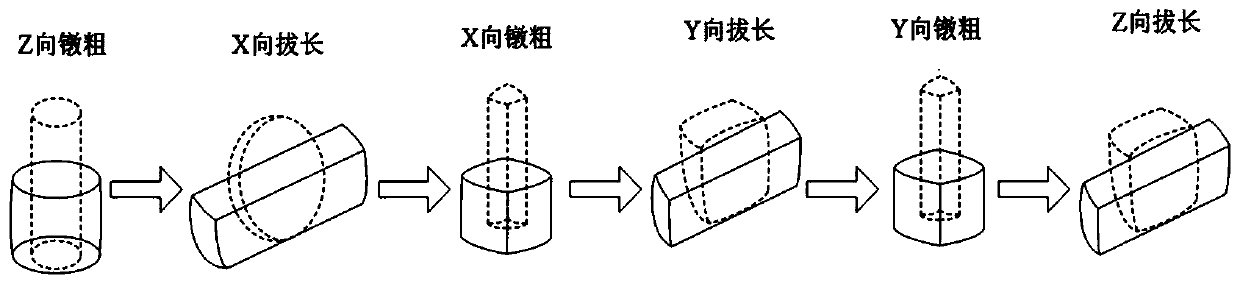

Three-directional near-isotropy high-performance aluminum alloy cylindrical forge piece manufacturing process

InactiveCN109759783AThree-way performance is nearly identicalImprove solubilityQuenchingHeat treated

The invention provides a three-directional near-isotropy high-performance aluminum alloy cylindrical forge piece manufacturing process. The manufacturing process specifically comprises the following steps of raw material size design, cast ingot quality detection, heating before ingot casting, multi-directional forging, return to a furnace for heating, Z-direction upsetting and punching, return toa furnace for heating, core shaft drawing out, return to a furnace for heating, saddle forging, machining, heating before rolling, ring rolling, solution treatment, aging treatment and quality detection. According to the manufacturing process, an aluminum alloy cylindrical forge piece is subjected to nearly equal deformation in three directions, so that the three-direction performance of a productis nearly isotropic; a thick residual crystalline phase in cast-state structure is fully crushed so as to provide structure preparation for second phase uniform dispersion distribution in the heat treatment process; a second phase in the structure is fully dissolved, the degree of supersaturation is improved, the material potential is excavated to the maximum extent, and the performance limit ofa material is exerted; and the small reduction rate is adopted, the quenching water temperature is increased, the stress in the product manufacturing process is reduced, so that the residual stress ofthe forge piece is controlled within a certain range.

Owner:天津航天长征技术装备有限公司

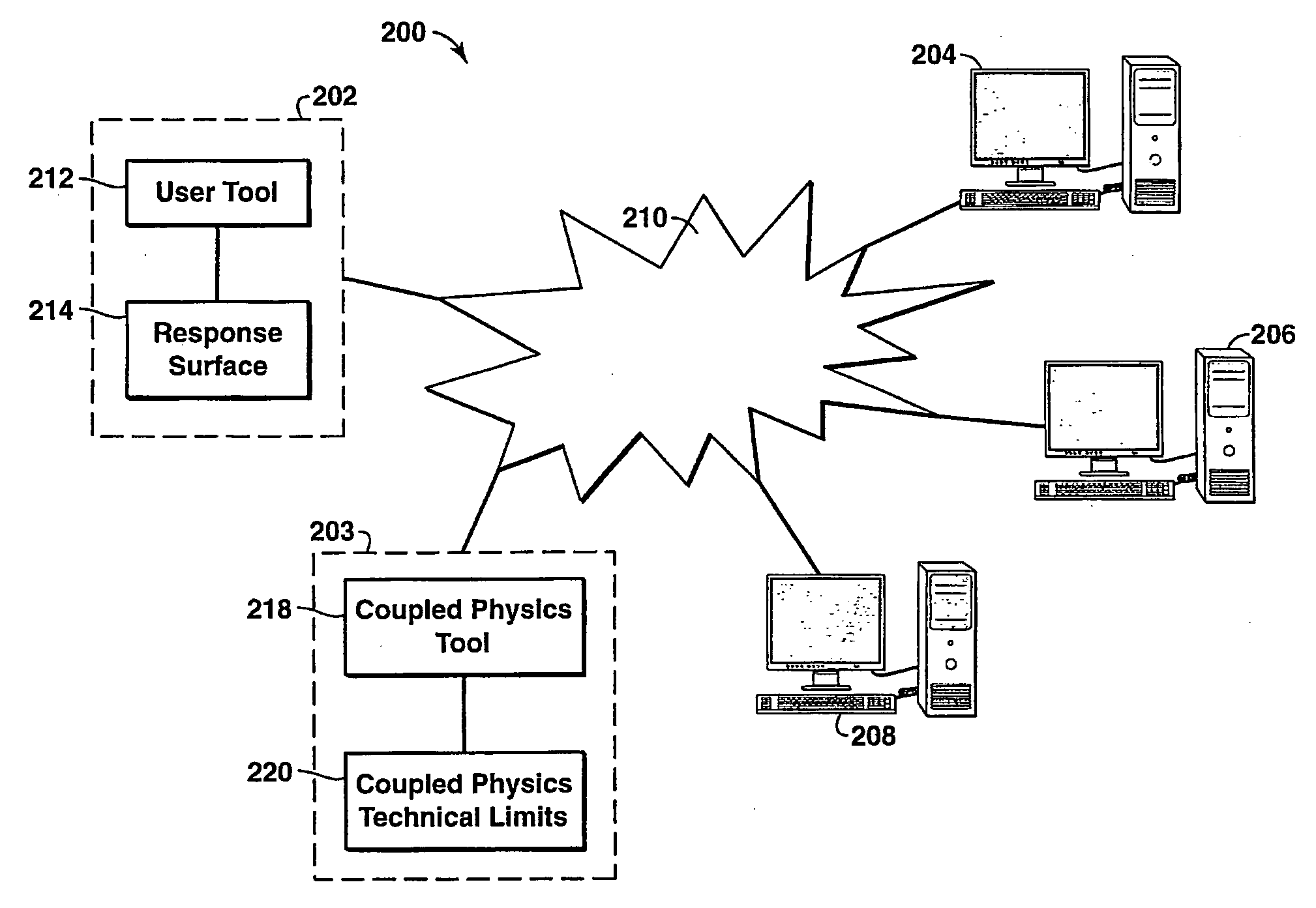

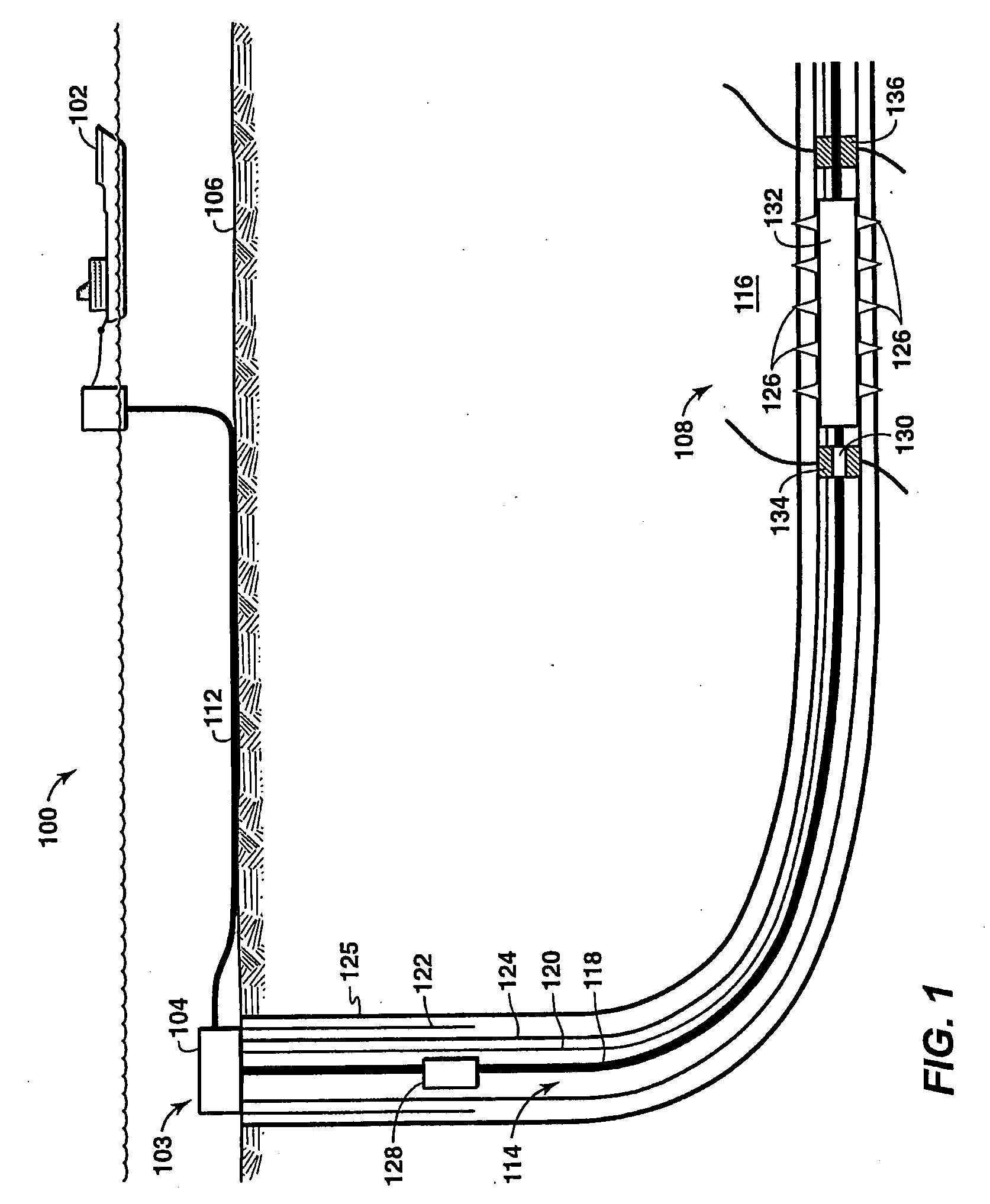

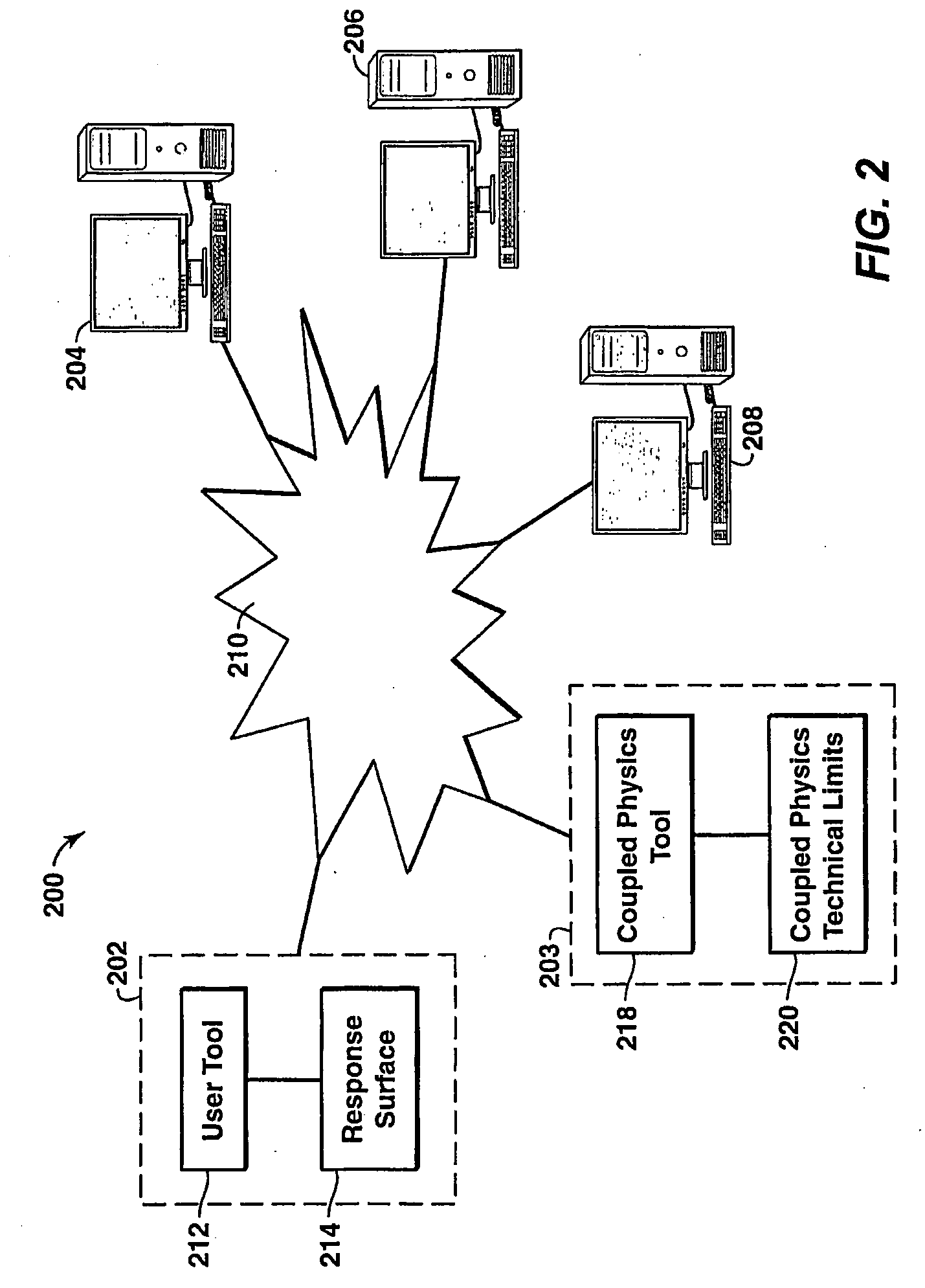

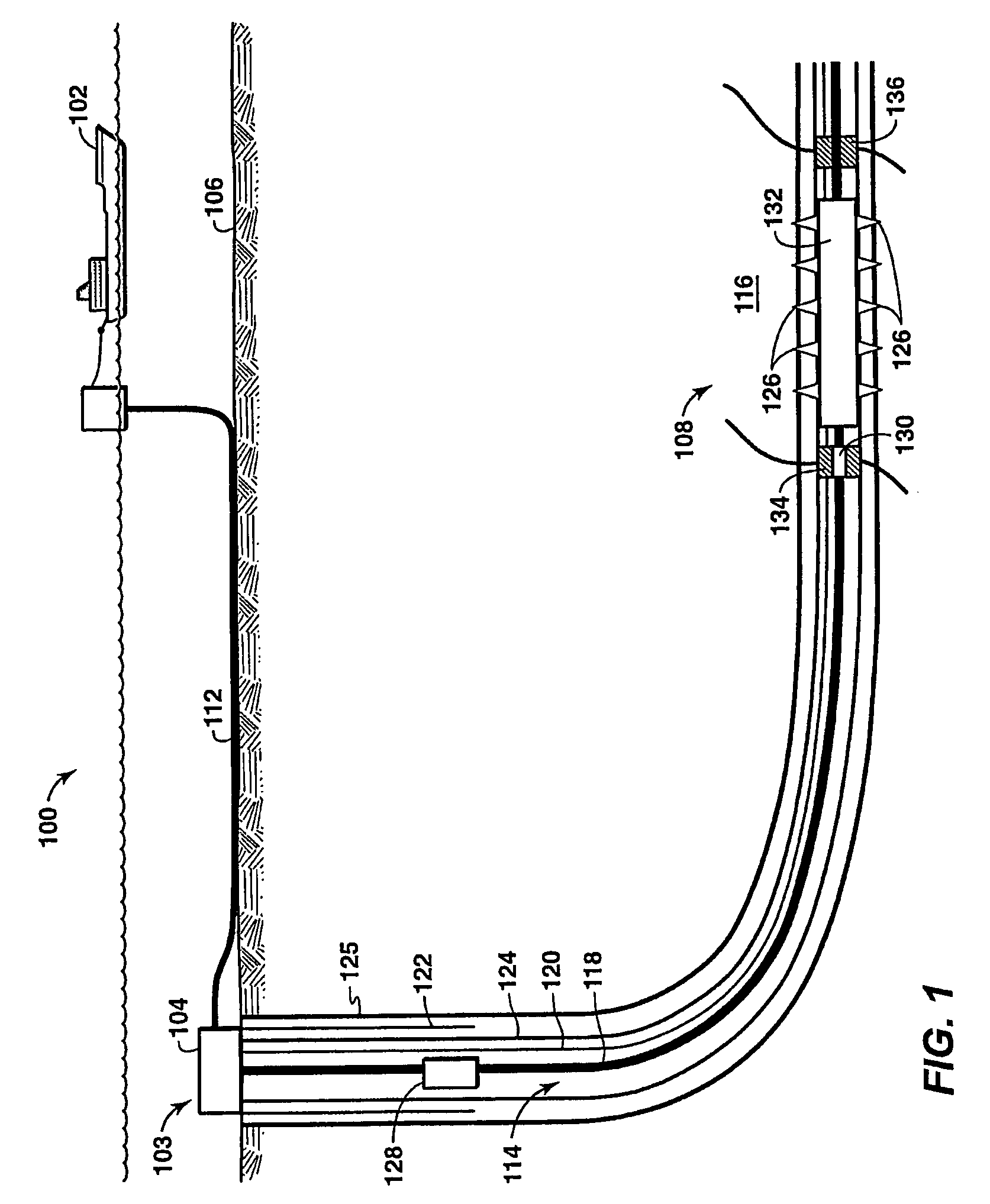

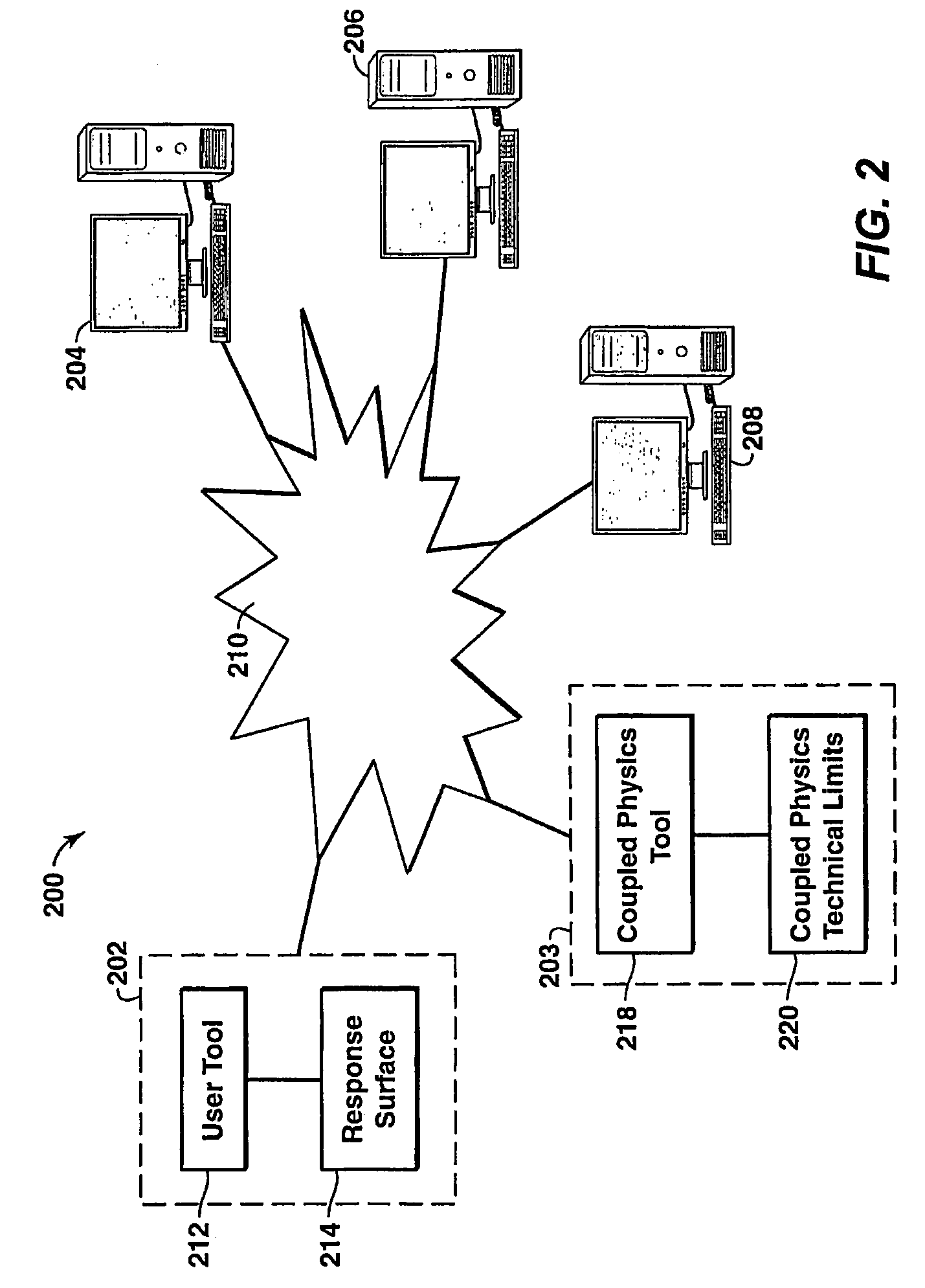

Well Modeling Associated With Extraction of Hydrocarbons From Subsurface Formations

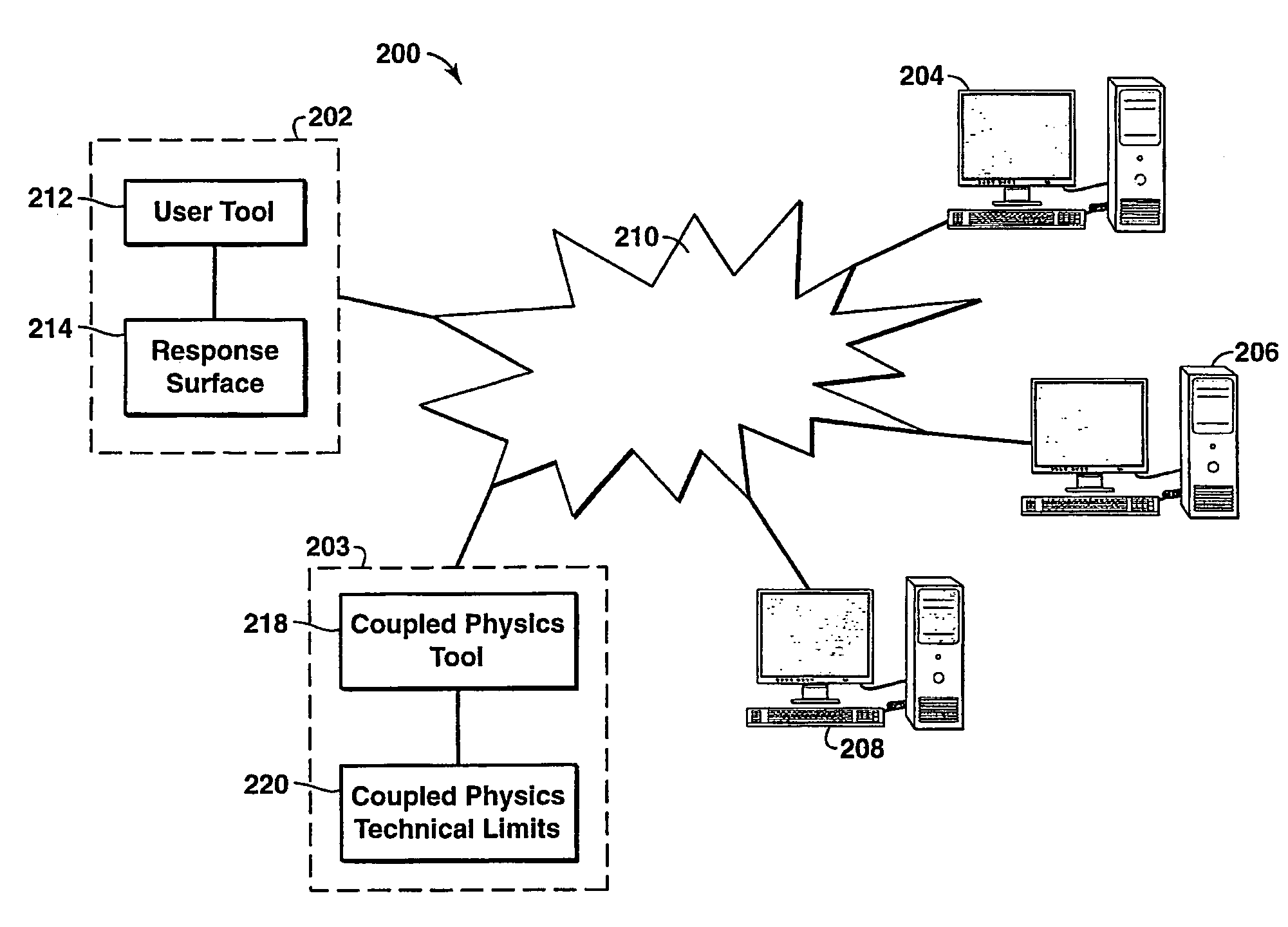

A method and apparatus associated with various phases of a well completion. In one embodiment, a method is described that includes identifying failure modes for a well completion. At least one technical limit associated with each of the failure modes is obtained. Then, an objective function for the well completion is formulated. Then, the objective function is solved to create a well performance limit.

Owner:EXXONMOBIL UPSTREAM RES CO

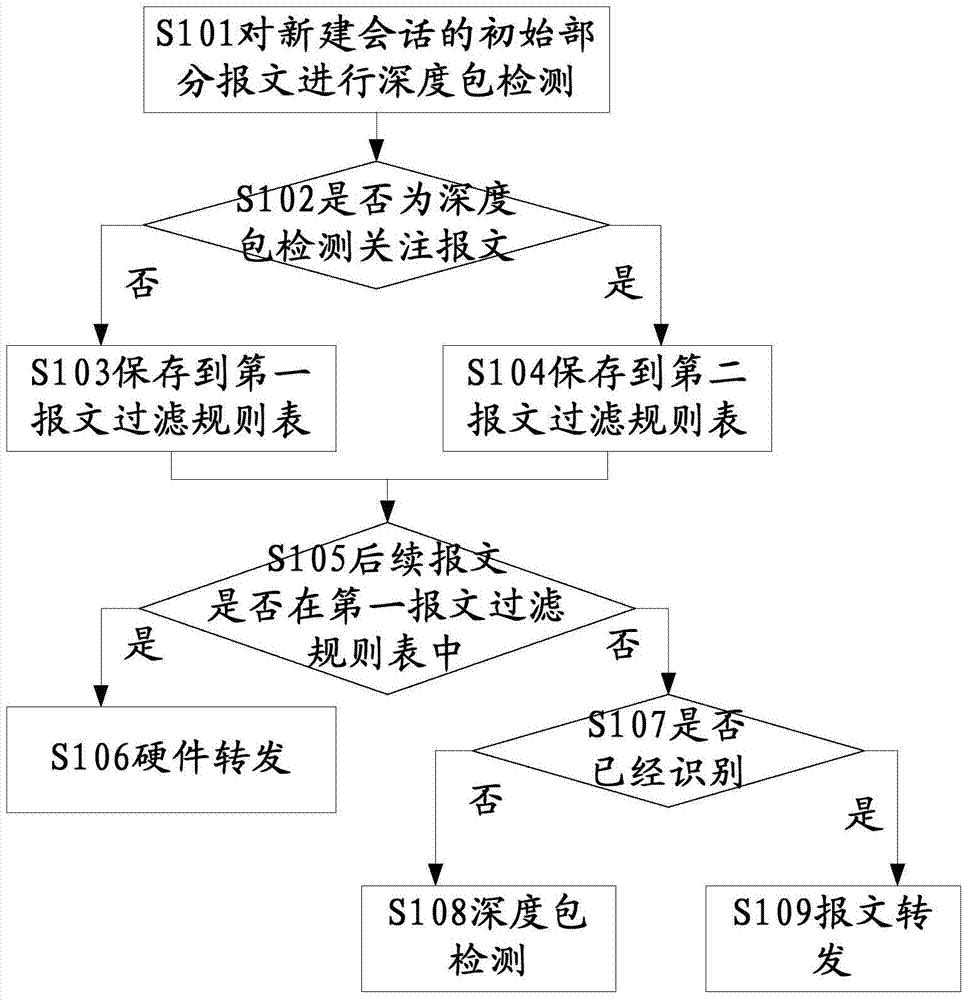

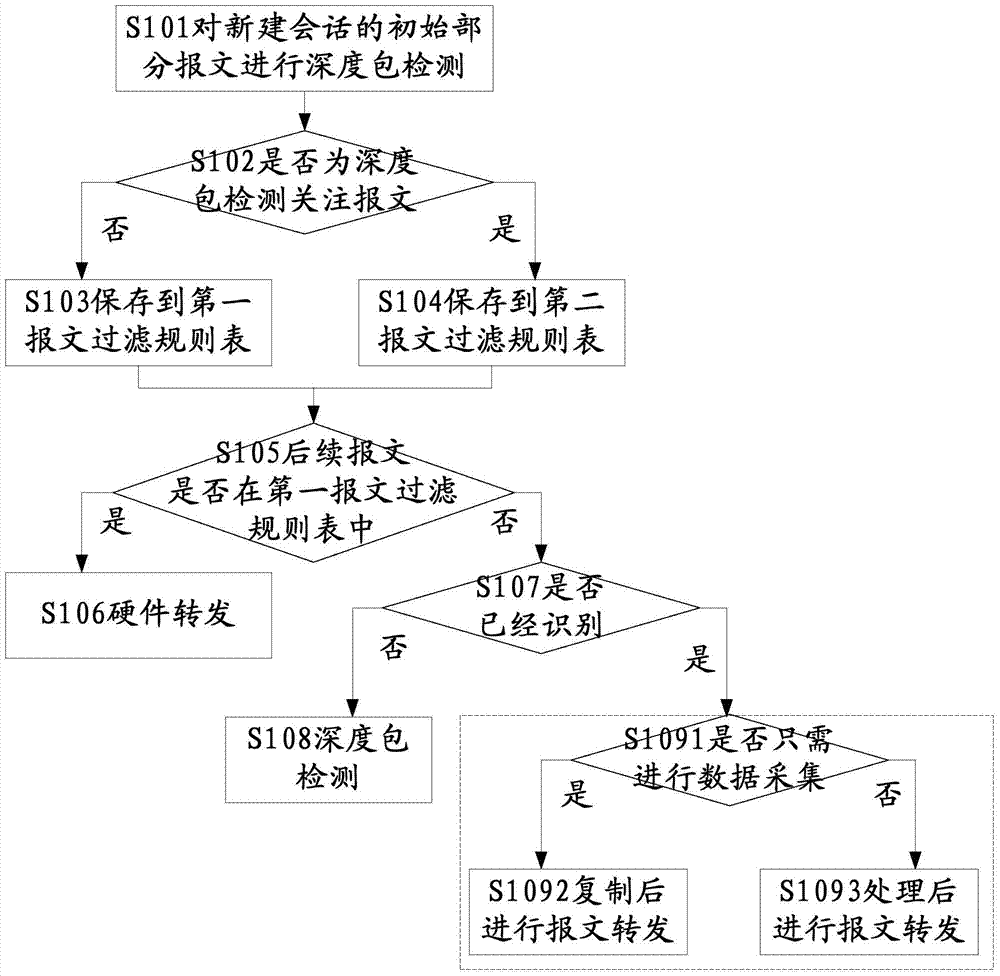

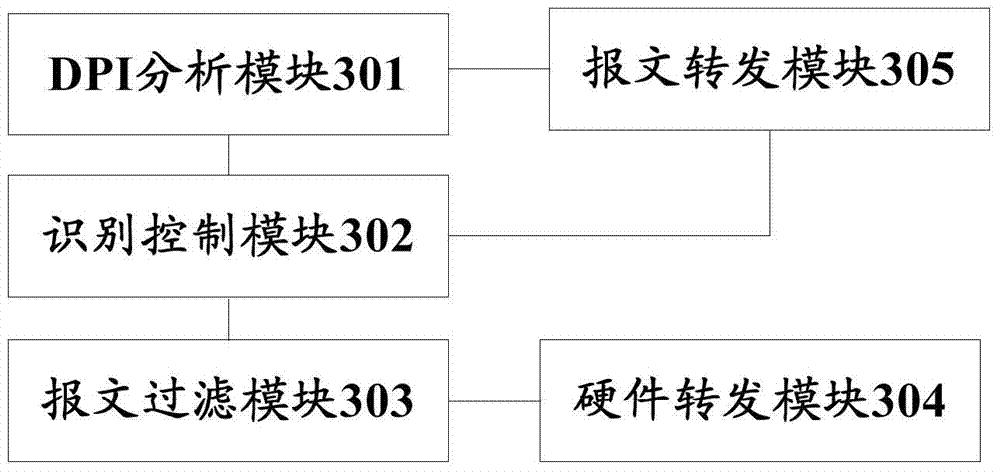

Deep packet inspection method and system

The invention discloses a deep packet inspection method and system based on an initial packet and relates to the technical field of deep packet inspection. According to the deep packet inspection method and system, an initial packet DPI identification mechanism is introduced, by conducting DPI analysis to first multiple packets of a new dialog establishment process, the service application type of the dialog is identified, then based on an identification result and an application processing strategy, a packet filtering rule list is established, then through the packet filtering at two levels, reasonable flow distribution is conducted by means of the functions such as hardware forwarding and packet forwarding, the immediate processing and forwarding of packets are achieved, and it is avoided that all the packets enter into a CPU and a DPI engine for processing, so that equipment performance consumption is reduced, the packet forwarding efficiency is improved, and the method and system are suitable for being achieved in equipment with the performance limited such as a household gateway.

Owner:CHINA TELECOM CORP LTD

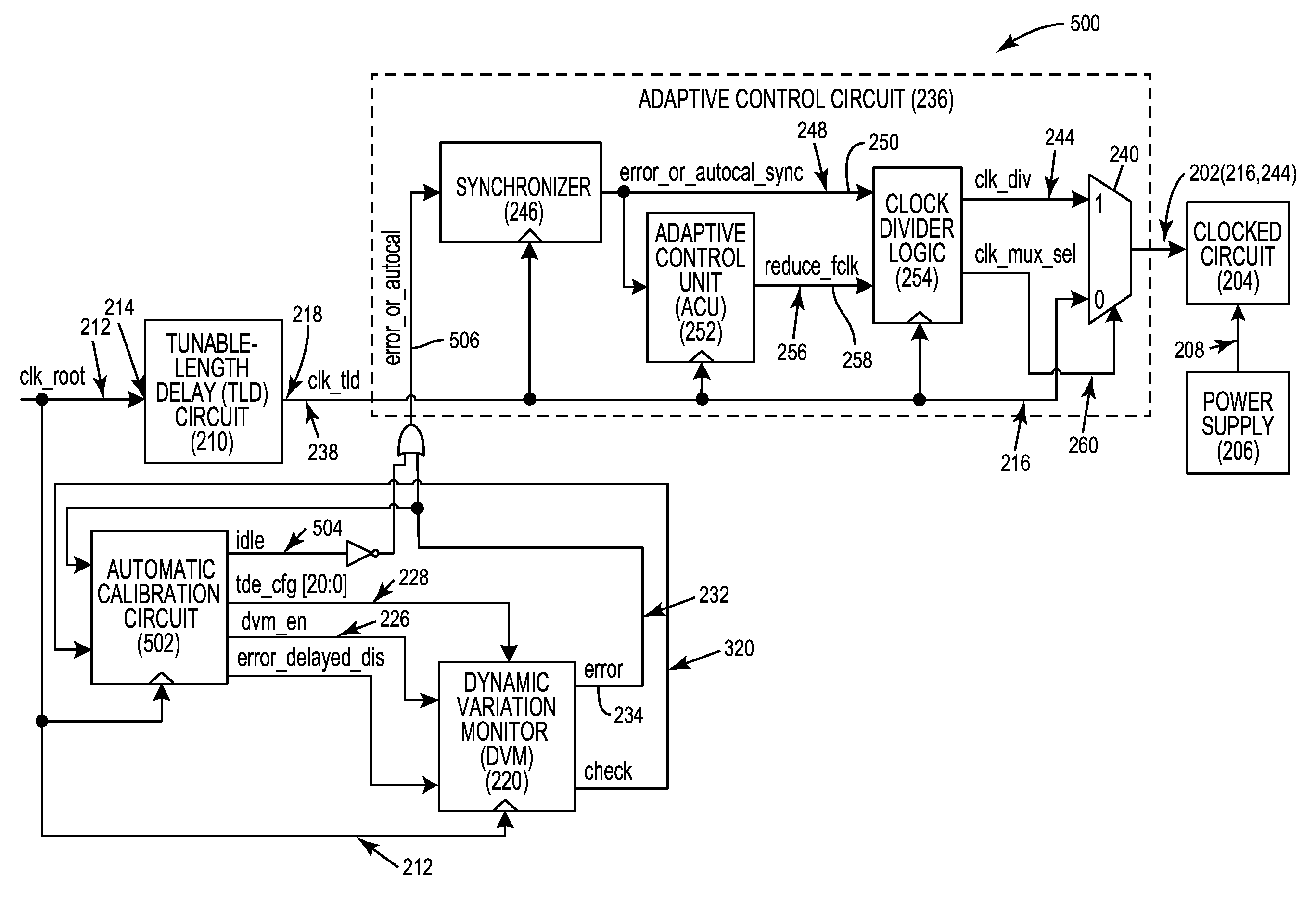

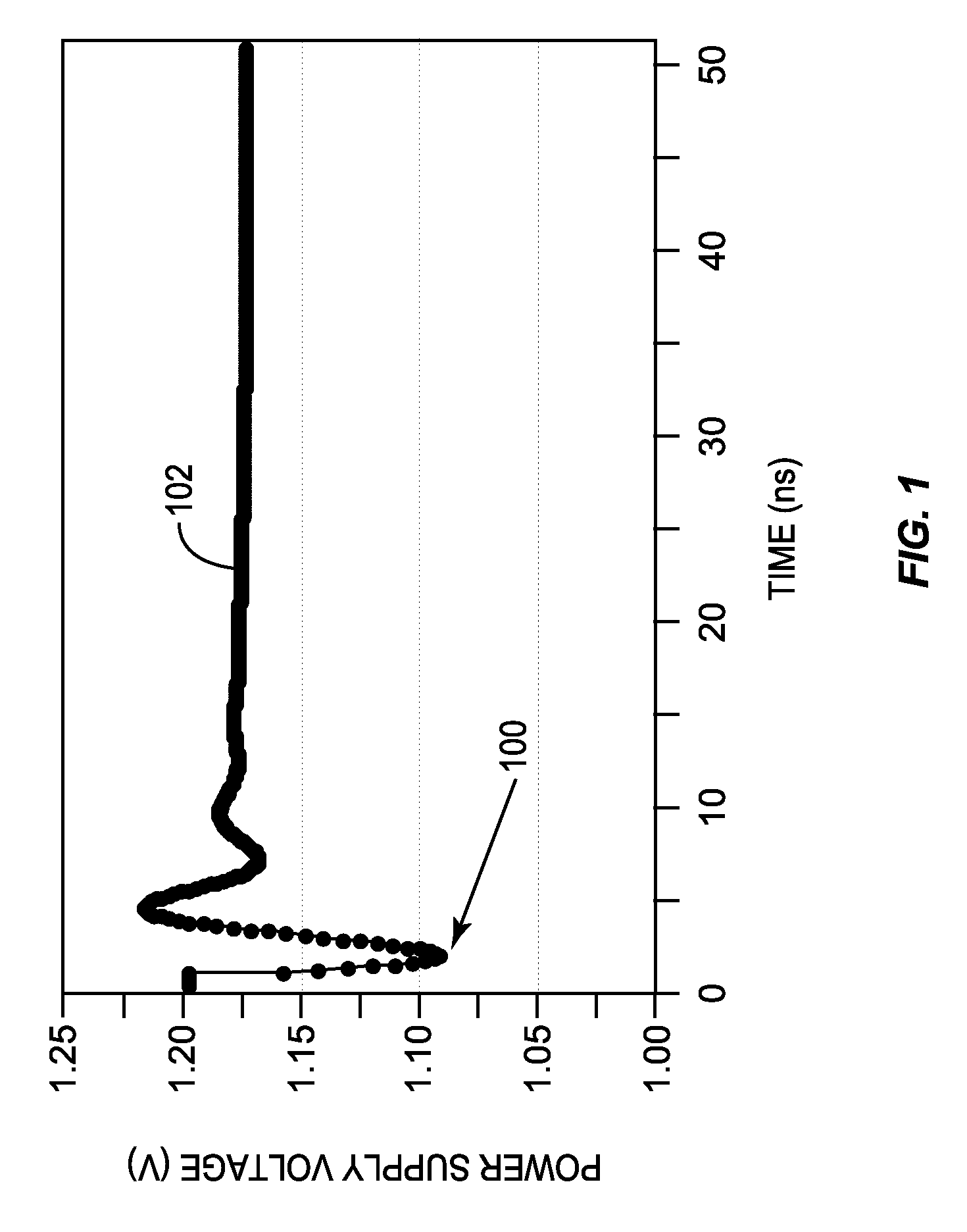

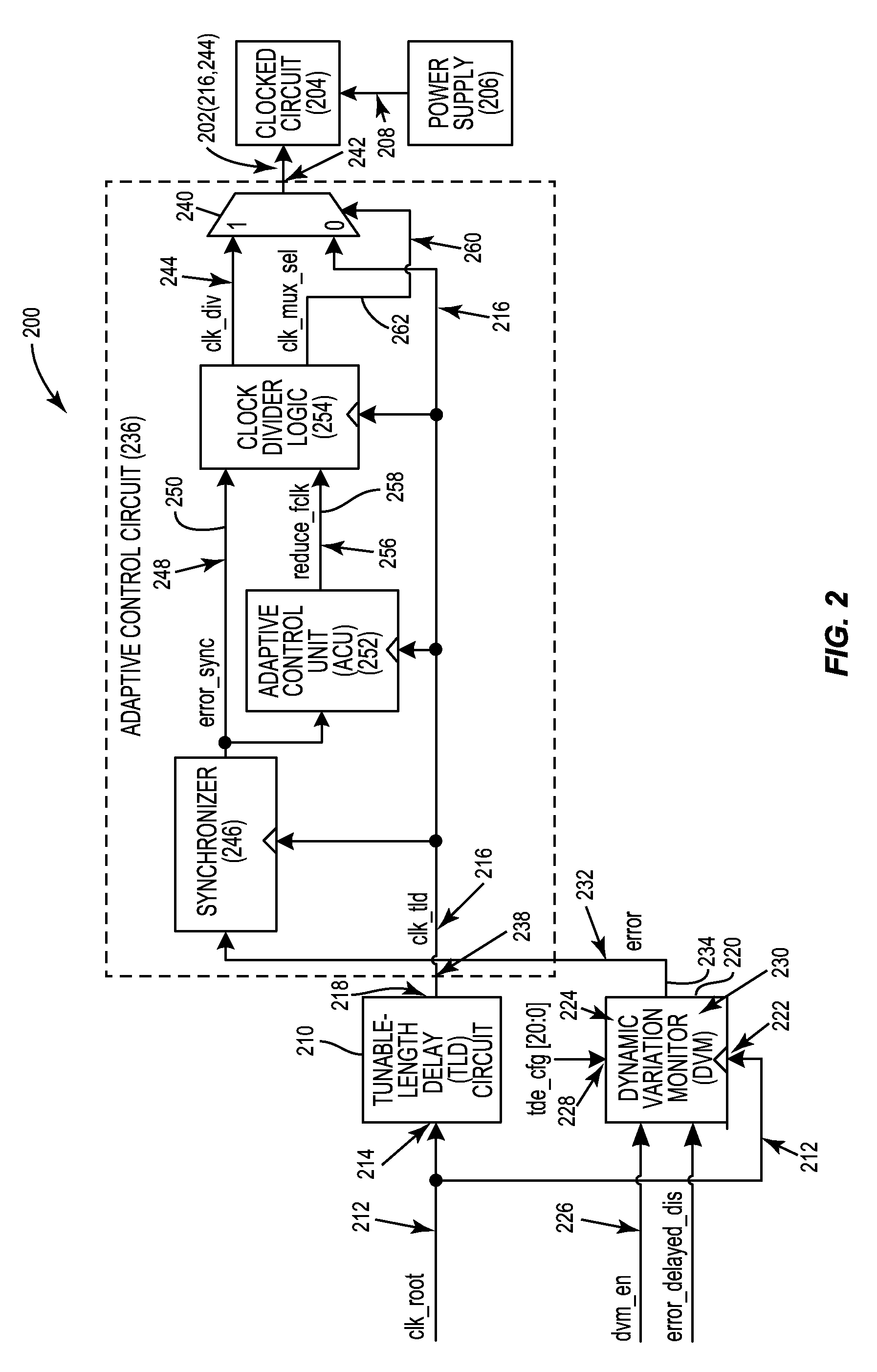

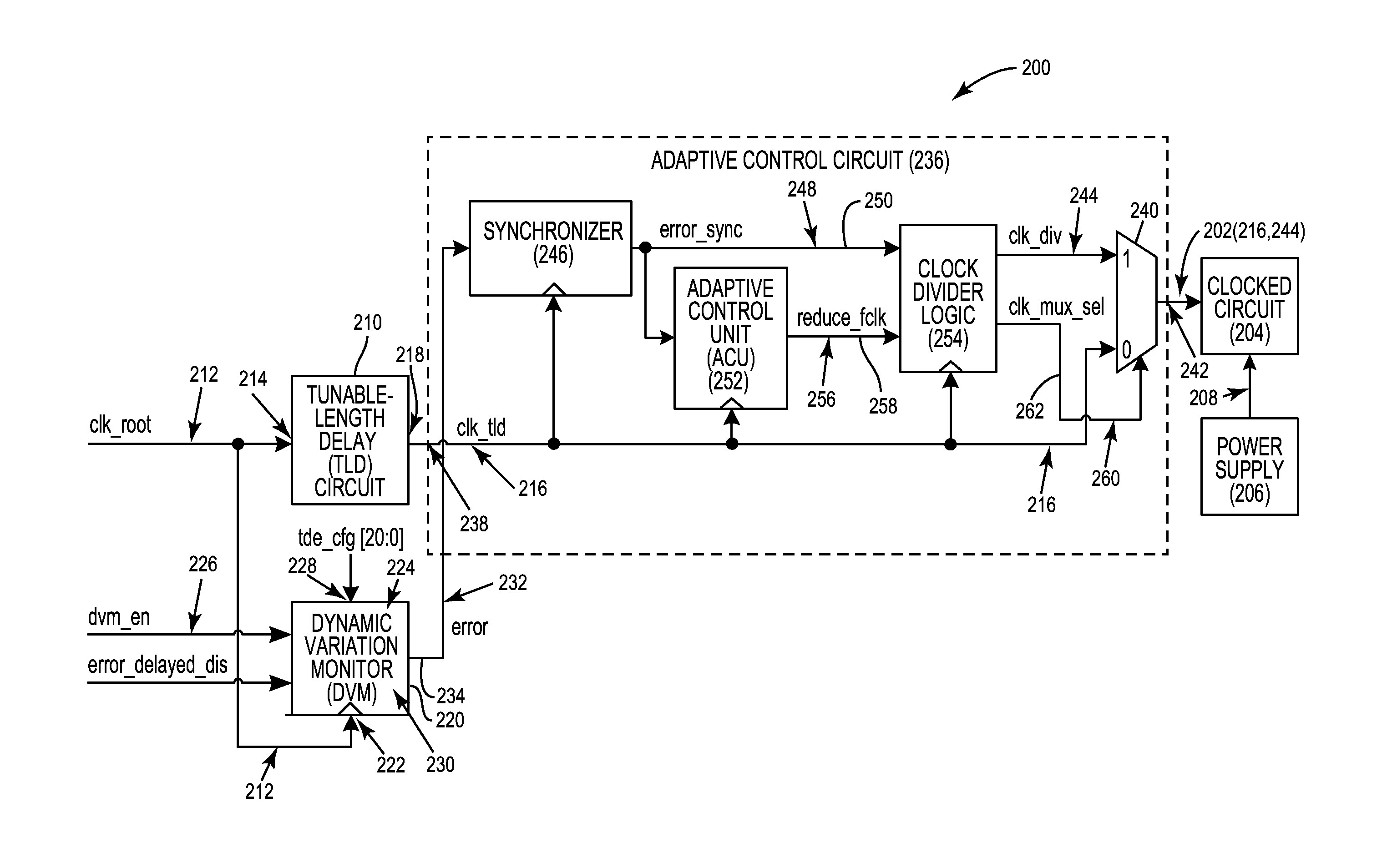

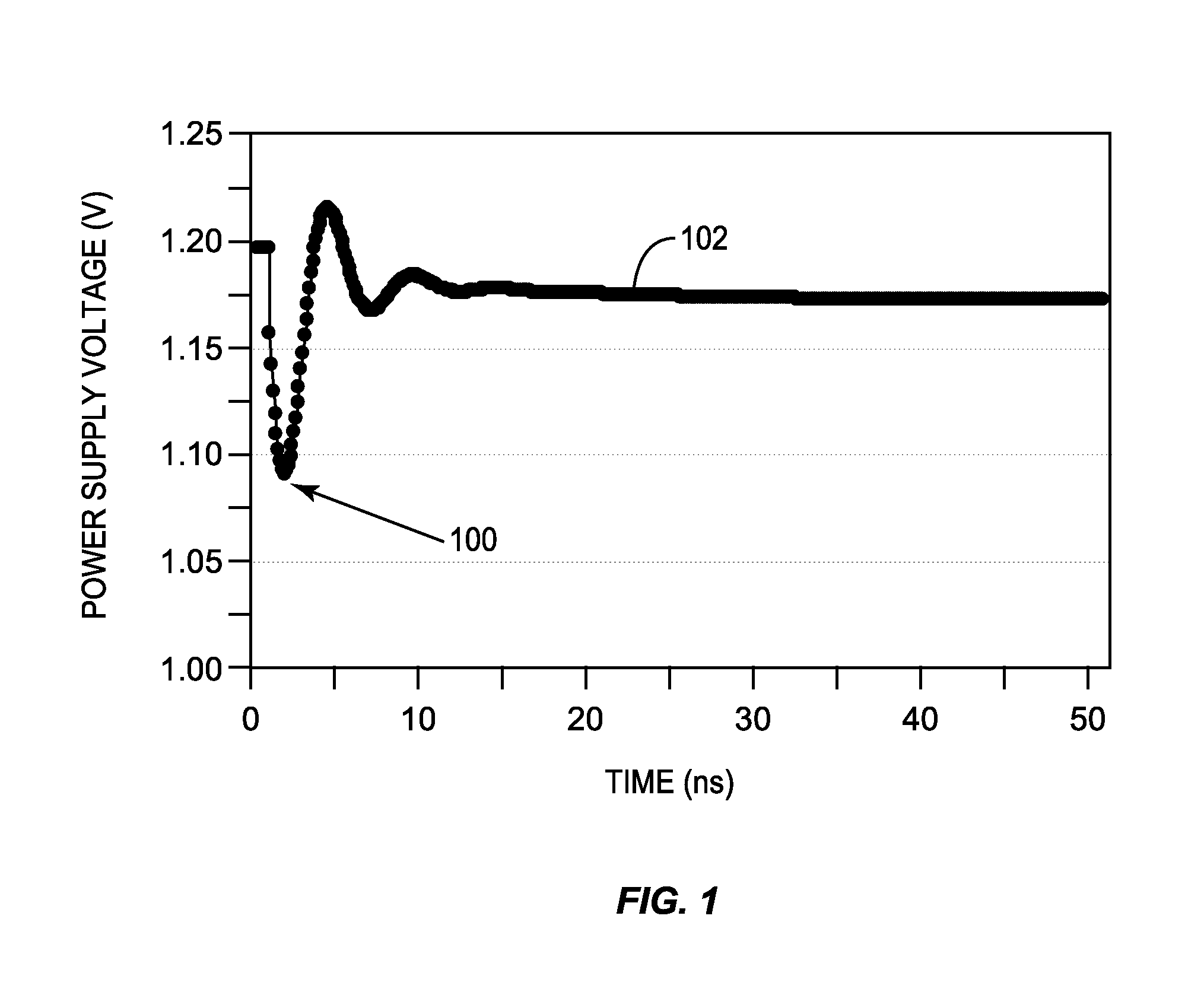

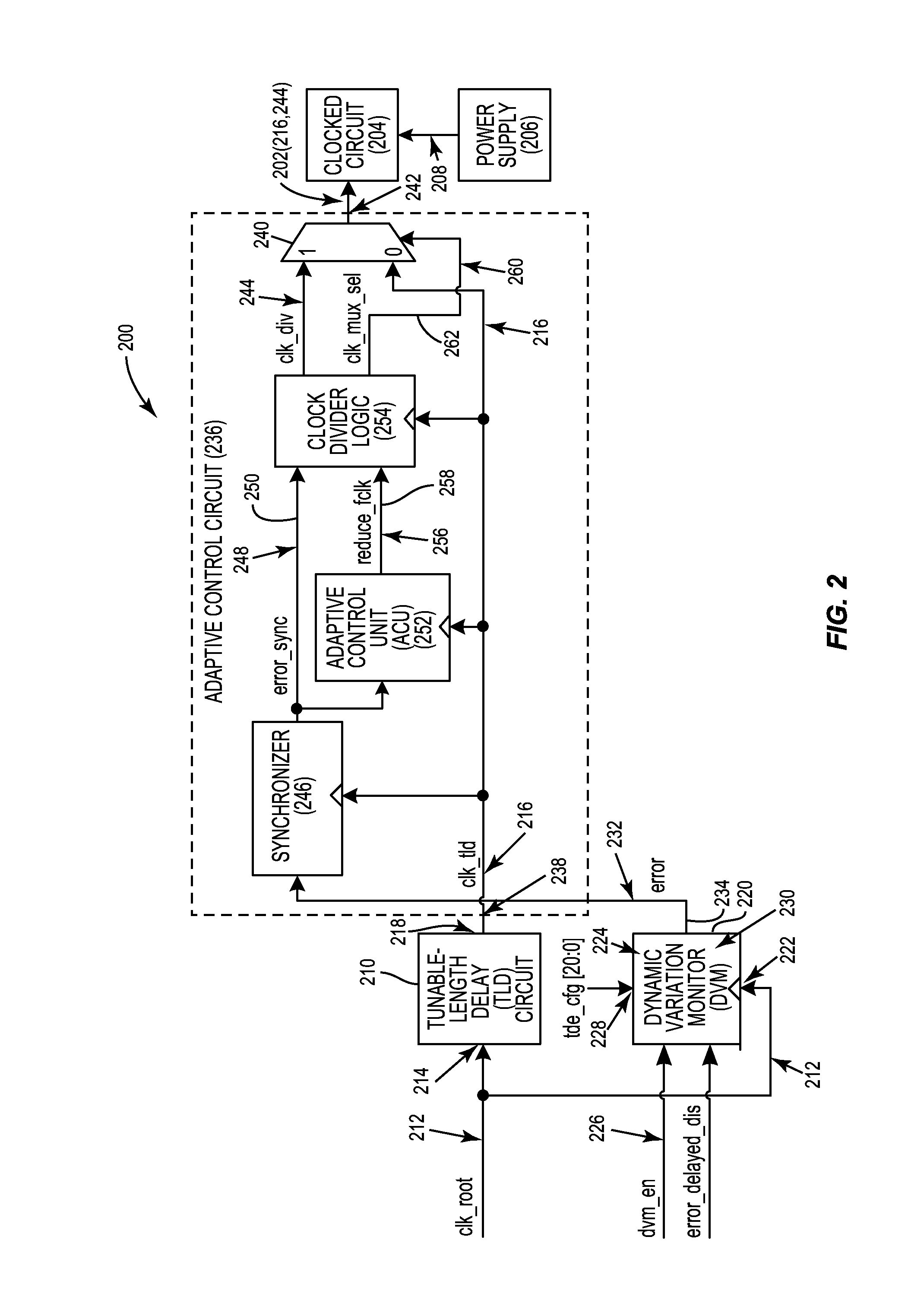

Automatic calibration circuits for operational calibration of critical-path time delays in adaptive clock distribution systems, and related methods and systems

ActiveUS9413344B2Costly overheadCostly timeContinuous to patterned pulse manipulationSingle output arrangementsTiming marginDistribution system

Automatic calibration circuits for operational calibration of critical-path time delays in adaptive clock distribution systems, and related methods and systems, are disclosed. The adaptive clock distribution system includes a tunable-length delay circuit to delay distribution of a clock signal provided to a clocked circuit, to prevent timing margin degradation of the clocked circuit after a voltage droop occurs in a power supply supplying power to the clocked circuit. The adaptive clock distribution system also includes a dynamic variation monitor to reduce frequency of the delayed clock signal provided to the clocked circuit in response to the voltage droop in the power supply, so that the clocked circuit is not clocked beyond its performance limits during a voltage droop. An automatic calibration circuit is provided in the adaptive clock distribution system to calibrate the dynamic variation monitor during operation based on operational conditions and environmental conditions of the clocked circuit.

Owner:QUALCOMM INC

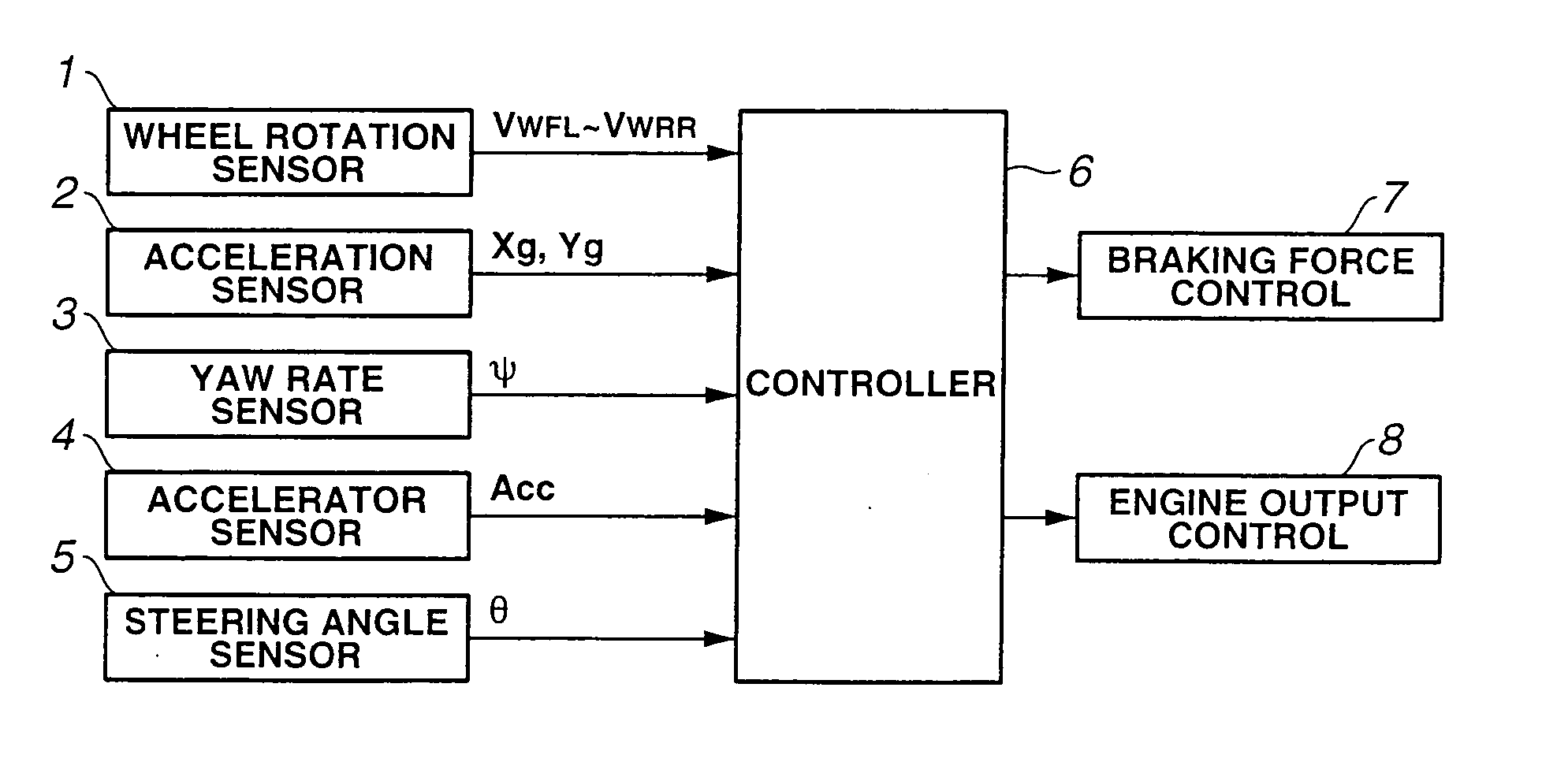

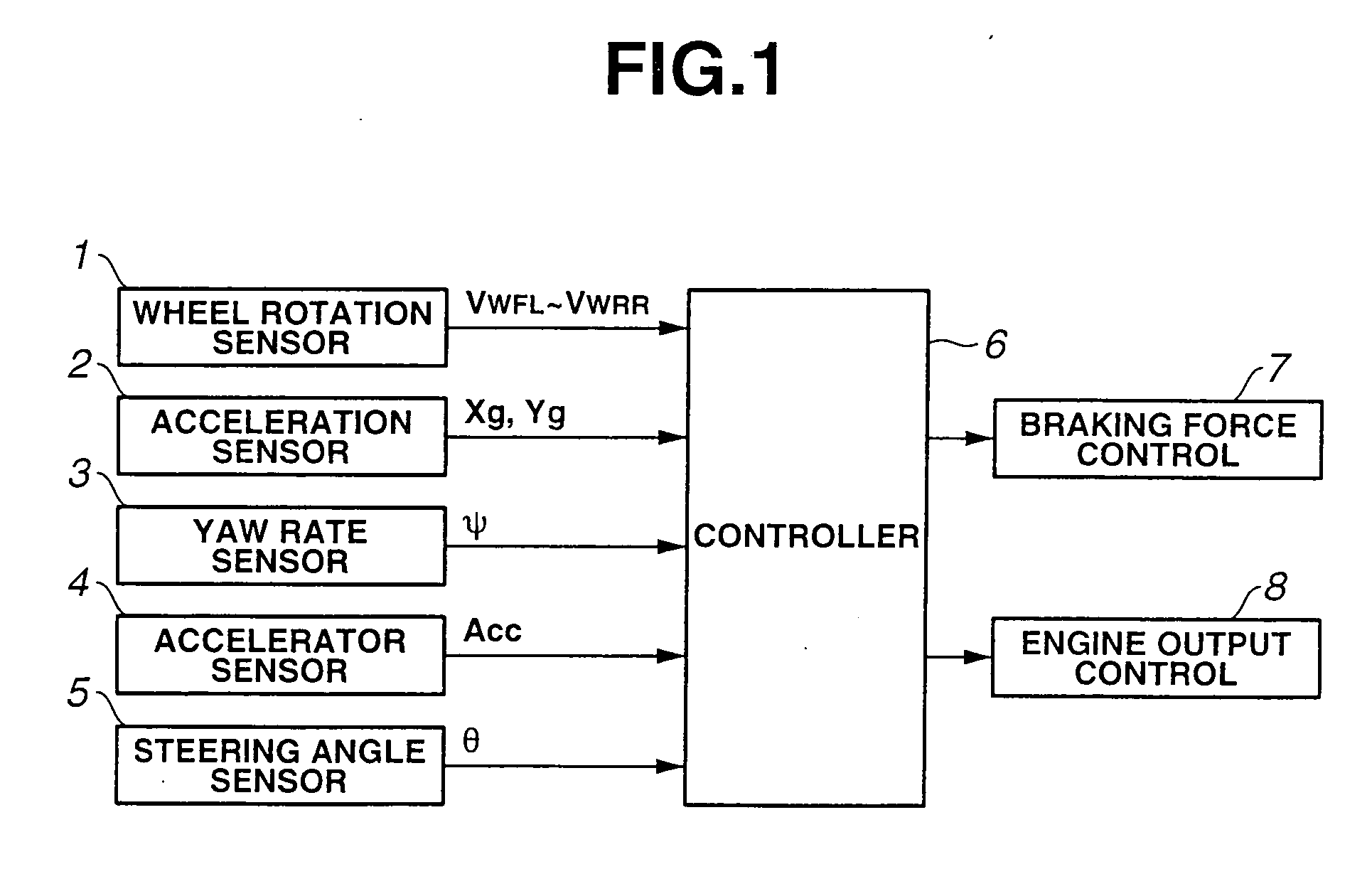

Turning motion control for vehicle

ActiveUS20060015239A1Hand manipulated computer devicesAnalogue computers for trafficActuatorControl theory

A vehicle turning motion control apparatus includes a turning condition sensor to sense a turning condition of the vehicle; and a controller to start a decelerating control to produce the braking force with a brake actuator when the turning condition surpasses a deceleration start threshold. There is further provided an accelerator operation quantity sensor to sense a driver's accelerator operation quantity. The controller adjusts the deceleration start threshold toward the turning performance limit when the accelerator operation quantity increases, and to start a preload or preliminary pressure control to produce a preload before the deceleration control when the turning condition surpasses a preload start threshold.

Owner:NISSAN MOTOR CO LTD

Automatic calibration circuits for operational calibration of critical-path time delays in adaptive clock distribution systems, and related methods and systems

ActiveUS20160072491A1Reduce calibration timeReduces delay variationContinuous to patterned pulse manipulationSingle output arrangementsTiming marginTime delays

Automatic calibration circuits for operational calibration of critical-path time delays in adaptive clock distribution systems, and related methods and systems, are disclosed. The adaptive clock distribution system includes a tunable-length delay circuit to delay distribution of a clock signal provided to a clocked circuit, to prevent timing margin degradation of the clocked circuit after a voltage droop occurs in a power supply supplying power to the clocked circuit. The adaptive clock distribution system also includes a dynamic variation monitor to reduce frequency of the delayed clock signal provided to the clocked circuit in response to the voltage droop in the power supply, so that the clocked circuit is not clocked beyond its performance limits during a voltage droop. An automatic calibration circuit is provided in the adaptive clock distribution system to calibrate the dynamic variation monitor during operation based on operational conditions and environmental conditions of the clocked circuit.

Owner:QUALCOMM INC

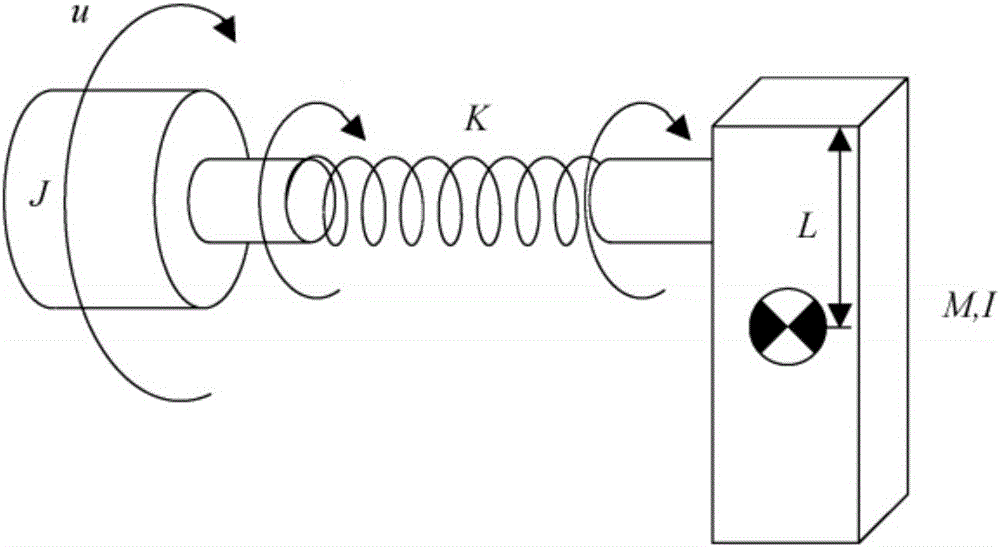

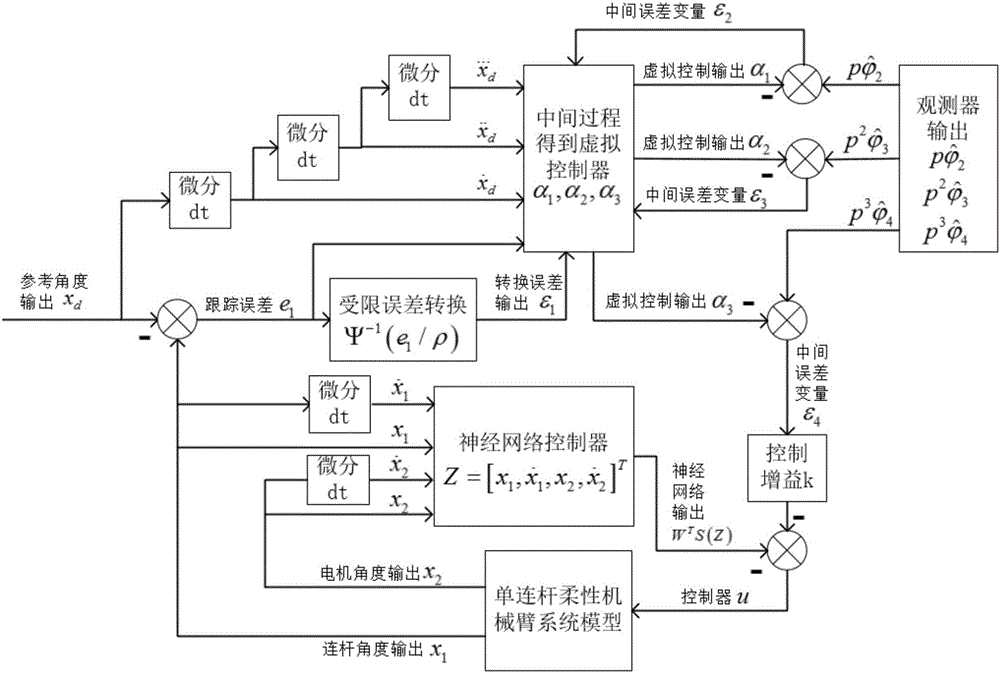

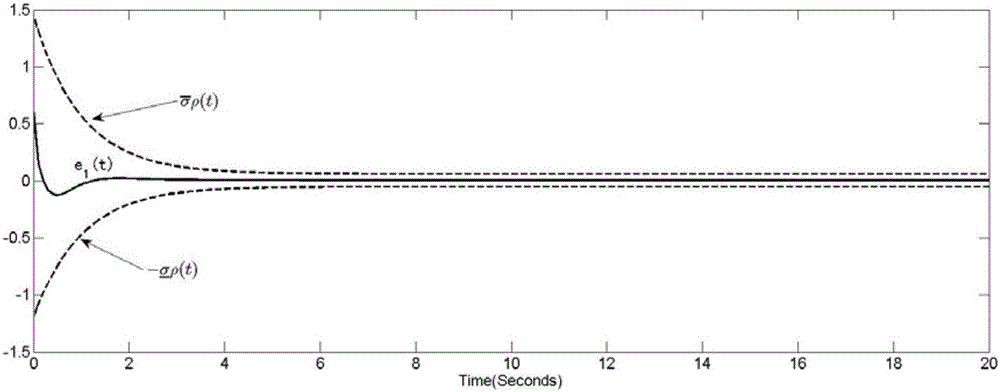

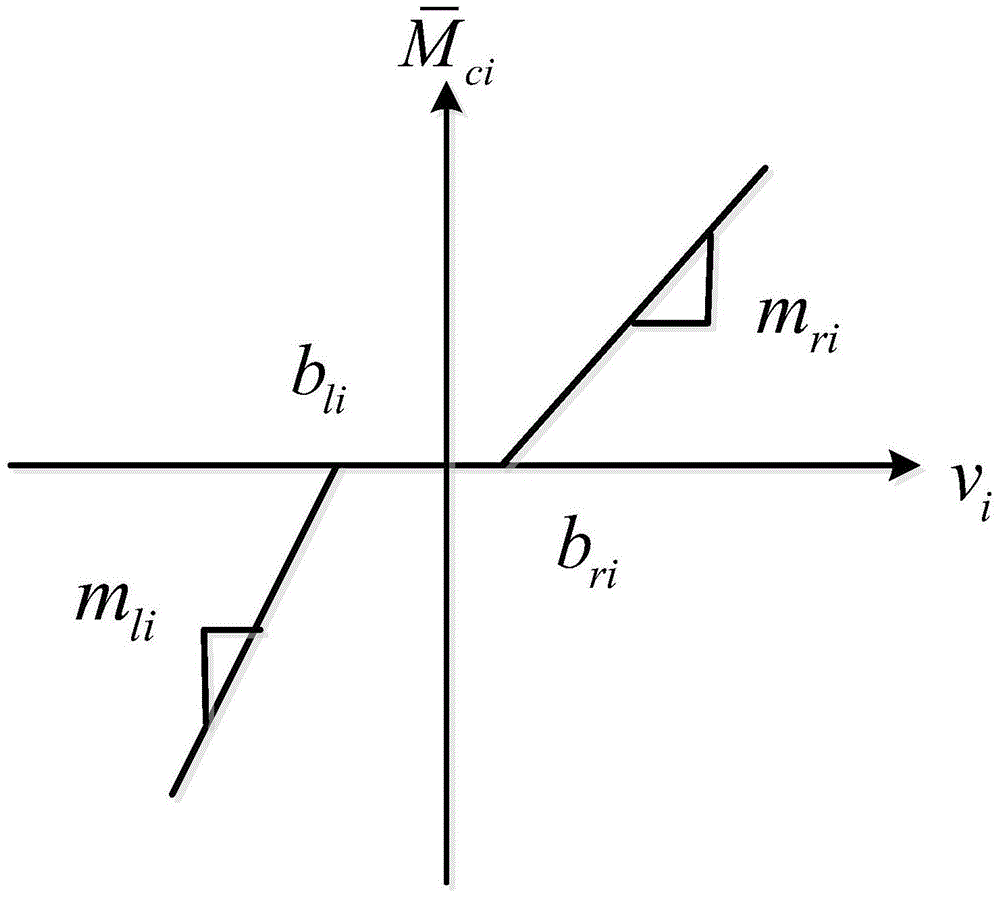

Performance limited flexible manipulator control method based on determining learning theory

ActiveCN106078741ASimple designRealize offline controlProgramme-controlled manipulatorNeural network controllerDynamic models

The invention discloses a performance limited flexible manipulator control method based on determining learning theory. Aiming at the indeterminacy of the dynamic model of the flexible manipulator, the method designs a tracking error to satisfy the limitation of constraint conditions, and forms an error controller. The method in the invention comprises the following steps: building a dynamic model of the flexible manipulator, building a system state observer, designing tracking error performance constraint conditions, designing a neural network controller based on the determining learning theory, and correcting the controller utilizing experiential knowledge. The method designed in the invention can realize the dynamic properties of rapid convergence and low overshoot, satisfy the limitation of set constraint conditions, avoid the on-line regulations to the neural network weights at the same time, and shorten the control time. In addition, the method can utilize the learned experiential knowledge to control the later same task rapidly.

Owner:SOUTH CHINA UNIV OF TECH

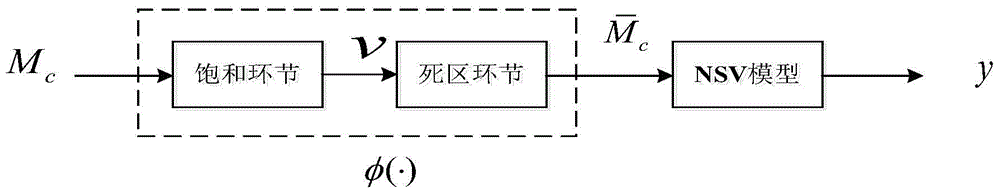

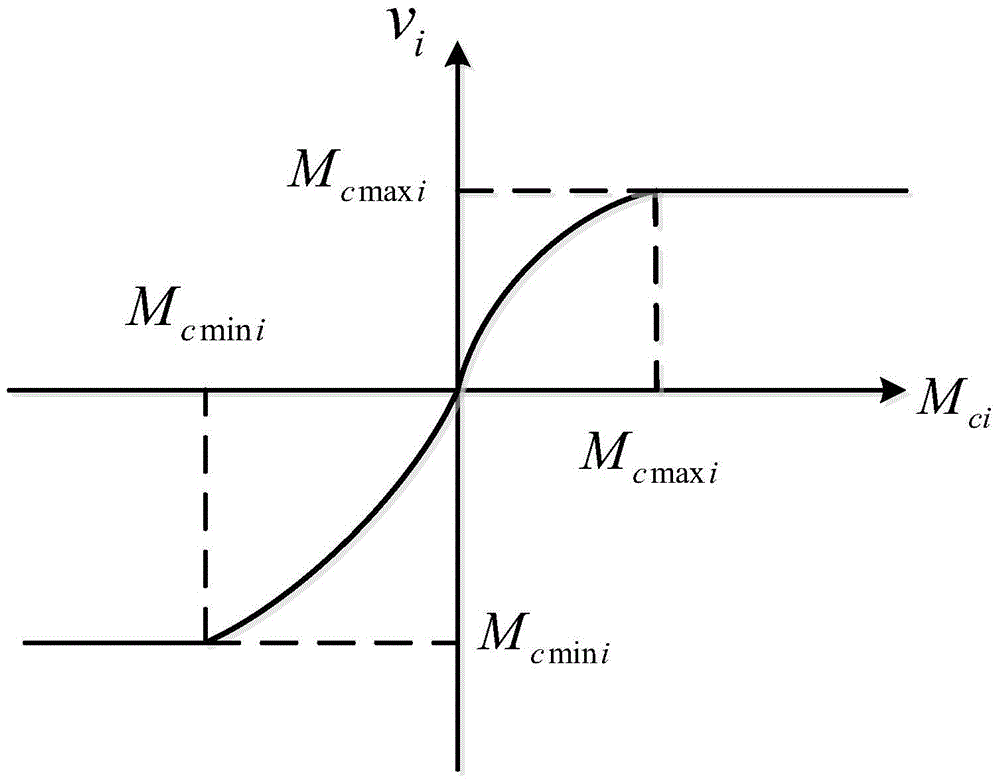

Near space vehicle preset performance attitude tracking control method with input nonlinearity

InactiveCN106444368ADefault Tracking Performance LimitsAttitude controlAdaptive controlBacksteppingSelf adaptive

The invention discloses a near space vehicle (NSV) preset performance attitude tracking control method with input nonlinearity. The method comprises the following steps: (1) enabling an input nonlinearity link including a dead zone and input saturation be equivalent to an input saturation link by means of an added dead zone right inverse function, and adding the input nonlinearity to a NSV attitude model; (2) introducing preset performance limit of tracking errors, adjusting the transient performance and the steady-state error of a tracking error signal at the same time, and converting the tracking error signal constrained by preset performance into a unconstrained converted error signal by means of an error conversion function; and (3) constructing an auxiliary system and designing an adaptive neural network attitude tracking controller by means of a backstepping method. The method enables the NSV attitude model to be capable of tracking a desired attitude angle signal with parameter uncertainty, external disturbances, and input nonlinearity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

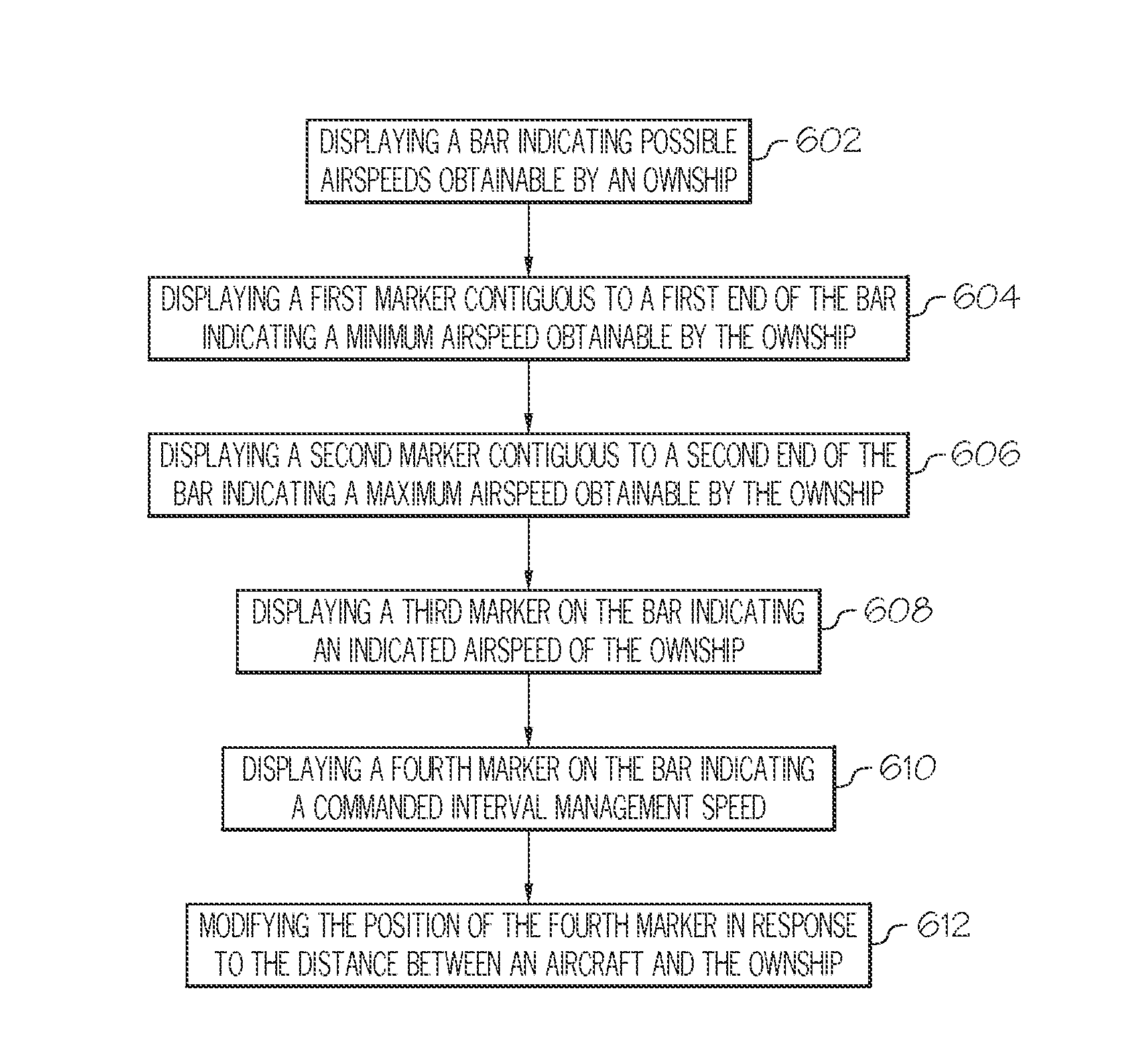

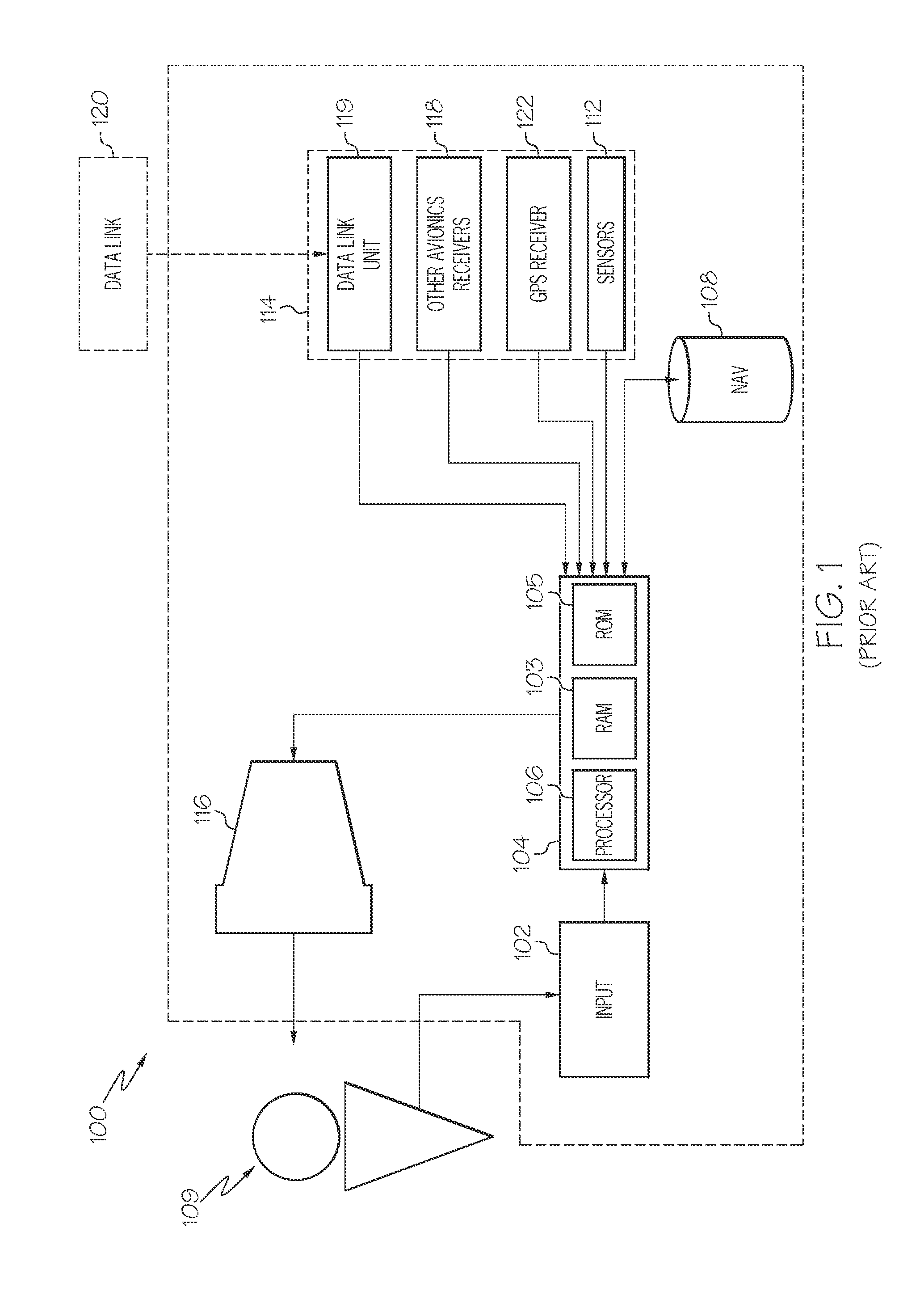

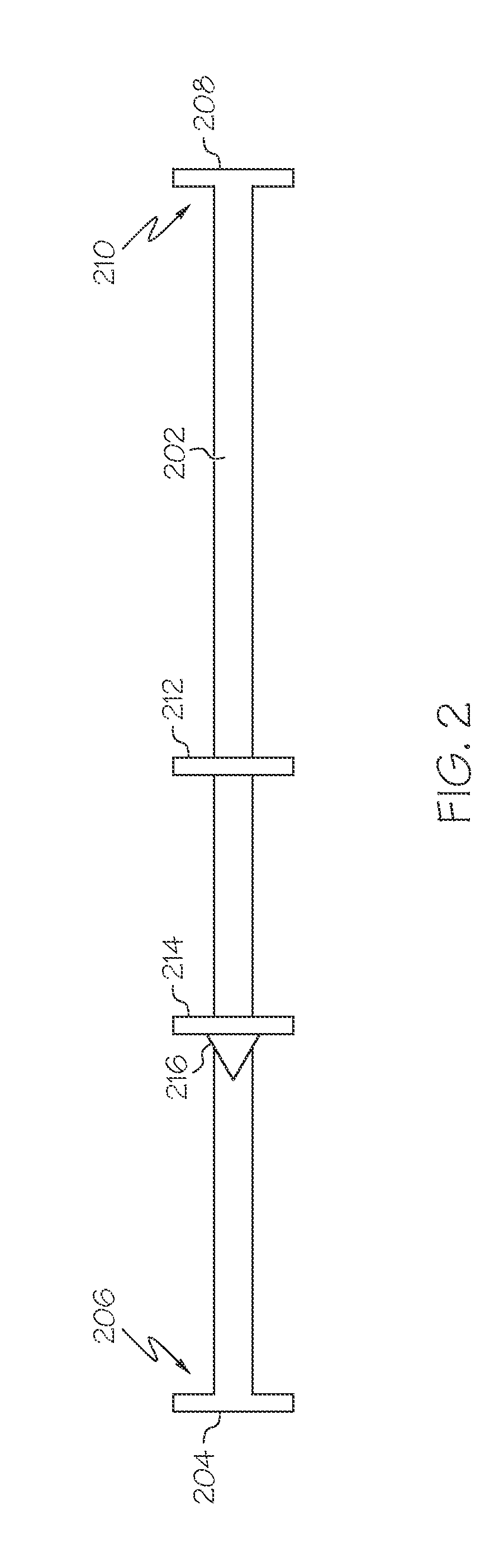

System and method for managing an interval between aircraft

InactiveUS20140249701A1Easily identifiableAnalogue computers for trafficComputations using stochastic pulse trainsFlight management systemPerformance limit

A system and method provide situational awareness for a pilot of an ownship in managing the longitudinal interval from an aircraft from which the ownship is following and maintaining the ownship within performance limits by displaying an airspeed bar containing markers representing the ownship minimum and maximum airspeeds, the ownship indicated airspeed, and a commanded interval management airspeed (CIMS) for providing speed situational awareness. A flight management system modifies the CIMS in response to a distance between the aircraft and the ownship. An optional pointer attached to the marker representing the CIMS indicates a trend in the in the CIMS.

Owner:HONEYWELL INT INC

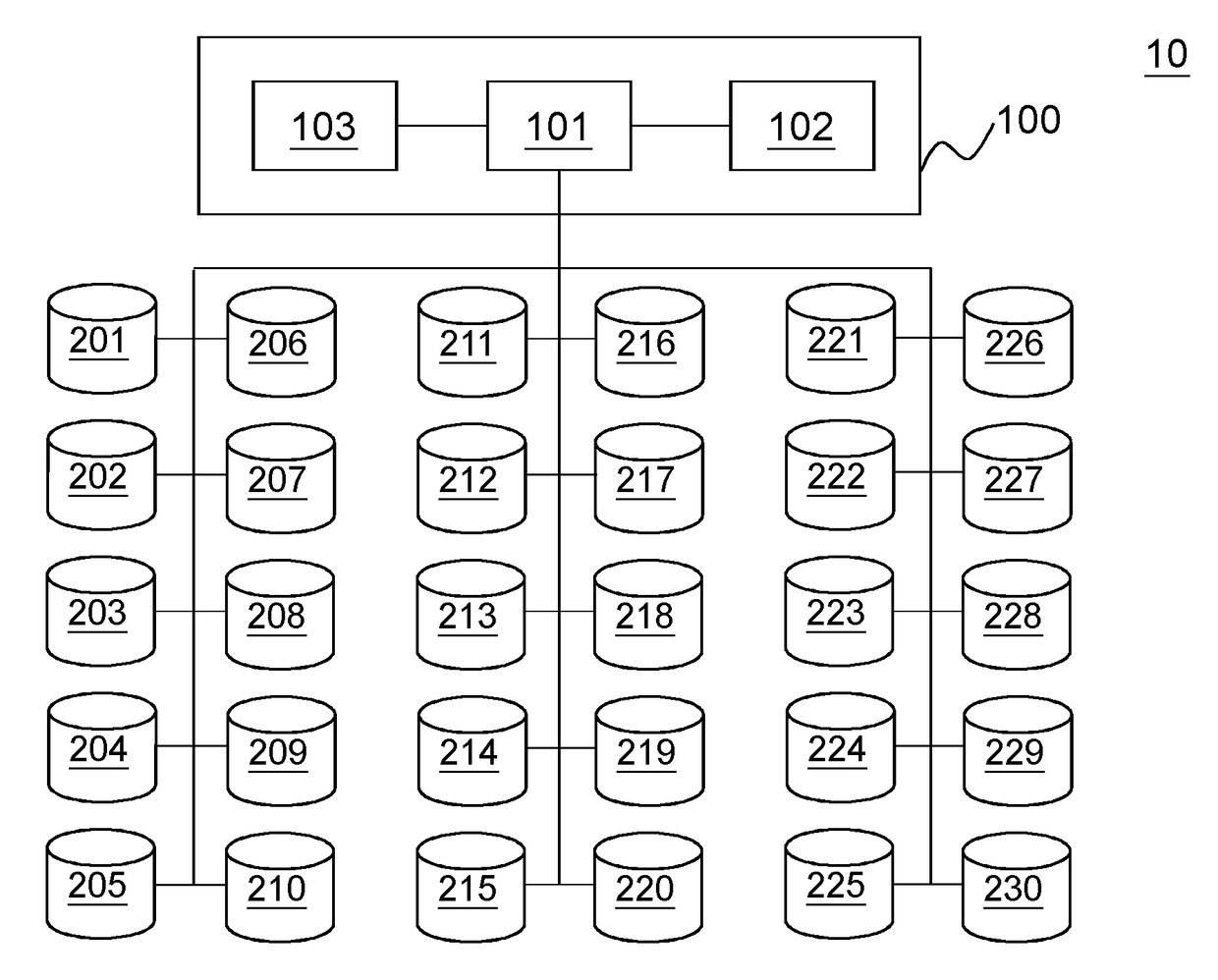

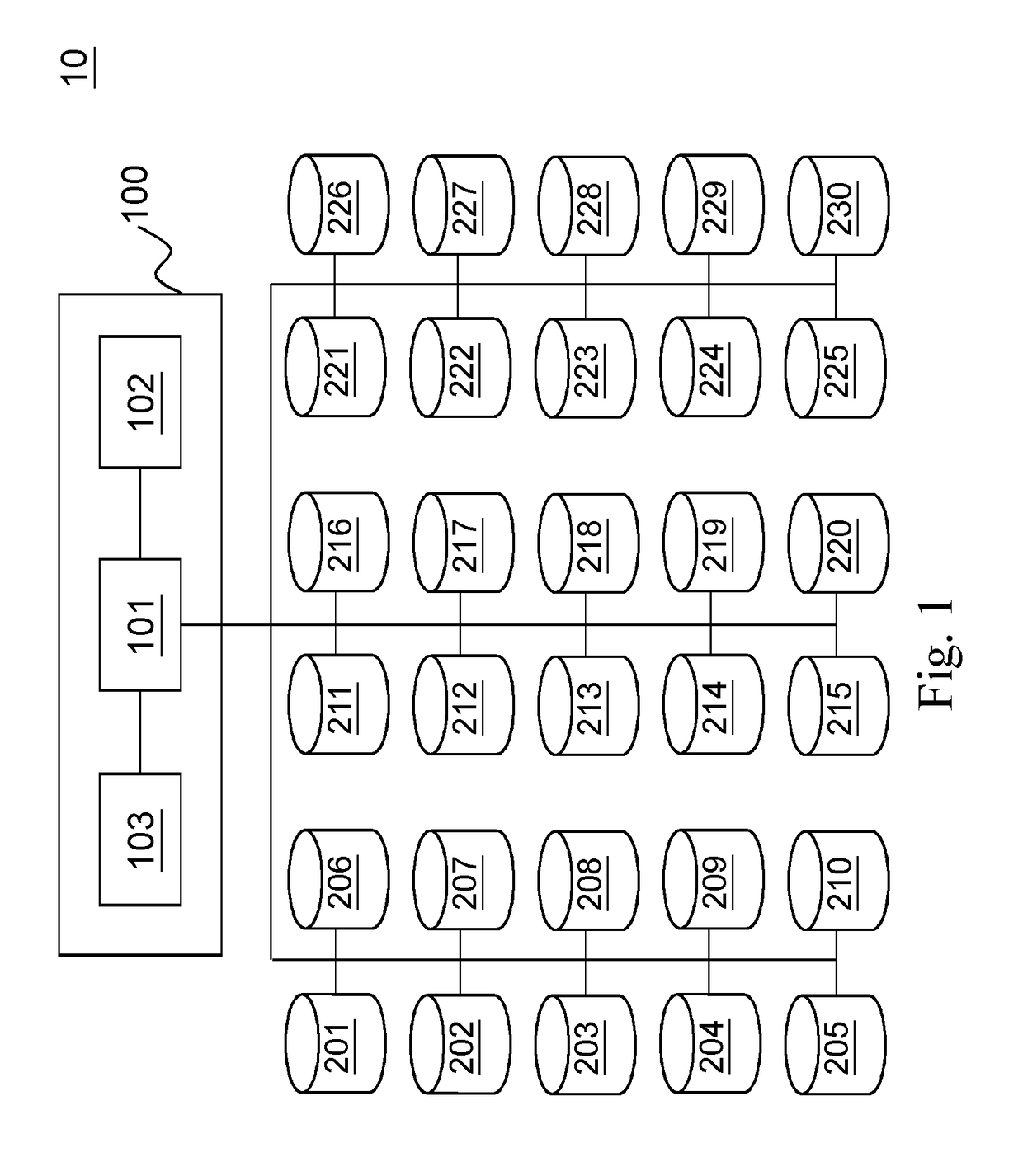

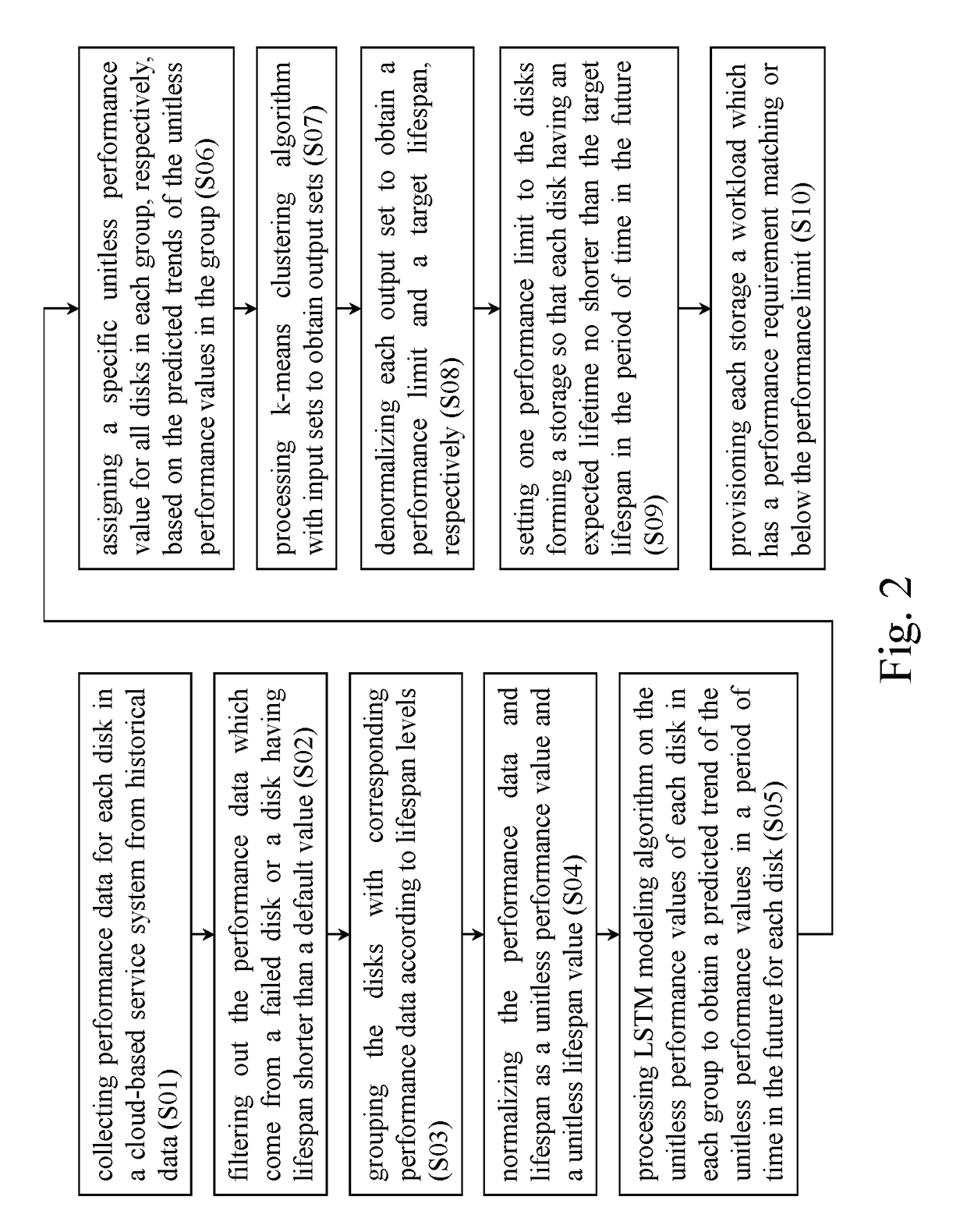

Method for extending life expectancy of disks in cloud-based service system and system using the same

ActiveUS20180101313A1Improve life expectancyEqually distributedInput/output to record carriersCluster algorithmCloud base

A system for extending life expectancy of disks in a cloud-based service system and the system using the method are disclosed. The present invention uses LSTM modeling and the k-means clustering algorithms to find out performance limit and target lifespan for a cluster of disks assigned for a specific workload running over the cloud-based service system. The disks can be predicted to have a minimum lifetime and the requirement of the workload can be satisfied. Meanwhile, the minimum lifetime is the longest life the disk can last.

Owner:PROPHETSTOR DATA SERVICES

Well modeling associated with extraction of hydrocarbons from subsurface formations

Owner:EXXONMOBIL UPSTREAM RES CO

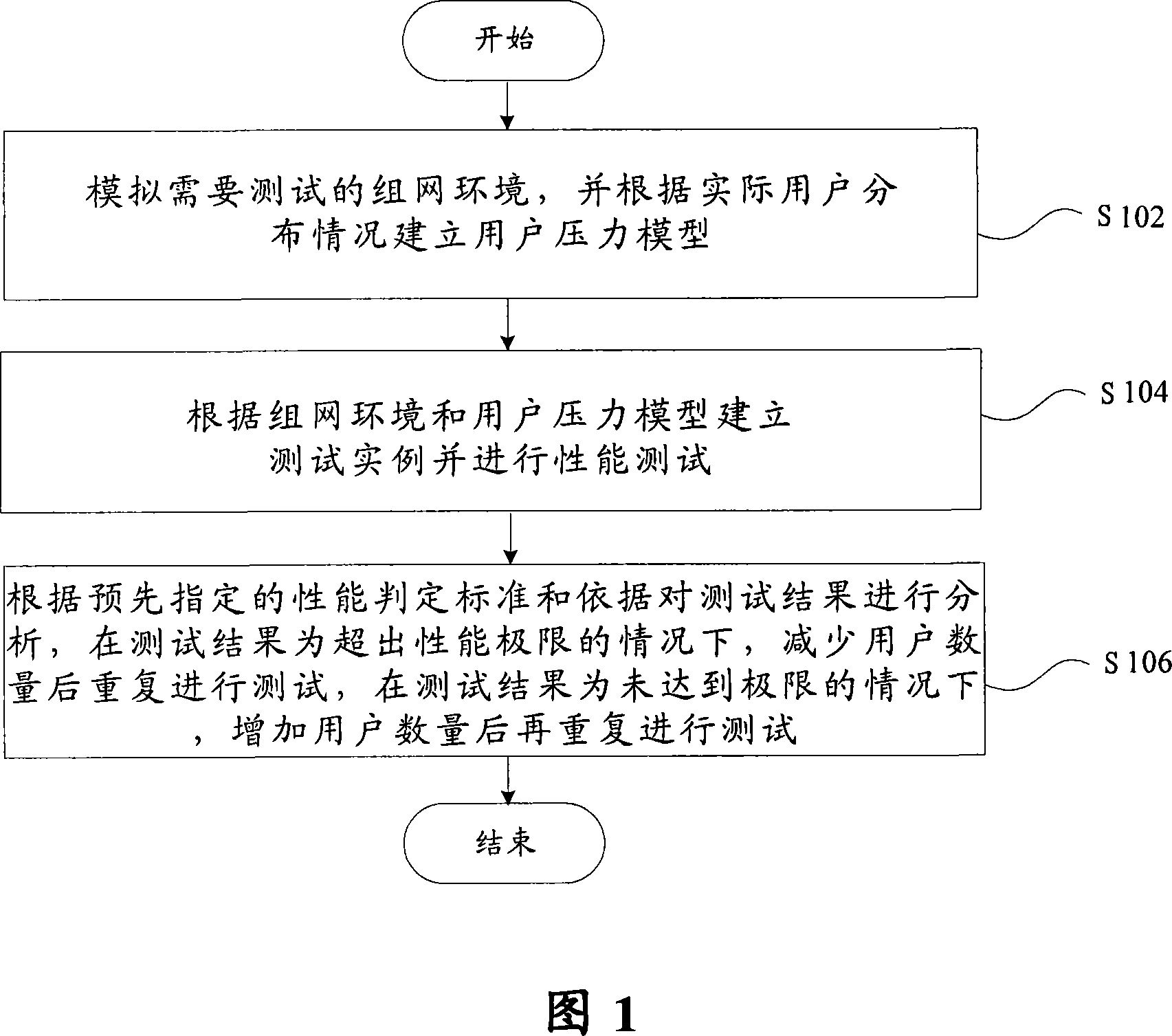

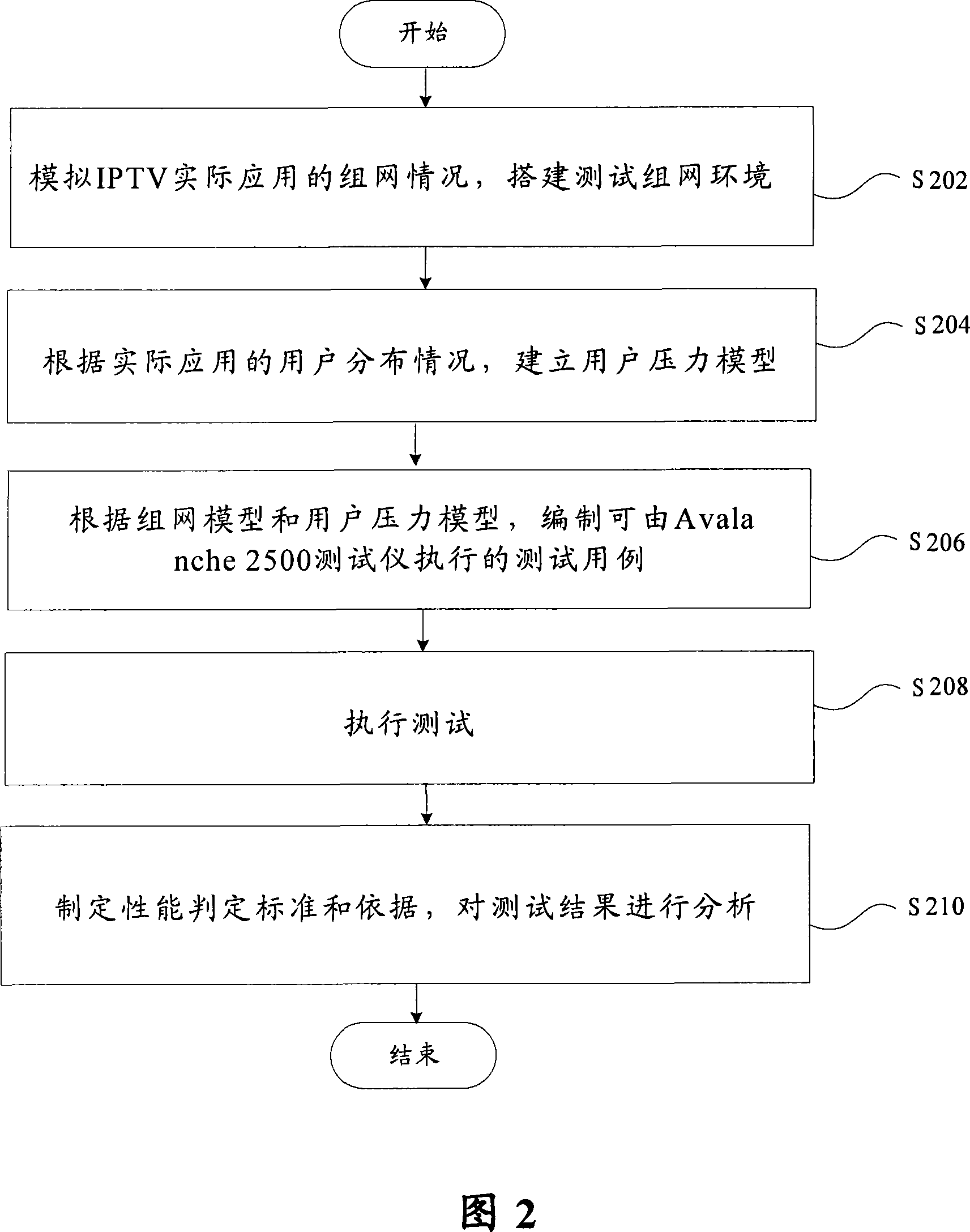

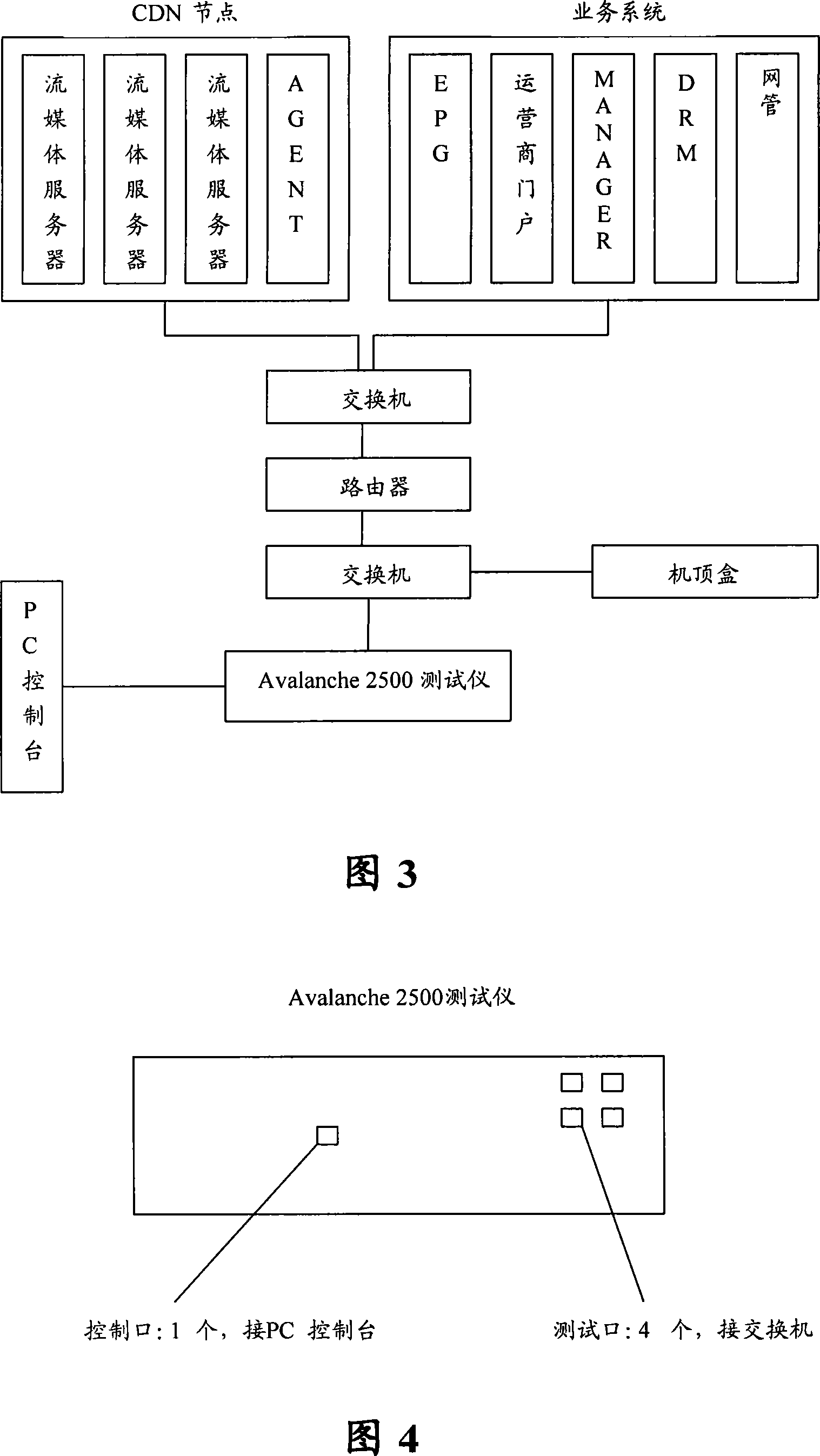

Flow media performance testing method

InactiveCN101072327AImprove performanceImprove stabilityTwo-way working systemsData switching networksTest performanceSimulation

The method for testing performance of stream media includes steps: step S102, simulating environment of network formation, and based on distribution condition of actual users to build pressure mould of users; step S104, based on environment of network formation and pressure mould of users to build test instance and carry out performance test; step S106, based on performance standard of criterion pointed in advance, and based on analysis for tested result, if tested result goes beyond performance limit, then test is carried out repeatedly after quantity of user is reduced; if tested result does not reach performance limit, then test is carried out repeatedly after quantity of user is increased. Test by the invention possesses advantages: good stability, high performance, reliable result, powerful result, and good generality.

Owner:ZTE CORP

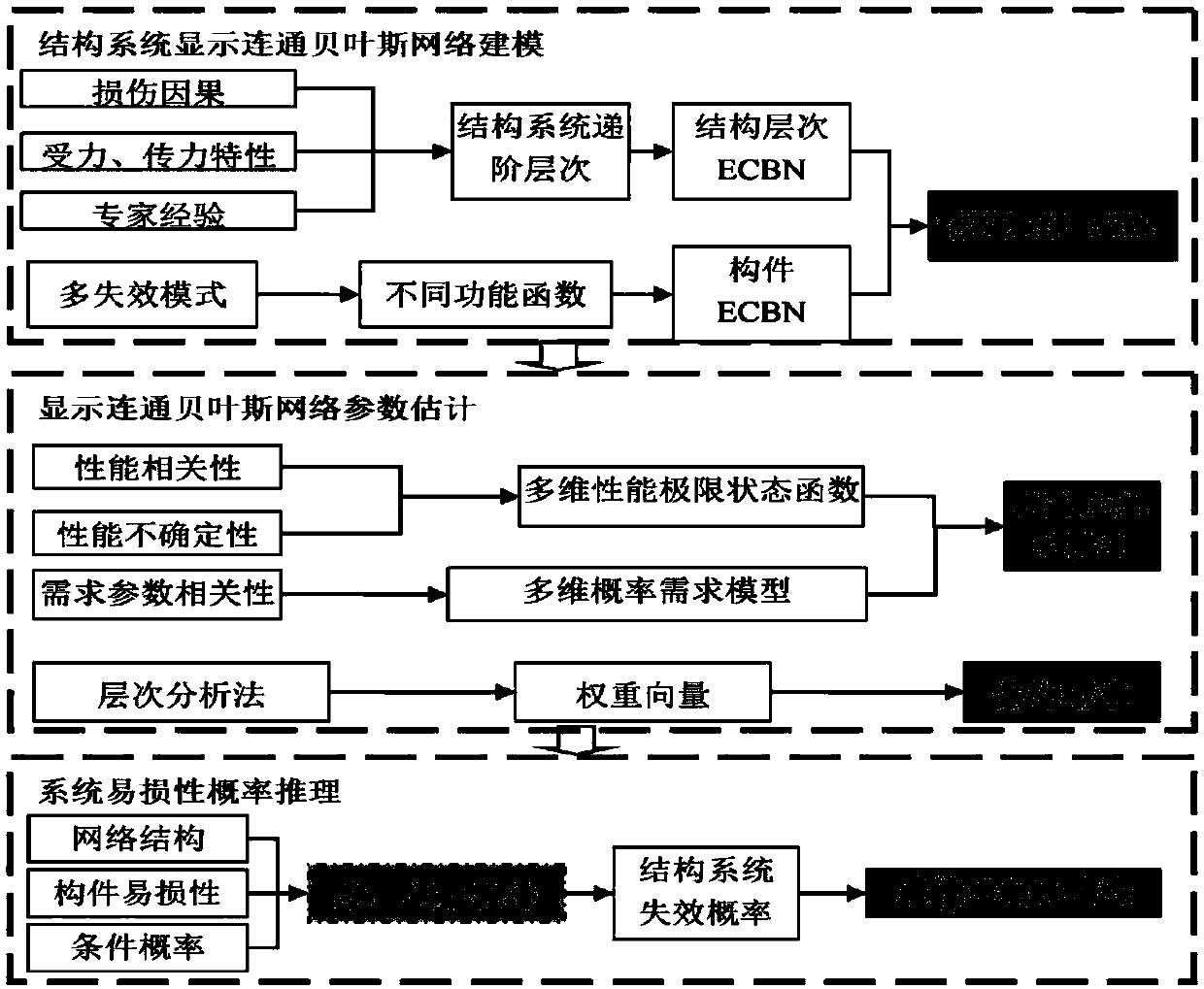

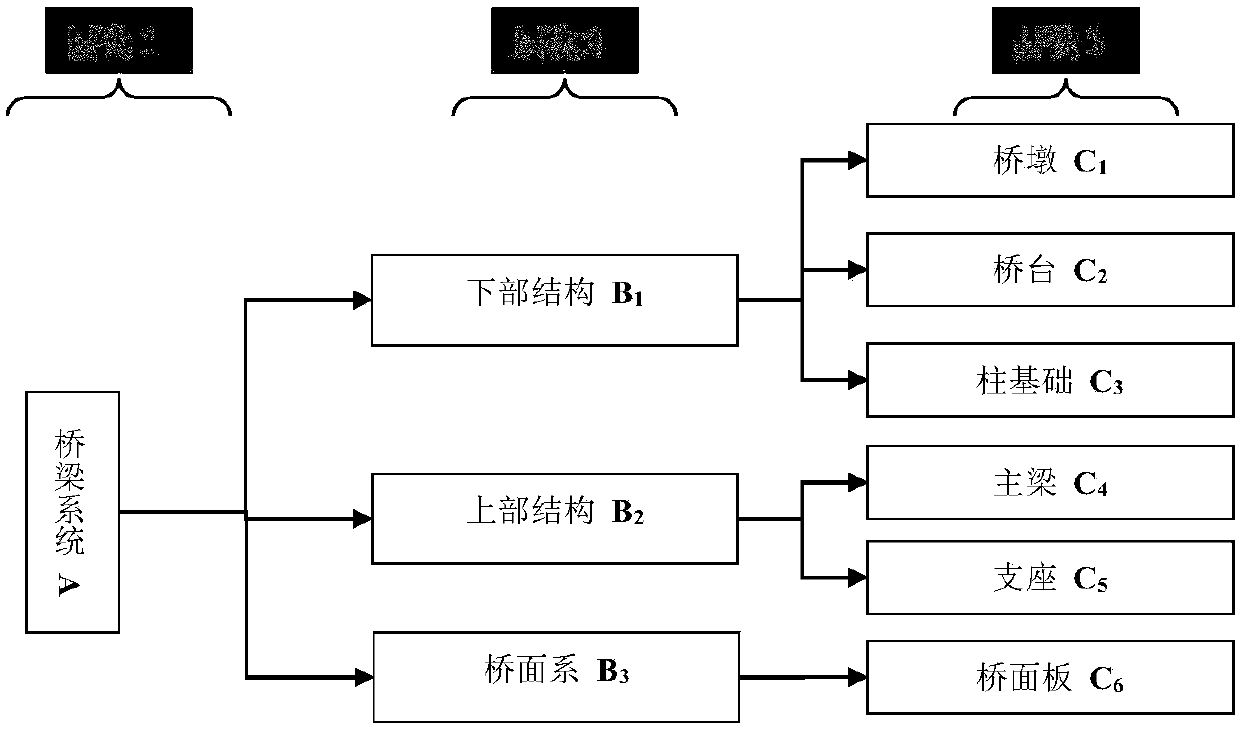

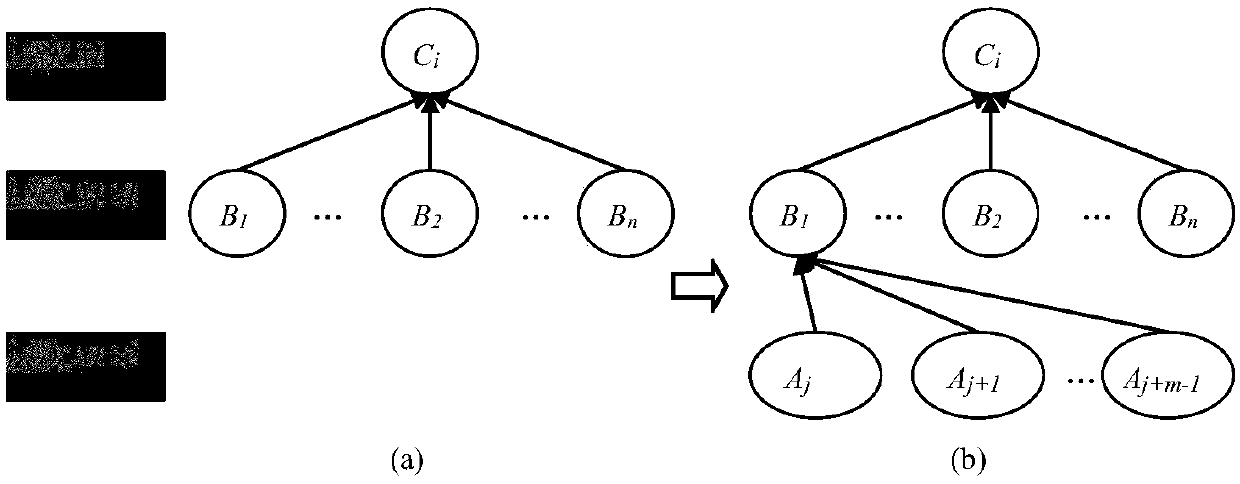

Structural system vulnerability evaluation method based on ECBN (Explicit Connectivity Bayesian Network)

ActiveCN108805205AMake up for lack of researchCharacter and pattern recognitionResourcesNODALEngineering structures

The invention discloses a structural system vulnerability evaluation method based on an ECBN (Explicit Connectivity Bayesian Network). The method aims at the limitations that conventional vulnerability analysis is mainly centralized at a component level and system failure probability reasoning is developed with little consideration to a probabilistic dependency relationship among components. The invention considers a combined effect of various component damages by the ECBN, discloses a root node prior probability evaluation model based on a multi-dimensional performance limit state equation, and strives to really reflect a component damage state and improve evaluation accuracy; the probabilistic dependency relationship among the components is considered by utilizing an analytic hierarchy process, and Bayesian network intermediate node condition probability information is constructed; and the method is particularly practical in a case of shortage of damage data, and finally, implementsreasoning from component vulnerability to structural system vulnerability by a variable elimination algorithm. Insufficient research on vulnerability evaluation of a large-sized engineering structuralsystem is made up, scientific supporting is provided for safety construction and effective operation of the important engineering structural system.

Owner:CHINA UNIV OF MINING & TECH

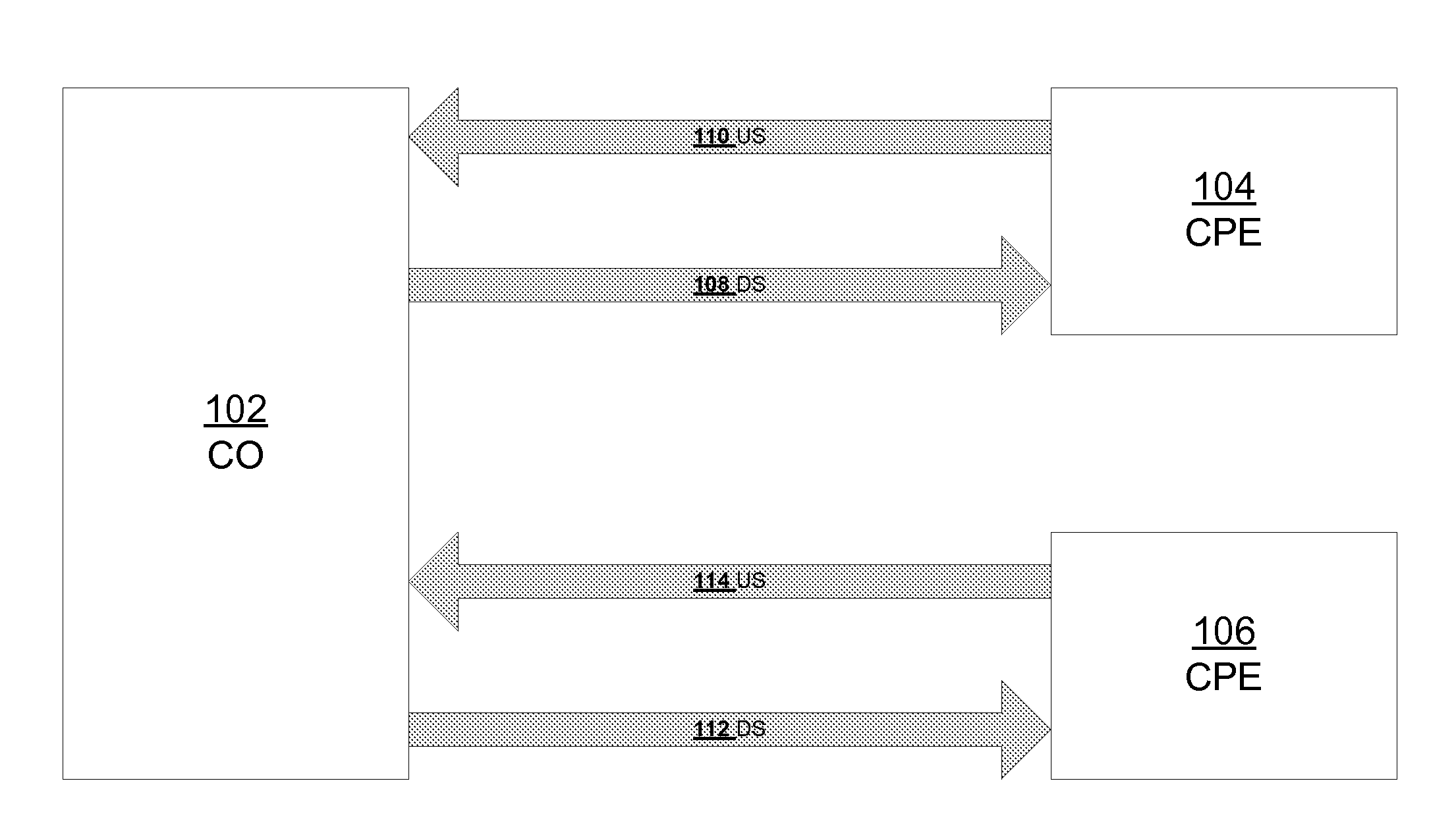

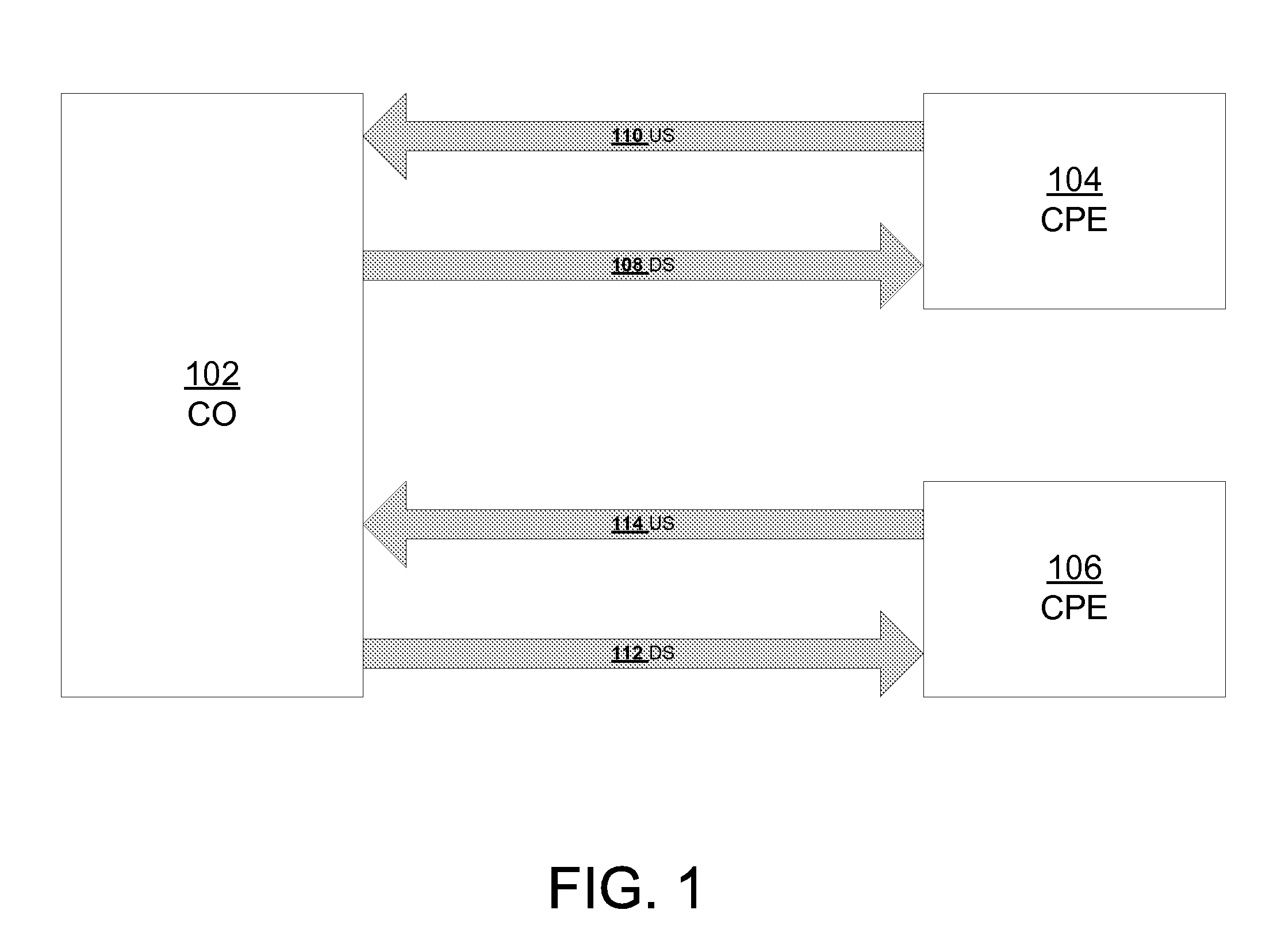

Crosstalk Recognition in Presence of Radio Frequency Interference

InactiveUS20080267392A1Remove background noiseInterconnection arrangementsSubstations coupling interface circuitsProximal pointNoise level

Crosstalk interference induced by the adjacent pairs is one of the major performance limiting factors of DSL systems. As there is a rapid increase in the deployment of DSL services worldwide, the need to provide information about noise related parameters to the operators and the service providers is of utmost importance. Satisfying such a need enables operators to anticipate the line capacity and understand the noise level characteristics of the loop environment. Specifically, crosstalk and more particularly upstream near end crosstalk (NEXT) in the presence of narrowband interference can be classified to isolate the particular service type causing the upstream NEXT. The identification of the service type of the upstream NEXT would enable operators to address the disturber.

Owner:IKANOS COMMUNICATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com