Lead powder and nitrogen gas closed-cycle static-pressure dense-phase sectional boosting pneumatic conveying system

A pneumatic conveying system and closed-loop technology, which is applied to conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of large lead powder conveying system equipment, serious injury to equipment maintenance personnel, and high equipment failure rate, reducing mechanical The effect of equipment maintenance, reduction of the number of mechanical equipment, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

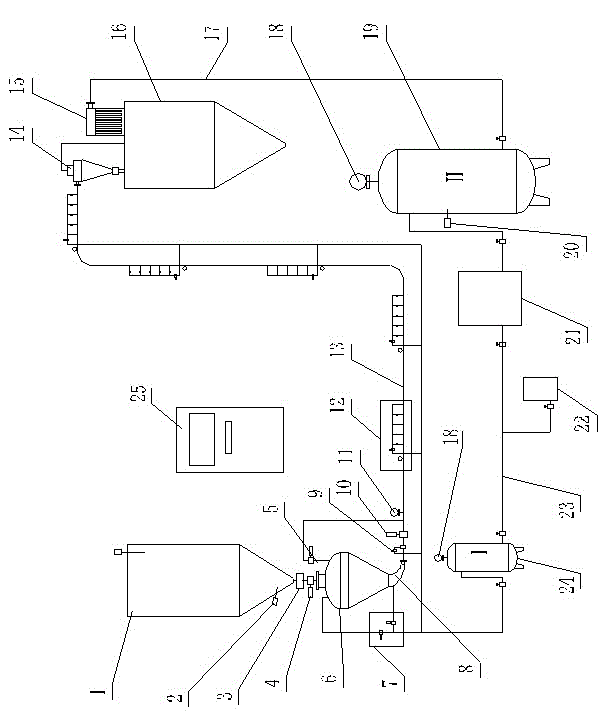

[0016] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0017] Such as figure 1 As shown, a lead powder nitrogen closed cycle static pressure dense phase sub-stage boosting pneumatic conveying system includes a lead powder storage bin 1, a lead powder unloading device 3, a pneumatic feed valve 4, and a delivery bin pump 6 connected in sequence , lead powder conveying main air source valve group 7, discharge fluidization device 8, storage pump discharge outlet booster device 9, pneumatic discharge valve 10, pressure sensor 11 in the ash conveying pipeline, segmented external pressure sensor with pressure sensor Built-in booster 12, ash conveying pipeline 13, gas-solid separation device 14, ultra-fine filter device 15, lead powder bin 16, nitrogen return pipeline 17, nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com