Hydrogen circulation compression pump

A cyclic compression, hydrogen technology, applied in pumps, pump components, rotary piston pumps, etc., can solve problems such as unfavorable compression, loss of compression performance and service life of circulating compression pumps, and achieve the effect of improving quality and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A hydrogen circulating compression pump provided by the present invention will be further described in detail and completely below in conjunction with the embodiments. The embodiments described below are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

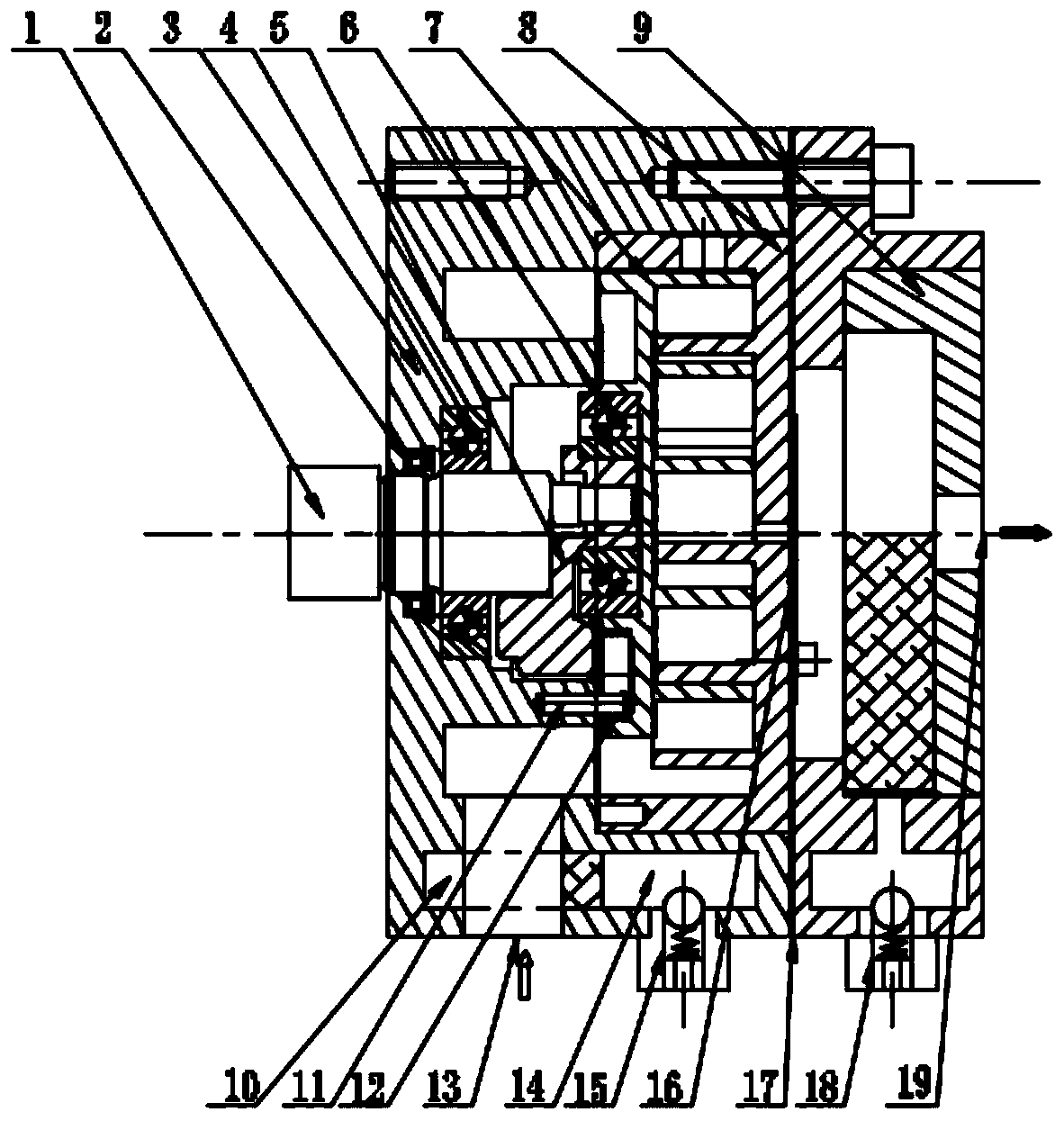

[0018] A hydrogen circulation compressor pump, such as figure 1 As shown, it includes a housing 3 and a drive shaft 1 installed on the housing 3, a movable scroll 7 and a fixed scroll 8, the drive shaft 1 is connected and drives the movable scroll 7 to rotate relative to the fixed scroll 8, A working chamber whose volume gradually changes is formed. Both the movable scroll 7 and the fixed scroll 8 are scroll-shaped, specifically, the movable scroll 7 is an involute moving scroll that eccentrically revolves and translates, and the fixed scroll 8 is a fixed involute scroll. The open scroll, the orbiting scroll 7 and the fixed scroll 8 cooperate to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com