Patents

Literature

117results about How to "Good superelasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

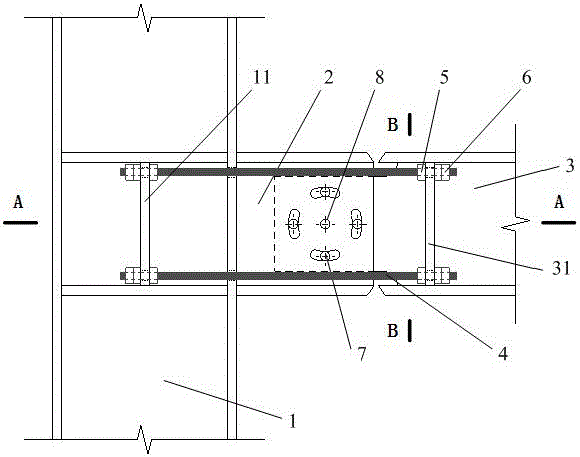

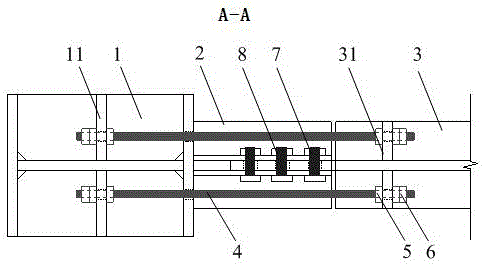

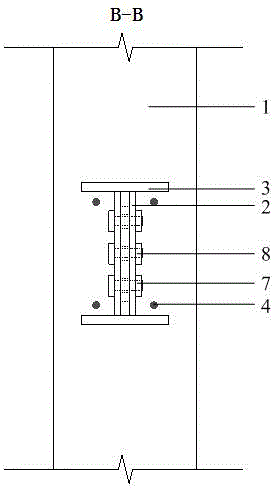

Shape memory alloy web friction self-reset steel frame joint

The invention relates to a shape memory alloy web friction self-reset steel frame joint.The joint is composed of a column, a bracket, beams, shape memory alloy stay rope units, tensioning nuts, fixing nuts, arc hole high-strength bolts and central high-strength bolts.The bracket is welded to the side, close to the beams, of the column, a double-web mode is adopted for the bracket, and the bracket is connected with beam webs through the high-strength bolts.Arc holes are formed in the parts, at the arc hole high-strength bolts, of double webs of the bracket, the contact faces of the beam webs and the double webs of the bracket are subjected to friction treatment, friction parameters are adjusted with prestress of the high-strength bolts, the upper portions and the lower portions of the beams are connected with the column through the shape memory alloy stay rope units respectively, and the initial states of shape memory alloy stay ropes are controlled by adjusting the tensioning nuts and the fixing nuts.The shape memory alloy web friction self-reset steel frame joint has the advantages of being simple in structure, high in practicability, definite in stress, high in energy dissipation, capable of achieving self-resetting and the like.

Owner:SUZHOU UNIV OF SCI & TECH

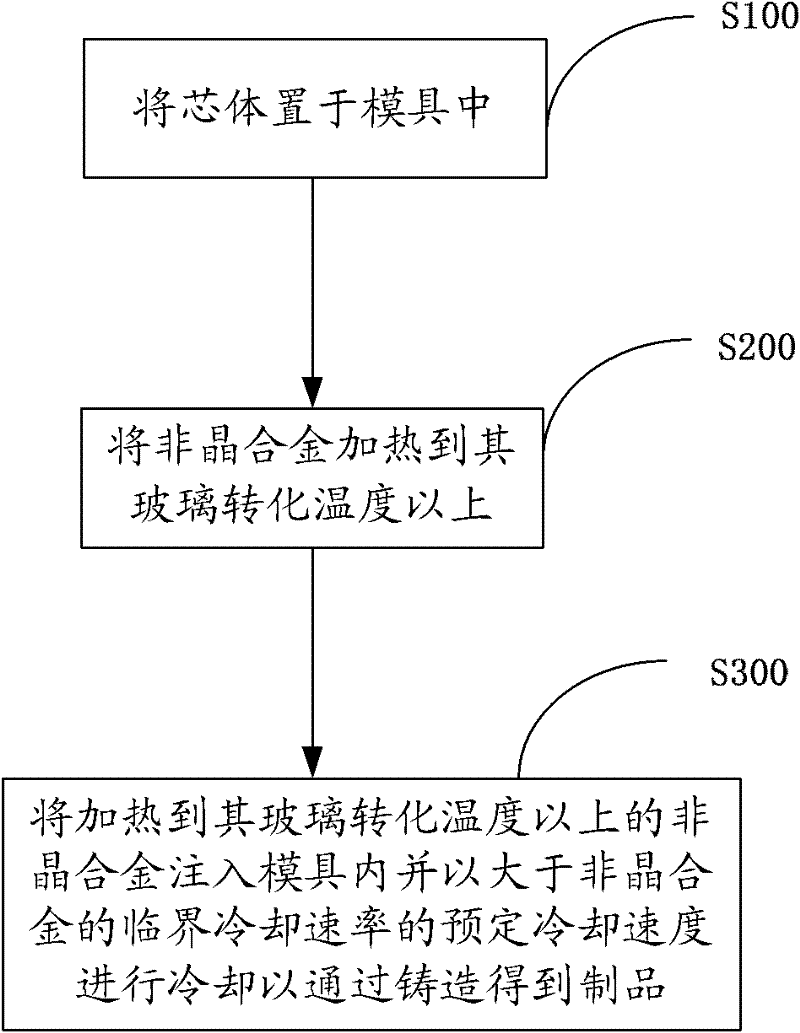

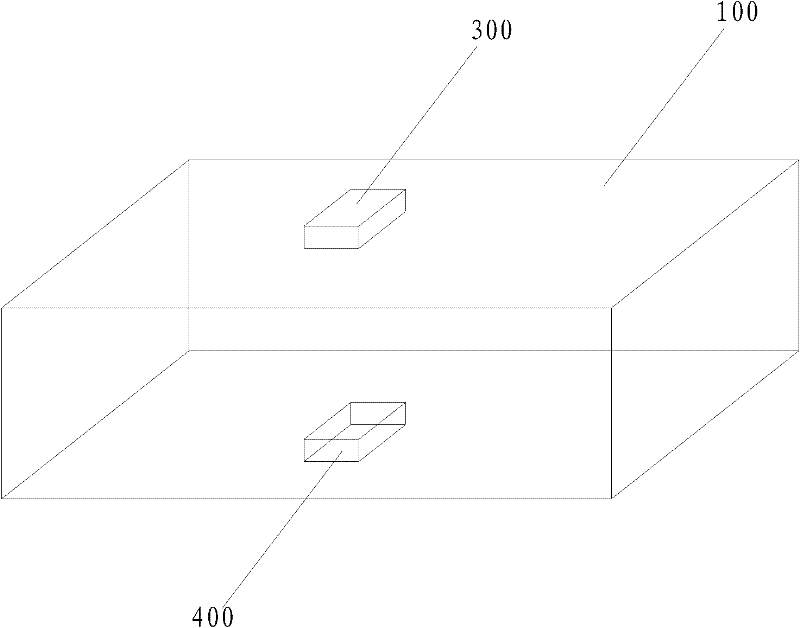

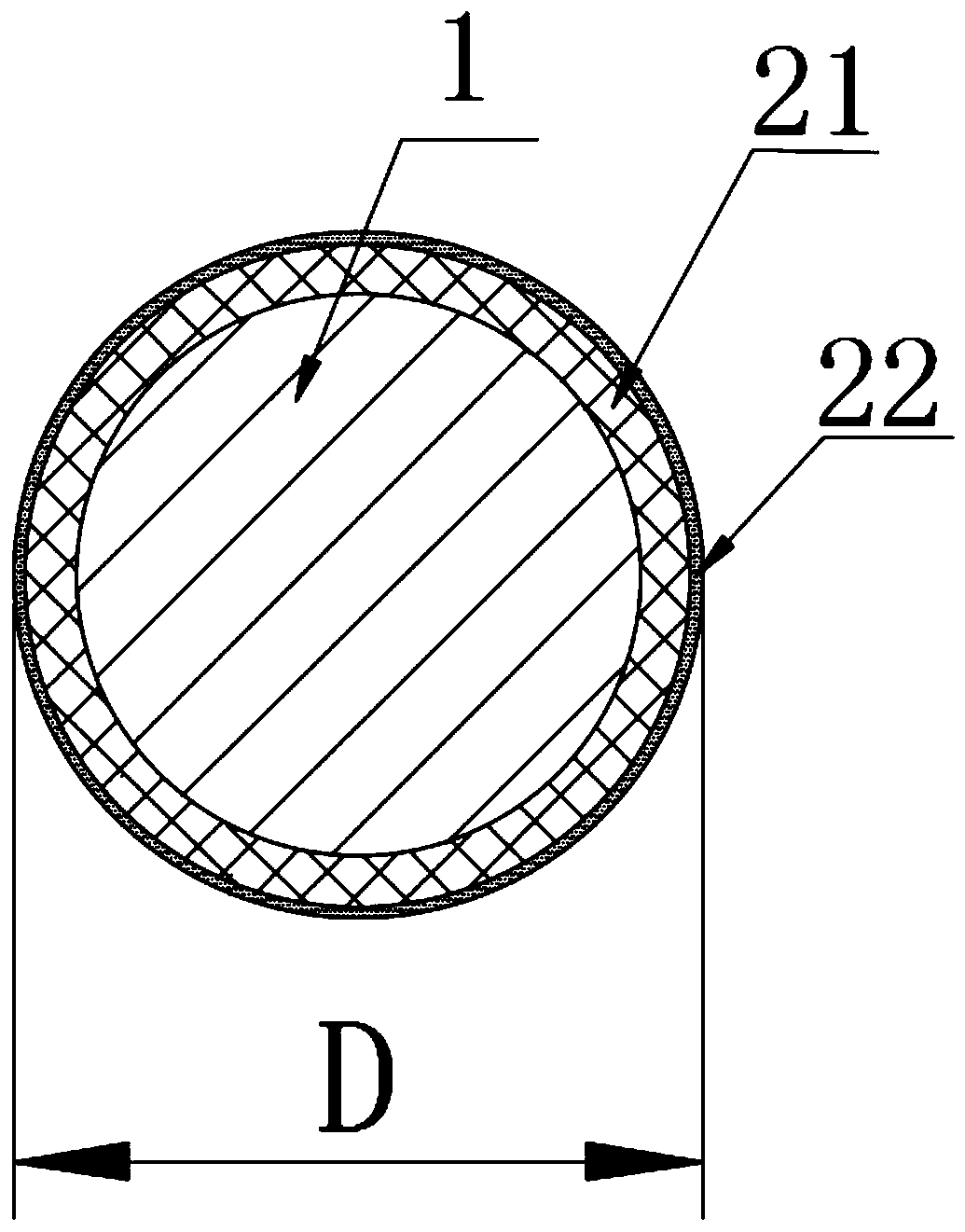

Product prepared from amorphous alloy and heterogeneous material and preparation method thereof

The invention provides a product prepared from amorphous alloy and heterogeneous material, and a preparation method of the product. The product prepared from amorphous alloy and heterogeneous material comprises a core body prepared from the heterogeneous material, and an outer wall, wherein the outer wall is prepared from the amorphous alloy coating the outer surface of the core body; and the critical dimension of the amorphous alloy is larger than or equal to 1mm. The product has the advantages of high yield strength, high hardness, high elasticity, high abrasion resistance, high corrosion resistance, and low manufacture cost, thereby improving the applicability of the amorphous alloy.

Owner:BYD CO LTD

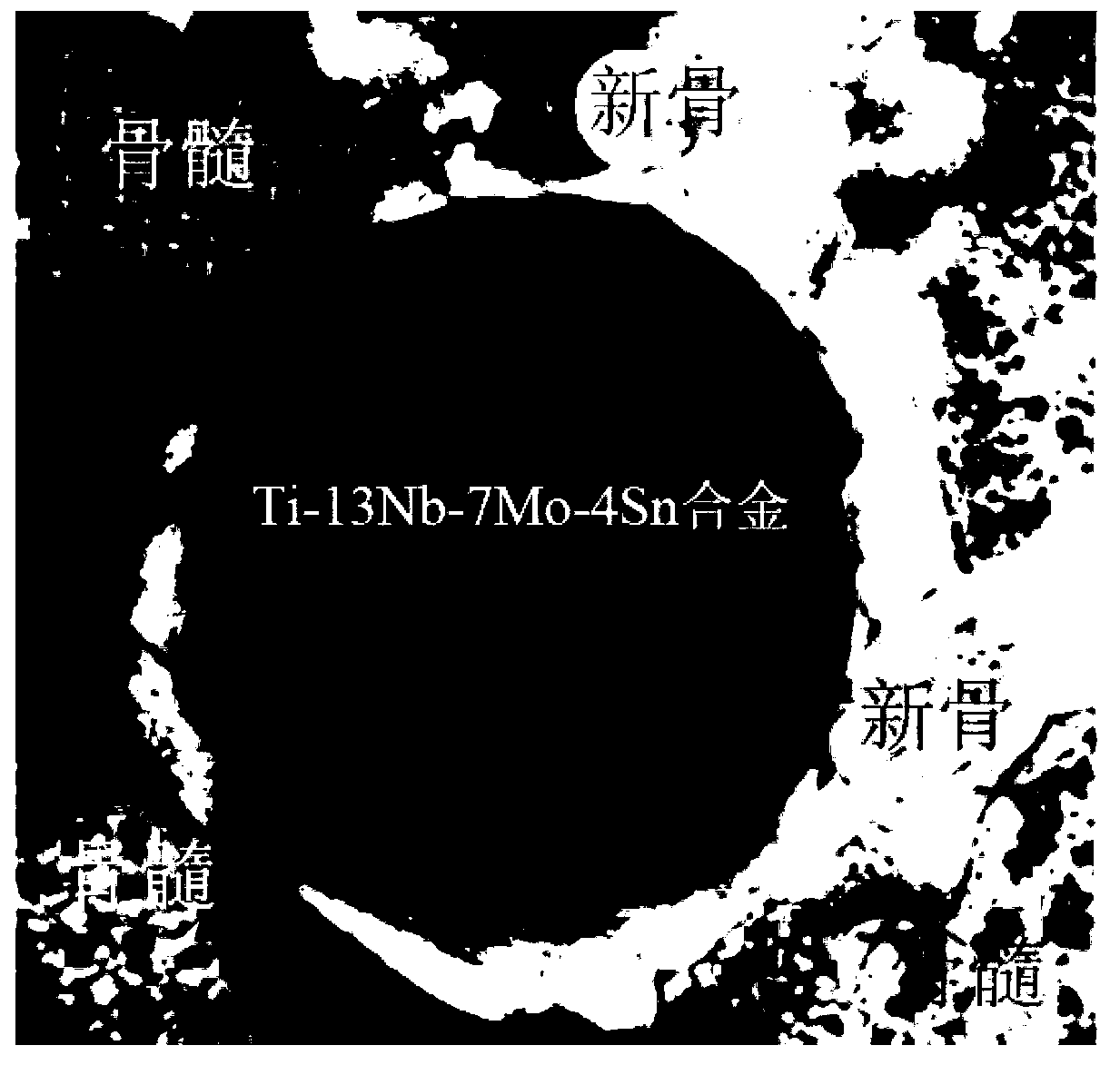

Preparation method of high-strength nanocrystalline type medical Beta titanium alloy for orthopaedic implanting

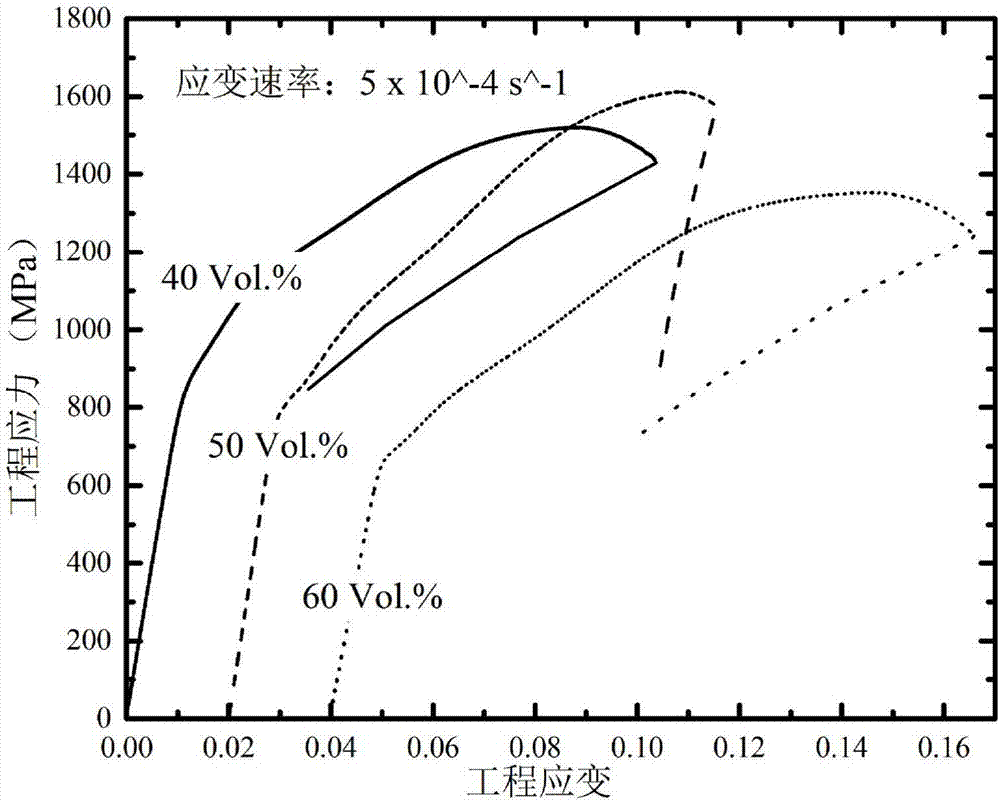

The invention discloses a preparation method of a high high-strength nanocrystalline type medical Beta titanium alloy for orthopaedic implanting. The titanium alloy is the Ti-Nb-Mo-Sn alloy prepared by the following steps in sequence: treating the alloy ingredients in a vacuum arc melting furnace, and sequentially carrying out the processes of quickly solidifying, rolling at a low temperature and instantaneously ageing at a high temperature, thus obtaining the large-dimension nanocrystalline type titanium alloy. The alloy has the average crystalline dimension less than 60 nanometers, and has strength of 1200 to 1600MPa, plasticity of 15 to 20%, elasticity modulus of 40 to 60 GPa, and super-elasticity recovery strain of 4 to 5%. According to the preparation method, the treatment processes of quick solidifying, low-temperature rolling and instantaneous ageing are creatively combined to treat the titanium alloy, thus, the purpose of unifying high strength, excellent processing performance, low elasticity modulus and excellent super-elasticity performance is realized, and high technological effect and huge potential economic value are brought.

Owner:XIANGTAN UNIV

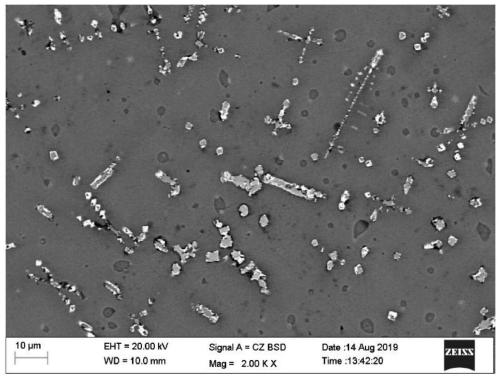

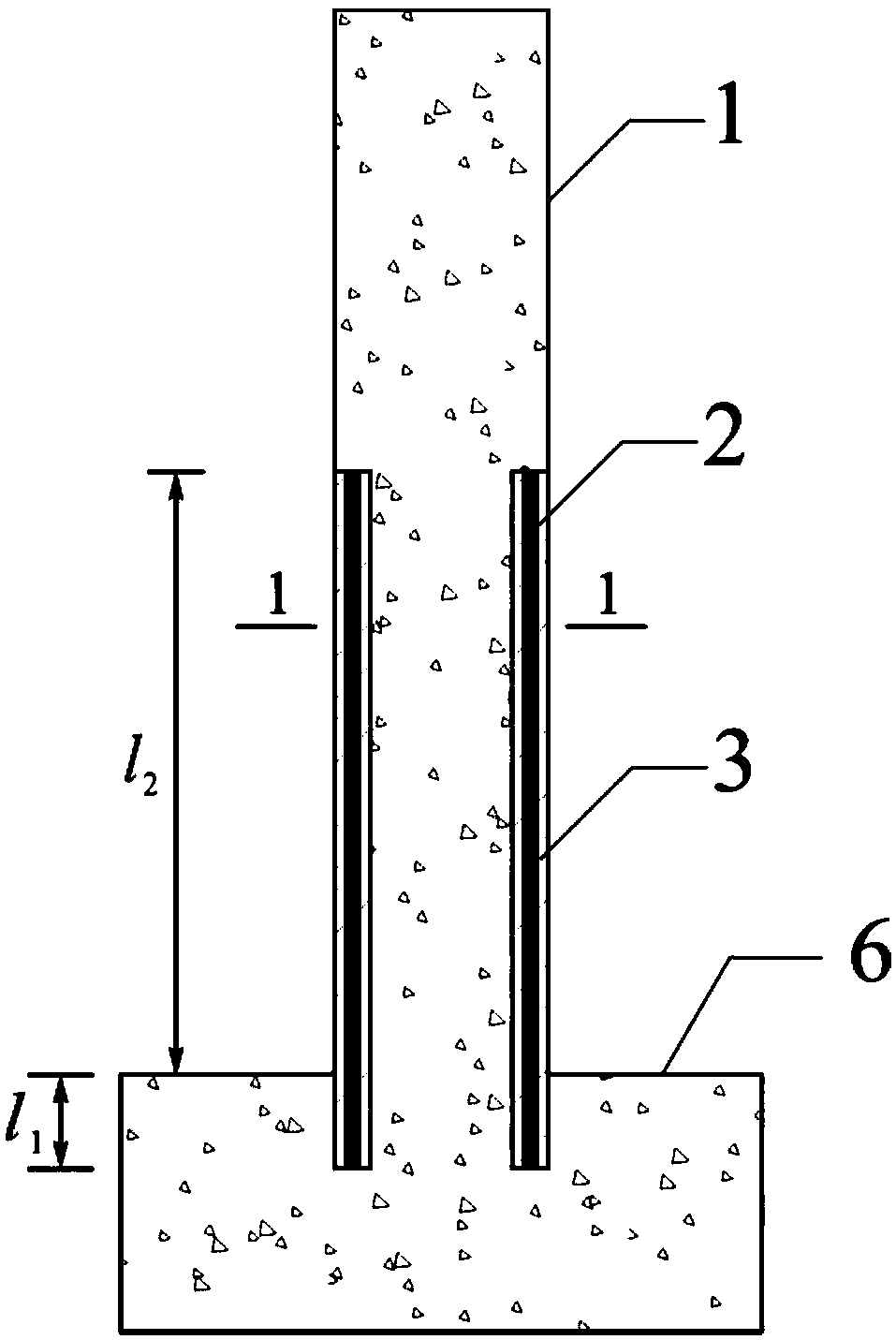

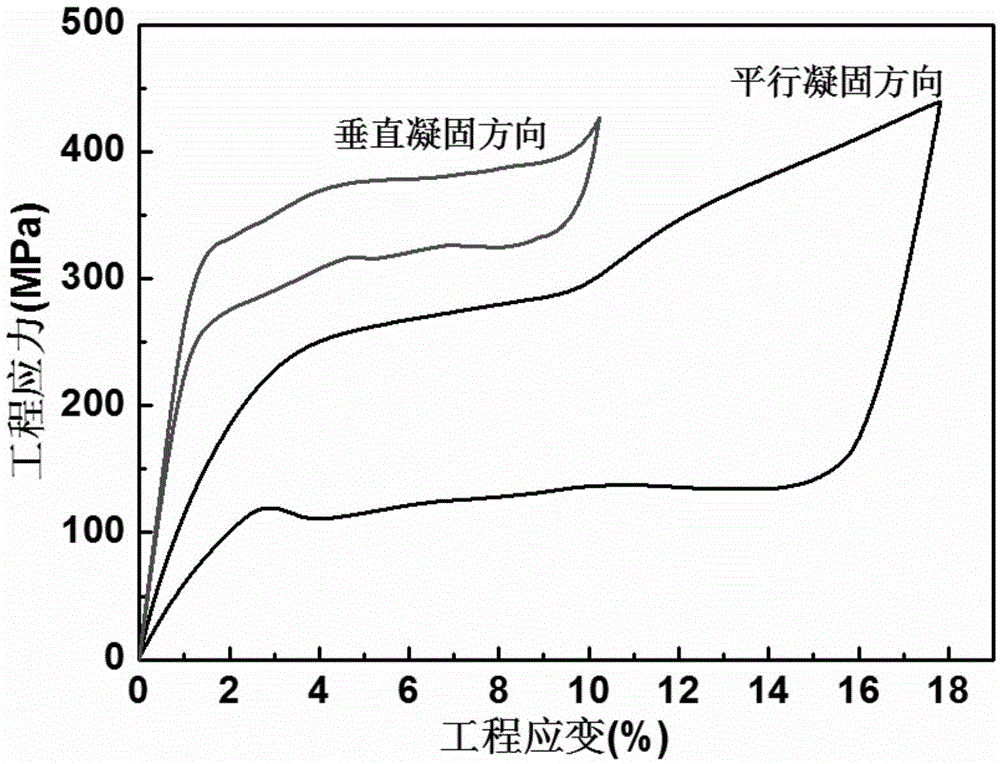

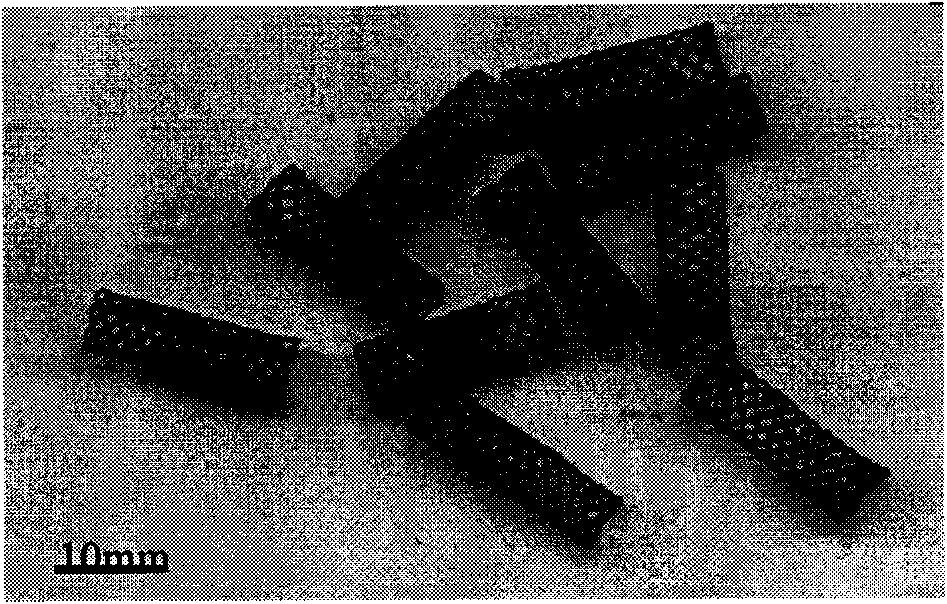

Cu-Al-Mn shape memory alloy damping and energy-absorbing device for civil construction and manufacturing method thereof

ActiveCN104863284ALow priceStrong energy absorption capacityShock proofingEnergy absorbingSteel plates

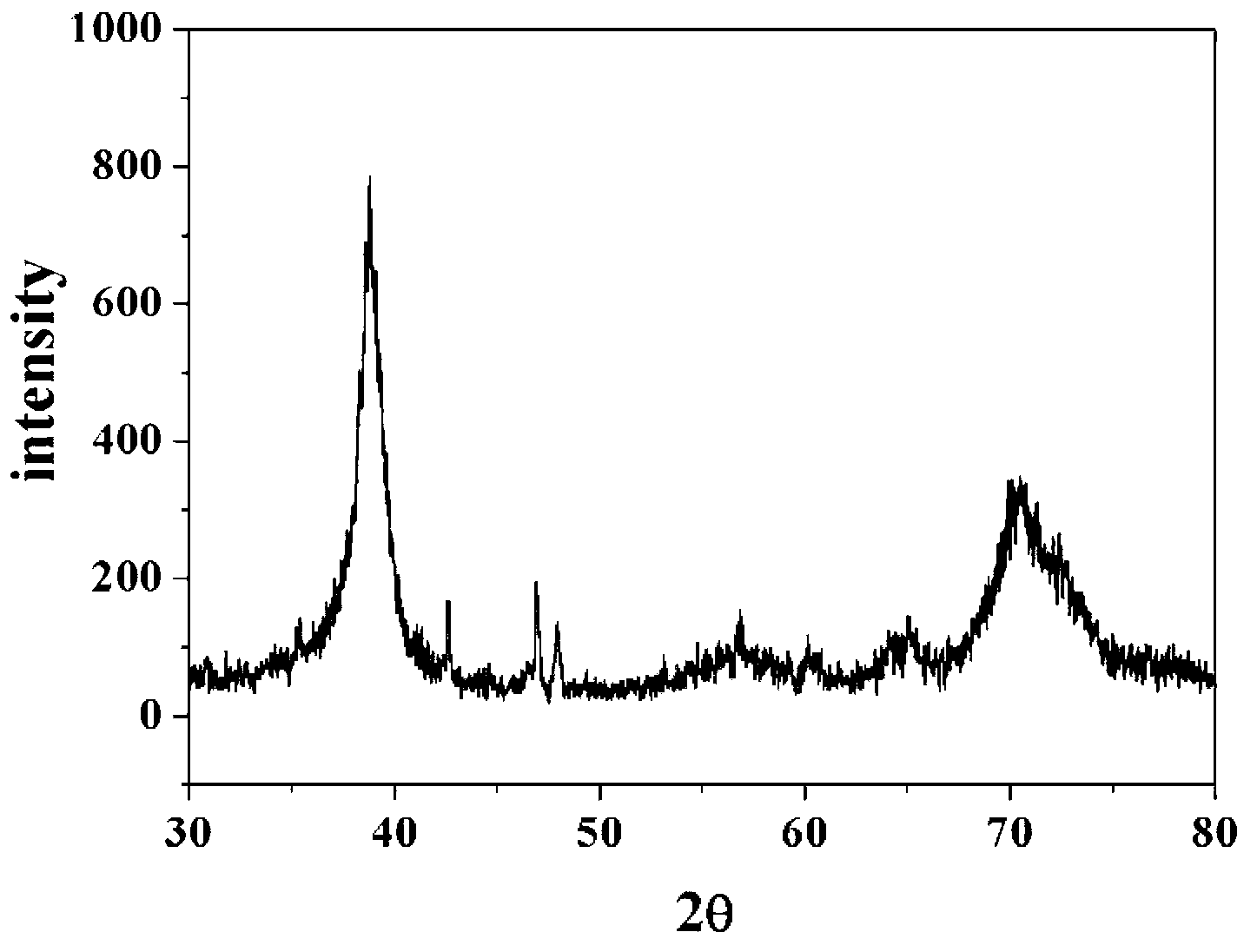

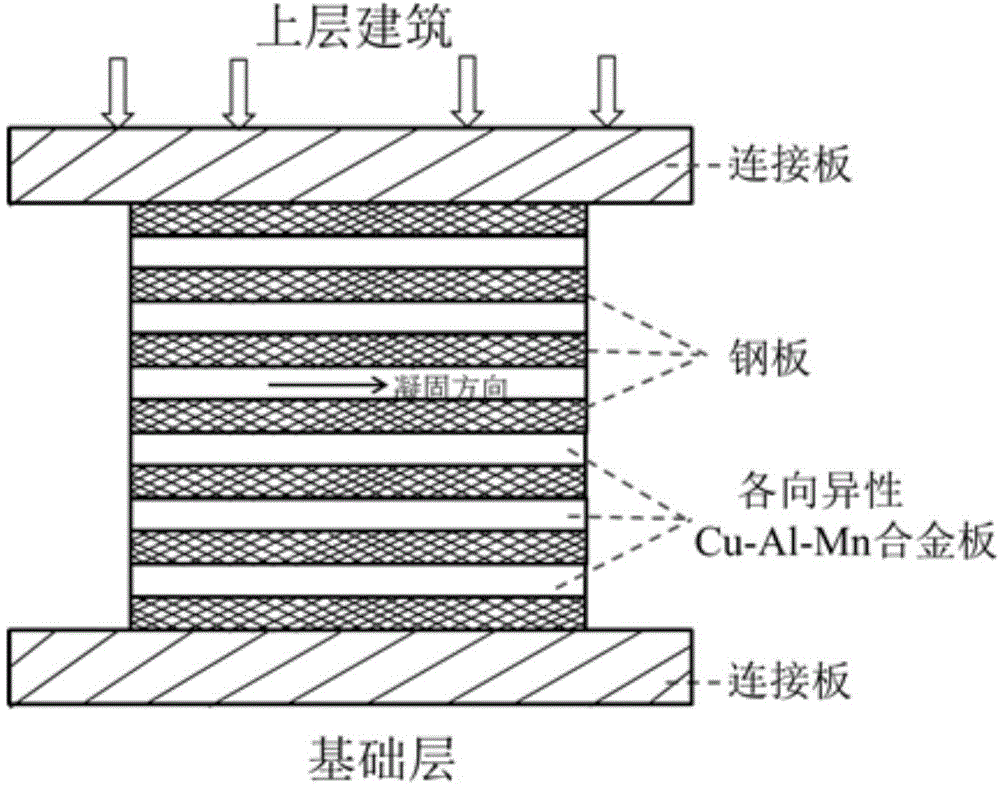

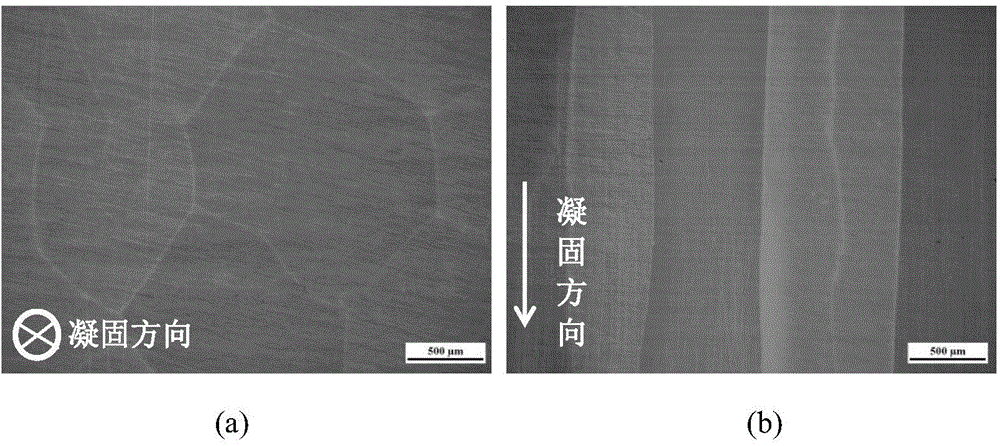

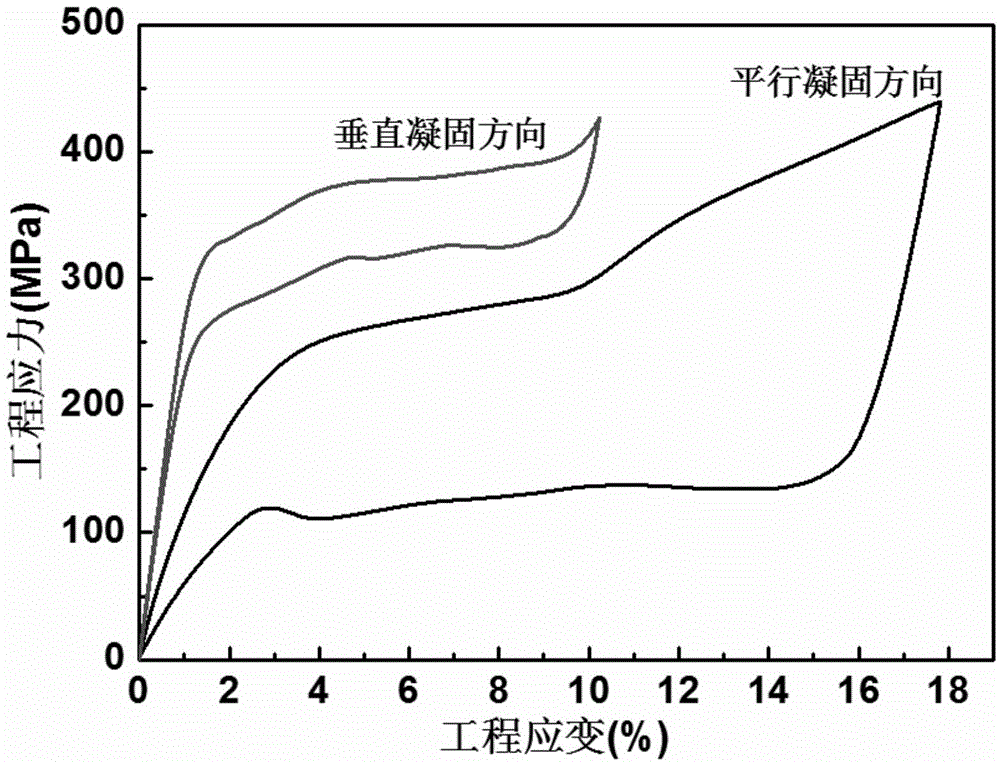

The invention provides a Cu-Al-Mn shape memory alloy damping and energy-absorbing device for civil construction and a manufacturing method thereof. The damping and energy-absorbing device comprises a connecting assembly, a damping and energy-absorbing assembly and an auxiliary assembly. The damping and energy-absorbing assembly is made of strongly anisotropic columnar crystal microstructure Cu-Al-Mn shape memory alloy plates. The auxiliary assembly is steel plates. The shape memory alloy plates and the steel plates are stacked alternately with the solidification direction of columnar crystals being parallel to the horizontal direction, so that the damping and energy-absorbing device is manufactured. The damping and energy-absorbing device is installed in a base of a building. The shape memory alloy plates are manufactured in a directional solidification method. The damping and energy-absorbing device has the advantages that the functional anisotropy is achieved; it means that over 10% of high recoverable strain can be provided in the horizontal direction, the building is allowed to swing horizontally at a great amplitude relative to a foundation under the conditions of an earthquake and the like, and therefore the horizontal shake energy is absorbed; over 7% of high recoverable strain is provided in the vertical direction, the functions of absorbing energy and reducing shock in the vertical direction are achieved, and the damping and energy-absorbing device has a higher bearing capacity.

Owner:UNIV OF SCI & TECH BEIJING

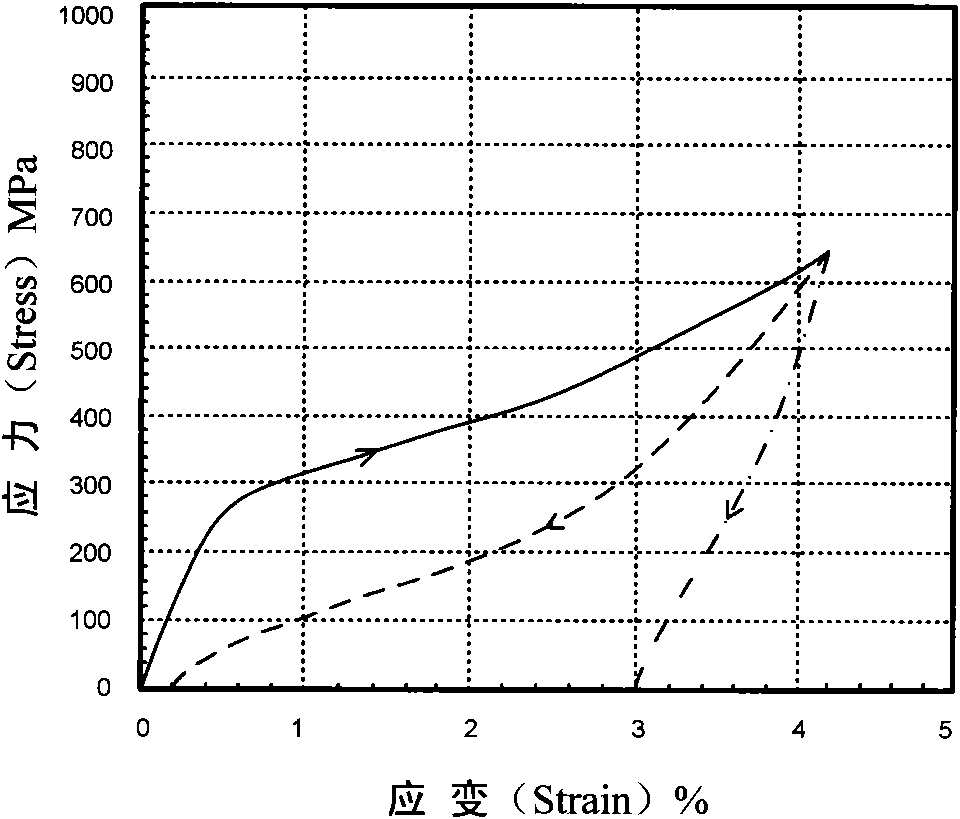

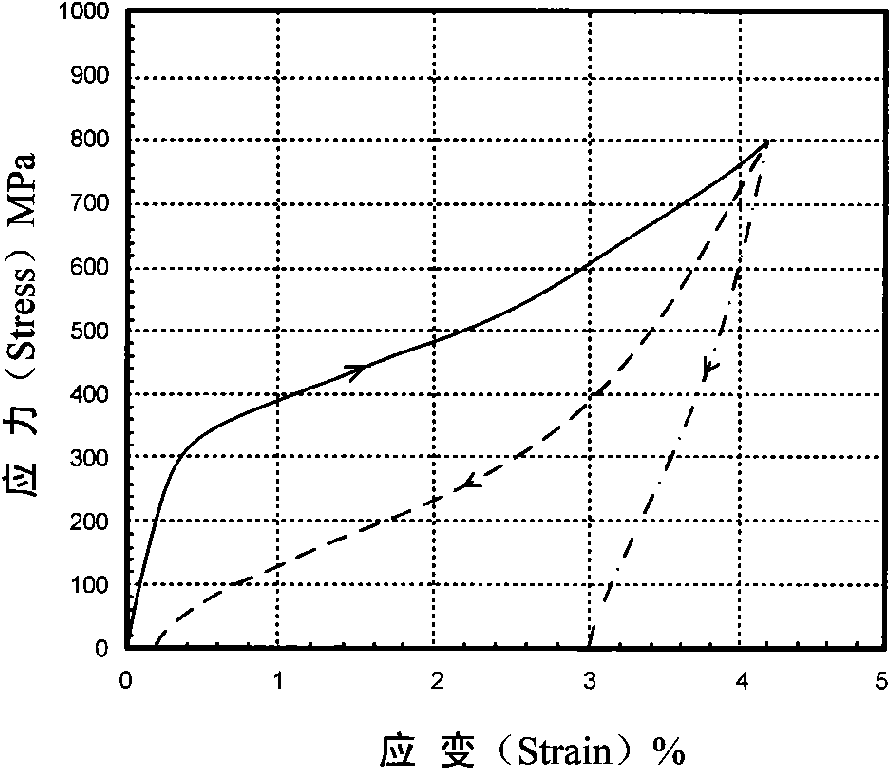

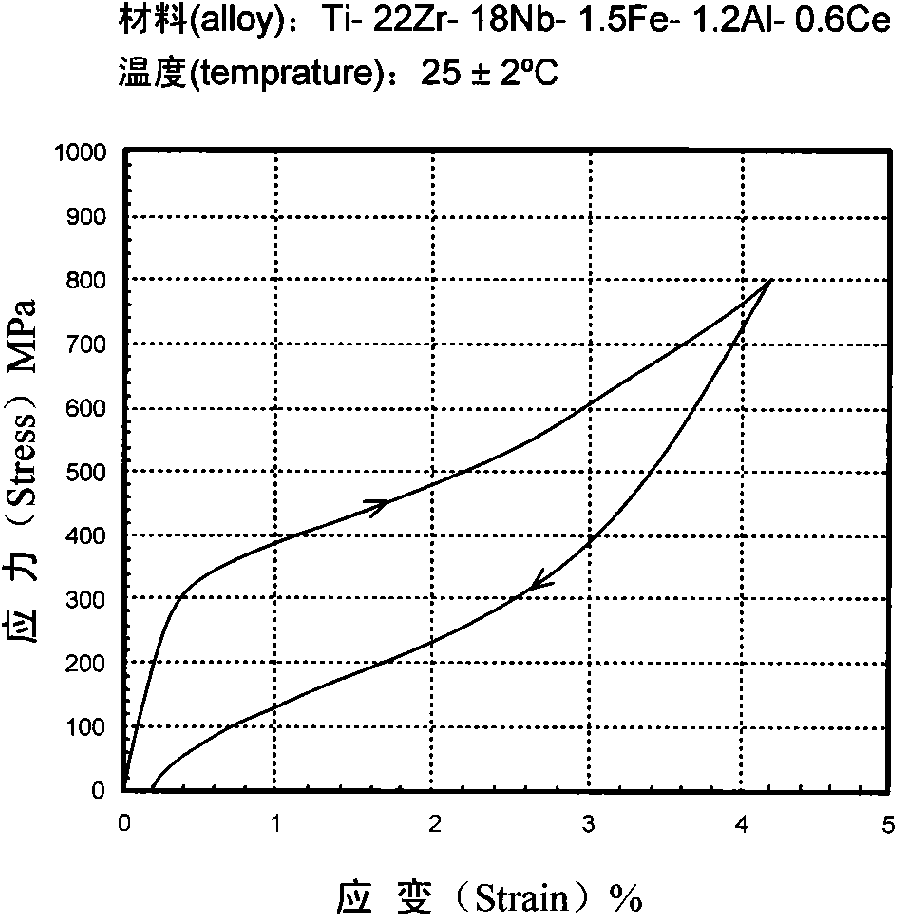

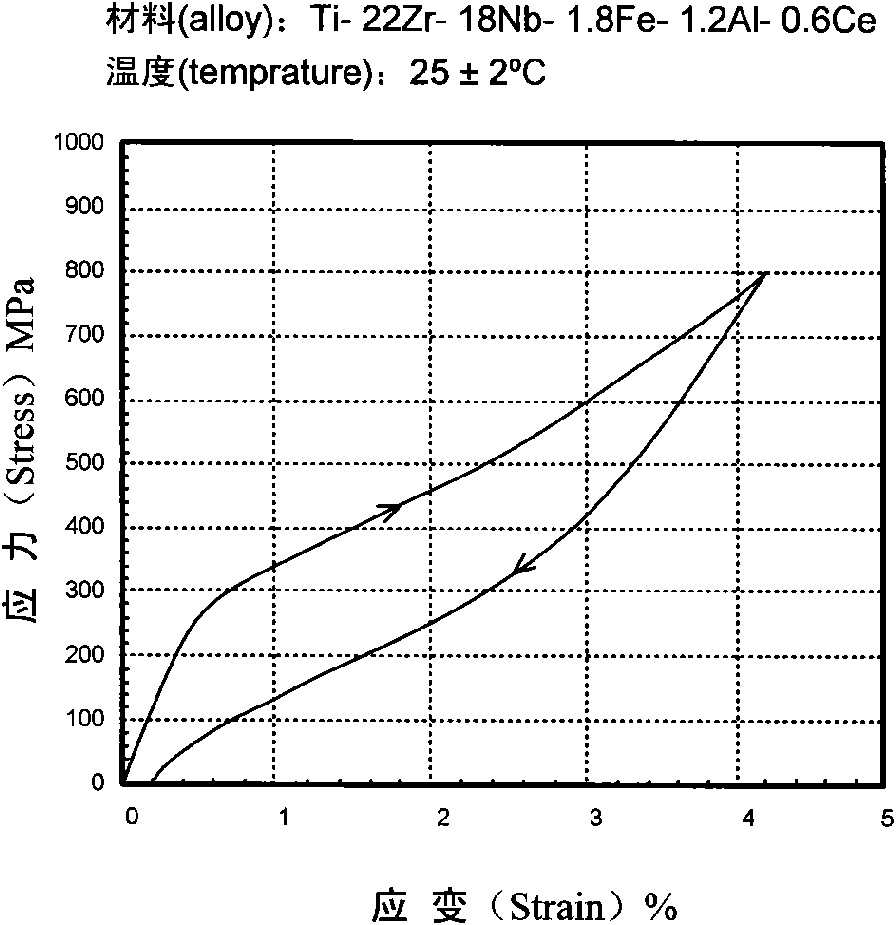

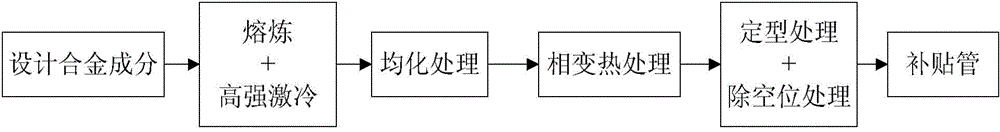

Ni-free super elastic Ti-based shape memory alloy and products thereof

InactiveCN101580907AImprove corrosion resistanceImprove high temperature oxidation resistanceImpression capsSurgeryDriven elementBiocompatibility Testing

The invention relates to a Ni-free super elastic Ti-based shape memory alloy and products thereof. Because of adding rare earths metal element Ce, the Ti-Zr-Nb-Fe-Al-Ce Ni-free super elastic Ti-based shape memory alloy has high erosion resistance and oxidation resistance as well as excellent welding performance, cold workability, phase-changing super elasticity, shape memory property and biocompatibility. The welding performance, the cold workability and the biocompatibility of the alloy are better than those of TiNi shape memory alloy, while the super elasticity and the shape memory property are equivalent to those of the TiNi shape memory alloy. The Ti-Zr-Nb-Fe-Al-Ce Ni-free super elastic Ti-based shape memory alloy not only can be used as biomaterial capable of being implanted in a human body for a long time, but also can be used as hyperelastic alloy manufacturing industrial products such as spectacle frame, bra support, golf club head, pipe joint, spring and drive element; moreover, the alloy has the advantages of easy processing, low cost and wide application range.

Owner:深圳市星河泉新材料有限公司

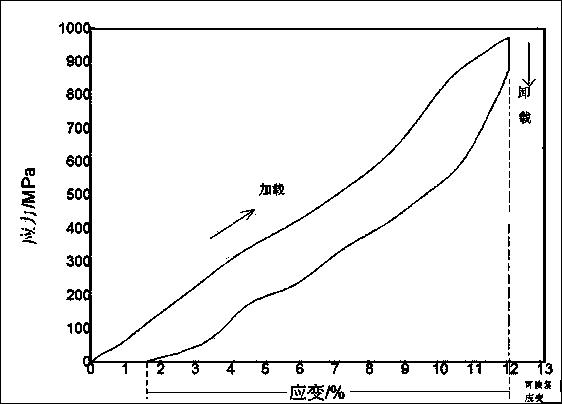

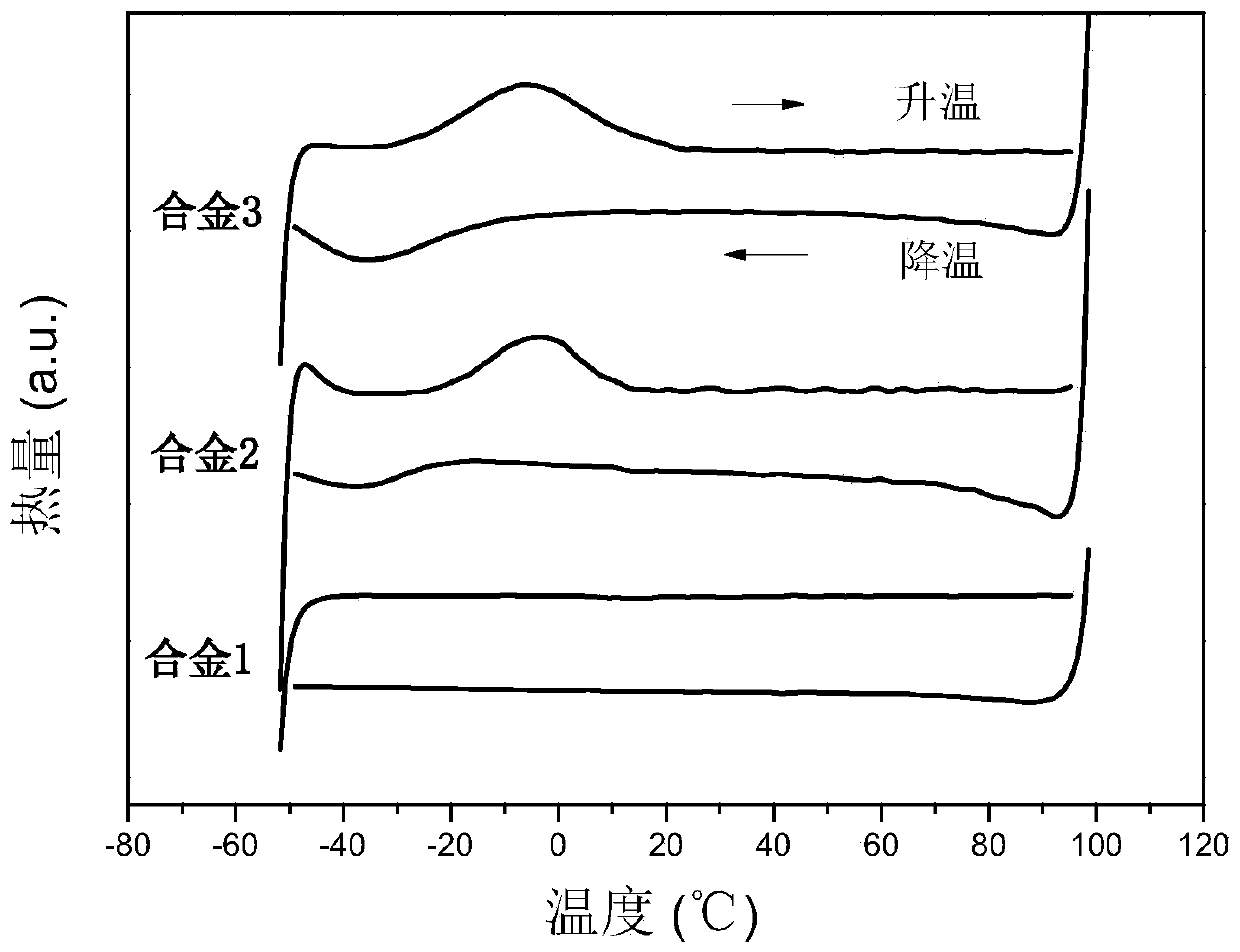

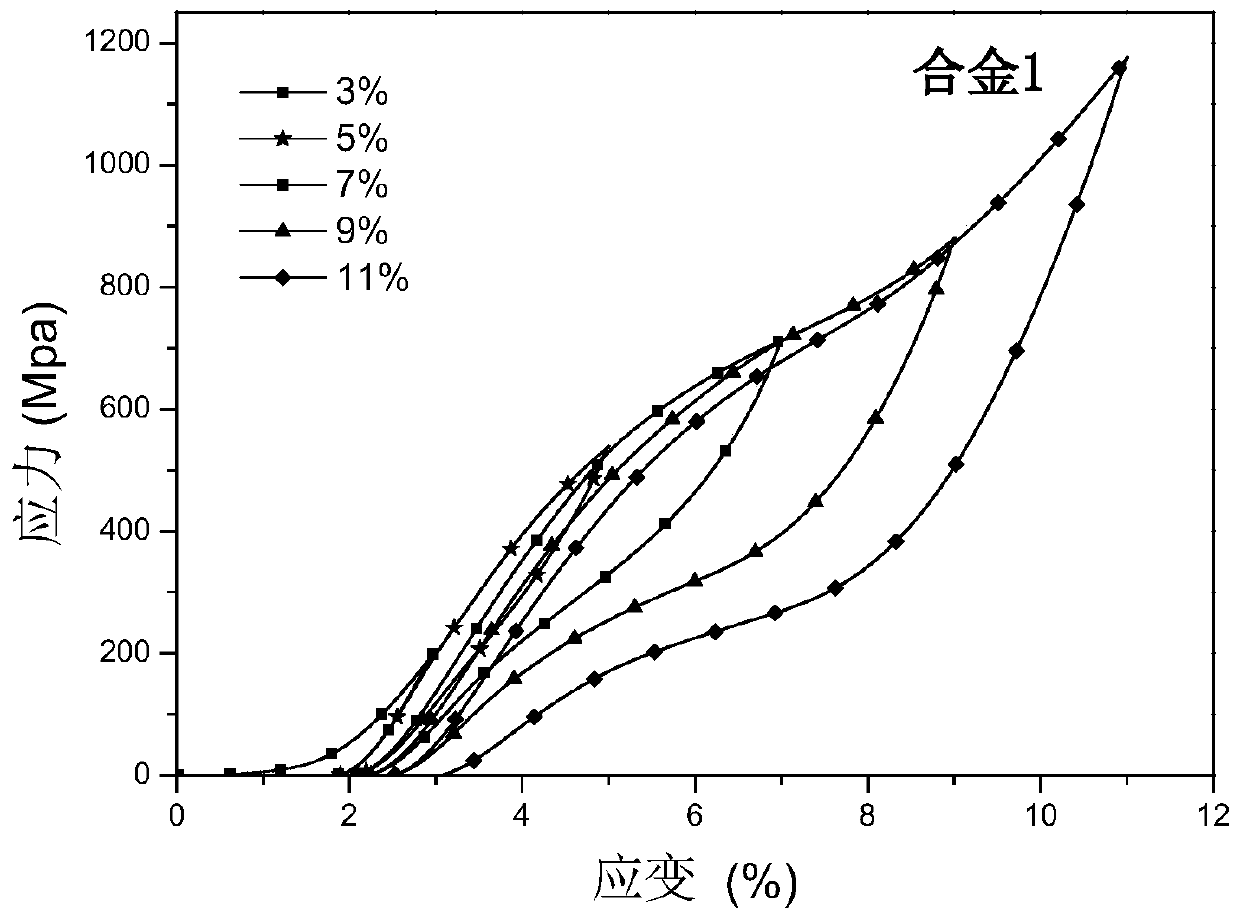

Polycrystalline Fe-Ni-Co-Al-Nb-B shape memory alloy with super elasticity and preparation method thereof

The invention relates to a polycrystalline Fe-Ni-Co-Al-Nb-B shape memory alloy with super elasticity and a preparation method thereof. The alloy comprises the following atoms: 30-50% of Fe, 28-40% of Ni, 10-30% of Co, 8-15% of Al, 1-4% of Nb and 0.1-3% of B. The preparation method of the alloy includes solid solution treatment and aging treatment. The shape memory alloy provided by the invention adopts a special alloy formula, and the preparation technology is simple and controllable. The shape memory alloy provided by the invention has significantly increased recoverable strain with the maximum recoverable strain reaching 10.5%, and shows excellent super elasticity.

Owner:NANCHANG UNIV

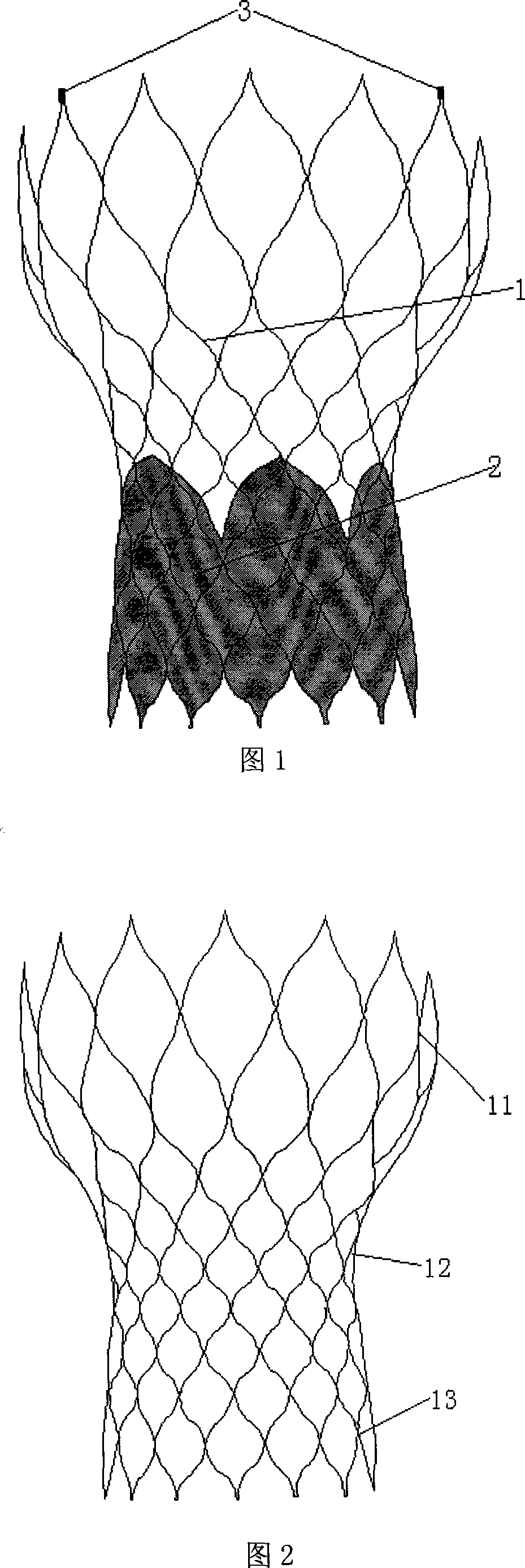

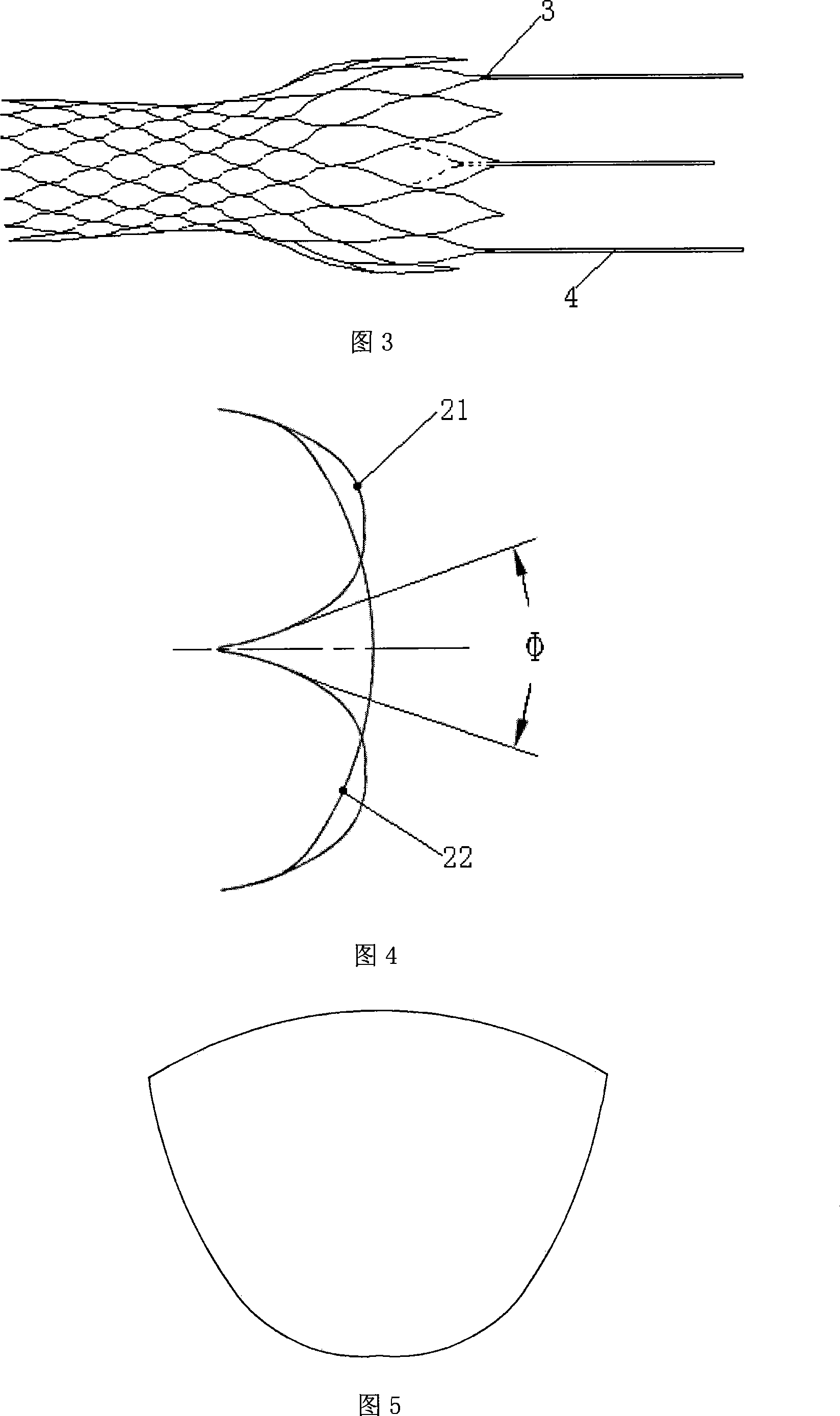

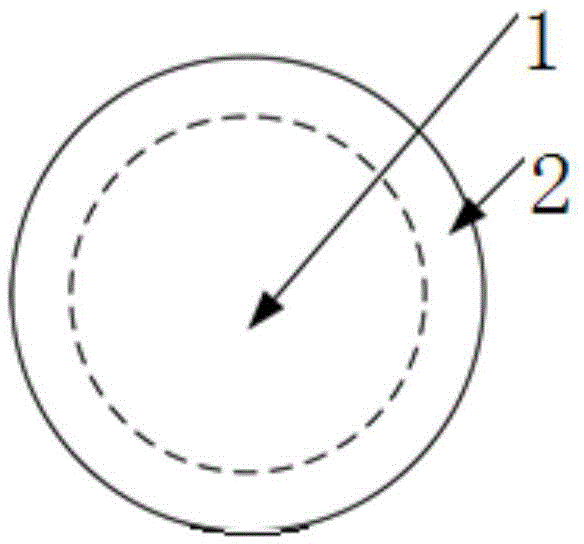

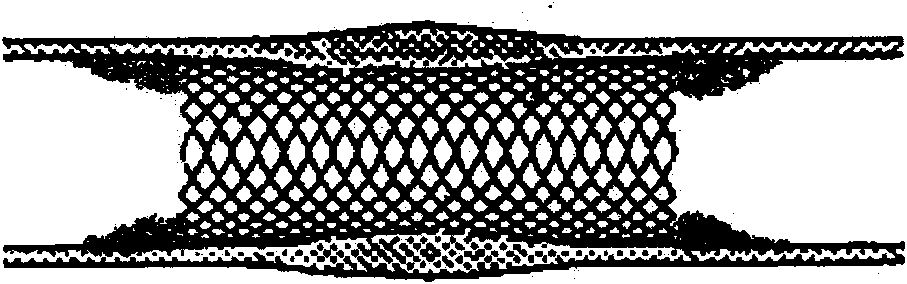

Aorta bracket with valve of recoverable and adjustable position

The invention relates to a recoverable position-adjusting aortic stent with valve, comprising a trumpet-shaped stent (1), an inner valve (2), and a control device; wherein, the trumpet-shaped stent (1) comprising a far-end big horn mouth (11), a middle waist (12) and a near-end small horn mouth (13), all carved with a hyperelastic nitimol tube into diamond mesh structure; the valve (2) is sewed between the near small horn mouth (13) and the middle waist (12). The diameter of the middle waist (12) is much smaller than the diameters of the far-end big horn mouth (11) and the near-end small horn mouth (13). The aortic stent has the advantages of convenient position adjusting, stent recovery, strong holding power, good hyperelasticity and compliance, easy compression, and is facilitated for inserting the pipe and unease to shift since the match between the stent and the root structure of the aorta, and avoids leaking around the valve.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

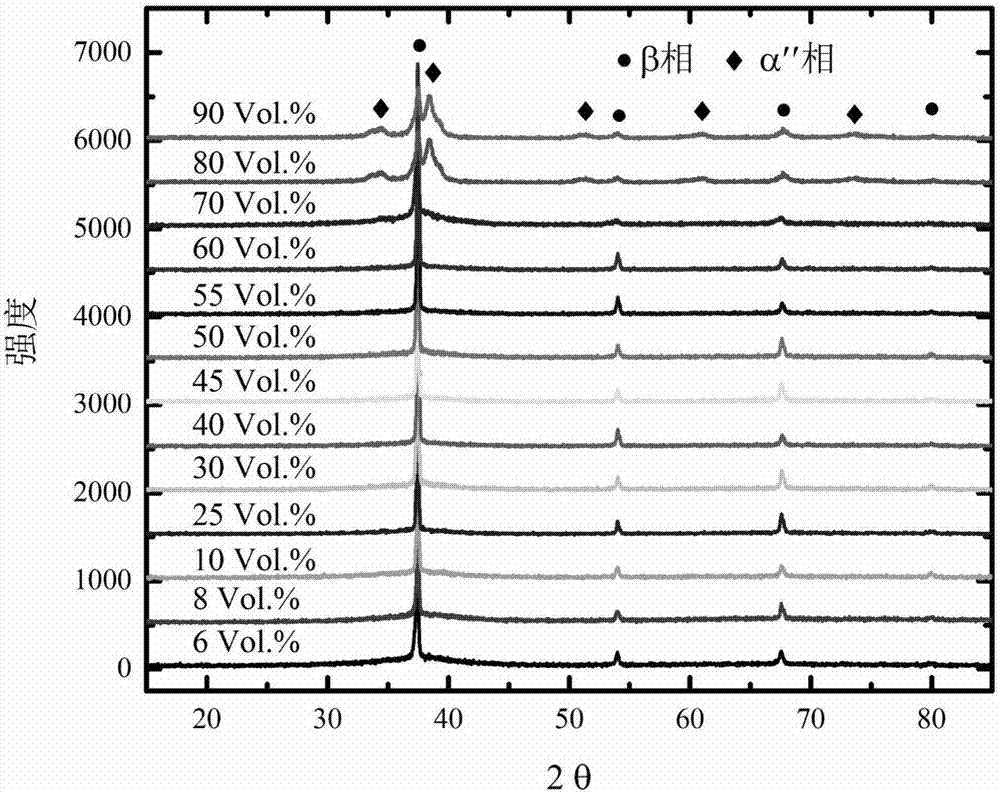

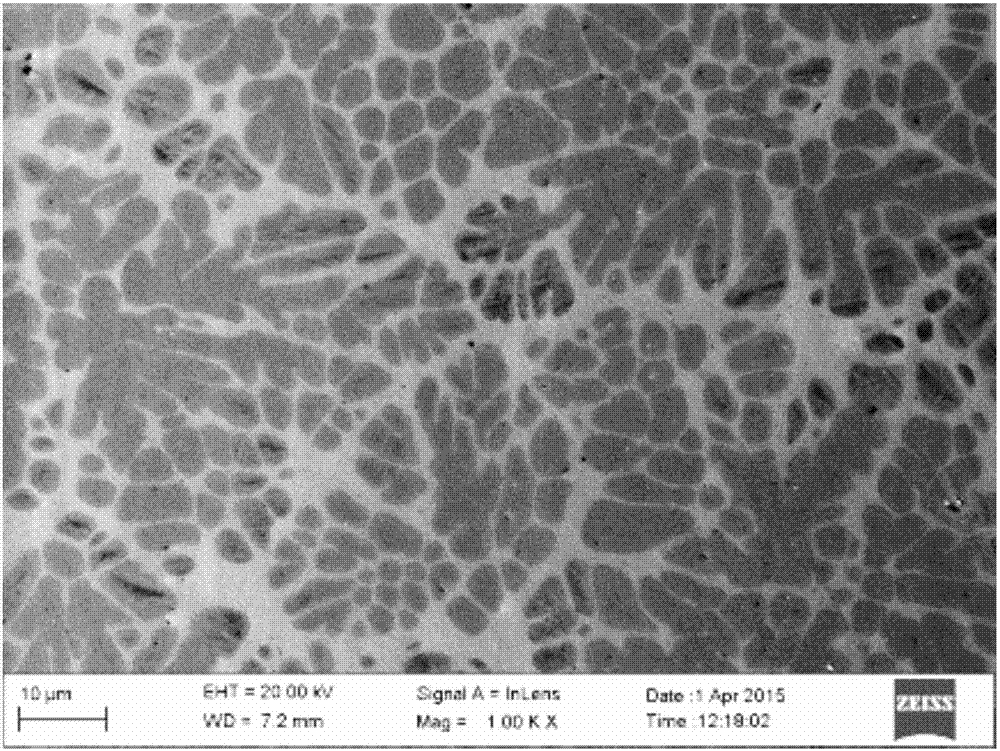

Ti-Zr-Cu-Be four-element amorphous composite with processing hardening capacity and preparation method thereof

ActiveCN107385365ASimple ingredientsImprove the ability to formMartensite transformationChemical composition

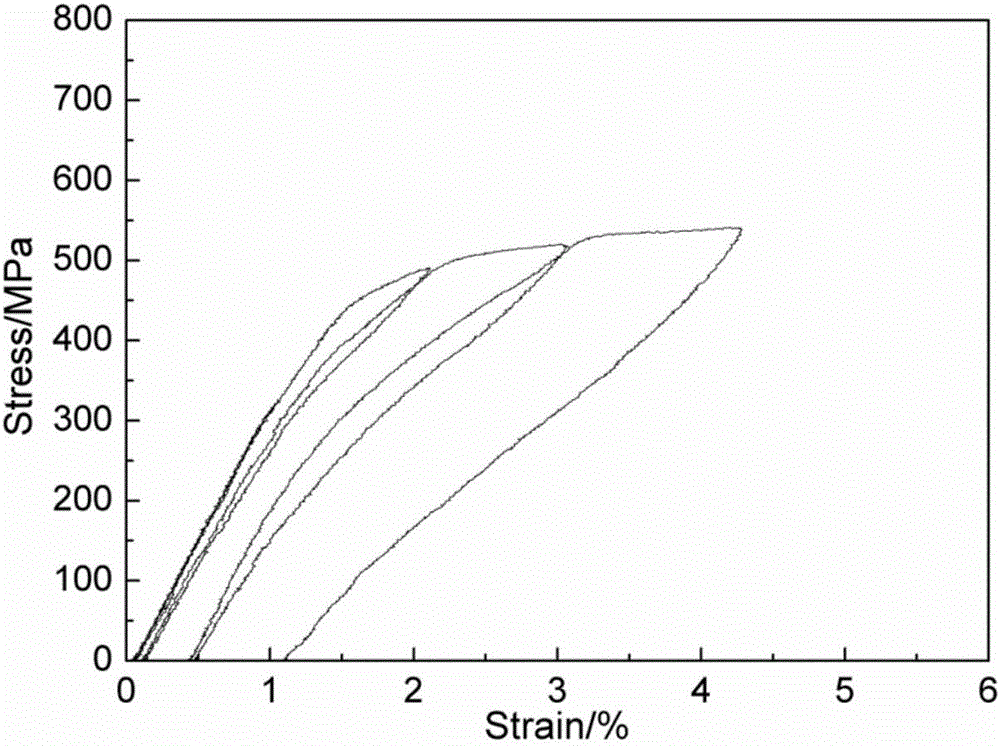

The invention discloses a Ti-Zr-Cu-Be four-element amorphous composite with the processing hardening capacity and a preparation method thereof. The composite is a type of amorphous alloy composite containing a dendritic crystal phase, wherein the dendritic crystal phase is prepared from the chemical components of 59-60 parts of Ti, 38-39 parts of Zr and 1-3 parts of Cu, the volume fraction of the dendritic crystal phase is 5-95%, and an amorphous matrix is prepared from the chemical components of 33-34 parts of Ti, 35-36 parts of Zr, 8-9 parts of Cu and 21-24 parts of Be. The dendritic crystal phase has the deformation-induced Martensite phase transformation characteristic, the composite shows excellent comprehensive mechanical properties of high strength, high plasticity, processing hardening and the like under the actions of tension and compression loads, for example, under the tension load, the processing hardening behavior is remarkable, the plastic deformation capacity is 6-15%, and the strength is 1100-1900 MPa. Meanwhile, by means of Martensite phase transformation, the composite has the super-elastic characteristic under the tension load through cyclic loading, for example, elastic deformation can be 2.7-3%. As for the composite, the chemical composition is simple, the chemical components of the second phase are relatively stable, and structural design and controllable preparation of the composite are facilitated.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Low-modulus medical titanium alloy and preparation method thereof

The invention discloses low-modulus medical titanium alloy comprising Nb with the molar concentration of 10-25%, Cr with the molar concentration of 1-8%, Sn with the molar concentration of 0-2% and the balance Ti. The invention further provides a preparation method of the low-modulus medical titanium alloy. The method includes the steps that under the argon protection atmosphere condition, a cast ingot is subjected to homogenizing annealing; solution treatment is conducted under the vacuum condition, and then the cast ingot is placed in water for quenching; cold machining forming is conducted at room temperature; a sample obtained after cold machining forming is re-crystallized and annealed under the vacuum condition, wherein re-crystallization and annealing temperature is 700-900 DEG C, time lasts for 0.5-2 h and a cooling mode is water quenching or ice water quenching; the low-modulus medical titanium alloy is obtained. The titanium alloy has good cold machining performance, and is high in strength, low in Young modulus, good in corrosion resistance and biocompatibility and suitable for the medical fields like bone implantation.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Iron-based alloy having shape memory properties and superelasticity and its production method

ActiveUS8083990B2Maintain good propertiesGood superelasticityMagnetic materialsHeat treatment process controlMartensite transformationCrystal orientation

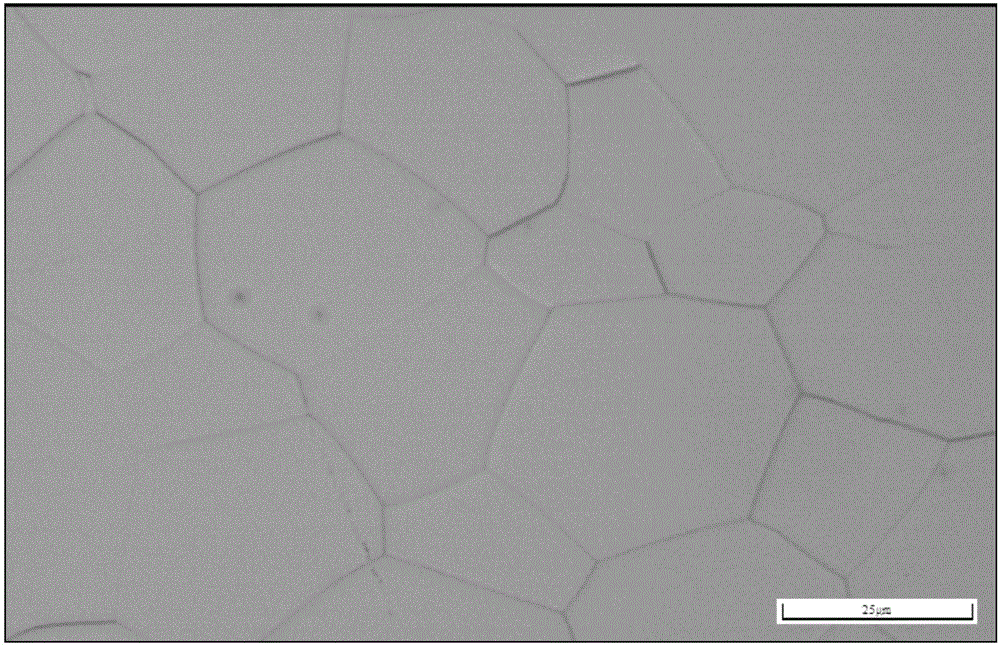

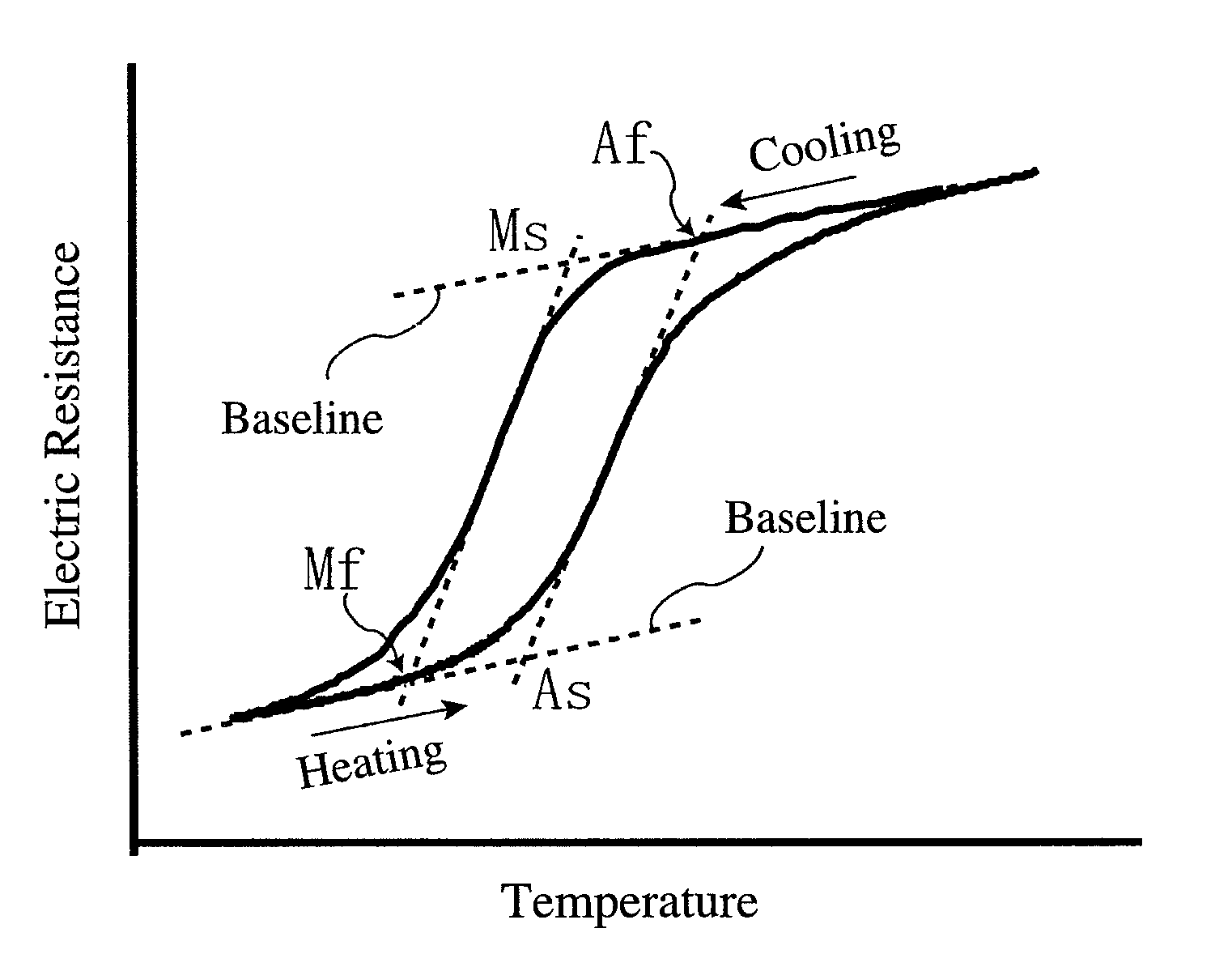

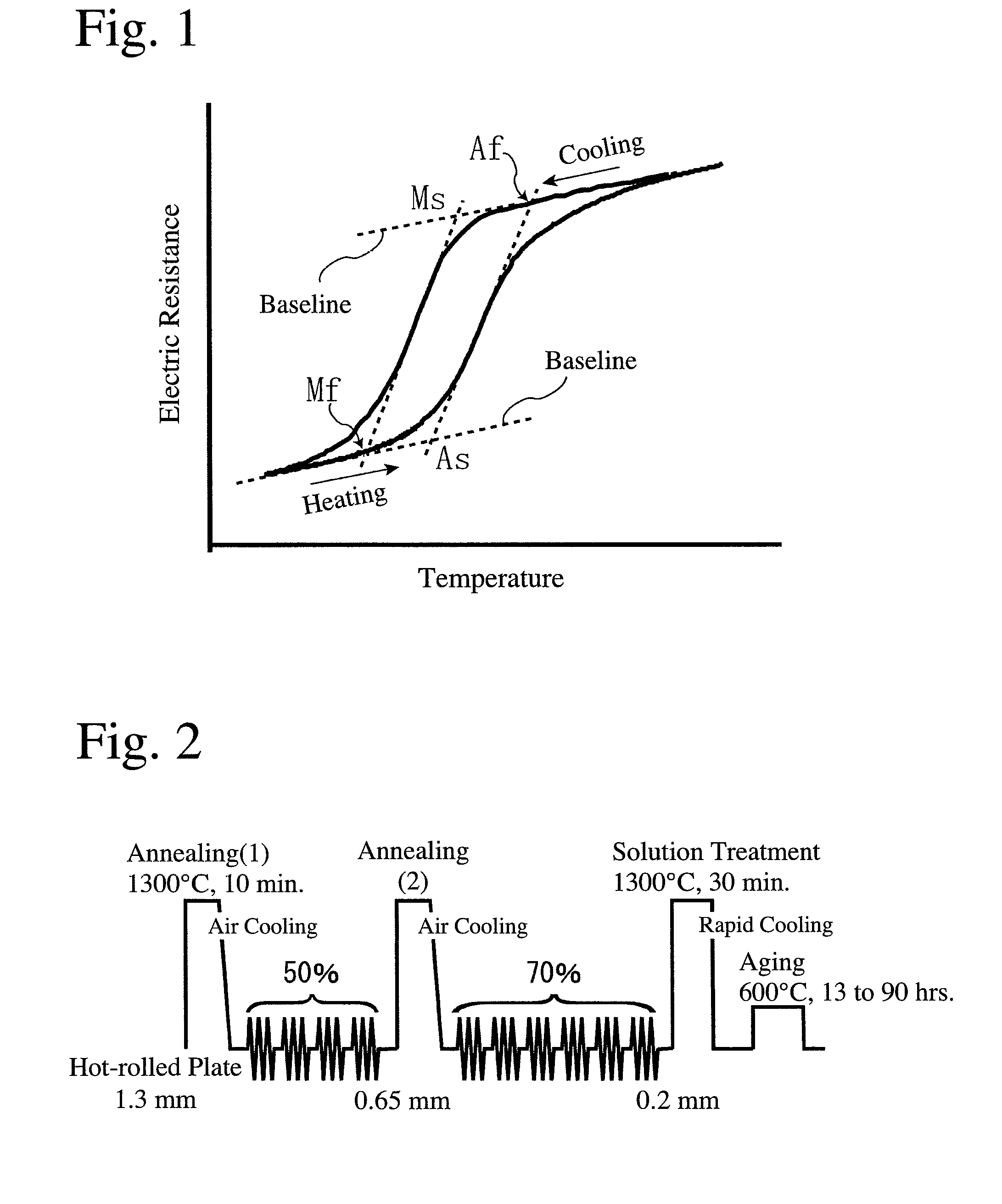

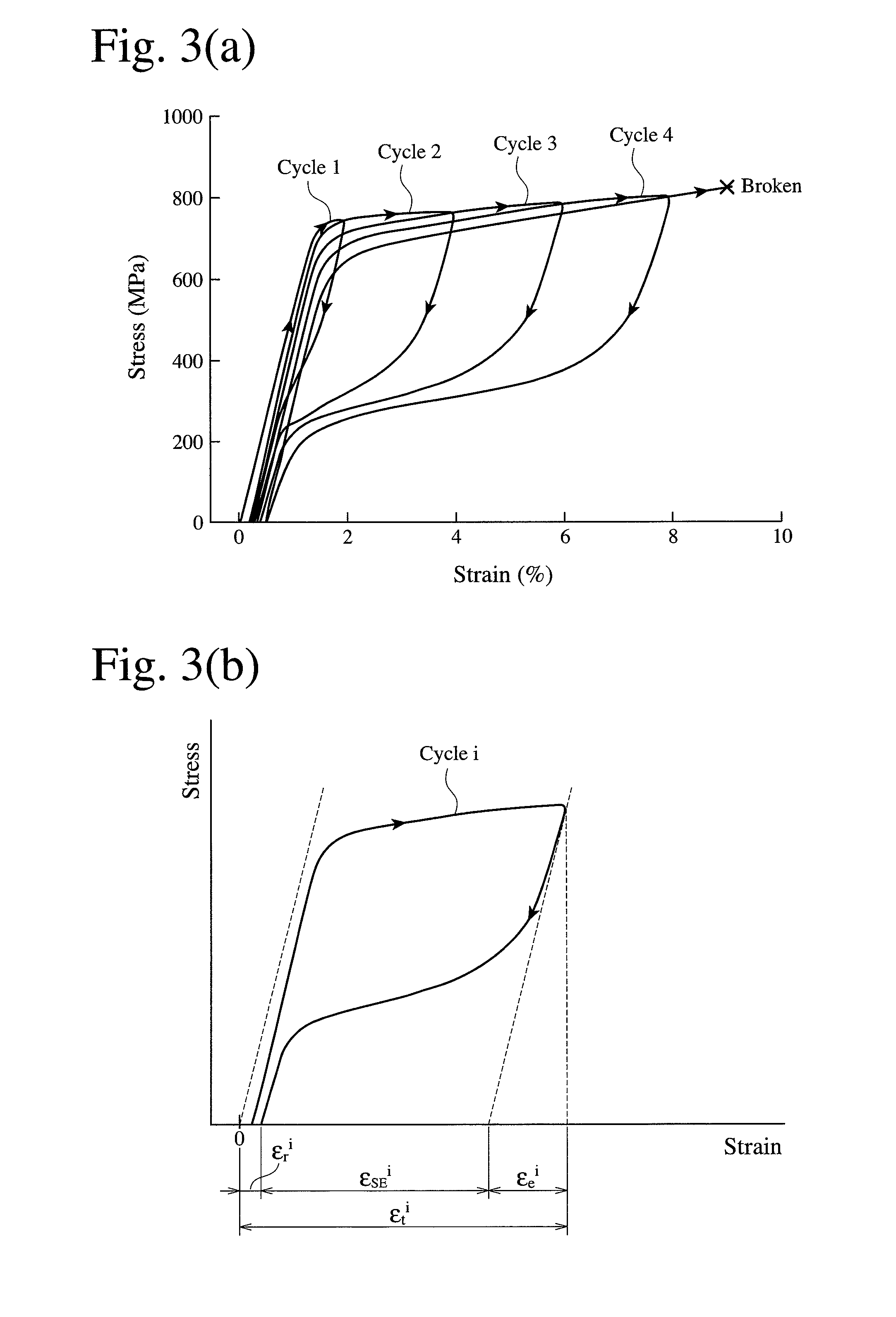

An iron-based alloy having shape memory properties and superelasticity, which has a composition comprising 25-35% by mass of Ni, 13-25% by mass of Co, 2-8% by mass of Al, and 1-20% by mass in total of at least one selected from the group consisting of 1-5% by mass of Ti, 2-10% by mass of Nb and 3-20% by mass of Ta, the balance being substantially Fe and inevitable impurities, and a recrystallization texture substantially comprising a γ phase and a γ′ phase, particular crystal orientations of the γ phase being aligned, and the difference between a reverse transformation-finishing temperature and a martensitic transformation-starting temperature being 100° C. or less in the thermal hysteresis of martensitic transformation and reverse transformation.

Owner:JAPAN SCI & TECH CORP

Industrial preparation method of titanium alloy casting ingot with high niobium content

The invention relates to an industrial preparation method of a titanium alloy casting ingot with high niobium content. The non-niobium included titanium alloy casting ingot with high niobium content and uniform chemical components can be prepared on an industrial scale by adopting the conventional vacuum consumable electric arc melting technology. The invention adopts the technical scheme that a consumable electrode of the titanium alloy casting ingot with high niobium content, which is suitably prepared by adopting the vacuum consumable electric arc melting technology, can be prepared; and the non-niobium included titanium alloy casting ingot with high niobium content and uniform chemical components can be prepared by adopting an industrial process similar to the conventional melting process for the titanium alloy casting ingot.

Owner:陕西群德材料科技有限公司

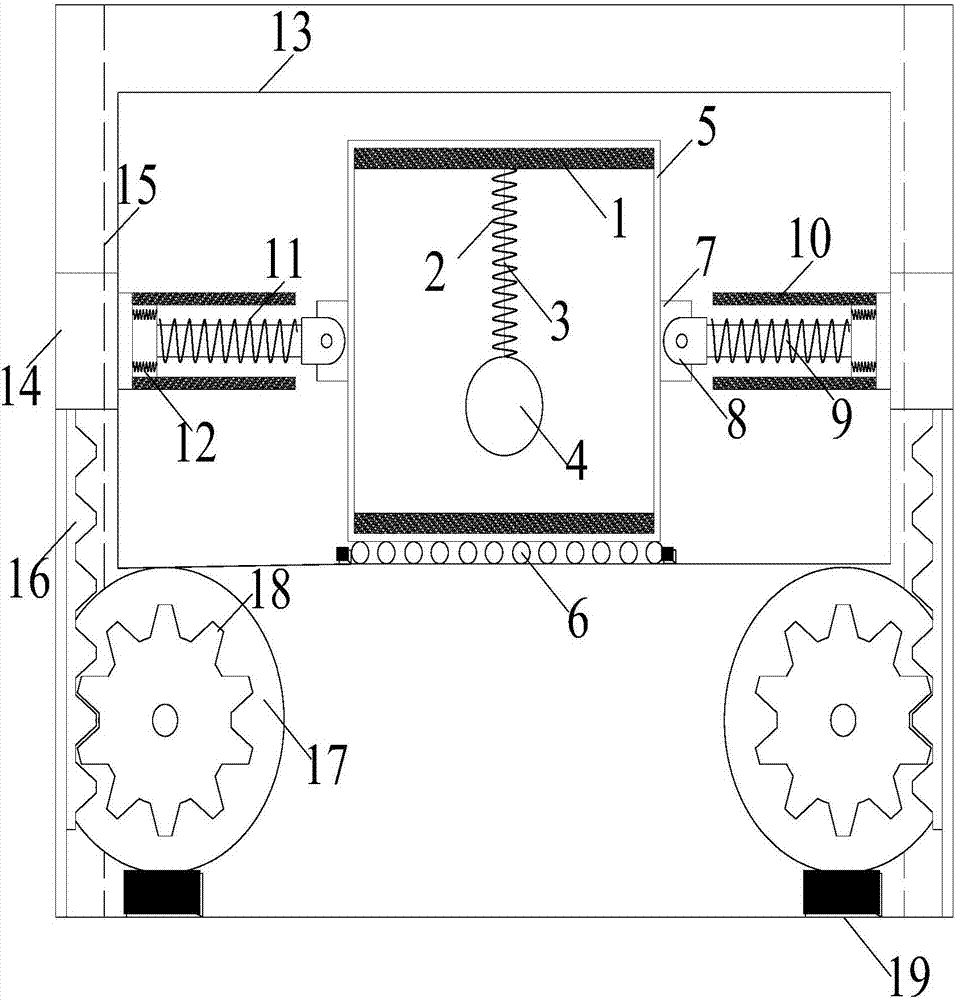

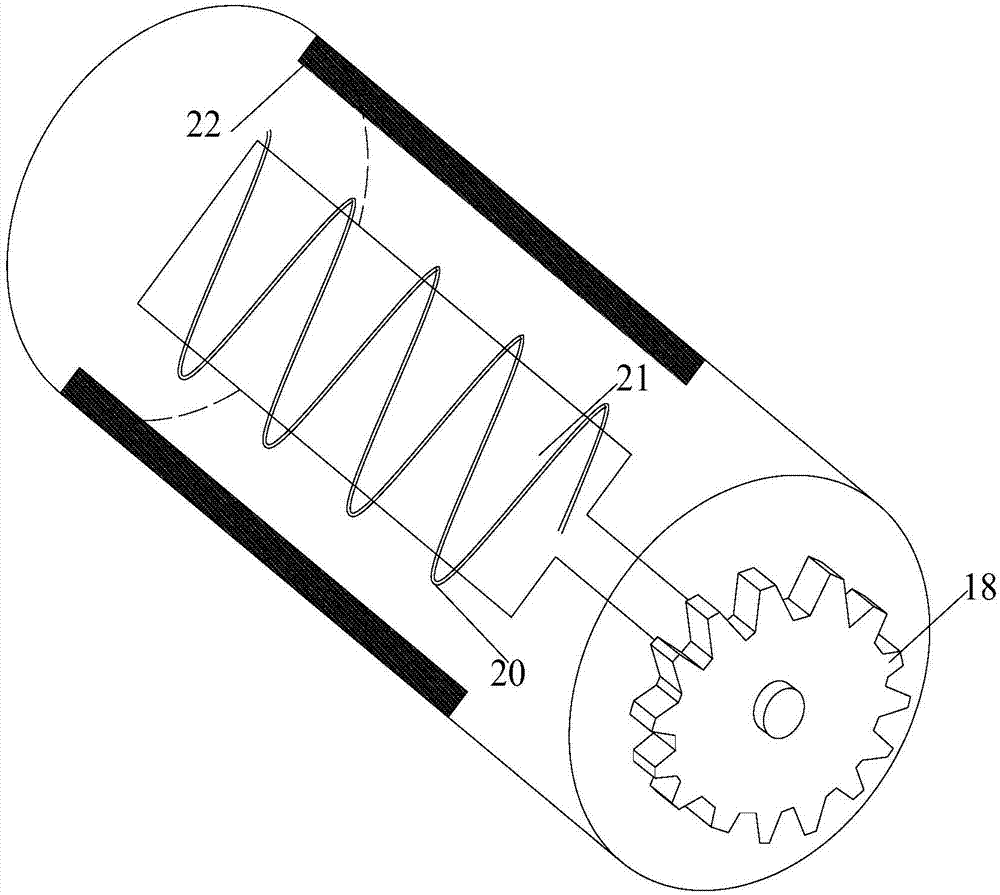

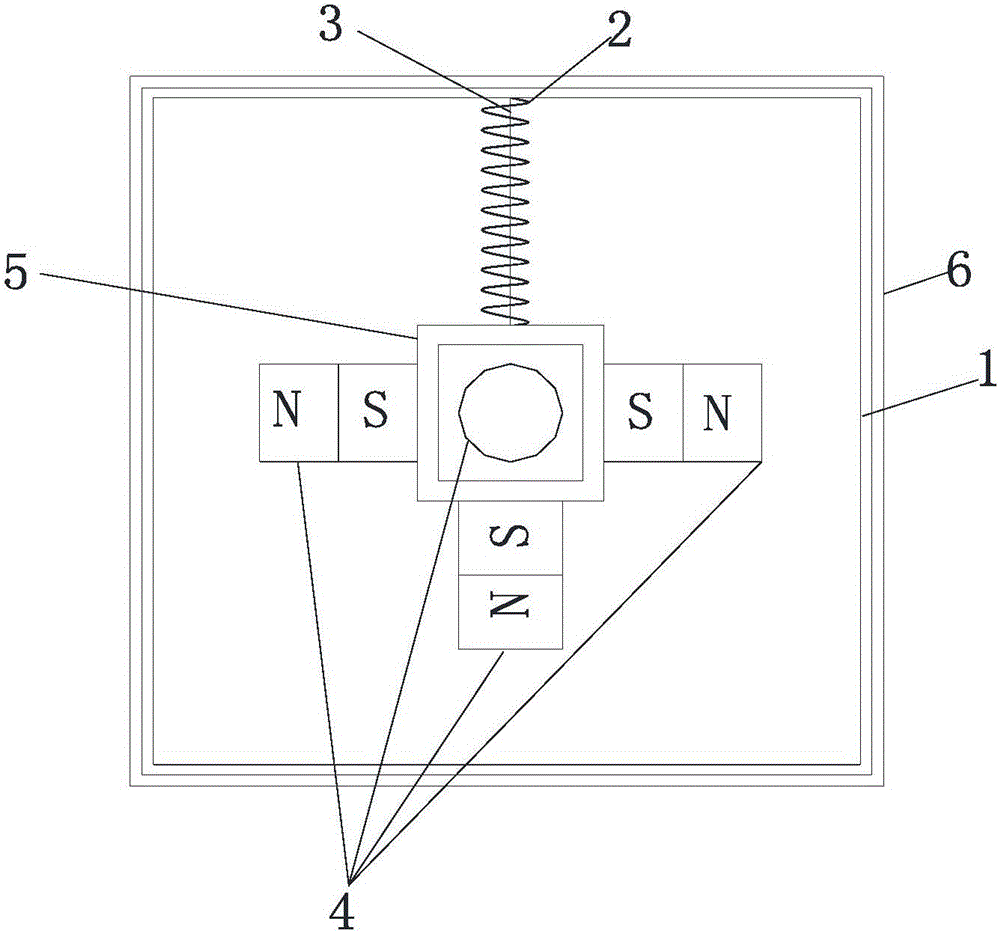

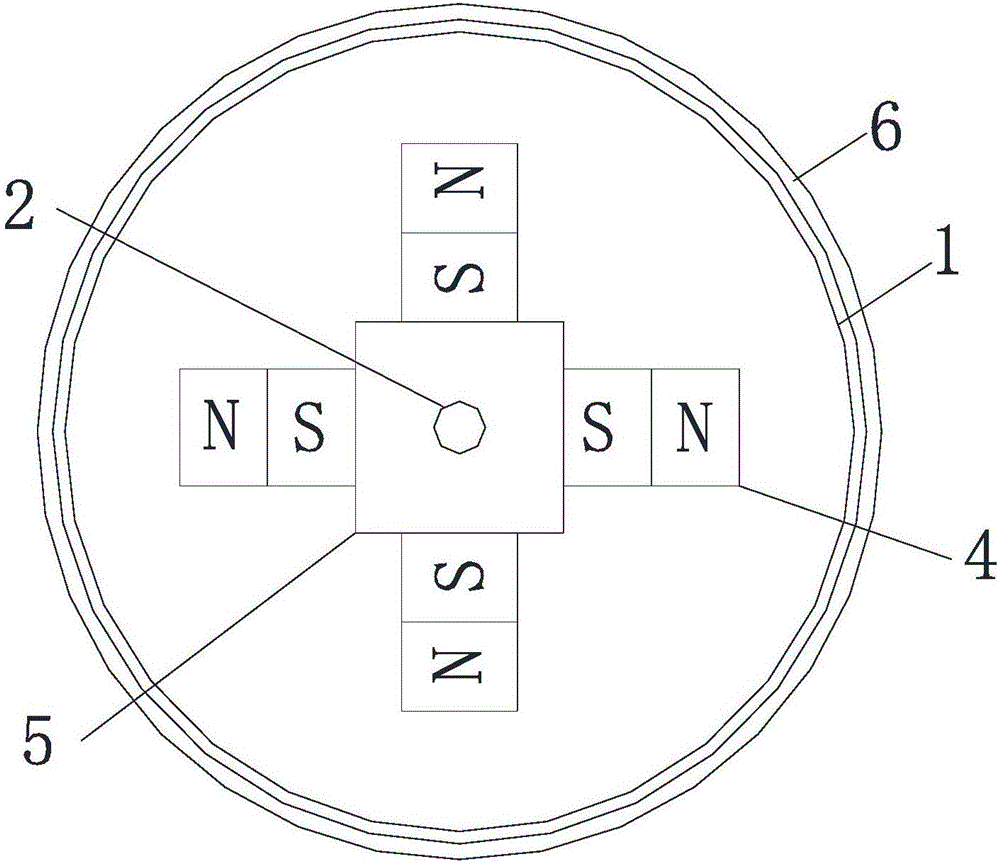

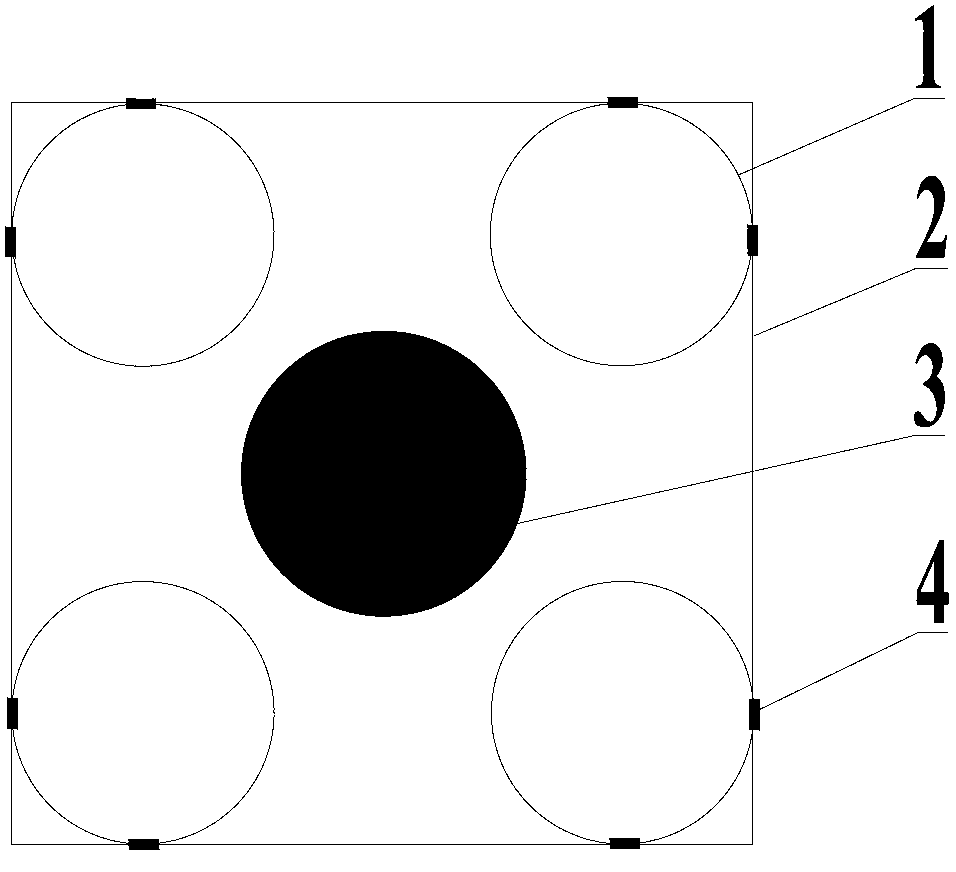

Multidirectional tuning electromagnetic energy dissipating and vibration reducing device

PendingCN107268824ASimple construction technologyCost-effectiveProtective buildings/sheltersShock proofingMultiple dimensionSpring pendulum

The invention discloses a multidirectional tuning electromagnetic energy dissipating and vibration reducing device which comprises an outer box and an inner box. A plurality of balls are arranged inside the outer box. The inner box is arranged on the balls so as to ensure free movement in the horizontal direction; the two sides of the inner box are connected with the inner side wall of the outer box through electromagnetic dampers, the inner top and the inner bottom of the inner box are each provided with a magnet, a spring pendulum is suspended to the top of the inner box and located inside the magnetic space formed by a magnet, and oscillation of the spring pendulum can cut magnetic induction lines; the outer side wall of the outer box can move along a guide rail under the external force action through a sliding block, and the sliding block is connected with a translation rack, the translation rack moves along with the sliding block and drives a rotating gear meshed with the translation rack to rotate, the rotating gear drives an inner core to rotate, the inner core is installed in an outer cylinder with a magnetic pole on the inner wall, a coil is wound around the inner core, the inner core rotates to cut the magnetic induction lines, and then an eddy current retarder is formed.

Owner:SHANDONG UNIV

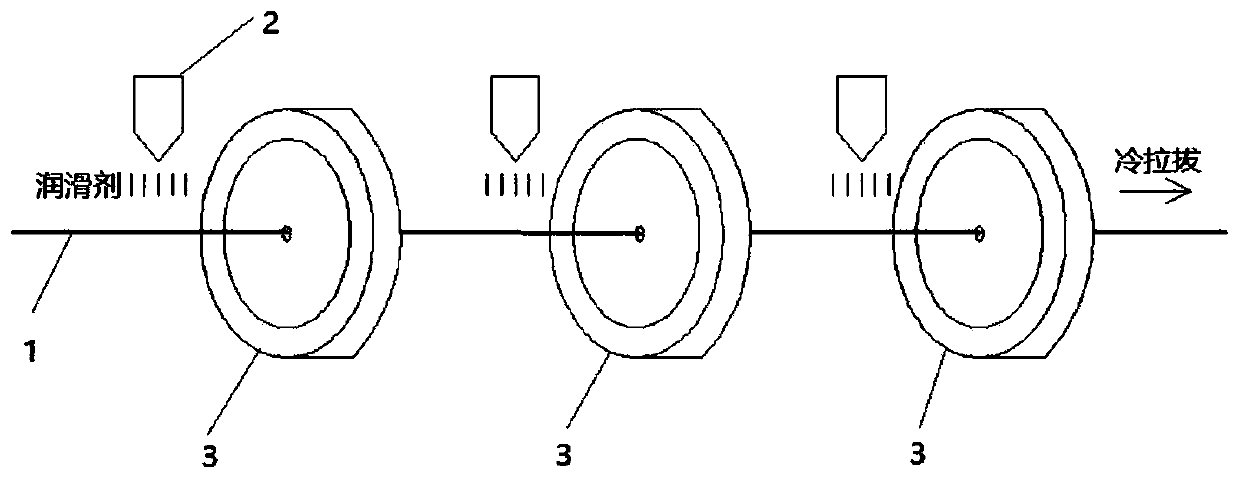

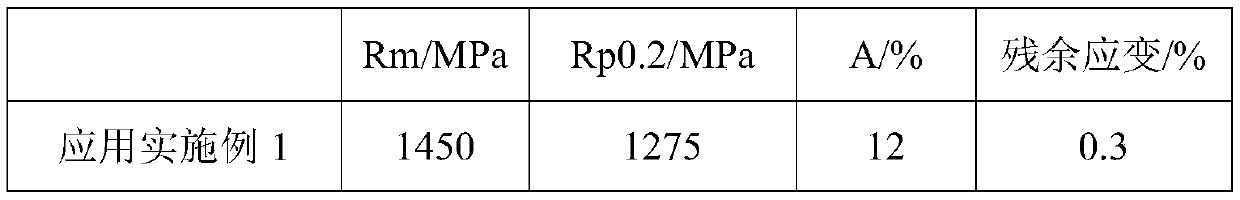

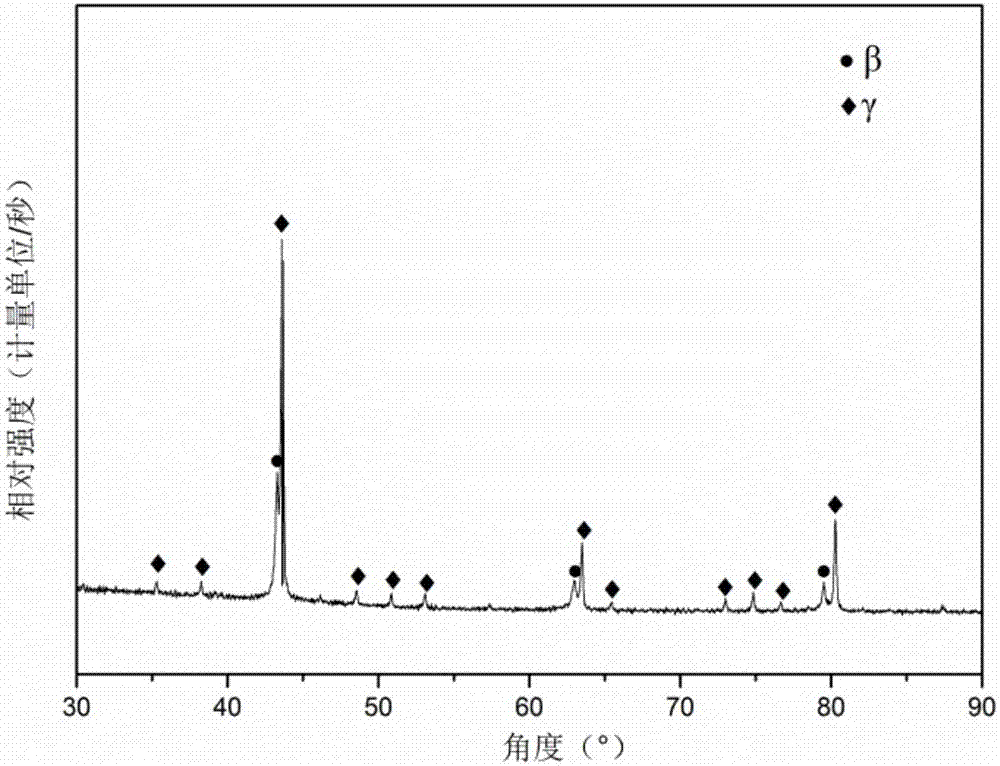

Processing method of nickel-titanium shape memory alloy high-strength wire material

ActiveCN111346942AImprove performanceHigh strengthExtrusion cleaning devicesShape-memory alloyTitanium

The invention discloses a processing method of a nickel-titanium shape memory alloy high-strength wire material. The processing method comprises the following steps that (1), a nickel-titanium alloy wire blank is subjected to peeling treatment, and the nickel-titanium alloy thick wire material is obtained; (2), the nickel-titanium alloy thick wire material in the first step is subjected to hot drawing, and the thick wire material in the nickel-titanium alloy is obtained; and (3), high-temperature annealing and water quenching are carried out on the thick wire material in the nickel-titanium alloy in the second step; (4), cold drawing and on-line annealing treatment are carried out on the thick wire material in the high-temperature annealed and water-quenched nickel-titanium alloy obtainedin the third step, and the nickel-titanium alloy fine wire material is obtained; and (5), on-line aging treatment and peeling treatment are carried out on the nickel-titanium alloy fine wire materialobtained in the fourth step, and the nickel-titanium shape memory alloy high-strength wire material is obtained.

Owner:西安华创新材料有限公司

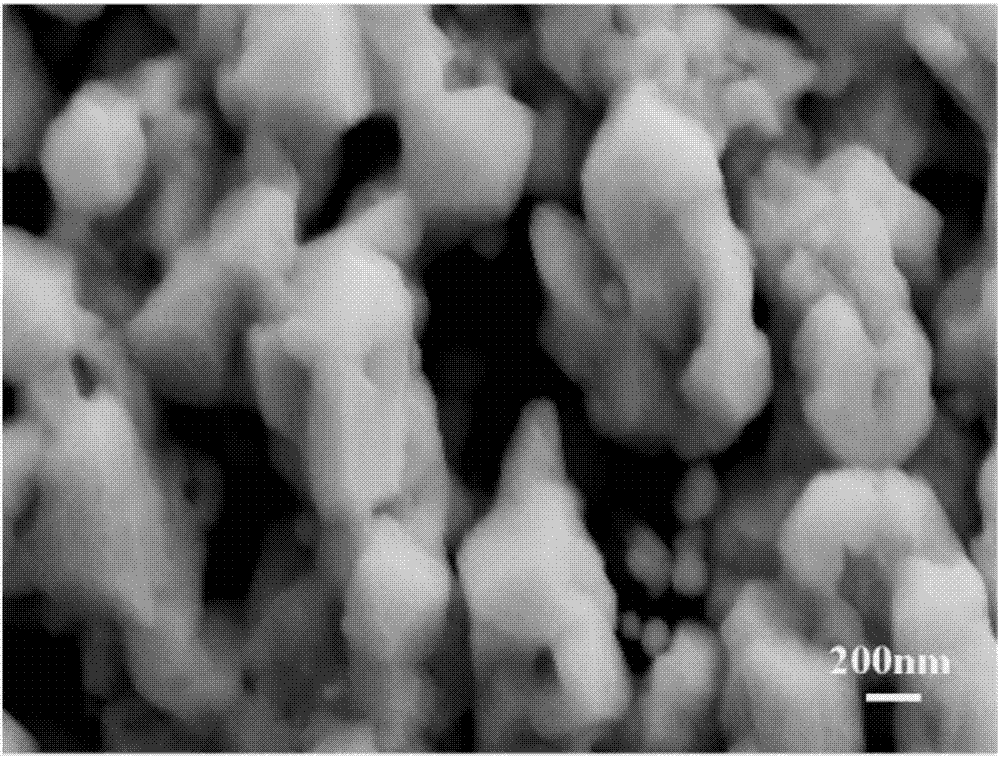

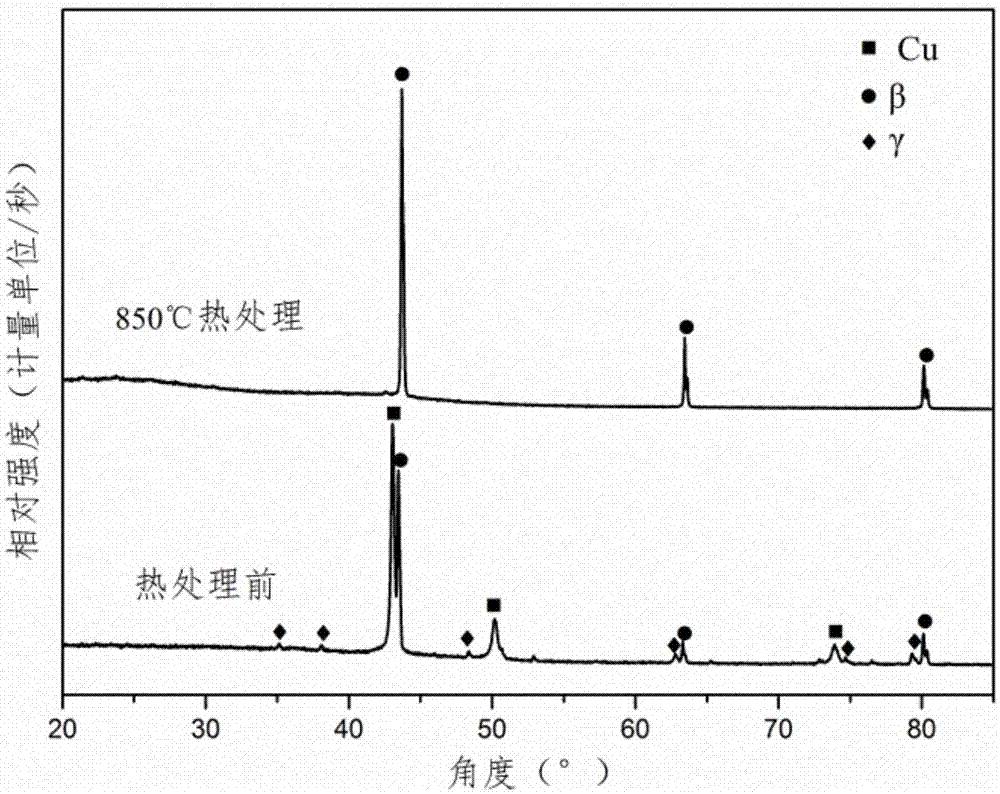

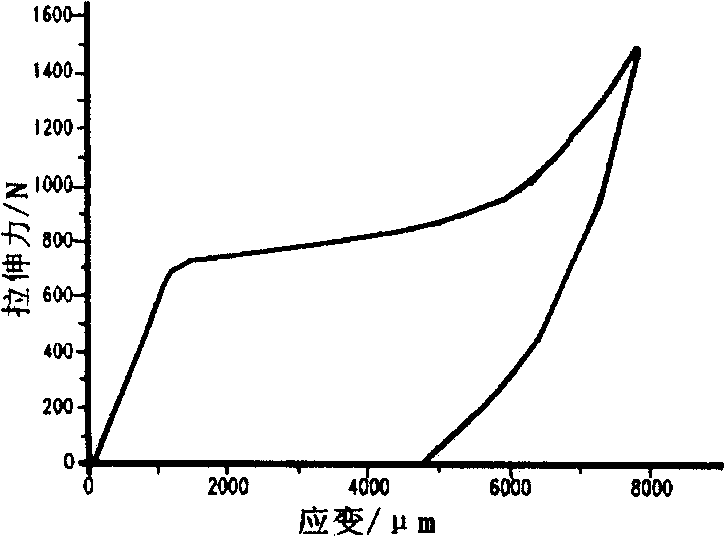

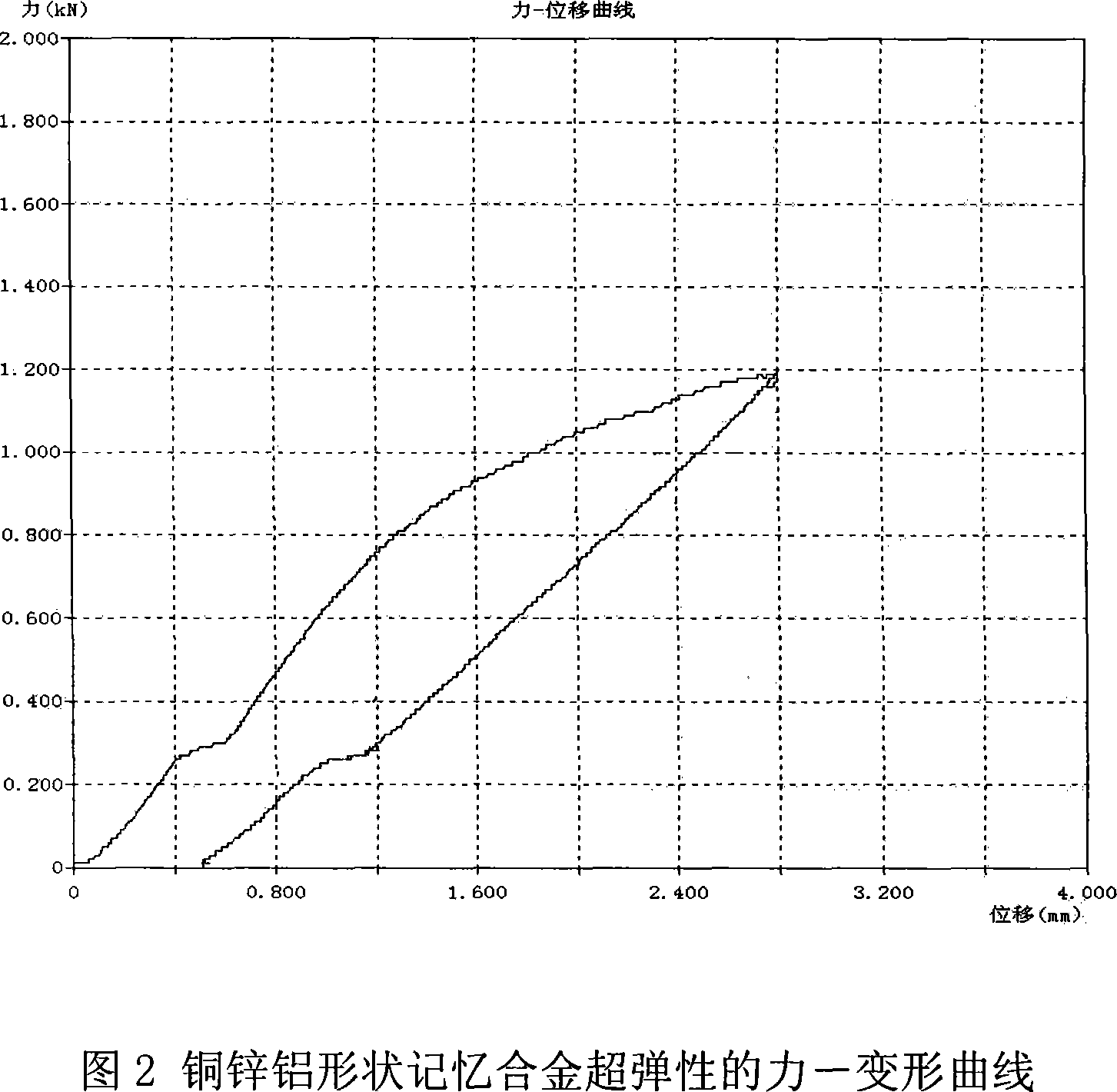

Nanometer porous CuZnAl shape memory alloy and preparation method and application thereof

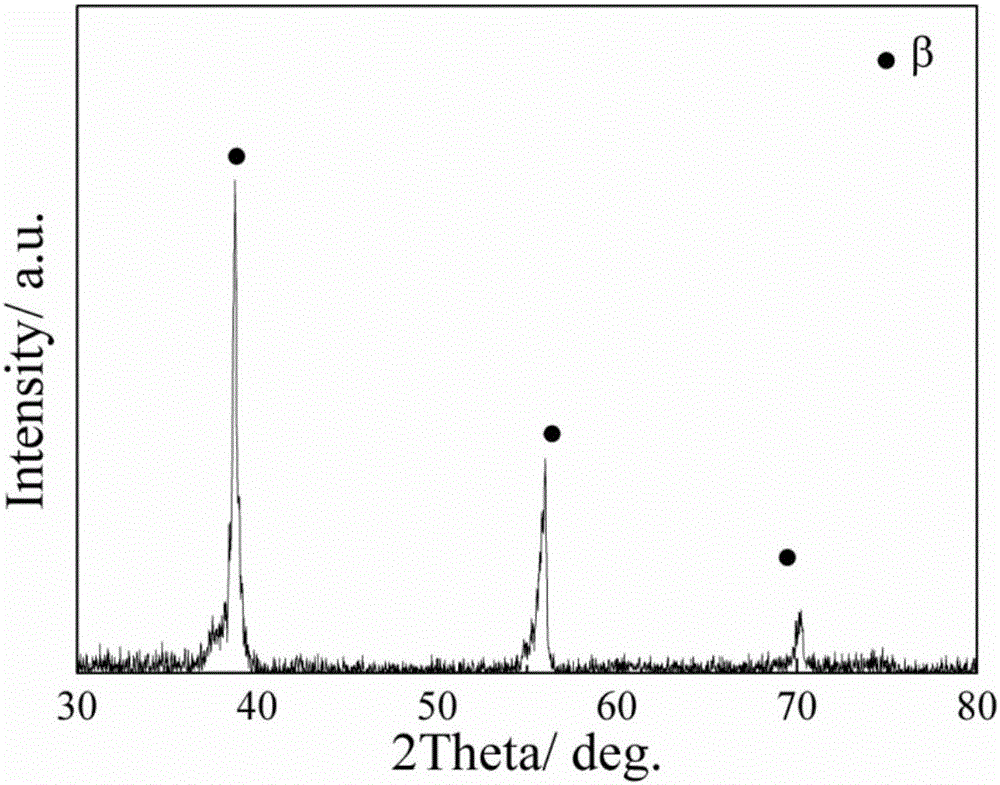

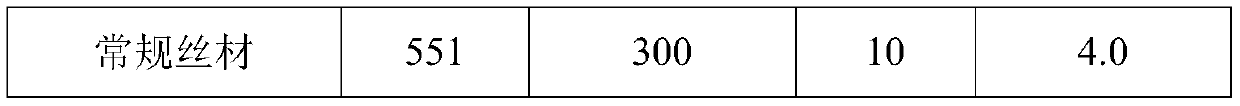

ActiveCN106935864AExhibit hyperelasticityGood superelasticityMaterial nanotechnologyElectrode carriers/collectorsShape-memory alloyControllability

The invention discloses nanometer porous CuZnAl shape memory alloy and a preparation method and application thereof. The method comprises the steps of matching a pure Cu block, a pure Zn block and a pure Al block according to a certain mass percent, and obtaining CuZnAl alloy ingot by smelting; performing melt-spinning on the obtained CuZnAl alloy ingot under vacuum protection by a copper roller rapid quenching method to obtain ultrathin strip-shaped CuZnAl master alloy, performing corrosion processing by employing a solution containing chloride ions to obtain a nanometer porous Cu / CuZnAl material, wherein the corrosion time is 10-300 minutes, and the corrosion temperature is 0-80 DEG C; and finally, sealing the nanometer porous CuZnAl material in a high-vacuum quartz tube for thermal processing, and acquiring the nanometer porous CuZnAl material with a super-elasticity single Beta phase under a room temperature. The preparation method is high in controllability and can be used for industrial preparation of a lithium ion secondary battery electrode material, and the cycle performance of the electrode material is remarkably improved.

Owner:SOUTH CHINA UNIV OF TECH

Low-temperature hyperelastic Ti-Ni-Cu-Y-Hf shape memory alloy and preparation method thereof

The invention relates to a low-temperature hyperelastic Ti-Ni-Cu-Y-Hf shape memory alloy and a preparation method thereof. The alloy is prepared from the following chemical components including, by atomic percent, 39%-47% of Ti, 42%-46% of Ni, 4%-8% of Cu, 0.5%-1.5% of Y and 2%-10% of Hf. The alloy is prepared by the following method of putting the raw materials including the Ti, the Ni, the Cu, the Y and the Hf in a vacuum arc melting furnace according to the component proportion, and repeatedly melting to obtain an alloy ingot; cutting the alloy ingot into a required shape, placing the alloyingot in a heat treatment furnace, filling argon, and performing homogenization treatment; rapidly putting the homogenized alloy ingot into an ice-water mixture, and carrying out quenching treatmentso as to obtain a solid solution state Ti-Ni-Cu-Y-Hf shape memory alloy; and cutting the solid solution state alloy into rod-shaped samples, and carrying out cyclic compression memory training to obtain the rod-shaped shape memory alloy with the higher recovery rate and superelasticity. The preparation method is low in cost, simple in process and easy to operate, and the prepared shape memory alloy has high recoverable strain and good low-temperature superelasticity and has potential application value.

Owner:CHINA THREE GORGES UNIV

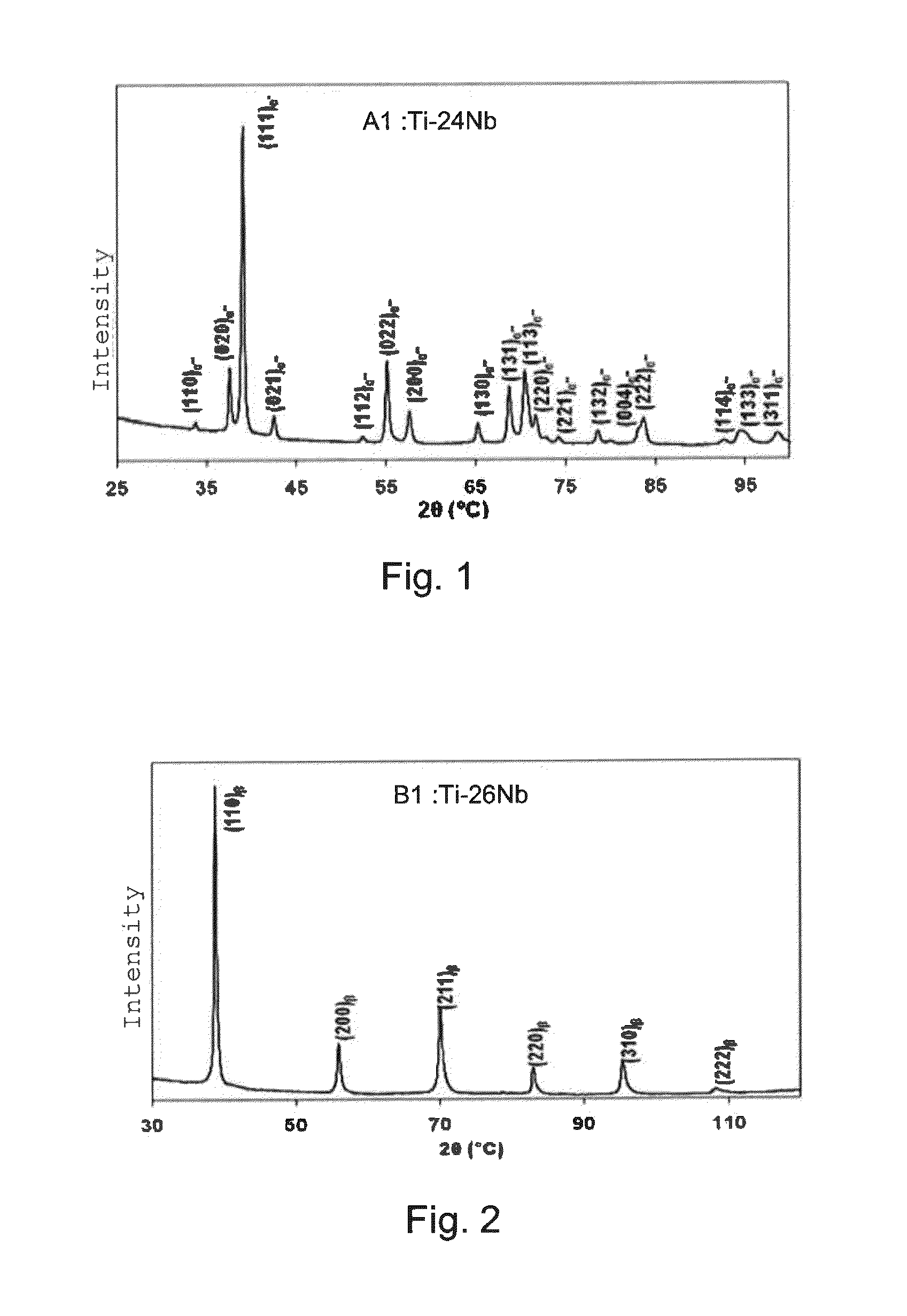

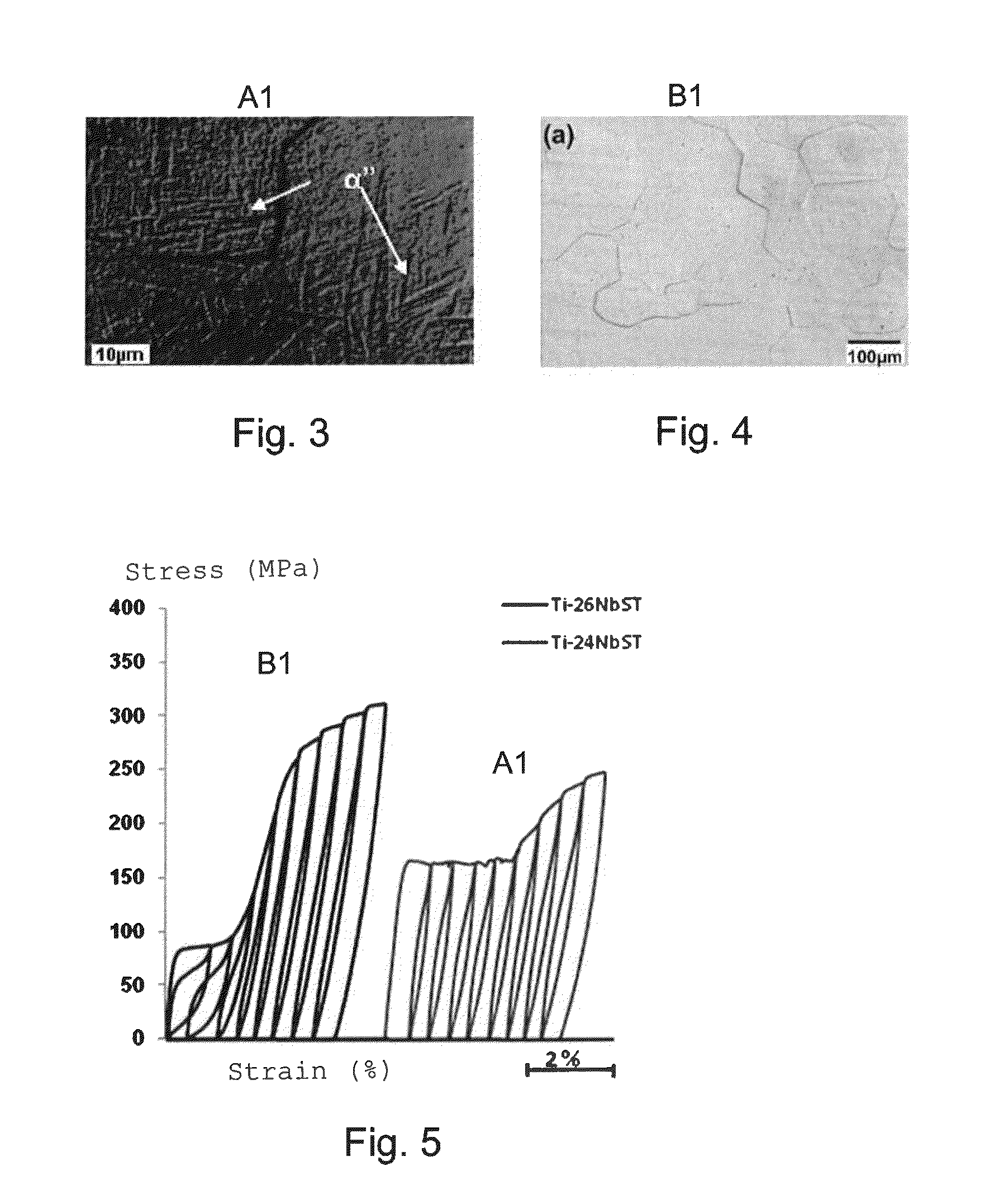

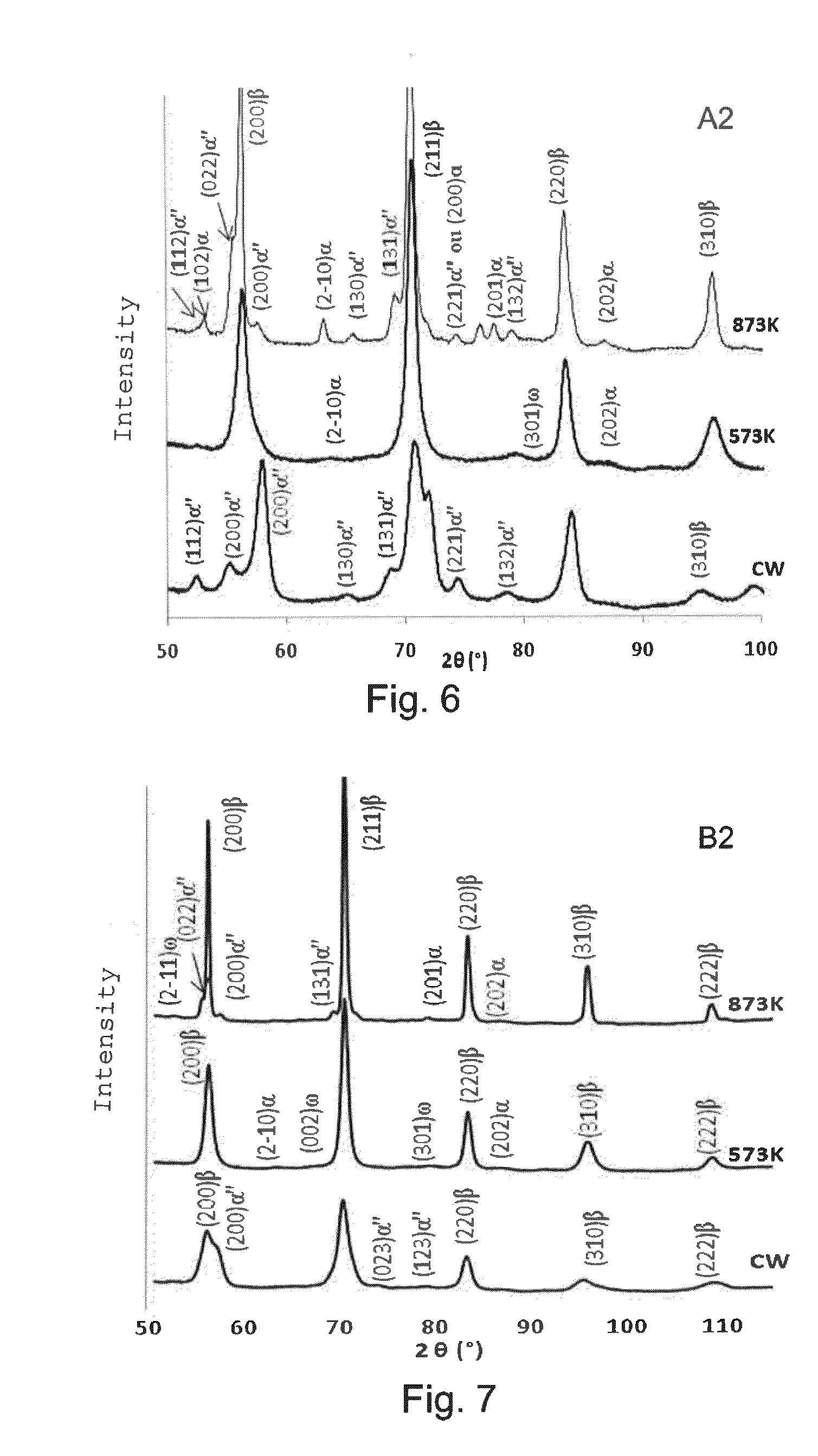

Method for the thermomechanical treatment of a titanium alloy, and resulting alloy and prosthesis

According to a thermomechanical treatment process for a titanium alloy including between 23 and 27% niobium in atomic proportion, between 0 and 10% zirconium, and between 0 and 1% oxygen, nitrogen and / or silicon, the following steps are performed:a) an increase of a sample of the alloy to a temperature higher than 900° C.,b) a fast quench,c) a severe cold strain,d) an ageing treatment at a temperature included between 200 and 600° C., the time of the ageing treatment being included between 10 seconds and 10 minutes. Alloy obtained by this process and prostheses made from such an alloy.

Owner:UNIVERSITY OF LORRAINE +4

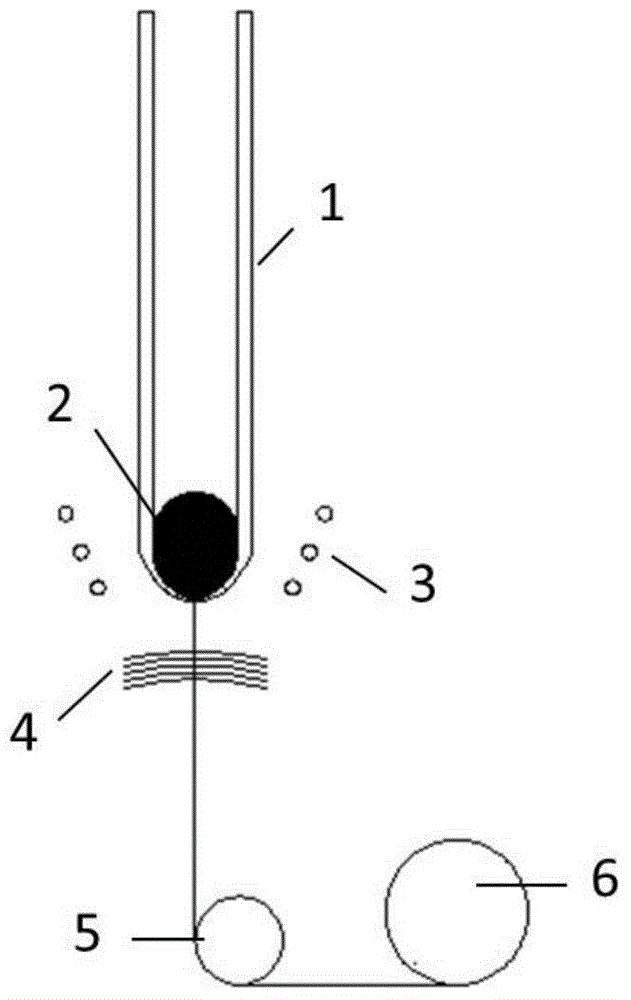

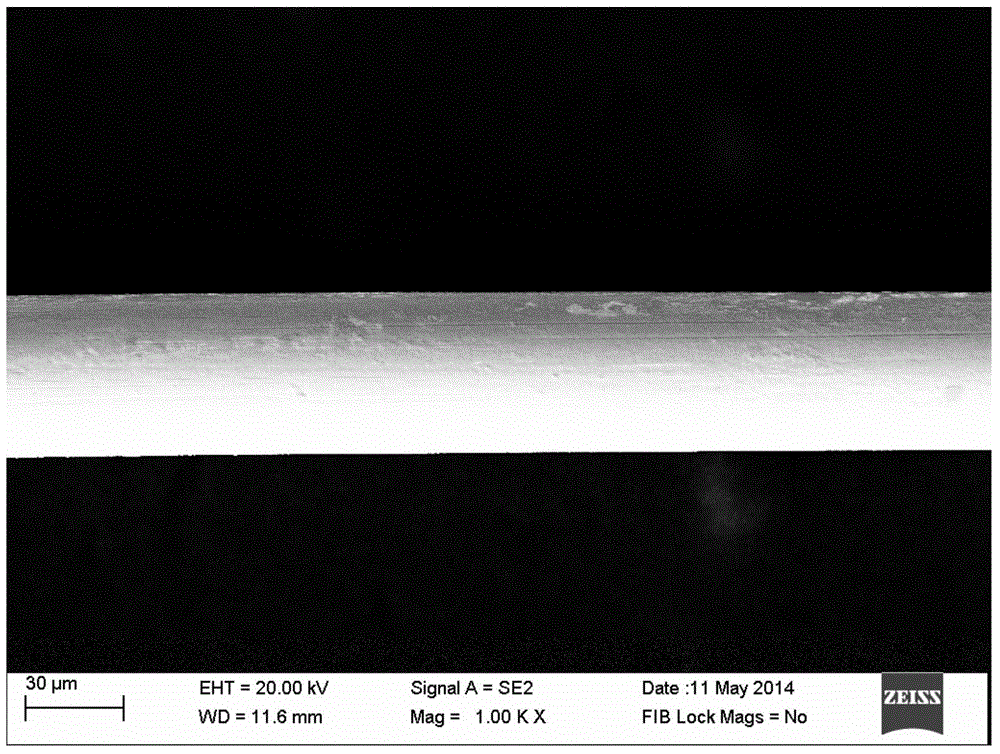

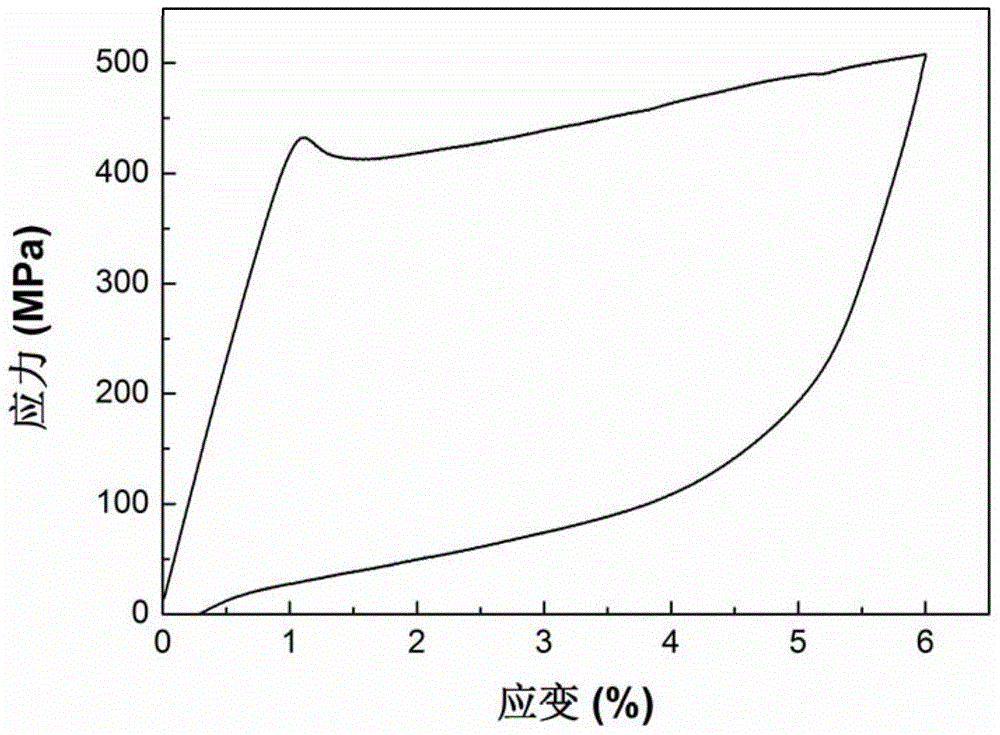

Copper-based hyperelastic shape memory alloy wire and preparation method thereof

The invention relates to a copper-based hyperelastic shape memory alloy wire and a preparation method thereof. The molecular formula of the alloy is Cu100-xSnx, wherein the x equals to 14-17. The preparation method adopts the method of wrapping spin with glass, and comprises the following steps: alloy ingots are gradually fused through a high frequency induction device within the range of 200-600A, and when the bottom glass tube is softened, the fused alloy liquid and the bottom glass tube form a micro melting bath; a glass-coated alloy material is pulled out from the softened glass tube bottom with a glass rod provided with a tip; the glass-coated alloy material is winded on a wire winding wheel after being cooled by sprayed water; the glass on the surface of a prepared micro wire is peeled off to obtain a bare copper-stannum hyperelastic shape memory alloy wire. The shape memory alloy wire is formed by one step, and simple in working procedures; the diameter of the prepared micro wire is 3-200 micron, can be wildly applicable to sensors and drives, is an intelligent material combining perception and drive, and has important significance for promoting the micromation of intelligent elements.

Owner:UNIV OF SCI & TECH BEIJING

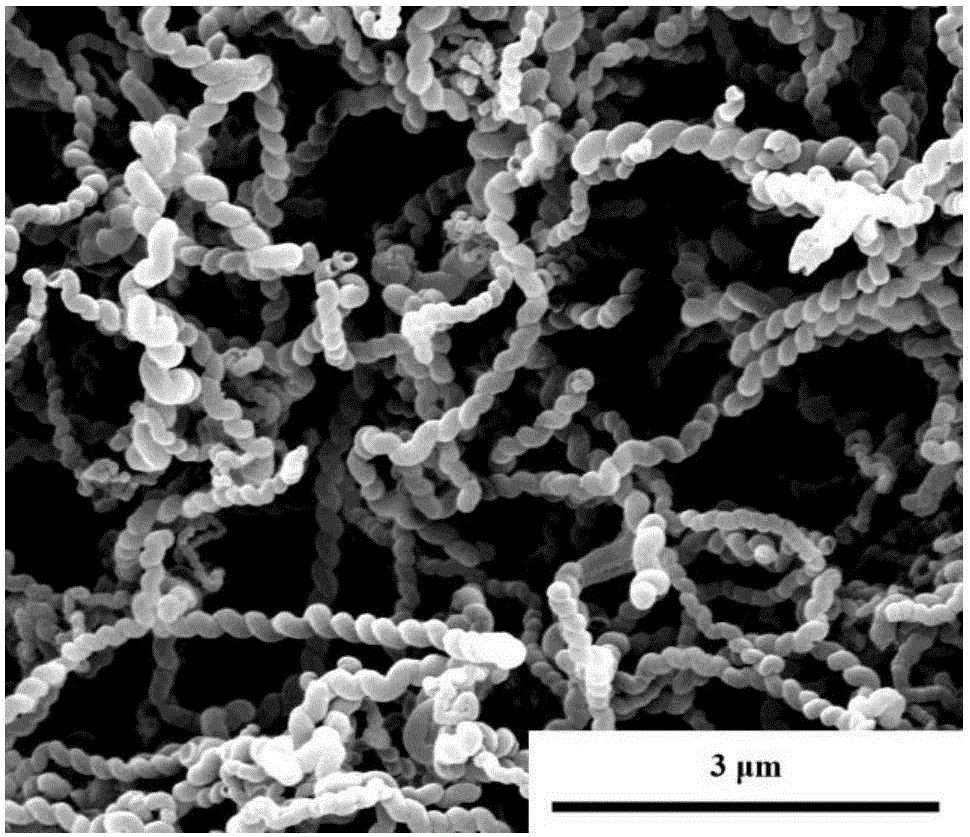

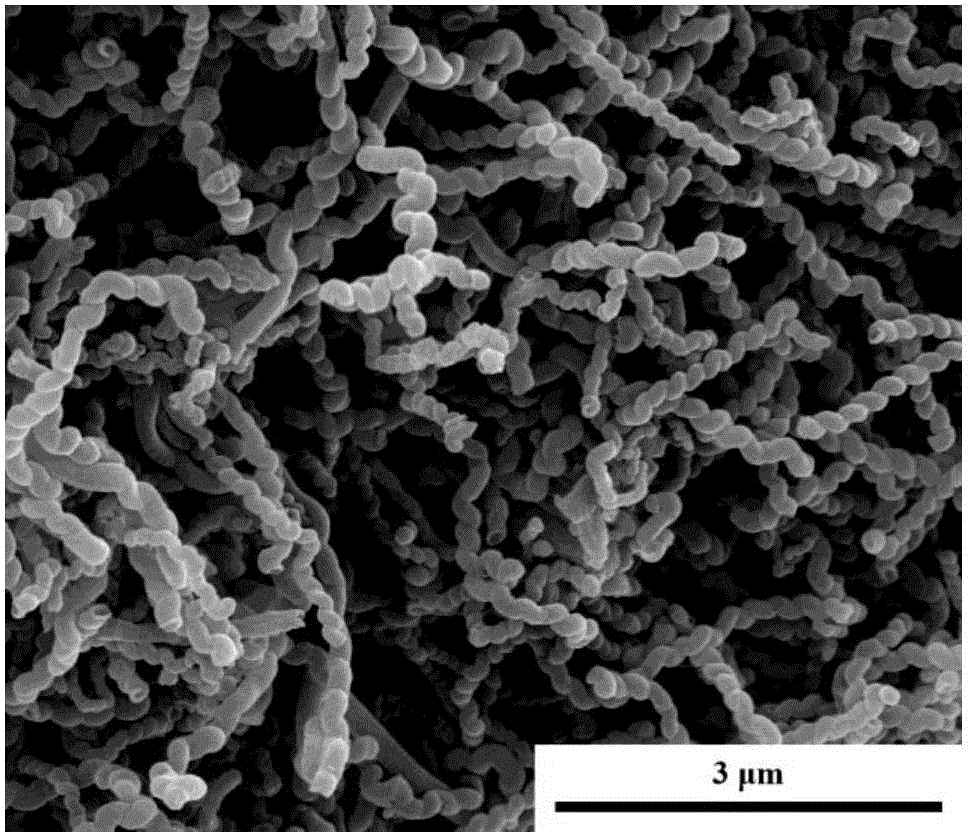

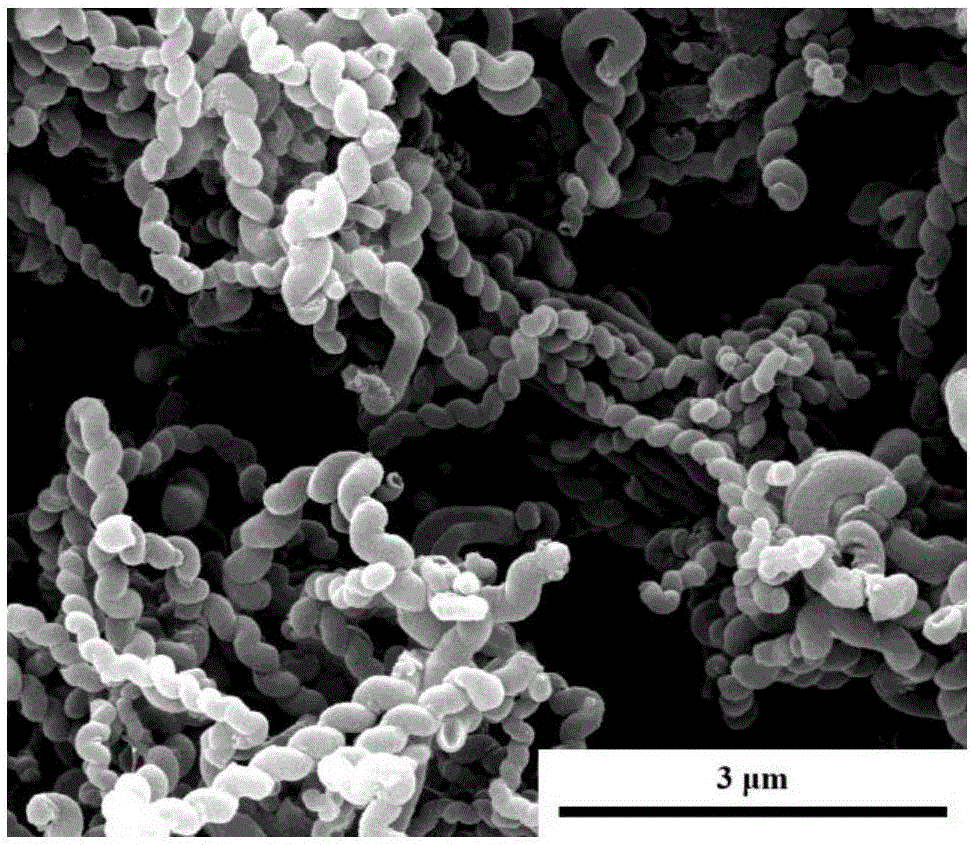

High-purity helical carbon nanotubes and preparation method thereof

ActiveCN106829926AHigh purityHigh yieldMaterial nanotechnologyCarbon nanotubesCarbon nanotubeCarbon source

The invention relates to high-purity helical carbon nanotubes and a preparation method thereof. The method comprises the following steps: (1) preparation of alpha-crystal-form nano iron oxide catalyst precursor: preparing the alpha-crystal-form nano iron oxide catalyst precursor by pre-precipitation in combination with a sol-gel process; and (2) preparation of high-purity helical carbon nanotubes: putting the alpha-crystal-form nano iron oxide catalyst precursor into a pipe furnace, reducing the alpha-crystal-form nano iron oxide catalyst precursor into a nano iron catalyst by an in-situ reduction process, introducing a carbon source and vapor as catalytic regulation aids, and keeping the temperature for 6-10 hours, thereby obtaining the igh-purity helical carbon nanotubes. The method is simple, safe and environment-friendly. The purity of the prepared helical carbon nanotubes is up to 99% or above, and the yield is up to 7709-8077 (g-HCNTs / g catalyst); and the product has uniform parameters (diameter, helical diameter, screw pitch and the like) and complete shape.

Owner:SOUTHWEST JIAOTONG UNIV

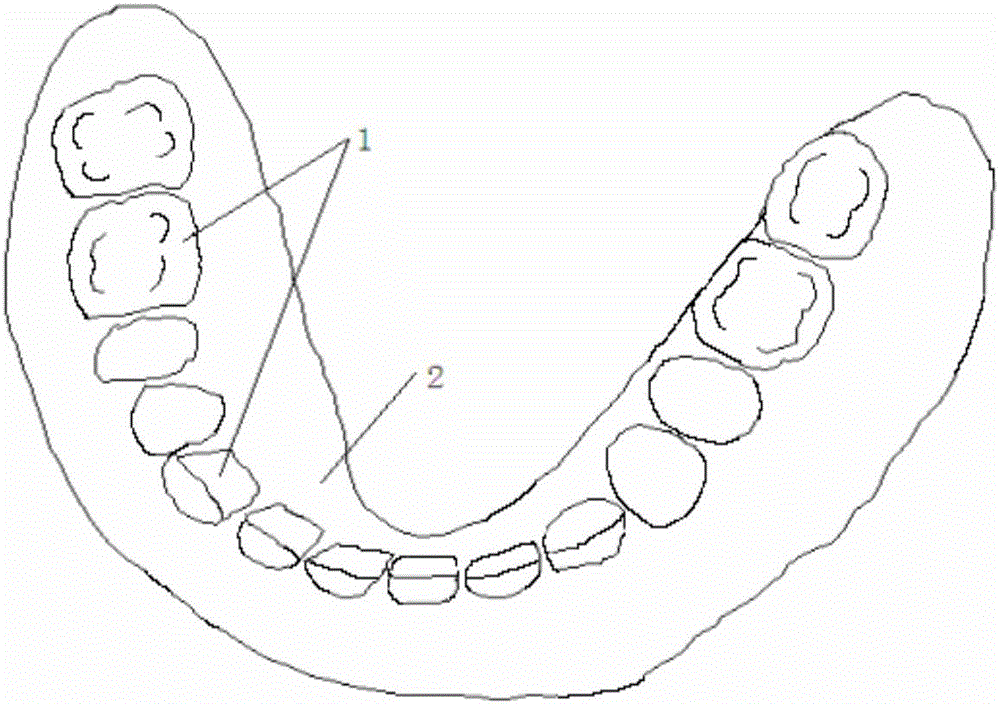

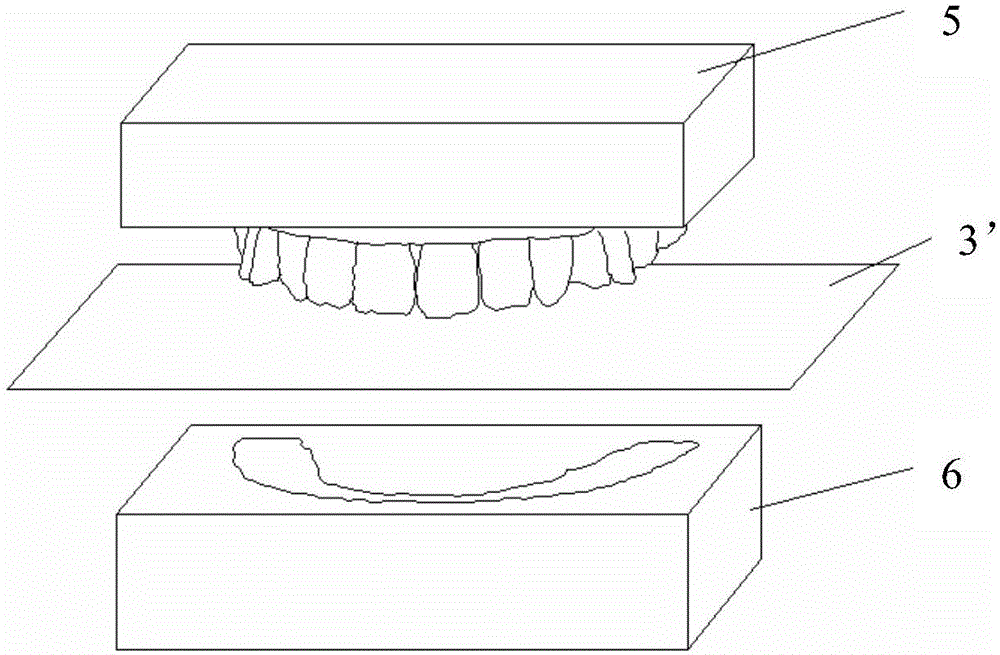

Memory alloy non-bracket invisible appliance and manufacturing method thereof

InactiveCN106725926AGood shape memory effectImprove flexibilityOthrodonticsTreatment effectShape-memory alloy

The invention discloses a memory alloy non-bracket invisible appliance and a manufacturing method thereof. The memory alloy non-bracket invisible appliance is composed of a base and a silicone rubber covering membrane, wherein the base is made of shape memory alloy filaments, and the silicone rubber covering membrane is coated on the surface of the base and displays dental primary color and gingiva color; the filaments are prepared from TiNi alloys good in shape memory effect, are good in flexibility at room temperature, and good in super elasticity at the oral temperature (32-37 DEG C). The manufacturing method of the appliance includes the steps of firstly obtaining a required original dentition model, processing an entity dentition model, conducting compression molding on a piece of rectangular dense mesh woven by the shape memory alloy filaments by using the entity dentition model to form an initial state base, and conducting heating and sizing; adjusting the phase-transition temperature, covering the base with the silicone rubber covering membrane, according to the complete denture manufacturing process, finishing the membrane to form a tooth-shaped part and a gingiva-shaped part, removing unwanted parts, dyeing the tooth-shaped part into dental primary color and dyeing the gingiva-shaped part into gingiva color. The memory alloy non-bracket invisible appliance has the advantages of being simple, easy to use, and high in orthodontic treatment effect.

Owner:GRINM MEDICAL INSTR BEIJING CO LTD

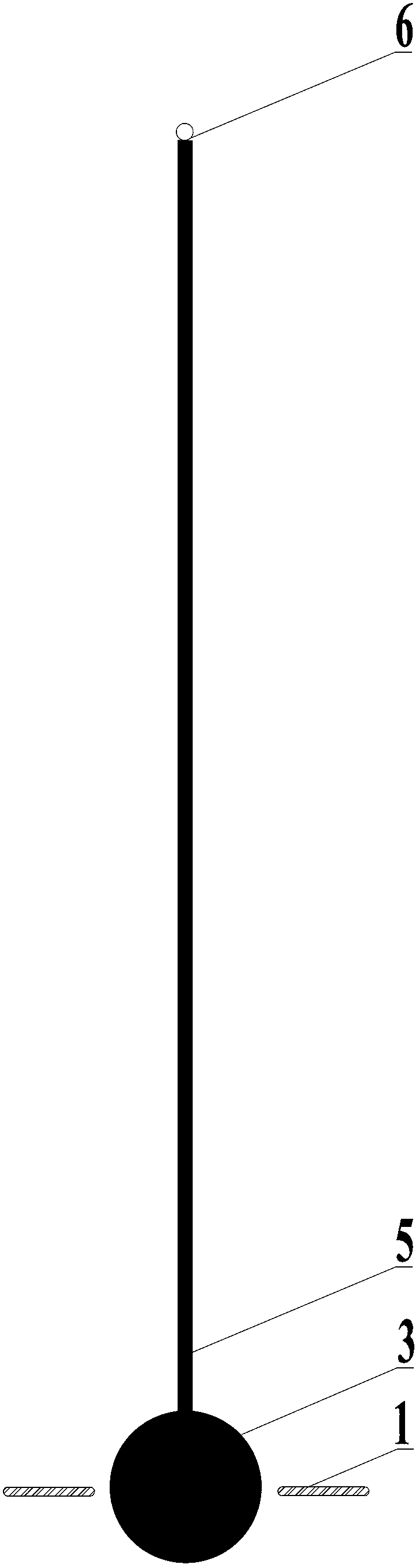

Vibration-attenuation control device for eddy current damper

InactiveCN106639470ASimple construction technologyLow costProtective buildings/sheltersShock proofingSpring pendulumMagnet

The invention discloses a vibration-attenuation control device for an eddy current damper. The vibration-attenuation control device comprises a box-shaped structure, wherein a spring pendulum which is connected with the top surface of the box-shaped structure is perpendicularly arranged in the box-shaped structure and can swing in various directions in the box-shaped structure; according to the movement mode of the spring pendulum, up-down vibration of a spring is coupled with swinging of the spring pendulum; the spring pendulum comprises the spring and a cylinder structure which is vertically connected to the lower end of the spring; magnets are respectively connected to the four horizontal directions of the cylinder structure and the lower end of the cylinder structure; the magnets can swing back and forth along with the cylinder structure and move relative to the box-shaped structure; eddy current can be generated on various surfaces of the box-shaped structure; and the box-shaped structure can be obstructed by an electromagnetic force to move relatively.

Owner:SHANDONG UNIV

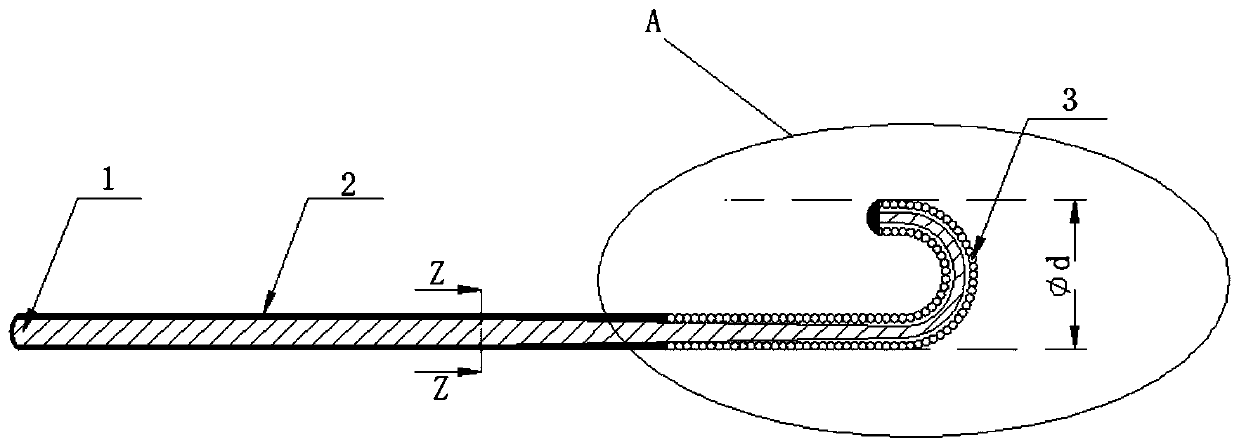

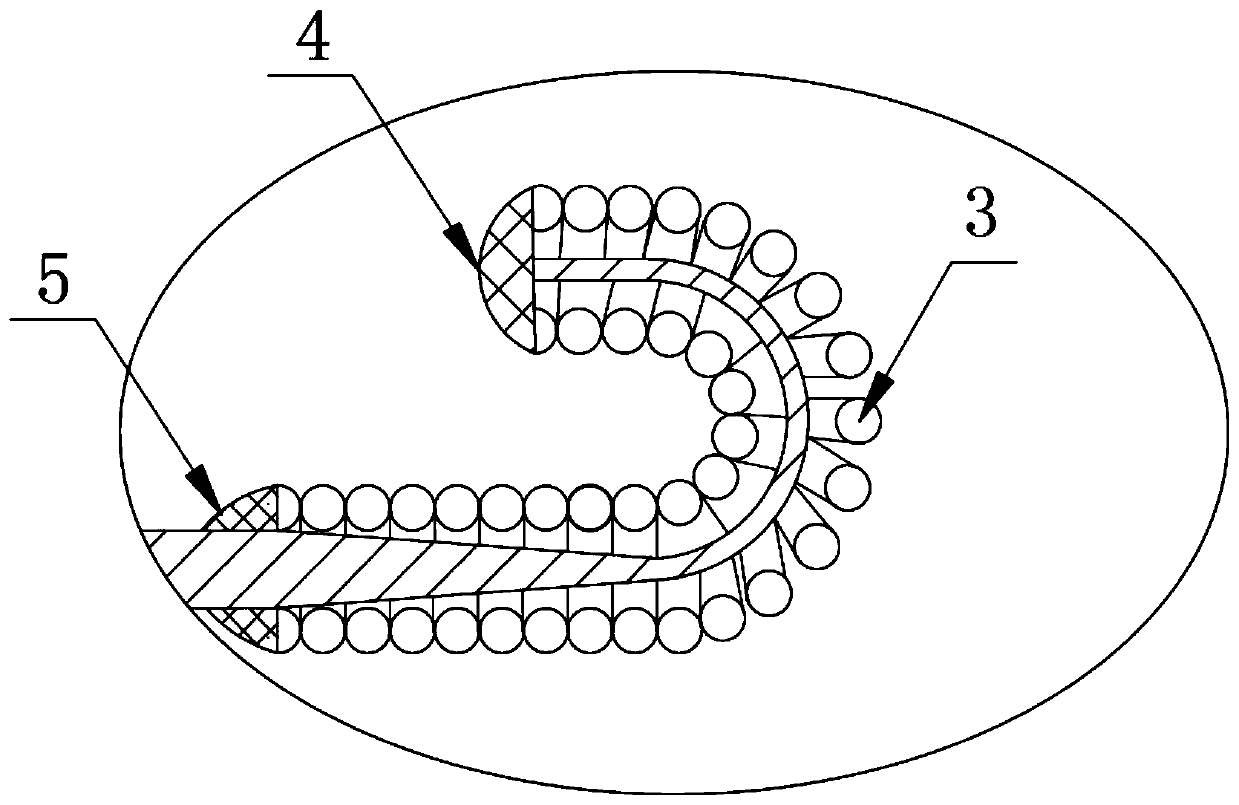

Contrast guide wire and preparation method thereof

InactiveCN110681031AEasy to useImprove lubricityWire articlesGuide wiresArterial bifurcationBiomedical engineering

The invention discloses a contrast guide wire and a preparation method thereof. The contrast guide wire includes an inner core wire, an outer distal spring coil sheath, and an outer proximal polymer sheath of which the surface is provided with a hydrophilic coating. The contrast guide wire provided by the invention is preformed as a J-shaped bent portion, so that the contrast guide wire is difficult to enter arterial bifurcations and prevents damage to inner walls of blood vessels. The J-shaped bent portion can be straightened when the spring coil sheath is squeezed, thereby facilitating the contrast guide wire to enter into and fit with instruments. The spring sheath at head end is designed to improve tactile feedback of an operator. Meanwhile, the hydrophilic coating on the surface of the contrast guide wire improves lubricity and allows the contrast guide wire to easily reach a target site of blood vessels.

Owner:APT MEDICAL HUNAN INC +1

Reinforced concrete column reinforcing structure and method

ActiveCN108824226AAchieving semi-active controlImprove energy consumptionBuilding repairsBridge erection/assemblySemi activeReinforced concrete column

The invention discloses a reinforced concrete column reinforcing structure and method. A reinforcing groove is vertically formed in a to-be-reinforced reinforced concrete column, and the interior of the reinforcing groove is coated with a filling material; the clean reinforcing groove is half filled with the filling material, then a memory alloy bar is placed into the clean reinforcing groove, andthe reinforcing groove is pressed into the filling material; then the reinforcing groove is filled with a filling material and compacted and leveled, so that the reinforced concrete column and the memory alloy bar form a whole. A near-surface reinforcing method is adopted, so that the bonding area of a reinforcing rib and the concrete is increased, the possibility of bonding stripping damage is reduced, and the bonding performance of the reinforcing rib and the concrete is improved. The characteristics of the memory alloy bar are utilized so that the energy dissipation capability of the reinforcing column can be remarkably improved, the residual deformation generated after stress of the concrete column is reduced, the damage self-repairing capability of a component is improved, rapid recovery of structure functions after earthquakes is achieved, and semi-active control over the reinforced concrete column is achieved.

Owner:CHANGAN UNIV

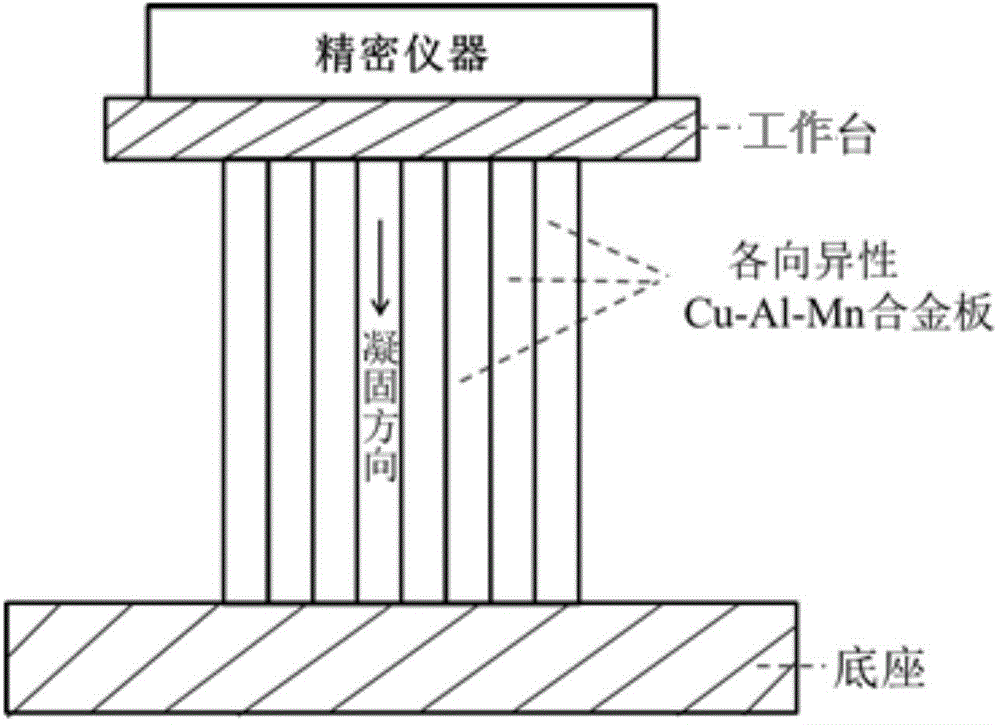

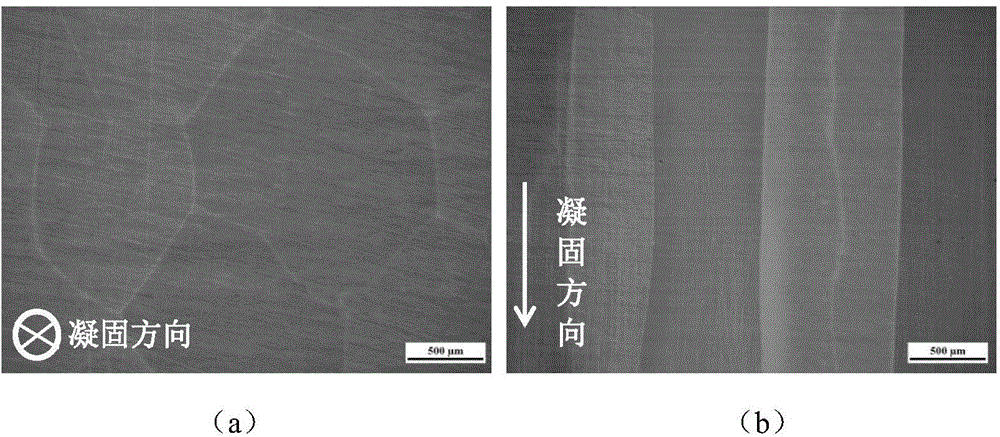

Cu-Al-Mn shape memory alloy damping device for precise instrument and manufacturing method of Cu-Al-Mn shape memory alloy damping device

ActiveCN104963994ALow priceImprove energy absorptionNon-rotating vibration suppressionDamping functionShape-memory alloy

The invention discloses a Cu-Al-Mn shape memory alloy damping device for a precise instrument and a manufacturing method of the Cu-Al-Mn shape memory alloy damping device. The damping device comprises a workbench, a damping assembly and a base. The damping assembly connects the workbench with the base. The damping assembly is composed of a plurality of columnar crystal tissue Cu-Al-Mn shape memory alloy plates with high anisotropism. The Cu-Al-Mn shape memory alloy damping device has the advantages that the damping device has the functional anisotropism, in other words, 10% or more high recovery strain can be provided in the vertical direction, the damping performance is superior, and good energy absorbing and damping functions are achieved; 7% or more high recovery strain in the horizontal direction can be provided, the energy absorbing and damping functions are achieved, and due to higher strength and rigidity of plates in the thickness direction, the damping device has good inclination resisting and shaking resisting functions, and the precise instrument can be kept stable in the using, or moving or transporting process.

Owner:UNIV OF SCI & TECH BEIJING

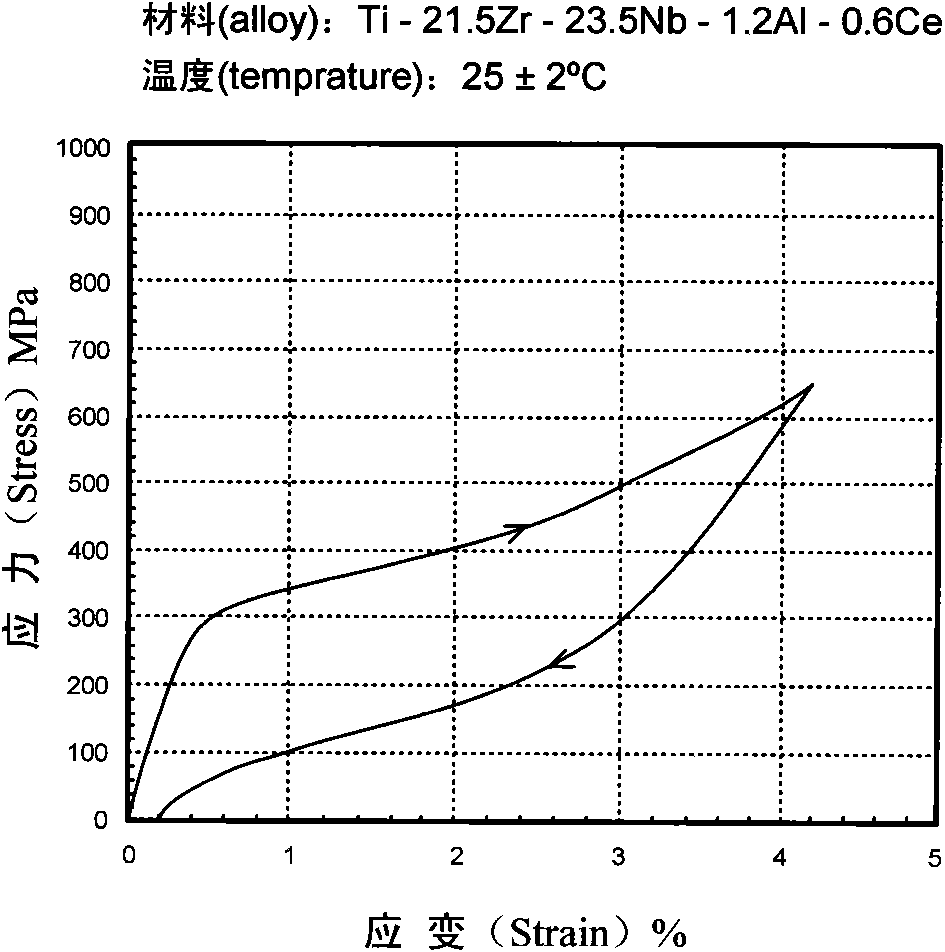

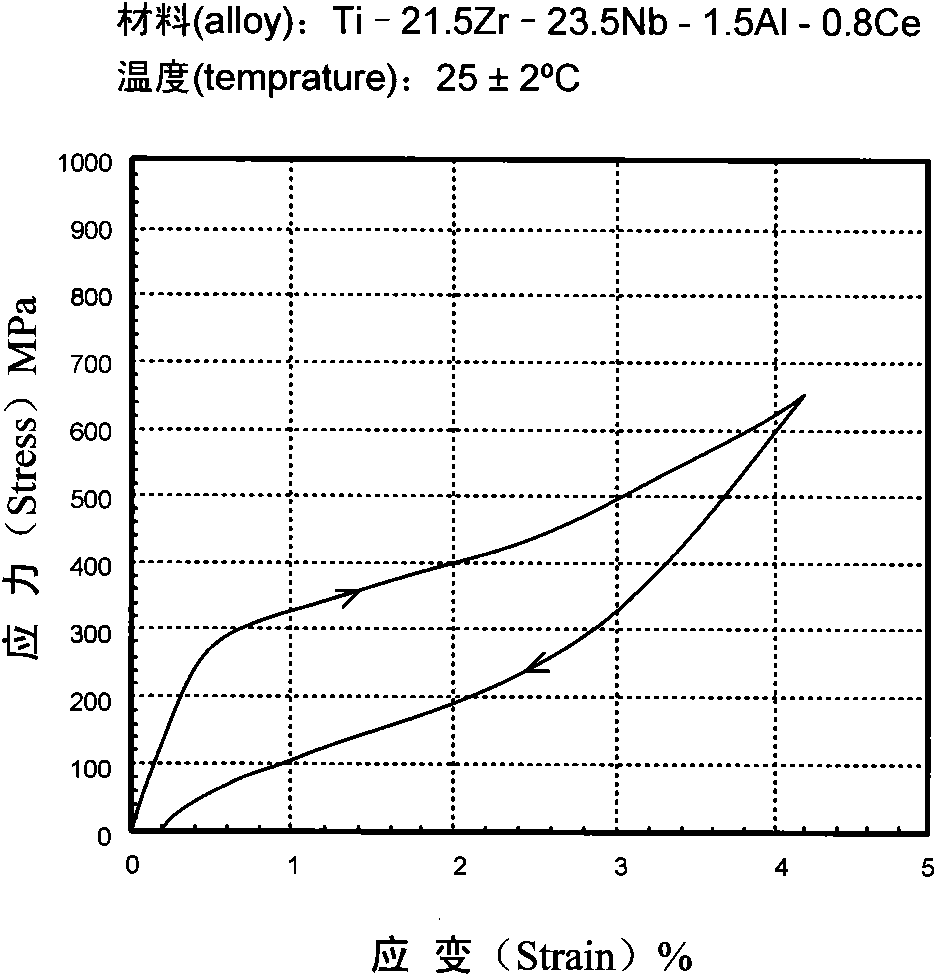

Ti-Zr-Nb-Fe-Al-Ce super elastic alloy and products thereof

InactiveCN101580906AImprove corrosion resistanceImprove high temperature oxidation resistanceImpression capsSurgeryBiocompatibility TestingShape-memory alloy

The invention relates to Ti-Zr-Nb-Fe-Al-Ce super elastic alloy and products thereof. Because of adding appropriate amount of Fe, Al and Ce elements, the super elastic alloy has high erosion resistance and oxidation resistance as well as excellent welding performance, cold workability, phase-changing super elasticity, shape memory property and biocompatibility. The welding performance, the cold workability and the biocompatibility of the alloy are better than those of TiNi shape memory alloy, while the super elasticity and the shape memory property are equivalent to those of the TiNi shape memory alloy. The Ti-Zr-Nb-Fe-Al-Ce super elastic alloy not only can be used as biomaterial capable of being implanted in a human body for a long time, but also can be used as industrial products made from the alloy such as spectacle frame, bra support, golf club head, pipe joint, spring and drive element; moreover, the alloy has the advantages of easy processing, low cost and wide application range.

Owner:深圳市星河泉新材料有限公司

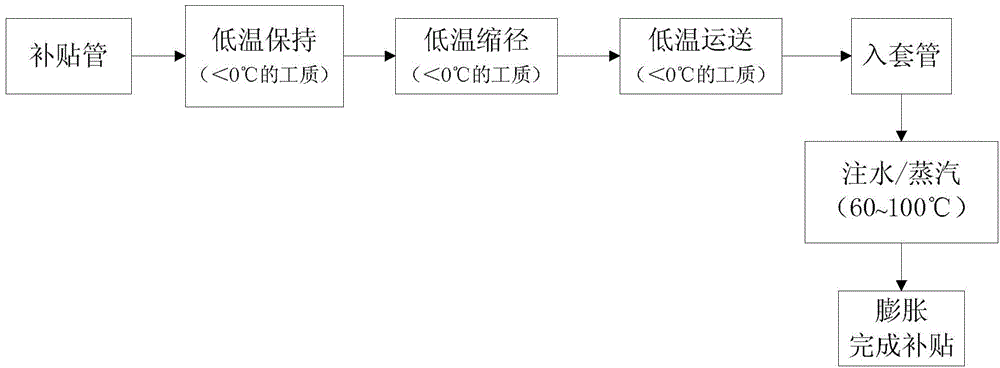

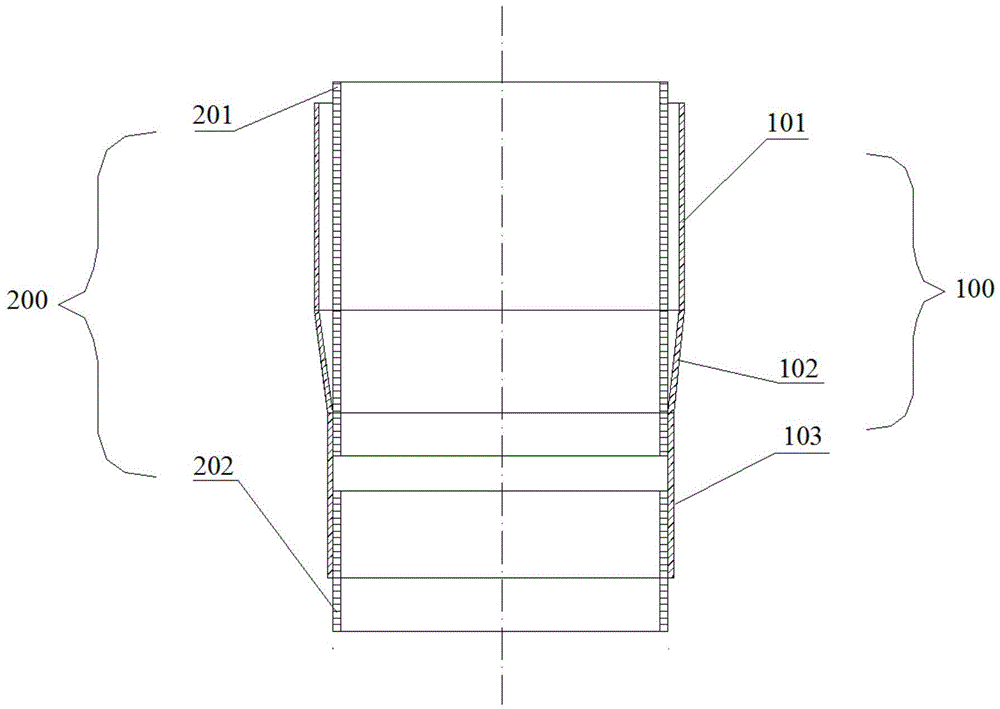

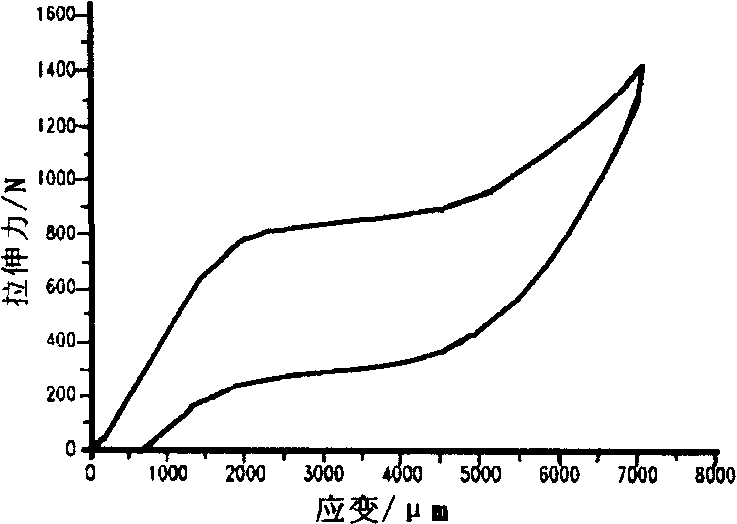

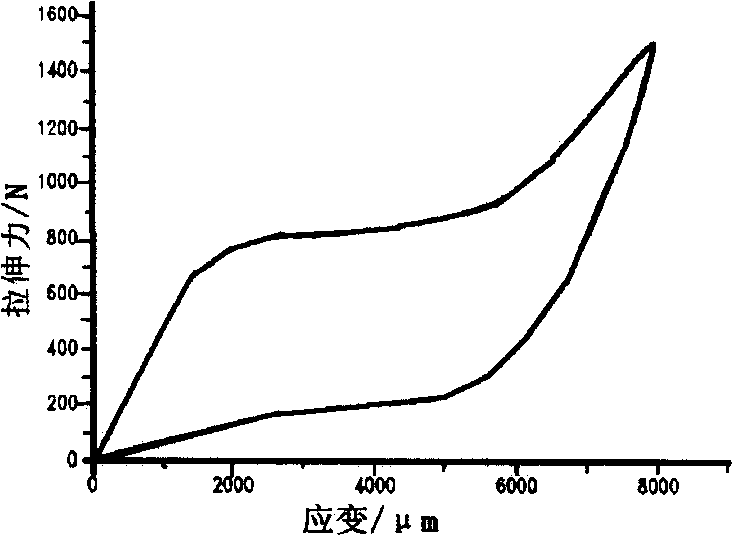

Copper-based memory alloy mended and patched pipe as well as preparation method, mending and patching method and application thereof

InactiveCN104831112AGood thermoelastic phase transition propertiesLow costBorehole/well accessoriesInterference fitShape-memory alloy

The invention provides a copper-based memory alloy mended and patched pipe as well as a preparation method, mending and patching method and application thereof. A copper-based memory alloy comprises the following elements by mass percent: 0.2-1.6% of Be, 6-14% of Al, 1-10% of Mn, 0-3% (more than 0) of Ga, 0-0.1% of impurities and the balance of Cu. The mended and patched pipe is formed by connecting an expansion component with connecting pipes, wherein the expansion component comprises an expanded cylinder, a conical connector and an internally threaded cylinder, which are connected with each other in sequence. The preparation method comprises the following steps: weighing the raw materials according to the alloy components, smelting the raw materials and then cooling the product in a directional solidification cooling system to prepare a cast ingot; then carrying out thermal mechanical treatment, thus obtaining the mended and patched pipe. The mended and patched pipe is simple in mending and patching process and can be in powerful interference fit with a casing to be mended and patched, thus generating great sealing pressure and friction between the mended and patched pipe and the casing and preventing oil leak and fall.

Owner:无锡源创机械科技有限公司

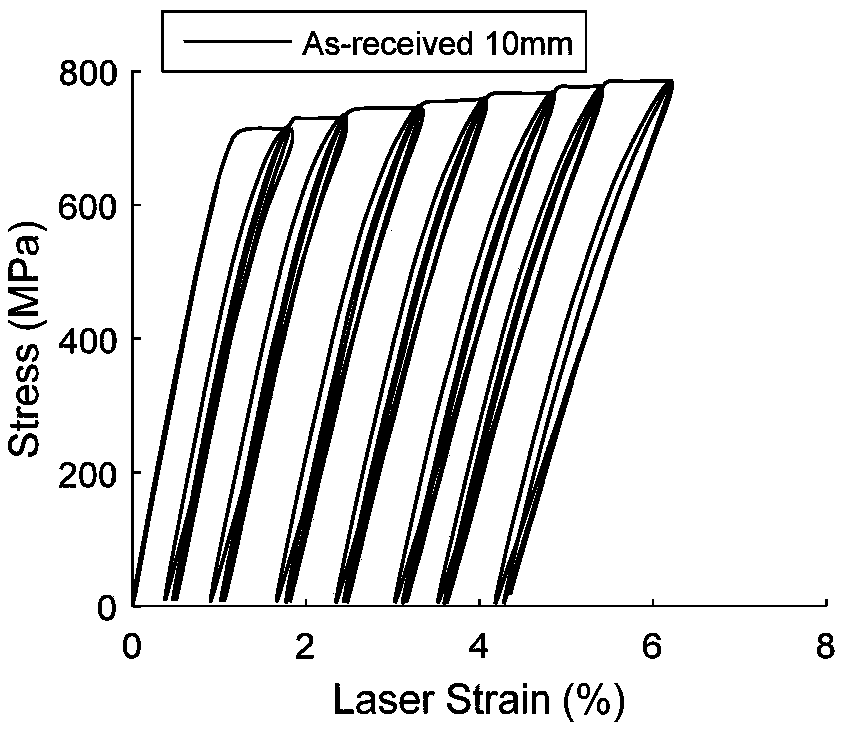

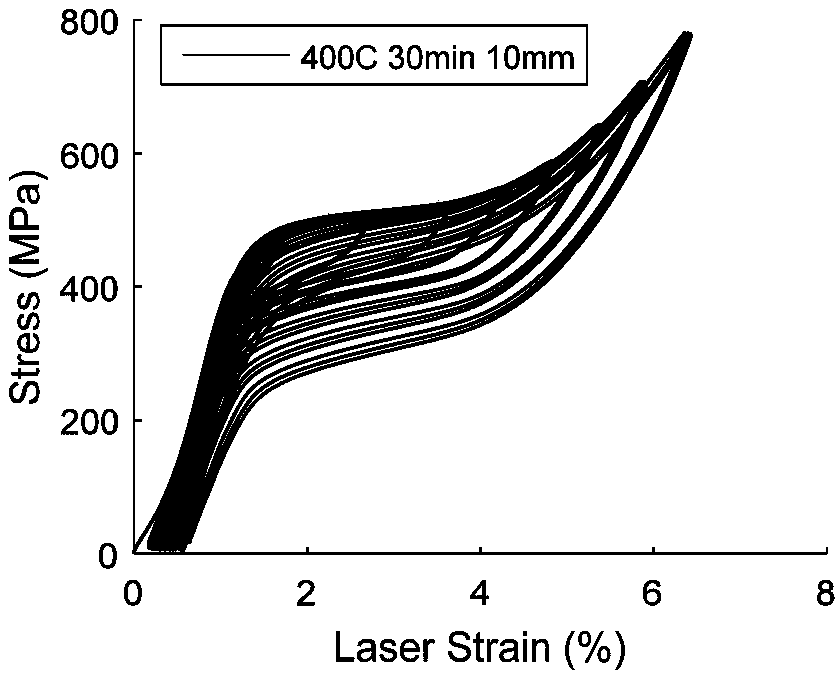

Mesothermal heat process method for improving hyperelasticity of NiTiV shape memory alloy

A middle temperature processing method for improving the superelasticity of NiTiV shape memory alloy is characterized by treating the NiTiV shape memory alloy( the component range is: 55.5 to 57.3 percent of Ni, 41.8 to 43.4 percent of Ti and 0.57 to 0.73 percent of V) with middle temperature processing. A phase transition point Af is equal to minus 35 DEG C to minus 5 DEG C; when the middle temperature processing temperature is 440 DEG C and the temperature is maintained for 20min, very perfect nonlinear superelasticity can be achieved and the superelasticity of the NiTiV shape memory alloy reaches maximum.

Owner:ZHENJIANG YINUOWEI SHAPE MEMORY ALLOYS

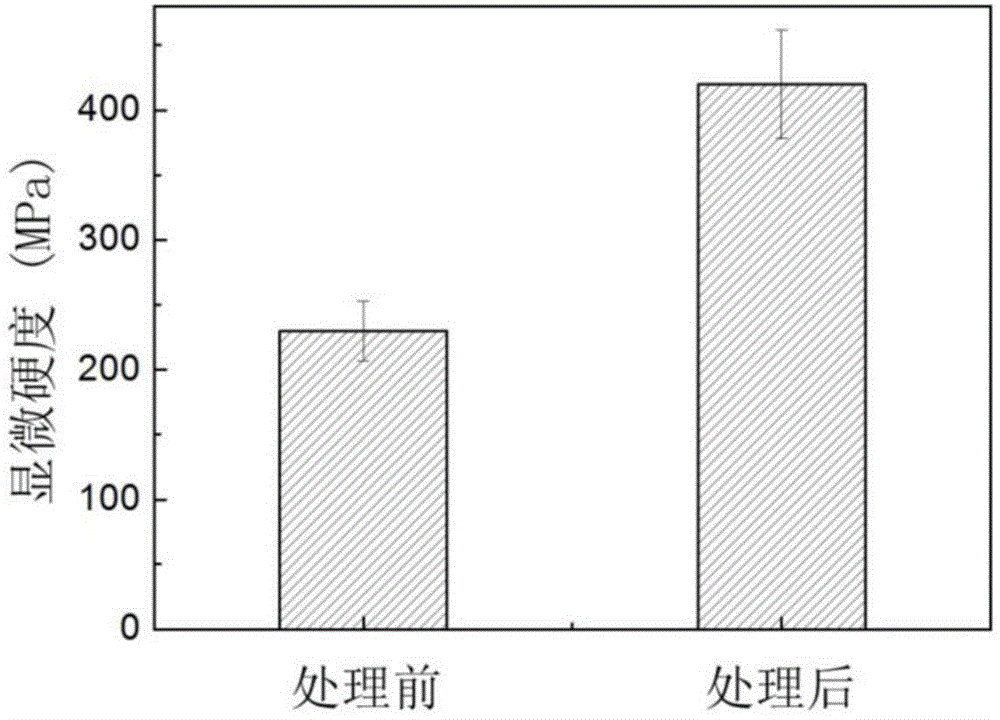

Surface modification method of NiTi alloy martensitic root canal file

ActiveCN104630730ALower phase transition temperatureImprove cutting efficiencyVacuum evaporation coatingSputtering coatingNiti alloyMetal coating

The invention provides a surface modification method of a NiTi alloy martensitic root canal file. According to the method, a metal coating is deposited on the surface of the root canal file by use of a magnetic sputtering process; annealing treatment is performed under the conditions that a vacuum degree is not lower than 10<-3>Pa and the temperature is 600-900 DEG C, so that the metal elements of the coating are diffused to enter a martensitic root canal file substrate, the surface of the root canal file is a parent phase at the operating temperature, and martensite is formed inside the root canal file. The surface modification method is provided mainly for solving the problems of low strength and non-ideal cutting efficiency of the NiTi alloy martensitic root canal file. The surface modification method is also used for solving the problem of low bonding strength between the coating and the substrate of the root canal file. The surface modification method is simple in process, and low in requirements on equipment; the prepared root canal file has the advantages of high cutting efficiency, high fatigue resistance and the like.

Owner:HARBIN ENG UNIV

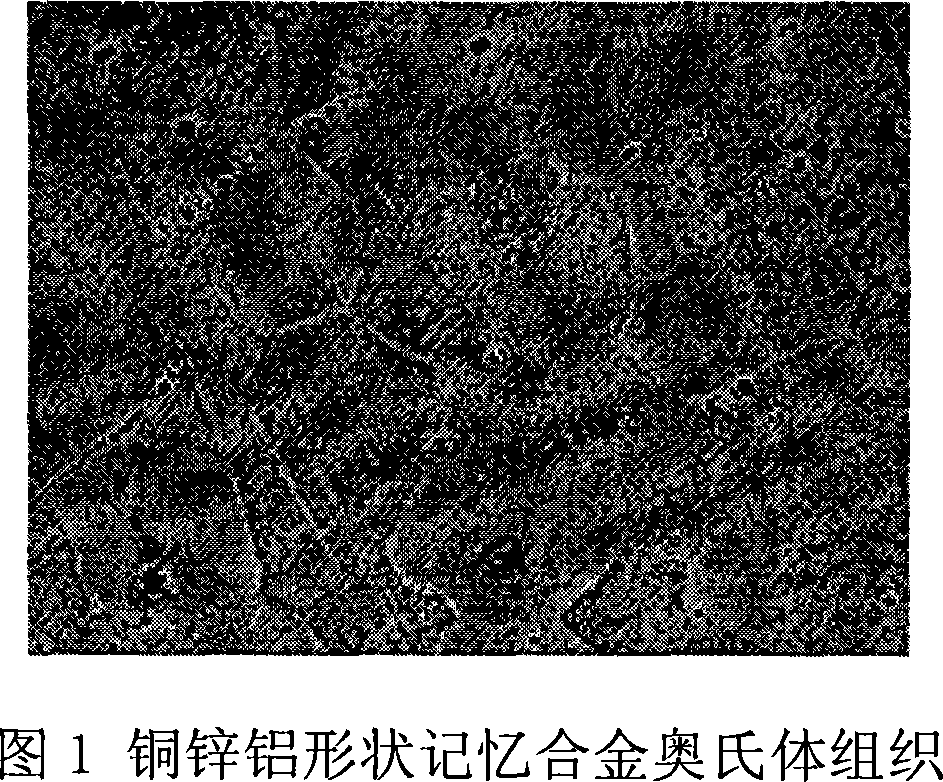

Method for manufacturing blank of shape memory alloy of cupper, zinc, and aluminum

This invention relates to a method for processing Cu-Zn-Al shape-memory alloy billet. The method comprises: removing the oxide layer from the Cu-Zn-Al shape-memory alloy billet, forging at 600-800 deg.C, rolling at 550-750 deg.C, annealing at 600-720 deg.C during rolling, stretching at 460-650 deg.C, and annealing at 600-690 deg.C. The final size after forging is 45 mmX45 mmX1000 mm. The obtained Cu-Zn-Al shape-memory alloy billet can be stretched into wires with different diameters according to different requirements, which can be used to produce spectacle frames with excellent elasticity.

Owner:ZHENJIANG YINUOWEI SHAPE MEMORY ALLOYS

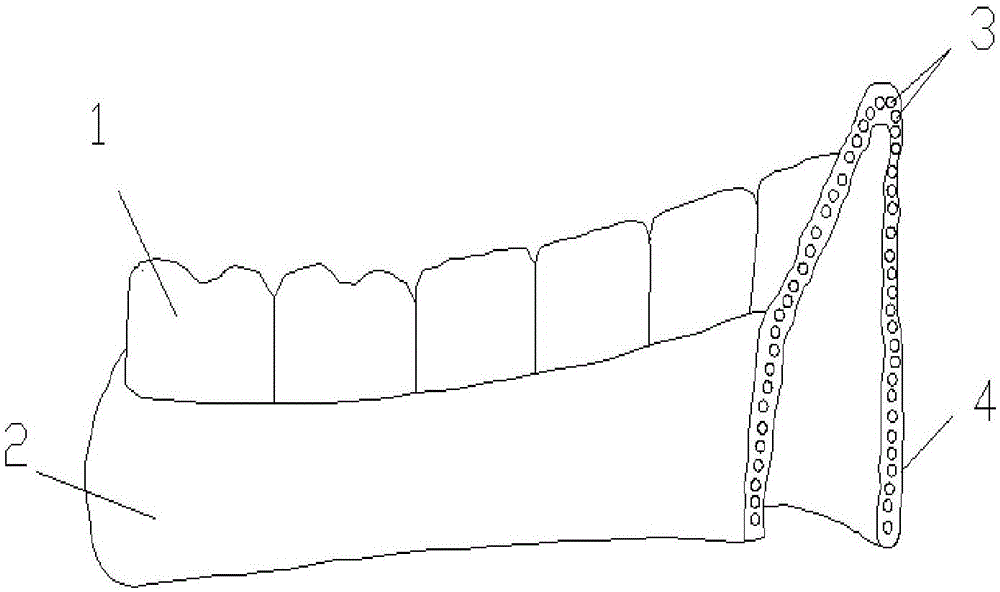

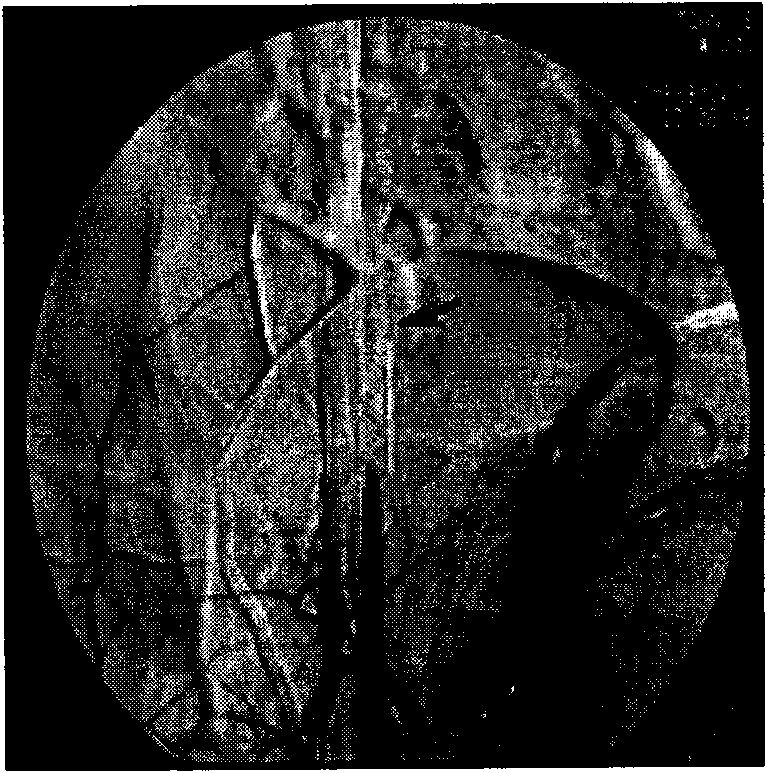

Preparation method for radioactivity TiNi alloy bracket without fringe effect

InactiveCN101627934AGood superelasticityImprove corrosion resistanceStentsRadiation therapyPercent Diameter StenosisIngot

A preparation method for radioactivity TiNi alloy bracket without fringe effect relates to a preparation method for a radioactivity bracket. The preparation method solves the problem of high restenosis rate of the edge of the bracket caused by weak penetrating power of a pure <32>P ray and uniform dosage around the bracket. The method comprises the following steps of: 1. preparing a cast ingot, 2. preparing cold-drawn wires; 3 twisting cold-drawn wires into a bracket, heat processing in vacuum, chemical polishing, ultrasonic washing and drying; 4. putting the dried bracket into a plasma-based injection system for slow neutrons irradiation; 5. annealing the irritated bracket and then cooling the irritated bracket, thus obtaining the radioactivity TiNi alloy bracket. The radioactivity TiNi alloy bracket obtained by the invention both preserves the excellent superelasticity, good corrosion resistance and biomedical science performances of the alloy, also can obtain mixed rays dominated by <32> P, and improves the uniformity of the dosage distribution of the rays around the bracket and is beneficial to inhibiting the fringe effect.

Owner:HARBIN INST OF TECH

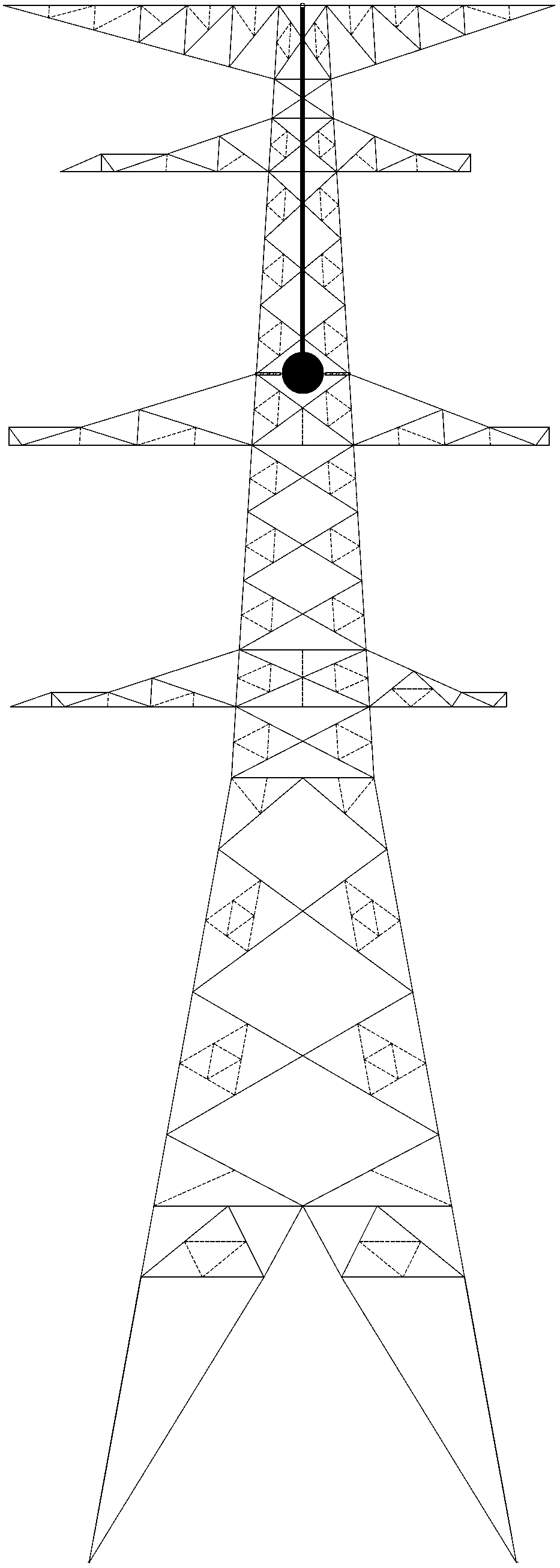

Lattice type power transmission tower horizontal vibration self-reset shock absorber

InactiveCN102936927AOffset adverse effectsQuick resetShock proofingSmall amplitudeShape-memory alloy

The invention discloses a lattice type power transmission tower horizontal vibration self-reset shock absorber which comprises shape memory alloy rings, a steel ball, an anchor bolt, a steel suspension rod and a steel suspension ring, wherein the lower end of the steel suspension rod is fixedly connected with the steel ball; the upper end of the steel suspension rod is fixedly connected with the steel suspension ring; the steel suspension ring is hung at the top center of a power transmission tower; four shape memory alloy rings are provided and anchored at the four corners of the tower body of the power transmission tower; the four shape memory alloy rings are all horizontally arranged and uniformly distributed around the periphery of the steel ball; the centers of the four shape memory alloy rings are located on the circumference of the same circle centered on the steel ball; the steel ball absorbs shock and consumes energy by use of the shake thereof in the case of small amplitude; and in the case of large amplitude, the steel ball can collide with the shape memory alloy rings to consume energy so as to realize shock absorption.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com