Cu-Al-Mn shape memory alloy damping and energy-absorbing device for civil construction and manufacturing method thereof

A cu-al-mn, civil construction technology, applied in building components, anti-vibration and other directions, can solve the problems of poor durability of shock absorbers, poor self-resetting performance, limited dissipation capacity, etc., and achieve good damping performance and self-resetting ability. Excellent, strong energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

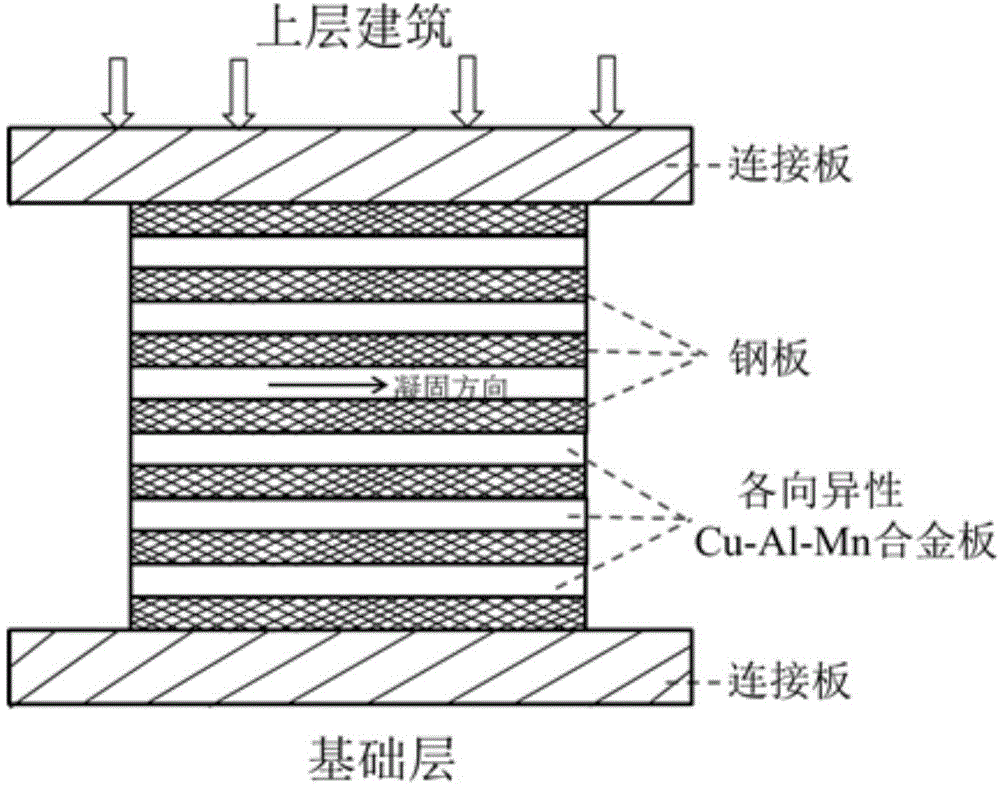

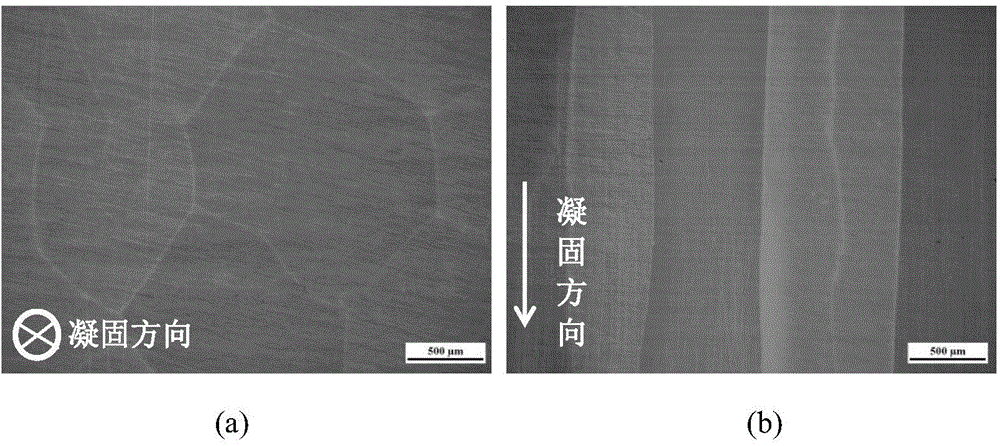

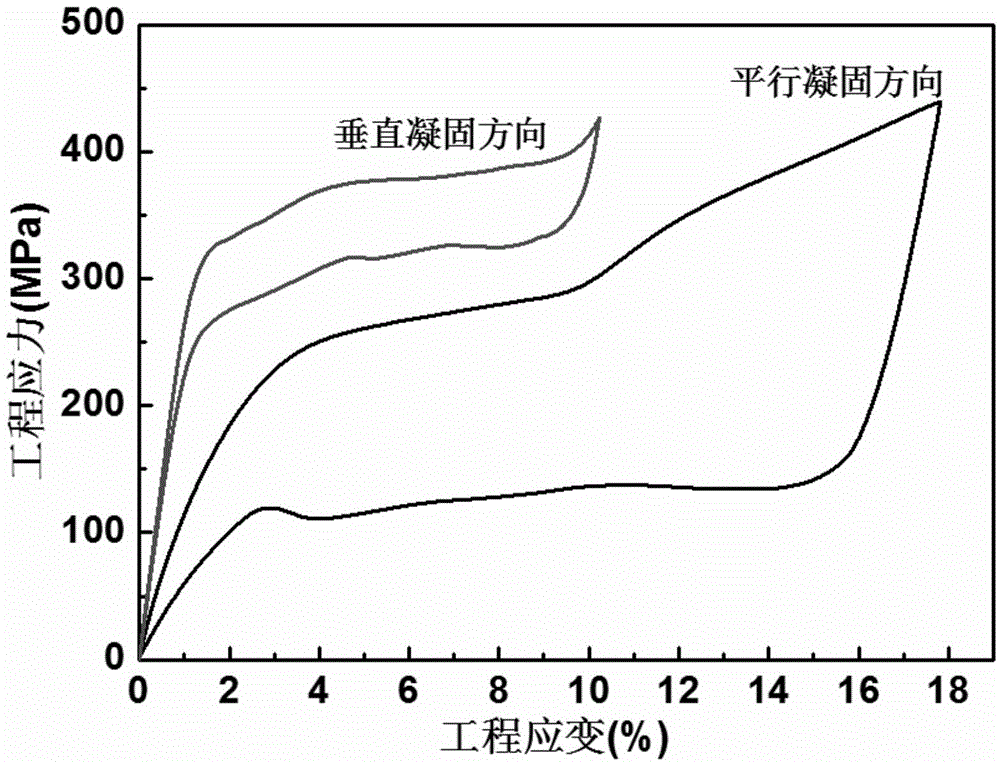

[0041] Adopt preparation process described in the present invention to prepare wide 50mm thick 4mm Cu 72 Al 18 mn 10 (at.%) alloy plate, the properties along the parallel and perpendicular solidification directions are shown in Table 1, the superelastic recoverable strain in the parallel solidification direction reaches 18%, the yield strength is 228.5MPa, and the superelastic recoverable strain in the perpendicular solidification direction reaches 9%, the yield strength is 312.1MPa, cut a plate with a length of 150mm, the length direction of the plate is along the solidification direction, press figure 1 The fabricated device is shown. The maximum bearing strain of the device in the horizontal direction is 18%, the maximum bearing strain in the vertical direction is 9%, and the maximum bearing pressure is 312MPa.

[0042] Table 1 Columnar grain structure Cu 72 Al 18 mn 10 Performance parameters of alloy plates parallel and perpendicular to solidification direction

[0...

Embodiment 2

[0045] Adopt preparation process described in the present invention to prepare wide 50mm thick 5mm Cu 72 Al 17 mn 11 (at.%) alloy plate, the properties along the parallel and perpendicular solidification directions are shown in Table 2, the superelastic recoverable strain in the parallel solidification direction reaches 16%, the yield strength is 268.9MPa, and the superelastic recoverable strain in the perpendicular solidification direction reaches 8.5%, the yield strength is 349.3Mpa, cut the plate with a length of 130mm, the length direction of the plate is along the solidification direction, according to figure 1 The fabricated device is shown. The maximum bearing strain in the horizontal direction of the device is 16%, the maximum bearing strain in the vertical direction is 8.5%, and the maximum bearing pressure is 349Mpa.

[0046] Table 2 Cu columnar grain structure 72 Al 17 mn 11 Performance parameters of alloy plates parallel and perpendicular to solidification di...

Embodiment 3

[0049] Adopt preparation process described in the present invention to prepare the Cu of wide 40mm thick 4mm 71 Al 20 mn 9 (at.%) alloy plate, the properties along the parallel and perpendicular solidification directions are shown in Table 3, the superelastic recoverable strain in the parallel solidification direction reaches 10%, the yield strength is 298.9MPa, and the superelastic recoverable strain in the perpendicular solidification direction reaches 7.5%, the yield strength is 382.1MPa, cut a plate with a length of 140mm, the length direction of the plate is along the solidification direction, press figure 1 The fabricated device is shown. The maximum bearing strain of the device in the horizontal direction is 10%, the maximum bearing strain in the vertical direction is 7.5%, and the maximum bearing pressure is 382MPa.

[0050] Table 3 Columnar grain structure Cu 71 Al 20 mn 9 Performance parameters of alloy plates parallel and perpendicular to solidification direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com