Surface modification method of NiTi alloy martensitic root canal file

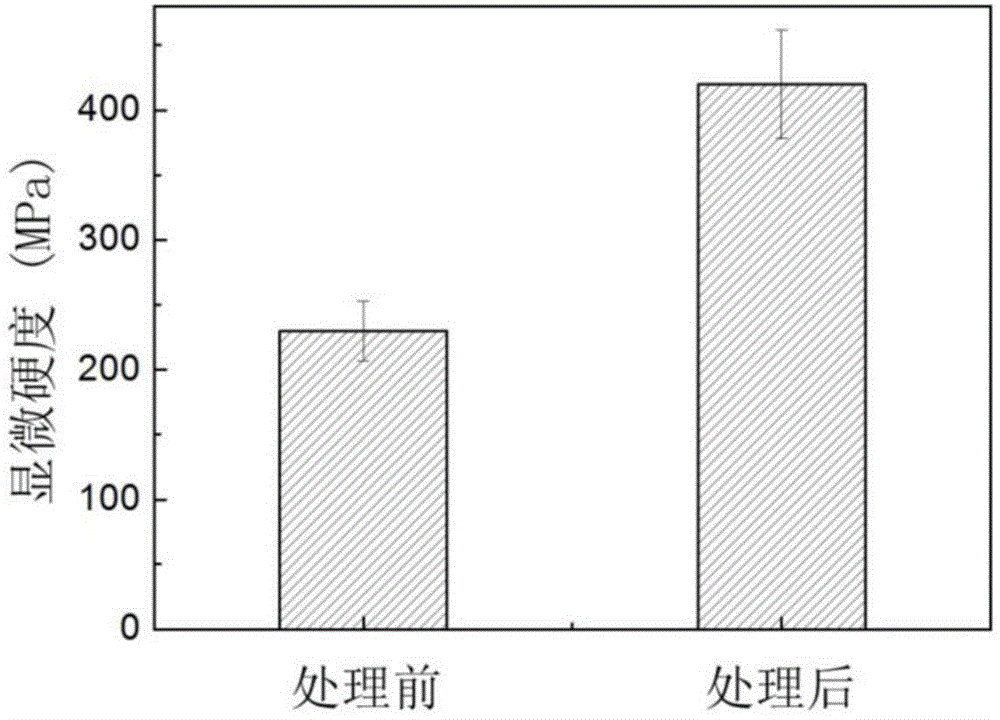

A technology of surface modification and root canal filing, applied in metal material coating process, ion implantation coating, coating and other directions, can solve the problem that the toughness of the bonding coating cannot be effectively guaranteed, and the mechanical properties of the coating are not ideal bonding strength, etc. It can solve the problem of unsatisfactory bonding strength, excellent superelasticity and high hardness, and improve the cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

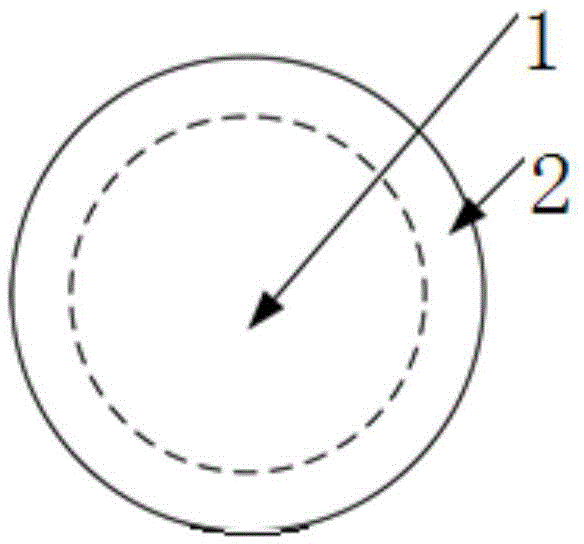

specific Embodiment approach 1

[0018] (1) Use the coated metal element as the sputtering target, and install it on the corresponding target position of the magnetron sputtering equipment; (2) Place the NiTi alloy martensitic root canal file on the sample stage of the vacuum chamber, and draw Vacuum to 1×10 -4 ~1×10 -5 Pa, filled with argon gas to a vacuum degree of 0.1-0.5Pa, sputtering and depositing a metal coating under the conditions of a sputtering power of 50-600W and a distance between the target and the substrate of 20-200mm; (3) depositing metal-coated root canal files in a vacuum of not less than 10 -3 Annealing treatment is carried out under Pa condition, and the annealing temperature is 600-900°C; (4) pickling is used to remove the residual metal coating on the surface, and a NiTi alloy root canal file with the parent phase on the surface and martensite inside can be obtained.

specific Embodiment approach 2

[0019] (1) Choose to use high-purity metal Ni as the sputtering target, and install it on the corresponding target position of the magnetron sputtering equipment. (2) Place the NiTi alloy martensitic root canal file on the sample stage of the vacuum chamber, and evacuate to 1×10 -4 ~1×10 -5 Pa, filled with argon gas to a vacuum of 0.1-0.5Pa, sputtering and depositing a metal coating under the conditions of a sputtering power of 50-600W and a distance between the target and the substrate of 20-200mm; during the sputtering process, the sample The table rotates axially around the root canal file while rotating around the central axis of the vacuum chamber. (3) The root canal files deposited with metal Ni coating should be kept at a vacuum degree of not less than 10 -3 The annealing treatment is carried out under the condition of Pa, the annealing temperature is 600-900°C, and the annealing time is 15min-120min. (4) Place the annealed root canal file in dilute nitric acid solut...

specific Embodiment approach 3

[0021] The difference between the present embodiment and the second embodiment is that the high-purity metal V is used as the target in the step (1) of the present embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com