Preparation method of intelligent temperature control color changing vanadium oxide film

A vanadium oxide thin film and intelligent temperature control technology, applied in the field of material chemistry, can solve the problems of difficult doping of tungsten coating solution with doped tungsten sources, low efficiency of phase transition temperature reduction, and difficulty in achieving effective doping, etc., achieving broad application prospects, Comprehensive performance improvement and long-term stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 1.25g of tungstic acid powder into a beaker, add 10mL of hydrogen peroxide with a concentration of 30wt% and 10mL of methanol into the beaker containing tungstic acid powder at the same time, heat and stir in a water bath at 45°C for 24h until the solid powder is completely dissolved, and centrifuge The transparent tungsten-containing sol with a tungsten ion concentration of 0.3 mol / L can be obtained by filtration.

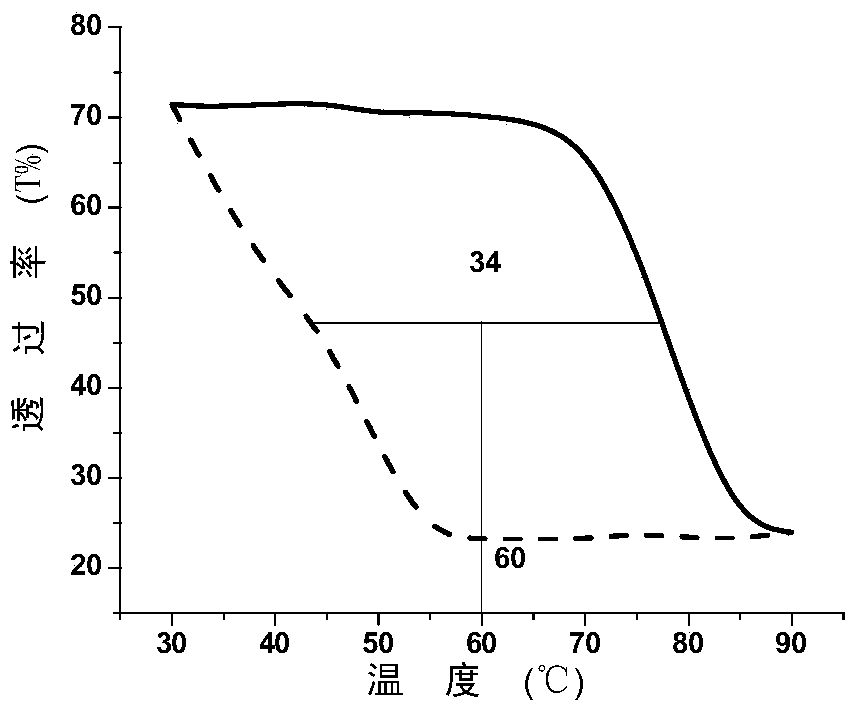

[0042] 0.663 g of vanadyl acetylacetonate was added to 25 mL of methanol, stirred at room temperature, and when the methanol was volatilized to 20 mL, centrifugal filtration was performed to obtain a dark green vanadium ion-containing sol. 1.5% by mass of polyvinylpyrrolidone (PVP) was added to the above sol, then 0.08 mL of the tungsten-containing sol prepared above was added to the above sol, and a stable tungsten-doped coating solution was obtained after stirring at room temperature for 18 hours. The molar ratio of tungsten to vanadium in the coati...

Embodiment 2

[0047] The tungsten-containing sol was prepared by the same method as in Example 1.

[0048] 0.663 g of vanadyl acetylacetonate was added to 25 mL of methanol, stirred at room temperature, and when the methanol was volatilized to 20 mL, centrifugal filtration was performed to obtain a dark green vanadium ion-containing sol. PVP with a mass percentage of 1.5% was added to the above sol, then 0.16 mL of tungsten-containing sol was added to the above sol, and a stable tungsten-doped coating solution was obtained after stirring at room temperature for 20 hours. The molar ratio of tungsten to vanadium in the coating solution was 2:100.

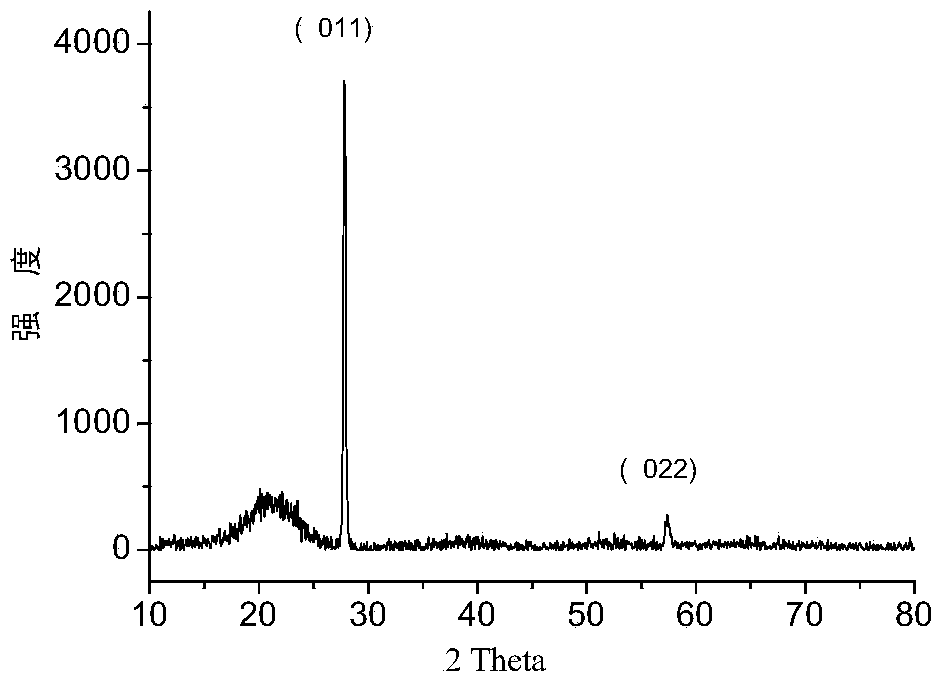

[0049] The quartz glass was ultrasonically washed successively with deionized water, acetone and ethanol, and the ultrasonic washing time was 15 minutes, and the cleaned quartz glass pieces were placed in alcohol and stored for later use. The spin coating method was used to coat the films. After each layer of film was plated, it was baked at 80 °C...

Embodiment 3

[0053] The tungsten-containing sol was prepared by the same method as in Example 1.

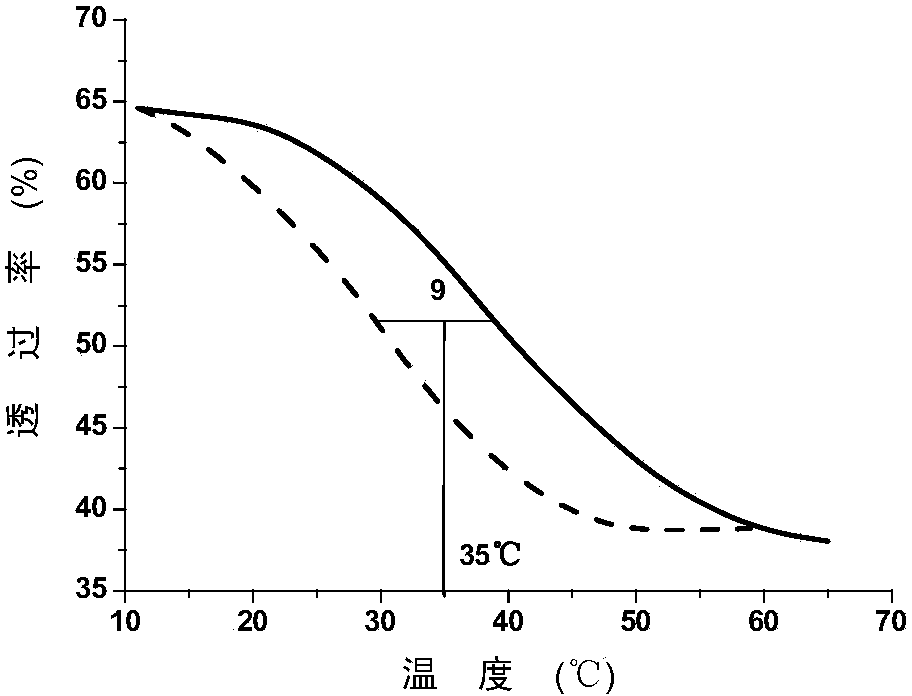

[0054] 0.663 g of vanadyl acetylacetonate was added to 25 mL of methanol, stirred at room temperature, and when the methanol was volatilized to 20 mL, centrifugal filtration was performed to obtain a dark green vanadium ion-containing sol. PVP with a mass percentage of 1.5% was added to the above sol, then 0.4 mL of tungsten-containing sol was added to the above sol, and a stable tungsten-doped coating solution was obtained after stirring at room temperature for 24 hours. The molar ratio of tungsten to vanadium in the coating solution was 5:100.

[0055] The quartz glass was ultrasonically washed successively with deionized water, acetone and ethanol, and the ultrasonic washing time was 20 minutes, and the cleaned quartz glass pieces were placed in alcohol and stored for later use. The spin coating method was used to coat the films. After each layer of film was plated, it was baked at 80 °C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com