Polycrystalline Fe-Ni-Co-Al-Nb-B shape memory alloy with super elasticity and preparation method thereof

A fe-ni-co-al-nb-b, memory alloy technology, applied in the field of polycrystalline Fe-Ni-Co-Al-Nb-B shape memory alloy and its preparation, to achieve excellent superelasticity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

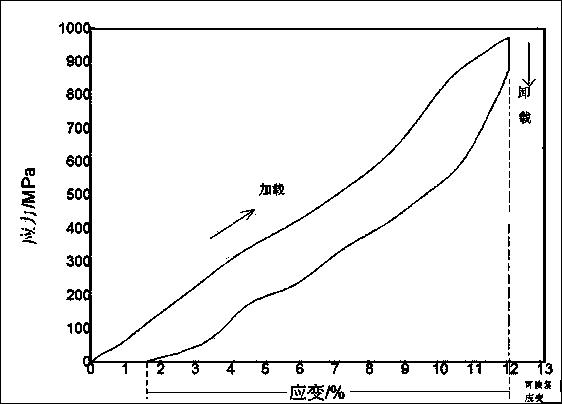

Image

Examples

Embodiment 1

[0024] Example 1: The composition and corresponding atomic percentages of the polycrystalline Fe-Ni-Co-Al-Nb-B shape memory alloy with superelasticity in this example are: Fe 30.35%, Ni 30%, Co 18% , Al 10.5%, Nb 2%, B 0.15%.

[0025] The preparation process and steps are as follows: prepare 60 g of industrially pure metal raw materials Fe, Ni, Co, Al, Nb, and B according to the polycrystalline Fe-Ni-Co-Al-Nb-B shape memory alloy composition of this embodiment, and then configure The material is melted in a vacuum non-consumable electric arc furnace under the protection of argon, and the melting current density is 250A / cm 2 , the smelted alloy was turned over and smelted 4 times; the alloy ingot obtained by smelting was first hot-rolled at 1000°C into a thin plate with a thickness of 3.5mm, and then solid solution treated at 1150°C for 30min, and cold-rolled into a thin plate with a thickness of 2.5mm after water quenching; The final material was solutionized at 1250°C for 30...

Embodiment 2

[0027] Embodiment 2: The alloy composition of this embodiment is the same as that of Embodiment 1.

[0028] Its preparation process and steps are as follows: prepare 60g of the polycrystalline Fe-Ni-Co-Al-Nb-B shape memory alloy composition of the industrial pure metal raw material Fe, Ni, Co, Al, Nb, B according to the present embodiment, and use vacuum The non-consumable electric arc furnace is smelted under the protection of argon, and the smelting current density is 250A / cm 2 , the smelted alloy was turned over and smelted 4 times; the alloy ingot obtained by smelting was first hot-rolled at 1000°C into a thin plate with a thickness of 3.5mm, then solution treated at 1150°C for 30min, and cold-rolled into a thin plate with a thickness of 2.5mm after water quenching; After rolling, the material was solid-dissolved at 1250°C for 30 minutes, and then quenched in water; after solution treatment, the material was aged at 600°C for 45 hours and then air-cooled.

[0029] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com