Patents

Literature

35results about How to "Offset adverse effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

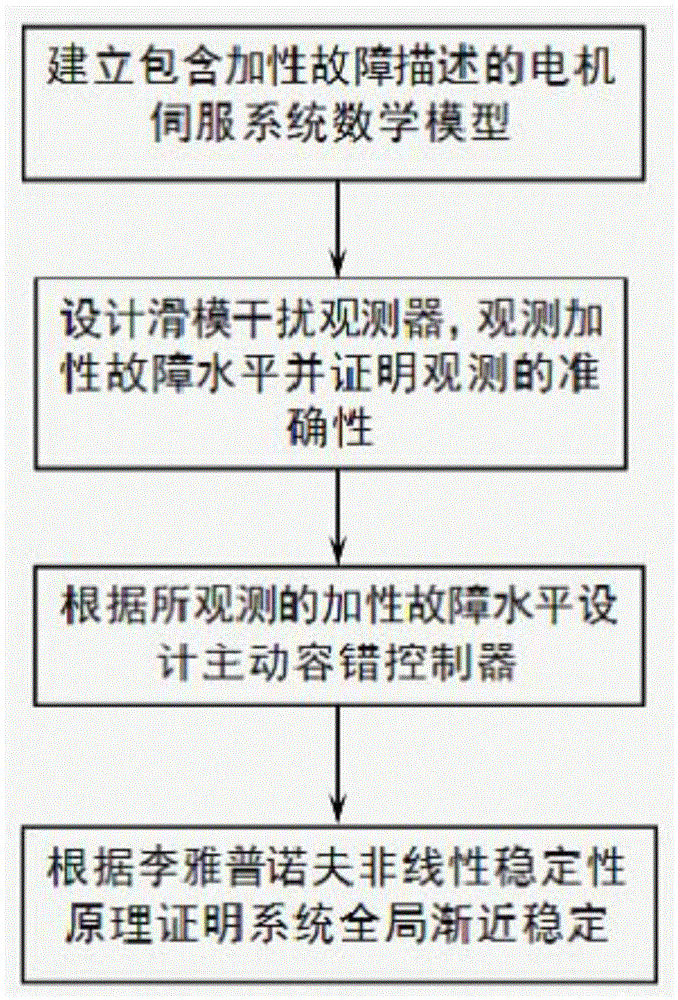

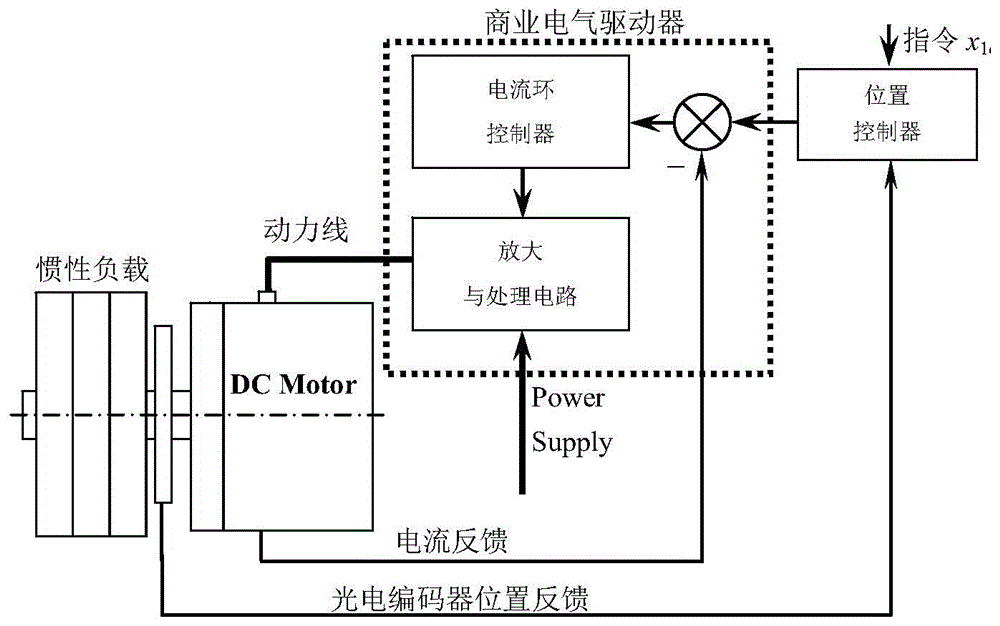

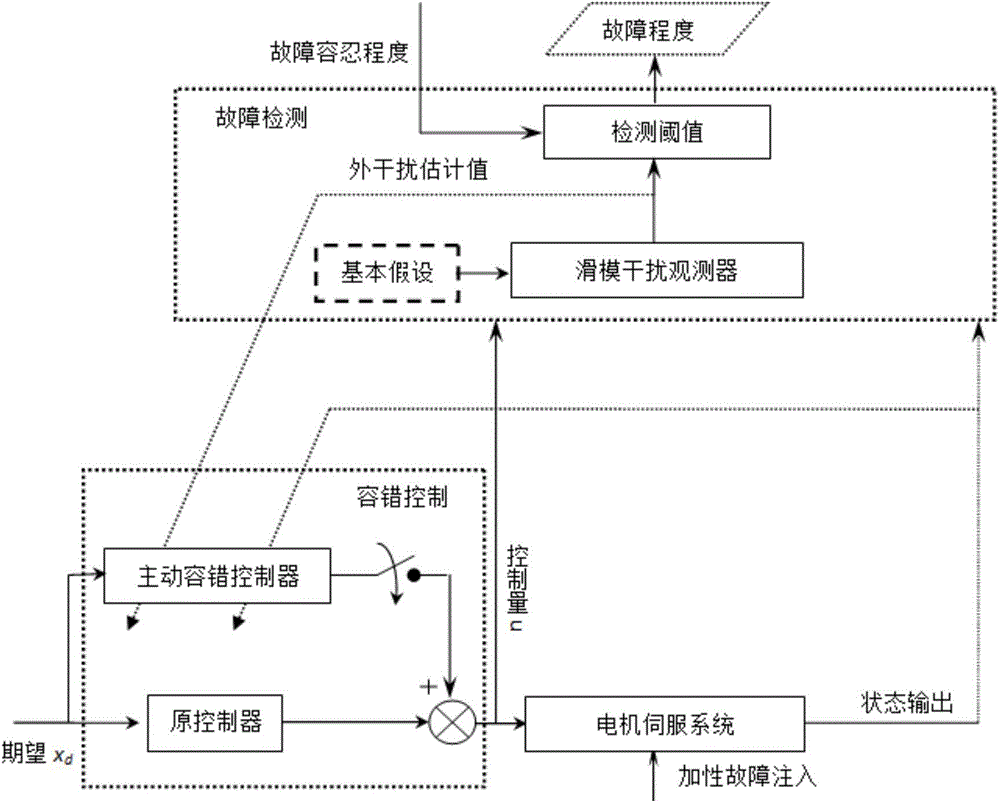

Motor servo system additivity fault detection and fault tolerant control method based on slip form

ActiveCN104808653AEliminate chatterGuaranteed real-timeElectric testing/monitoringMathematical modelNonlinear stability

The invention discloses a motor servo system additivity fault detection and fault tolerant control method based on a slip form. The method includes building a motor servo system mathematical model containing additivity fault description, designing a slip form disturbance observer to observe additivity fault level and demonstrate observation accuracy, designing an initiative fault tolerant controller according to the observed additivity fault, and demonstrating system overall gradual stability according to the Lyapunov nonlinear stability principle. By means of the control method, the reasonable fault tolerance degree can be set to ensure that effects caused by various model uncertainties are kept in the designed fault tolerance range all the time when the system has no fault, false alarming of the system is avoided, and fault detection robustness is improved. The additivity fault level of the system can be observed on line, real-time performance of additivity fault detection is guaranteed while system control performance is not affected, active detection missing and fault tolerant control of minor faults can be achieved, and timely warning of severe faults is also achieved.

Owner:NANJING UNIV OF SCI & TECH

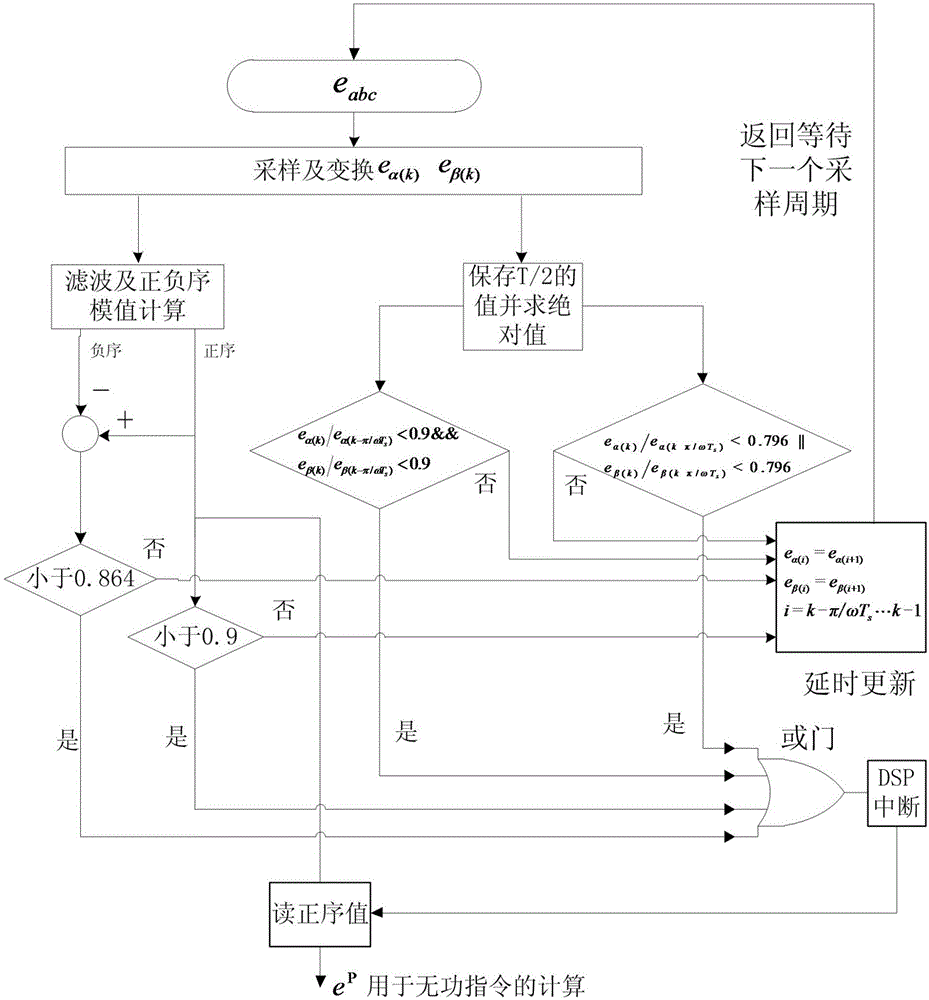

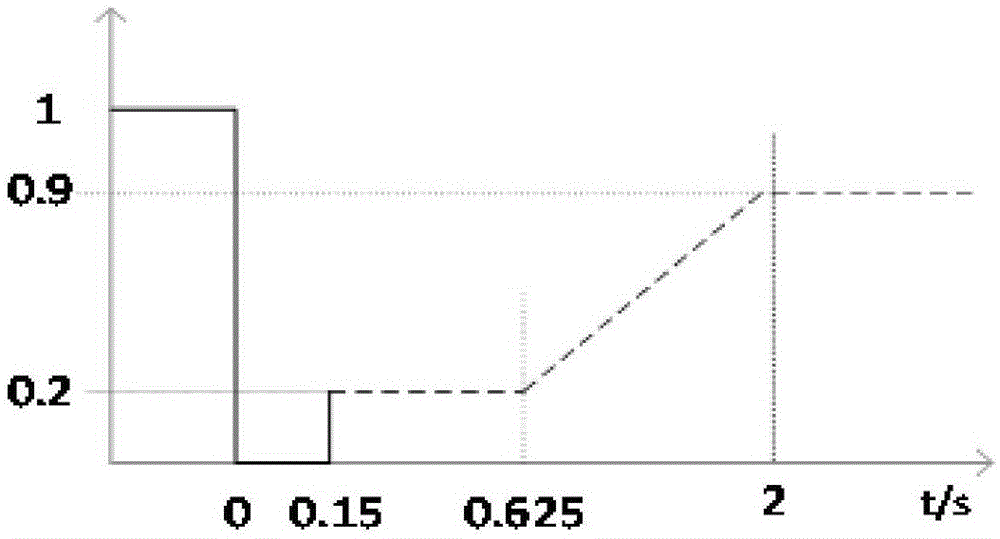

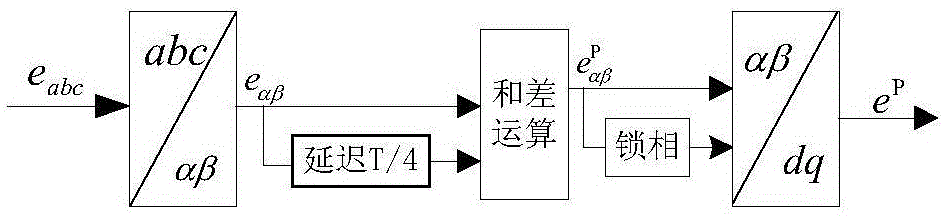

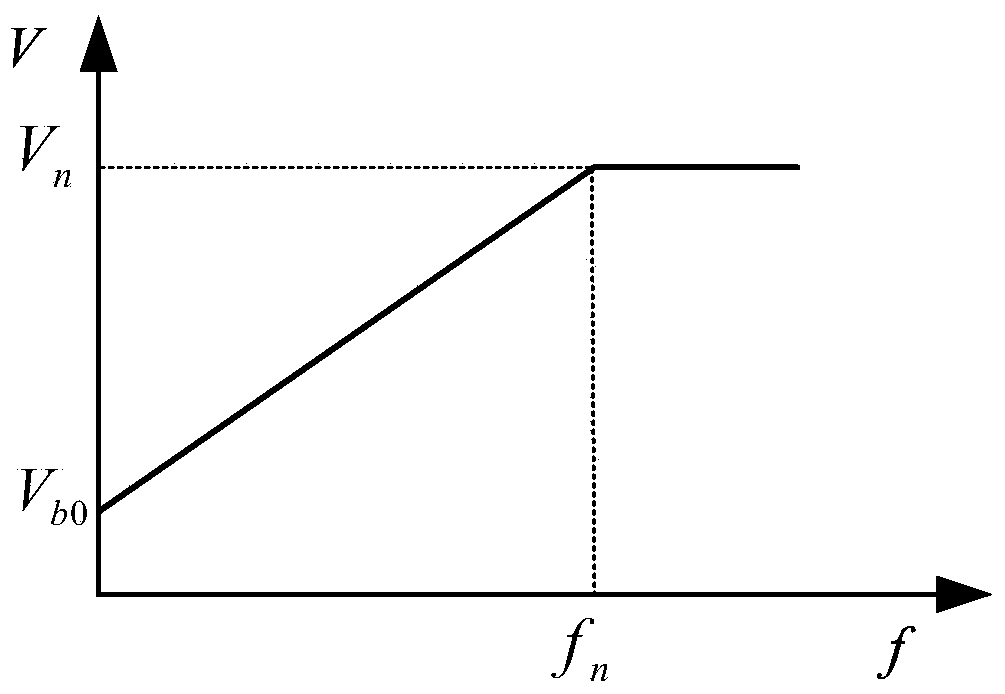

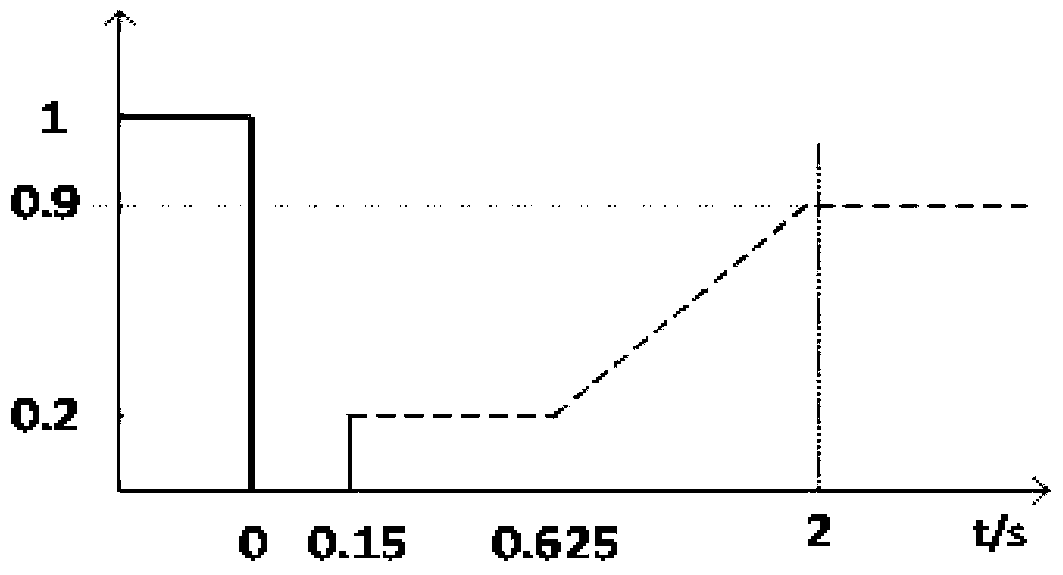

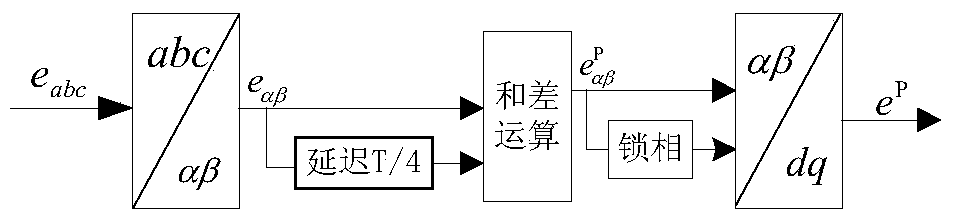

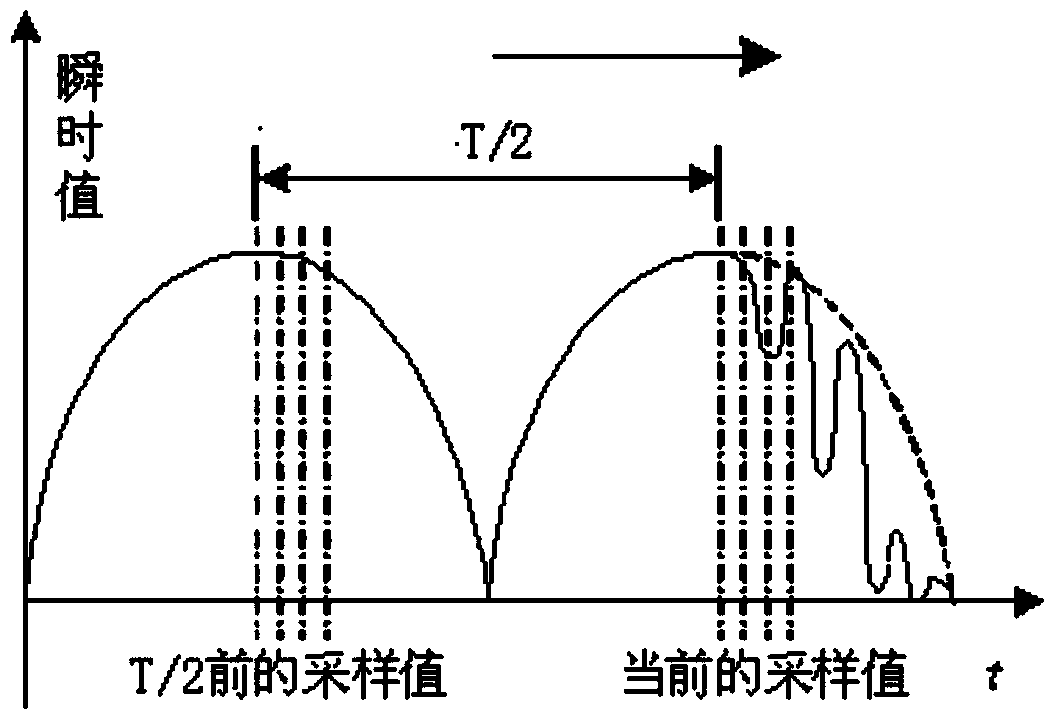

Voltage drop detection method suitable for power grid voltage large harmonic content

ActiveCN105116195AOffset adverse effectsGuaranteed accuracyCurrent/voltage measurementOvercurrentHarmonic

The present invention relates to the electric energy transformation technology field, in particular to a voltage drop detection method suitable for a power grid voltage large harmonic content. The method comprises the steps of real-timely detecting a power grid voltage, calculating a positive sequence module value eP and a negative sequence module value eN of the power grid voltage, and carrying out the steady state judgment according to a calculation result; real-timely detecting the power grid voltage, calculating the voltage components e alpha and e beta of the power grid voltage in an alpha-beta stationary reference frame, carrying out the instant judgment according to the calculation result. When the instant judgment is used to limit an instant overcurrent, and the steady state judgment is used to determine a reactive current, the instant judgment pays attention to the rapidity, and the steady state judgment pays attention to the stability and accuracy. The two methods are combined to use, and make up the insufficiency mutually, thereby guaranteeing the accuracy and the stability of a judgment result.

Owner:NAVAL UNIV OF ENG PLA +1

Ultrahigh-strength self-compacting concrete for giant special-shaped steel pipe column and preparation method thereof

InactiveCN110606709AComplementary performance shortcomingsOffset adverse effectsWork performanceCrushed stone

The invention belongs to the technical field of building materials, and particularly relates to ultrahigh-strength self-compacting concrete suitable for a giant special-shaped steel pipe column and apreparation method thereof. The ultrahigh-strength self-compacting concrete comprises a cementing material, aggregate, super absorbent resin, an additive and water; wherein the cementing material is prepared from 375 to 425 parts of cement, 70 to 120 parts of fly ash, 30 to 60 parts of mineral powder, 30 to 40 parts of silica fume and 45 to 55 parts of expanding agent; the aggregate is prepared from 1000 to 1055 parts of crushed stone and 660 to 710 parts of mixed sand; the super absorbent resin accounts for 0.2% of the total mass part of the cementing material; the concrete also includes 15.8to 16.5 parts of the additive, and 135 to 140 parts of the water. According to the invention, the working performance of the ultrahigh-strength self-compacting concrete meets the first-grade self-compacting performance requirement, the gap passing ability is good, and the ultrahigh-layer pumping problem of the ultrahigh-strength concrete is solved.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

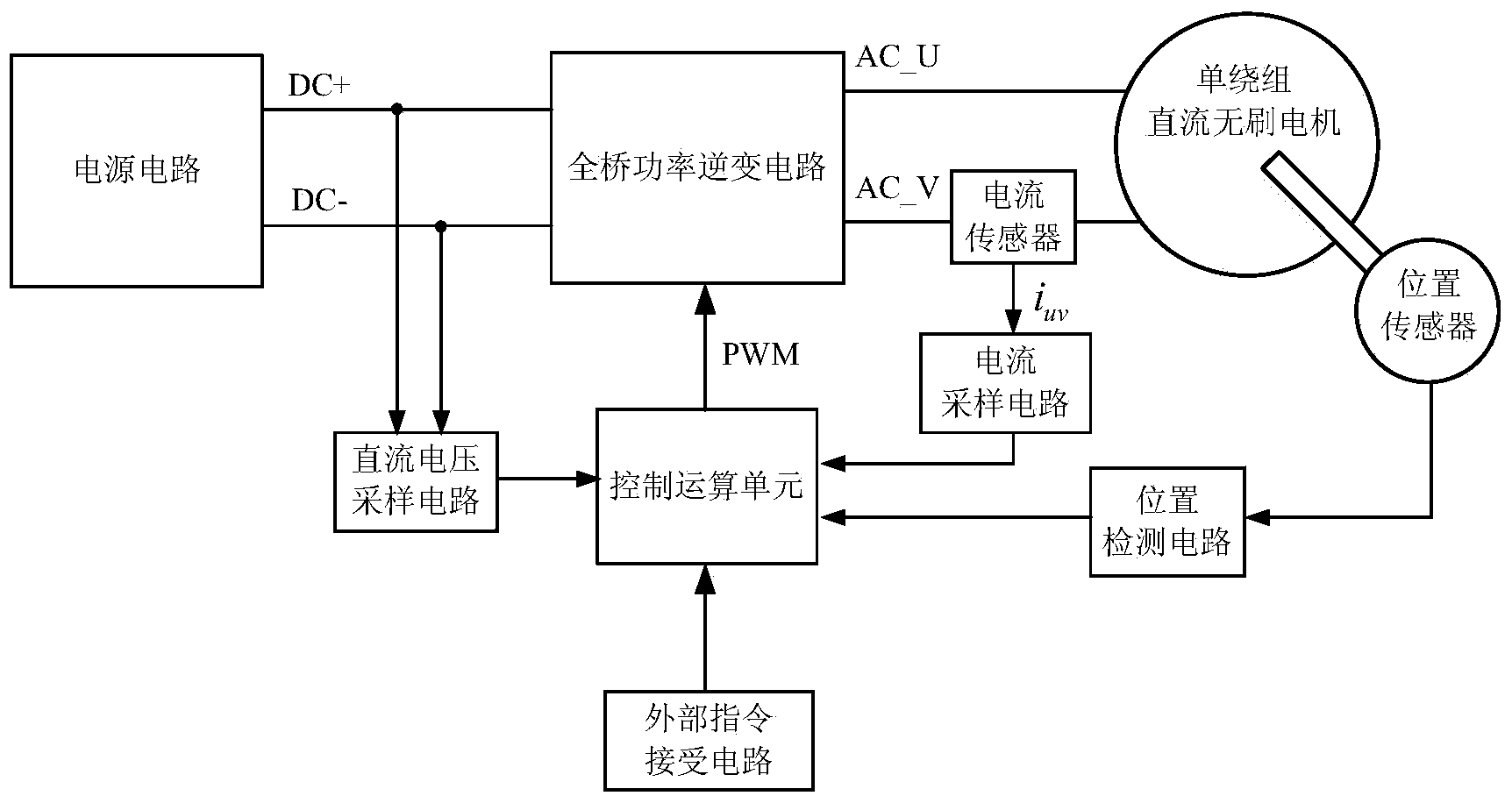

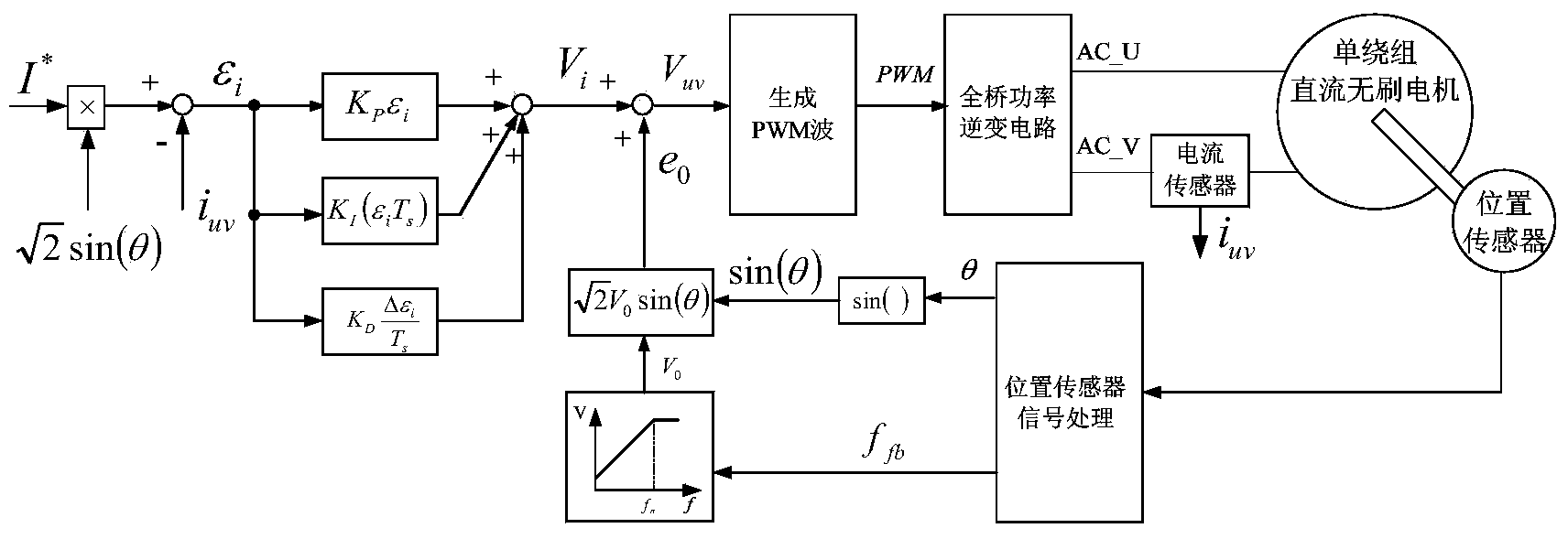

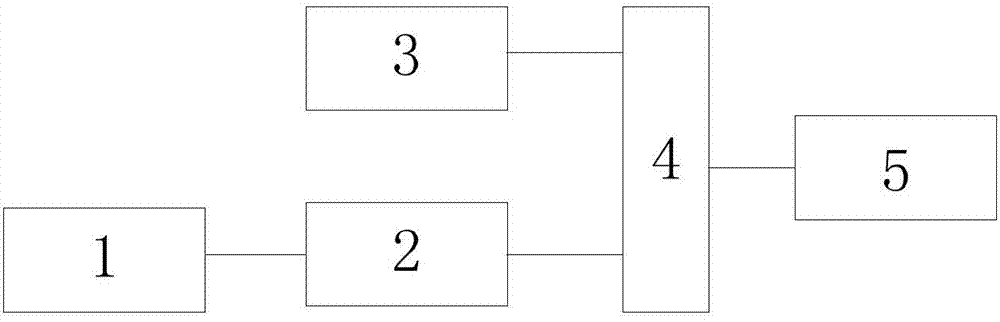

Sine-wave current driving system of single-winding brushless direct current motor and control method thereof

ActiveCN104038115AImprove the disadvantage of difficult startingSolve the difficulty of startingTorque ripple controlElectronic commutatorsBrushless motorsFull bridge

The invention relates to a motor driving system, in particular to a sine-wave current driving system of a single-winding brushless direct current motor and a control method thereof. The driving system and the control method calculate an input current phase angle instantaneous value and an input current instruction value according to the motor rotation frequency acquired by a position sensor, further sequentially obtain a circuit control voltage item, an instantaneous sensing voltage value and an output voltage instruction value, finally obtain the output duty ratio alpha so as to generate a PWM wave signal, transmits the signal to a full-bridge power inverter circuit so as to control a high-power switch device and accordingly achieves driving control of the single-winding brushless direct current motor. The driving control of the single-winding brushless direct current motor is performed by adopting the driving system and the control method, the motor is easy to start, the manufacture cost is low, vibration and noise are small during motor running, and an application range is wide.

Owner:JIANGSU REYA ELECTRIC

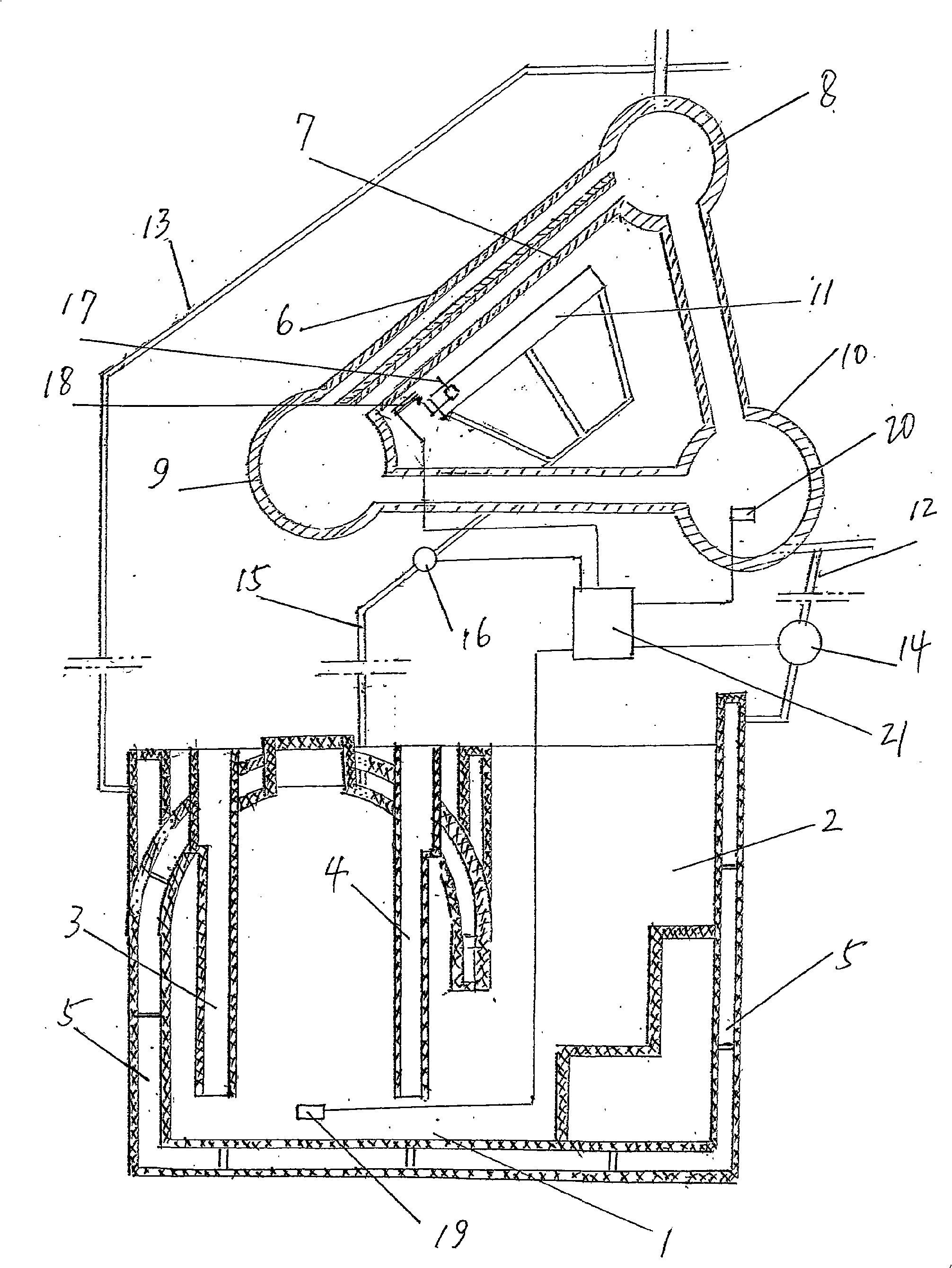

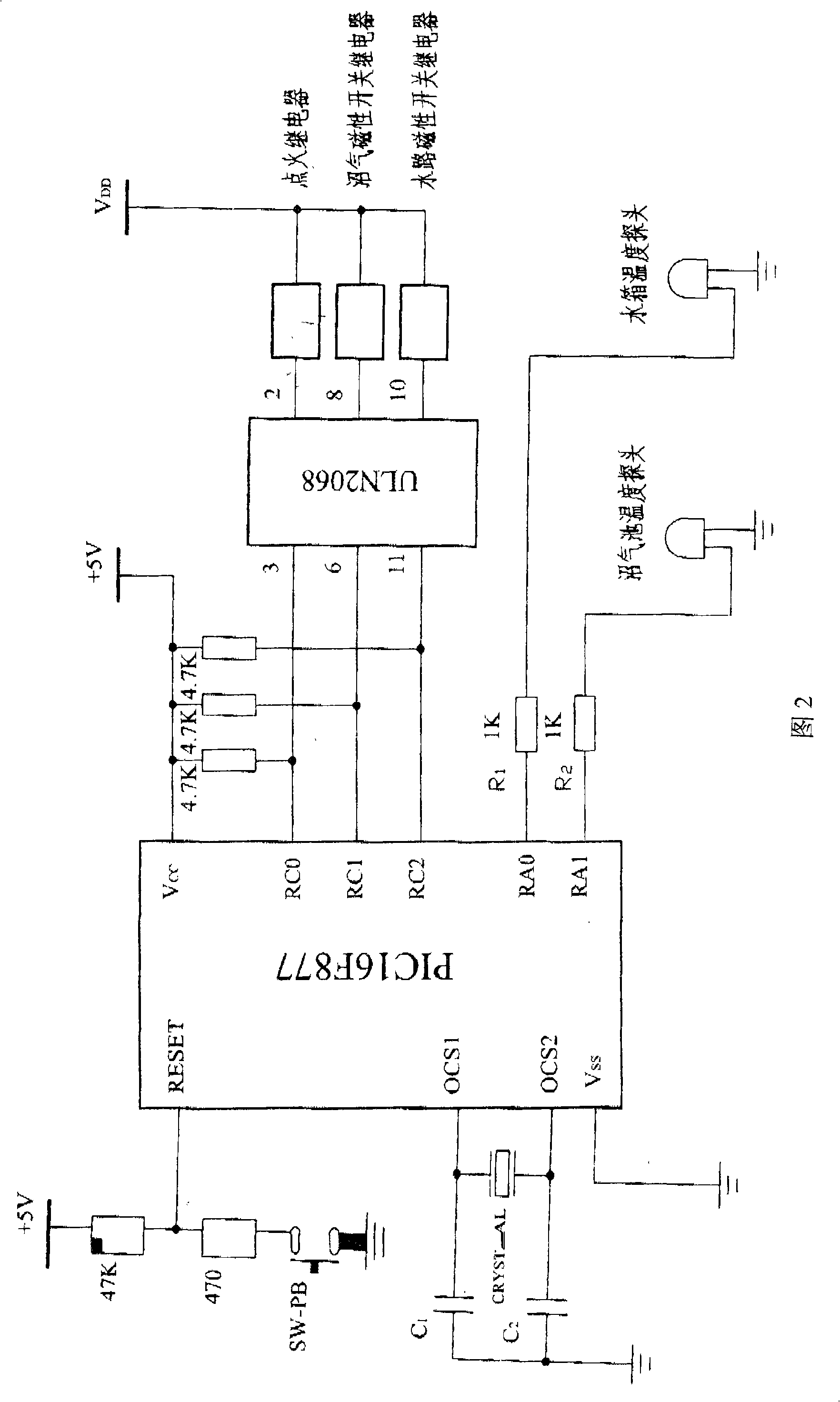

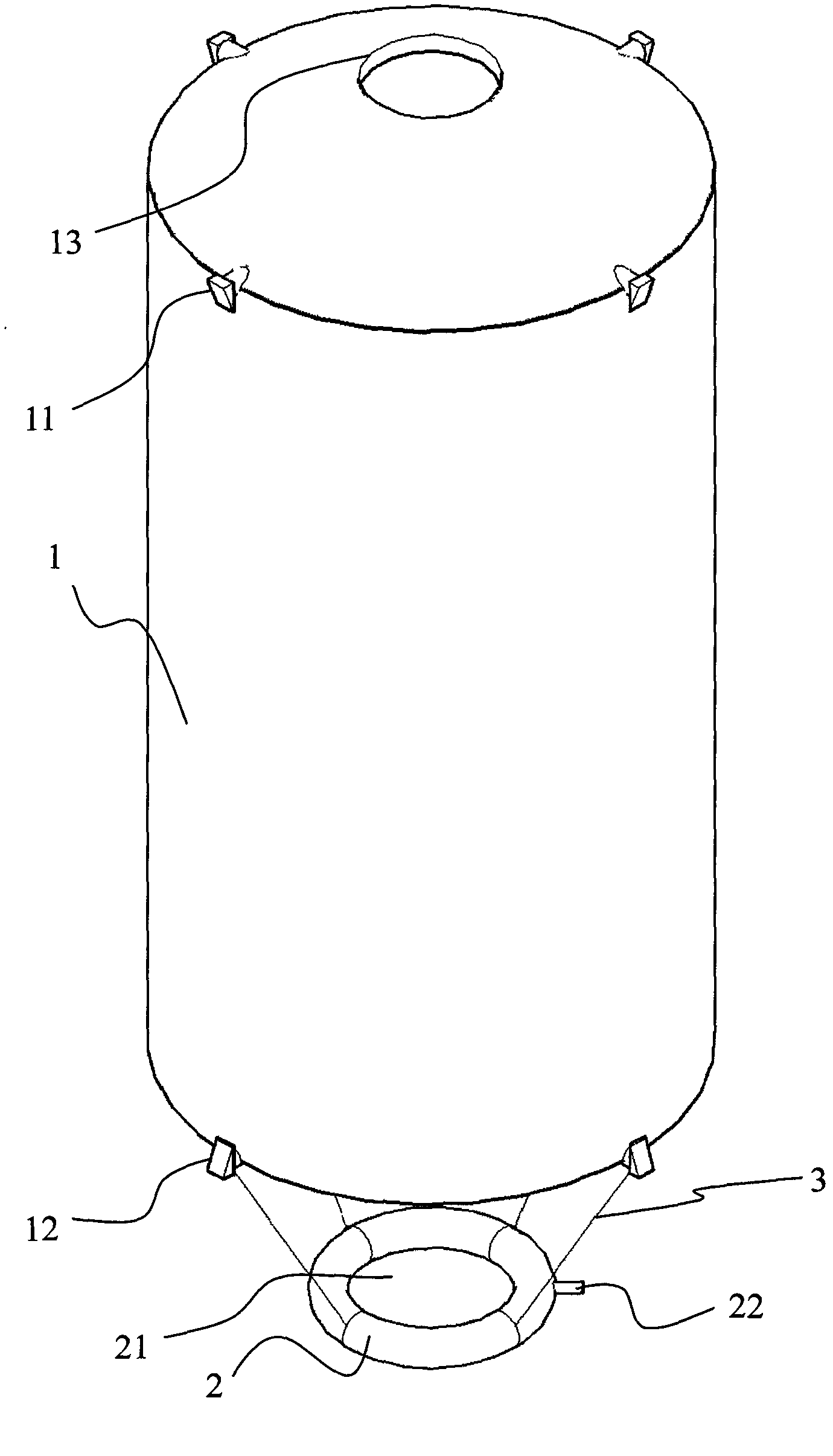

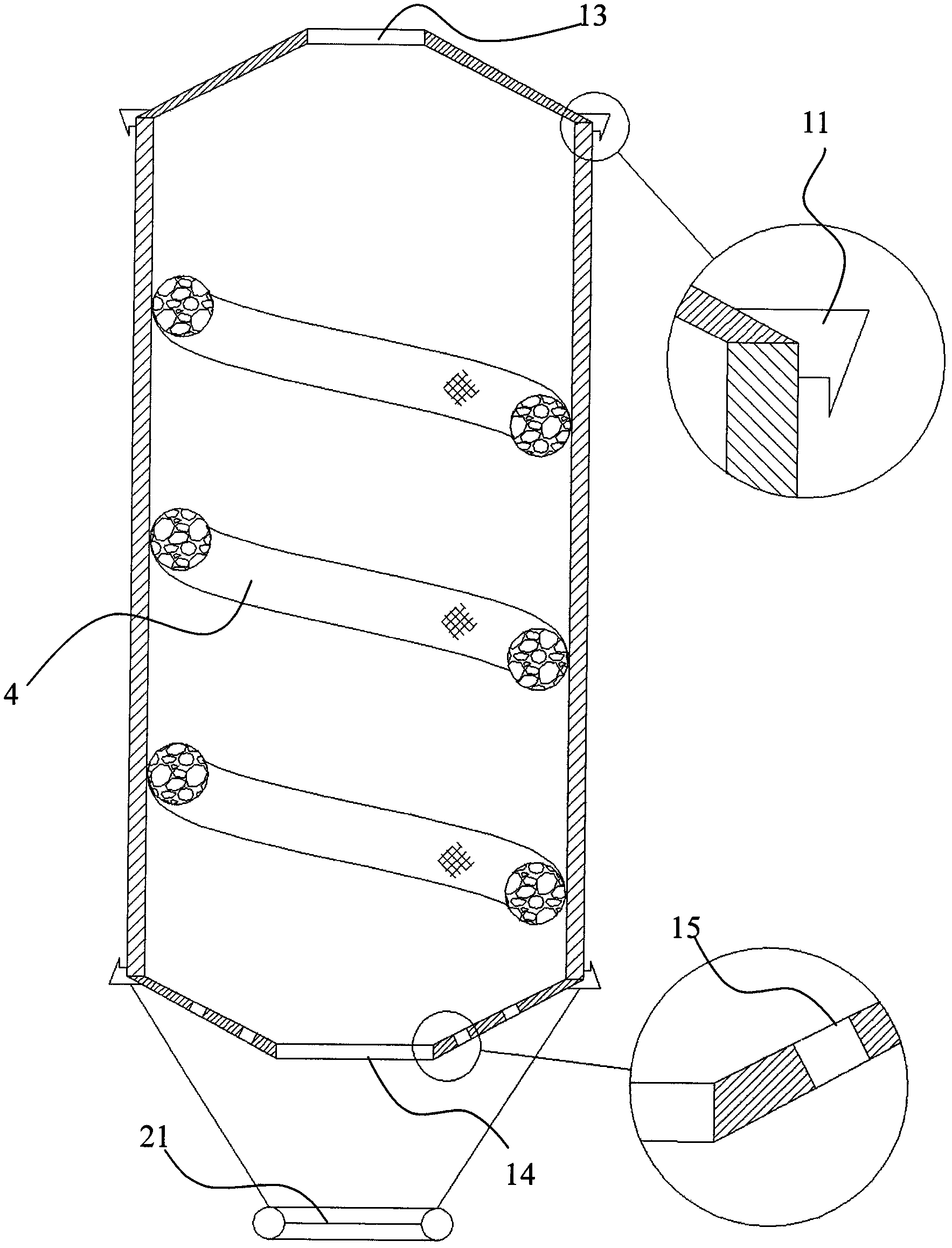

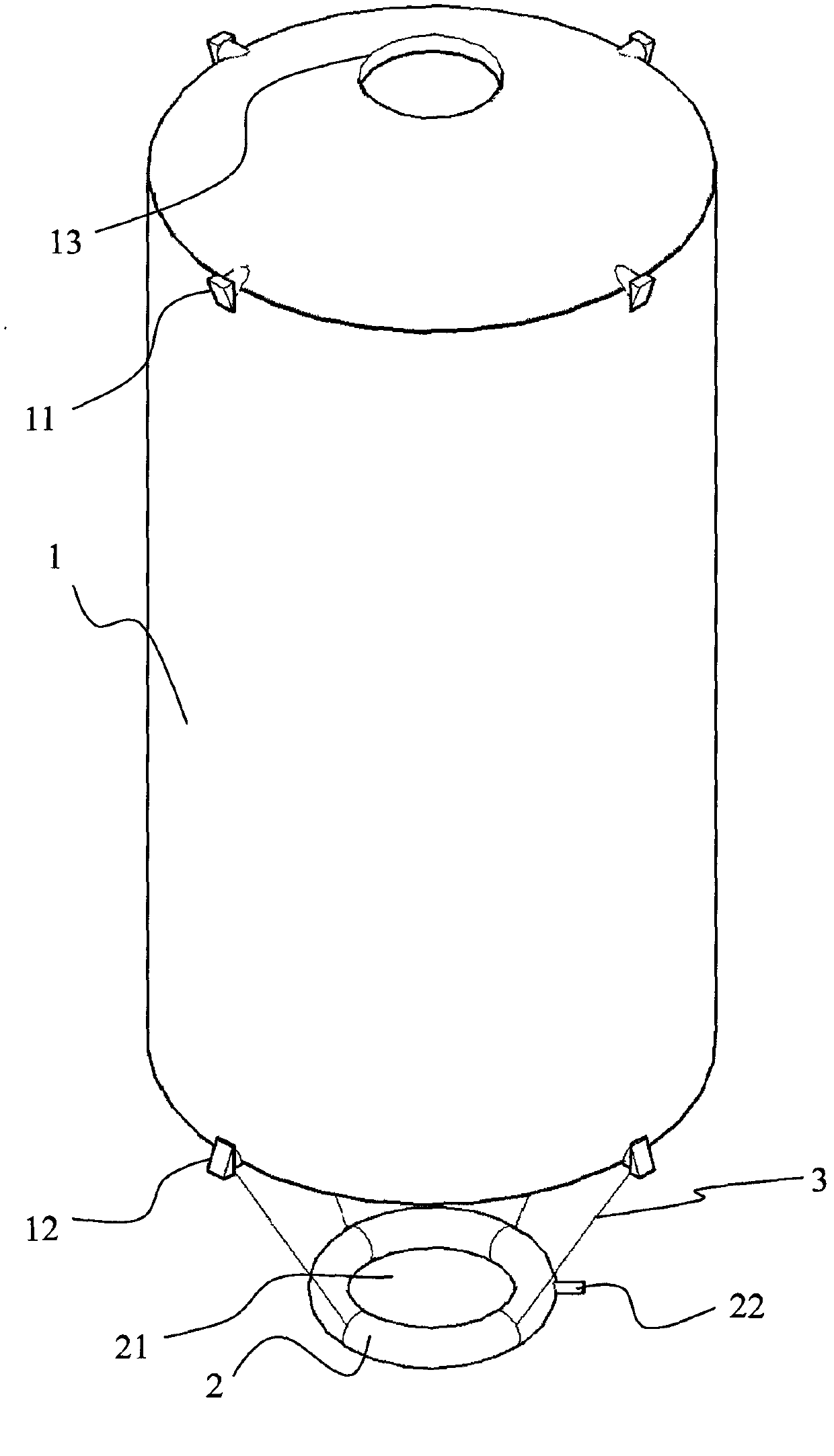

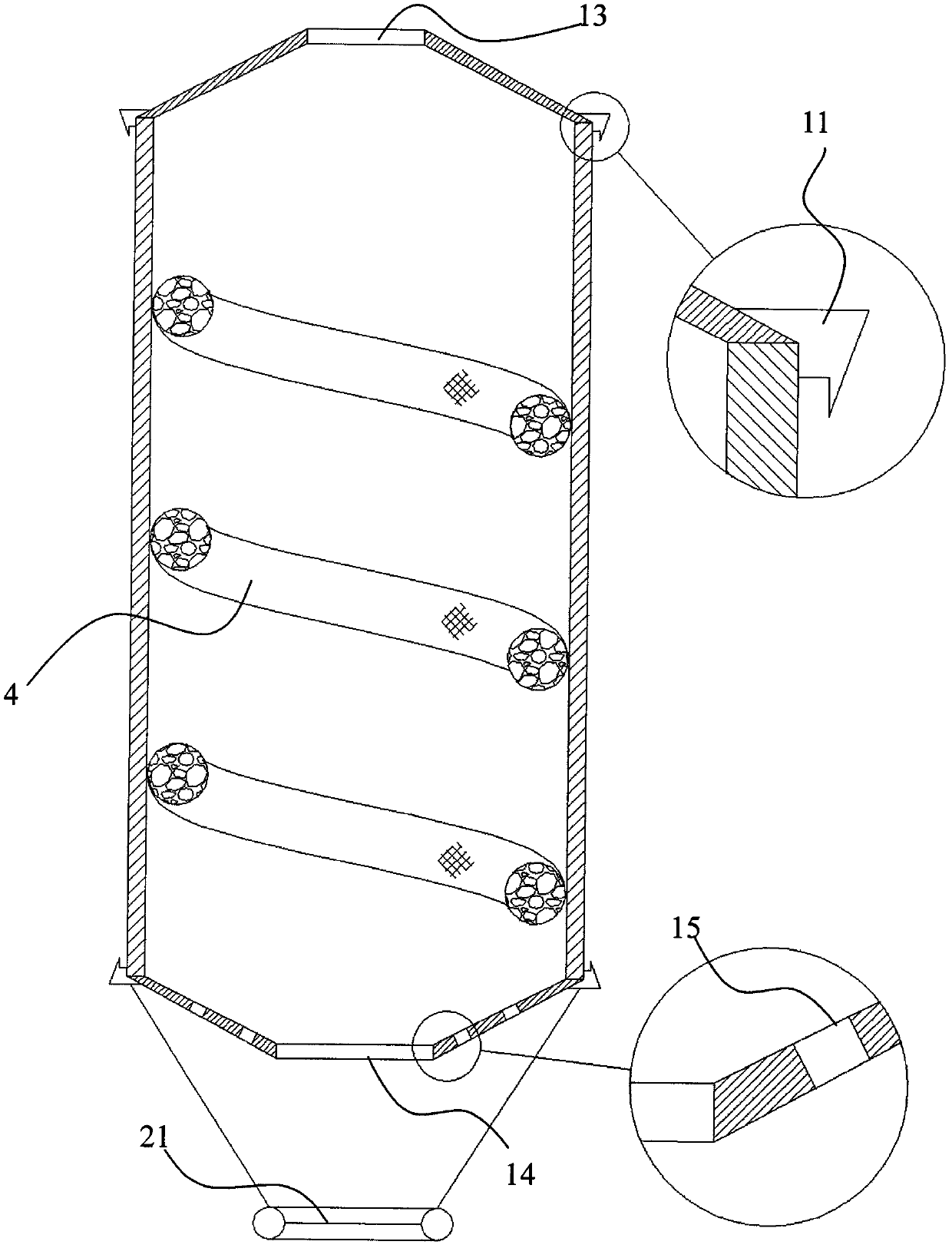

Solar constant temperature fermentation methane tank

ActiveCN101323834AOffset adverse effectsEfficient productionGas production bioreactorsWaste based fuelWater circulationSolar water

The invention relates to a solar constant temperature fermentation biogas tank which pertains to the field of biochemistry, can eliminate the effect of natural environment on fermentation temperature and overcomes the disadvantages that the current biogas fermentation tank is unstable in output and even cannot produce gas in cold areas. The made improvement is that the wall or the wall and the bottom of the fermentation tank are two-layered and an interlayer for circulating water is formed between the two layers. A solar water heater is added. The interlayer connecting the solar water heater and the fermentation tank forms a water circulation circuit. A water pipe is provided with a pump. A biogas burner is arranged at the back of the absorber plate of the solar water heater. The pump and the biogas burner are controlled by a temperature sensor and a temperature signal processing circuit which are positioned in the fermentation tank and the water heater. The fermentation biogas tank of the invention has the advantages of utilizing the solar water heater and circulating water in the interlayer under particular cases, in which the fermentation tank is the biogas tank to heat and preserve heat, to realize the fermentation of the fermentation biogas tank under the optimum temperature condition, thus offsetting the unfavorable effects of the change of natural temperature on the fermentation and obtaining the effect of stable and high efficient biogas production in cold areas where temperature changes greatly.

Owner:吉林省康福环保能源有限责任公司

Intelligent primary air pressure target value control system and method

InactiveCN104848250AReduce throttling lossReduce power consumptionAir supply regulationComputer moduleControl logic

The invention discloses an intelligent primary air pressure target value control system and method. The system comprises a first control logic module, a second logic control module, a controller, a summator, and a collecting module for collecting AGC instructions sent out by an electric energy management system. The output end of the collecting module is connected with the input end of the second logic control module. The output end of the second logic control module is connected with the output end of the first control logic module and the input end of the summator. The output end of the summator is connected with the input end of the controller. The output end of the controller is connected with the control end of a hot air baffle in a primary air duct. By means of the system and method, primary air power consumption can be effectively lowered.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

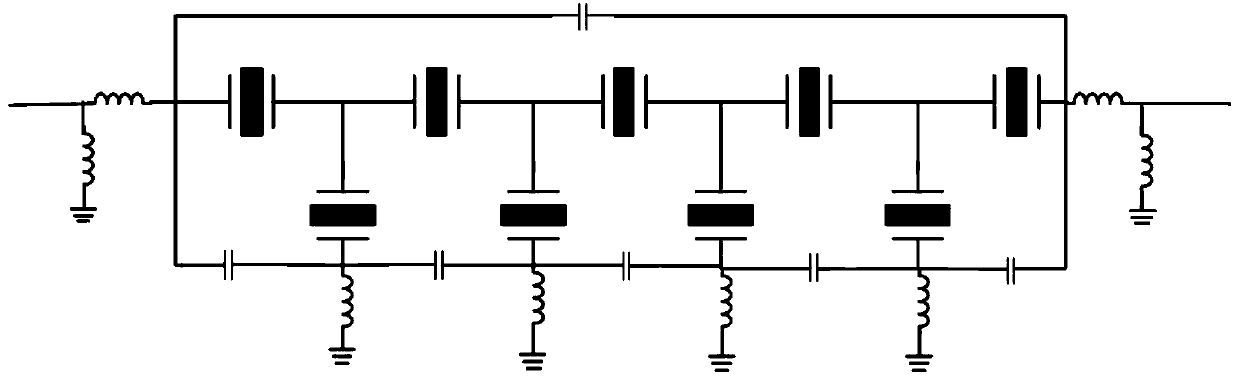

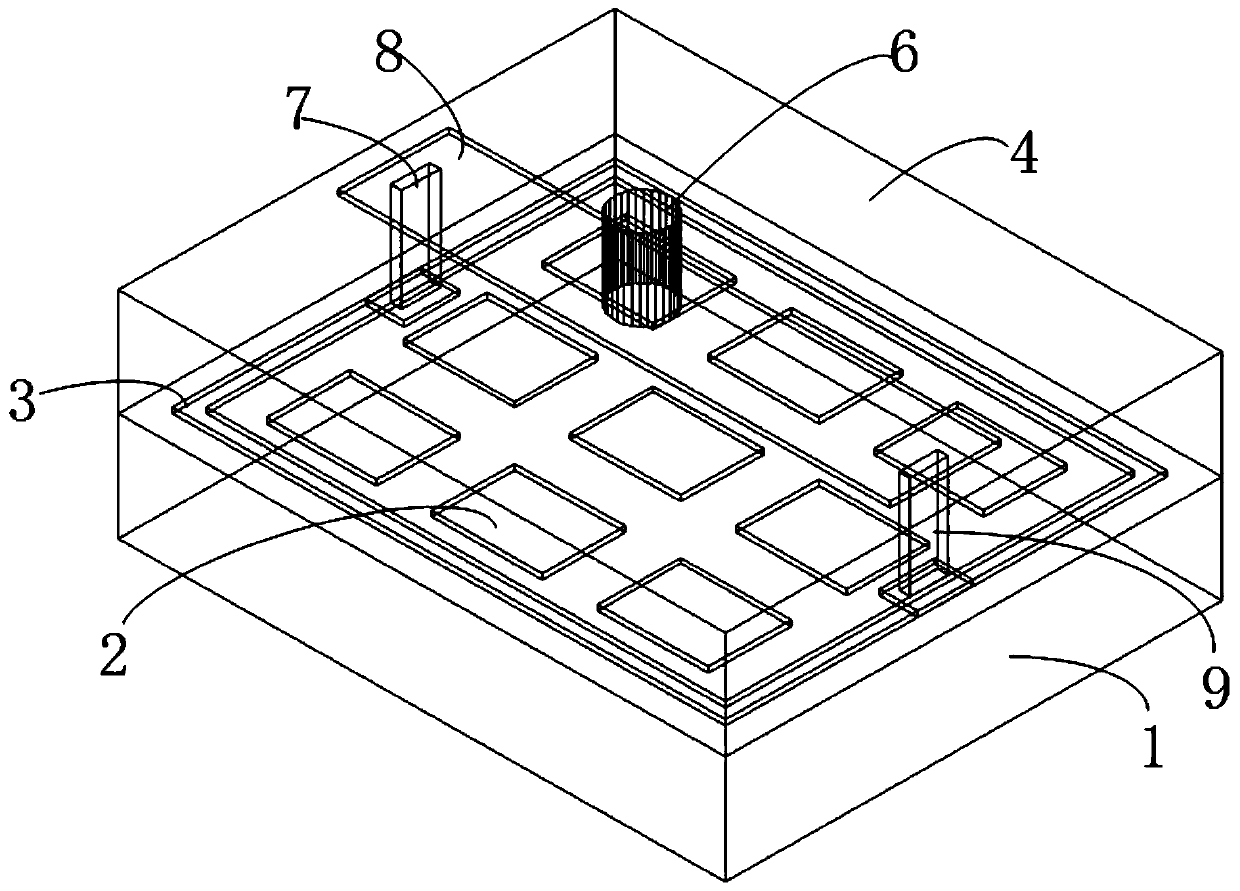

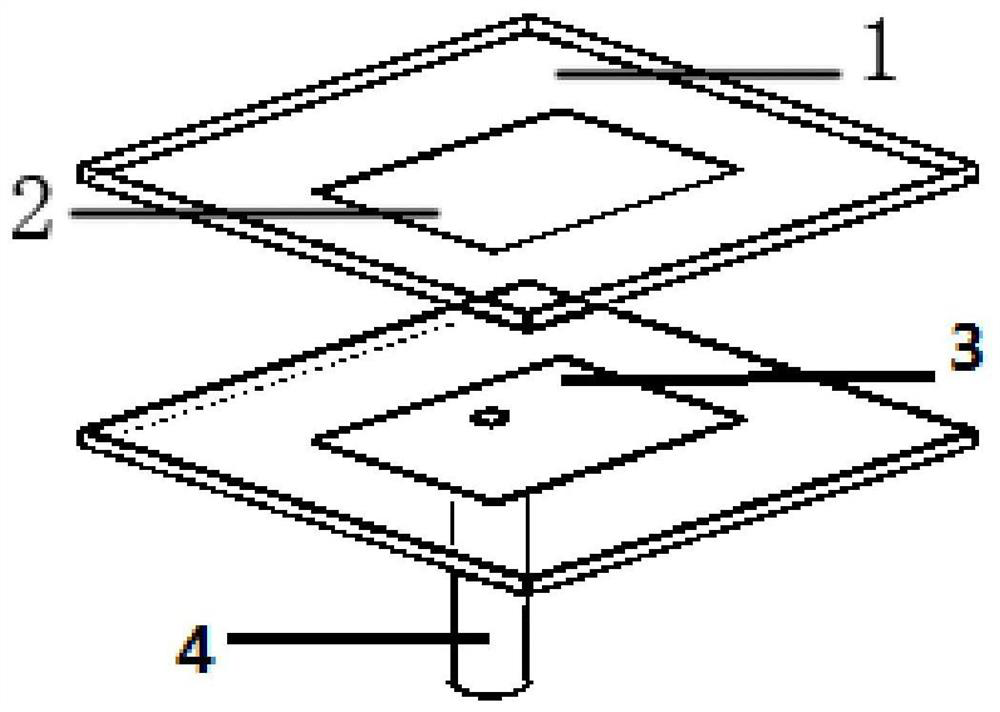

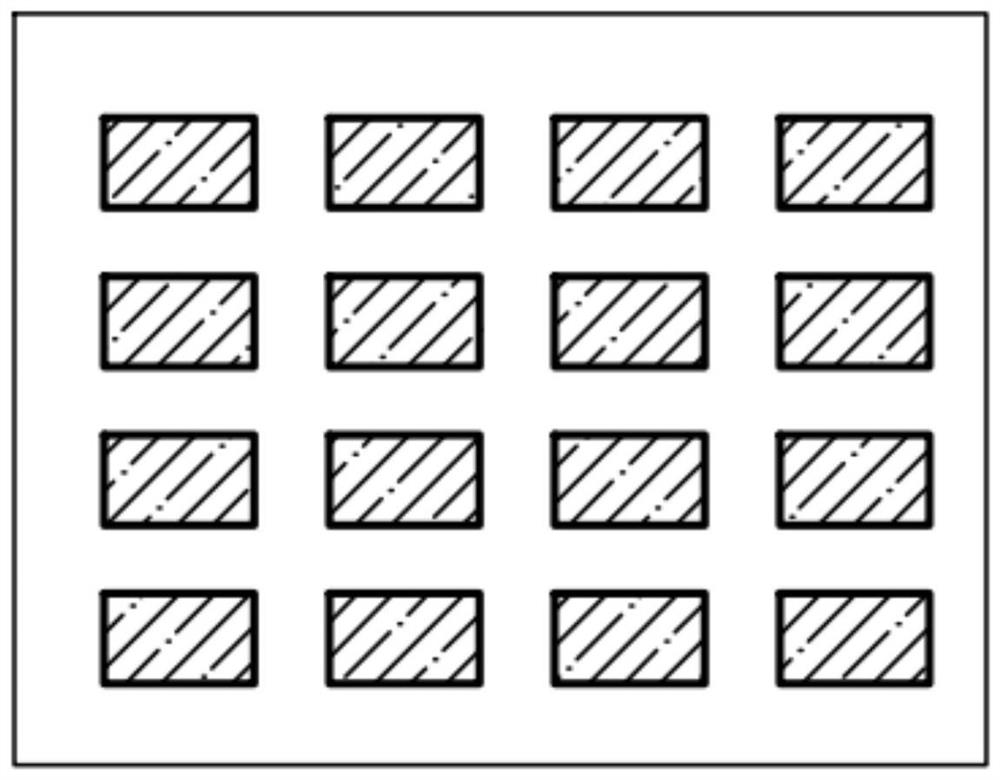

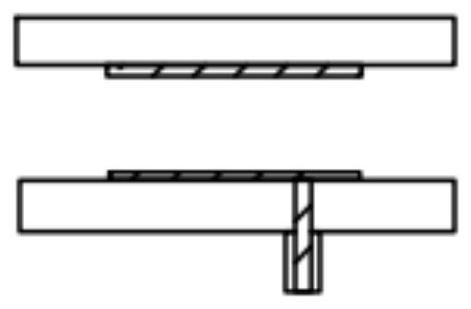

Bulk acoustic wave filter and electronic equipment

PendingCN110504942AHigh out-of-band rejectionEnhanced inhibitory effectImpedence networksMetal stripsSurface layer

According to the bulk acoustic wave filter capable of improving near-stop band suppression and the electronic equipment. Sealing rings are connected to the reference ground plane of the carrier platethrough the solder balls, so that coupling between the resonators and coupling between the resonators and the sealing rings are eliminated, and near-stop band suppression is further improved. The bulkacoustic wave filter comprises a chip main body, a protective cap and a carrier plate, wherein a plurality of resonators are sequentially arranged on the surface layer of the chip main body, and a sealing ring is arranged at the periphery of the plurality of resonators; the protective cap is arranged on the chip main body, the two sides of the sealing ring are respectively connected with a metalcolumn, the bottom ends of the two metal columns are respectively connected with the sealing ring, the top ends of the two metal columns penetrate through the surface layer of the protective cap to beconnected with a metal strip, and the metal strip is connected with the carrier plate through metal balls.

Owner:TIANJIN UNIV +1

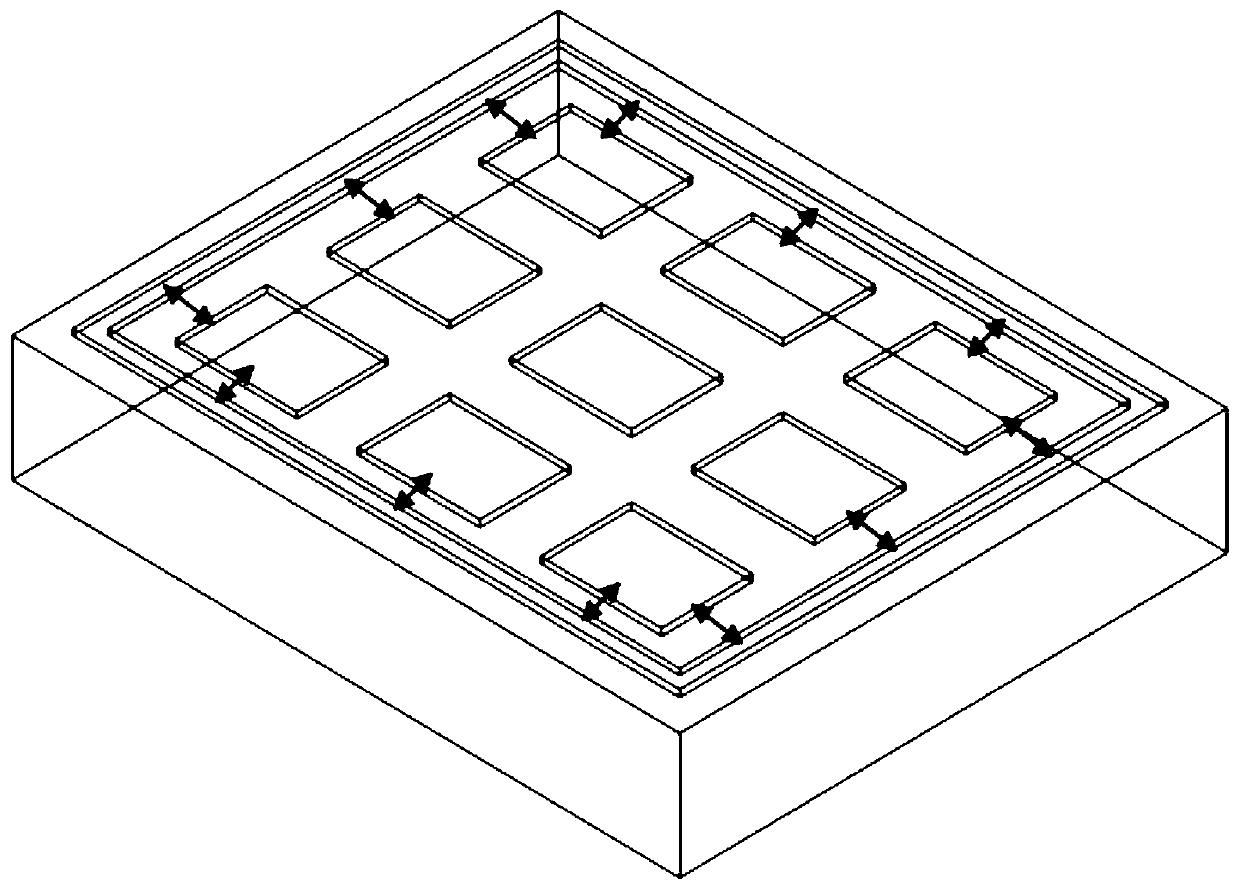

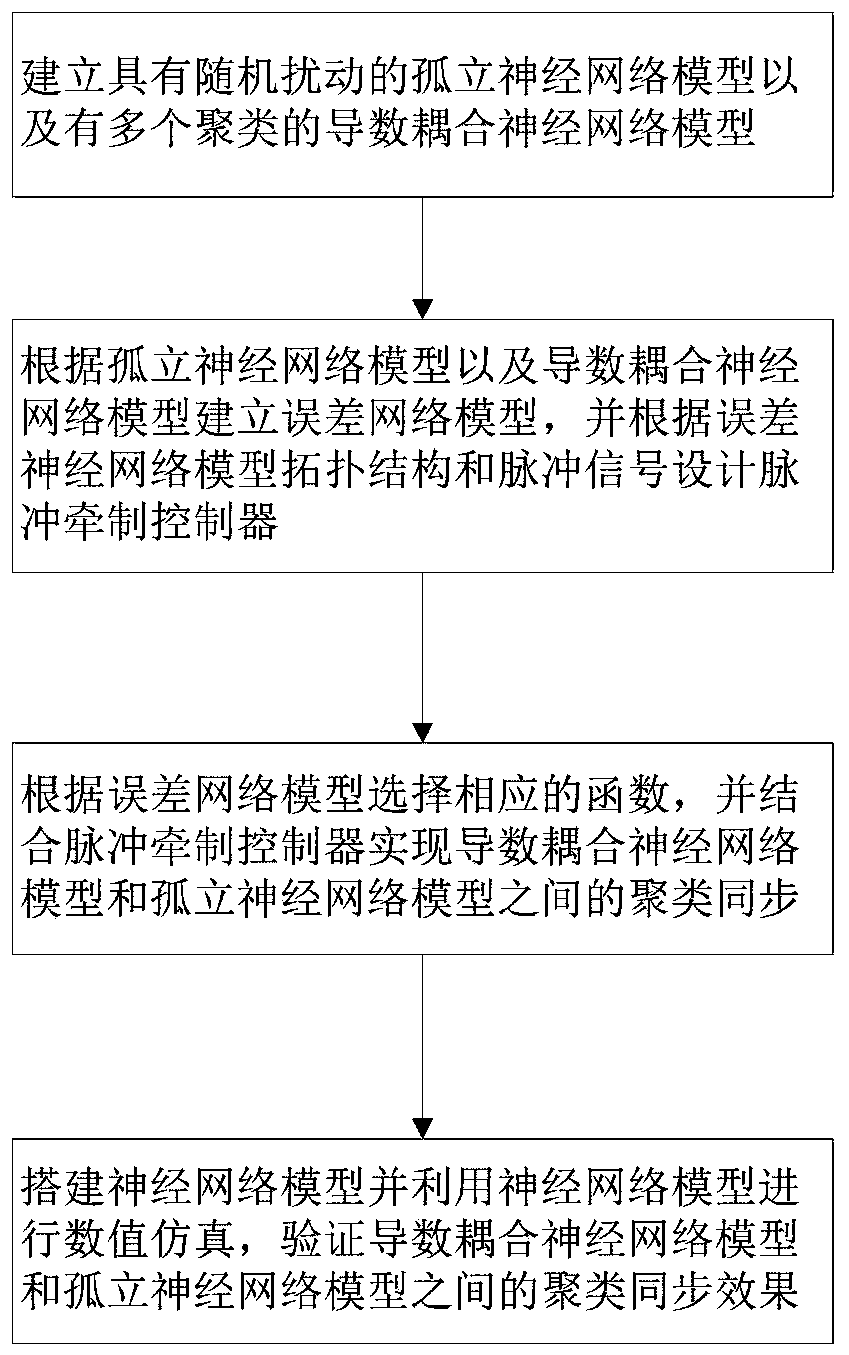

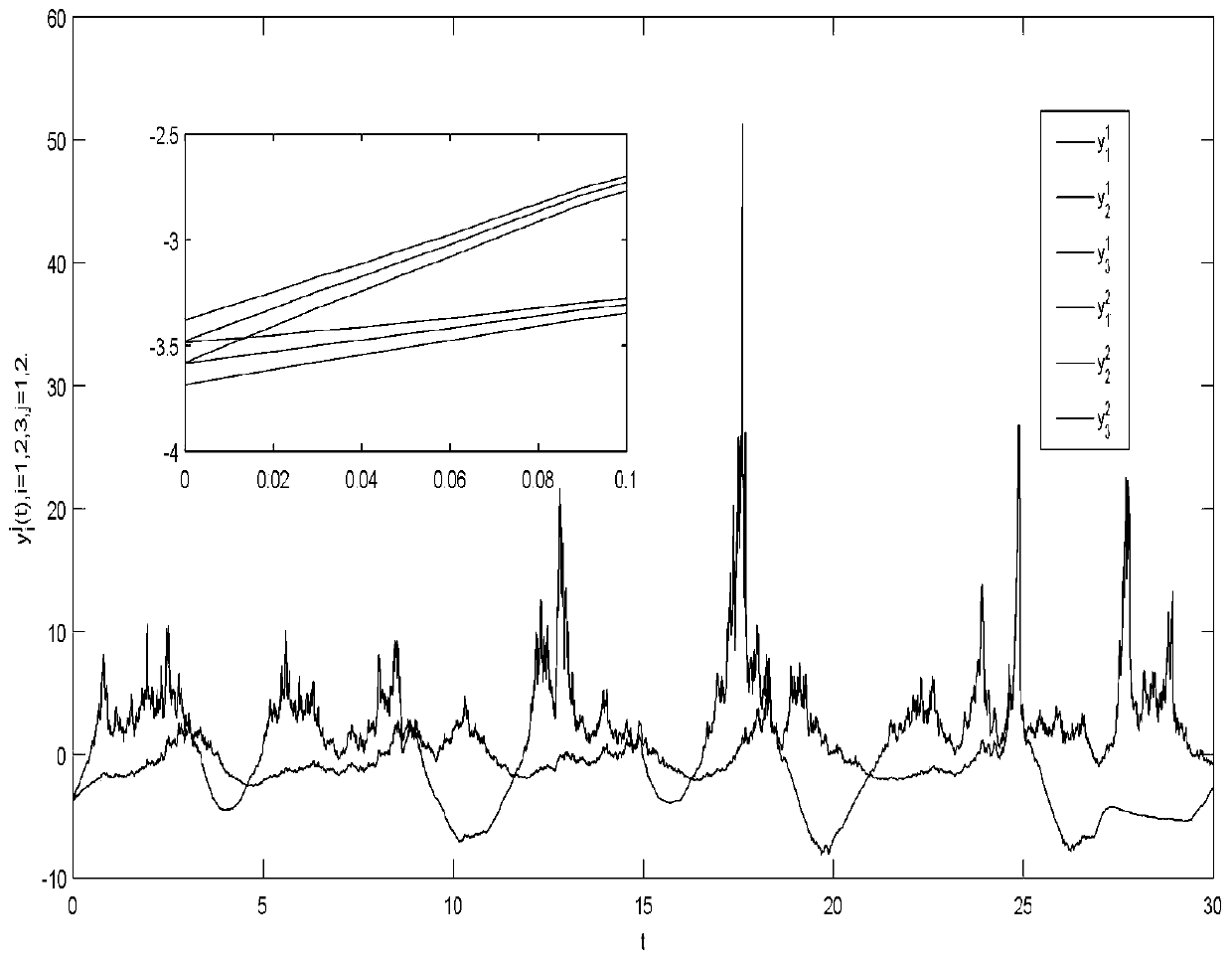

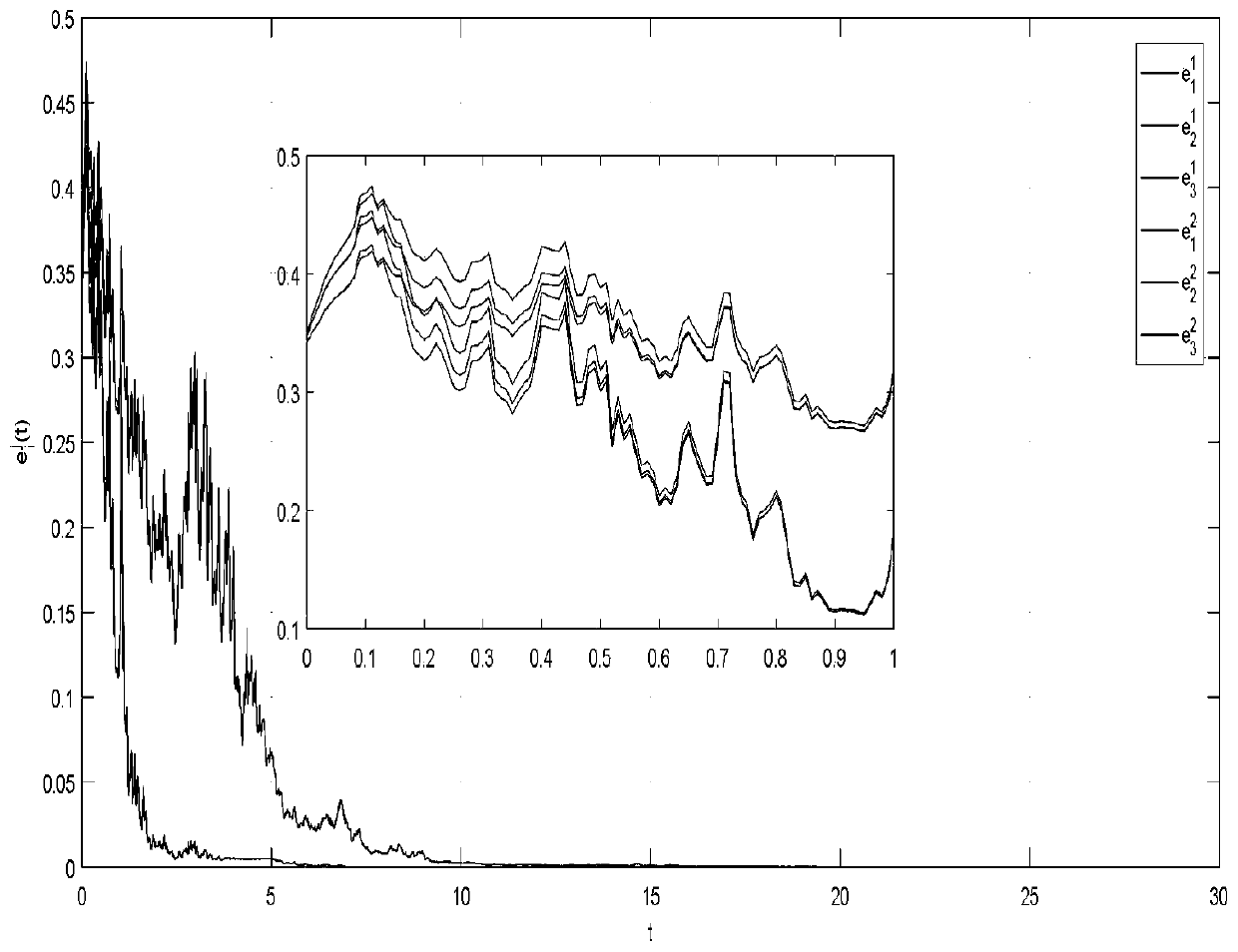

Neural network pulse synchronization method and system containing clustering topology coupling

ActiveCN111523648APrecisely control the sync rateRealize cluster synchronizationCharacter and pattern recognitionDesign optimisation/simulationAlgorithmEngineering

The invention relates to a neural network pulse synchronization method and system containing clustering topology coupling. The method comprises the steps that an isolated neural network model with random disturbance and a derivative coupling neural network model with multiple clusters are established; establishing an error network model according to the isolated neural network model and the derivative coupling neural network model, and designing a pulse containment controller according to a topological structure of the error neural network model and the pulse signal; selecting a correspondingfunction according to the error network model, and realizing clustering synchronization between a derivative coupling neural network model and an isolated neural network model in combination with thepulse containment controller; and establishing a neural network model and performing numerical simulation by using the neural network model to verify a clustering synchronization effect between the derivative coupling neural network model and the isolated neural network model. The method is low in cost and is beneficial to accurately controlling the synchronization rate.

Owner:JIANGNAN UNIV

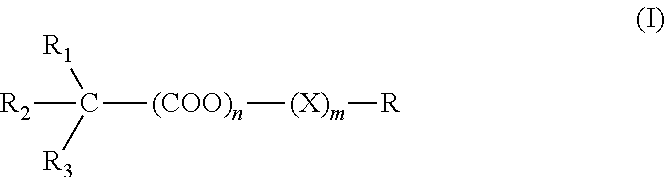

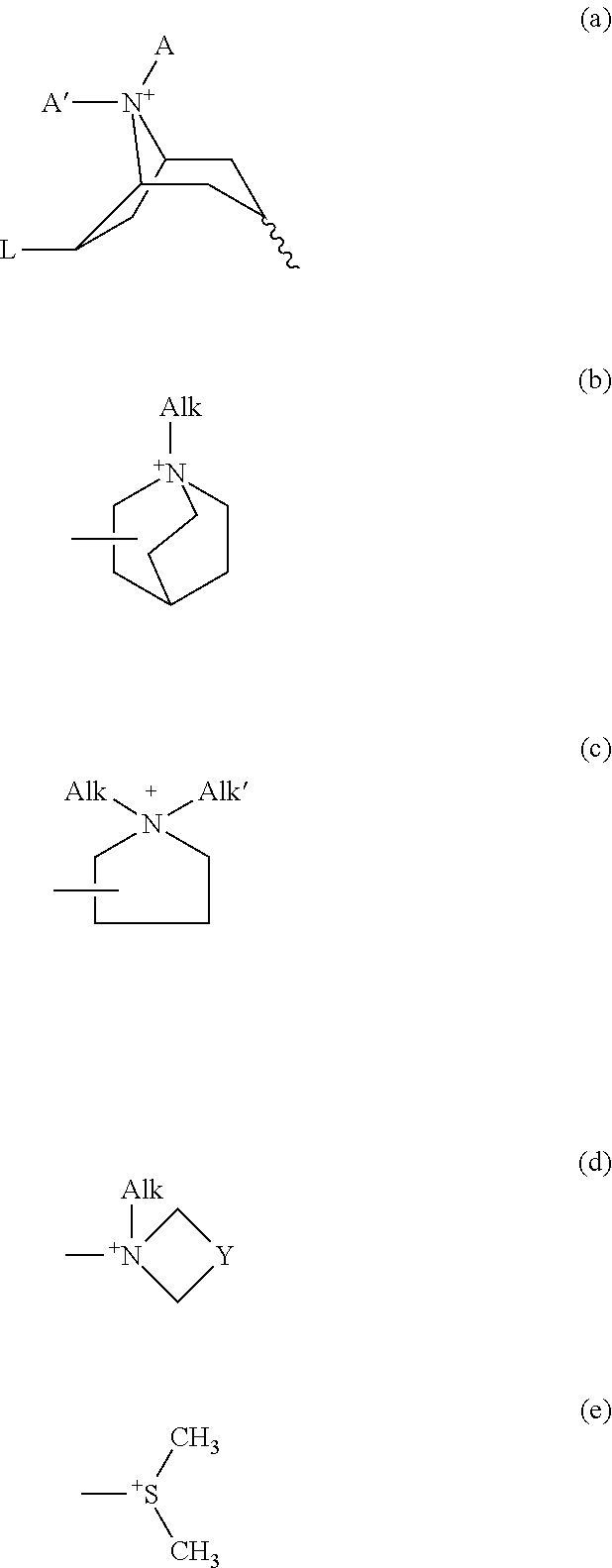

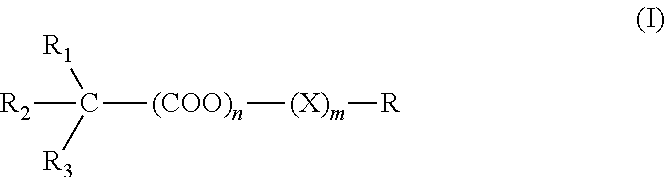

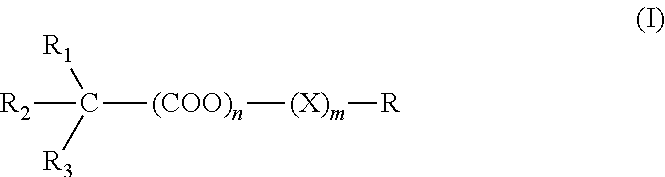

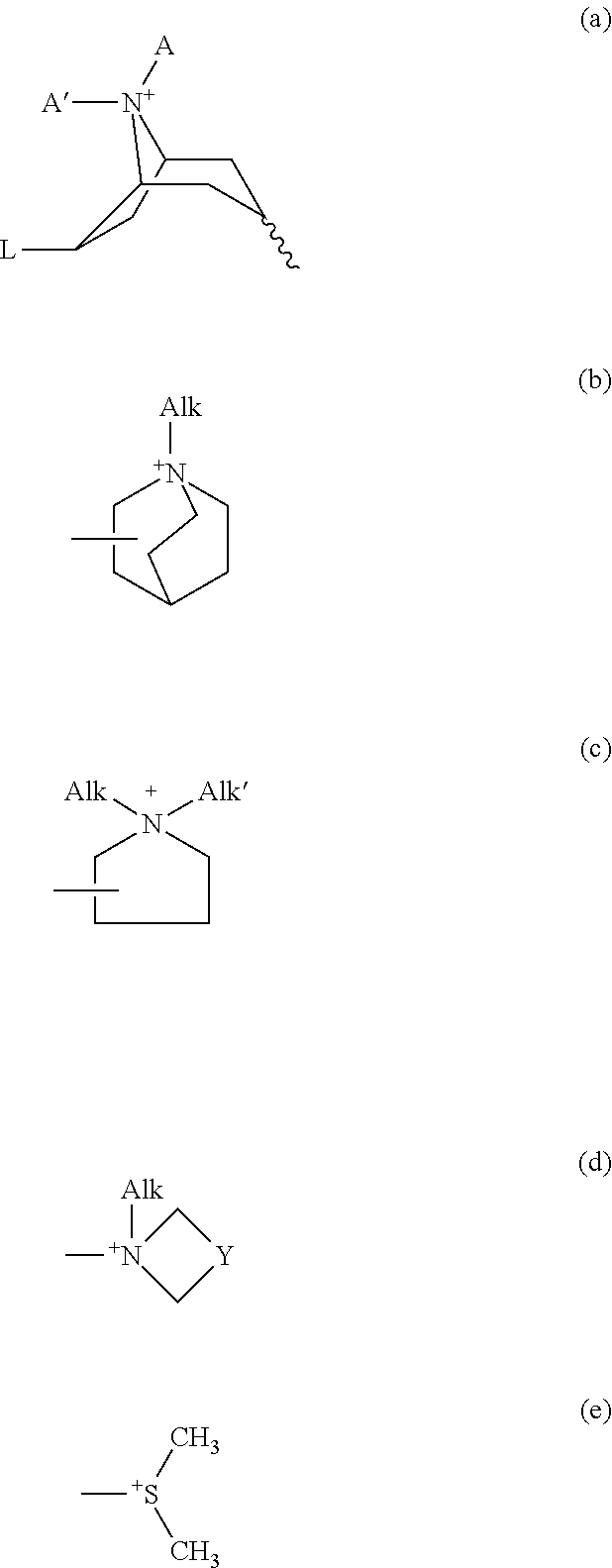

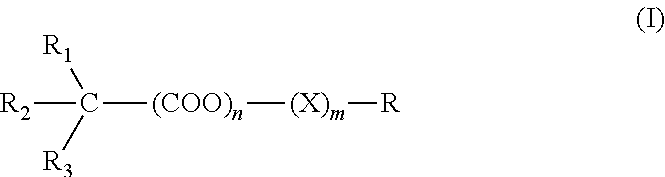

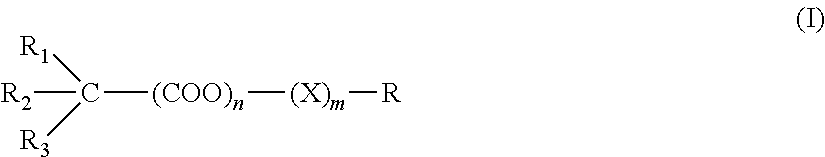

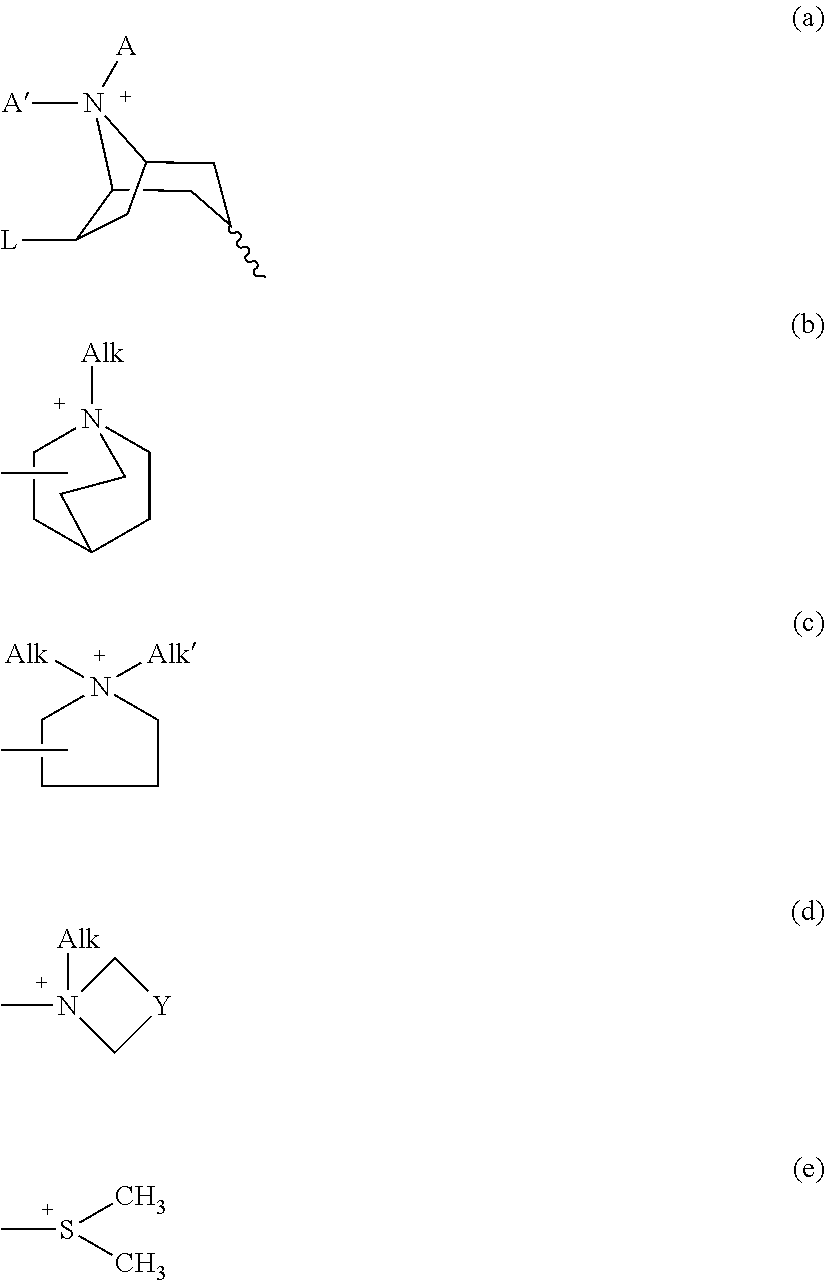

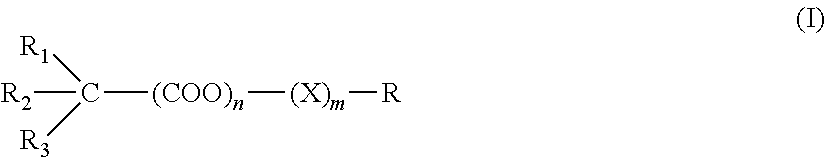

Muscarinic combinations and their use for combating hypocholinergic disorders of the central nervous system

ActiveUS20160375001A1Neutralize adverse effectIncrease concentrationOrganic chemistrySheet deliveryNervous systemAnticholinergic agents

A combination of a muscarinic cholinergic receptor agonist, a non-anticholinergic antiemetic agent and a non-selective, peripheral anticholinergic agent for the treatment of hypocholinergic disorders of the central nervous system.

Owner:CHASE PHARMA CORP

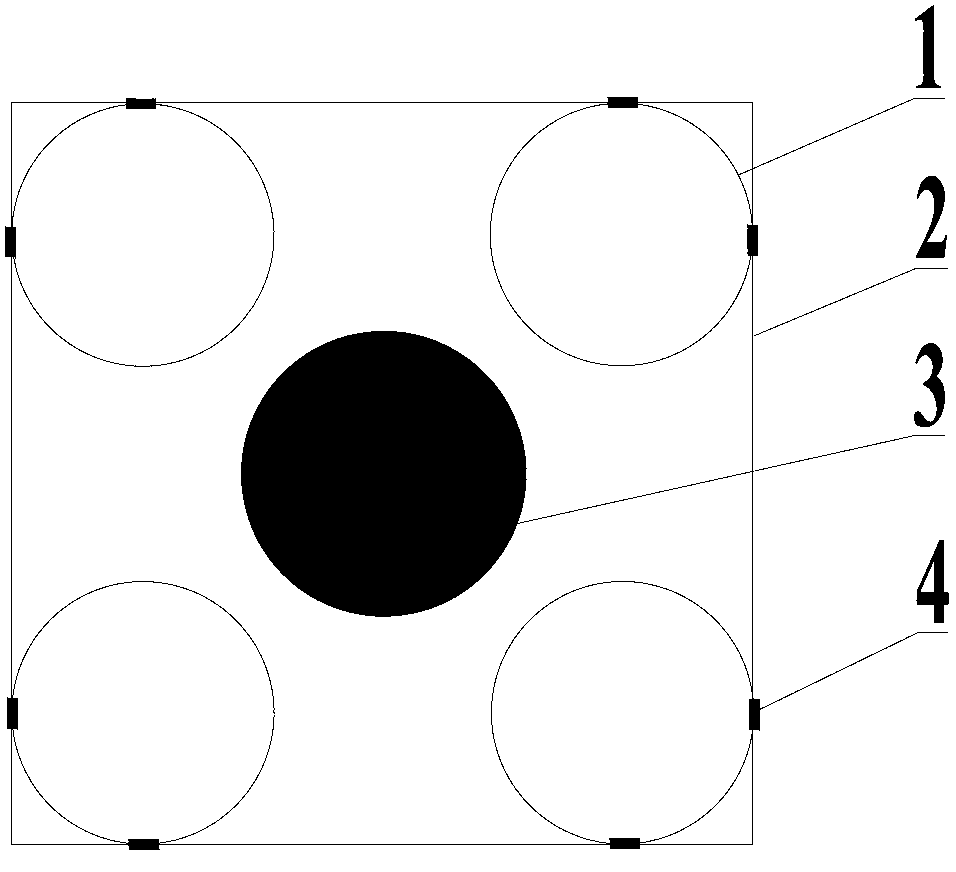

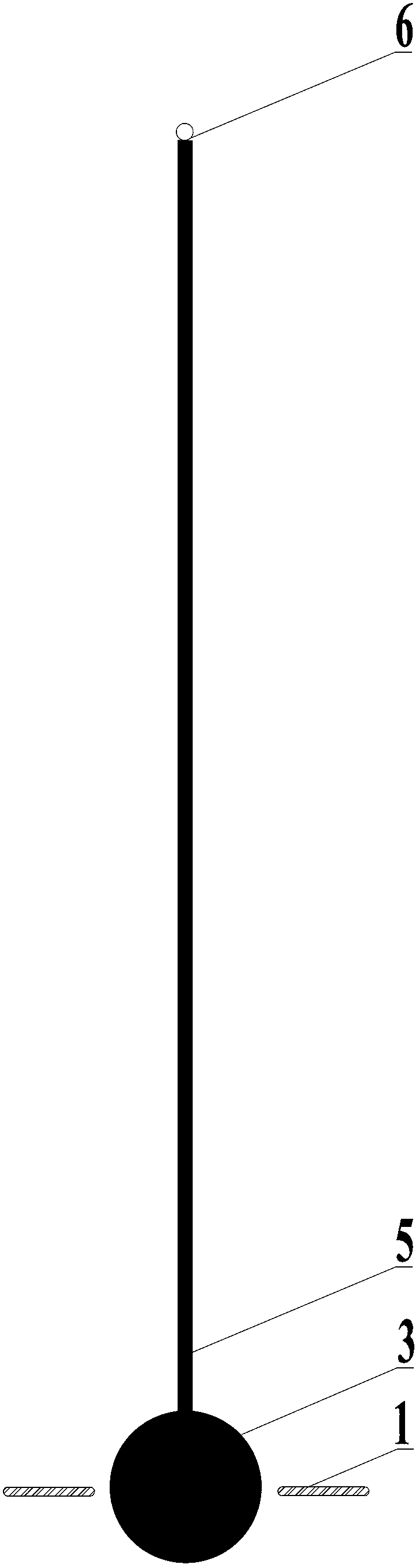

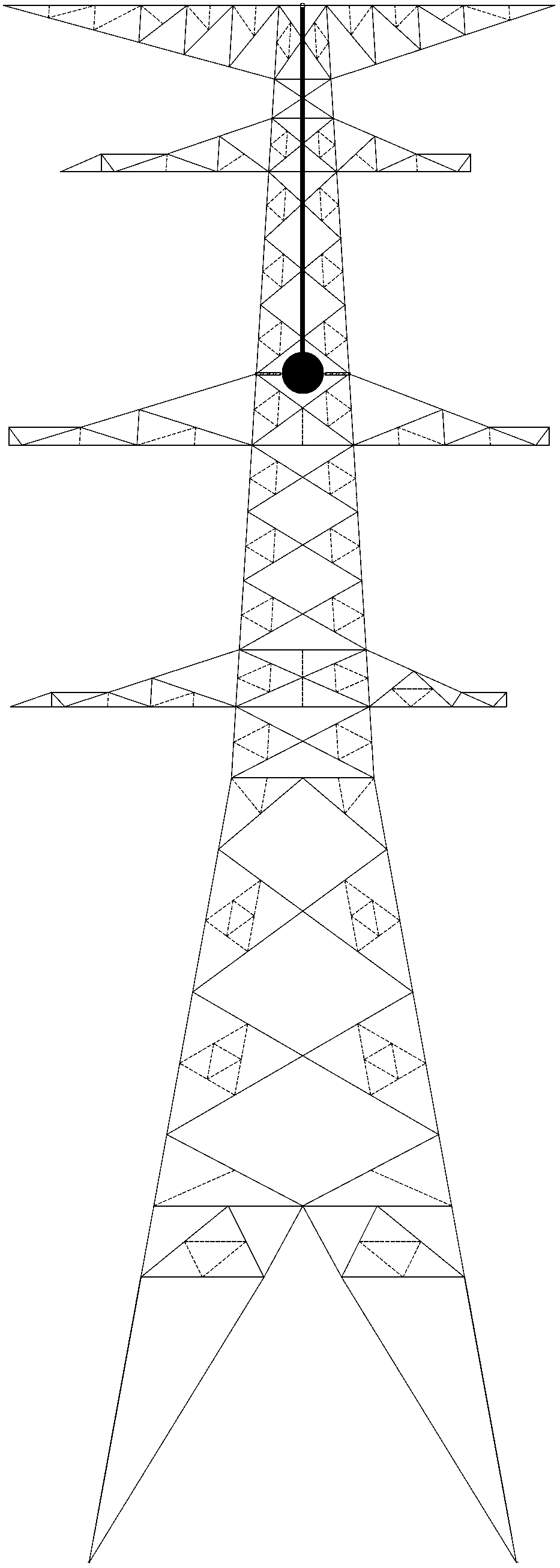

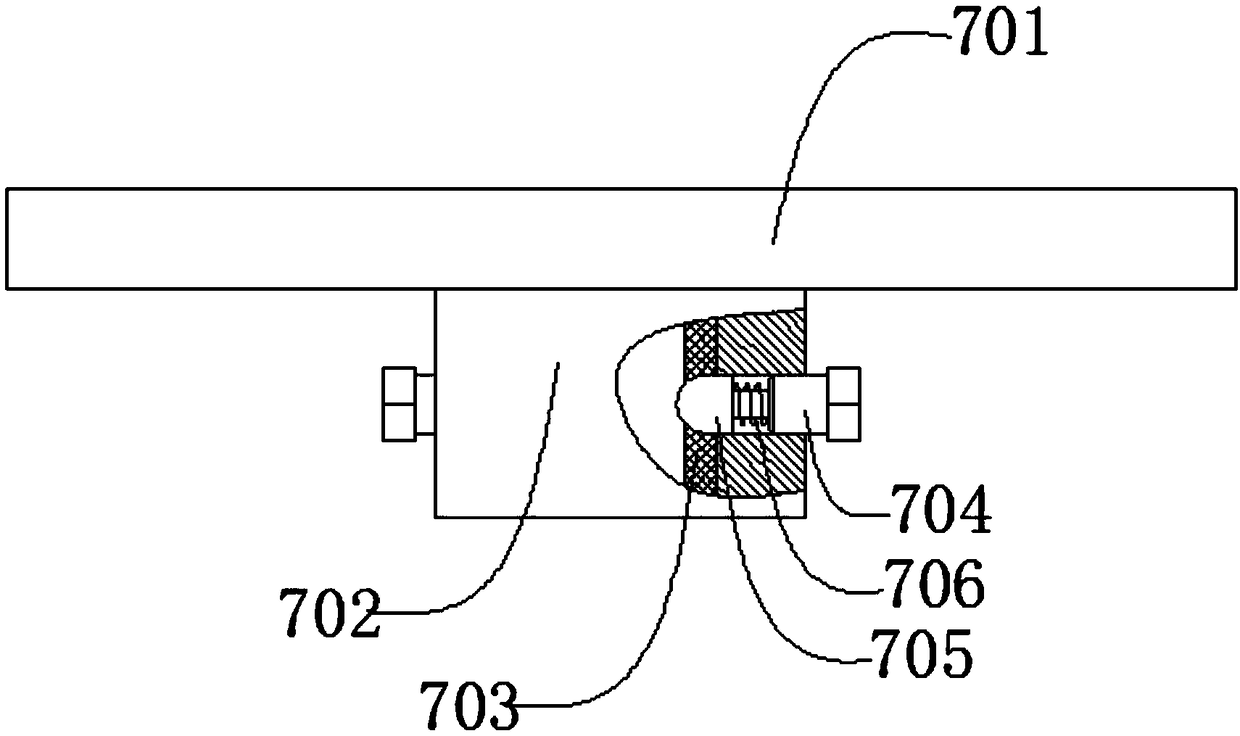

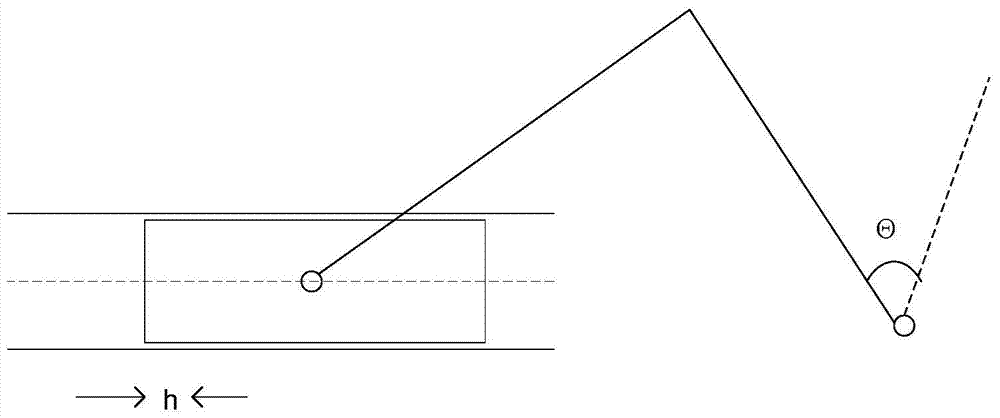

Lattice type power transmission tower horizontal vibration self-reset shock absorber

InactiveCN102936927AOffset adverse effectsQuick resetShock proofingSmall amplitudeShape-memory alloy

The invention discloses a lattice type power transmission tower horizontal vibration self-reset shock absorber which comprises shape memory alloy rings, a steel ball, an anchor bolt, a steel suspension rod and a steel suspension ring, wherein the lower end of the steel suspension rod is fixedly connected with the steel ball; the upper end of the steel suspension rod is fixedly connected with the steel suspension ring; the steel suspension ring is hung at the top center of a power transmission tower; four shape memory alloy rings are provided and anchored at the four corners of the tower body of the power transmission tower; the four shape memory alloy rings are all horizontally arranged and uniformly distributed around the periphery of the steel ball; the centers of the four shape memory alloy rings are located on the circumference of the same circle centered on the steel ball; the steel ball absorbs shock and consumes energy by use of the shake thereof in the case of small amplitude; and in the case of large amplitude, the steel ball can collide with the shape memory alloy rings to consume energy so as to realize shock absorption.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

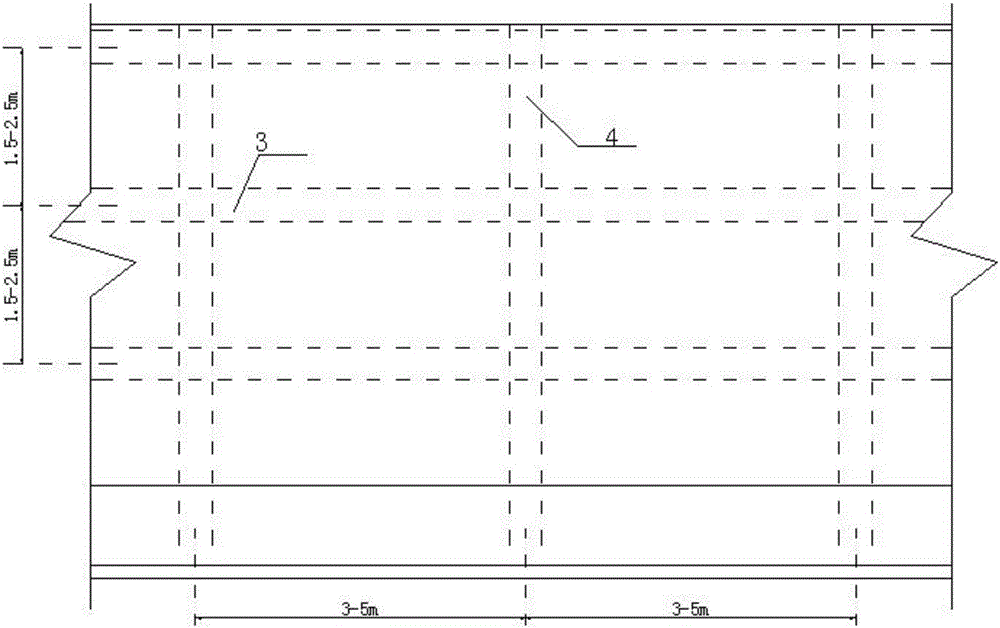

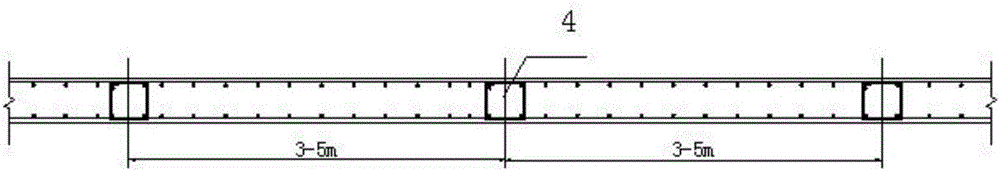

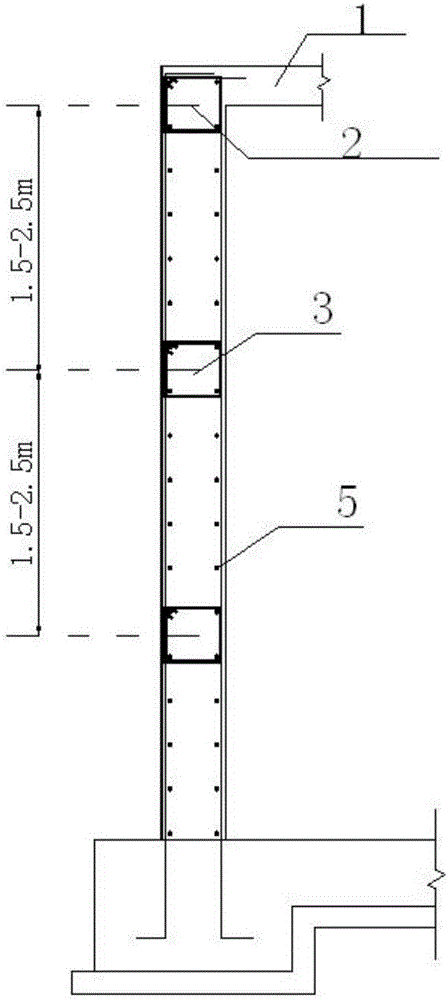

Crack preventing reinforced concrete wall structure and construction method thereof

InactiveCN106836559AIncrease lateral stiffnessImprove crack resistanceWallsReinforced concreteEngineering

Disclosed is a crack preventing reinforced concrete wall structure. A reinforced concrete wall is of a vertical cantilever structure. Double rows of reinforcement net pieces are configured in the reinforced concrete wall. The lower end of the wall is connected with a foundation. The upper end of the wall is connected with a plate or a beam. When the wall is of the vertical cantilever structure and is only connected with the beam, a streak of concealed beams is arranged on the top of the wall, and the concealed beams are arranged in the vertical direction with the spacing being 1.5 m-2.5 m, and concealed columns are arranged in the longitudinal direction with the spacing being 3.0 m-5.0 m. When the top of the wall is connected with the plate, the concealed beams do not need to be arranged on the top of the wall, the concealed beams are only arranged in the vertical direction with the spacing being 1.5 m-2.5 m, and the concealed columns are arranged in the longitudinal direction with the spacing being 3.0 m-5.0 m. The structure and a construction method thereof are easy and feasible, the probability of occurrence of cracks of the reinforced concrete wall can be effectively reduced, and safety and normal using of the reinforced concrete wall structure are guaranteed.

Owner:MCC TIANGONG GROUP

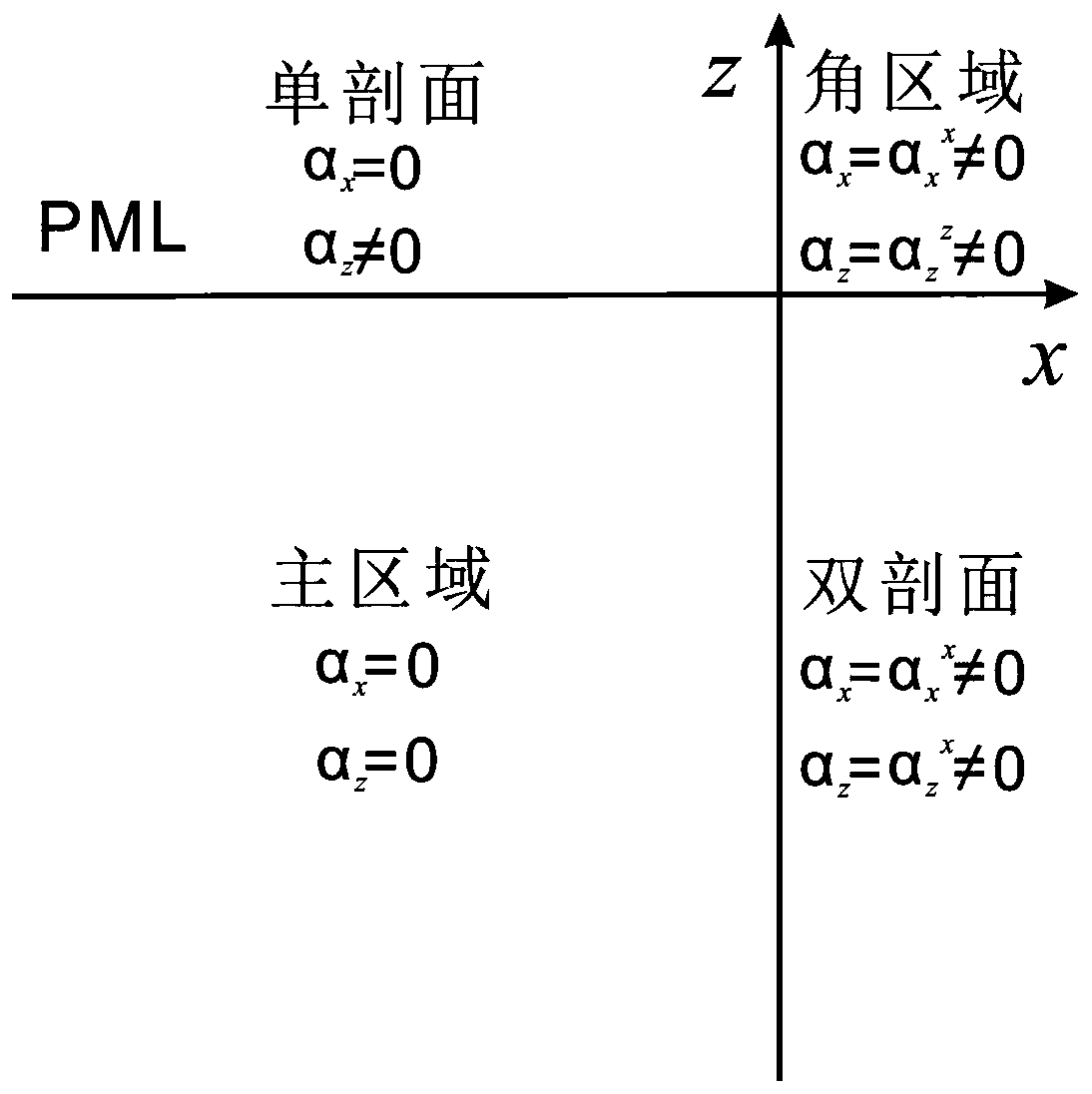

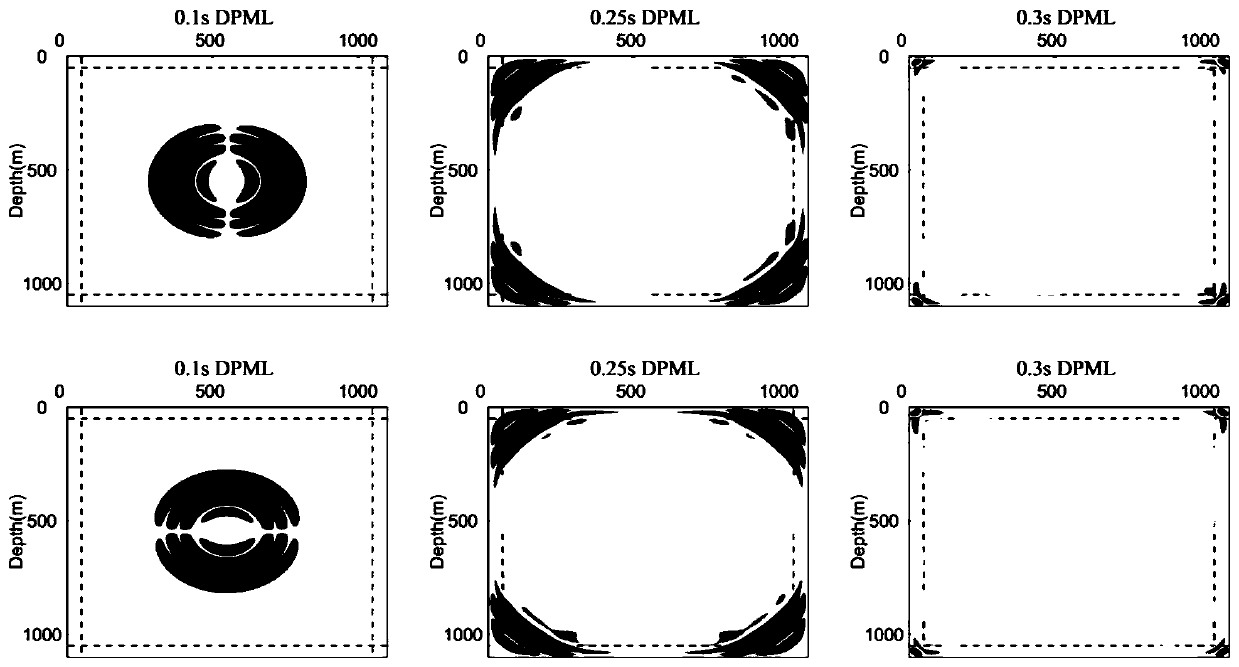

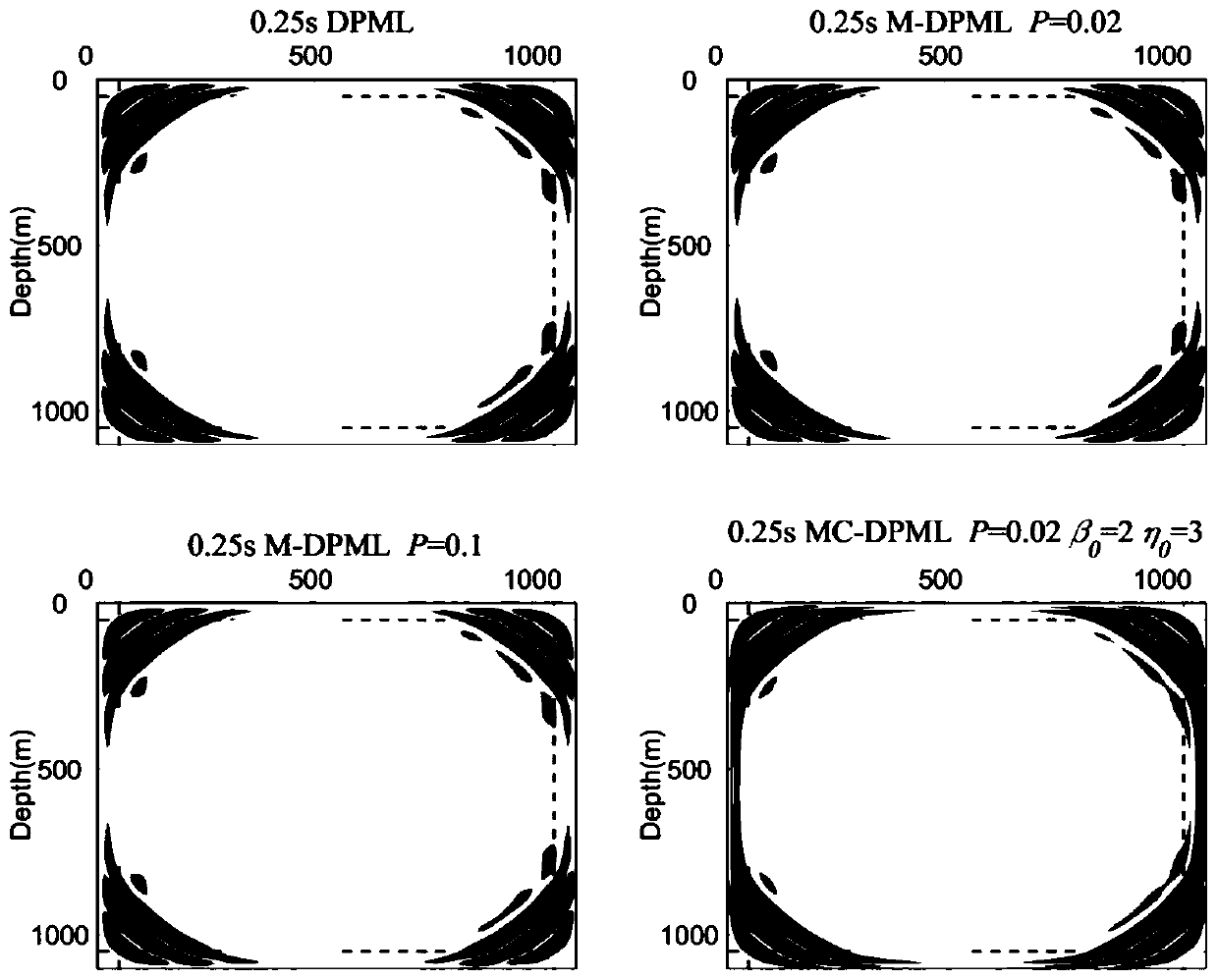

Non-split complete matching layer absorption boundary method

ActiveCN111208563AEliminate time partial derivativesSimple equationSeismic signal processingComputational physicsIncident wave

The invention relates to a non-split complete matching layer absorption boundary method, a lower medium is semi-infinite, and a calculation space is limited such that an absorption boundary needs to be introduced when seismic wave propagation is simulated. The absorption boundary does not truly exist in an underground medium, reflection is not formed when actual seismic waves are transmitted to the absorption boundary, and certain false reflection can be brought by artificial boundaries. By adopting a residual error complete matching layer provided by the invention, incident waves can be effectively absorbed, and seismic waves are prevented from being transmitted back to a main area. According to the method, the form of an original equation is not changed, programming implementation is facilitated, and the method can be popularized to more complex medium simulation; an auxiliary equation eliminates a time partial derivative term of an original variable, and the popularization to high-precision forward modeling is more facilitated. Meanwhile, complex frequency shift transformation is successfully realized on the basis of the residual error complete matching layer such that grazing-in waves can be absorbed, and the generation of low-frequency singular values is avoided; and a complete matching layer structure with double attenuation sections is adopted such that the stability isimproved.

Owner:JILIN UNIV

Preparation method of waterborne peelable coating

InactiveCN106811081AEffectively control the reaction rateHigh strengthPolyurea/polyurethane coatingsEpoxyRoom temperature

The invention discloses a preparation method of a waterborne peelable coating. The preparation method comprises the following procedures: (1) preparing an epoxy resin-butanone solution; (2) adding isophorone diisocyanate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (3) adding dimethylolpropionic acid and the like into the primary product, so as to obtain an epoxy-modified polyurethane emulsion; (4) adding silica sol and the epoxy-modified polyurethane emulsion into a third reaction kettle, so as to obtain a mixed emulsion; (5) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle, so as to obtain a mixed base solution; (6) adding the mixed emulsion into the mixed base solution, so as to obtain the waterborne peelable coating; (7) carrying out wiping and air-drying on a plastic film, and diluting the waterborne peelable coating; (8) spraying waterborne peelable coating to the plastic film, and airing, so as to obtain a waterborne peelable coating paint film. The paint film prepared by virtue of the preparation method can be used for conveniently testing the properties such as tensile property, corrosion resistance, vapor permeability and peel strength of the coating.

Owner:重庆市共赢包装制品有限公司

A-position co-substituted piezoelectric ceramic material with high piezoelectric constant and preparation method

InactiveCN103724013AHigh piezoelectric constantImprove piezoelectric performanceElectromechanical coupling coefficientDielectric permittivity

The invention provides an A-position co-substituted piezoelectric ceramic material with a high piezoelectric constant. The material is characterized in that the composition is Pb1-e-f-BaeLaf(Ni1 / 3Nb2 / 3)x(Zn1 / 3Nb2 / 3)yZrmTinO3+awt%Al2O3+bwt%Sb2O3+cwt%Fe2O3+dwt%Bi2O3, wherein (e+f) is more than or equal to 0.04 and less than or equal to 0.2; (x+y) is more than or equal to 0.05 and less than or equal to 0.3; (x+y+m+n)=1; a=0-0.5; b=0-0.5; c=0-0.5; d=0-0.5. A preparation method of the piezoelectric ceramic material comprises burdening, mixing, pre-sintering for synthesizing, smashing, finely grinding, molding, discharging glue, sintering and loading onto an electrode for polarizing. By means of A-position co-substituting and proper doping, the piezoelectric constant can be increased greatly. The A-position co-substituted piezoelectric ceramic material has the characteristics of high relative dielectric constant epsilonT33 / epsilon0 and high piezoelectric constants d33 and d31, the electromechanical coupling coefficient Kp is 0.6-0.75, and the mechanical quality factor Qm is less than 50. The material can be applied to a plurality of piezoelectric sensors and actuators.

Owner:重庆胜普昂凯科技有限公司

Method for preparing water-based aliphatic polyurethane emulsion type strippable coating

InactiveCN106810986AEffectively control the reaction rateImprove water resistanceCoatingsWater basedPolymer science

The invention discloses a method for preparing a water-based aliphatic polyurethane emulsion type strippable coating. The method comprises the following procedures: (1) adding isophorone diisocyanate and the like into a first reaction kettle at room temperature to obtain a primary product; (2) adding dimethylolpropionic acid and the like into the primary product to prepare acrylate modified aliphatic polyurethane emulsion; (3) adding silica sol and the acrylate modified aliphatic polyurethane emulsion into a third reaction kettle at room temperature to obtain mixed emulsion; (4) adding a proper amount of an acrylate copolymer potassium salt and the like into a fourth reaction kettle in which distilled water is contained to obtain a mixed base solution; (5) adding the mixed emulsion into the mixed base solution to obtain the water-based aliphatic polyurethane emulsion type strippable coating. By the prepared coating, a protected object can be effectively sealed and protected, and can be prevented from being polluted, corroded and damaged. In addition, the coating is also high in water resistance and strippability and stronger in cohesive force and coating film strength.

Owner:重庆市共赢包装制品有限公司

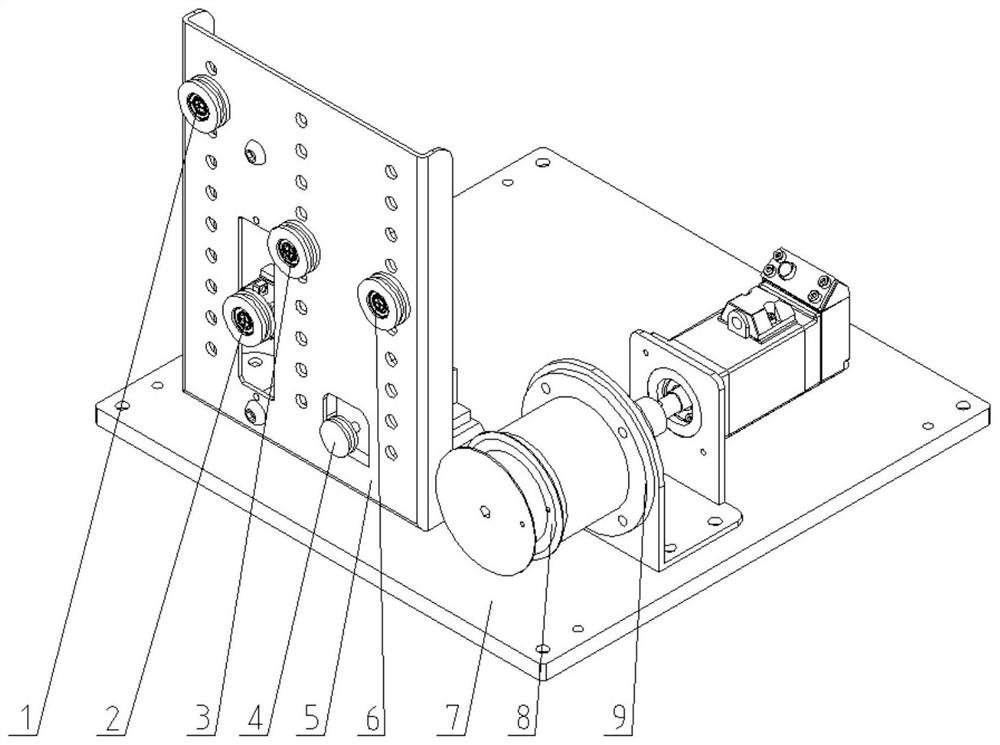

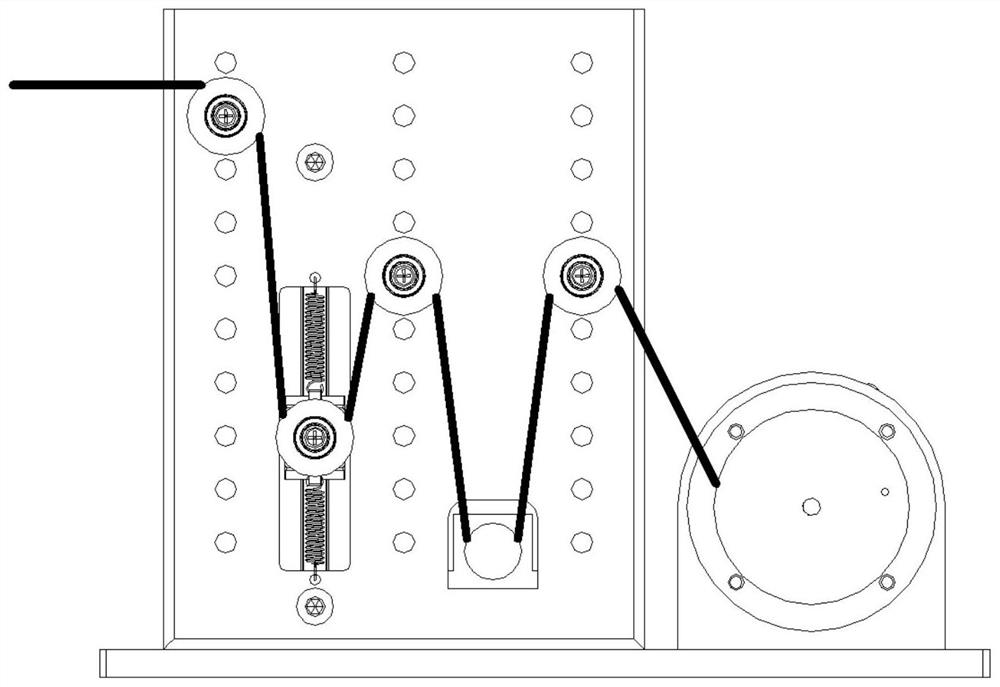

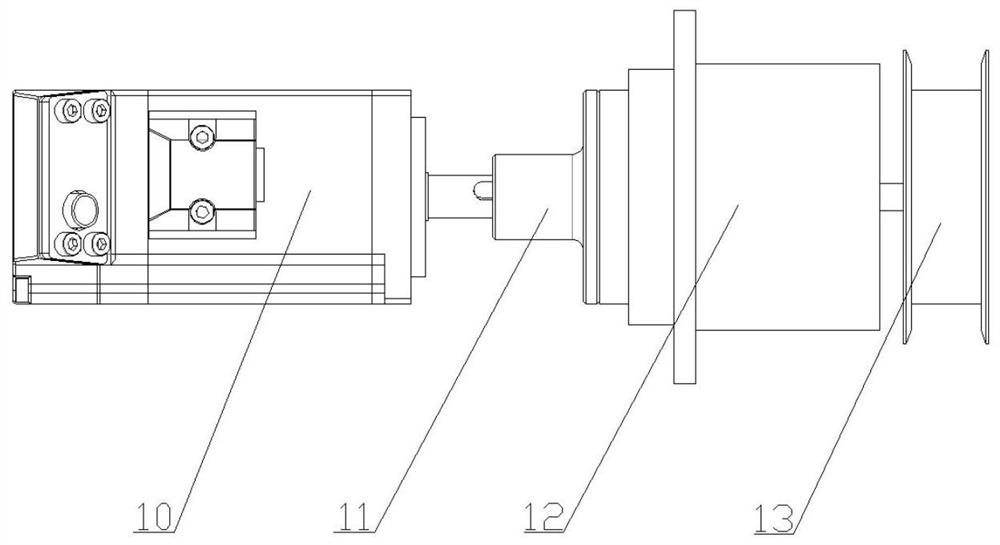

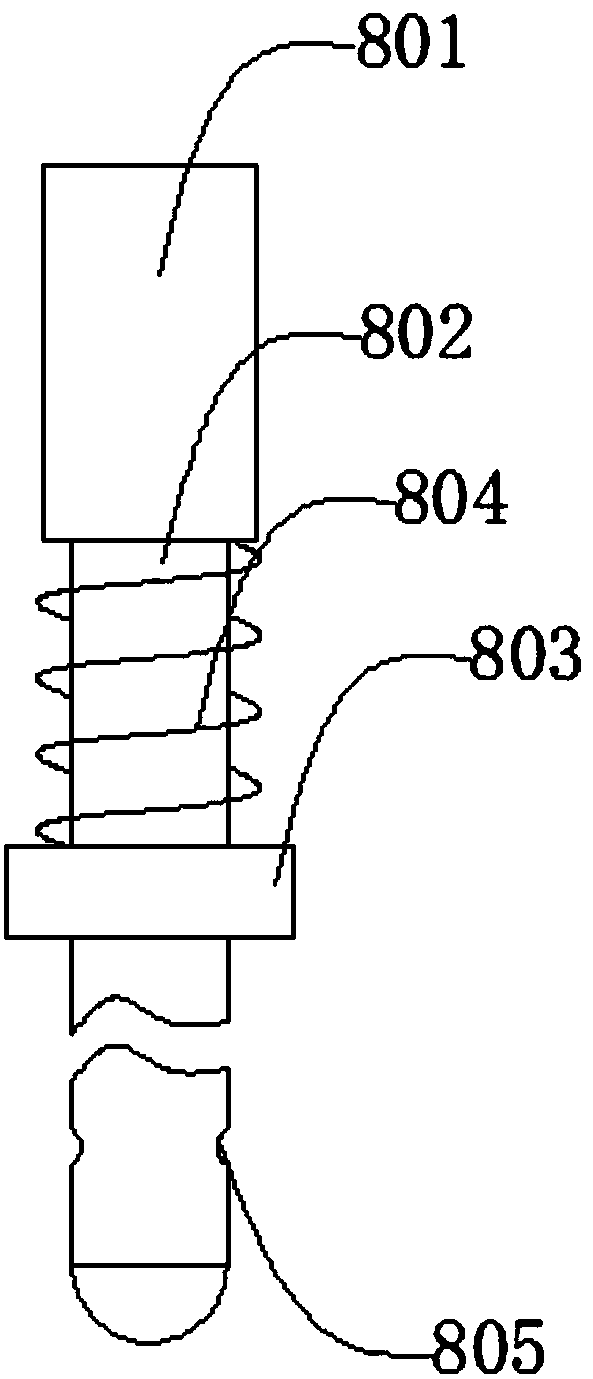

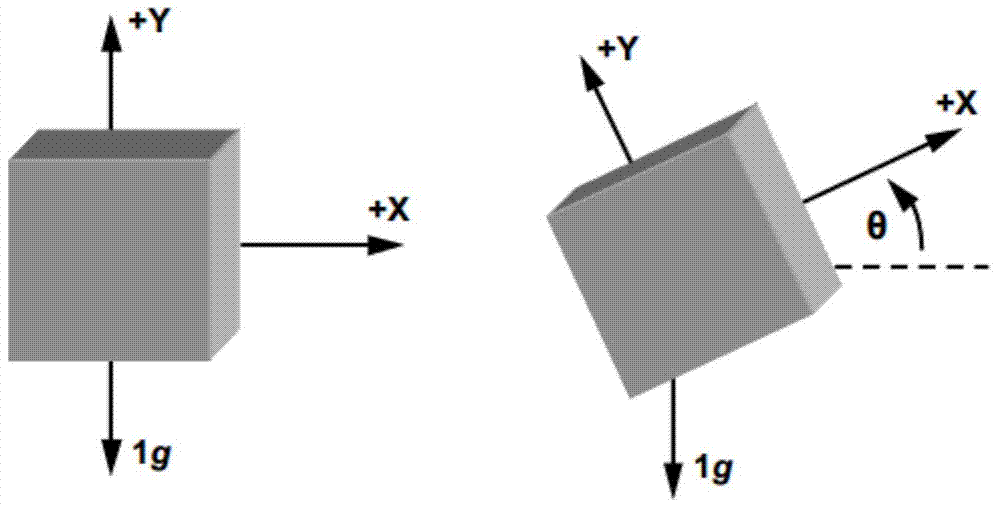

Constant tension control device and control method

ActiveCN112249777AAchieve constant tension controlHigh control precisionWebs handlingElectric machineryBlock and tackle

The invention discloses a constant tension control device and a control method. The constant tension control device comprises a first guide wheel, a floating pulley assembly, a second guide wheel, a measuring and monitoring mechanism, a guide wheel mounting plate, a third guide wheel, a bottom plate, a driving mechanism and an encoder; one end of a base material is attached to a winding roller ina winding manner, and the other end of the base material sequentially penetrates through the third guide wheel, the measuring and monitoring mechanism, the second guide wheel, the floating pulley assembly and the first guide wheel from the winding roller; and the driving mechanism is used for driving the winding roller to rotate according to a tension value, displayed by the measuring and monitoring mechanism, of the base material, so that winding or unwinding of the base material is achieved, and the tension of the base material is kept constant. According to the constant tension control device, a motor-driven magnetic powder clutch is used as an actuating mechanism, and the floating pulley assembly is used for passive adjustment, so that the tension of a controlled target is well controlled; and the tension of the controlled target is accurately controlled by adopting a method of combining feedforward control and feedback control, so that the control precision is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

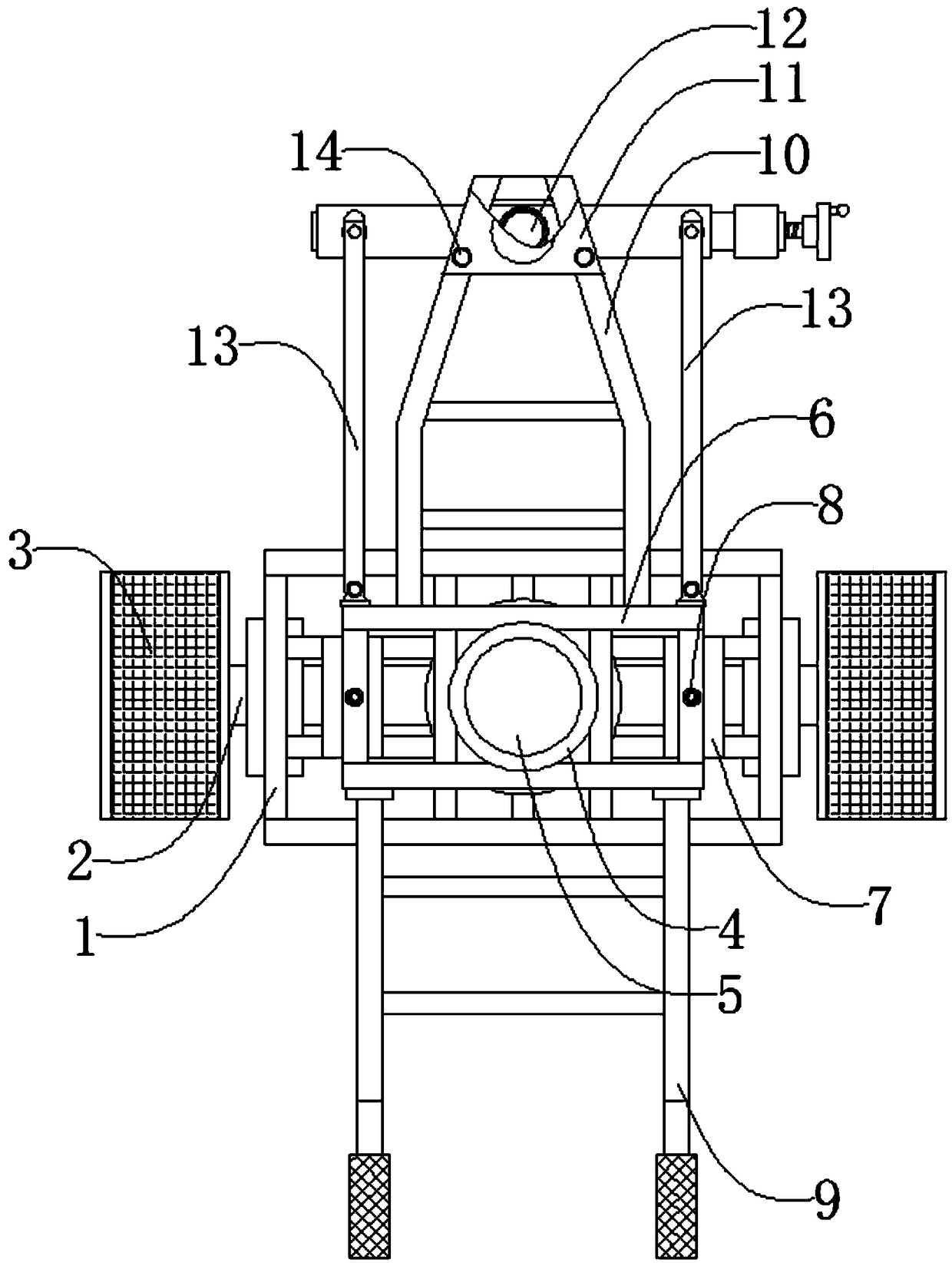

Conveying device for curb construction

InactiveCN108792592AOffset adverse effectsExtended service lifeConveyor partsLocking mechanismEngineering

The invention discloses a conveying device for curb construction. The device comprises a lower frame, a wheel axle, a wheel, a central rotation shaft, a central rotation sleeve, an upper frame, a limiting mechanism, an operation mechanism, a handrail, a bracket, a front rotation sleeve, a curb capture mechanism, a locking mechanism and a first plug bush. The device is simple in structure and is capable of changing curbs from a horizontal state into a vertical state; primary clamping is carried out by adoption of a chuck and secondary fastening is carried out by adoption of a flexible bridle, so that the curbs can be effectively locked and prevented from falling; meanwhile, primary direction adjustment is formed by the central rotation sleeve and the central rotation shaft, so that the whole positions of the curbs can be adjusted; and secondary direction adjustment is formed by a front rotation shaft and the front rotation sleeve, so that horizontal angles of the curbs can be adjusted,so as to effectively improve the conveying efficiency and construction efficiency and effectively avoid the potential safety hazard of curb falling.

Owner:MAANSHAN JULI SCI & TECH

Muscarinic combinations and their use for combating hypocholinergic disorders of the central nervous system

ActiveUS10307409B2Improve concentrationOffset adverse effectsSheet deliveryHeterocyclic compound active ingredientsMuscarinic cholinergicNervous system

A combination of a muscarinic cholinergic receptor agonist, a non-anticholinergic antiemetic agent and a non-selective, peripheral anticholinergic agent for the treatment of hypocholinergic disorders of the central nervous system.

Owner:CHASE PHARMA CORP

Muscarinic combinations and their use for combating hypocholinergic disorders of the central nervous system

InactiveUS20190314354A1Improve concentrationOffset adverse effectsSheet deliveryHeterocyclic compound active ingredientsDiseaseMuscarinic cholinergic

A combination of a muscarinic cholinergic receptor agonist, a non-anticholinergic antiemetic agent and a non-selective, peripheral anticholinergic agent for the treatment of hypocholinergic disorders of the central nervous system.

Owner:CHASE PHARMA CORP

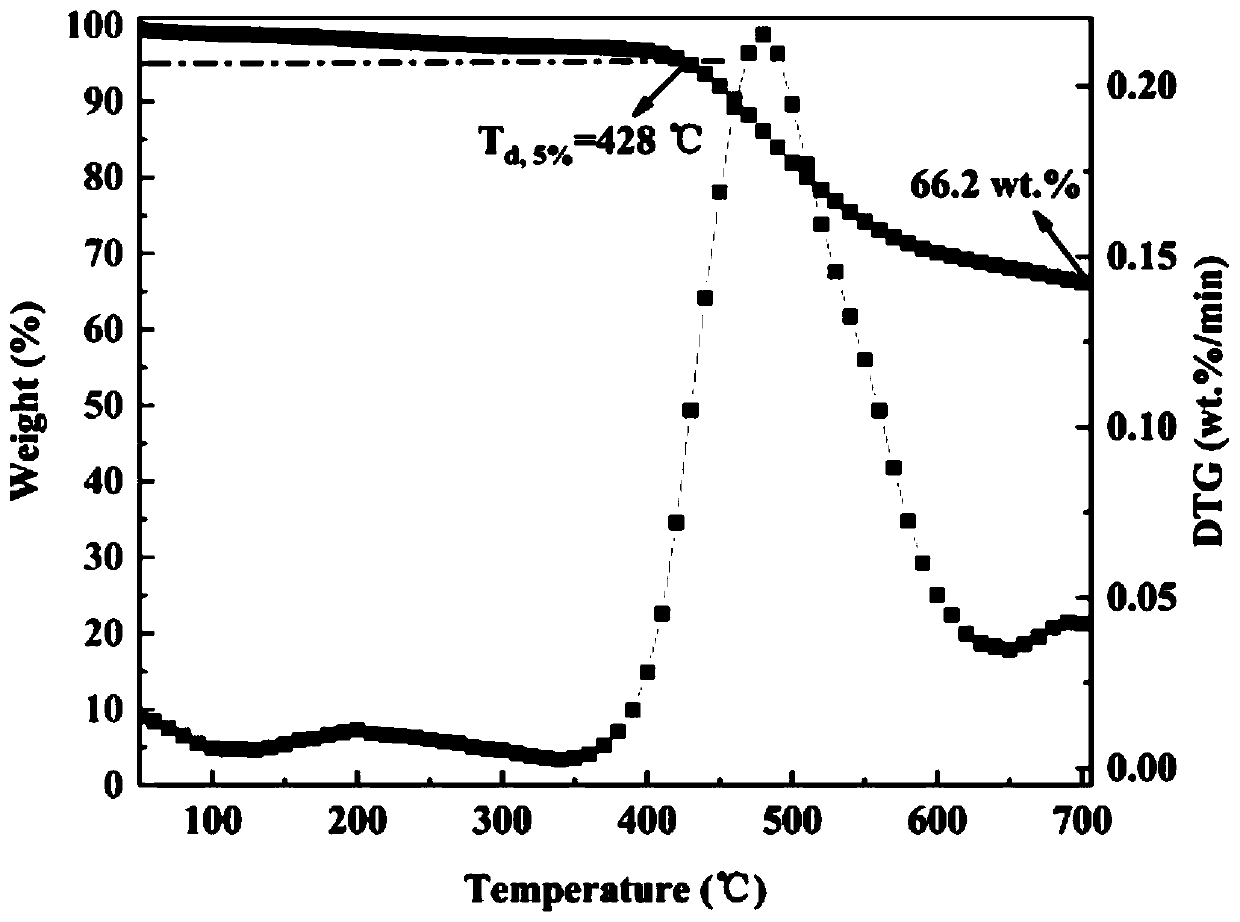

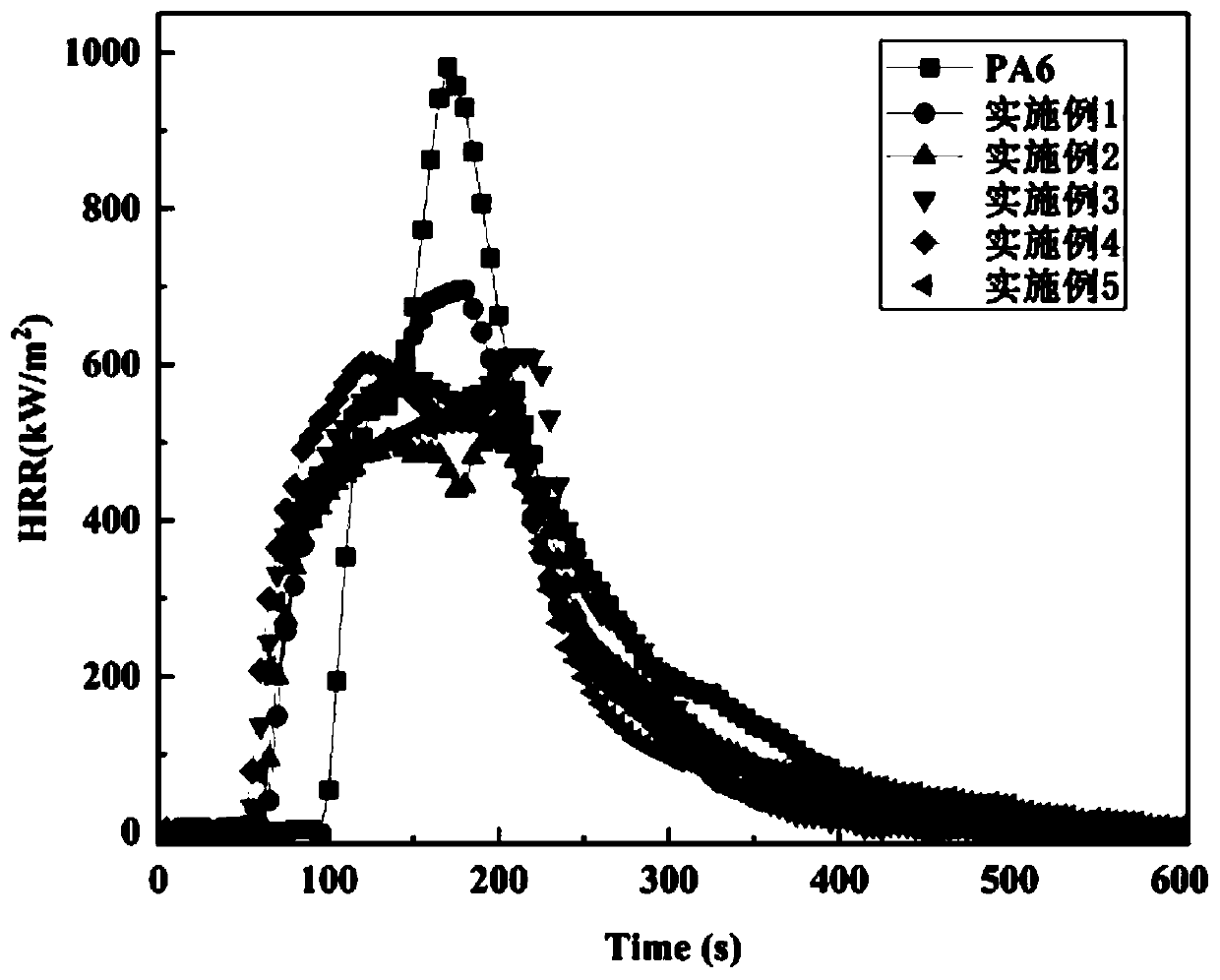

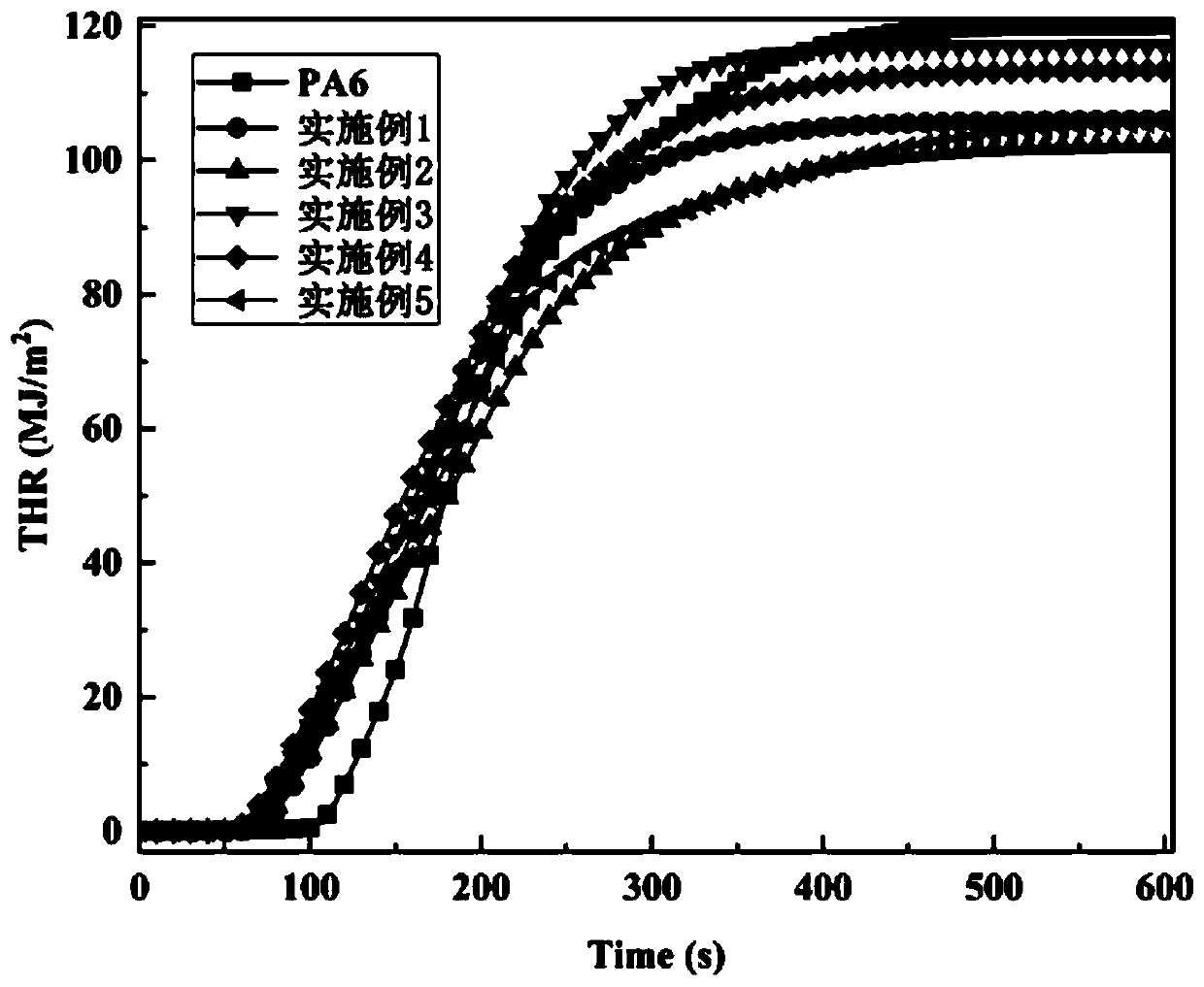

Halogen-free flame-retardant PA6 and preparation method thereof

ActiveCN111574827AHigh thermal decomposition temperatureHigh carbon residue yieldPhosphateAntioxidant

The invention relates to a halogen-free flame-retardant PA6 composite material which comprises the following components in percentage by mass: 66%-90% of a PA6 base material, 9%-25% of a compound halogen-free flame retardant, 0.1%-2.0% of a main antioxidant, 0.2%-4.0% of an auxiliary antioxidant and 0.7%-3.0% of a lubricant, wherein the compound halogen-free flame retardant is prepared from a hypophosphite-cyclotetrasiloxane double-base synergistic compound and a nitrogen flame retardant together. Hypophosphite-cyclotetrasiloxane double groups are used for cooperation, the flame retardant hasextremely good charring performance and an excellent flame retardant effect, the addition amount of the halogen-free flame retardant can be greatly reduced, the compatibility problem of the flame retardant and a matrix is improved, and the mechanical property of the matrix can be enhanced due to the existence of a Si crosslinking structure contained in a siloxane group so that adverse effects caused by the addition of the flame retardant are further counteracted; the halogen-free flame-retardant PA6 composite material has the advantages of high flame-retardant efficiency, no halogen, low smoke, low toxicity, dripping resistance and excellent processability and is widely applicable.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Preparation method of aromatic polyurethane emulsion water-based paint

InactiveCN106811069AEffectively control the reaction rateImprove water resistanceAntifouling/underwater paintsPaints with biocidesEpoxyWater based

The invention discloses a preparation method of an aromatic polyurethane emulsion water-based paint. The preparation method comprises the following steps: 1) preparing an epoxy resin-butanone solution; drying raw materials; 2) adding toluene diisocyanate and the like into a first reaction kettle to obtain a primary product; 3) adding dimethylolpropionic acid into the primary product, and adding triethylamine to obtain an epoxy modified aromatic polyurethane emulsion; 4) adding a silica sol and the epoxy modified aromatic polyurethane emulsion into a third reaction kettle at room temperature to obtain a mixed emulsion for later use; 5) adding right amounts of acrylic acid copolymer potassium salt and the like into a distilled-water-containing fourth reaction kettle to obtain a mixed substrate; and 6) adding the mixed emulsion into the mixed substrate to obtain the aromatic polyurethane emulsion water-based paint. The paint disclosed by the invention has the advantages of excellent water resistance, higher stability, higher cohesive force, favorable peelability and higher coated film strength.

Owner:重庆市共赢包装制品有限公司

Nursery pond heavy metal removal device

InactiveCN102273424AEcological impactImprove exchange efficiencyPisciculture and aquariaWater flowEnvironmental engineering

The invention discloses a heavy metal removing device for a seedling growing pool, the heavy metal removing device is provided with a rectifying casing with a hollow inner cavity, and the rectifying casing inner cavity is provided with a spiral exchange group capable of absorbing heavy metal ions; the upper part of the rectifying casing is provided with a water outlet; the center of the lower part of the rectifying casing is provided with a water inlet, and flow mixing holes go through the periphery of the water inlet in a uniform distribution; an annular air stone is hung at the lower side of the rectifying casing. During inflation and oxygenation of the annular air stone, water is driven to form a rising flow, which flows by the spiral exchange group from the water inlet, and flows out from the water outlet. In the process, the water flow flows by the spiral exchange group, and the heavy metal ions in the water are absorbed by the spiral exchange group, reaching effect of removing the heavy metal ions. The heavy metal removing device in the invention is advantaged by firm structure, high safety, wide application scope, high absorption efficiency of ions, and small harm upon fry.

Owner:ZHEJIANG OCEAN UNIV

Preparation method of environment-friendly packaging material

InactiveCN106810987AEffectively control the reaction rateHigh peel strengthAnti-corrosive paintsRoom temperatureDistilled water

The invention discloses a preparation method of an environment-friendly packaging material. The preparation method comprises the following procedures: (1) adding toluene diisocynate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (2) adding dimethylolpropionic acid and the like into the primary product, so as to obtain an acrylate modified aromatic waterborne polyurethane emulsion; (3) adding silica sol and the acrylate modified aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature, so as to obtain a mixed emulsion; (4) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle containing distilled water, so as to obtain a mixed base solution; (5) adding the mixed emulsion into the mixed base solution, so as to obtain the environment-friendly packaging material; (6) carrying out wiping and air-drying on a plastic film, and diluting the environment-friendly packaging material; and (7) spraying the environment-friendly packaging material to the plastic film, so as to obtain an environment-friendly packaging material paint film. By utilizing the environment-friendly packaging material prepared by virtue of the preparation method, a to-be-protected object can be effectively closed and protected, and the pollution, corrosion and damage of the object are prevented.

Owner:重庆市共赢包装制品有限公司

An intelligent control system and method for primary wind pressure target value

InactiveCN104848250BReduce throttling lossReduce power consumptionAir supply regulationComputer moduleEngineering

The invention discloses an intelligent control system and method for a primary wind pressure target value, comprising a first control logic module, a second logic control module, a controller, an adder, and an acquisition module for collecting AGC instructions issued by a power management system ; The output of the acquisition module is connected with the input of the second logic control module, the output of the second logic control module is connected with the output of the first control logic module and the input of the adder, the output of the adder The terminal is connected with the input terminal of the controller, and the output terminal of the controller is connected with the control terminal of the hot air baffle in the primary air duct. The invention can effectively reduce the power consumption of primary wind.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

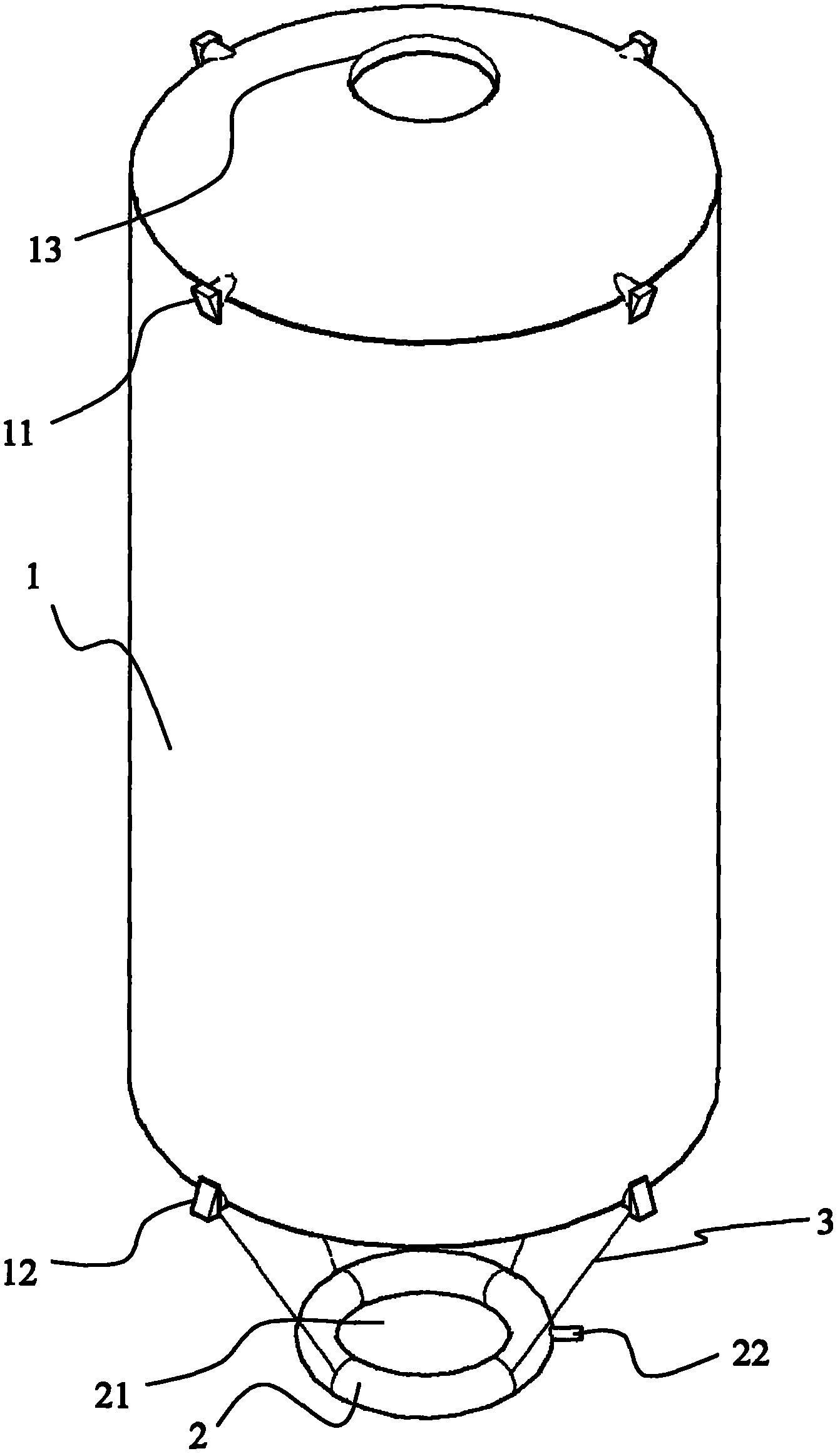

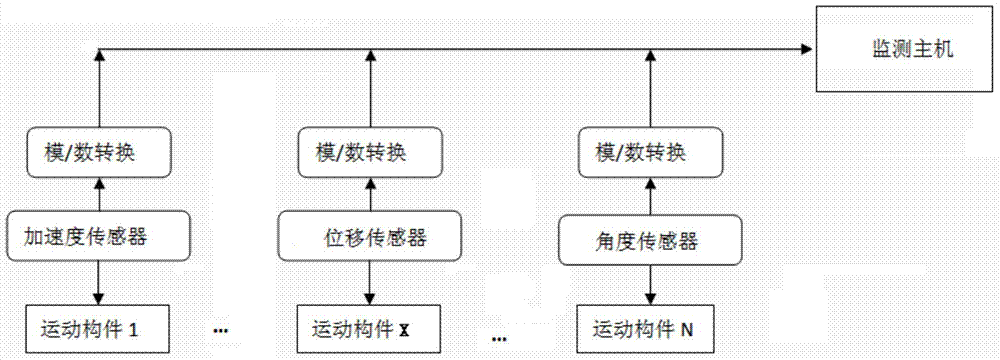

Method and system for monitoring and evaluating the mechanical state of intelligent high-voltage switching device

InactiveCN104502074ASports judgmentPerformance judgmentMachine part testingKinematic pairEngineering

The invention relates to a method and a system for monitoring and evaluating the mechanical state of an intelligent high-voltage switching device. The system comprises a monitoring host which is communication connection with a corresponding sensor of each kinematic pair on a kinematic chain. The monitoring host is used for monitoring kinematic parameters of at least two kinematic pairs on the kinematic chain, and recording the kinematic parameters in real time. The transmission performance of the kinematic chain is evaluated according to the transmission relationship among the kinematic pairs by comparing and judging the recorded information of the kinematic pairs. According to the method for monitoring and evaluating the mechanical state of an intelligent high-voltage switching device of the invention, the kinematic performance of a whole kinematic chain is comprehensively analyzed and judged according to the transmission relationship among a plurality of kinematic pairs selected from the kinematic chain instead of being represented with data of a single kinematic pair.

Owner:PINGGAO GRP +1

Heavy metal removing device for seedling growing pool

InactiveCN102273424BImprove exchange efficiencyCounteract the hindrancePisciculture and aquariaWater flowEngineering

Owner:ZHEJIANG OCEAN UNIV

Antenna housing capable of improving antenna performance and signal transceiving device

InactiveCN111883926AOffset adverse effectsHigh gainRadiating element housingsElectromagnetic responseSide lobe

The invention discloses an antenna housing capable of improving antenna performance and a signal transceiving device, and the antenna housing comprises a housing body; an accommodating cavity for accommodating an antenna is formed in the radome body, a skin layer is arranged on the outer side of the radome body, a metal patch layer is arranged on the inner side of the radome body, and the metal patch layer is opposite to the skin layer. The metal patch layer is attached to the inner side of the cover body, electromagnetic response can be generated with an internal antenna, the adverse effect of the skin layer on the antenna is counteracted, and the gain of the antenna is improved; besides, when the antenna array performs small-angle scanning, the radome can suppress side lobes, provides abetter protection environment for normal work of the antenna, and can be widely applied to the technical field of antenna protection devices.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of acrylate modified polyurethane protecting packaging film composition

InactiveCN106811106AEffectively control the reaction rateEffective closed protectionPolyurea/polyurethane coatingsChemistryToluene

The invention discloses a preparation method of an acrylate modified polyurethane protecting packaging film composition. The preparation method comprises the following procedures: (1) adding toluene diisocynate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (2) adding dimethylolpropionic acid and the like into the primary product, so as to obtain an acrylate modified aromatic waterborne polyurethane emulsion; (3) adding silica sol and the acrylate modified aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature, so as to obtain a mixed emulsion; (4) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle containing distilled water, so as to obtain a mixed base solution; and (5) adding the mixed emulsion into the mixed base solution, so as to obtain the acrylate modified polyurethane protecting packaging film composition. By utilizing the packaging film composition prepared by virtue of the preparation method, a to-be-protected object can be effectively closed and protected, and the pollution, corrosion and damage of the object are prevented. The packaging film composition further has excellent water tolerance, relatively high stability, relatively strong cohesion, good peelable property and relatively high paint film strength.

Owner:重庆市共赢包装制品有限公司

Preparation method of high-coating-strength packaging body composition

InactiveCN106811065AImprove securityImprove stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPotassium

The invention discloses a preparation method of a high-coating-strength packaging body composition. The method comprises the following processes: (1) preparing an epoxy resin-butanone solution; dewatering and drying raw materials; (2) adding toluene diisocynate and the like into a first reaction kettle to obtain a primary product; (3) adding dimethylolpropionic acid into the primary product, and then adding triethylamine to prepare epoxy-modified aromatic polyurethane emulsion; (4) adding silica sol and the epoxy-modified aromatic polyurethane emulsion into a third reaction kettle at the room temperature to obtain mixed emulsion for later use; (5) adding right amount of acrylic copolymer potassium salt and the like into a fourth reaction kettle filled with distilled water to obtain a mixed base solution; (6) adding the mixed emulsion into the mixed base solution to obtain the high-coating-strength packaging body composition. The high-coating-strength packaging body composition prepared by the method has higher safety, excellent water resistance, higher stability, stronger cohesion, good strippable property and higher coating strength.

Owner:重庆市共赢包装制品有限公司

A voltage drop detection method suitable for grid voltage with large harmonic content

ActiveCN105116195BOffset adverse effectsGuaranteed accuracyCurrent/voltage measurementHarmonicOvercurrent

The present invention relates to the electric energy transformation technology field, in particular to a voltage drop detection method suitable for a power grid voltage large harmonic content. The method comprises the steps of real-timely detecting a power grid voltage, calculating a positive sequence module value eP and a negative sequence module value eN of the power grid voltage, and carrying out the steady state judgment according to a calculation result; real-timely detecting the power grid voltage, calculating the voltage components e alpha and e beta of the power grid voltage in an alpha-beta stationary reference frame, carrying out the instant judgment according to the calculation result. When the instant judgment is used to limit an instant overcurrent, and the steady state judgment is used to determine a reactive current, the instant judgment pays attention to the rapidity, and the steady state judgment pays attention to the stability and accuracy. The two methods are combined to use, and make up the insufficiency mutually, thereby guaranteeing the accuracy and the stability of a judgment result.

Owner:NAVAL UNIV OF ENG PLA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com