Solar constant temperature fermentation methane tank

A constant temperature fermentation and fermentation tank technology, applied in the field of biochemistry, can solve the problems of unstable gas production and inability to produce gas, and achieve the effect of offsetting adverse effects and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The embodiments of the present invention are given below in conjunction with the drawings.

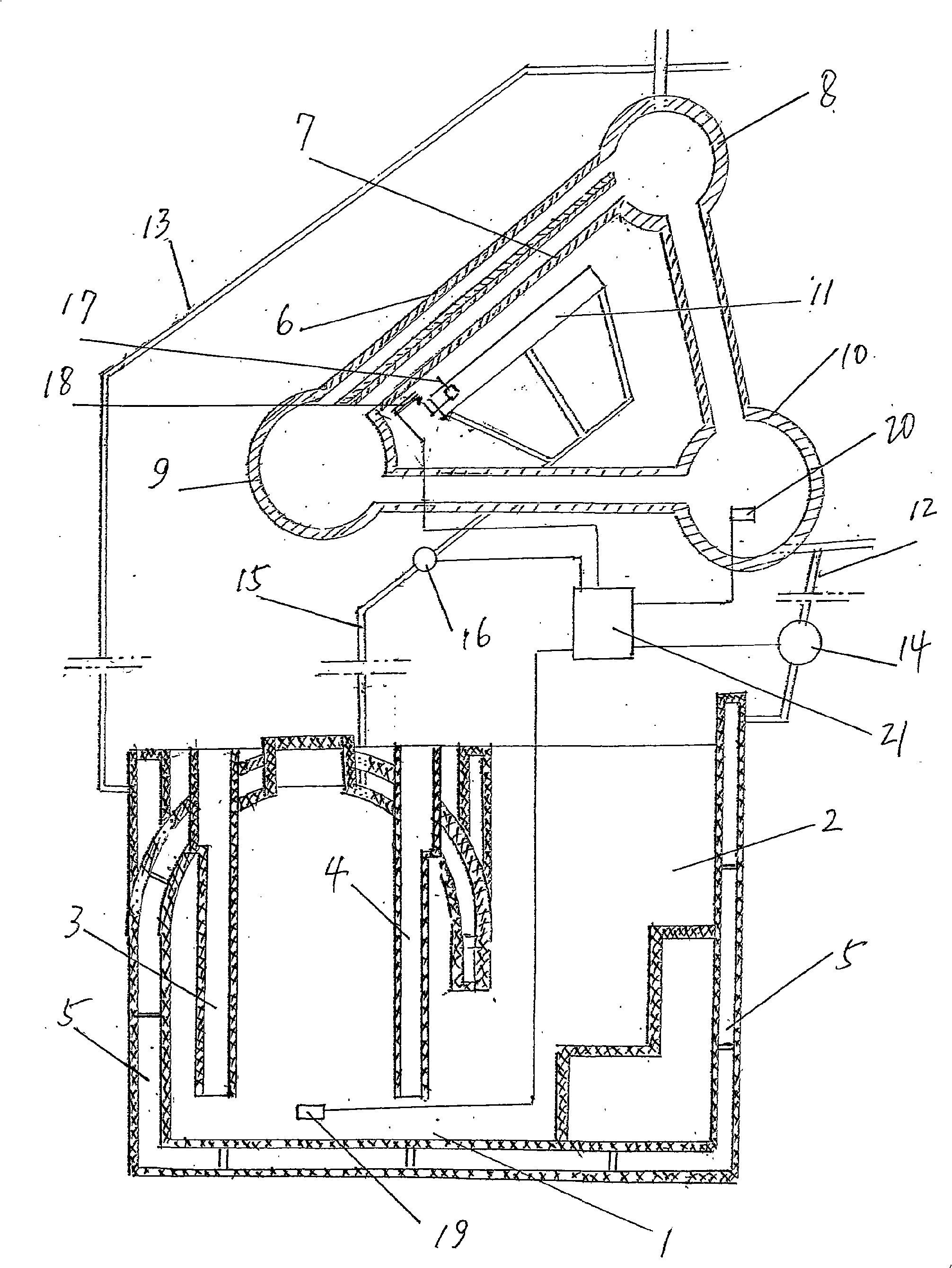

[0010] The structure of the existing biogas digester is injection molded or welded with plastic materials including figure 1 Shown are the two walls of the fermentation room 1, the water pressure room 2, the feeding port 3, the slag outlet 4, and the methane tank with an interlayer 5 at the bottom. The solar water heater including the heat collection tube 6, the heat collection plate 7, the upper circulation tube 8, the lower circulation tube 9, the water storage tank 10 and the inlet and outlet pipes is manufactured. A biogas burner 11 is installed on the back of the heat collecting plate 7. Fix solar water heaters on the ground or on the roof. The solar water heater is installed in the windproof insulation box. Connect the water supply pipe 12 and the water return pipe 13 between the interlayer of the solar water heater and the biogas tank. A circulating water pump 14 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com