Patents

Literature

38results about How to "Effectively control the reaction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation process of high-purity phosphorus pentafluoride

ActiveCN101844754AEffective control of feed rateControl feed ratePhosphorus halides/oxyhalidesPhysical chemistryHydrogen chloride

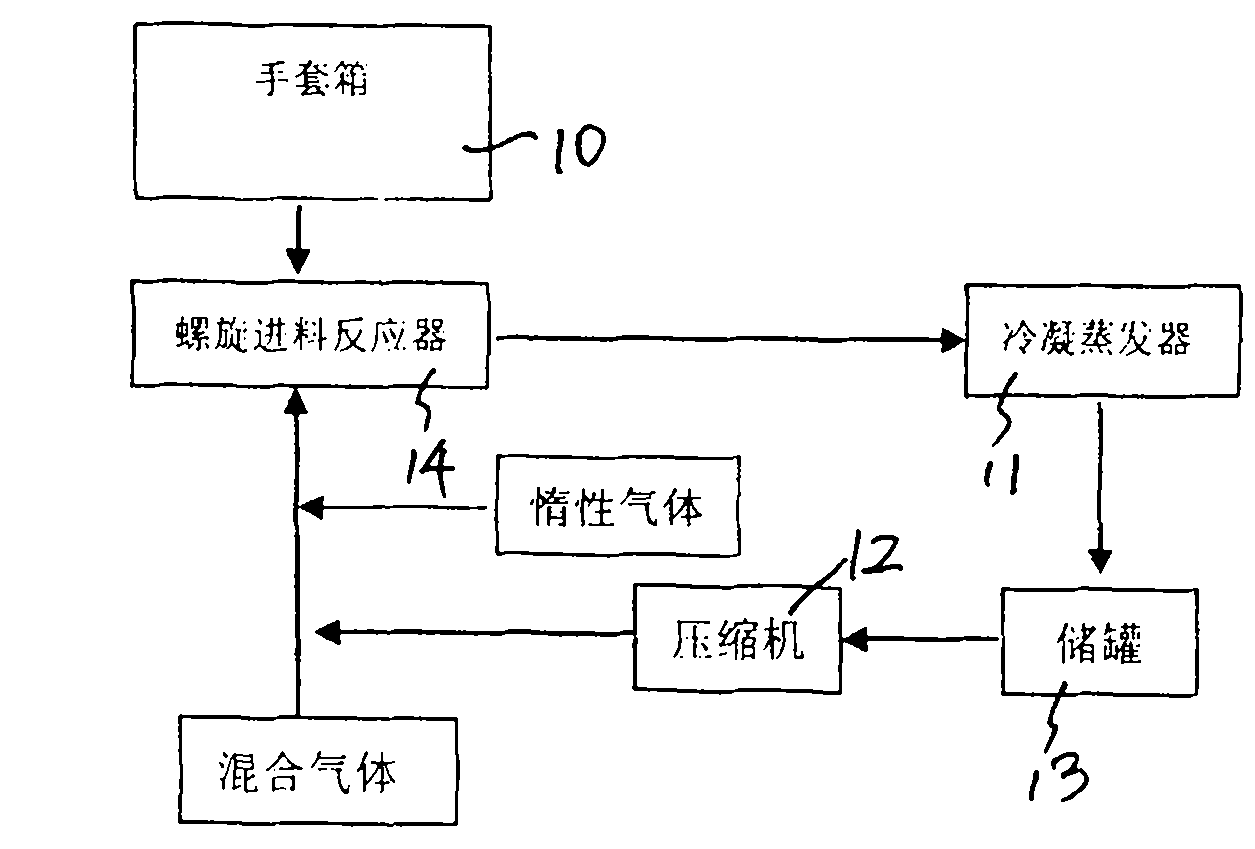

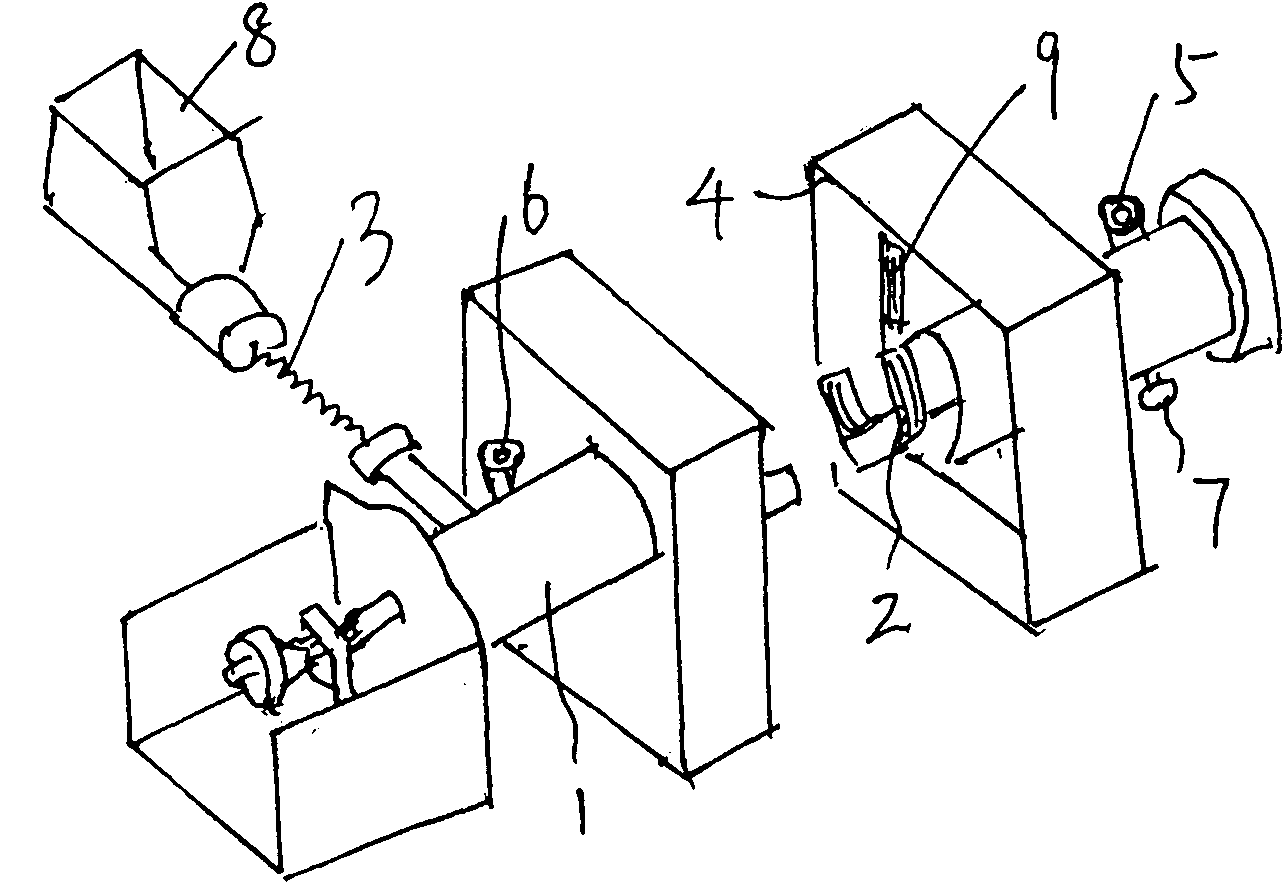

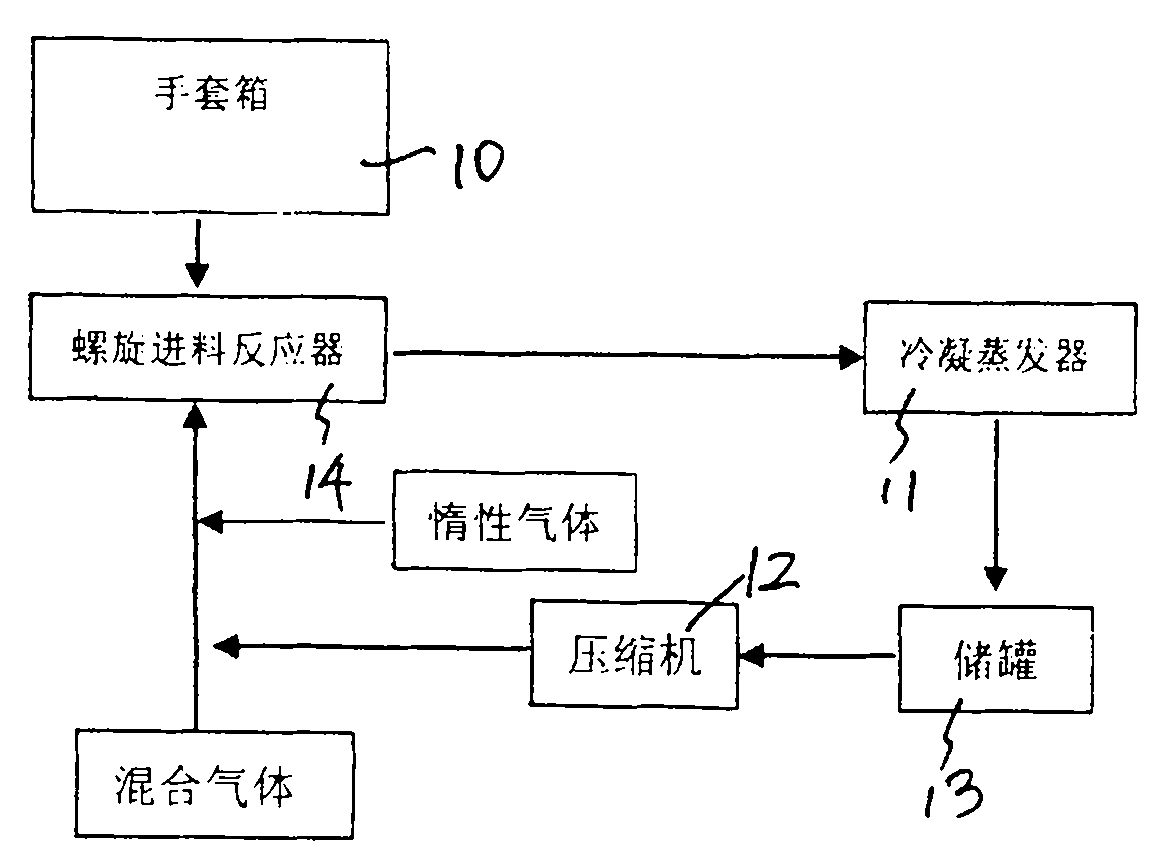

The invention discloses a preparation process of high-purity phosphorus pentafluoride, which comprises the following steps of: firstly adding phosphorous pentachloride into a feed hopper of a spiral feeder under the protection of dry gas in a glove box to assemble a gas circulation loop, and simultaneously adding inert gas into the gas circulation loop in advance; starting a spiral stirring reaction furnace, simultaneously injecting mixed gas of hydrogen fluoride and fluorine gas into the spiral stirring reaction furnace, and controlling the reaction process by controlling the rotation frequency of the phosphorous pentachloride in the spiral feeder, the temperature of gas flow at the outlet of the spiral stirring reaction furnace and the pressure of the gas circulation loop; freezing the phosphorus pentafluoride gas and the hydrogen fluoride gas generated in the reaction process and unreacted hydrogen fluoride gas by a condenser-evaporator, and collecting high-purity phosphorus pentafluoride gas after reaction. The method is simple and effective and can be operated easily.

Owner:JIANGSU JIUJIUJIU TECH

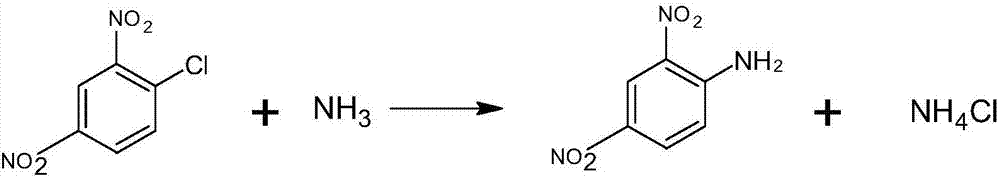

Production method of 2,4-dinitraniline

InactiveCN107382739AEffectively control the reaction rateControl reaction rateOrganic compound preparationAmino compound preparationThermal insulationAmmonium hydroxide

The invention discloses a production method of 2,4-dinitraniline. 2,4-dinitrochlorobenzene and ammonium hydroxide are taken as raw materials; the method comprises steps as follows: bottom water is added to a reaction kettle, heated to 50-70 DEG C, mixed with 2,4-dinitrochlorobenzene and then heated, ammonium hydroxide is dropwise added, the mixture is heated to 90-100 DEG C after addition, the pressure is controlled at 0.05-0.1 MPa, the thermal insulation reaction is performed for 1-3 hours, and 2,4-dinitraniline is obtained through centrifugal filtration. 2,4-dinitraniline is produced with a low-temperature and low-pressure method, the reaction conditions are mild, the production safety risk is low, a high-quality product is obtained through centrifugal filtration after the reaction ends, further purification and separation are not required, and the production cost is low.

Owner:浙江大井化工有限公司

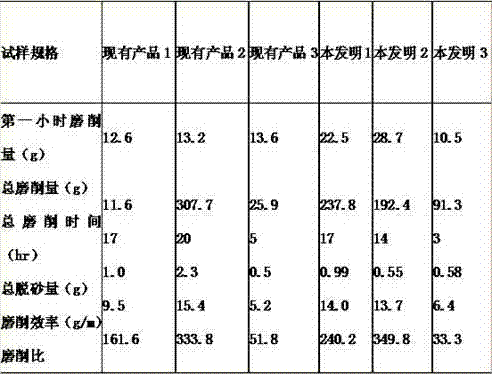

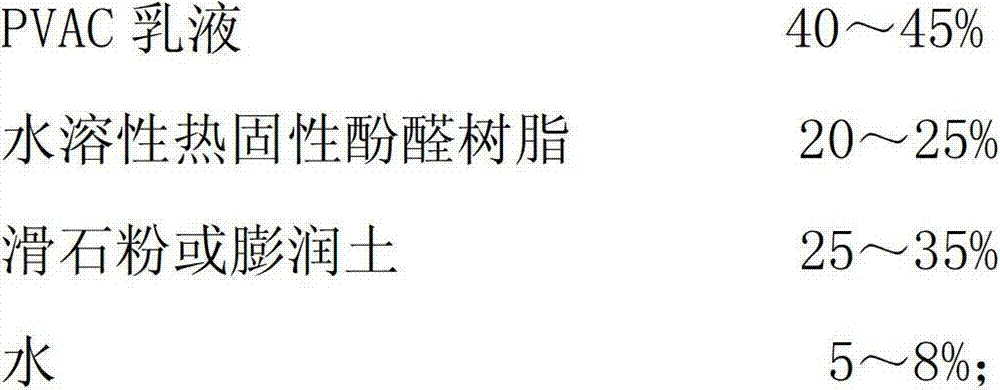

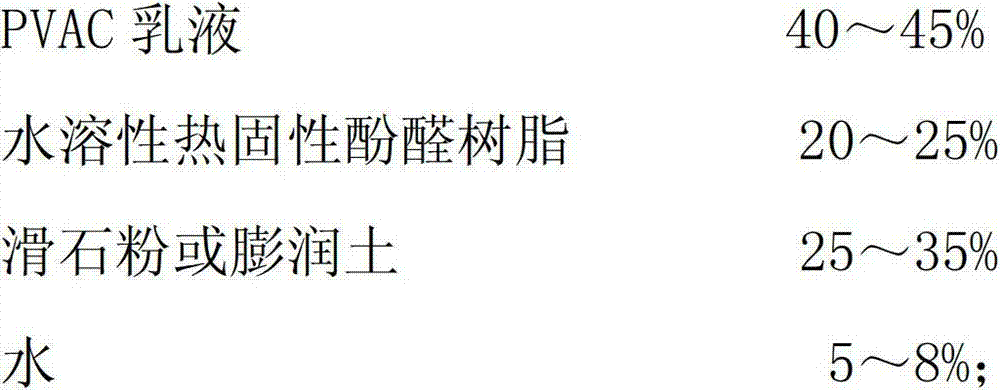

Preparation method for green shallow-cured phenolic resin coated grinding tool

ActiveCN102513943ADecreased responsivenessLow costFibre treatmentAbrasion apparatusPolymer scienceEmulsion

The invention relates to a preparation method for a coated grinding tool, and discloses a preparation method for green shallow-cured phenolic resin coated grinding tool. The preparation method includes steps of treating a base fabric; preparing impregnation liquid; adding from 30 to 50 grams of water-soluble thermosetting phenolic resin and from 70 to 170 grams of water into every 100 grams of PVAC (polymer vinyl acetate) emulsion; realizing once or twice impregnation for the base fabric by the aid of the impregnation liquid, drying and ironing the base fabric after impregnation, realizing press polish, and scratching paste according to conventional process; applying primer; planting sand for a substrate according to conventional process after the primer is applied, drying the substrate planted with the sand at the temperature ranging from 50 DEG C to 60 DEG C for 20 to 25 minutes, then drying the substrate at the temperature ranging from 80 DEG C to 90 DEG C for 15 to 20 minutes and then drying the substrate at the temperature ranging from 100 DEG C to 108 DEG C for 30 to 60 minutes; and gluing again. The primer applied at first consists of components including, by weight percentage, from 20 to 25% of packing, from 45 to 50% of water-soluble thermosetting phenolic resin and from 30 to 35% of water, and primer for the step of gluing comprises components including, by weight percentage, from 50 to 60% of water-soluble thermosetting phenolic resin, from 20 to 30% of calcium carbonate, from 0 to 5% of iron oxide and from 15 to 20% of water. The preparation method has the advantages that cost can be lowered, curing temperature is reduced, curing period is shortened, an adhesion performance is improved, and color is light.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

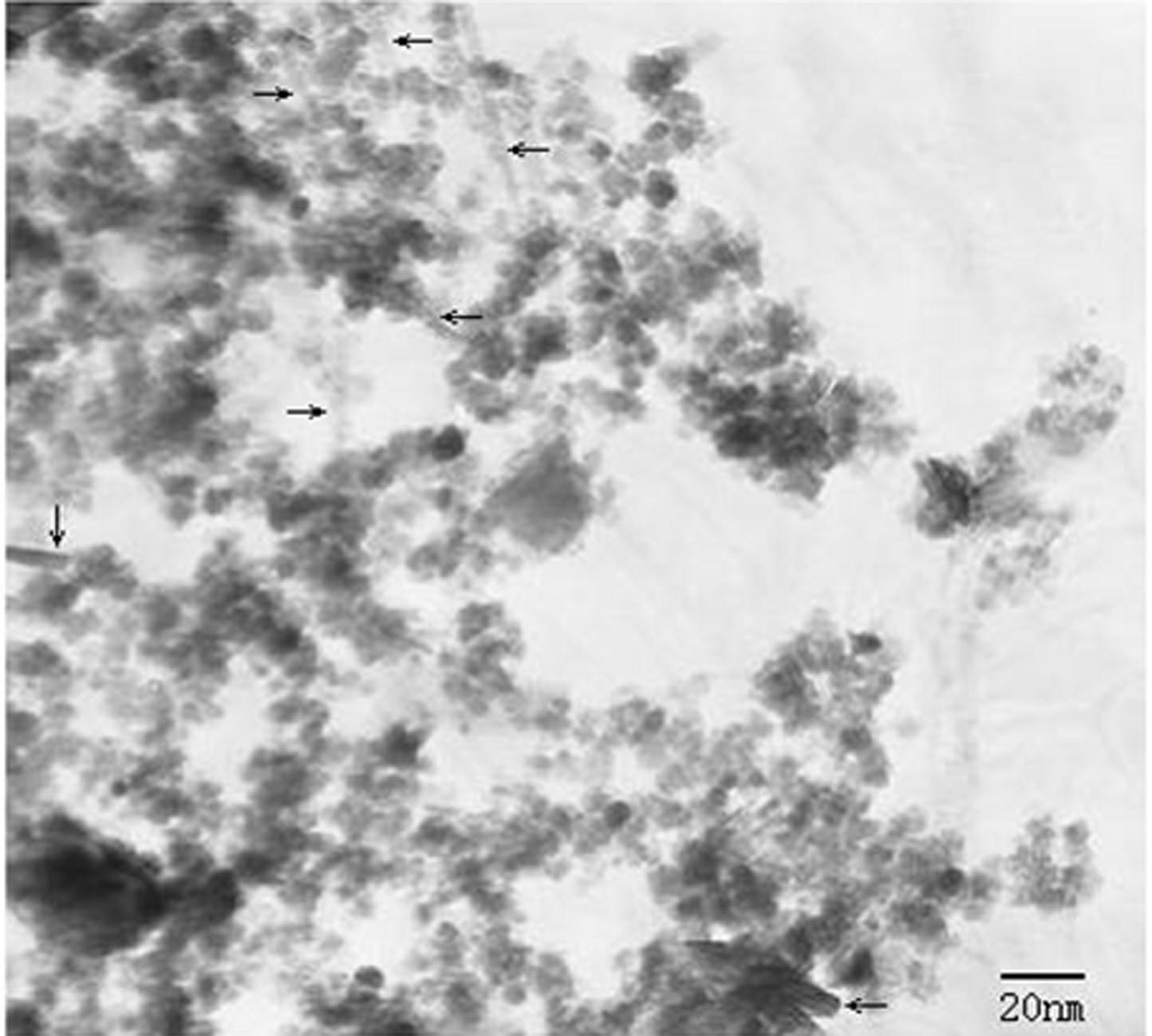

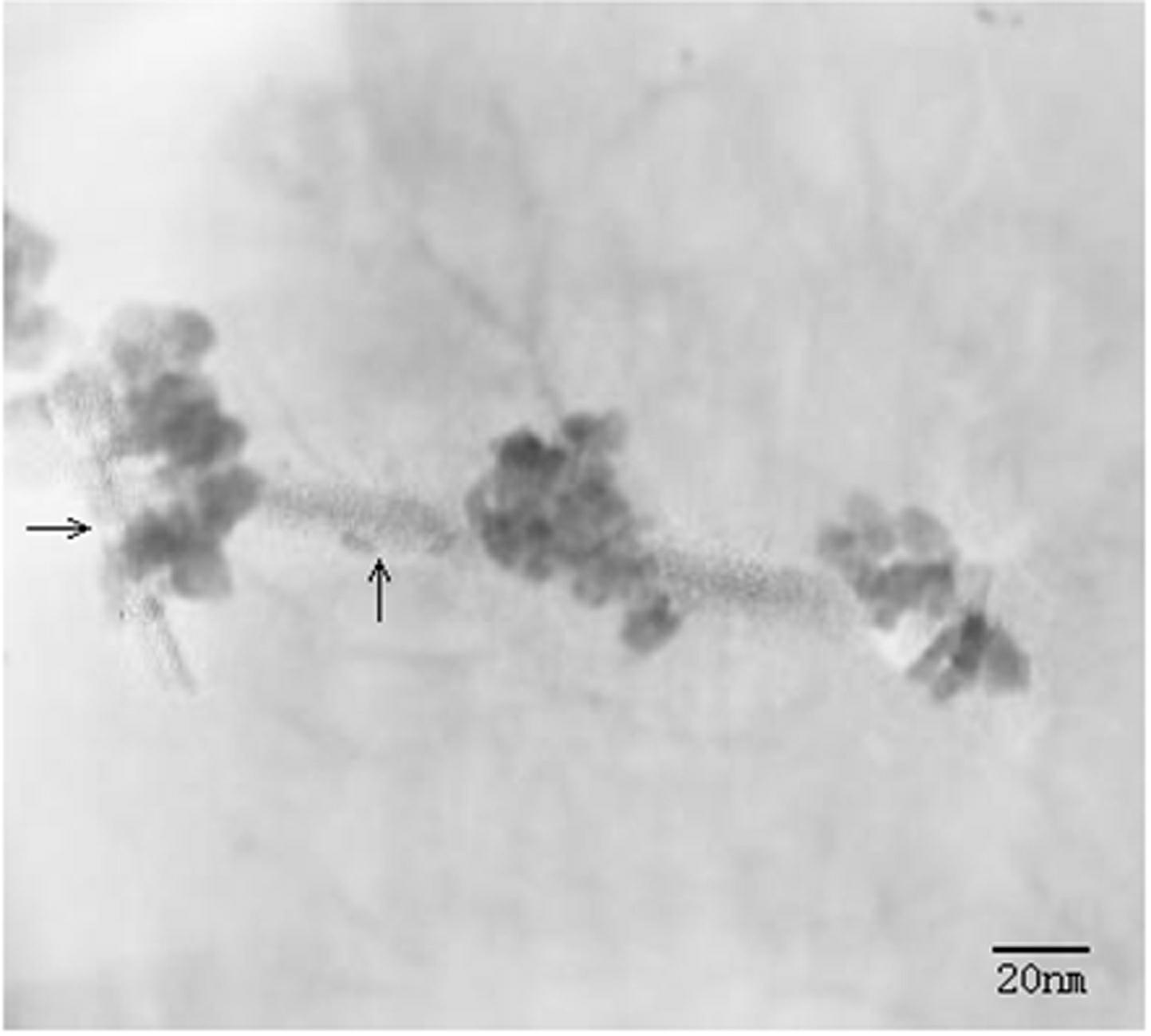

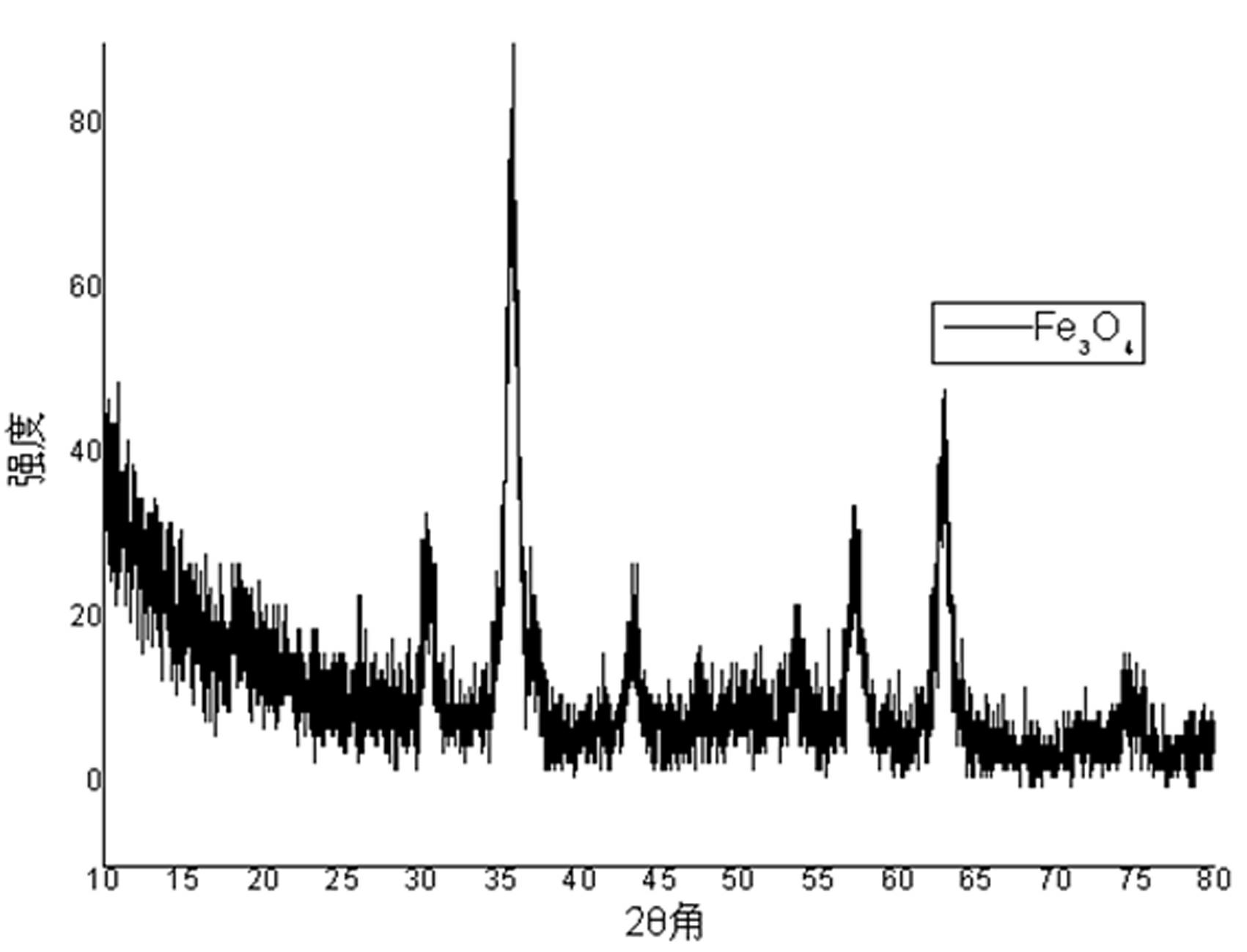

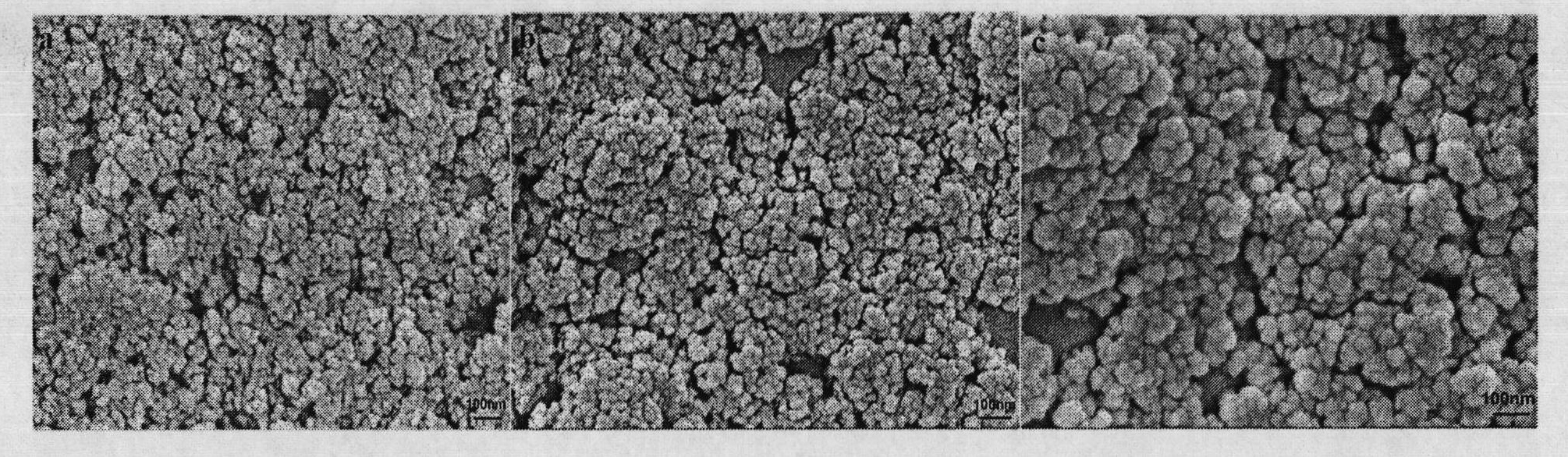

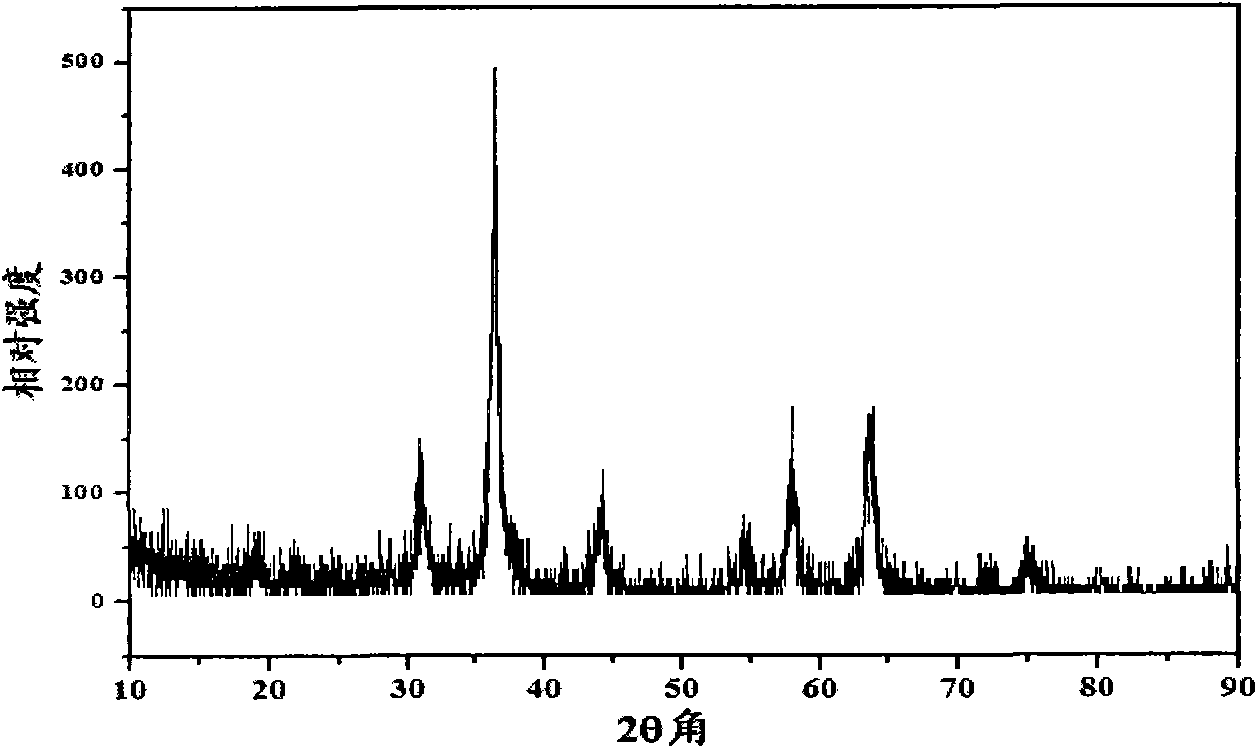

Method for compositing Fe3O4 nanorod by utilizing magnetic induction gas-liquid interface method

InactiveCN102616863AHigh magnetic responsivenessOvercome the disadvantage of only providing a small effective reaction area in the reaction solutionFerroso-ferric oxidesNanotechnologySuperparamagnetismTargeted therapy

The invention provides a method for compositing a Fe3O4 nanorod structure through a gas-liquid interface under the magnetic induction. The method comprises the following steps of: introducing ammonia into a solution dissolved with iron ions and ferrous ions under the regulation of an external magnetic field, and standing for 70-90 minutes at the temperature of 55-75 DEG C until a black brown sediment appears in the solution; and cooling to room temperature, washing with distilled water and alcohol respectively, vacuum-drying, and obtaining a Fe3O4 nanorod with the length of the namorod structure being 30-120 nm. The magnetism of the Fe3O4 nanorod structure can be analyzed and discovered by using a vibrating sample magnetometer, the residual magnetism and a coercive force of the Fe3O4 nanorod structure both can be omitted under the condition without the external magnetic field, the saturation magnetization is 75-80 emu / g, and the superparamagnetism is expressed at the room temperature; and simultaneously, the Fe3O4 nanorod structure also has a higher magnetic responsibility and has a potential application prospect in fields of targeted therapy and shielding.

Owner:NORTHWEST NORMAL UNIVERSITY

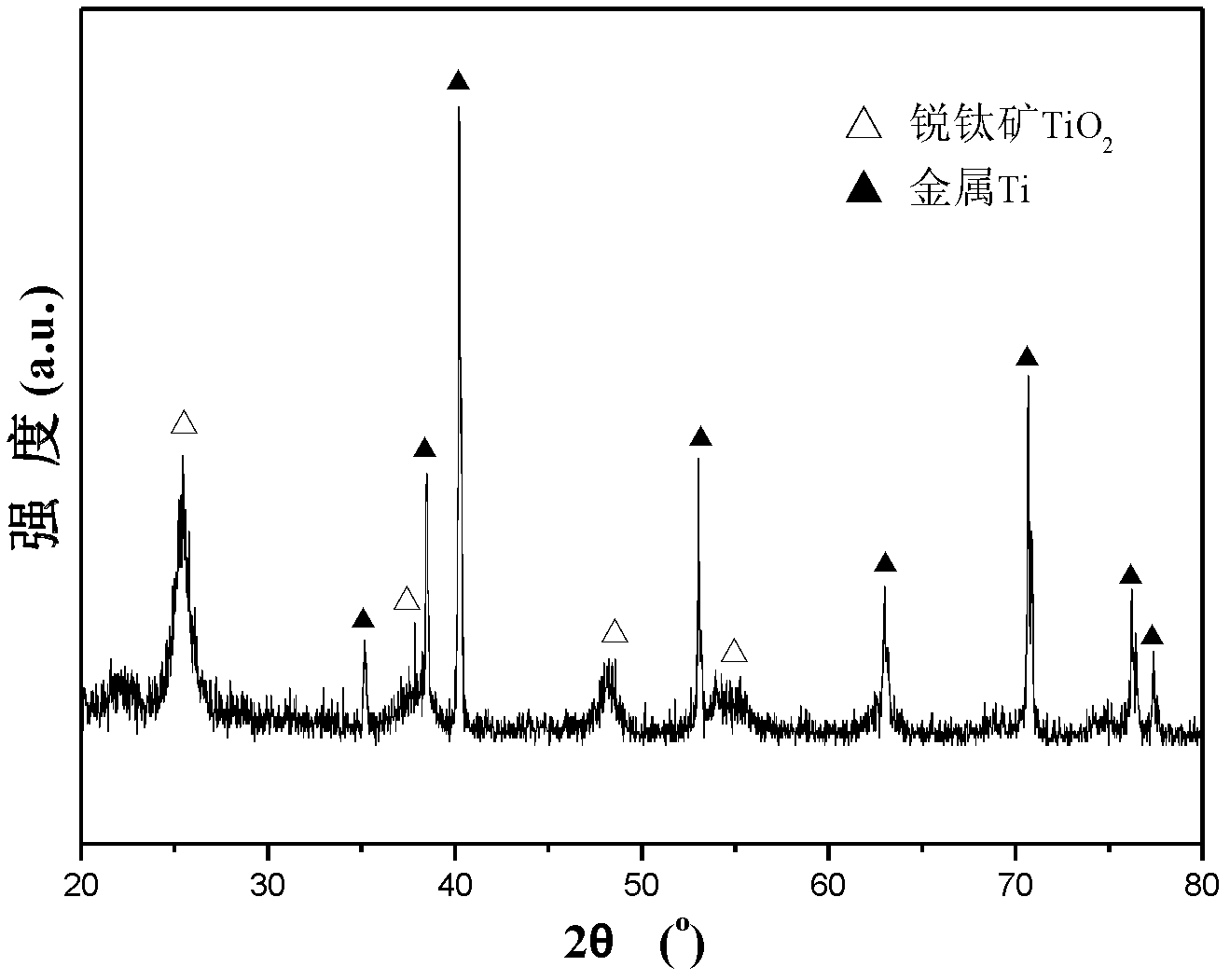

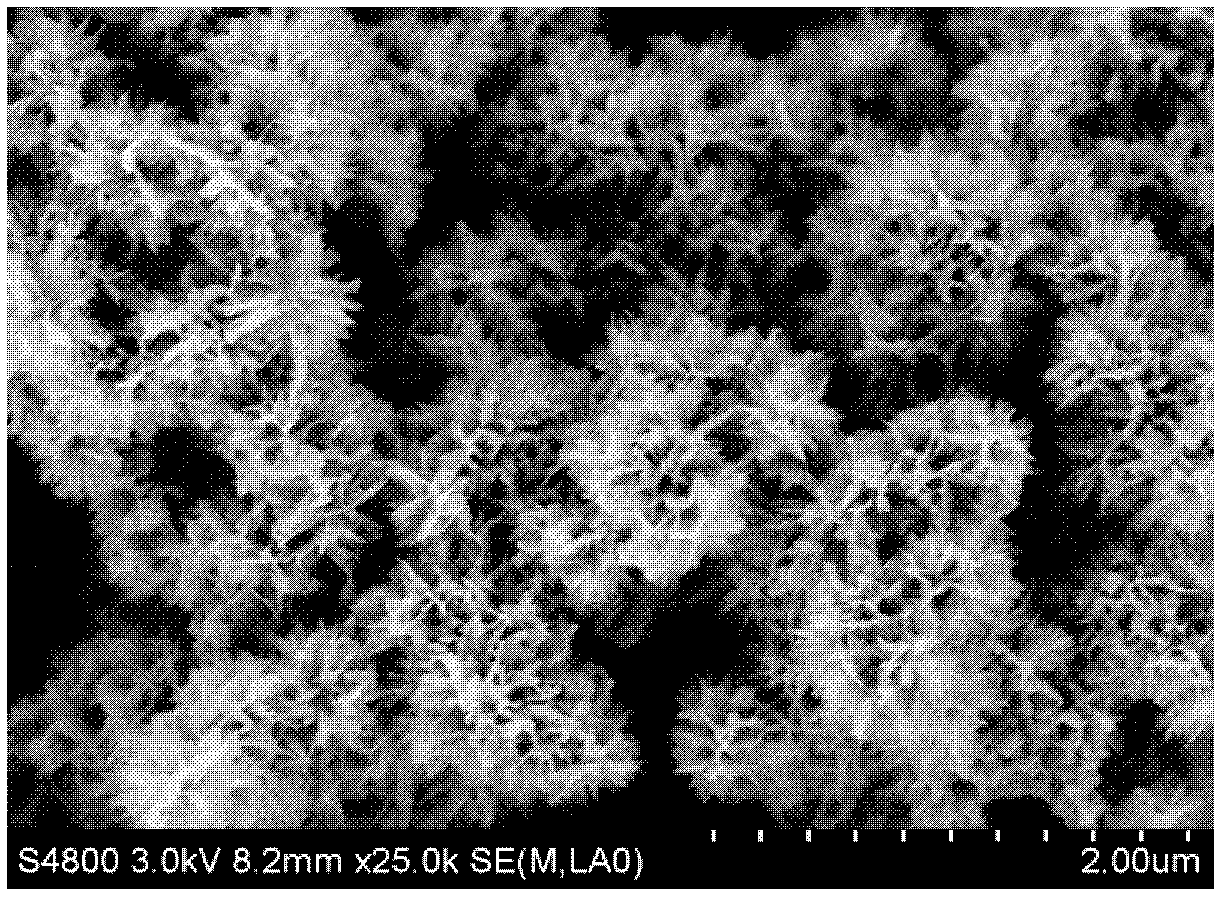

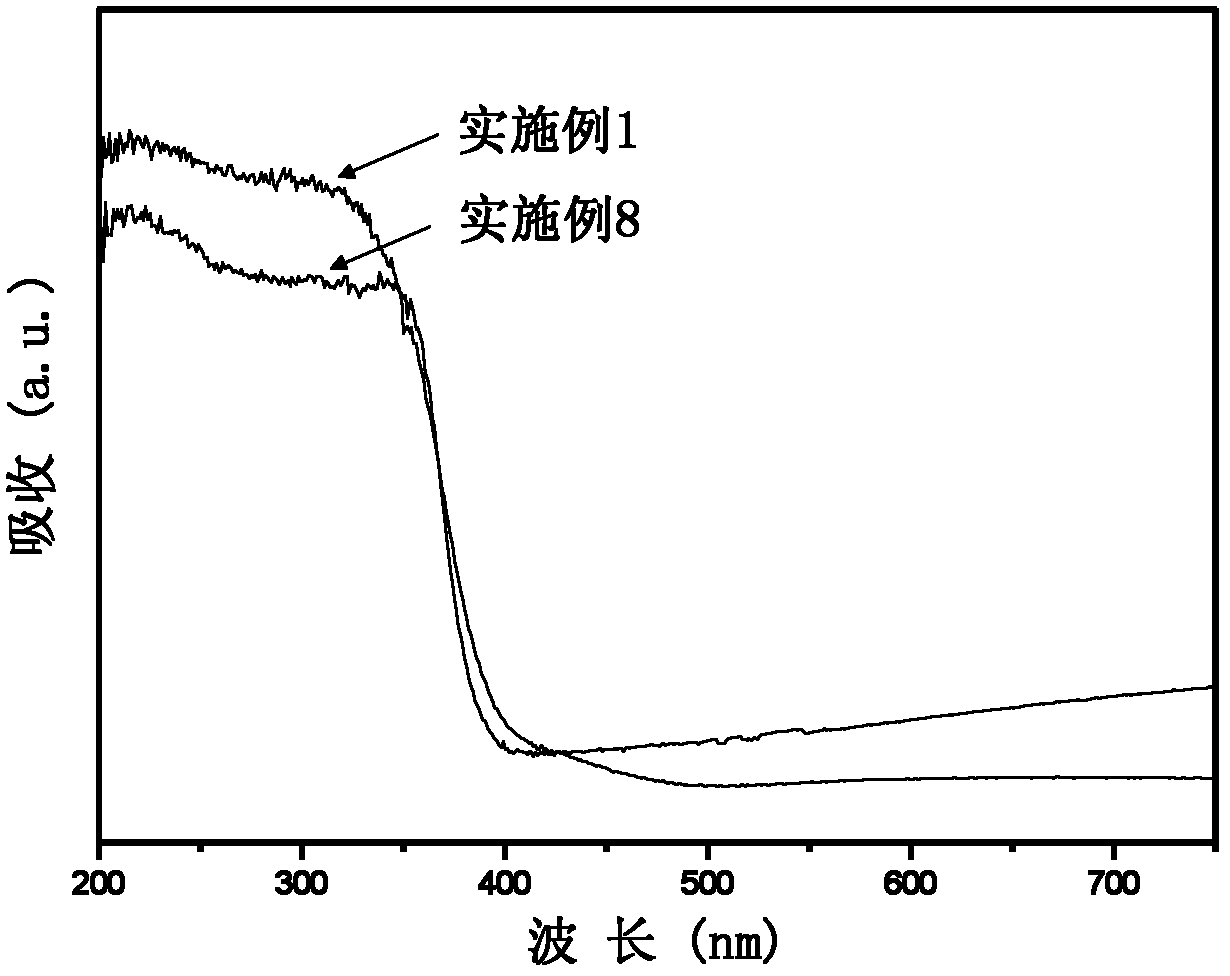

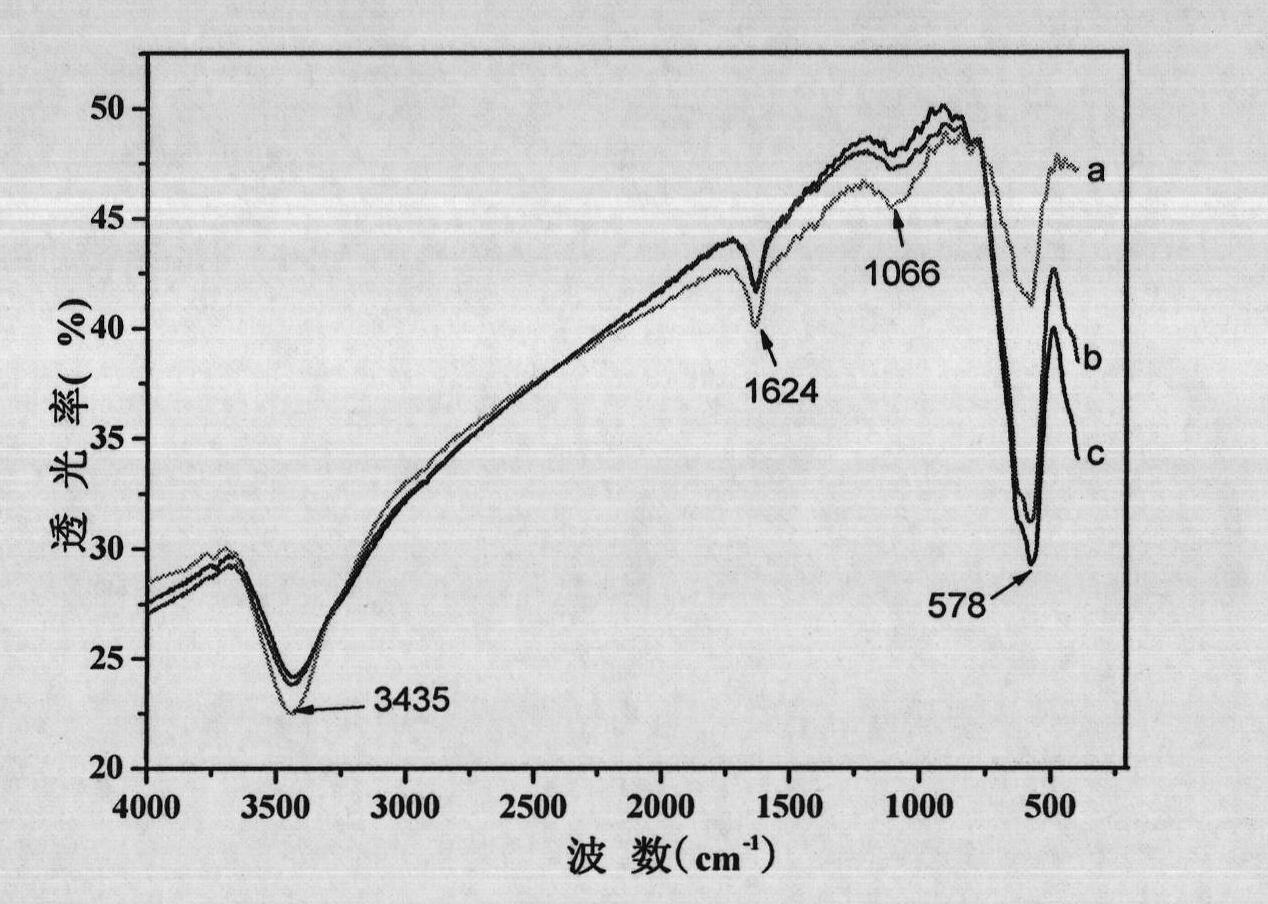

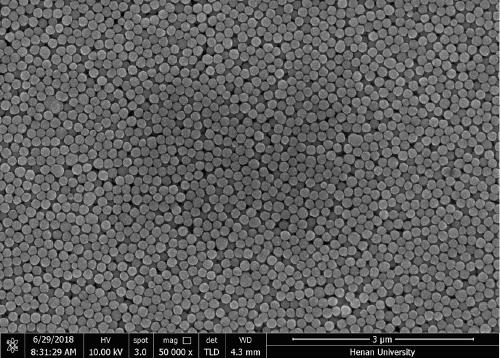

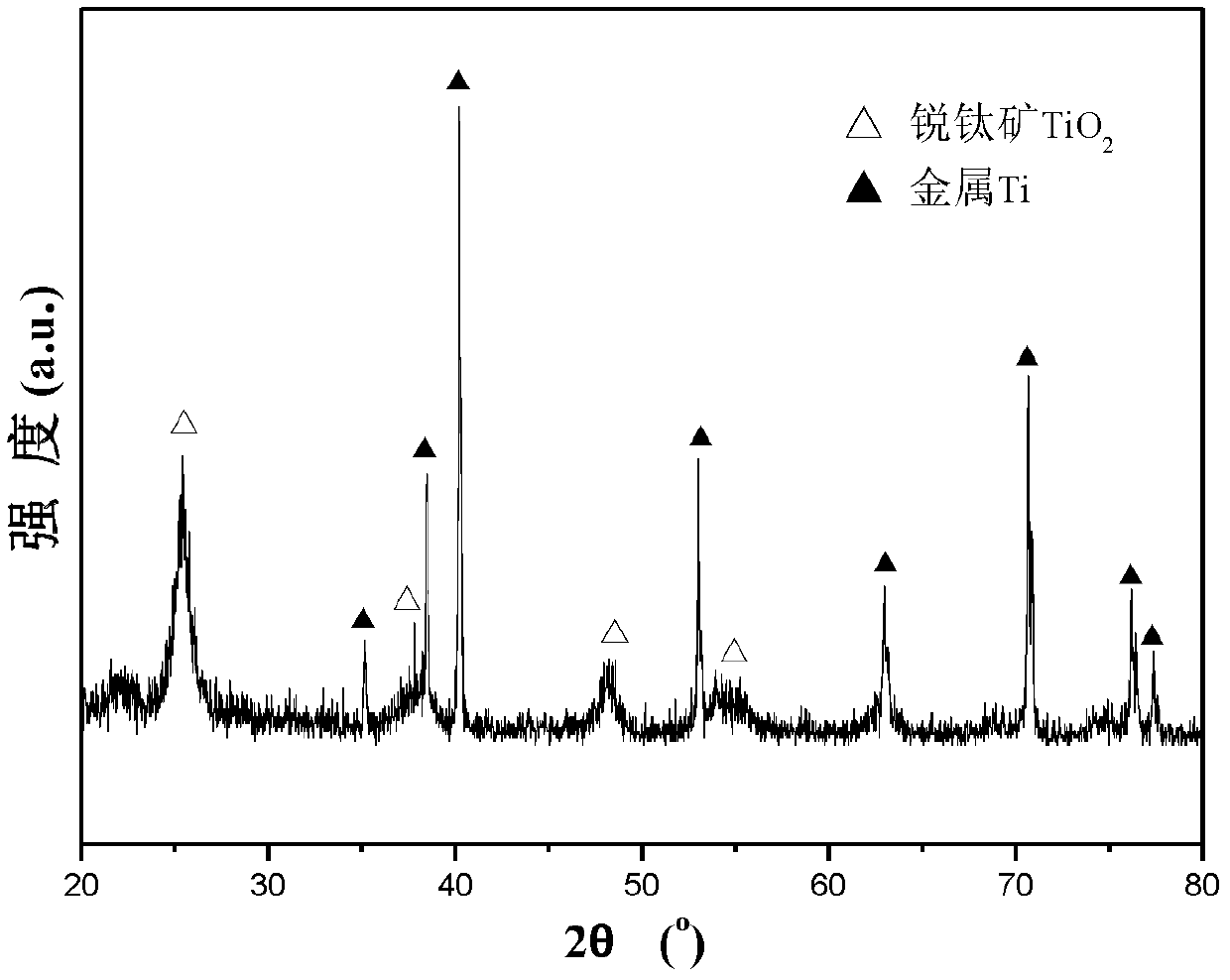

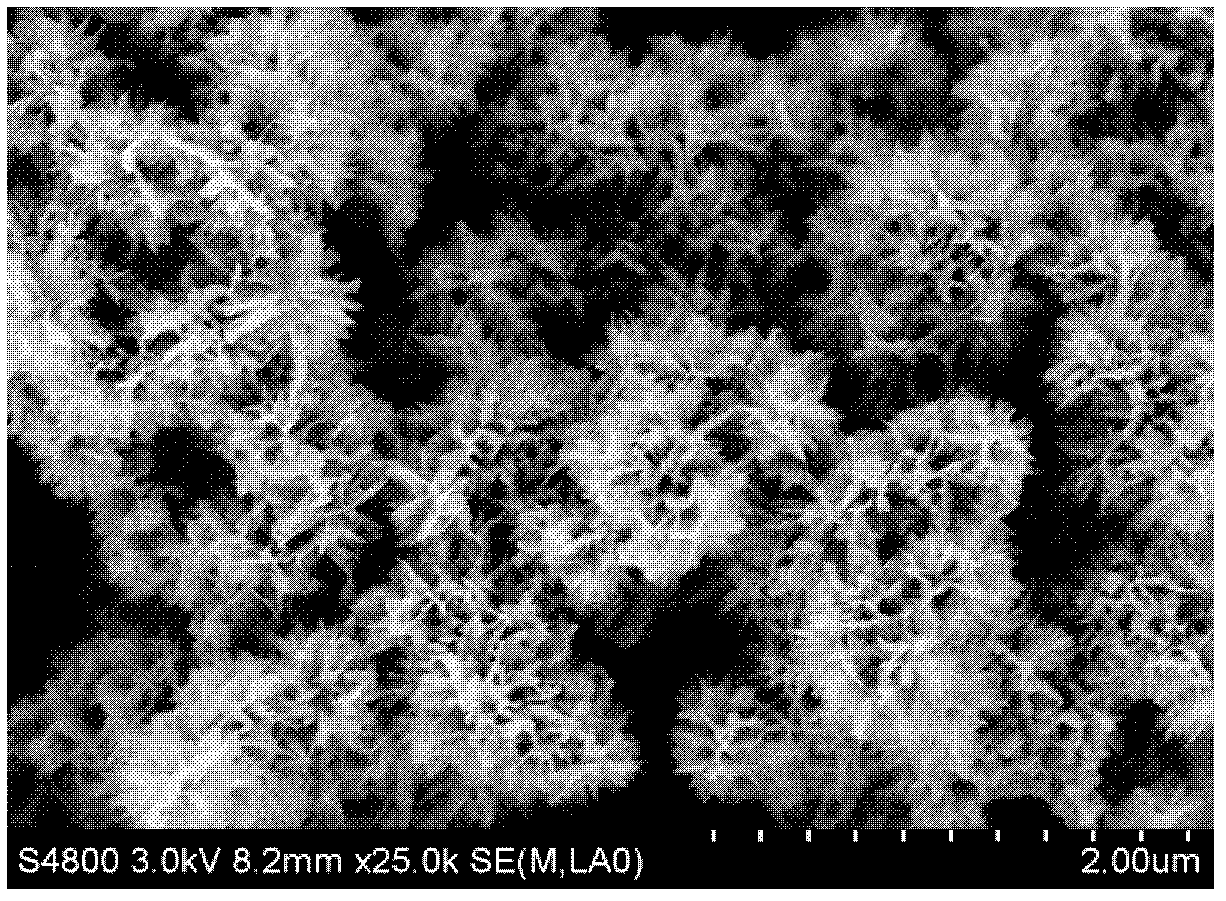

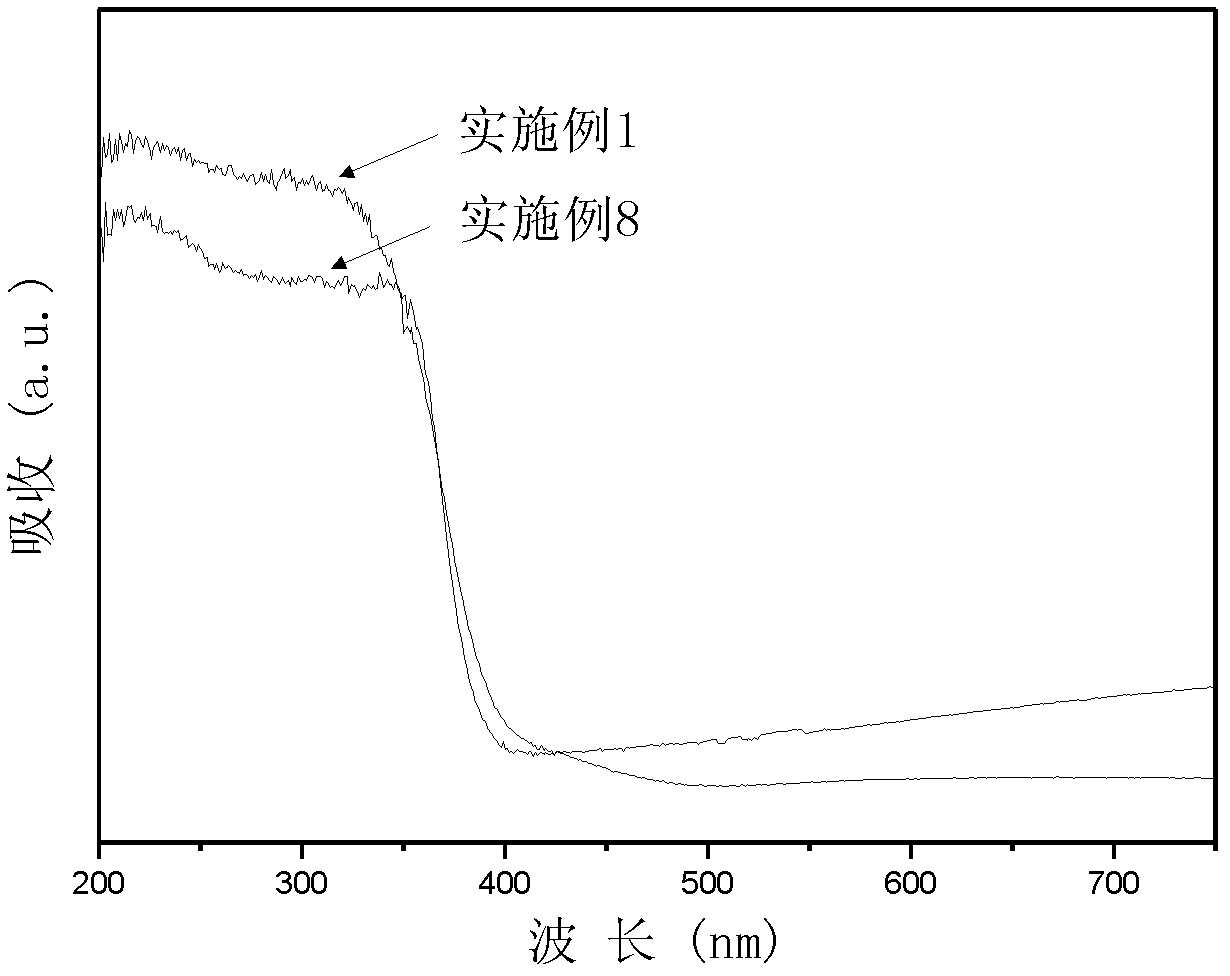

Porous titanium dioxide photocatalyst film and preparation method thereof

InactiveCN102600819AEasy to operateImprove bindingPhysical/chemical process catalystsCooking & bakingCrystallinity

The invention discloses a porous titanium dioxide photocatalyst film and a preparation method thereof. A substrate participates in an oxidizing reaction, an ionic liquid is taken as a template agent, and the reaction speed is controlled, so that a pure anatase phase titanium oxide film can be directly obtained on the surface of a titanium sheet. The preparation method comprises the following steps of: preparing a mixed solution of a hydrogen peroxide solution and an ionic liquid, i.e., 1-butyl-3-methylimidazolium tetrafluoroborate; soaking a metal titanium sheet into a reaction liquid for reacting in a baking oven of 80 DEG C for couple hours; and taking the reacted titanium sheet out, and baking to obtain a titanium dioxide film. The preparation method has the advantages of readily-available raw materials, simple process, easiness for controlling conditions, short preparing period and easiness for amplifying on a large scale. The prepared pure anatase structure titanium dioxide film high the advantages of high crystallinity, high purity, firm combination with the substrate, high stability and repeatability.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for ultrasonically preparing Fe3O4 nano-particle through ammonia dispersion

InactiveCN101935069AEffectively control the reaction rateControl reaction rateFerroso-ferric oxidesSuperparamagnetismVacuum drying

The invention provides a method for ultrasonically preparing a Fe3O4 nano-particle in the condition of ammonia dispersion, comprising the following steps of: under protection of nitrogen, leading ammonia into a solution dissolved with iron ions and ferrous iron particles, ultrasonically dispersing for 30-70 mins at the temperature of 25-45 DEG C, and producing a pitchy sediment product in the solution; cooling to the room temperature, washing respectively with distilled water and ethanol and vacuum drying to finally obtain the Fe3O4 nano-particle. Discovered by analyzing the magnetic performance of the product by a vibrating sample magnetometer that, in the condition without an external magnetic field, the remanence and the coercivity of the particle can both be neglected, the saturation magnetization is 62-75 emu / g, and the particle shows superparamagnetism at the room temperature, also has higher magnetic responsiveness and has potential application prospect in a drug delivery system and the catalysis field.

Owner:NORTHWEST NORMAL UNIVERSITY

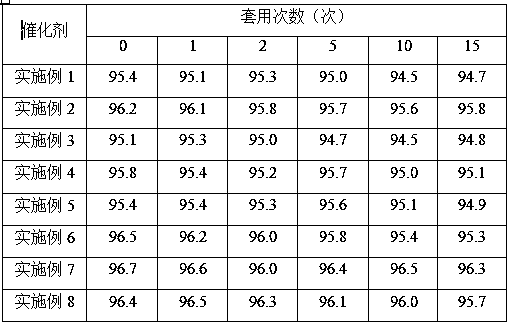

Catalyst for preparing 2,3-dichloropyridine and preparation method and application of catalyst

ActiveCN109453786AHas dechlorination activityAvoid dechlorination side reactionsOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsActivated carbonCorrosion

The invention discloses a catalyst for preparing 2,3-dichloropyridine and a preparation method and application of the catalyst. The catalyst is prepared from an activated carbon carrier, metal Pd, noble metal S1 and transition metal S2, wherein the weight percentage of Pd is 1-4%, the weight percentage of S1 is 0-3%, the weight percentage of S2 is 0-2%, the balance is the activated carbon carrier;the sum of the weights of Pd, S1 and S2 accounts for 2-6% of the total weight of the catalyst; the content of S1 and the content of S2 could not be 0 at the same time; S1 is one of spongy Ir, Au or Pt; and S2 is one of Mn, Co or Zn. The catalyst provided by the invention has dechlorination activity to a certain extent, but can avoid an excessive dechlorination side effect. When the catalyst is used for preparing the 2,3-dichloropyridine, the conversion rate is 100%, and the selectivity of the 2,3-dichloropyridine is greater than 95%; corrosion to a reaction still and subsequent pipelines canbe avoided.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

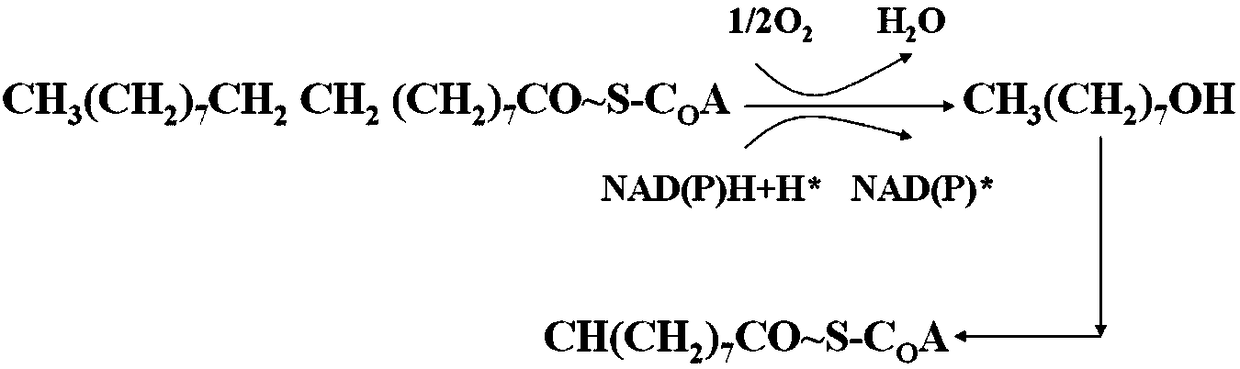

Device and method for preparing fuel oil from illegal cooking oil and animal fats

PendingCN108774552AEasy to operateStrong process controllabilityFatty acid oxidationLiquid carbonaceous fuelsUnsaturated fatty acidRenewable energy

The invention discloses a device for preparing fuel oil from illegal cooking oil and animal fats, and belongs to the technical field of production of fuel oils. The device mainly comprises a solar energy collector, a steam box, a reactor and a mixed oil tank. The animal fats is oxidatively dehydrogenated into unsaturated fatty acids under heating conditions by using a desaturase, and the unsaturated fatty acids are mixed with gasoline, the illegal cooking oil and a pour point depressant to form the fuel oil. The device can effectively convert the waste animal fats into vegetable-like oil by using solar thermal, and the vegetable-like oil is mixed with the waste illegal cooking oil, gasoline and the pour point depressant to form the fuel oil, so the device has the advantages of changing ofwastes into valuables, simple structure, low cost and effectiveness in utilization of renewable energy.

Owner:张俊霞

Method for producing glyoxylate

InactiveCN109574843AAvoid excessive oxidationAvoid decompositionOrganic compound preparationCarboxylic acid esters preparationActive componentDehydrogenation

The invention relates to a method for producing glyoxylate. The method comprises the step of enabling oxygen-containing gas to pass through a reactor with a catalyst under the condition of oxidative dehydrogenation. The reactor comprises n sections of catalyst bed layers; the contents of catalyst active components in the n catalyst bed layers from an inlet to an outlet of the reactor are graduallyincreased; and n is an integer between 2 and 10. The method can be used for industrial production of the glyoxylate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of epoxy-modified polyurethane packaging coating

The invention discloses a preparation method of an epoxy-modified polyurethane packaging coating. The preparation method comprises the following processes: (1) preparing an epoxy resin-butanone solution; adding toluene diisocynate and the like into a first reaction kettle to obtain a primary product; (2) adding dimethylolpropionic acid into the primary product, and then adding triethylamine to prepare epoxy-modified aromatic polyurethane emulsion; (3) adding silica sol and the epoxy-modified aromatic polyurethane emulsion into a third reaction kettle at the room temperature to obtain mixed emulsion for later use; (4) adding right amount of acrylic copolymer potassium salt and the like into a fourth reaction kettle filled with distilled water to obtain a mixed base solution; (5) adding the mixed emulsion into the mixed base solution to obtain the epoxy-modified polyurethane packaging coating. The epoxy-modified polyurethane packaging coating prepared by the method has excellent water resistance, higher stability, stronger cohesion, good strippable property and higher coating strength.

Owner:重庆市共赢包装制品有限公司

Preparation method of freeze-tolerant packaging film composition

InactiveCN106893474AEffectively control the reaction rateStrong cohesionAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceMeth-

The invention discloses a preparation method of a freeze-resistant packaging film composition, which includes the following steps: 1) adding isophorone diisocyanate and the like into a first reaction kettle at room temperature to obtain a primary product; 2) adding two Methylolpropionic acid, and then carry out vacuum distillation to obtain secondary products; 3) Disperse the secondary products in the second reaction kettle, add diethylenetriamine aqueous solution to prepare aliphatic water-based polyurethane emulsion; 4) Add to the second reaction kettle Add silica sol and aliphatic water-based polyurethane emulsion to the third reaction kettle to obtain a mixed emulsion for later use; 5) Add an appropriate amount of potassium salt of acrylic acid copolymer to the fourth reaction kettle to obtain a mixed bottom liquid; 6) Add it to the mixed bottom liquid The mixed emulsion is added to obtain a freeze-resistant packaging film composition. The packaging film composition prepared by the invention has strong cohesive force, good peelability, high coating film strength and good safety and environmental protection performance.

Owner:杨富元

Preparation method of high-strength protective film composition coated film

InactiveCN106810708AEffectively control the reaction rateHigh strengthAntifouling/underwater paintsPaints with biocidesTectorial membraneWater based

The invention discloses a preparation method of a high-strength protective film composition coated film. The preparation method comprises the following steps: 1) adding isophorone diisocyanate and the like into a first reaction kettle to obtain a primary product; 2) adding dimethylolpropionic acid into the primary product to obtain an aliphatic water-based polyurethane emulsion; 3) adding the aliphatic water-based polyurethane emulsion into a third reaction kettle to obtain a mixed emulsion for later use; 4) adding right amounts of acrylic acid copolymer potassium salt and the like into a distilled-water-containing fourth reaction kettle to obtain a mixed substrate; 5) adding the mixed emulsion into the mixed substrate to obtain a high-strength protective film composition; 6) wiping and airing the plastic film, and diluting the high-strength protective film composition for later use; and 7) spraying the high-strength protective film composition onto the plastic film, and airing to obtain the high-strength protective film composition coated film. The coated film is convenient for testing the tensile property, corrosion resistance, moisture permeability, peel strength and other properties of the protective film composition.

Owner:重庆市共赢包装制品有限公司

Preparation method of strippable coating for protection

InactiveCN106811061AEffectively control the reaction rateImprove stabilityPolyurea/polyurethane coatingsPotassiumDistilled water

The invention discloses a preparation method of a strippable coating for protection. The preparation method comprises the following processes: (1) adding toluene diisocynate and the like into a first reaction kettle at the room temperature to obtain a primary product; (2) adding dimethylolpropionic acid into the primary product, and then adding triethylamine to prepare aromatic waterborne polyurethane emulsion; (3) adding silica sol and the aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature to obtain mixed emulsion for later use; (4) adding right amount of acrylic copolymer potassium salt and the like into a fourth reaction kettle filled with distilled water to obtain a mixed base solution; (5) adding the mixed emulsion into the mixed base solution to obtain the strippable coating for protection. The coating prepared by the method can be used for effectively sealing and protecting an object to be protected so as to prevent the object from being contaminated, corroded and damaged. Furthermore, the coating also has higher stability, stronger cohesion, good strippable property and higher coating strength.

Owner:重庆市共赢包装制品有限公司

Preparation method of high-water-resistance packaging paint coated film

InactiveCN106811092AEffectively control the reaction rateImprove stabilityLiquid surface applicatorsPolyurea/polyurethane coatingsWater basedToluene diisocyanate

The invention discloses a preparation method of a high-water-resistance packaging paint coated film. The preparation method comprises the following steps: 1) adding toluene diisocyanate and the like into a first reaction kettle at room temperature to obtain a primary product; 2) adding dimethylolpropionic acid into the primary product to obtain an aromatic water-based polyurethane emulsion; 3) adding a silica sol and the aromatic water-based polyurethane emulsion into a third reaction kettle to obtain a mixed emulsion; 4) adding right amounts of acrylic acid copolymer potassium salt and the like into a distilled-water-containing fourth reaction kettle to obtain a mixed substrate; 5) adding the mixed emulsion into the mixed substrate to obtain a high-water-resistance packaging paint; 6) wiping and airing the plastic film, and diluting the high-water-resistance packaging paint for later use; and 7) spraying the high-water-resistance packaging paint onto the plastic film, and airing to obtain the high-water-resistance packaging paint coated film. The coated film is convenient for testing the tensile property, corrosion resistance, moisture permeability, peel strength and other properties of the paint.

Owner:重庆市共赢包装制品有限公司

Preparation method of flexible protecting film composition

InactiveCN106811076AEffective closed protectionImprove stabilityAnti-corrosive paintsPolyurea/polyurethane coatingsTectorial membranePolymer science

The invention discloses a preparation method of a flexible protecting film composition. The preparation method comprises the following procedures: (1) dewatering and drying the raw materials; (2) adding toluene diisocynate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (3) sequentially adding dimethylolpropionic acid and triethylamine into the primary product, so as to obtain an aromatic waterborne polyurethane emulsion; (4) adding silica sol and the aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature, so as to obtain a mixed emulsion; (5) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle containing distilled water, so as to obtain a mixed base solution; and (6) adding the mixed emulsion into the mixed base solution, so as to obtain the flexible protecting film composition. By utilizing the flexible protecting film composition prepared by virtue of the preparation method, a protected object can be effectively closed and protected, and the pollution, corrosion and damage to the object are prevented. Meanwhile, the flexible protecting film composition further has relatively high stability, relatively strong cohesion, good peelable property and relatively high film strength.

Owner:重庆市共赢包装制品有限公司

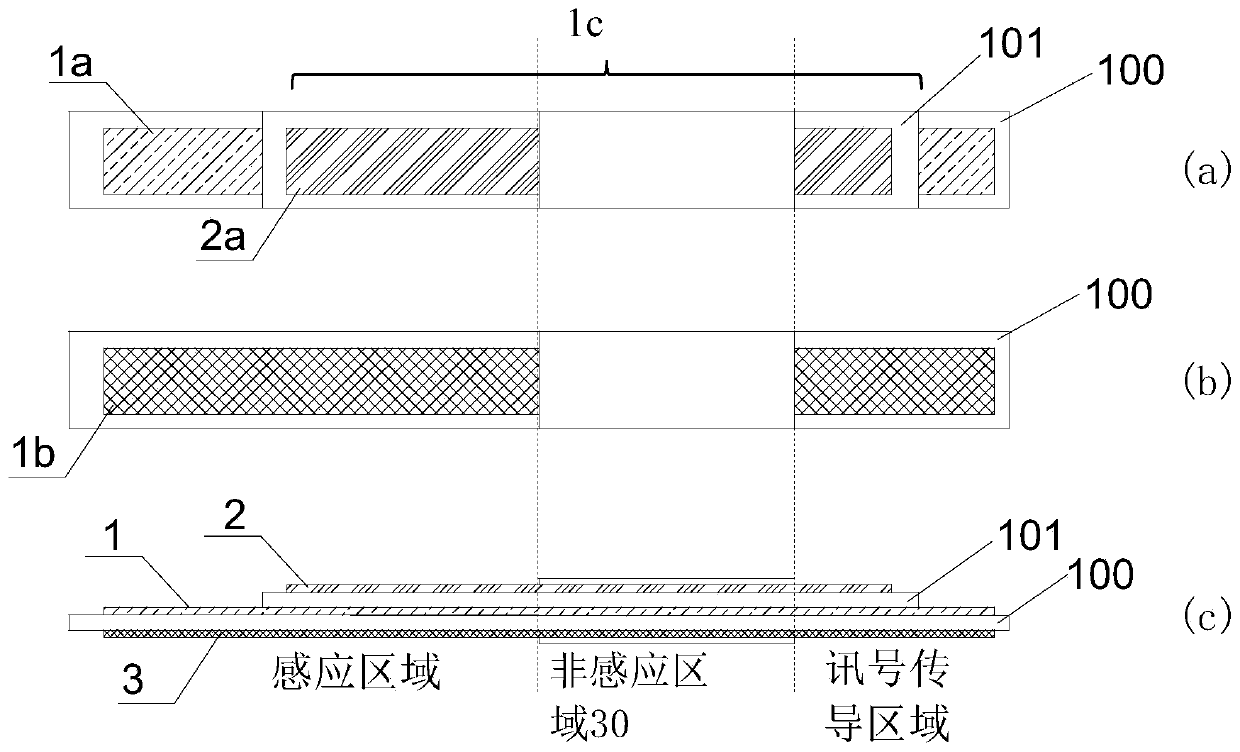

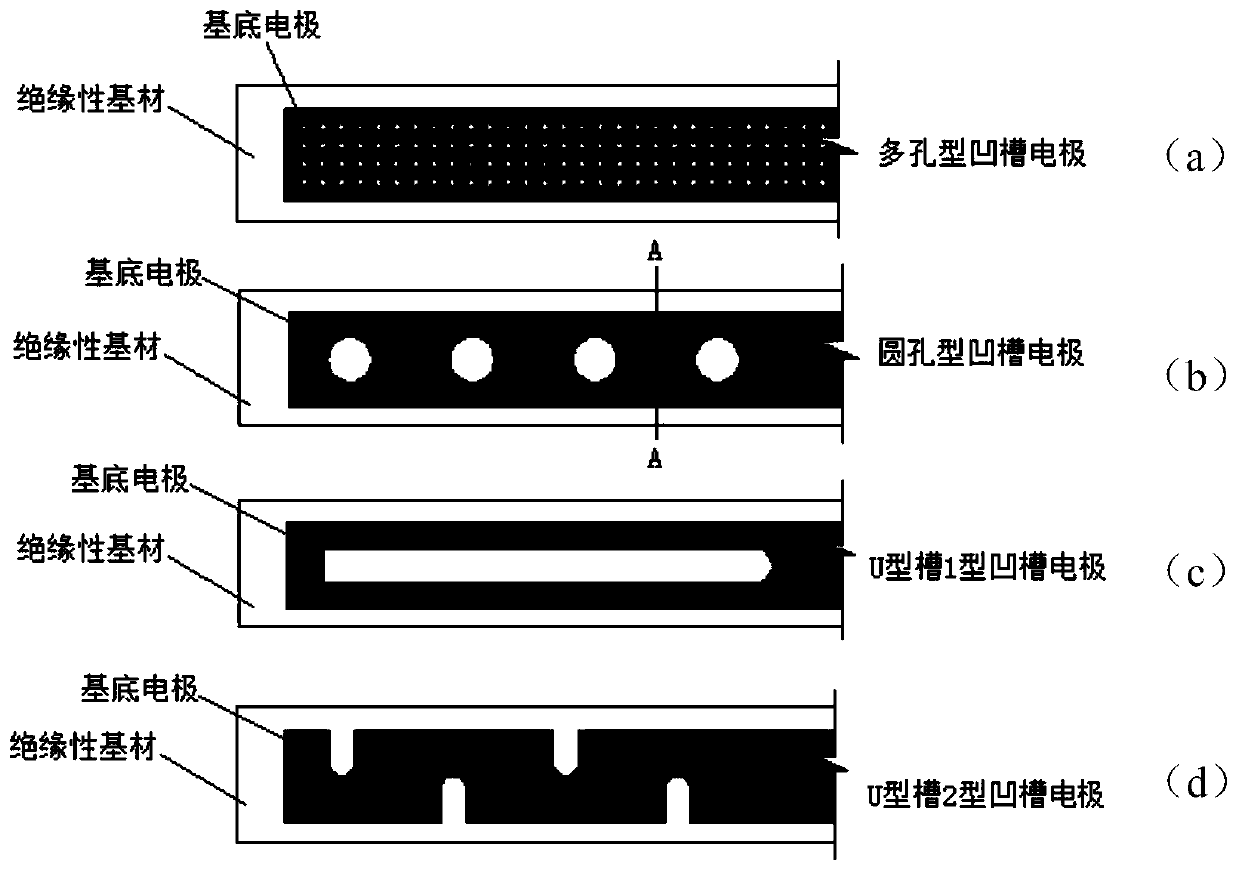

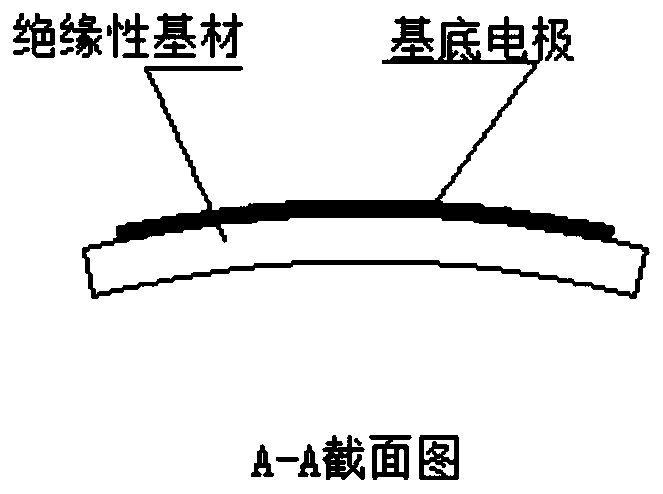

Biosensor

PendingCN111096754AGuaranteed reliabilityEasy to implantMaterial analysis by electric/magnetic meansCatheterEngineeringMaterials science

The invention discloses a biosensor. The biosensor includes a sensor body, wherein the sensor body includes a plurality of physical surfaces, each physical surface is provided with at least one functional electrode, and the physical surface further includes a non-sensing area; and the non-sensing area of at least one of the physical surface is further provided with the other functional electrode,each of the functional electrodes is provided with a corresponding signal conducting area, and each of the functional electrodes is connected with the corresponding signal conducting area. According to the biosensor, since the multiple functional electrodes are distributed on the multiple physical surfaces of the sensor, the length of the sensor can be shortened effectively through the design on the premise of the same sensing area of the sensor; and when the biosensor is compared with a sensor with electrodes which are arranged on one side of the sensor, the length can be shortened by 50% through the design under ideal conditions, and meanwhile the test precision of the sensor can be improved further, so that the problem of contradiction between the test precision and wearing experience of an existing sensor is solved.

Owner:上海硕创生物医药科技有限公司

Preparation method of peelable protecting film composition

InactiveCN106811084AStrong cohesionExcellent peelabilityPolyurea/polyurethane coatingsPolymer scienceDistillation

The invention discloses a preparation method of a peelable protecting film composition. The preparation method comprises the following procedures: (1) dewatering and drying the raw materials; (2) adding isophorone diisocyanate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (3) adding dimethylolpropionic acid into the primary product, and carrying out reduced pressure distillation, so as to obtain a secondary product; (4) dispersing the secondary product into a second reaction kettle, and adding a diethylenetriamine water solution, so as to prepare an aliphatic waterborne polyurethane emulsion; (5) adding the silica sol and the aliphatic waterborne polyurethane emulsion into a third reaction kettle, so as to obtain a mixed emulsion for later use; (6) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle, so as to obtain a mixed base solution; and (7) adding the mixed emulsion into the mixed base solution, so as to obtain the peelable protecting film composition. The peelable protecting film composition prepared by virtue of the preparation method has relatively strong cohesion, good peelable property, relatively high film strength and relatively good safety and environmental protection property.

Owner:重庆市共赢包装制品有限公司

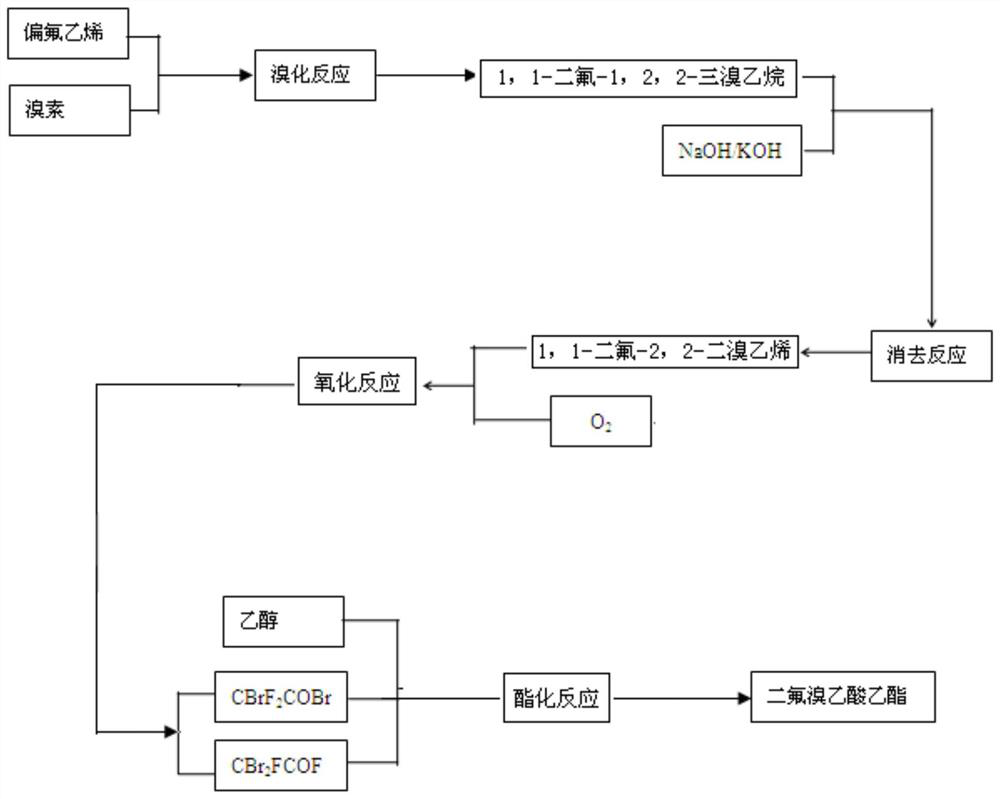

Production process of ethyl bromodifluoroacetate

PendingCN112079721AIncrease profitLow costPreparation by hydrogen halide split-offPreparation from carboxylic acid halidesPtru catalystBromine

The invention discloses a production process of ethyl bromodifluoroacetate. The production process comprises the following steps: 1, bromination reaction; 2, elimination reaction; 3, oxidation reaction; 4, esterification reaction. Compared with other methods, the bromination addition reaction only needs to be carried out at normal pressure and under the catalysis of infrared light, so that the cost is saved compared with other catalysts, other impurities are not introduced, and the utilization rate of bromine is increased. The elimination reaction adopts a dropwise adding mode, so the reactionrate can be effectively controlled, and the flooding phenomenon which is easy to generate is avoided. The purity of the prepared finished product is greater than or equal to 99.0%, and the yield is greater than or equal to 80.0%.

Owner:NANTONG BAOKAI CHEM

Preparation method of environment-friendly packaging material

InactiveCN106810657AEffective closed protectionAvoid pollutionPolyurea/polyurethane coatingsRoom temperaturePotassium

The invention discloses a preparation method of an environment-friendly packaging material. The preparation method comprises the following processes: (1) adding toluene diisocynate and the like into a first reaction kettle at the room temperature to obtain a primary product; (2) adding dimethylolpropionic acid into the primary product, and then adding triethylamine to prepare aromatic waterborne polyurethane emulsion; (3) adding silica sol and the aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature to obtain mixed emulsion for later use; (4) adding right amount of acrylic copolymer potassium salt and the like into the mixed emulsion to obtain a crude product; (5) adding talcum powder into the crude product to obtain the environment-friendly packaging material. The environment-friendly packaging material prepared by the method has the advantages of being simple and convenient to operate and high in production efficiency, and can be used for effectively and temporarily sealing and protecting an object to be protected.

Owner:重庆市共赢包装制品有限公司

Preparation method of aromatic polyurethane emulsion water-based paint

InactiveCN106811069AEffectively control the reaction rateImprove water resistanceAntifouling/underwater paintsPaints with biocidesEpoxyWater based

The invention discloses a preparation method of an aromatic polyurethane emulsion water-based paint. The preparation method comprises the following steps: 1) preparing an epoxy resin-butanone solution; drying raw materials; 2) adding toluene diisocyanate and the like into a first reaction kettle to obtain a primary product; 3) adding dimethylolpropionic acid into the primary product, and adding triethylamine to obtain an epoxy modified aromatic polyurethane emulsion; 4) adding a silica sol and the epoxy modified aromatic polyurethane emulsion into a third reaction kettle at room temperature to obtain a mixed emulsion for later use; 5) adding right amounts of acrylic acid copolymer potassium salt and the like into a distilled-water-containing fourth reaction kettle to obtain a mixed substrate; and 6) adding the mixed emulsion into the mixed substrate to obtain the aromatic polyurethane emulsion water-based paint. The paint disclosed by the invention has the advantages of excellent water resistance, higher stability, higher cohesive force, favorable peelability and higher coated film strength.

Owner:重庆市共赢包装制品有限公司

Preparation method of environment-friendly packaging material

InactiveCN106810987AEffectively control the reaction rateHigh peel strengthAnti-corrosive paintsRoom temperatureDistilled water

The invention discloses a preparation method of an environment-friendly packaging material. The preparation method comprises the following procedures: (1) adding toluene diisocynate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (2) adding dimethylolpropionic acid and the like into the primary product, so as to obtain an acrylate modified aromatic waterborne polyurethane emulsion; (3) adding silica sol and the acrylate modified aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature, so as to obtain a mixed emulsion; (4) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle containing distilled water, so as to obtain a mixed base solution; (5) adding the mixed emulsion into the mixed base solution, so as to obtain the environment-friendly packaging material; (6) carrying out wiping and air-drying on a plastic film, and diluting the environment-friendly packaging material; and (7) spraying the environment-friendly packaging material to the plastic film, so as to obtain an environment-friendly packaging material paint film. By utilizing the environment-friendly packaging material prepared by virtue of the preparation method, a to-be-protected object can be effectively closed and protected, and the pollution, corrosion and damage of the object are prevented.

Owner:重庆市共赢包装制品有限公司

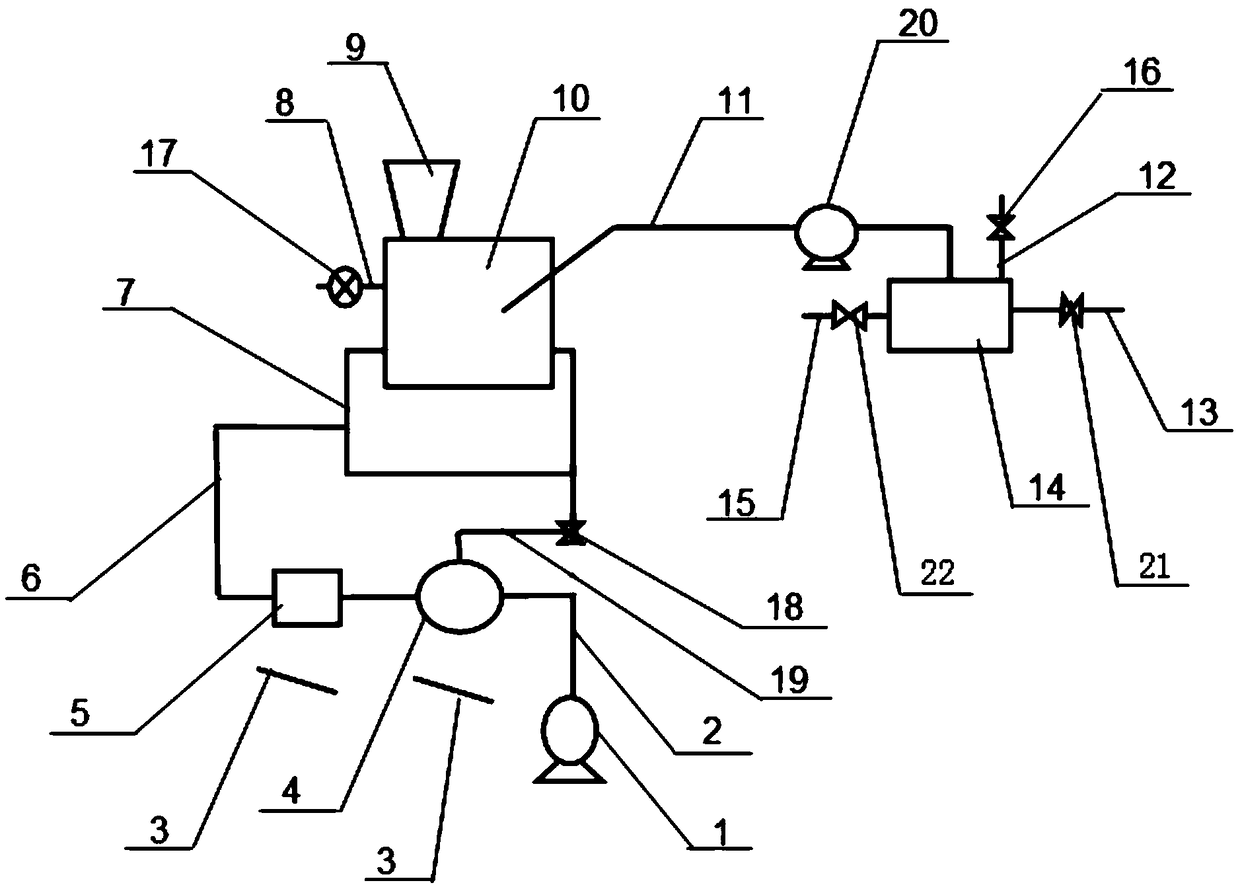

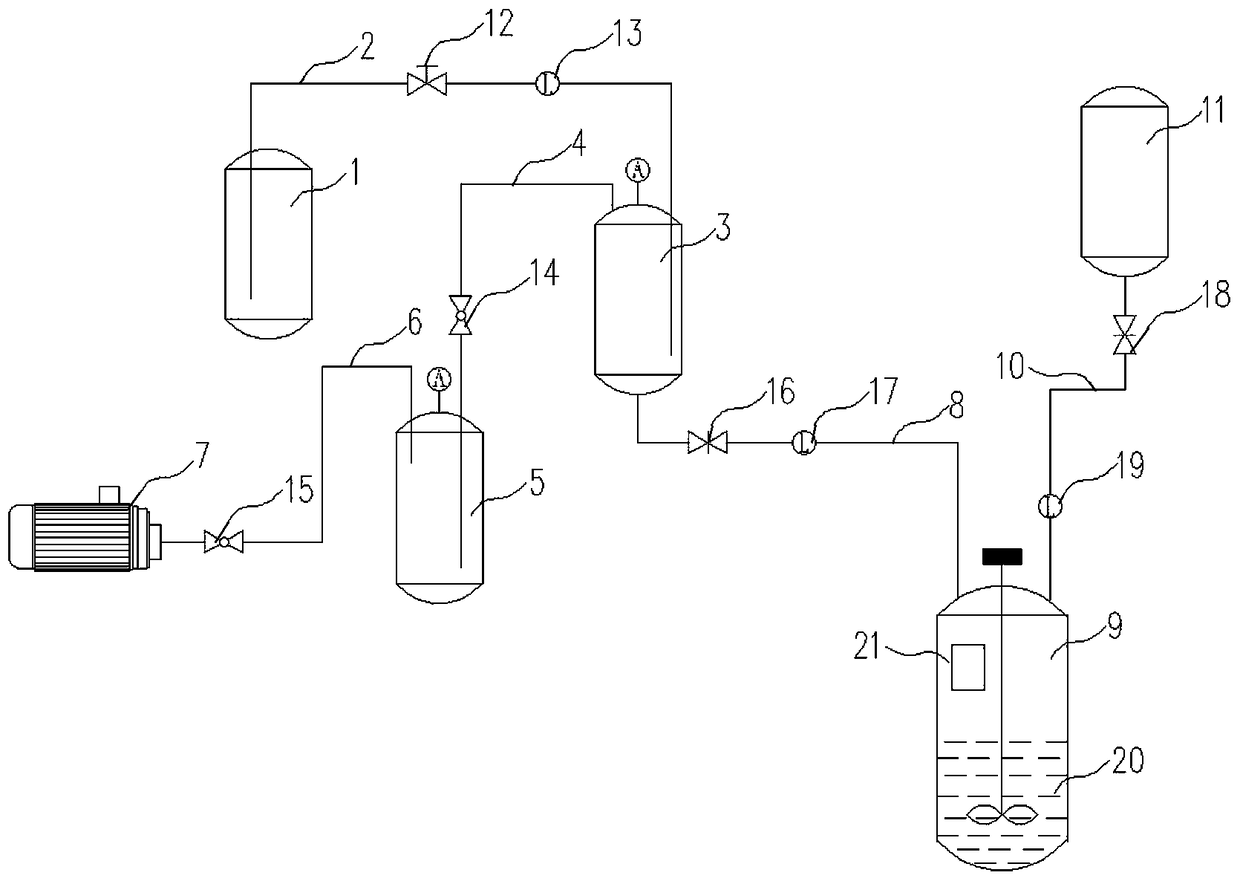

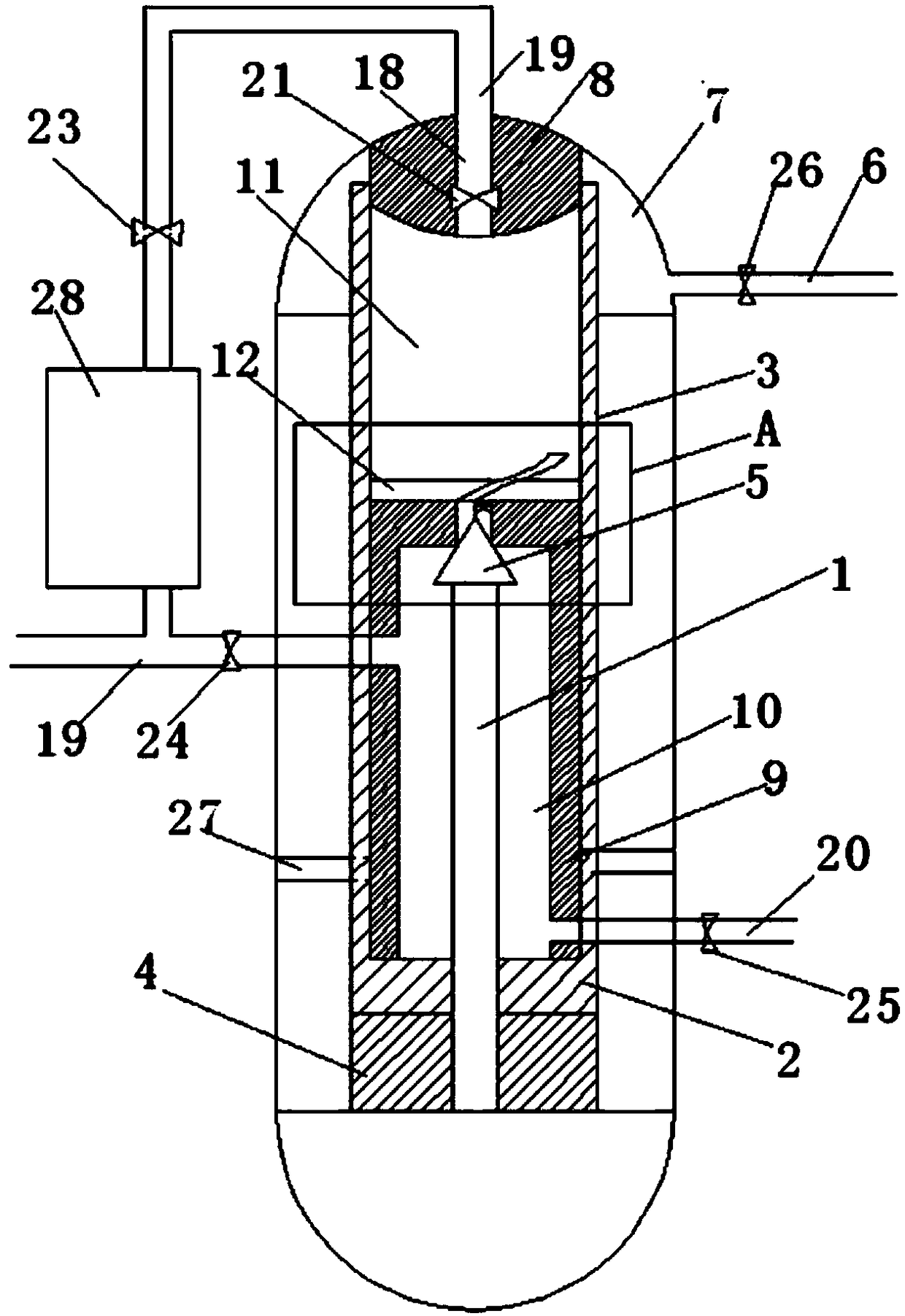

A production device for preparing titanium hydroxide sol

The invention relates to a production device for preparing titanium hydroxide sol. The production device comprises a storing tank (1) which is connected with a first buffer tank (3) through a first pipeline (2), the first buffer tank is connected with a second buffer tank (5) through a second pipeline (4), the second buffer tank is connected with a vacuum pump (7) through a third pipeline (6), the first buffer tank is further connected with a reaction kettle (9) through a fourth pipeline (8), the reaction kettle is filled with pure water (20), and the reaction kettle is further connected with an alkali solution storing tank (11) through a fifth pipeline (10). The production device has the advantages that the problem that acid mist is generated in the hydrolytic process of a titanium source solution like a titanium tetrachloride solution or a titanyl sulfate solution is solved, the rate of the reaction of the titanium source solution and an alkali solution is effectively controlled, the leakage of reaction solutions is avoided, the temperature in the kettle, the vacuum degree of the vacuum pump and operation of all levels of valves are effectively controlled, and the safe production operation for preparing the titanium hydroxide sol through hydrolysis of the titanium source solution like the titanium tetrachloride solution or the titanyl sulfate solution is achieved.

Owner:安徽凯盛应用材料有限公司

Preparation method for green shallow-cured phenolic resin coated grinding tool

ActiveCN102513943BDecreased responsivenessLow costFibre treatmentAbrasion apparatusPolymer scienceEmulsion

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

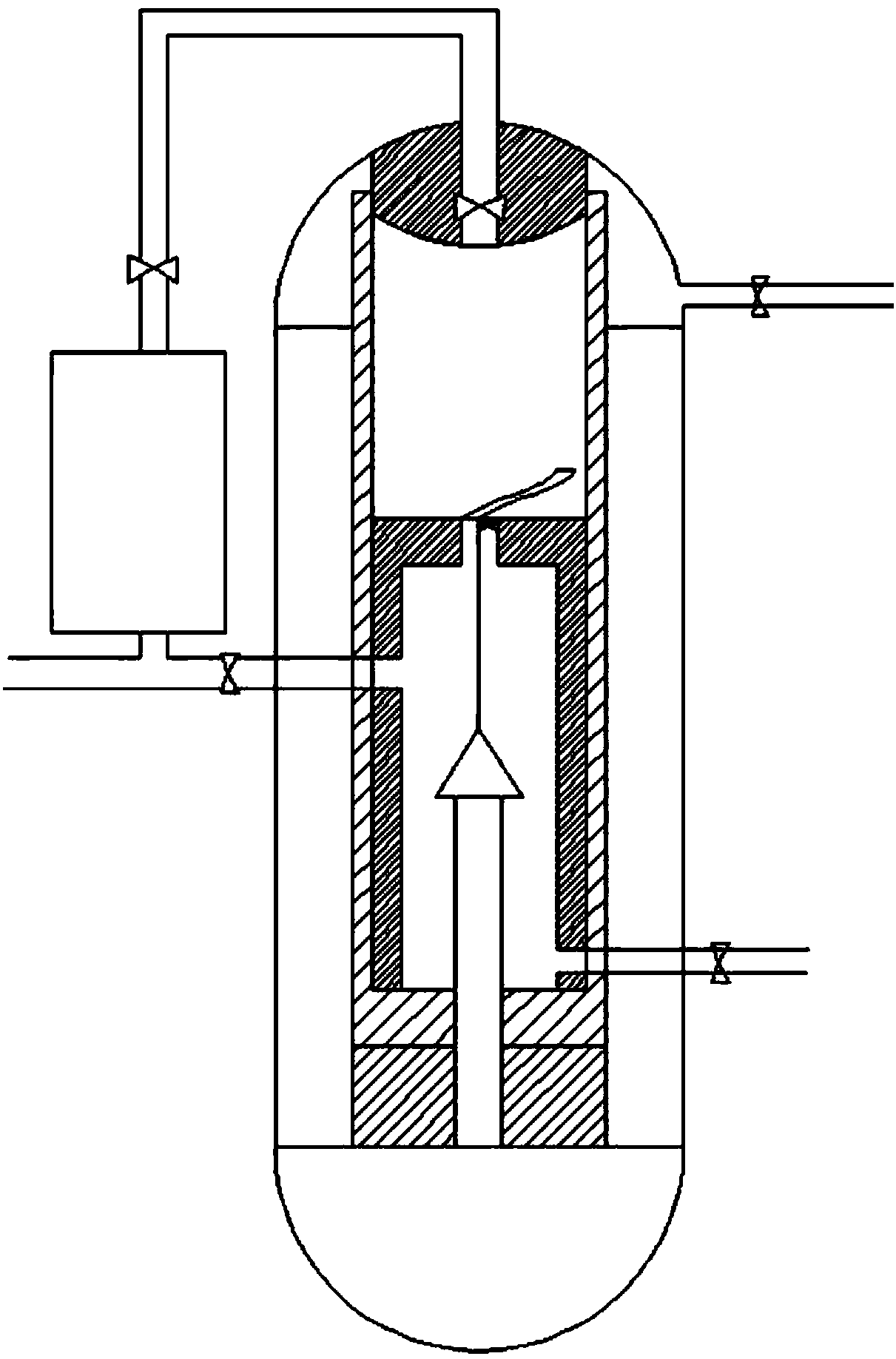

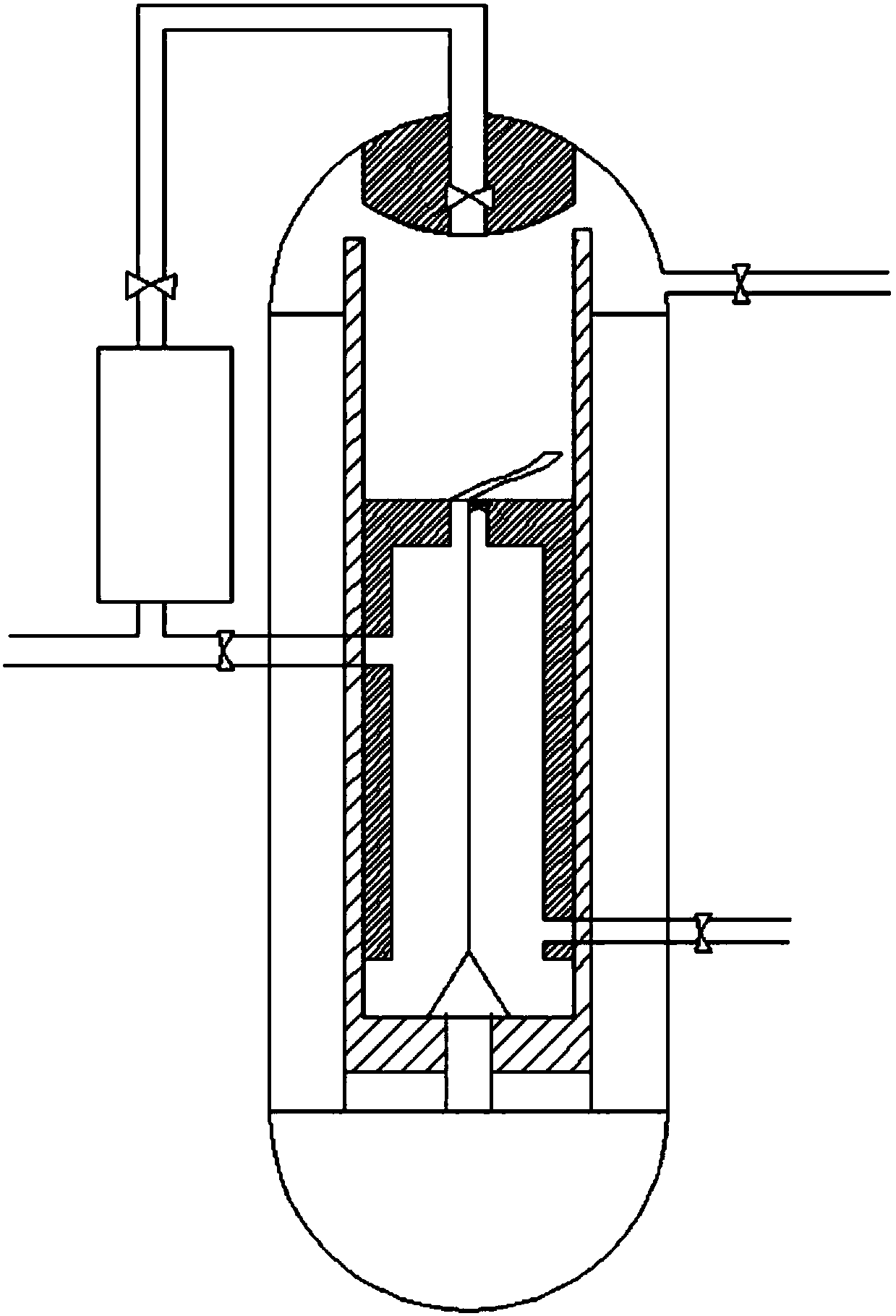

Control method of reformed alkali production reactor

ActiveCN108543502ARealize self-control propulsionEffectively control the reaction rateProcess control/regulationChemical/physical/physico-chemical stationary reactorsInlet channelReaction rate

The invention relates to the technical field of reactors and particularly belongs to a control method of a reformed alkali production reactor. CO2 is introduced into a telescopic rod moving cavity through a CO2 inlet channel and is then guided to a reaction cavity through a right channel; CO2 reacts with an aqueous solution of ammonia gas to generate NH4HCO3; a telescopic rod drives a conical plugto continuously descend until the conical plug presses the bottom of a cylindrical baffle bracket; an Nacl solution flows from an Nacl cavity into the reaction cavity; a filtering device filters outNH4cl, and NH4cl flows into the telescopic rod moving cavity through the right channel and then flows out through an NH4cl outlet pipeline; the NaHCO3 precipitate is left in the reaction cavity and decomposed; and CO2 enters a CO2 storage tank through a CO2 outlet channel for use in the next reaction. The method provided by invention has the advantages that the self-control advancement of reactionprocesses can be realized, the reaction rate can be effectively controlled, and multiple steps of reactions can be completed in one device.

Owner:山东三岳化工有限公司

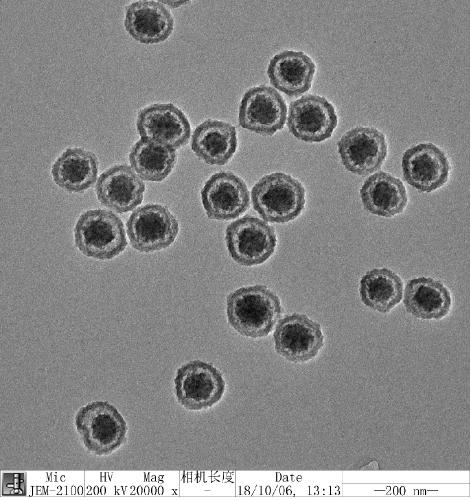

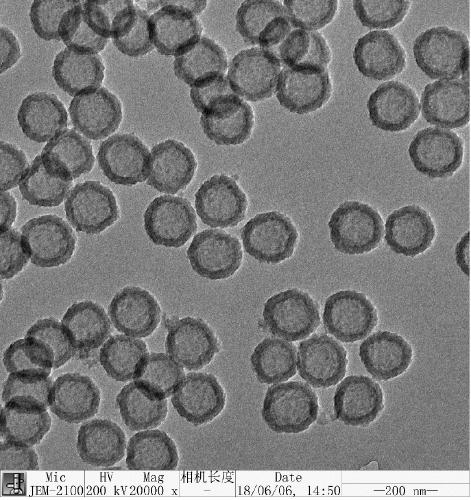

A kind of monodisperse hollow Prussian blue nano microsphere, its preparation method and application

ActiveCN110251482BGuarantee a high degree of decentralizationUniform shapeOrganic active ingredientsEnergy modified materialsDrug carrierPrussian blue

Owner:新沂市棋盘工业集中区建设发展有限公司

Preparation method of anti-corrosion coating

InactiveCN106811088AEffectively control the reaction rateImprove securityAntifouling/underwater paintsPaints with biocidesMeth-Propanoic acid

The invention discloses a preparation method of the anti-corrosion coating. The preparation method comprises the following procedures: (1) adding toluene diisocynate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (2) sequentially adding dimethylolpropionic acid and triethylamine into the primary product, so as to obtain an aromatic waterborne polyurethane emulsion; (3) adding silica sol and the aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature, so as to obtain a mixed emulsion for later use; (4) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle containing distilled water, so as to obtain a mixed base solution; and (5) adding the mixed emulsion into the mixed base solution, so as to obtain the anti-corrosion coating. By utilizing the anti-corrosion coating by prepared by virtue of the preparation method, a protected object can be effectively closed and protected, and the pollution, corrosion and damage of the object are prevented. Meanwhile, the coating further has relatively high stability, relatively strong cohesion, good peelable property and relatively high film strength.

Owner:重庆市共赢包装制品有限公司

Preparation method of waterborne peelable protecting film composition

InactiveCN106811077AEffectively control the reaction rateEffective closed protectionAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

Owner:重庆市共赢包装制品有限公司

Preparation method of high temperature-resistant packaging film composition

InactiveCN106893071AStrong cohesionExcellent peelabilityAnti-corrosive paintsPolyurea/polyurethane coatingsDistillationDiethylenetriamine

The invention discloses a preparation method of a high temperature-resistant packaging film composition. The method comprises the following steps: 1, adding isophorone diisocyanate into a first reaction kettle at room temperature to obtain a primary product; 2, adding dimethylolpropionic acid to the primary product, and carrying out reduced pressure distillation to obtain a secondary product; 3, dispersing the secondary product in a second reaction kettle, and adding an aqueous diethylenetriamine solution to prepare an aliphatic aqueous polyurethane emulsion; 4, adding silica sol and the aliphatic aqueous polyurethane emulsion into a third reaction kettle to prepare a mixed emulsion for later use; 5, adding a proper amount of a potassium salt of an acrylic copolymer into a fourth reaction kettle to obtain a mixed base solution; and 6, adding the mixed emulsion to the mixed base solution to obtain the high temperature-resistant packaging film composition. The high temperature-resistant packaging film composition prepared through adopting the method has the advantages of strong cohesive force, good strippable property, high coating strength and good safety and environmentally-friendly performance.

Owner:张世禄

Porous titanium dioxide photocatalyst film and preparation method thereof

InactiveCN102600819BEffectively control the reaction rateEasy to operatePhysical/chemical process catalystsCrystallinityTitanium oxide

The invention discloses a porous titanium dioxide photocatalyst film and a preparation method thereof. A substrate participates in an oxidizing reaction, an ionic liquid is taken as a template agent, and the reaction speed is controlled, so that a pure anatase phase titanium oxide film can be directly obtained on the surface of a titanium sheet. The preparation method comprises the following steps of: preparing a mixed solution of a hydrogen peroxide solution and an ionic liquid, i.e., 1-butyl-3-methylimidazolium tetrafluoroborate; soaking a metal titanium sheet into a reaction liquid for reacting in a baking oven of 80 DEG C for couple hours; and taking the reacted titanium sheet out, and baking to obtain a titanium dioxide film. The preparation method has the advantages of readily-available raw materials, simple process, easiness for controlling conditions, short preparing period and easiness for amplifying on a large scale. The prepared pure anatase structure titanium dioxide film high the advantages of high crystallinity, high purity, firm combination with the substrate, high stability and repeatability.

Owner:SHANGHAI NORMAL UNIVERSITY

Preparation method of acrylate modified polyurethane protecting packaging film composition

InactiveCN106811106AEffectively control the reaction rateEffective closed protectionPolyurea/polyurethane coatingsChemistryToluene

The invention discloses a preparation method of an acrylate modified polyurethane protecting packaging film composition. The preparation method comprises the following procedures: (1) adding toluene diisocynate and the like into a first reaction kettle at the room temperature, so as to obtain a primary product; (2) adding dimethylolpropionic acid and the like into the primary product, so as to obtain an acrylate modified aromatic waterborne polyurethane emulsion; (3) adding silica sol and the acrylate modified aromatic waterborne polyurethane emulsion into a third reaction kettle at the room temperature, so as to obtain a mixed emulsion; (4) adding a proper amount of acrylic copolymer sylvite and the like into a fourth reaction kettle containing distilled water, so as to obtain a mixed base solution; and (5) adding the mixed emulsion into the mixed base solution, so as to obtain the acrylate modified polyurethane protecting packaging film composition. By utilizing the packaging film composition prepared by virtue of the preparation method, a to-be-protected object can be effectively closed and protected, and the pollution, corrosion and damage of the object are prevented. The packaging film composition further has excellent water tolerance, relatively high stability, relatively strong cohesion, good peelable property and relatively high paint film strength.

Owner:重庆市共赢包装制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com