Method for compositing Fe3O4 nanorod by utilizing magnetic induction gas-liquid interface method

A gas-liquid interface, nanorod technology, applied in the field of nanomaterials, can solve the problems of high surface energy and magnetism, unfavorable applications and composite reactions, and achieve the effect of high magnetic responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

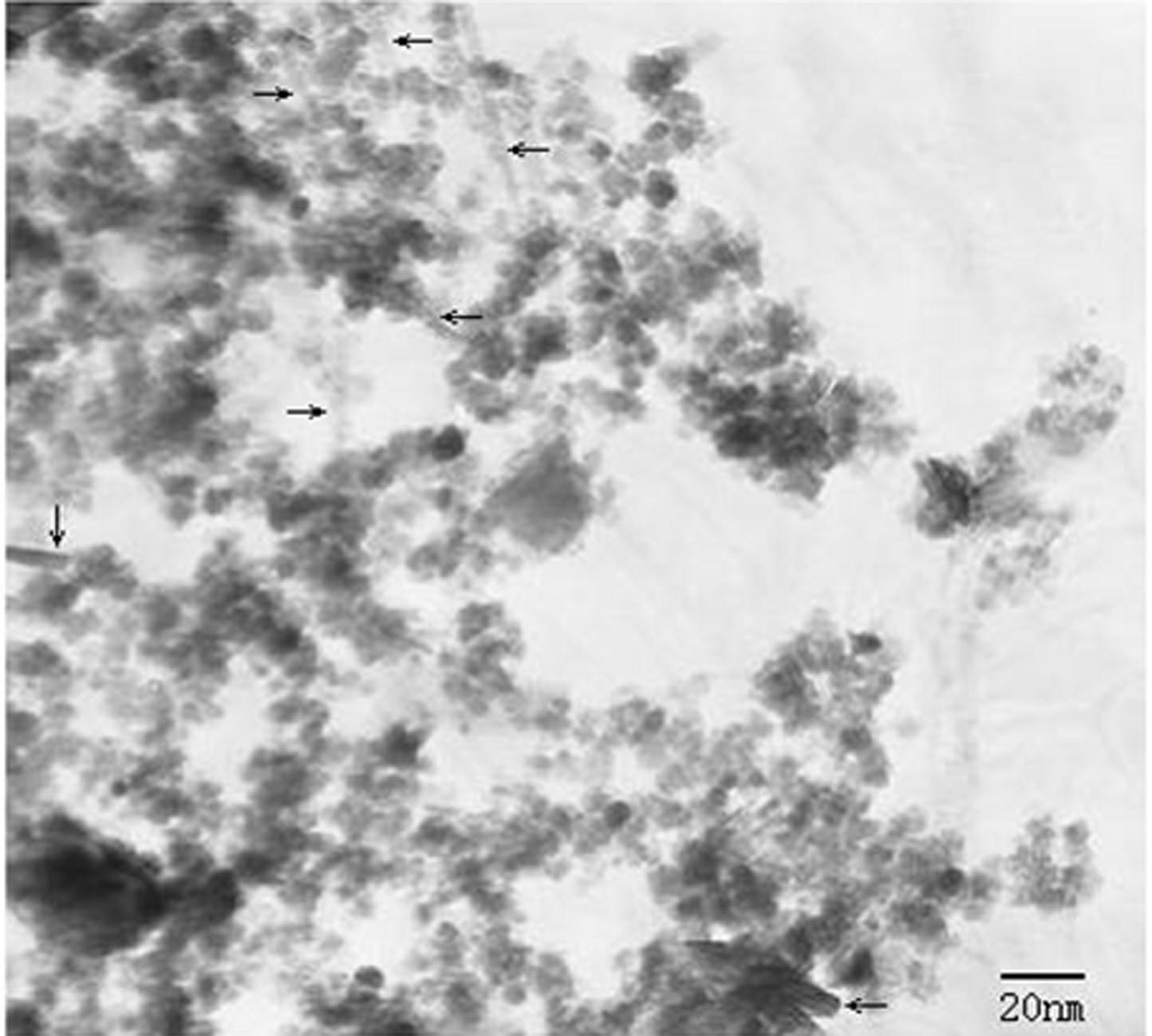

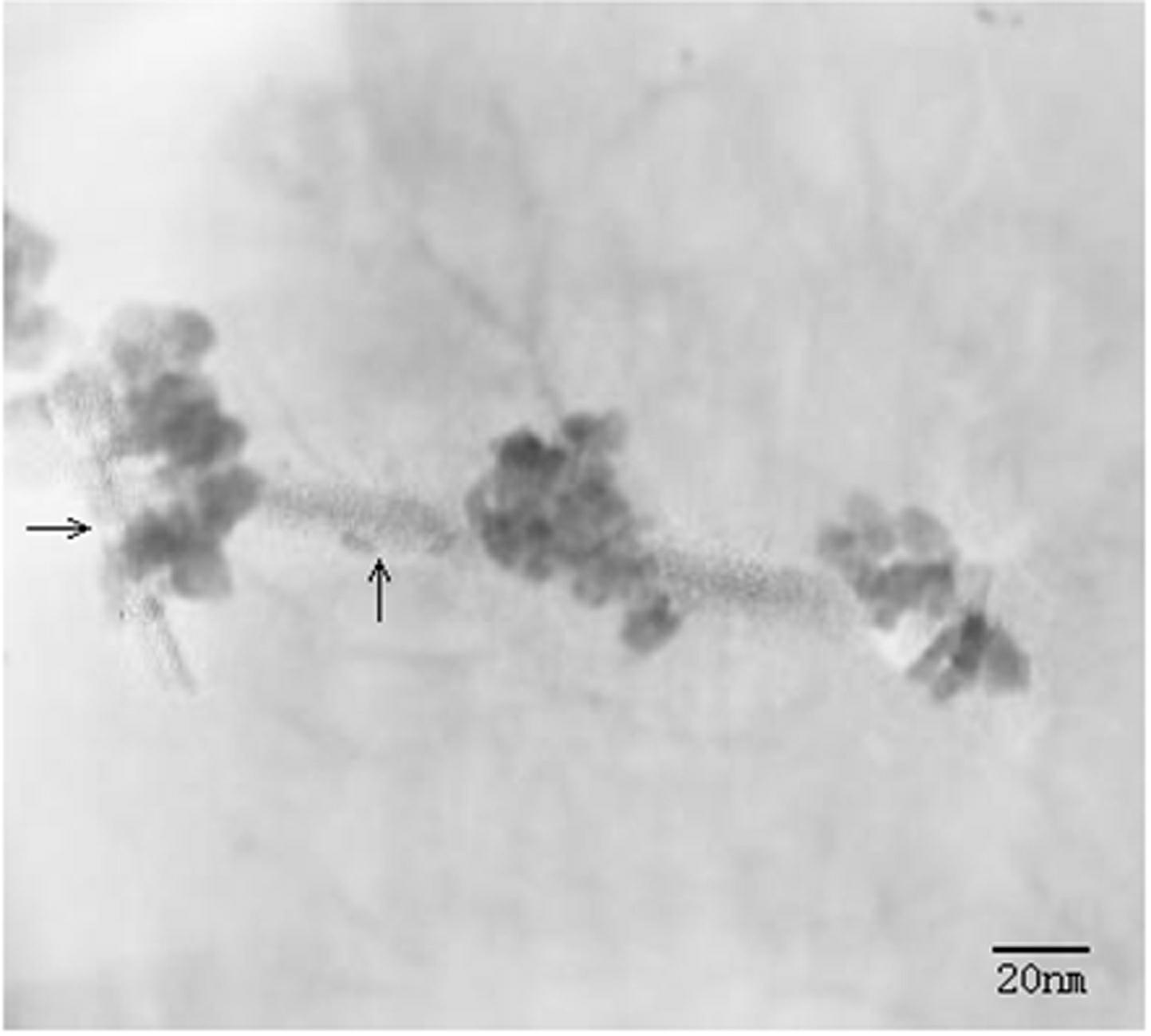

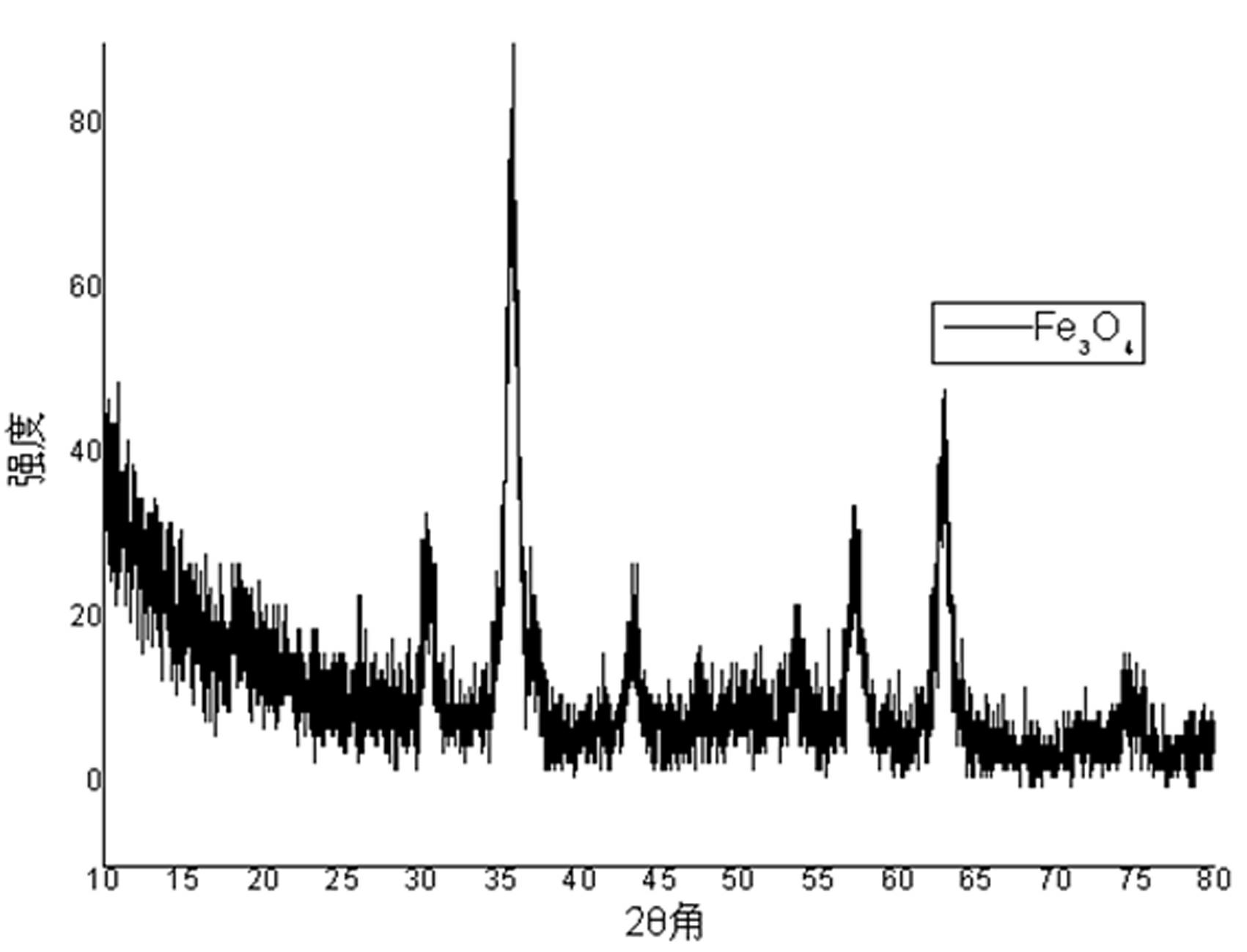

Embodiment 1

[0028] In the reaction vessel, prepare FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 Mixed solution of O, ultrasonic dispersion; FeCl in mixed solution 3 ·6H 2 O and FeSO 4 ·7H 2The molar ratio of O is 1.75:1; seal the reaction vessel, evacuate the reactor through the connecting pipe, and fill it with nitrogen, so that the reaction vessel is under nitrogen protection; place the reaction vessel in a water bath at 65°C, and apply a magnetic field of 4000Gs ; Feed ammonia into the mixed solution of the reaction vessel, the feed amount of ammonia is 17% of the solution quality, control the feed rate of ammonia 0.4g / min; heating reaction 80min in the water bath, the reaction solution presents dark brown precipitation ; Cool to room temperature, wash the product with distilled water and ethanol respectively; dry in a vacuum oven at 25°C for 12h to obtain Fe 3 o 4 Magnetic nanorods, the length of the rod-like structure is about 60-90nm, and the saturation magnetization is 75 emu / g.

Embodiment 2

[0030] In the reaction vessel, prepare FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 Mixed solution of O, ultrasonic dispersion; FeCl in mixed solution 3 ·6H 2 O and FeSO 4 ·7H 2 The molar ratio of O is 2:1; seal the reaction vessel, evacuate the reactor through the connecting pipe, and fill it with nitrogen, so that the reaction vessel is under nitrogen protection; place the reaction vessel in a water bath at 75°C, and apply a magnetic field of 6000Gs ; Feed ammonia into the mixed solution of the reaction vessel, the feed amount of ammonia is 17% of the solution quality, control the feed rate of ammonia 0.4g / min; heating reaction 80min in the water bath, the reaction solution presents dark brown precipitation ; Cool to room temperature, wash the product with distilled water and ethanol respectively; dry in a vacuum oven at 25°C for 12h to obtain Fe 3 o 4 Magnetic nanorods, the length of the rod-like structure is 70-100nm, and the saturation magnetization is 78emu / g.

Embodiment 3

[0032] In the reaction vessel, prepare FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 Mixed solution of O, ultrasonic dispersion; FeCl in mixed solution 3 ·6H 2 O and FeSO 4 ·7H 2 The molar ratio of O is 1.75:1; seal the reaction vessel, evacuate the reactor through the connecting pipe, and fill it with nitrogen, so that the reaction vessel is under nitrogen protection; place the reaction vessel in a water bath at 75°C, and apply a magnetic field of 8000Gs ; Feed ammonia into the mixed solution of the reaction vessel, the feed amount of ammonia is 17% of the solution quality, control the feed rate of ammonia 0.6g / min; heating reaction 70min in the water bath, the reaction solution presents dark brown precipitation ; Cool to room temperature, wash the product with distilled water and ethanol respectively; dry in a vacuum oven at 25°C for 12h to obtain Fe 3 o 4 Magnetic nanorods, the length of the rod-like structure is 75-100nm, and the saturation magnetization is 79emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com