Control method of reformed alkali production reactor

A control method and reactor technology, applied in chemical methods, chemical instruments and methods, and control/regulation processes for reacting liquid and gaseous media, can solve the problem of low utilization rate of salt raw materials and achieve effective control of reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

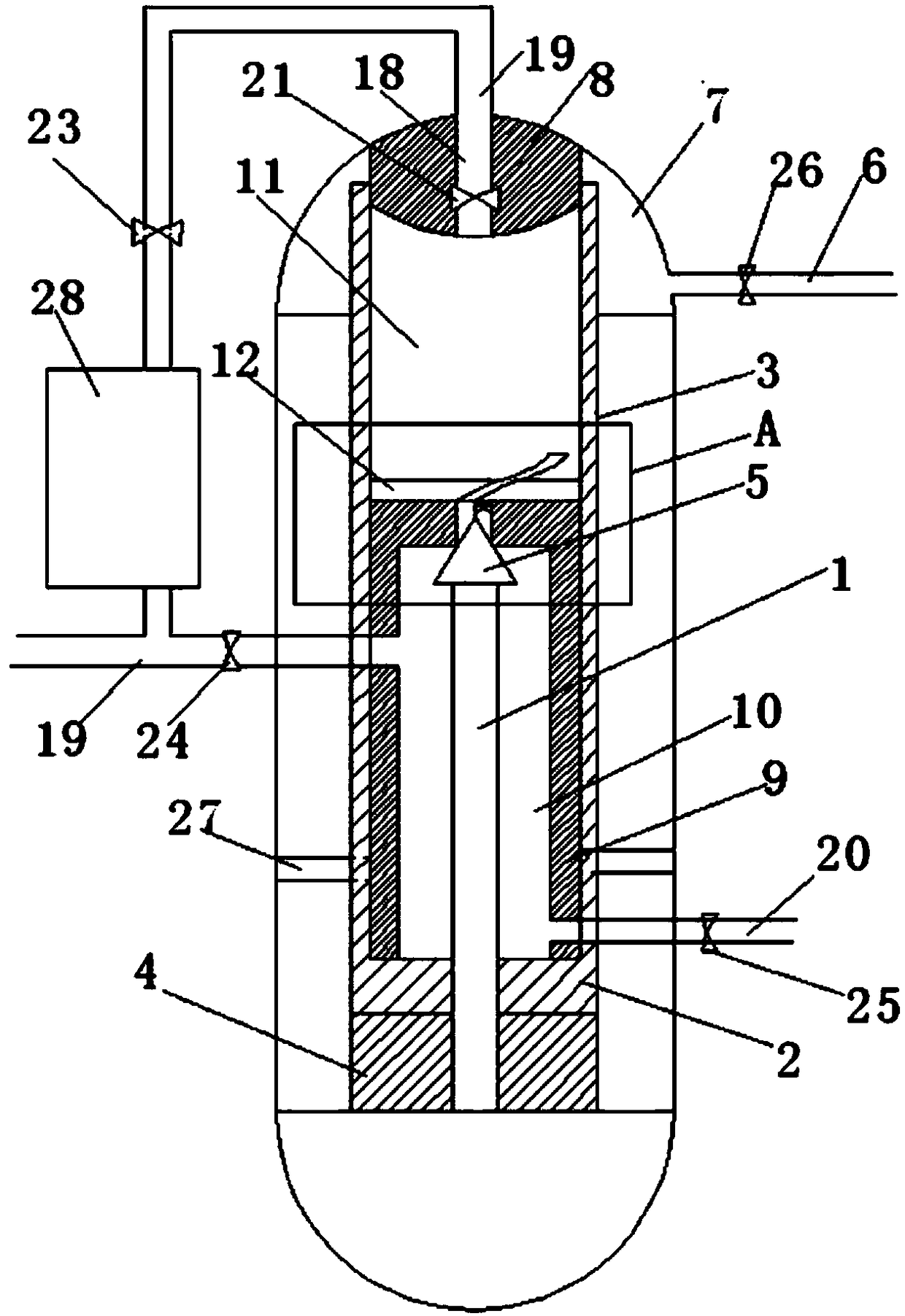

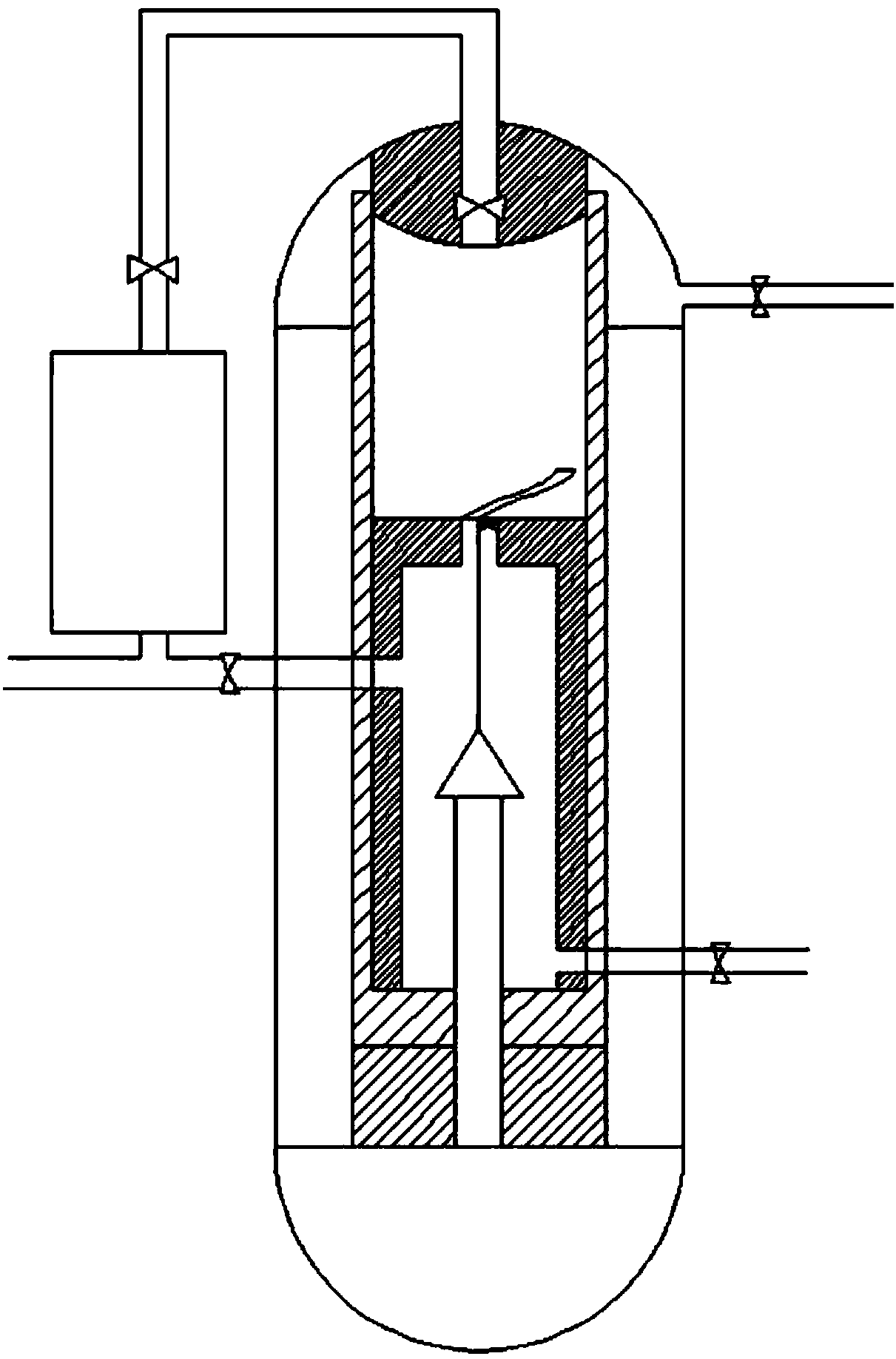

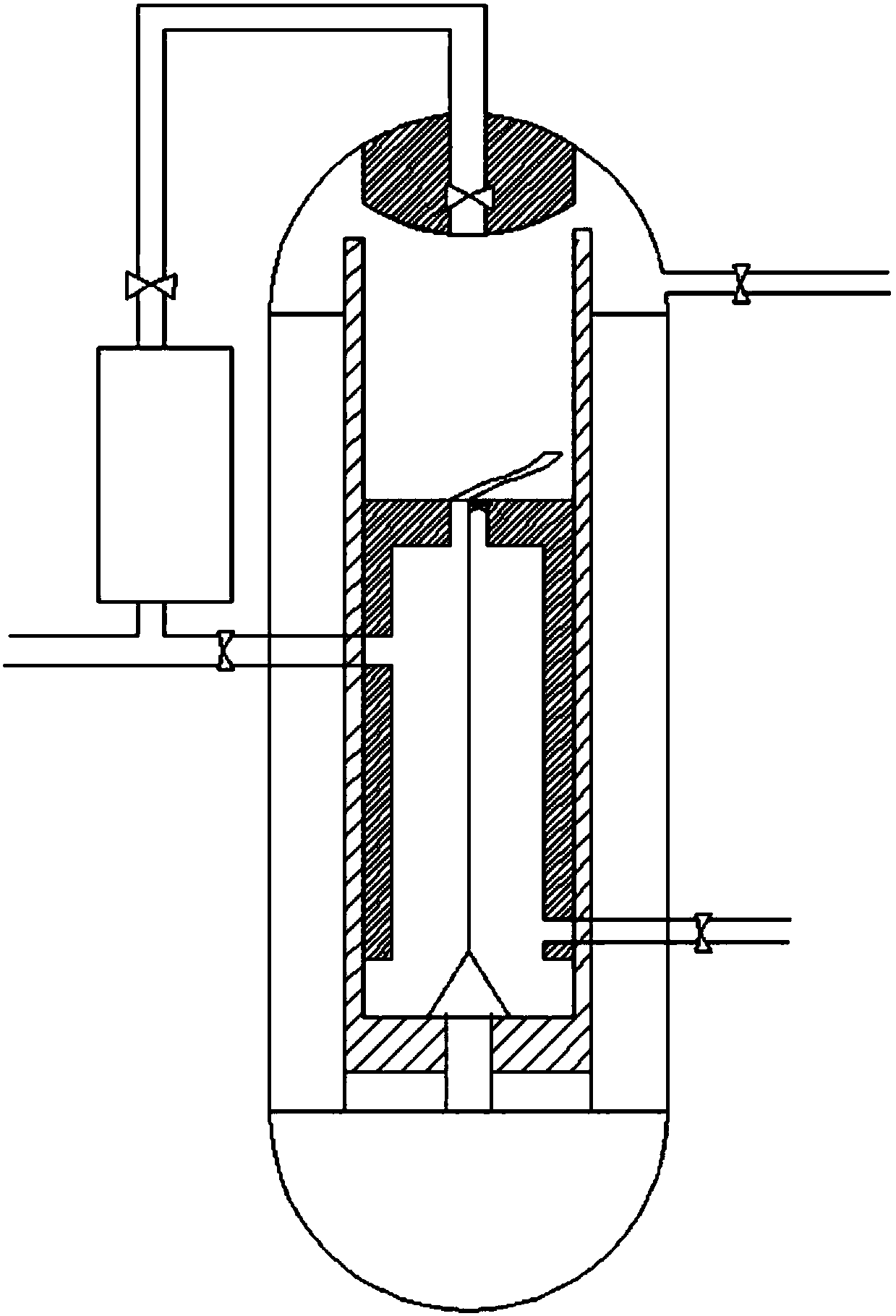

[0025] The modified soda reaction kettle includes an actuator; the actuator includes a telescopic rod 1, a cylindrical baffle bracket 2, a cylindrical baffle 3 and an elastic mechanism 4; an elastic mechanism 4 is installed at the bottom of the kettle body, and the elastic mechanism 4 Install a cylindrical baffle bracket 2 on the upper part, and a cylindrical baffle 3 is arranged on the upper part of the cylindrical baffle bracket 2. The lower end of the telescopic rod 1 is installed at the bottom of the kettle body, and the upper end of the telescopic rod 1 is provided with a tapered plug 5. The telescopic rod 1 passes through the bottom of the cylindrical baffle bracket 2 and the elastic mechanism 4; the Nacl inlet pipe 6 is connected to the Nacl cavity 7 on the top of the tower, the inner surface of the kettle top is provided with a boss 8, and the middle of the kettle body is provided with an inverted cylindrical Structure 9, the structure is fixedly connected with the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com