Production method of 2,4-dinitraniline

A technology of dinitroaniline and its production method, applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the problems of low production cost, high energy consumption, high production safety risk, etc., and achieve low production cost , control the reaction rate, and reduce the production safety risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

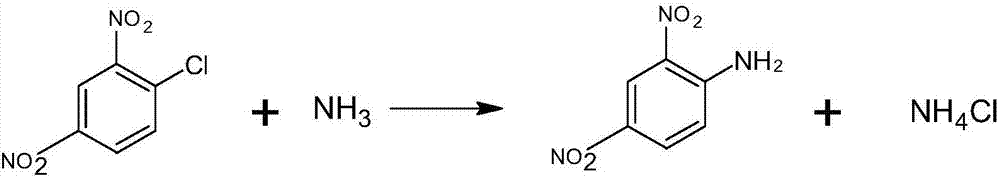

Image

Examples

Embodiment 1

[0023] Add 980L of water to the reaction kettle, raise the temperature to 62°C, add 1180Kg 2,4-dinitrochlorobenzene, raise the temperature to 82°C again, add 1475Kg of ammonia water with a concentration of 18wt% dropwise at a uniform speed, and control the temperature at 83-85°C. The pressure is controlled at 0.05MPa, and the dropping time is 4 hours and 10 minutes. After the dropping is completed, the temperature is raised to 95°C, the pressure is at 0.09MPa, and the reaction is kept for 2 hours. The end point is detected by liquid chromatography. That is, a light yellow powdery 2,4-dinitroaniline product was obtained, with a product purity of 99.52% and a product yield of 99.12%. After the product was dried, the fineness of the product was 20-40 mesh, accounting for 95.3% by mass.

Embodiment 2

[0025] Add 1063L of water to the reactor, heat up to 65°C, add 1250Kg of 2,4-dinitrochlorobenzene, heat up to 81°C again, add 1587Kg of ammonia water with a concentration of 18wt% dropwise at a constant speed, and control the temperature at 81-84°C. The pressure is controlled at 0.06MPa, and the dropping time is 4 hours and 05 minutes. After the dropping is completed, the temperature is raised to 96°C, the pressure is at 0.10MPa, and the reaction is kept for 2 hours. The end point is detected by liquid chromatography. That is, the light yellow powdery 2,4-dinitroaniline product is obtained, the product purity is 99.43%, and the product yield is 99.21%. After the product is dried, the fineness of the product is 20-40 mesh, accounting for 92.1% by mass.

Embodiment 3

[0027] Add 985L of water to the reaction kettle, raise the temperature to 63°C, add 1200Kg of 2,4-dinitrochlorobenzene, raise the temperature to 80°C again, add 1475Kg of ammonia water with a concentration of 18wt% dropwise at a uniform speed, and control the temperature at 81-85°C. The pressure is controlled at 0.05MPa, and the dropping time is 3 hours and 55 minutes. After the dropping is completed, the temperature is raised to 92°C, the pressure is at 0.10MPa, and the reaction is kept for 2 hours. The end point is detected by liquid chromatography. The light yellow powdery 2,4-dinitroaniline product was obtained, the product purity was 99.23%, and the product yield was 99.06%. After the product was dried, the fineness of the product was 20-40 mesh, accounting for 90.4% by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com