Method for ultrasonically preparing Fe3O4 nano-particle through ammonia dispersion

A nanoparticle and ammonia technology, applied in the field of nanomaterials, can solve the problem of not being able to disperse quickly, and achieve the effects of low cost, mild reaction conditions, and prevention of uneven particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

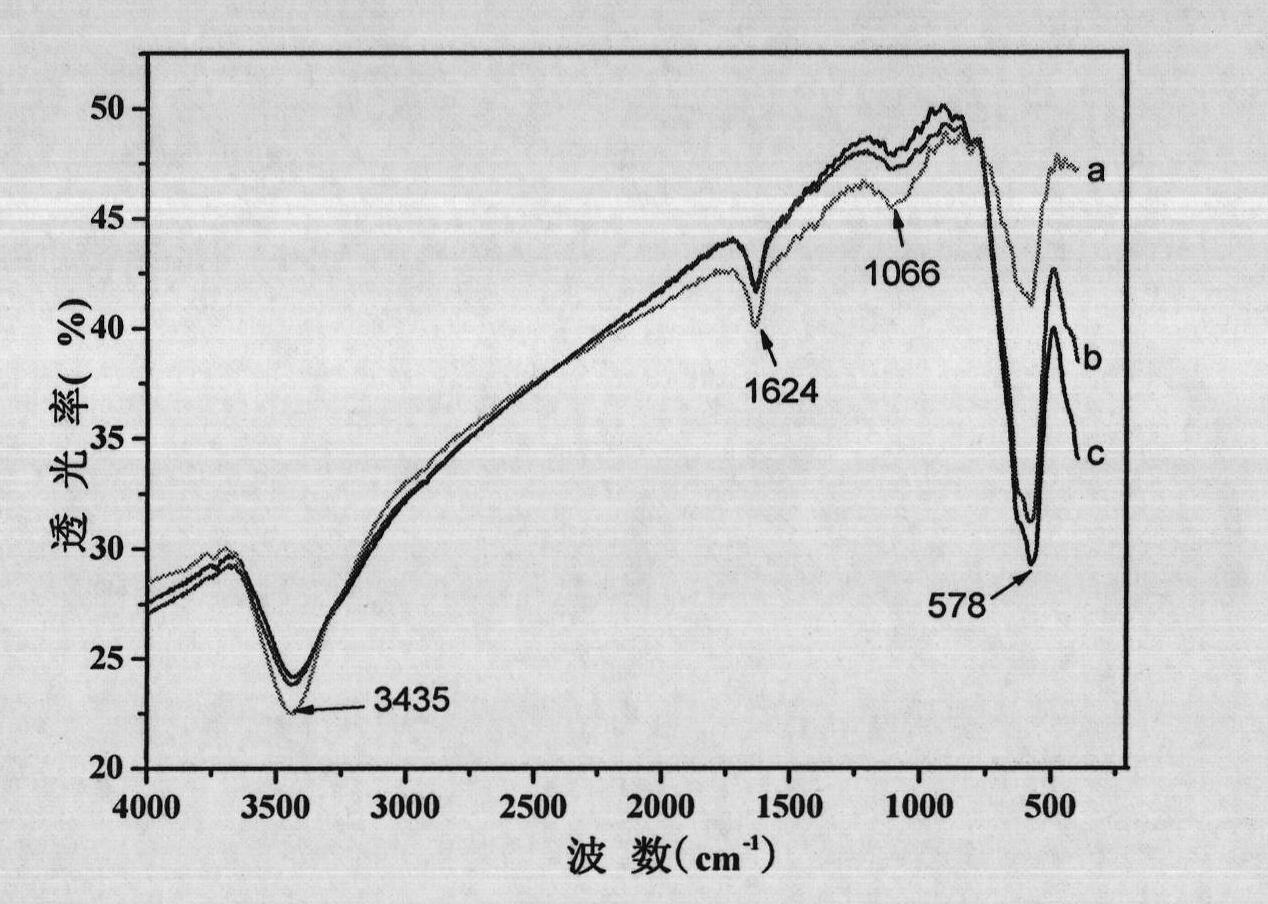

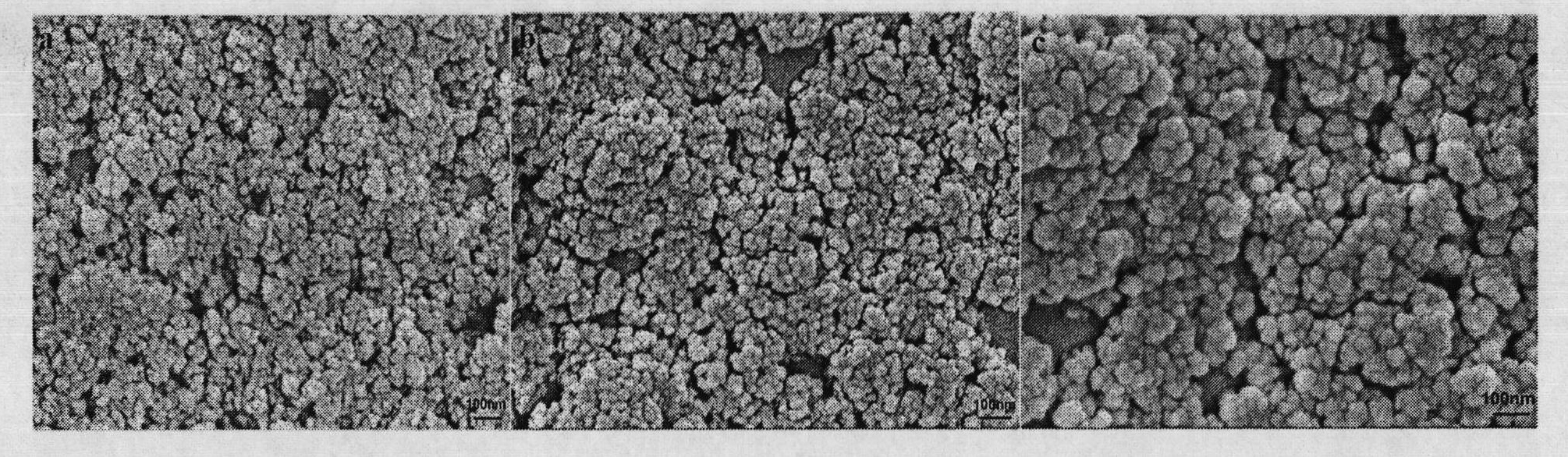

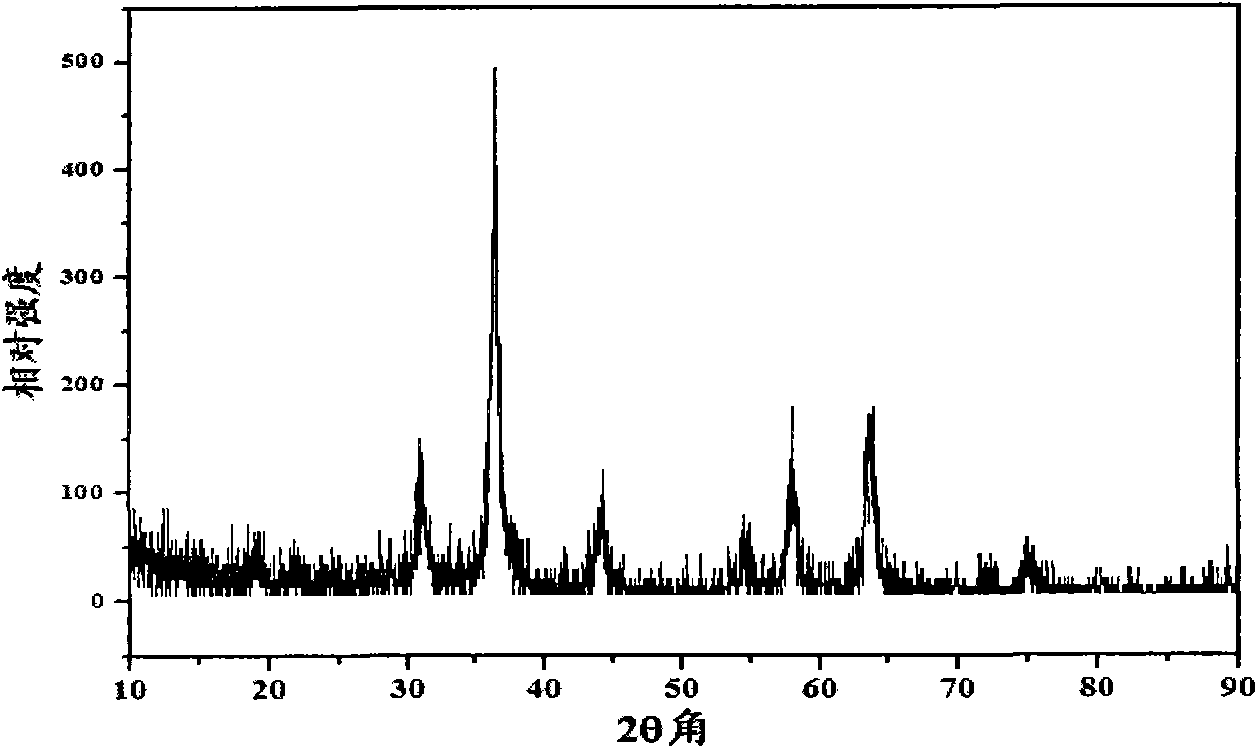

[0034] In the reaction vessel, prepare FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 A mixed solution of O. FeCl in the mixed solution 3 ·6H 2 O and FeSO 4 ·7H 2 The molar ratio of O is 1.75:1, and the concentrations of ferric ions and ferrous particles are 0.044M and 0.025M, respectively.

[0035] Seal the reaction vessel, evacuate it, and fill it with nitrogen, so that the reaction vessel is under nitrogen protection; place the reaction vessel in a 200W ultrasonic instrument, adjust the temperature of the ultrasonic wave to 25°C, and radiate the intensity to 40KHZ; at the same time, mix the reaction vessel with Feed ammonia gas in the solution, the feed amount of ammonia gas is 17% of solution quality; Control the feed speed of ammonia gas 0.4g / min; Ultrasonic radiation 30 minutes, reaction solution presents dark brown precipitation; Cool to room temperature, use respectively Wash the product with distilled water and ethanol; then dry it in a vacuum oven at 25°C for 12 hours to ob...

Embodiment 2

[0037] In the reaction vessel, prepare FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 A mixed solution of O. FeCl in the mixed solution 3 ·6H 2 O and FeSO 4 ·7H 2 The molar ratio of O is 2:1, and the concentrations of ferric ions and ferrous particles are 0.05M and 0.025M, respectively.

[0038] Seal the reaction vessel, vacuumize it, and fill it with nitrogen, so that the reaction vessel is under nitrogen protection; place the reaction vessel in a 200W ultrasonic instrument, adjust the temperature of the ultrasonic wave to 35°C, and radiate at 40KHZ; at the same time, mix the reaction vessel with Feed ammonia gas in the solution, and the feeding amount of ammonia gas is 17% of solution quality; Control the feeding speed of ammonia gas 0.4g / min; Ultrasonic radiation 50 minutes, reaction solution presents pitchy precipitation; Cool to room temperature, use respectively Wash the product with distilled water and ethanol; then dry it in a vacuum oven at 25°C for 12 hours to obtain Fe 3 ...

Embodiment 3

[0040] In the reaction vessel, prepare FeCl 3 ·6H 2 O and FeSO 4 ·7H 2 A mixed solution of O. FeCl in the mixed solution 3 ·6H 2 O and FeSO 4 ·7H 2 The molar ratio of O was 1.75:1, and the concentrations of ferric ions and ferrous particles were 0.035M and 0.02M, respectively.

[0041] Seal the reaction vessel, vacuumize it, and fill it with nitrogen, so that the reaction vessel is under nitrogen protection; place the reaction vessel in a 200W ultrasonic instrument, adjust the temperature of the ultrasonic wave to 35°C, and radiate at 40KHZ; at the same time, mix the reaction vessel with Feed ammonia gas in the solution, the feed amount of ammonia gas is 20% of solution quality; Control the feed speed of ammonia gas 0.4g / min; Ultrasonic radiation 50 minutes, reaction solution presents pitchy precipitation; Cool to room temperature, use respectively Wash the product with distilled water and ethanol; then dry it in a vacuum oven at 25°C for 12 hours to obtain Fe 3 o 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com