Preparation method for green shallow-cured phenolic resin coated grinding tool

A technology of phenolic resin and coated abrasives, which is applied in abrasives, manufacturing tools, metal processing equipment, etc. It can solve the problems of limited storage period, high curing temperature, and darkening of color, so as to reduce the curing temperature and cycle, and improve the viscosity. The effect of reducing junction performance and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

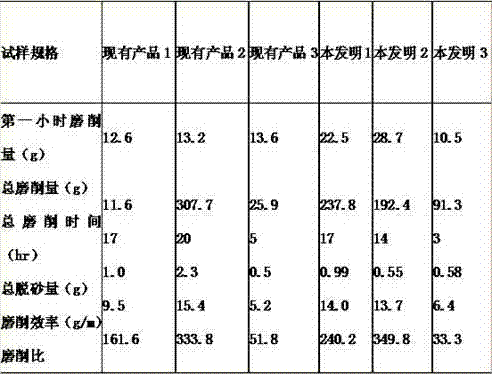

Examples

Embodiment 1

[0033] A kind of preparation method of green shallow cured phenolic resin coated abrasive tool is carried out according to the following steps:

[0034] ⑴Matrix cloth treatment: preparation of impregnation solution: add 30 grams of water-soluble thermosetting phenolic resin and 70 grams of water for every 100 grams of PVAC emulsion, the solid content of the impregnation solution is 25%; use the impregnation solution to impregnate the matrix cloth once, dry and iron Flat, calendered, squeegee according to the conventional process, the thickness of the squeegee is preferably to block the gauze holes of the base cloth and impermeable to the resin glue, the squeegee used for the squeegee is a water-resistant abrasive cloth squeegee, and the water-resistant abrasive cloth squeegee is determined by weight percentage The composition of the above components: PVAC emulsion: 40%, SF-7001 resin: 25%, talcum powder: 30%, water: 5%; after scraping, dry for 1 hour at a drying temperature of ...

Embodiment 2

[0039] A kind of preparation method of green shallow cured phenolic resin coated abrasive tool is carried out according to the following steps:

[0040] ⑴Matrix cloth treatment: preparation of impregnation solution: add 40 grams of water-soluble thermosetting phenolic resin and 100 grams of water to every 100 grams of PVAC emulsion, the solid content of the impregnation solution is 35%; use the impregnation solution to impregnate the matrix cloth twice, dry and iron Flat, calendered, squeegee according to the conventional process, the thickness of the squeegee is preferably to block the gauze holes of the base cloth and impermeable to the resin glue, the squeegee used for the squeegee is a water-resistant abrasive cloth squeegee, and the water-resistant abrasive cloth squeegee is determined by weight percentage The above components are composed of: PVAC emulsion: 45%, SF-7602 resin: 20%, bentonite: 27%, water: 8%; after scraping, dry for 1.5 hours at a drying temperature of 95°...

Embodiment 3

[0045] A kind of preparation method of green shallow cured phenolic resin coated abrasive tool is carried out according to the following steps:

[0046] ⑴Matrix cloth treatment: preparation of impregnation solution: add 50 grams of water-soluble thermosetting phenolic resin and 170 grams of water for every 100 grams of PVAC emulsion, the solid content of the impregnation solution is 45%; use the impregnation solution to impregnate the matrix cloth twice, dry and iron Flat, calendered, squeegee according to the conventional process, the thickness of the squeegee is preferably to block the gauze holes of the base cloth and impermeable to the resin glue, the squeegee used for the squeegee is a water-resistant abrasive cloth squeegee, and the water-resistant abrasive cloth squeegee is determined by weight percentage The above components are composed of: PVAC emulsion: 42%, SF-7001 resin: 23%, talcum powder: 28%, water: 7%; after scraping, dry for 2 hours at a drying temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com