Patents

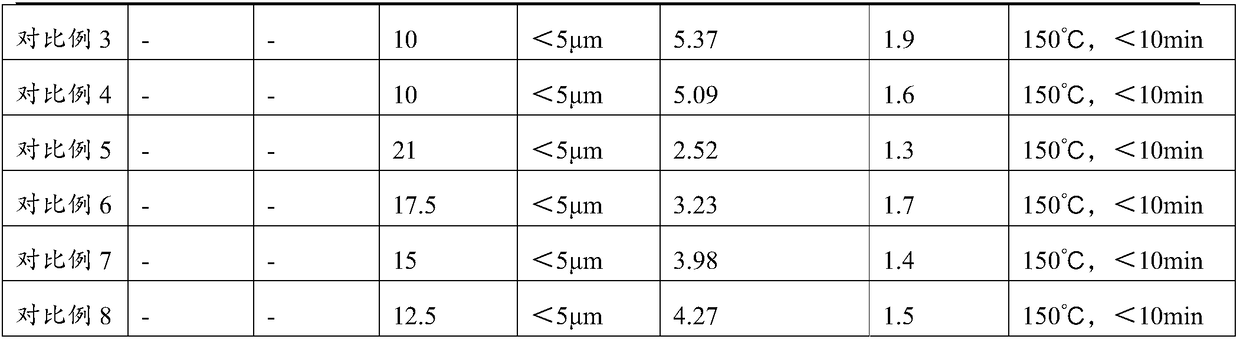

Literature

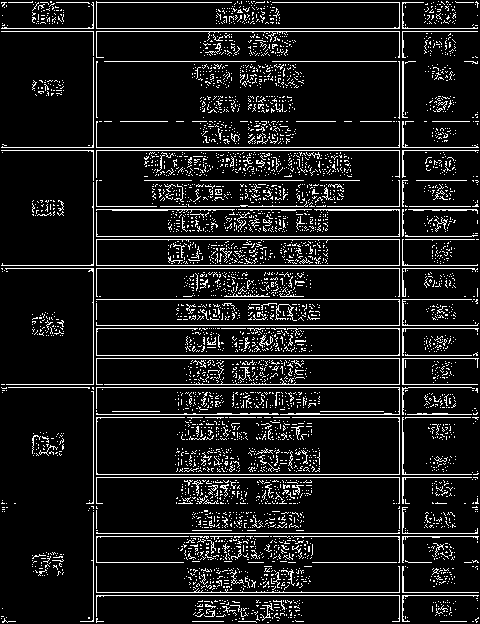

119results about How to "Shorten curing cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

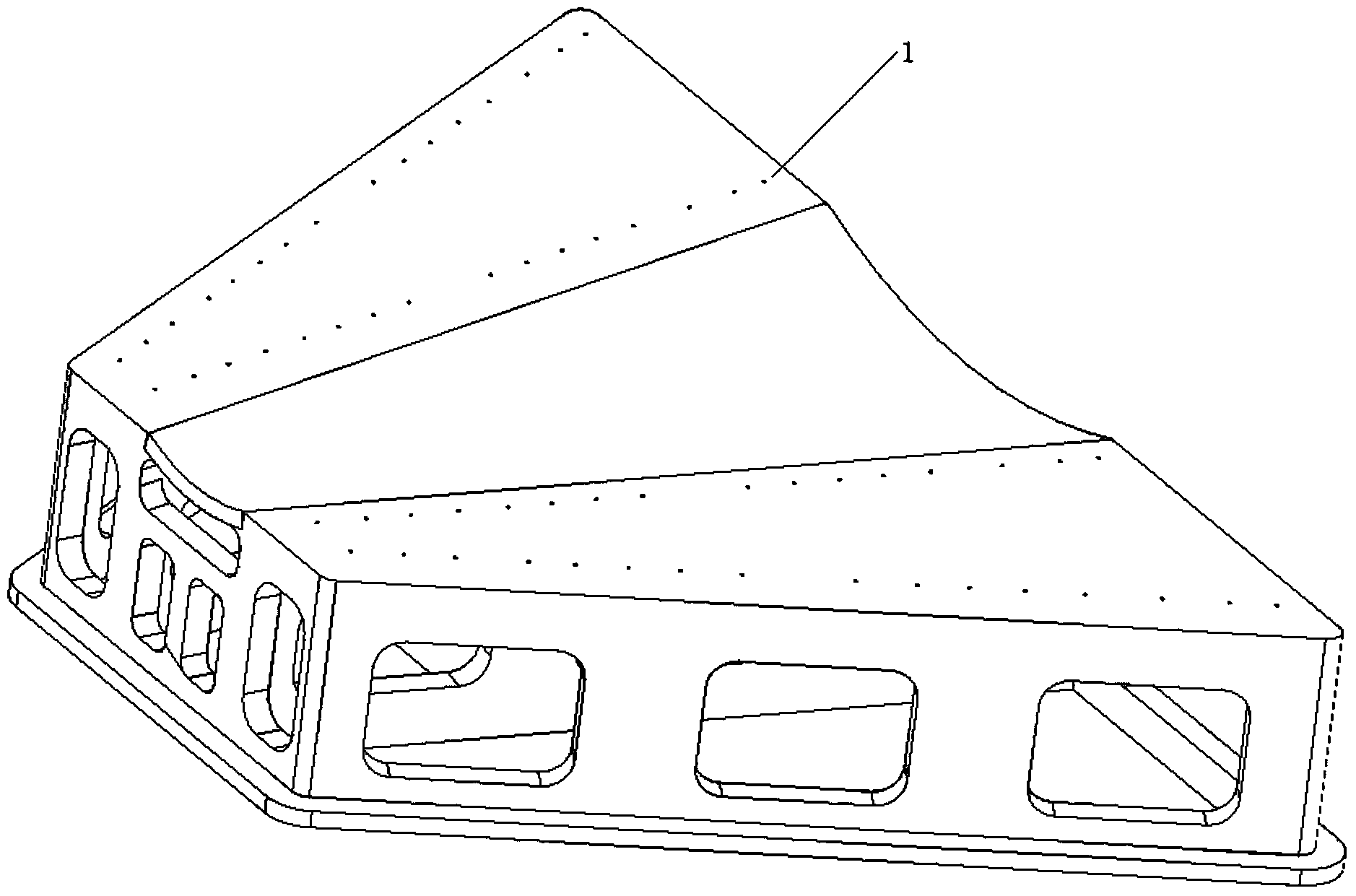

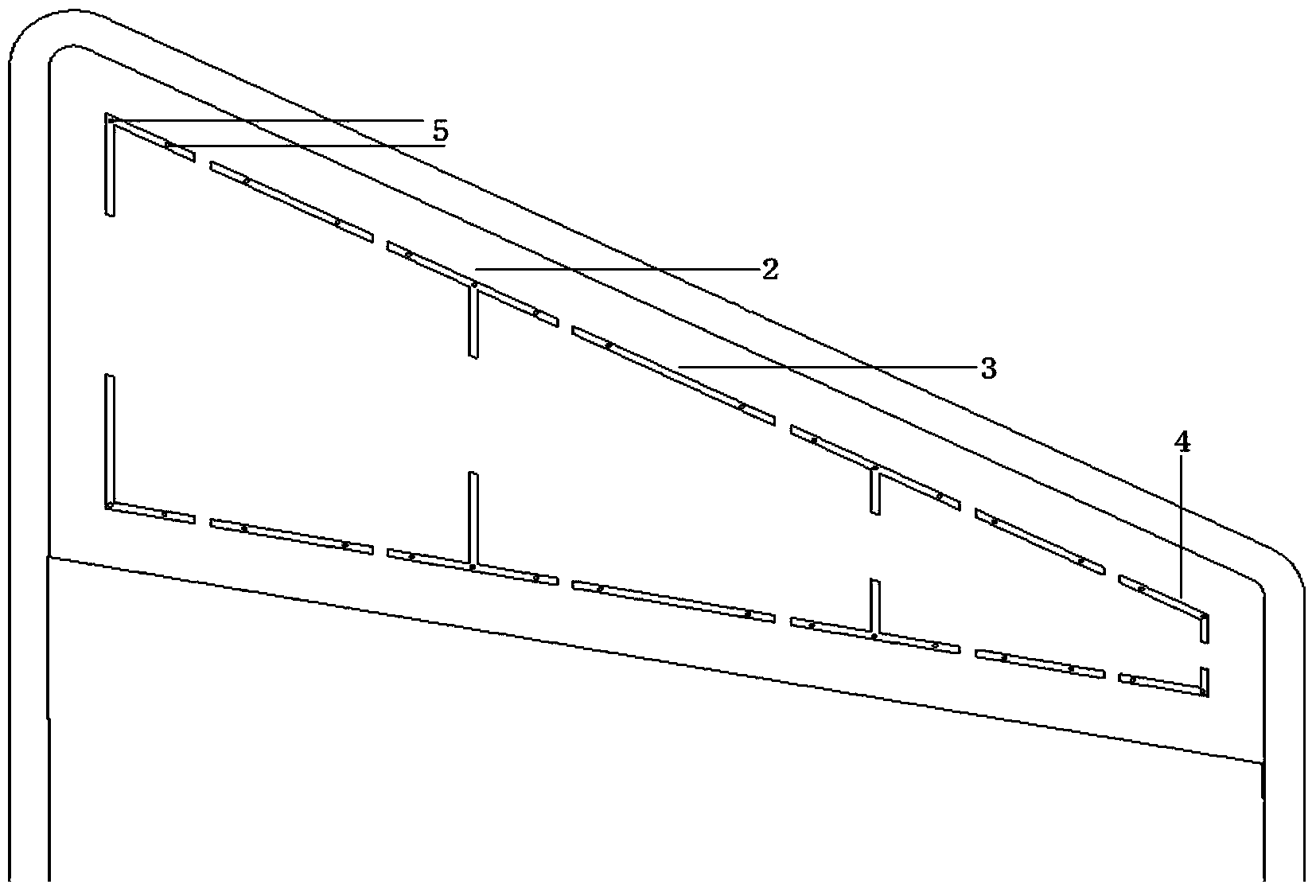

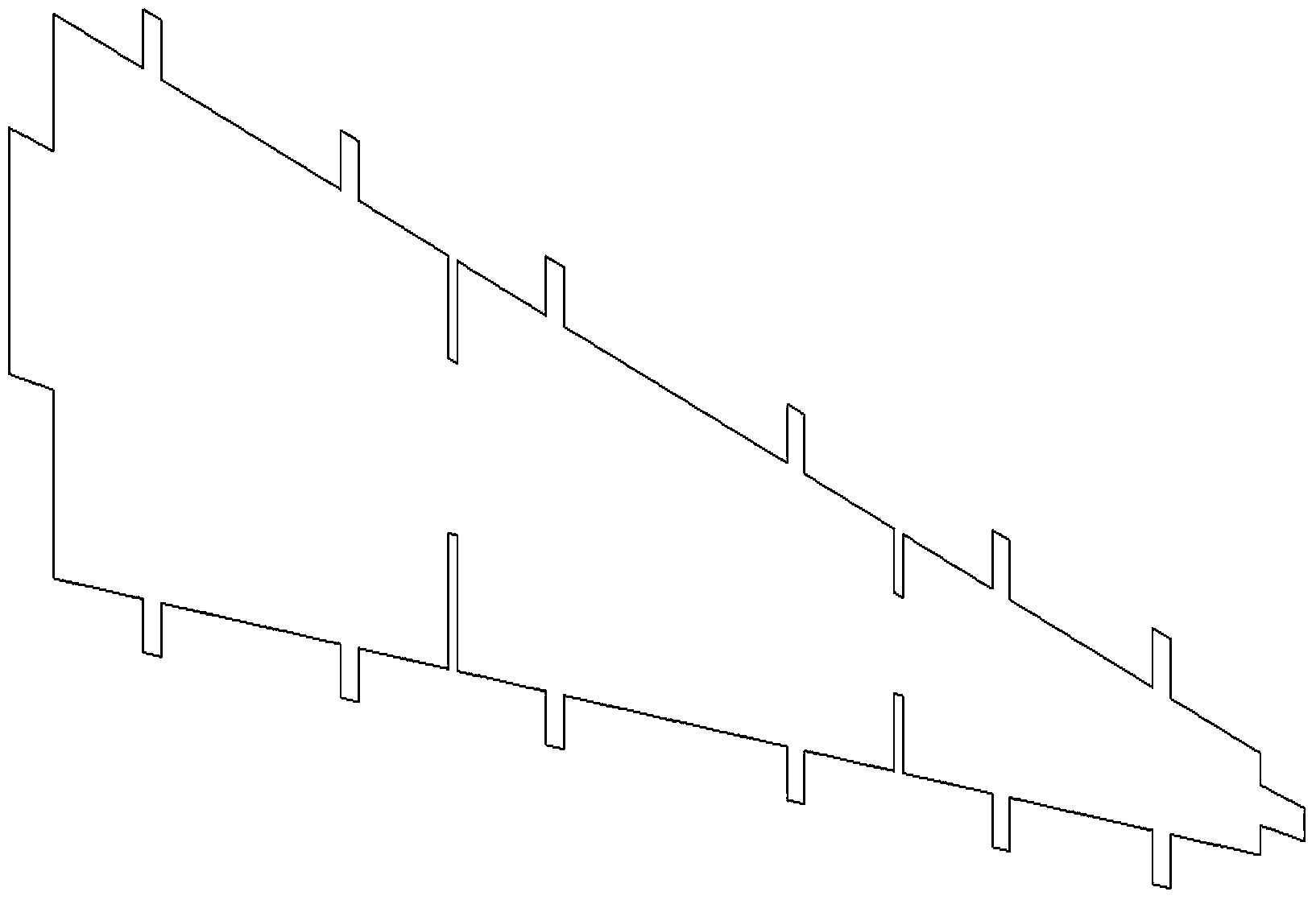

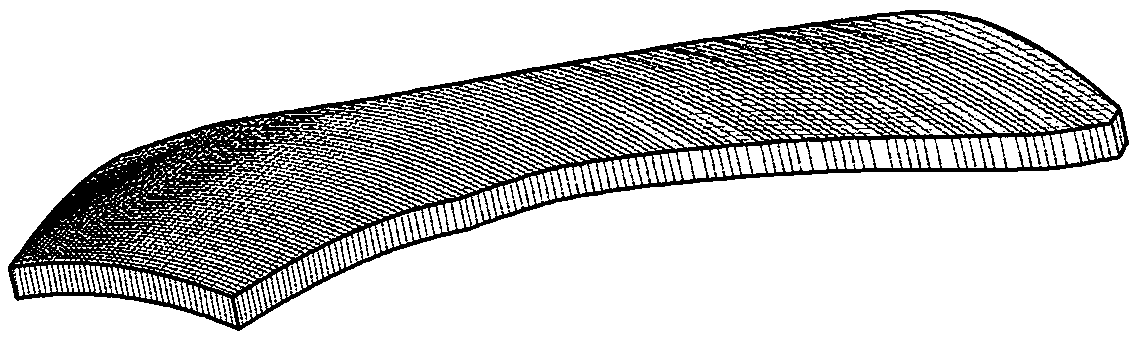

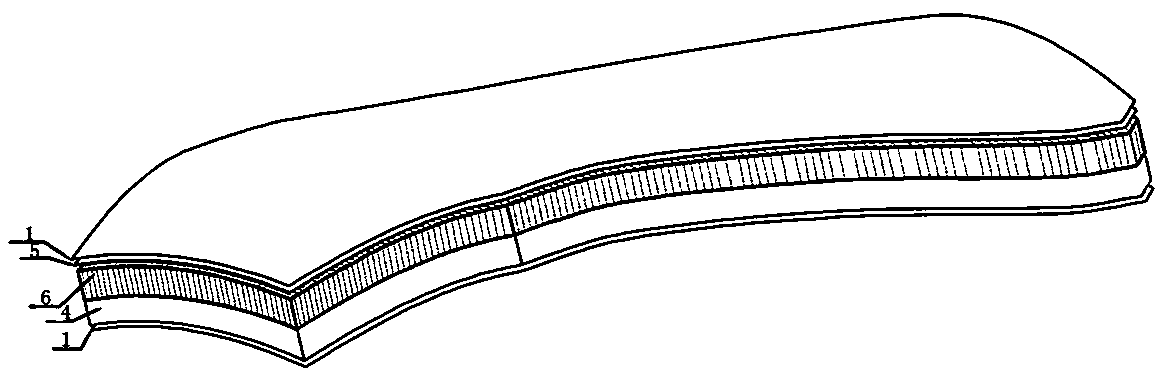

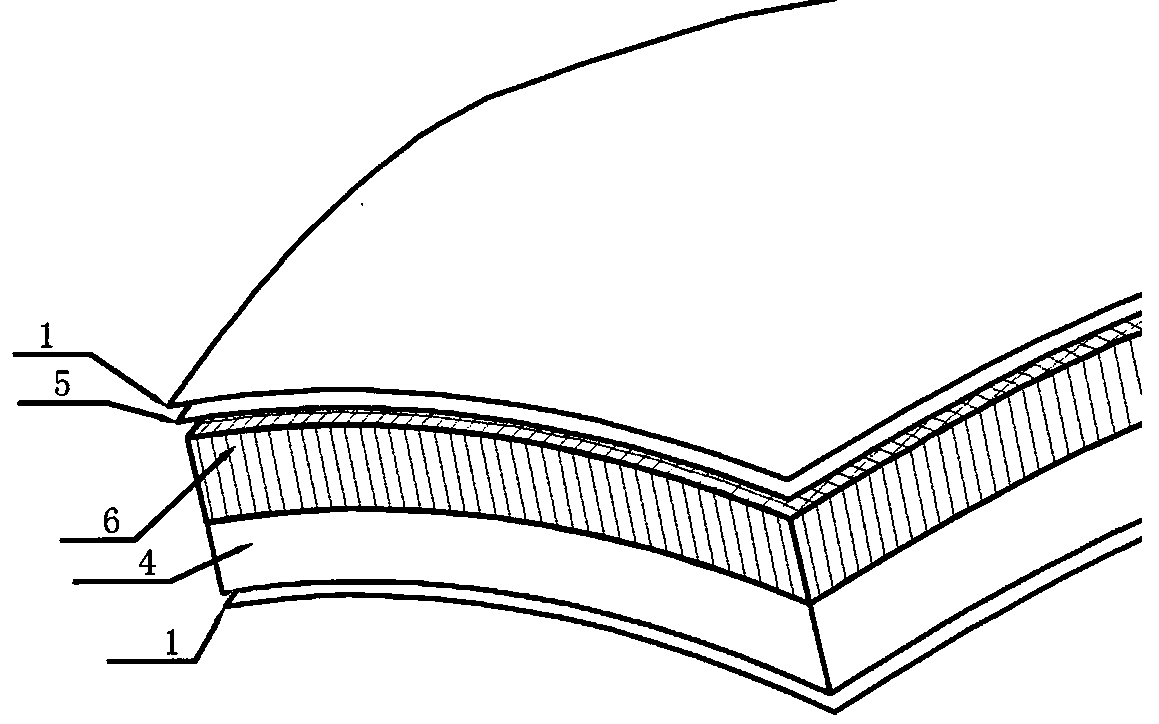

Manufacturing method of wing-body integrated honeycomb sandwiched composite material skin

The invention provides a manufacturing method of a wing-body integrated honeycomb sandwiched composite material skin. The manufacturing method comprises the steps of preparing a hot-pressing die of the wing-body integrated honeycomb sandwich composite material skin, laying and hot-pressing, wherein a plurality of antiskid positioning holes having the diameter of 0.5mm are formed in the profile of the die along honeycomb mounting edges. Flexible honeycomb antiskid positioning ribs are mounted on the profile of the die and a beneficial solidification process in a hot-pressing tank is obtained by virtue of lots of tests, so that shortcomings caused by the deviation of a honeycomb sandwich in a co-solidification process are eliminated thoroughly, the solidification period is shortened and the solidification cost is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

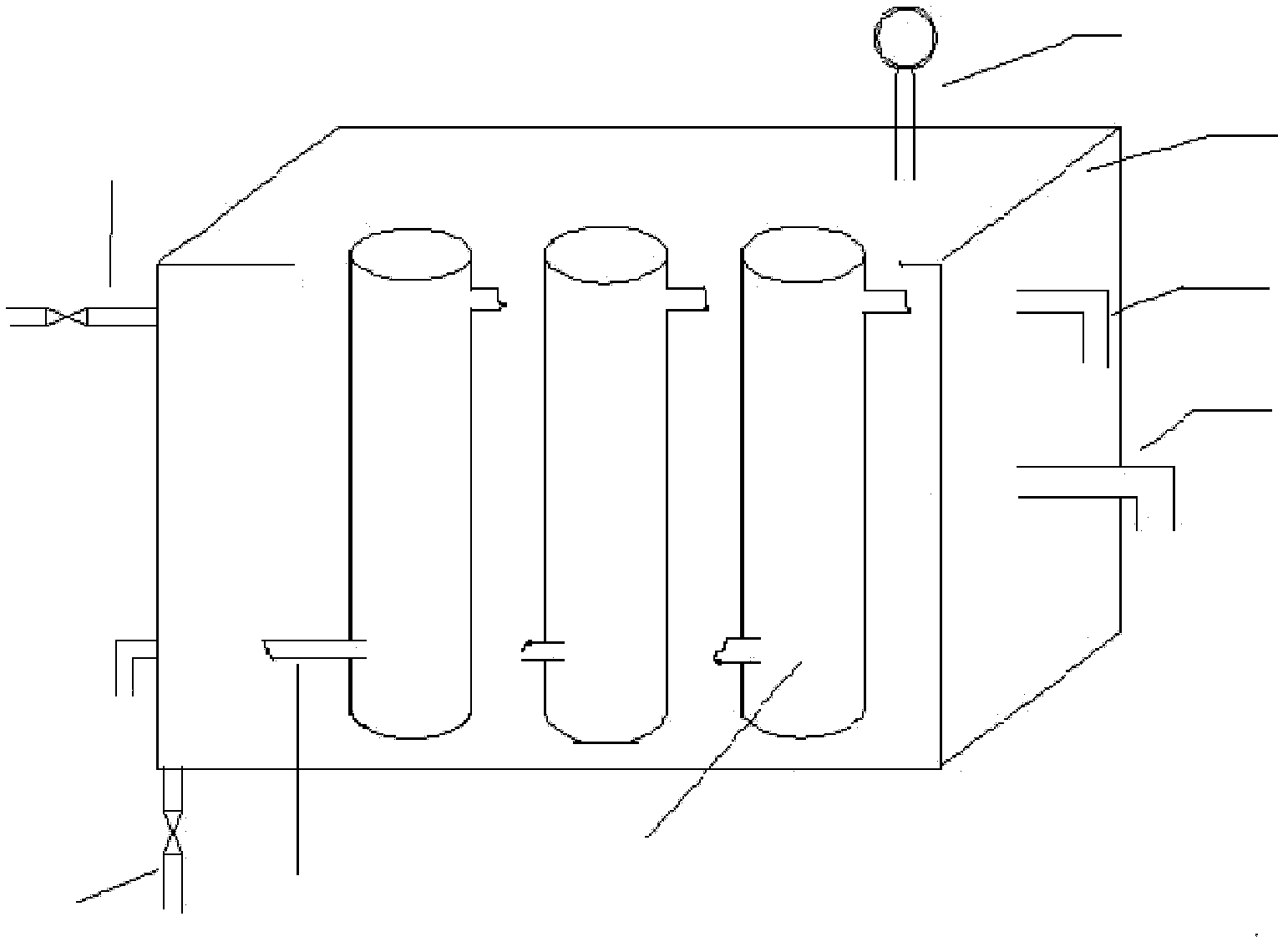

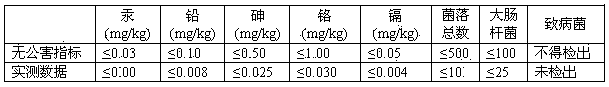

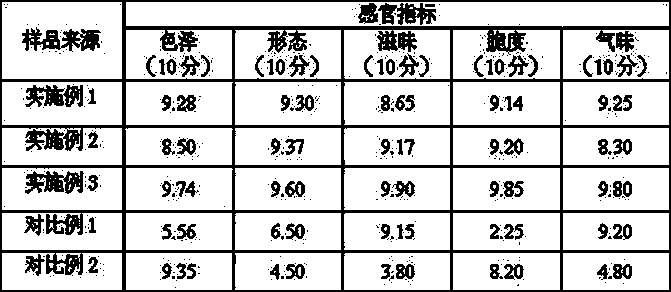

Method and system for producing runny preserved duck egg semi-continuously and rapidly through vacuum decompression

ActiveCN103110137AShorten curing cycleIncrease productivityFood preparationPressure differenceZoology

The invention relates to a method for producing a runny preserved duck egg semi-continuously and rapidly through vacuum decompression. The preserved duck egg is soaked by adopting a vacuum decompression semi-continuously production technology, air in the duck egg can be pumped out through repeated vacuumizing, then in the process of rising to normal pressure, alkali liquor can permeate into the duck egg rapidly due to the pressure difference of the interior and the exterior of the duck egg at the beginning of salting, so that the salting period of the preserved duck egg is shortened. The method has high degree of mechanization, can be operated semi-continuously, can improve the production efficiency of the preserved duck egg, uses unleaded feed liquid, and can prepare safe and harmless preserved duck eggs.

Owner:TIANJIN DIMUSHENG TECH CO LTD +1

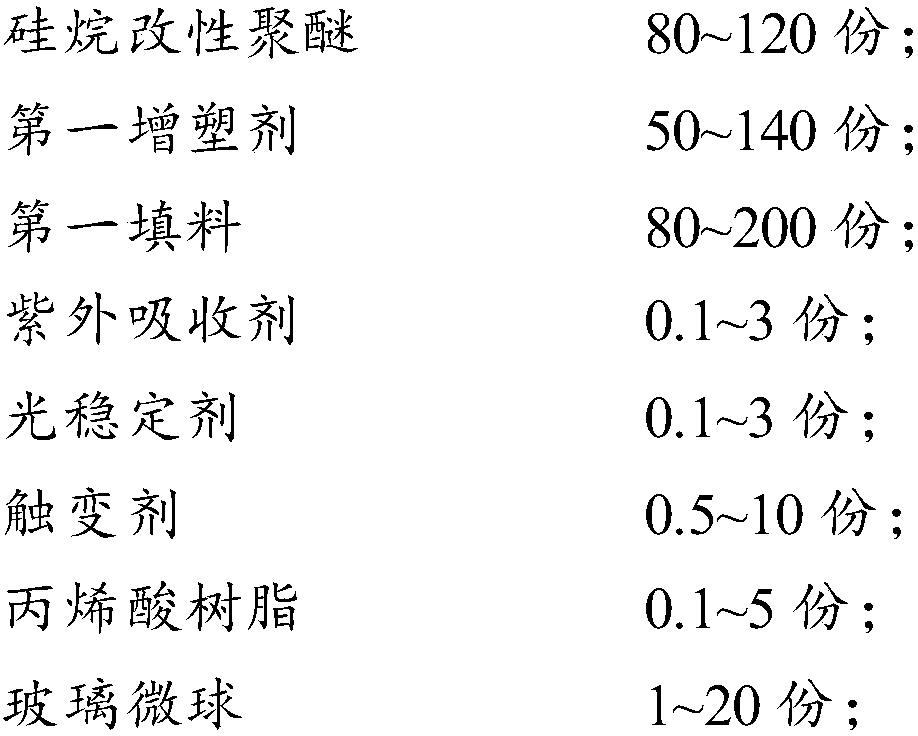

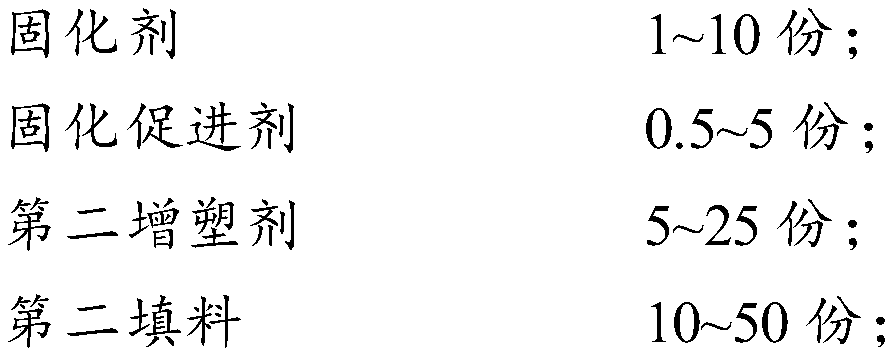

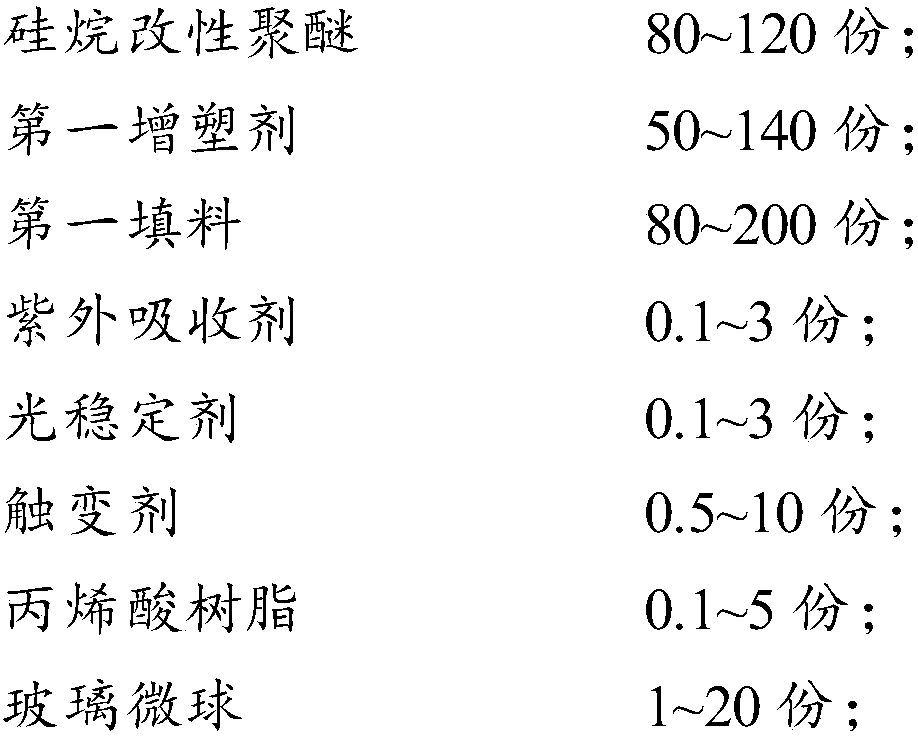

Double-component modified polyether sealant and preparation method thereof

InactiveCN108676506AShorten curing cycleLong operating timeNon-macromolecular adhesive additivesMacromolecular adhesive additivesSilyleneEnd-group

The invention provides a double-component modified polyether sealant and a preparation method thereof. The sealant provided by the invention is prepared from a material A and a material B, wherein thematerial A is prepared from silane-modified polyether, a first plasticizer, a first filler, an ultraviolet absorbent, a light stabilizer, a thixotropic agent, acrylic resin and glass microspheres; the silane-modified polyether is selected from one or more of organosilyl polyether with the end group being triethoxy, and organosilyl polyether with the end group being methyl dimethoxy; the materialB is prepared from a curing agent, a curing accelerator, a second plasticizer and a second filler; the curing agent is an organic tin curing agent; the curing accelerator is an amine accelerator; themass ratio of the material A to the material B is 100: (4 to 15). The material A and the material B are combined. The curing period of the sealant can be shortened, and the operable time is prolonged.

Owner:HANGZHOU ZHIJIANG NEW MATERIAL CO LTD +1

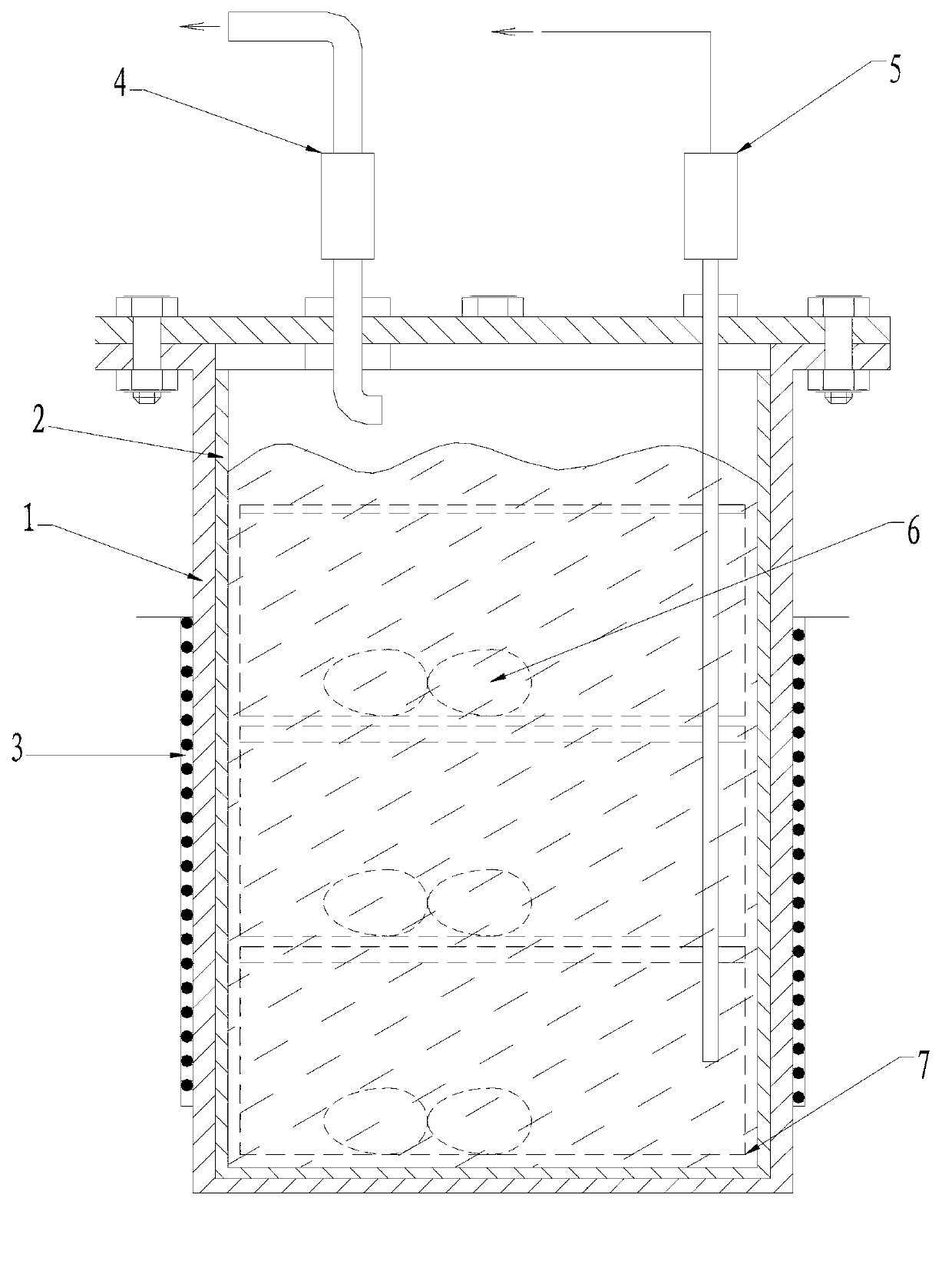

Method and device for fast and cyclically pickling salted eggs

ActiveCN102613603AImprove pickling efficiencyEase of industrial productionFood preparationPickling saltDissolution

The invention discloses a method for cyclically pickling salted eggs. The method comprises the following steps that: A, selecting fresh poultry eggs, cleanly washing the poultry eggs, and placing the eggs into a vacuum pickling tank; B, solution A and solution B for pickling are prepared, 1L of solution A comprises common salt and slaked lime, and 1L of solution B comprises white spirit, acid additives and natural spice; C, the solution A for pickling is filled into a sterilization device with a built-in liquid storage groove and is pumped into the tank containing the poultry eggs after beingsubjected to ultraviolet sterilization, the solution B is filled into an ultrasonic wave dissolution device provided with a built-in liquid storage groove and a stirring paddle, the stirring is carried out, the pump is started, and the solution B passes through a filtering device and the sterilization device and is then pulped into the tank; D, the pump is started, the flow rate is monitored through a flow rate counting meter so that the pickling solution circulates in a pickling device at the specified flow speed; and E, after the cyclic pickling fro a certain time, the eggs are taken out and are cleanly washed, and finished products are obtained. The salinity of the salted eggs is uniform, the flavor is very good, the pickling period is shortened, the shelf life can be prolonged, the utilization rate of the pickling solution is improved, meanwhile, the continuous production can also be realized, the factory building area is reduced, and the environment is protected.

Owner:HUBEI SHUANGGANG AGRI SCI & TECH TRADE CO LTD

Spicy salted duck egg pickling liquid, preparation method and salted duck egg production method

The invention discloses spicy salted duck egg pickling liquid, a preparation method and a salted duck egg production method. The pickling liquid comprises following components in parts by weight: 20g-40g of peppers, 20g-40g of fresh ginger, 20g-40g of fennels, 3g-60g of garlic, 20g-40g of cinnamons, 5g-15g of fructus piperis longi, 150g-300g of table salt, 30g-60g of white spirit and the balance of water. The preparation method comprises the following steps: after washing and disinfecting fresh duck eggs; treating by using a pickling auxiliary agent; adding the fresh duck eggs into the prepared pickling liquid to be pickled to be cooked; washing and sterilizing; pre-boiling and bagging in vacuum; and sterilizing to obtain a finished product. Salted duck eggs produced by the preparation method disclosed by the invention are moderate in saltiness degree and small in air chamber; the egg white is pure white and tender and the yolk is red, yellow and bright in color and luster and is fine, soft and loose; an egg shell is brown or light brown; the salted duck eggs have slight faint scent, lasting taste and short pickling period. Material liquid can be repeatedly utilized so that the production cost is reduced.

Owner:JIANGXI TIANYUN AGRI DEV

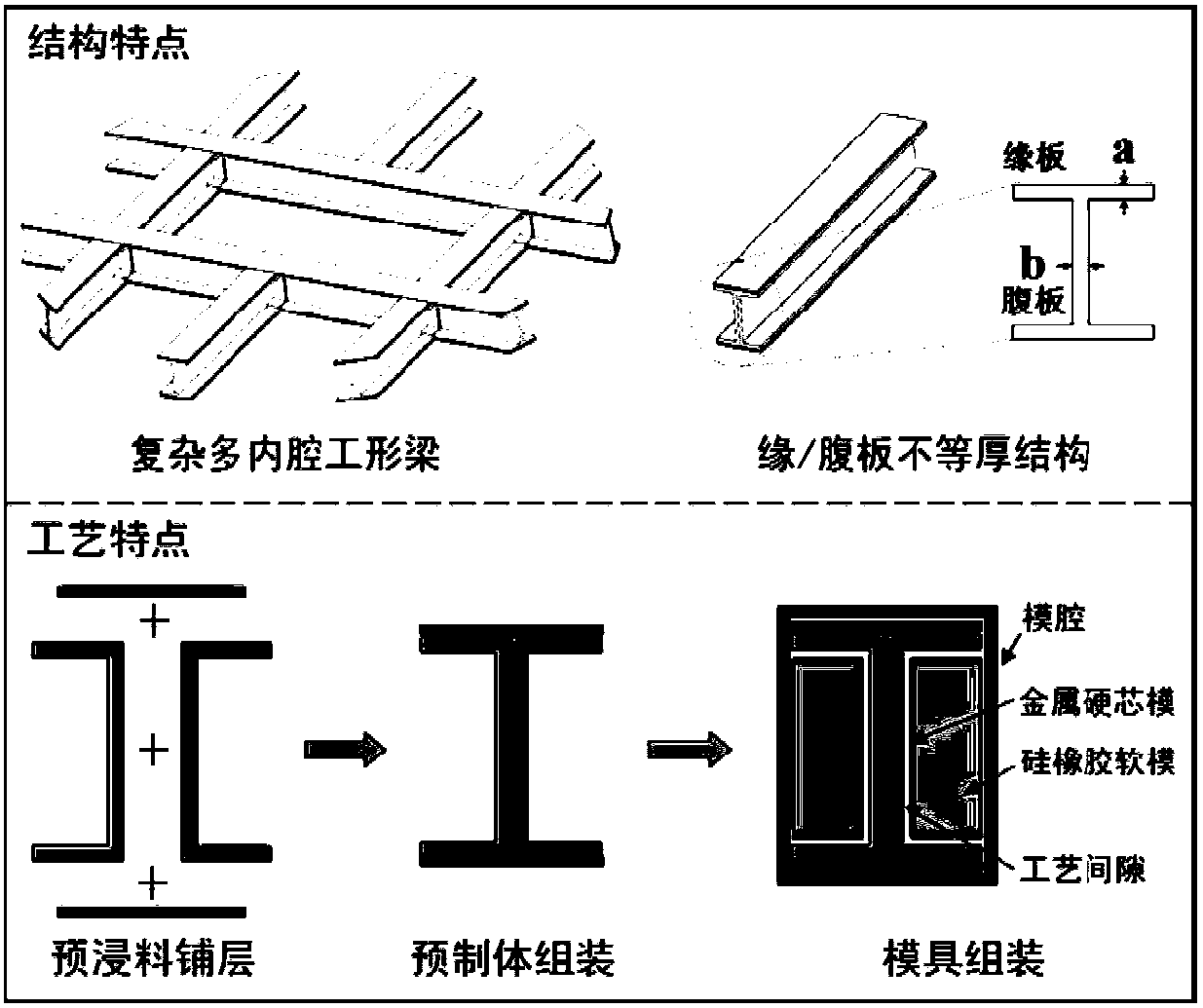

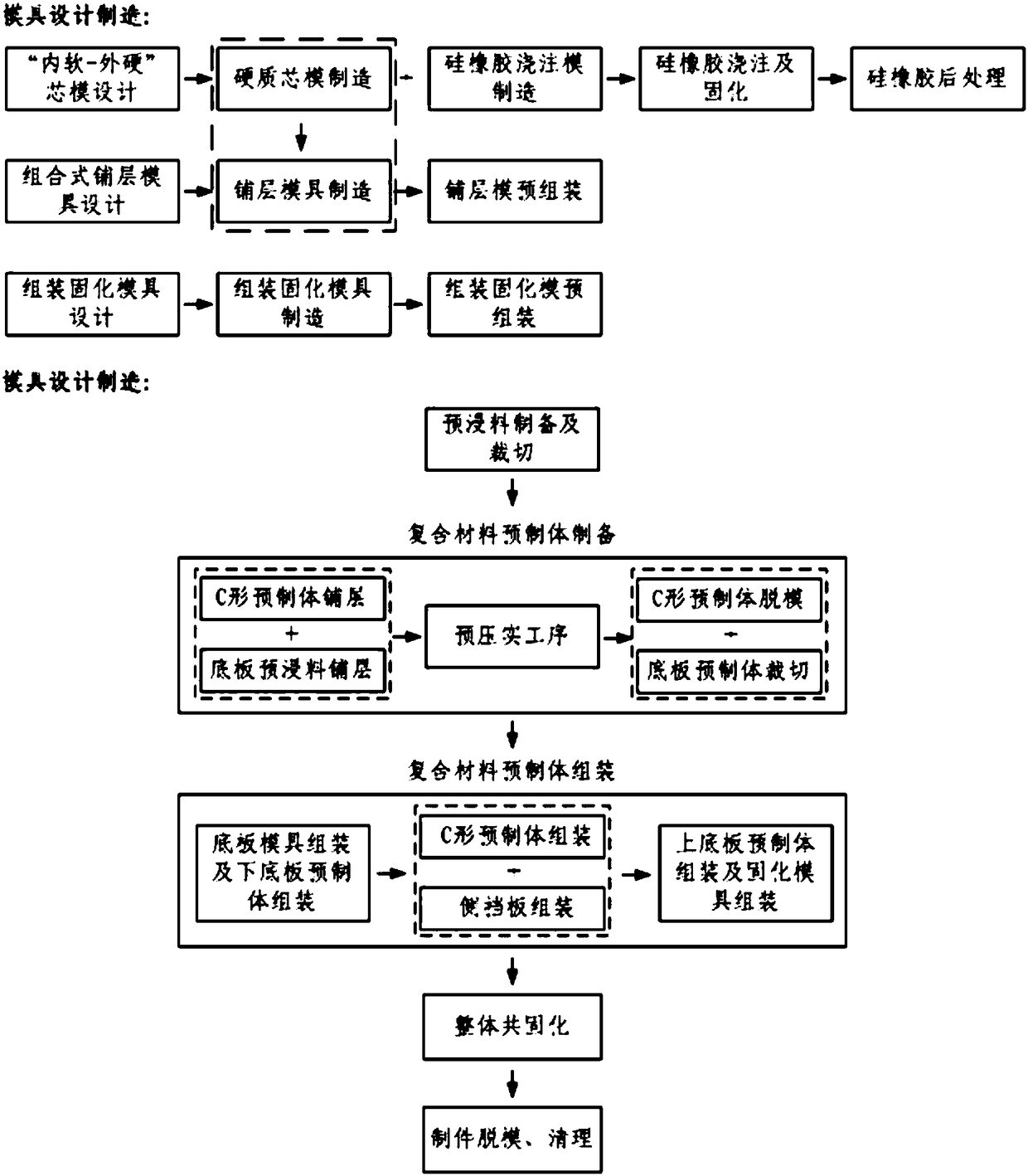

Multi-cavity I-beam and high-precision soft mold forming and defect control method thereof

The invention provides a multi-cavity I-beam and a high-precision soft mold forming and defect control method thereof. Aiming at structural features of multiple cavities, multiple molded surfaces, unequal thickness of marginal / web plates and high precision of molded surfaces inside cavities, silicone rubber soft mold pressurization is adopted to achieve the overall co-curing molding of the I-beamwith a complex structure. The multi-cavity I-beam comprises at least two main beams and at least six secondary beams, the main beams and the secondary beams are in the same plane, the main beams are not intersected with each other, the secondary beams located between the main beams are used for connecting the main beams, and the secondary beams located outside the main beams are used for connecting with the outside; equitable distribution of pressure in the X / Y / Z direction is achieved by adopting silicone rubber soft mold process gap compensation design, and the problem of unequal thickness pressurization of the marginal / web plates is solved; an internal soft-external hard pressure equalization design method is utilized to avoid the pressure deviation caused by uneven expansion of a soft mold, and the dimensional accuracy and internal defects of the molded surfaces inside the cavities are improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

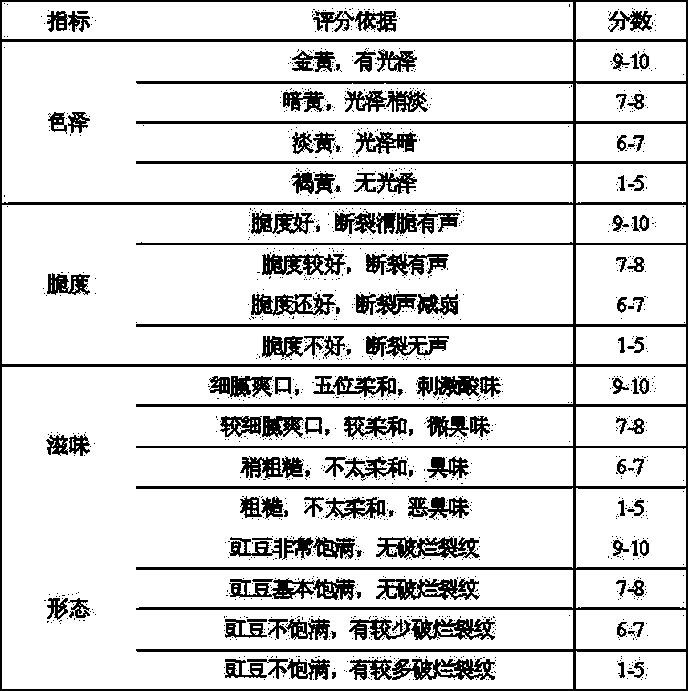

Method for cowpea sauce product with low salt

The invention discloses a method for cowpea sauce product with low salt. The method adopts temperature-reduction low-salt pickling technology, and utilizes the manner of continuously reducing the temperature for three times, decreasing the usage amount of salt, and fermenting and pickling by latterly introduced lactobacillus, not only can the concentration of salt in pickling liquid be effectively reduced, but also the pickling period can be shortened and the quality and flavor can be improved, and the obtained cowpea is crisp and tender and palatable, low-salt, pure in sauce color, abundant in mouth feeling, and high in nutritional value.

Owner:HUBEI UNIV OF TECH

Method and device for pickling salted eggs in pressure circulation manner

The invention relates to a method for pickling salted eggs in a pressure circulation manner. The method comprises the following steps of: cleaning and airing fresh eggs after being tested; sorting, airing, and transferring the eggs into a pickling turnover box; putting the eggs into a sealed pressure tank, adding a saturated salt solution, and beginning to pickle in the pressure circulation manner, wherein the pickling in the pressure circulation comprises the steps of: circularly changing the air pressure inside the tank between constant pressure of 0.1Mpa and the pressure of 0.15Mpa; firstly, pressurizing to be up to 0.15Mpa and maintaining for 10min; and decompressing to be up to the constant pressure of 0.1Mpa for 2-3min, and then maintaining the constant pressure for 20min, so as to finish a regular cycle. The method disclosed by the invention has the advantages of simplicity and reliability; the conventional formulation, and new pressure processing devices and technologies are adopted; the original devices in a factory are fully utilized; a production line with automatic operation can be formed; the pickling period is shortened from 15-40 days to 3-4 days; the product quality is ensured; the dispensing quantity of salt is reduced; picking feed liquid can be reused for 5-6 times after fabrication treatment; and the salt can be saved, and the environmental pollution is also avoided.

Owner:ANHUI IND & TRADE VOCATIONAL TECHN COLLEGE

Low-temperature fast curing polyester moulding compound and preparation method thereof

The invention discloses a low-temperature fast curing polyester moulding compound and preparation method thereof. The solidification process of the material is adjusted by mixing and matching multiple solidified agents and being aided with novel compound polymerization retardor, the demoulding flatness of materials is improved by adding a novel viscosity reduction impregnating compound, and the material moulding process is improved by adding the predispersed step of adding little fiber after the solidifying system, thus ensuring that the moulding temperature obviously reduce to be only 110 DEG C to 130 DEG C on the condition that the polyester moulding compound reserves the original favorable feature; and meanwhile, the solidifying period is shortened to be 8 to 10 S / mm, thus saving the energy and reduces the manufacturing cost for enterprises. The polyester moulding compound of the invention is an energy-saving environmental protection material with excellent mechanical behavior, electrical property and heat resistance. The polyester moulding compound is widely suitable for electrical equipment, instruments and automobile manufacture field, aviation field, traffic field, building field, etc.

Owner:无锡新宏泰电器科技股份有限公司

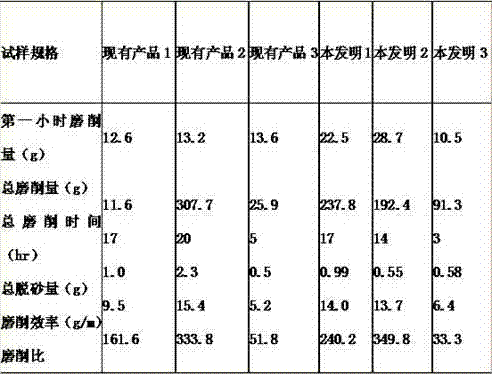

Preparation method for green shallow-cured phenolic resin coated grinding tool

ActiveCN102513943ADecreased responsivenessLow costFibre treatmentAbrasion apparatusPolymer scienceEmulsion

The invention relates to a preparation method for a coated grinding tool, and discloses a preparation method for green shallow-cured phenolic resin coated grinding tool. The preparation method includes steps of treating a base fabric; preparing impregnation liquid; adding from 30 to 50 grams of water-soluble thermosetting phenolic resin and from 70 to 170 grams of water into every 100 grams of PVAC (polymer vinyl acetate) emulsion; realizing once or twice impregnation for the base fabric by the aid of the impregnation liquid, drying and ironing the base fabric after impregnation, realizing press polish, and scratching paste according to conventional process; applying primer; planting sand for a substrate according to conventional process after the primer is applied, drying the substrate planted with the sand at the temperature ranging from 50 DEG C to 60 DEG C for 20 to 25 minutes, then drying the substrate at the temperature ranging from 80 DEG C to 90 DEG C for 15 to 20 minutes and then drying the substrate at the temperature ranging from 100 DEG C to 108 DEG C for 30 to 60 minutes; and gluing again. The primer applied at first consists of components including, by weight percentage, from 20 to 25% of packing, from 45 to 50% of water-soluble thermosetting phenolic resin and from 30 to 35% of water, and primer for the step of gluing comprises components including, by weight percentage, from 50 to 60% of water-soluble thermosetting phenolic resin, from 20 to 30% of calcium carbonate, from 0 to 5% of iron oxide and from 15 to 20% of water. The preparation method has the advantages that cost can be lowered, curing temperature is reduced, curing period is shortened, an adhesion performance is improved, and color is light.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Pickled radish product and low-salt three-section pickling method

ActiveCN104187506ASignificant progressReduce salt contentFood ingredient functionsFood preparationNutritive valuesSalt content

The invention discloses a pickled radish product and a low-salt three-section pickling method thereof. The pickled radish product is prepared from radish by low-salt three-section pickling; the low-salt three-section pickling method can effectively reduce the salt content of the pickled radish product, and shorten the pickling cycle; by use of the temperature control fermentation technology, the flavor main structure can be adjusted, enrichment of head aroma compounds and flavor characteristic flavor substances can be promoted, the effective dissolving out of nutrients can be promoted, the prepared pickled radish product has the advantages of pure color, unique flavor, low salt, high brittleness, and high nutritional value.

Owner:HUBEI UNIV OF TECH

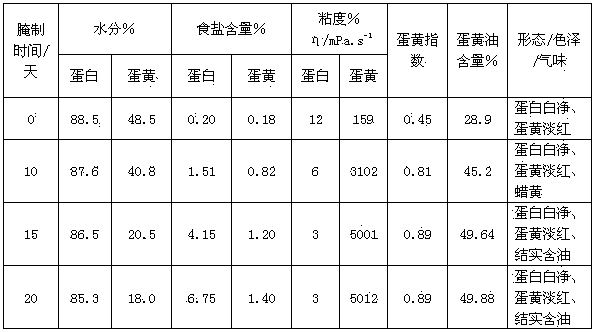

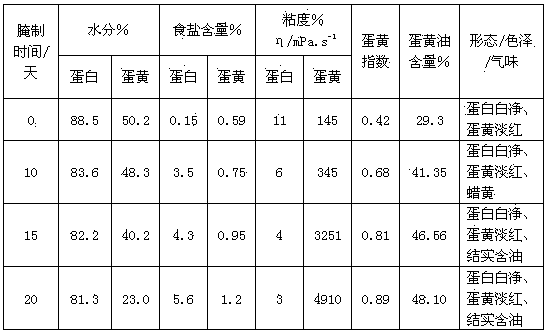

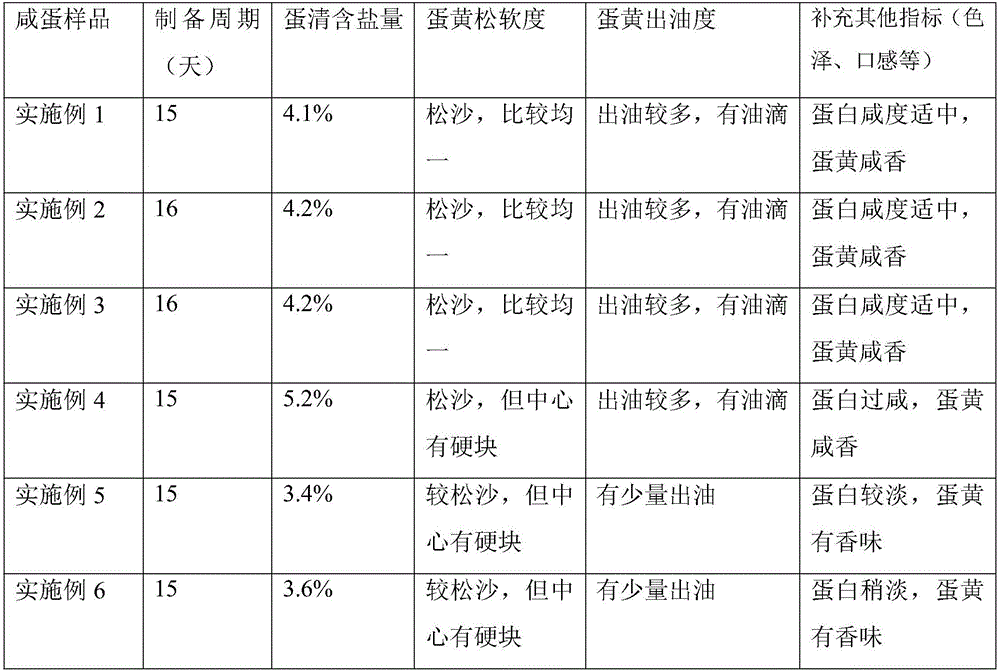

Fast processing method of salted duck eggs

ActiveCN105995616AReduce viscosityImprove permeabilityFood ingredientsFood ultrasonic treatmentHealthy dietYolk

The invention discloses a fast processing method of salted duck eggs and belongs to the field of food processing. The processing method comprises the following steps: 1, fresh duck eggs are washed and graded by weight, and broken duck eggs are removed; 2, the duck eggs are subjected to ultrasonic pre-treatment; 3, the fresh duck eggs are put into a container, mixed with a salting solution A and salted for 7-8 days under a sealed condition, then salting is stopped, and the salting solution is discharged; 4, the salting solution discharged in the step 3 is diluted with water until the concentration of edible salt is 3.0%-4.0%, other salting solution ingredients are added in the dilution proportion, a salting solution B is prepared and injected into the salted duck eggs in the step 3, and the duck eggs are salted for 7-10 days continuously under a sealed condition; 5, the salted duck eggs obtained after the step 4 are sterilized for 20-30 minutes at the temperature of 1-21 DEG C. With the adoption of the method, the salt content of egg white of the salted duck eggs is low, yolk emits oil, is loose and tastes granulated, the salting cycle is shortened, the processing efficiency is improved, and the prepared salted duck eggs meet requirements of modern people for healthy diet.

Owner:JIANGNAN UNIV

Mint coconut fragrant low-salt duck egg and preparation method thereof

The present invention discloses a mint coconut fragrant low-salt duck egg prepared from the following parts by weight of raw materials: 70-80 parts of fresh duck eggs, 10-12 parts of mint leaves, 6-8 parts of strawberries, 8-10 parts of green olives, 4-5 parts of broadleaf holly leaf, 2-3 parts of radix isatidis, 4-5 parts of achene of great burdock, 1-2 parts of calyx seu fructus physalis, 3-4 parts of gotu kola, 2-3 parts of Indian Kalimeris herb, 4-5 parts of loquat flower, 20-30 parts of high-degree Chinese liquor, 40-50 parts of coconut milk, and proper amount of yellow sand, white vinegar and table salt; the duck eggs are soaked with the white vinegar for formation of small holes on eggshell to facilitate the exchange of substances such as salt and the like, then duck eggs are first pickled with a pickle liquid and then pickled with a pickle wine with same salt content with that of the pickle liquid, the osmotic pressure of egg white and the osmotic pressure outside the shell are consistent, so that salt permeates into egg yolk for dehydration of the egg yolk, salt content of the egg white may not rise, the first phase is quickly completed by vacuum pickling, by addition of the Chinese liquor, the coagulation of protein is accelerated, the egg yolk releases oil quickly, the egg white of cooked salted duck eggs tastes appropriate, the egg yolk is loose, oily and smooth, and the mint coconut fragrant low-salt duck egg is overflowed in liquor aroma, rich in coconut flavor, and rich in mint flavor.

Owner:柳培健

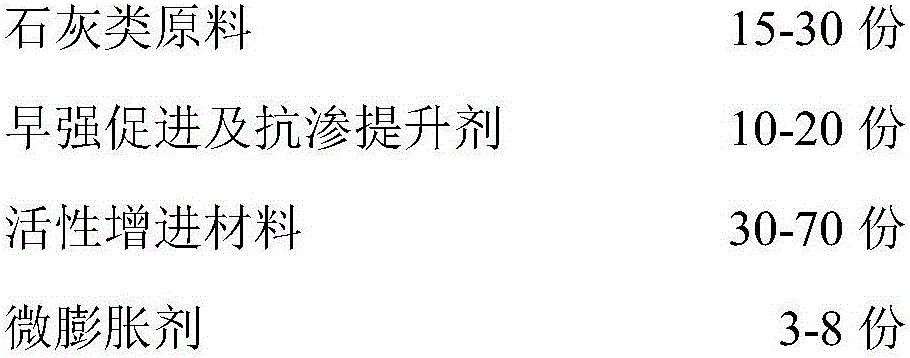

Early-strength micro-expanding type soil solidifying agent and preparation method thereof

InactiveCN106747190AAchieving micro-expansion propertiesPrevent shrinkage crackingShrinkage crackingSlag

The invention discloses an early-strength micro-expanding type soil solidifying agent and a preparation method thereof. The soil solidifying agent is prepared from the following raw materials in parts by weight: 15-30 parts of a lime raw material, 10-20 parts of an early-strength promoting and anti-permeability promoting agent, 30-70 parts of an active enhancing material and 3-8 parts of a micro-expanding agent, wherein the lime raw material is any one or mixture of slaked lime, quick lime and carbide slag; the early-strength promoting and anti-permeability promoting agent is rice hull ash or white carbon black or a combination of the rice hull ash and the white carbon black; the active enhancing material is coal ash or slag powder or a combination of the coal ash and the slag powder; the micro-expanding agent is a gypsum material. By virtue of the actions of the early-strength promoting and anti-permeability promoting agent and the like, the early strength of a soil body solidified by virtue of lime soil solidifying agents is remarkably enhanced, the solidifying period is shortened, and the water stability of the soil body is improved; the sustainable growth of the strength of the solidified water body is realized, and meanwhile, the soil solidifying agent has the micro-expanding property, so that the shrinkage cracking is inhibited; by utilizing a large number of solid waste such as carbide slag, coal ash, slag, rice hull ash and ardealite, the economic and environment-friendly benefits are remarkable.

Owner:WUHAN UNIV OF TECH

Preserved pork ribs

The invention discloses preserved pork ribs, and relates to food, in particular to food made of pork ribs. The preserved pork ribs are prepared by the following steps of: preparing raw materials, pickling, and air-drying. According to the preserved pork ribs prepared by the process, nitrate for the traditional pickling is replaced by iodized table salt, and relatively low salt consumption is adopted; the preserved pork ribs prepared by the process are low in salt content, and the content of nitrite of the preserved pork ribs is far lower than the national related standard; and the pickling period of the preserved pork ribs is shortened, the pickling quality is improved, and the preserved pork ribs can be massively produced to meet daily increasing eating requirements.

Owner:芮茂能

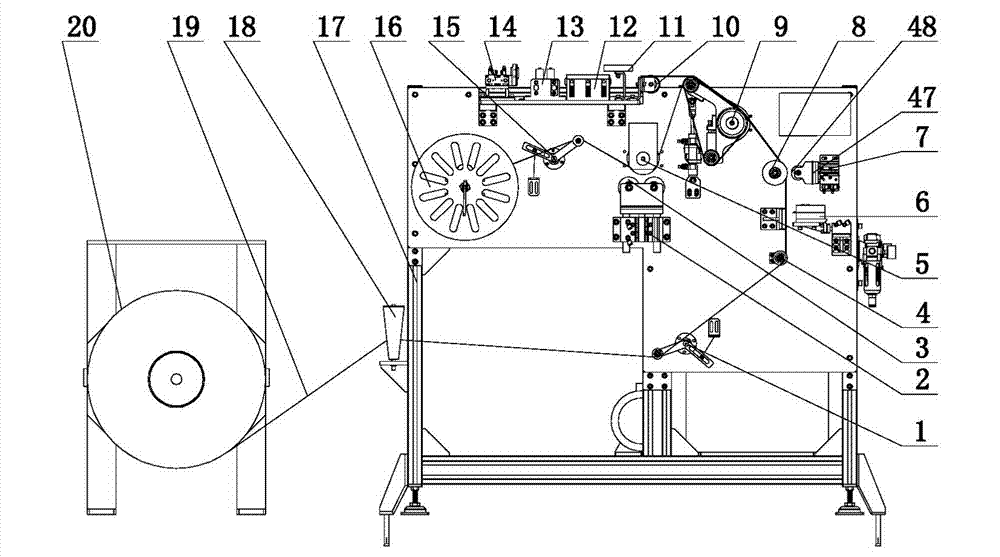

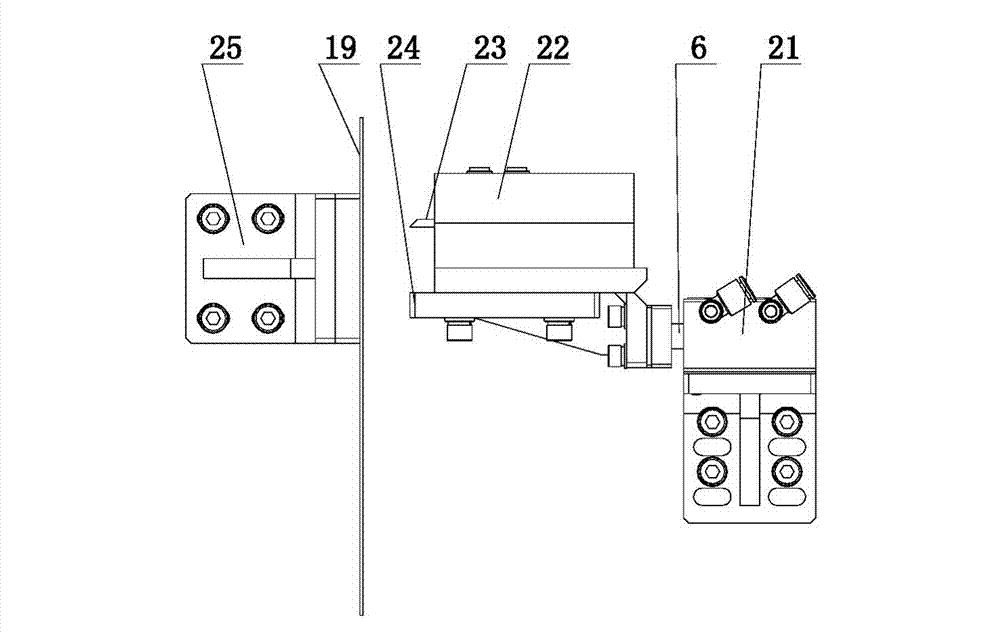

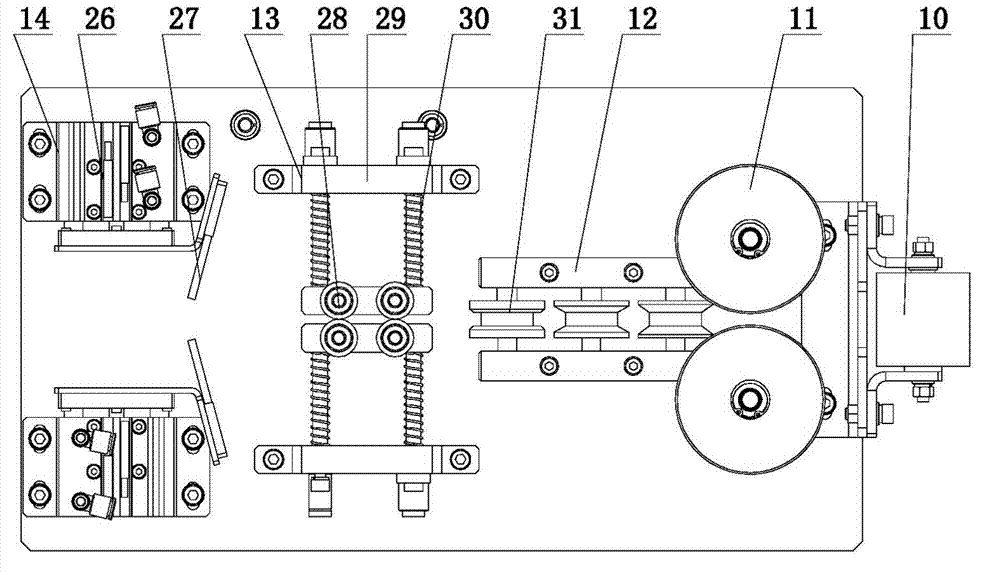

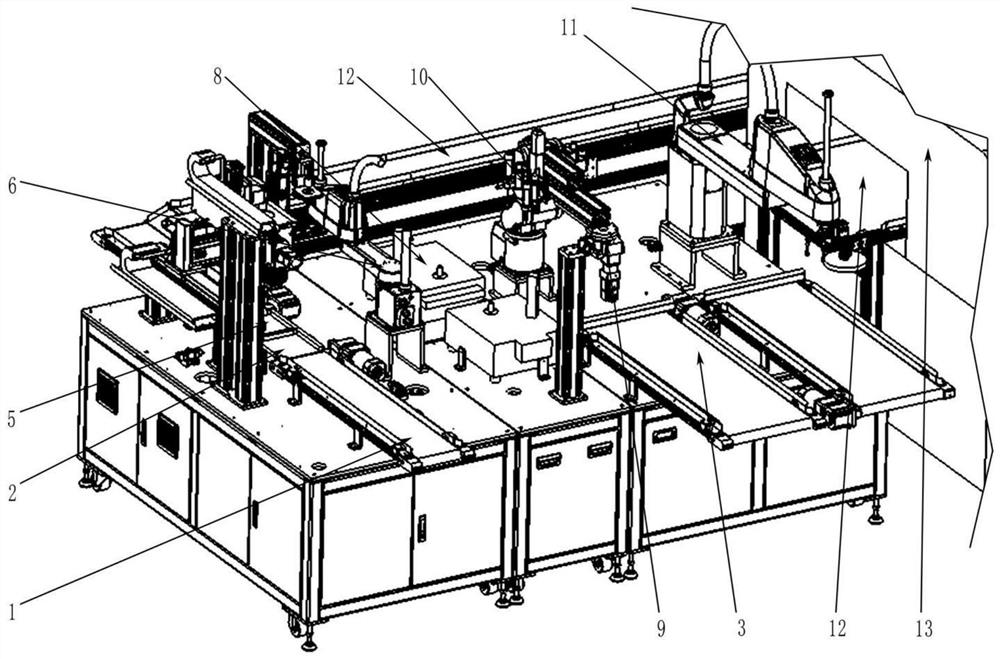

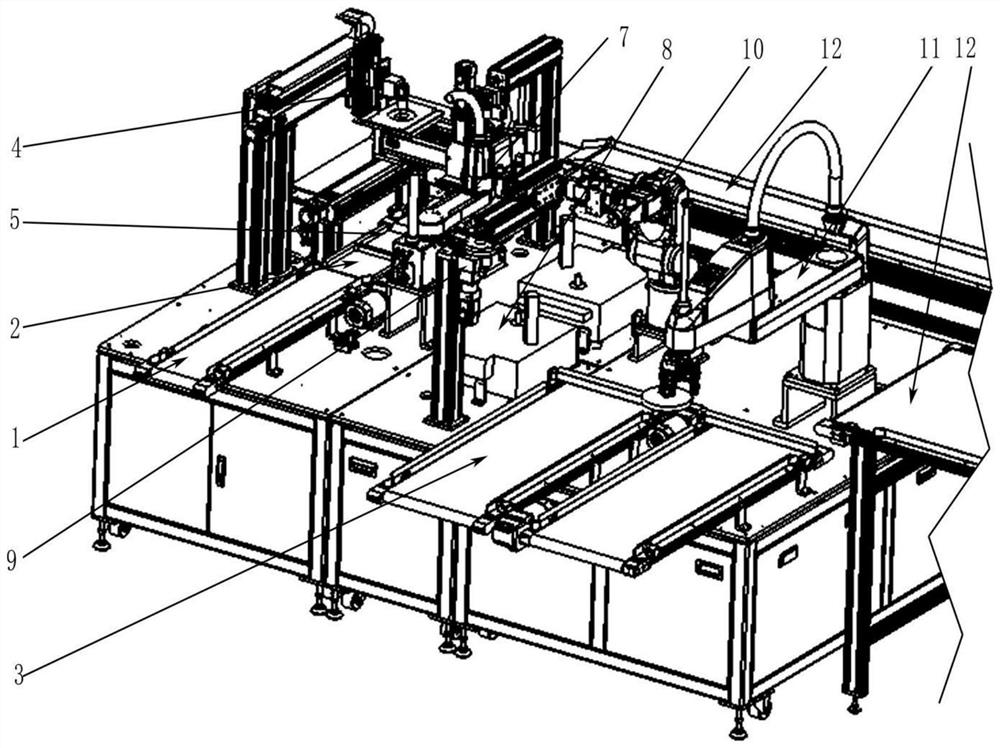

Solar cell assembly substrate automatic sealing-tape machine

The invention provides a device capable of wrapping sealing tape on the periphery of a cell substrate and relates to automatic production devices in the field of photovoltaic, in particular to a solar cell assembly substrate automatic sealing-tape machine. The solar cell assembly substrate automatic sealing-tape machine comprises an unwinding device and an edge wrapping device corresponding to the unwinding device and is characterized in that the edge wrapping device comprises a frame. A guiding device corresponding to the unwinding device is arranged on the frame, and a shearing device corresponding to the guiding device is arranged on the frame. An edge wrapping component is arranged at the upper end of the frame, and an active sealing tape pulling device is arranged on the frame below the edge wrapping component.

Owner:YINGKOU JINCHEN MACHINERY

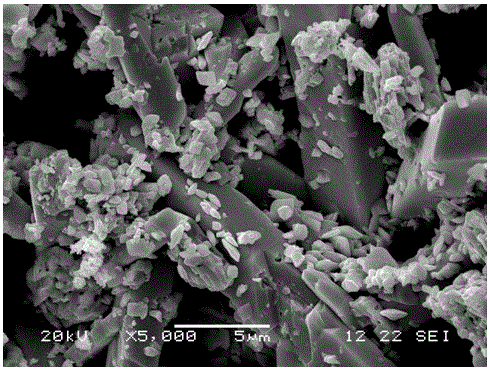

Structure of integral boron carbide bulletproof plugboard and ceramic pretreatment process

The invention relates to a structure of an integral boron carbide bulletproof plugboard and a ceramic pretreatment process, and belongs to the field of individual soldier human body protection products. The integral boron carbide bulletproof plugboard structure comprises a face packaging layer, a super-strong damping layer, a bulletproof ceramic super-strong constraint body and a bulletproof fiberlaminated board. On the surface of the bulletproof ceramic, a bulletproof fiber filament is adopted for carrying out full-circumference constraint winding, and a bulletproof ceramic super-strong constraint body is formed. The bulletproof ceramic super-strong constraint body and the bulletproof fiber laminated board are bonded by adopting an adhesive, so that the bonding strength of the compositeinterface of the bulletproof ceramic super-strong constraint body and the bulletproof fiber laminated board is ensured. The integral boron carbide bulletproof plugboard obtained by adopting the structure and the ceramic pretreatment process is excellent in anti-foaming bullet attack performance, the integral boron carbide can still keep a whole under the protection of an ultra-strong constraint when being hit by a first gun, a second gun and a third gun are protected with a relatively complete ceramic large block, and finally the problem that the anti-multiple elastic capability of the bulletproof ceramic whole plate is insufficient is solved.

Owner:中硼科技(大连)有限公司

AGM (absorptive glass mat) switch on-off storage battery positive plate curing process

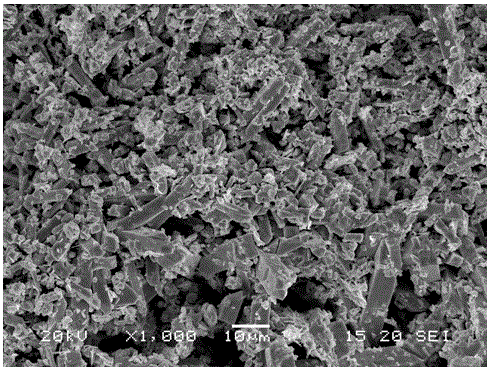

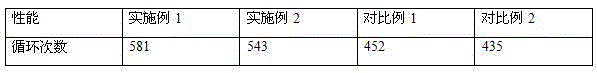

ActiveCN105070886AHigh bonding strengthImprove cycle lifeLead-acid accumulator electrodesHigh humidityMechanical engineering

The invention discloses an AGM (absorptive glass mat) switch on-off storage battery positive plate curing process. The process comprises a medium-temperature high humidity stage, a low-temperature high humidity stage, a medium-temperature humidity exhaust stage and a high-temperature drying stage. With the curing process, excellent bonding strength can be obtained between positive plate lead plaster and between lead plaster and the surface of the grid, 4BS crystals with controllable number and sizes can be formed, the size of the formed 4BS crystals is within 10-25 mu m, and the cycle life of the battery is prolonged; in addition, the total time of the curing process is controlled within 40-55h, so that the curing period is shortened, and the production efficiency is improved.

Owner:CAMEL GRP XIANGYANG BATTERY

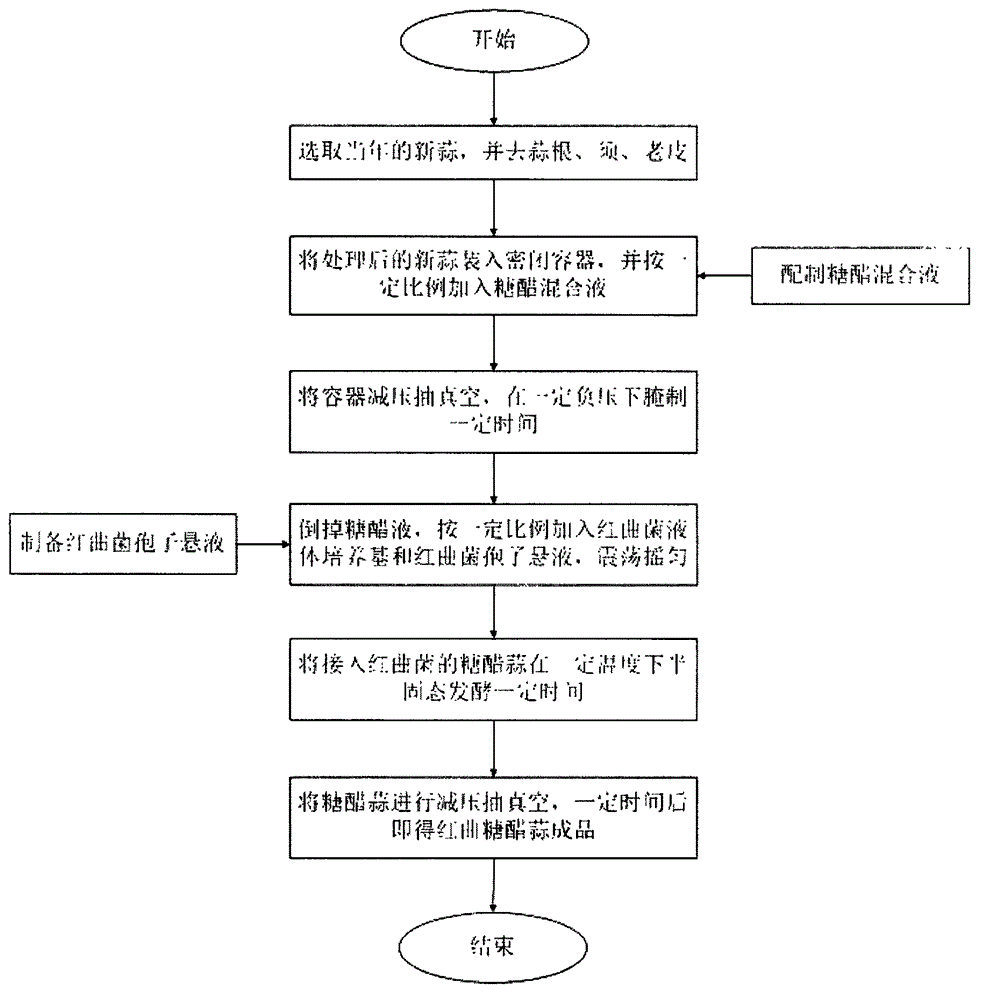

Making method of monascus sweet and sour garlic

InactiveCN104686974AImprove and enhance nutritional valueImprove and enhance health functionFood preparationSporeAdditive ingredient

The invention relates to a making method of monascus sweet and sour garlic. The method mainly includes the steps of adding sugar and vinegar mixed liquor in appropriate proportion into a closed container with fresh garlic, making sweet and sour garlic through a depressurization vacuumizing method, removing the sugar and vinegar mixed liquor, adding a monascus fluid medium in certain proportion, adding monascus spore liquid in appropriate proportion, fermenting for a certain period of time at a certain temperature, conducting depressurization vacuumizing, removing the fermenting liquid, and obtaining the monascus sweet and sour garlic. The monascus sweet and sour garlic made through the method is red and bright in color and luster, unique in flavor and crisp and tender in taste and has functional components of monascus. The making method is short in cycle and simple and easy to implement and has good economic value.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

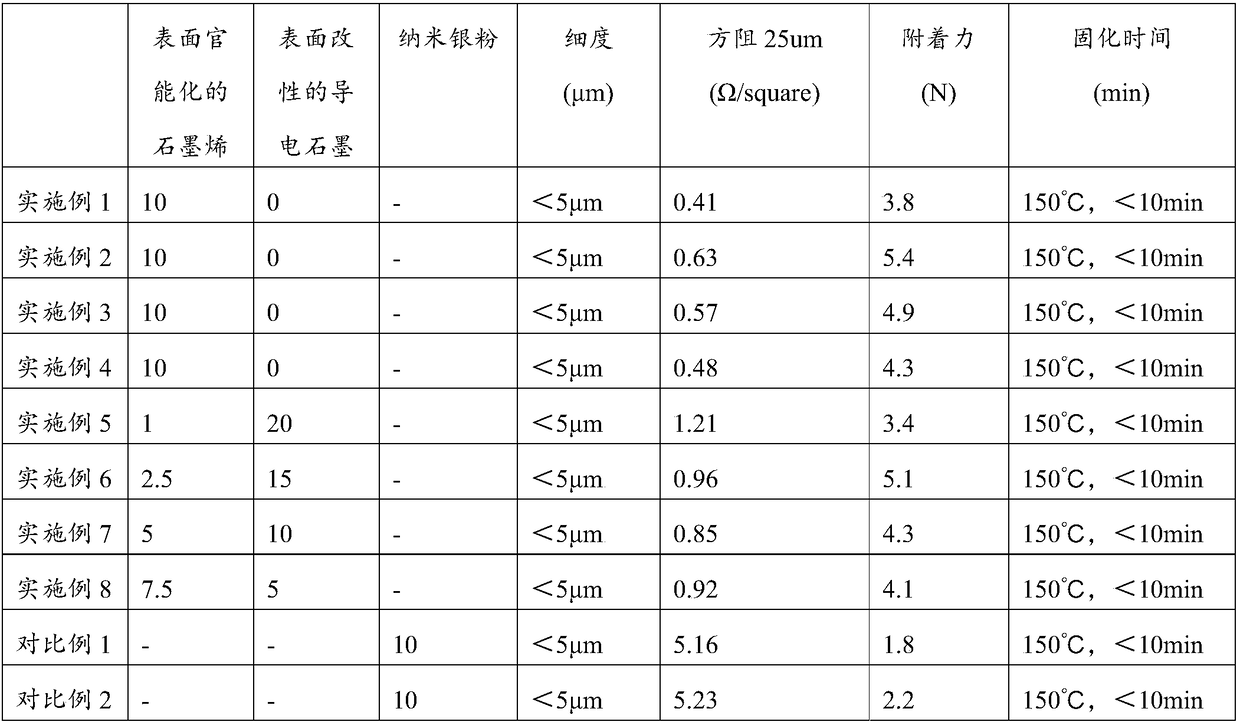

Graphene conductive paste and preparation method thereof

ActiveCN108257710AExcellent bonding strengthGood flexibility and resistance to photothermal degradationNon-conductive material with dispersed conductive materialCable/conductor manufactureSilane couplingSiloxane

The application relates to the field of conductive pastes, in particular to a graphene conductive paste. The graphene conductive paste comprises the following components, by weight: 1 to 10 parts of epoxy-functionalized graphene, 4 to 15 parts of epoxy resin, 2 to 6 parts of epoxy-modified siloxane, 2 to 6 parts of epoxy reactive diluents, and 0.1 to 0.8 parts of latent curing agents. Furthermore,the graphene conductive paste also includes 5 to 20 pars, by weight, of conductive black modified with a silane coupling agent. In addition, the application also provides a method for preparing the graphene conductive paste. The method includes: carrying out epoxy functionalization of graphene powder; carrying out epoxy modification of siloxane; carrying out mixing and stirring of all components;and carrying out conductive black modification. According to the graphene conductive paste provided by the application, the high dispersibility of graphene and good adhesion of the conductive paste are realized; and with the conductive black, the amount of graphene is reduced and the cost is lowered.

Owner:SHENZHEN HOVERBIRD ELECTRONICS TECH CO LTD

Method for processing marinated fruits and vegetables

ActiveCN103637134AImprove penetration efficiencyReduce salinityFood dryingFood ultrasonic treatmentBiotechnologyBiology

The invention discloses a method for processing marinated fruits and vegetables. The method comprises the following steps: selecting, cleaning, drying and cutting marinating raw materials, adding edible salt and pure water, and marinating the raw materials by virtue of three-frequency ultrasonic assistance to obtain marinated fruits and vegetables, wherein the three-frequency ultrasonic assistance is specifically as follows: the upper marinating layer is 20-30KHz, the middle marinating layer is 90-100KHz, and the lower marinating layer is 50-60KHz, namely the upper layer is 10-30cm deep, the middle layer is 30-80cm deep, and the lower layer is 80-100cm deep; taking out marinated fruit and vegetable embryos and centrifugally removing water; putting the marinated fruit and vegetable embryos into a cylinder to implement natural fermentation so as to obtain fermented marinated fruit and vegetable products; performing seasoning preparation, microwave drying and packaging. According to the method disclosed by the invention, the marinated fruits and vegetables are processed by a three-frequency ultrasonic assistance marinating technology and a microwave drying technology; compared with the prior art, the method has the advantages that the salinity of a product is reduced, the production efficiency is improved, the production period is shortened, and the product quality is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

Spicy low-salt duck eggs and making method thereof

The invention discloses spicy low-salt duck eggs. The spicy low-salt duck eggs are prepared from, by weight, 60-70 parts of fresh duck eggs, 8-10 parts of red pepper, 6-8 parts of green red pepper, 4-5 parts of vanilla powder, 5-6 parts of pepper leaves, 2-3 parts of common cnidium fruit, 1-2 parts of hairyvein agrimonia herb and buds, 4-5 parts of pericarpium granati, 1-2 parts of herba polygoni avicularis, 2-3 parts of sessile stemona roots, 3-4 parts of elm seeds, 20-30 parts of hot pepper oil, 30-40 parts of high-degree baijiu, an appropriate amount of yellow sand, an appropriate amount of white vinegar and an appropriate amount of salt. The duck eggs are soaked the white vinegar, and small holes are formed in egg shells, so that exchange of substances of salt and the like is facilitate; the duck eggs are pickled through pickling liquid and pickling wine of which the salt content is the same as that of the pickling liquid, due to the fact that the osmotic pressure of egg white is in accordance with that outside the shells , the salt penetrates into egg yolks to make the egg yolks dewatered, and the effects of achieving looseness and oil formation are achieved; the salt content of the egg white does not rise any more, decompressing pickling is adopted to enable the first stage to be completed rapidly, baijiu is added, protein coagulation is accelerated, oil is rapidly generated in the egg yolks, and the cooked salted duck eggs are appropriate in mouthfeel, the egg yolks are loose and rich in oil, wine fragrance is rich, and the spicy low-salt duck eggs are spicy and delicious.

Owner:柳培健

Method for sousing vacuum-soused spiced green tea salted duck eggs

The invention discloses a method for sousing vacuum-soused spiced green tea salted duck eggs. The method comprises the following steps of manufacturing mixed media according to raw materials, by weight, 45-51 percent of fine salt, 25-30 percent of green tea, 3-5 percent of Chinese prickly ash, 6-8 percent of anise, 5-7 percent of cinnamon, 5-8 percent of white sugar and 5-8 percent of aginomoto; mixing and smashing the raw materials except the fine salt, screening the mixture through a 50-mesh sieve, then fully mixing the mixture and the fine salt as mixed media for using; selecting duck eggs which are clean, fresh, free of flaw and about 70+ / -5 grams weight, steeping the eggs in white spirits of 60 degrees for twenty to thirty minutes, scooping up the eggs and laying the eggs on a bamboo sieve, using white spirits remaining on the surfaces of the eggs as adhesive, rolling the duck eggs as fast as possible to sieve the mixed media on the surfaces of the eggs evenly, wherein adopted amount of the mixed media on each egg is 5.4 grams to 6 grams on average, putting the eggs into plastic packaging bags in a sleeved mode to carry out single independent vacuum packaging, and finally putting the eggs in a constant temperature room with the temperature of 37 DEG C to 39 DEG C and carrying out storage and curing for 16 days to 18 days to finish sousing. The finished products are low in salt content, the salinity of egg white and yolk is even, and adopted materials are economical.

Owner:沈正一

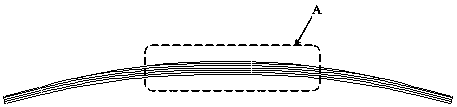

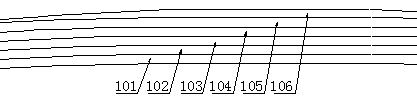

Process for high-efficiency molding of composite plate spring

ActiveCN108928012AIncrease productivityRealize automated mass productionDomestic articlesCompression moldingEngineering

The invention discloses a process for high-efficiency molding of a composite plate spring. The process comprises the following steps: (1) subjecting a plate spring to modeling and carrying out layeredmodeling on a plate spring model from bottom to top; (2) preparing a curved-surface workbench according to each single-layer model; (3) separately carrying out paving and pasting on each curved-surface workbench by using an automatic tape laying machine so as to form a whole piece of a blank material and cutting the whole piece of the blank material with a cutting machine so as to form a plurality of single blank materials with the same structure; and (4) piling up the plurality of single blank materials and carrying out compression molding so as to form the plate spring. With such a technical scheme, the process for high-efficiency molding of the composite plate spring greatly improves the production efficiency of the composite plate spring prepared through molding and can realize automatic batch production of the composite plate spring.

Owner:AVIC COMPOSITES

Low-salt temperature change curing method of leaf mustard sauce products

ActiveCN104026522AReduce salt contentShorten curing cycleFood preparationBiotechnologyNutritive values

The invention discloses a low-salt temperature change curing method of leaf mustard sauce products. The leaf mustard sauce product comprises the following raw materials in parts by weight: leaf mustard 280-300, Welsh onion 30-40, garlic 20-30, five spice powder 15-25, red Chilli powder 10-20, pepper powder 7-15, oyster juice 10-15, vegetable oil 10-15, and salt 15-30. The curing method adopts the low-salt temperature change curing technology and the multi-strain coupling fermentation technology and also adopts three-time cooling salt-reduction and two-time desalination way, so as to effectively reduce the salt content of the sauce pickles and shorten the curing period; with regard to the multi-strain coupling fermentation technology, the multiple pure strain mixing starter-making can be artificially controlled, the period can be shortened, and the quality and flavor can be improved, so that the obtained leaf mustard sauce products have features of pure sauce color, low salt, high crispness, rich essential amino acids and diet fibers, unique flavor and high nutrition value.

Owner:HUBEI UNIV OF TECH

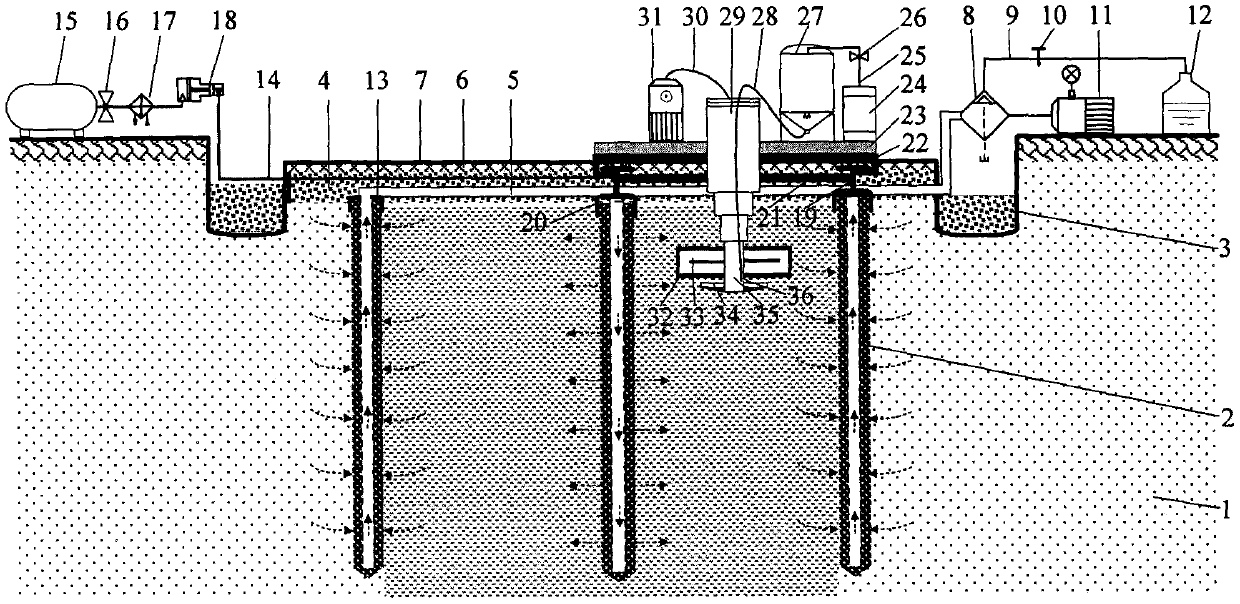

Reinforcing method of vacuum preloading lead pipe pile gas injection carbonized super-soft foundation

ActiveCN110512591AImprove compactionImprove displacement effectSoil preservationSites treatmentResource utilization

The invention discloses a reinforcing method of a vacuum preloading lead pipe pile gas injection carbonized super-soft foundation, and belongs to the technical field of super-soft foundation reinforcing treatment of geotechnical engineering. The reinforcing method comprises the steps of site treatment and exploration, first pile group construction and beating, spraying mixing equipment placement and debugging, curing agent spraying and mixing, first treatment system layout, vacuum preloading-gas injection carbonized treatment, first site treatment completing, continuous construction, final treatment and the like. The reinforcing method has the advantageous of a vacuum preloading method, a magnesium oxide carbonization curing method and a pipe pile composite foundation, the drainage efficiency and the infiltration diffusion efficiency of carbon dioxide are greatly improved through coordination work of vacuum preloading and pipe pile gas injection, the compacting displacement action of apipe pile on soft soil is fully utilized, mud soil is effectively glued through hydration products and carbonization products, thus the intensity of the soft soil composite foundation is enhanced, and the stability is improved. The reinforcing method has the characteristics that the treatment effect is good, the period is short, and low-carbon and environmentally-friendly and economic efficiencyare achieved, and resource utilization of industrial waste in soft foundation treatment is achieved.

Owner:NANJING FORESTRY UNIV

Potherb mustard-pickled product and low-salt fast pickling method thereof

ActiveCN104172038AAdvantages and Notable ImprovementsReduce nitrite levelsFood preparationBiotechnologyMicrobiology

The invention discloses a potherb mustard-pickled product and a low-salt fast pickling method of the potherb mustard-pickled product. The potherb mustard-pickled product is prepared by adopting a low-salt fermentation pickling technology three times, low-salt fermentation pickling is performed at different temperatures in the first time and the second time, a mixture of garlic, ginger, red hot chili pepper and pricklyash peel is added in the third time and then lactobacillus plantarum is inoculated for performing low-salt fermentation pickling. By adopting the low-salt fermentation pickling technology three times, the content of nitrites in potherb mustard is reduced, the pickling period is shortened, and the potherb mustard and other auxiliary materials can be fully fermented, so that the quality and the flavor of the potherb mustard are improved.

Owner:HUBEI UNIV OF TECH

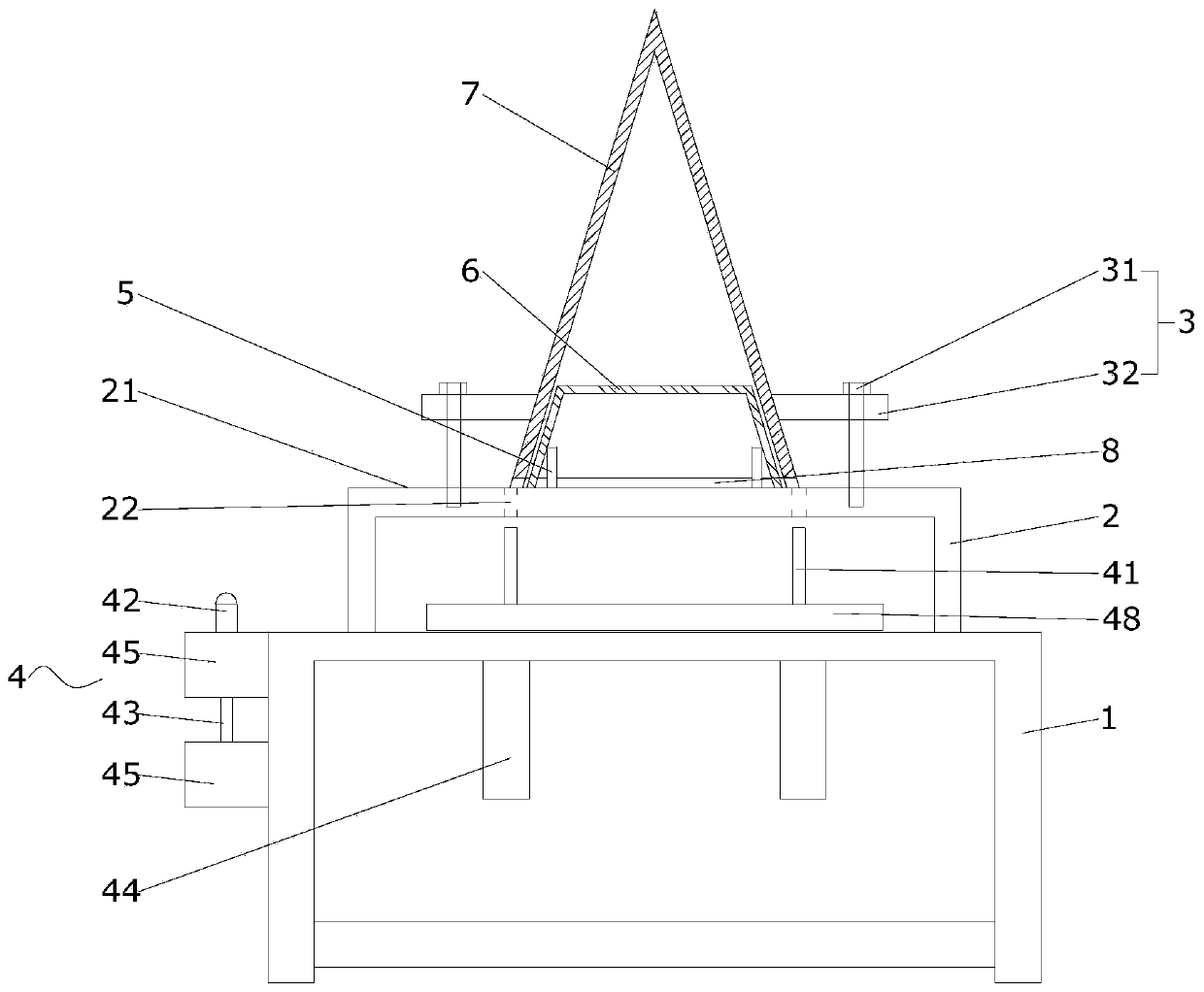

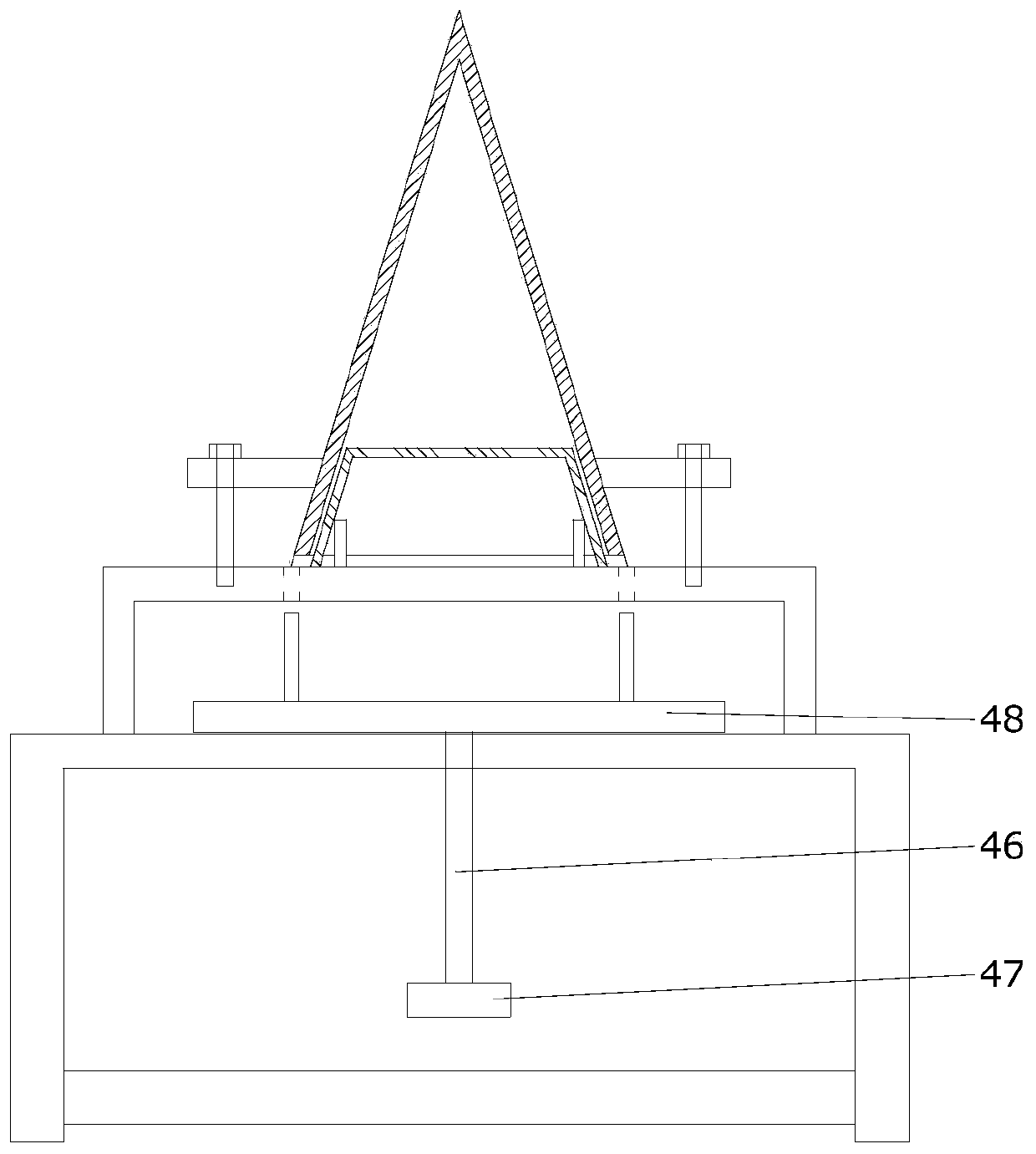

Radome bonding tool and bonding method thereof

The invention discloses a radome bonding tool. The radome bonding tool is characterized in that a bonding platform is installed on a base, a positioning piece is arranged on the working face of the bonding platform so as to position a metal ring, a lifting device is arranged below the bonding platform, the lifting device comprises jacking columns, the jacking columns are upwards lifted to penetrate through the bonding platform and support a radome placed over the metal ring, and a fastening device is installed on the bonding platform, is located around the radome and abuts against the radome.Meanwhile, the invention discloses a method for bonding the radome by using the bonding tool. Bonding is carried out through forward mounting of the radome, the bonding effect between the radome and the metal ring is excellent, the situation that an adhesive flows to the inner wall surface of the radome is avoided for a formed product, and the cost control optimization caused by the use of the adhesive is reduced; the bonding process shortens the curing period and is beneficial to mass production; and by using the bonding tool, manual contact with the radome is reduced, the human risk is reduced, the labor cost is reduced, and the mechanization level is improved.

Owner:FESHER AVIATION COMPONENTS ZHENJIANG

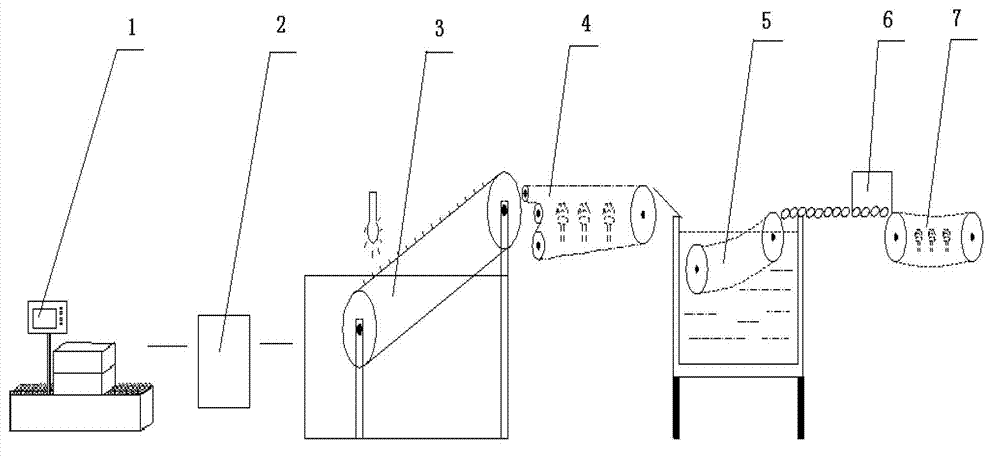

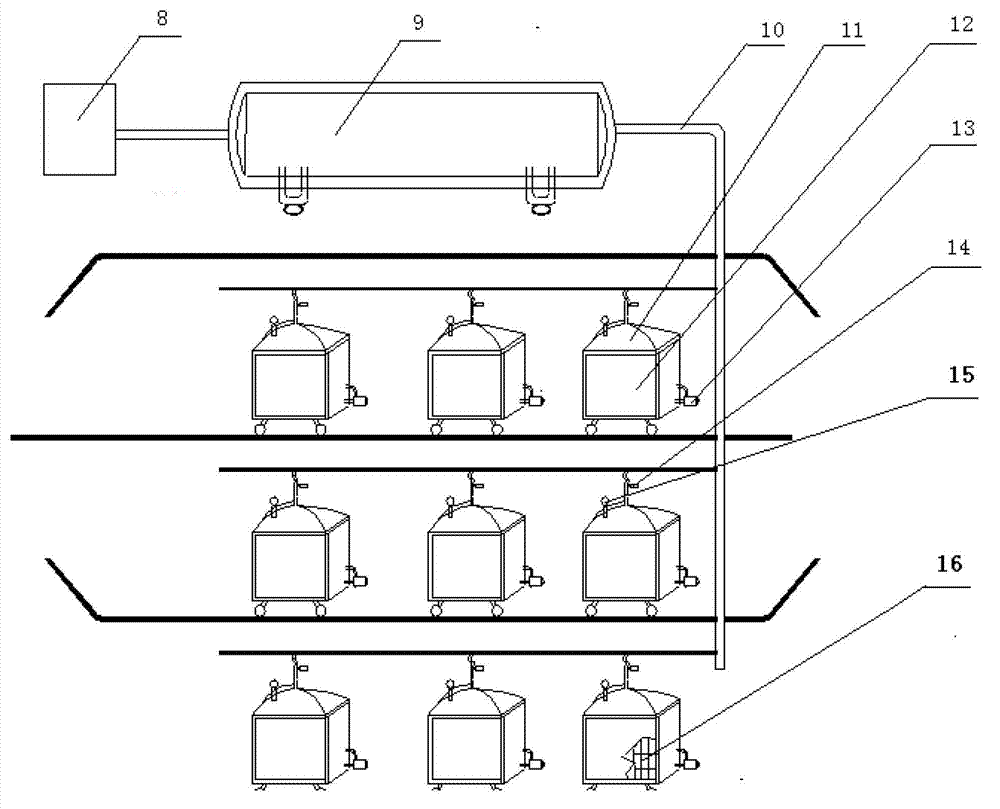

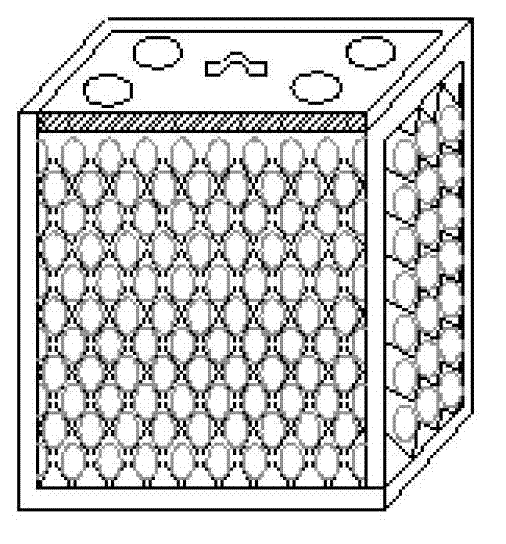

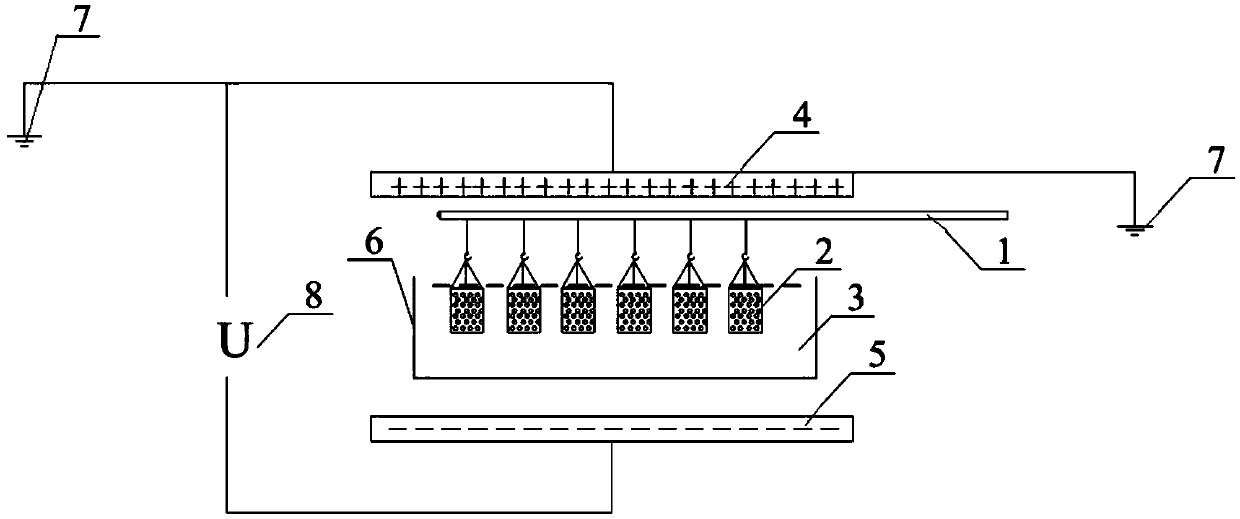

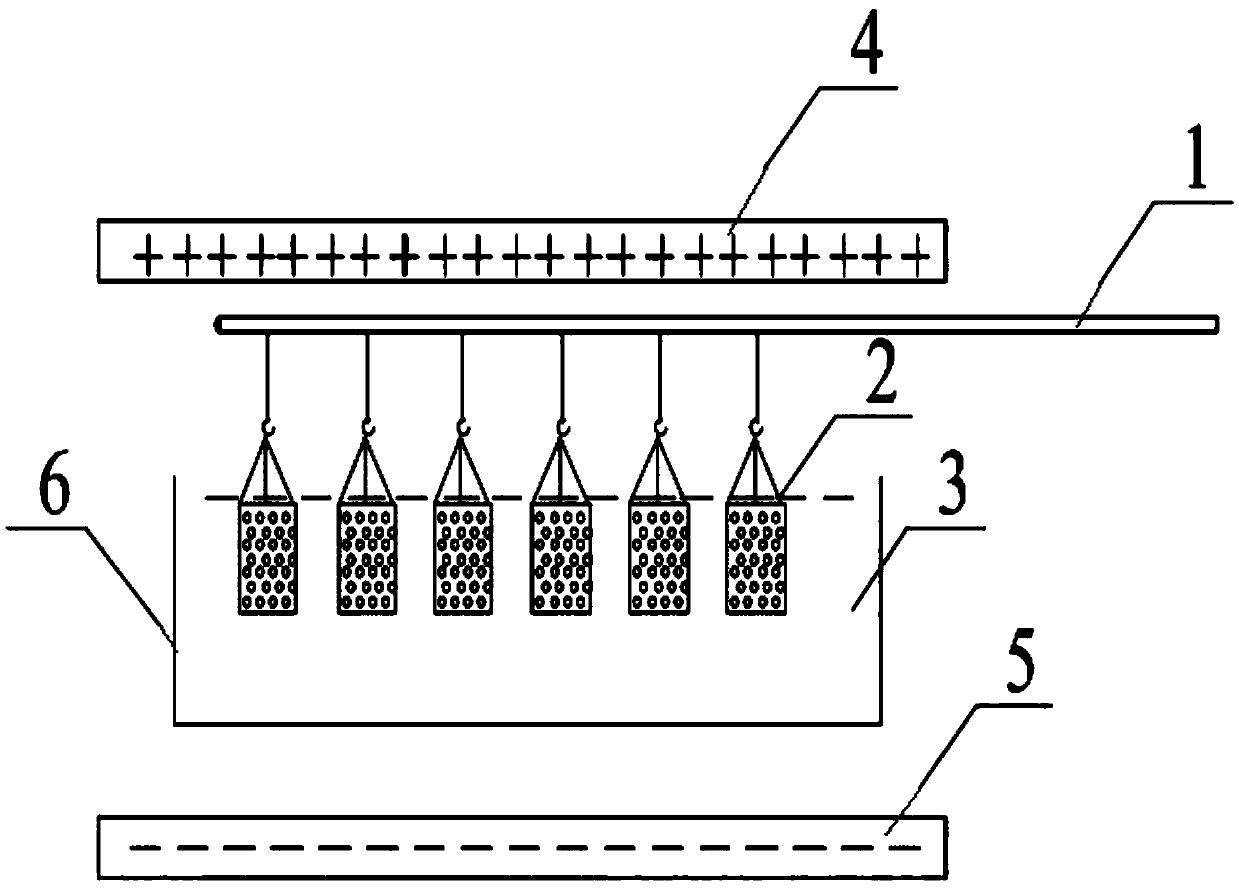

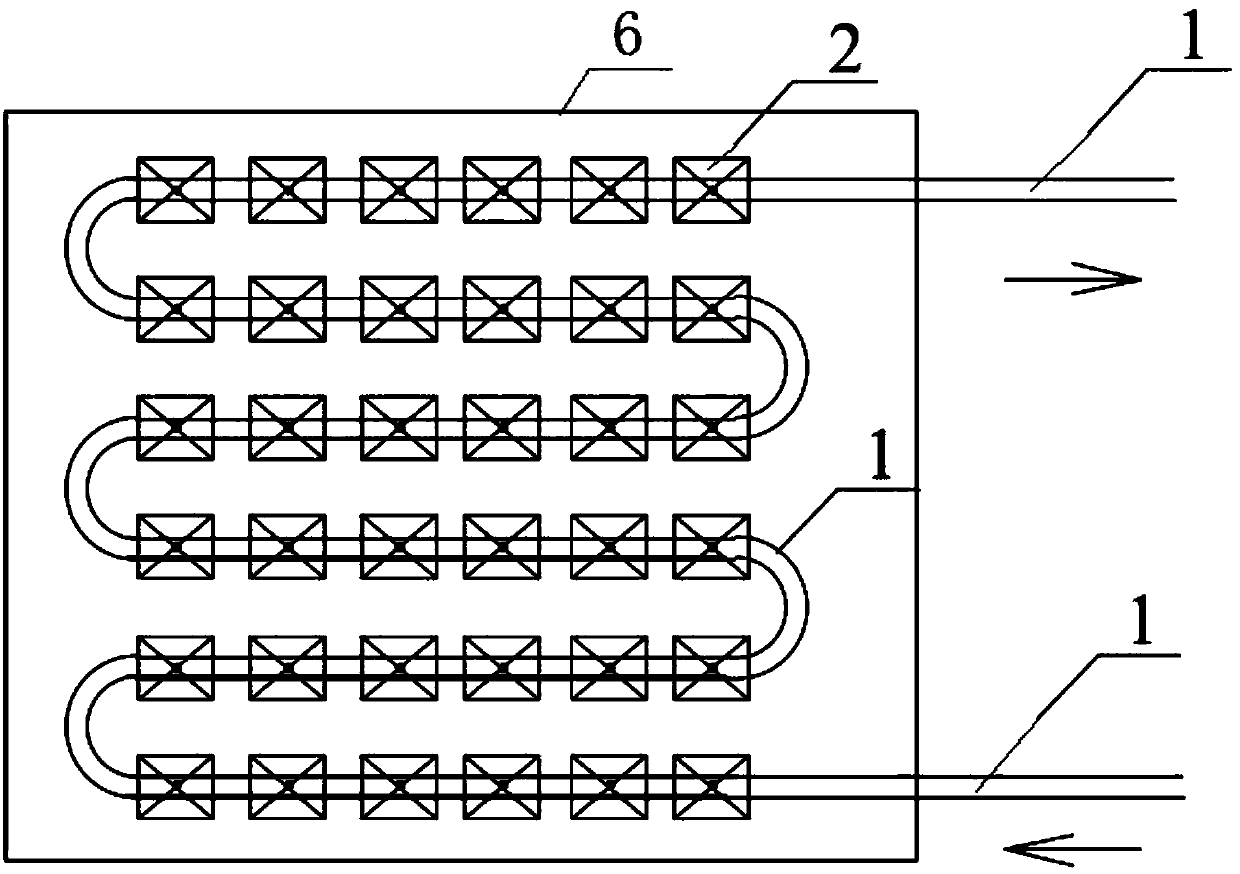

Rapid reformed egg manufacturing system and method using medium-high voltage electric field

The invention relates to a rapid reformed egg manufacturing system and method using a medium-high voltage electric field. The system comprises an overhead rail delivering system, a medium-high voltageelectric field pickling system, and a washing system. Eggs to be processed is introduced into the system from the input end of the overhead rail delivering system; the output end of the overhead raildelivering system is connected to the input end of the washing system; the medium-high voltage electric field pickling system is arranged between the overhead rail delivering system and the washing system; the overhead rail delivering system can drive the eggs to go through the medium-high voltage electric field pickling system; eggs are pickled in the medium-high voltage electric field picklingsystem after the eggs enter the medium-high voltage electric field pickling system; and the washing system can wash and dry pickled eggs. The structure is simple, the operation is convenient, automation is easy to realize; the system can be applied to production lines in a factory, the efficiency is high, energy is saved, environment is protected, industrial production is easy to realize, and thesystem can be applied to large scale production of reformed eggs.

Owner:TIANJIN UNIV OF SCI & TECH

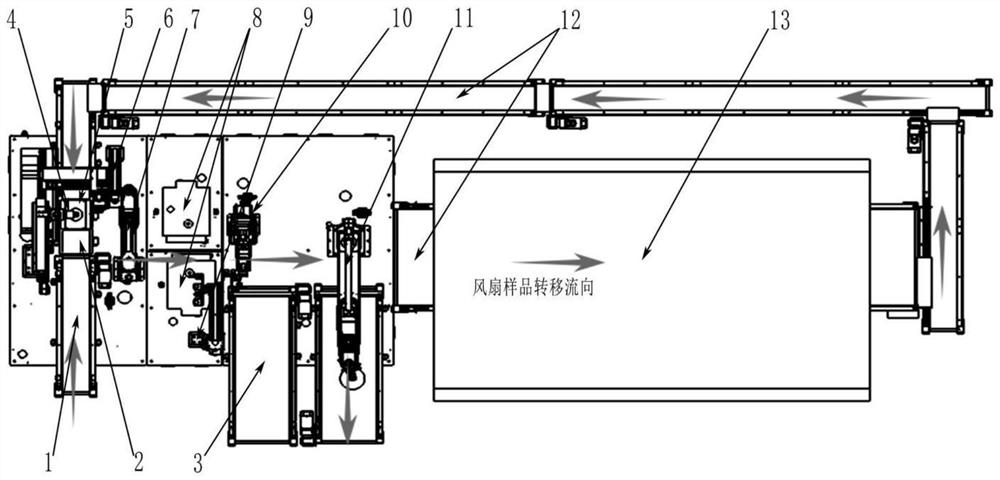

Fan sample balance test glue supplementing equipment

InactiveCN112371449AIncrease productivityQuality assuranceLiquid surface applicatorsStatic/dynamic balance measurementProcess engineeringMachine

The invention discloses fan sample balance test glue supplementing equipment, and relates to the field of fan manufacturing. The fan sample balance test glue supplementing equipment comprises a balance test machine, a transfer mechanism for transferring fan samples, a glue dispensing mechanism for supplementing unqualified fan samples with glue and a central controller. The balance test machine isused for testing the balance degree of fan samples, the glue supplementing position and the glue supplementing amount of the unqualified fan samples are determined and transferred to the glue supplementing position of the glue dispensing mechanism, quantitative flexible precise glue supplementing is carried out at the glue supplementing position of the fan samples through the glue dispensing mechanism, finally, the fan samples are transferred to a constant-temperature and constant-humidity test box for solidification after glue supplementing, the solidification period is shortened, after gluesupplementing is completed, the balance degree of the fan samples is tested again through the balance test machine till the fan samples are qualified, and the situation that the defect position is determined manually in the past, then solid balance soil is cut manually through hand feeling, and then the solid balance soil is plugged into the defect position is changed; and the production efficiency of the fan samples is improved, and the quality of the fan samples is further ensured.

Owner:中电九天智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com