Method and device for pickling salted eggs in pressure circulation manner

A pressure and equipment technology, applied in the field of pickled salted eggs, can solve problems such as difficulty in improving production efficiency, poor working environment, and lax process control, and achieve the effects of improving production efficiency, avoiding environmental pollution and saving salt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: a kind of quick salted egg pickling production equipment, including the following aspects:

[0024] (1) Fully automatic sealed pressure pickling tank:

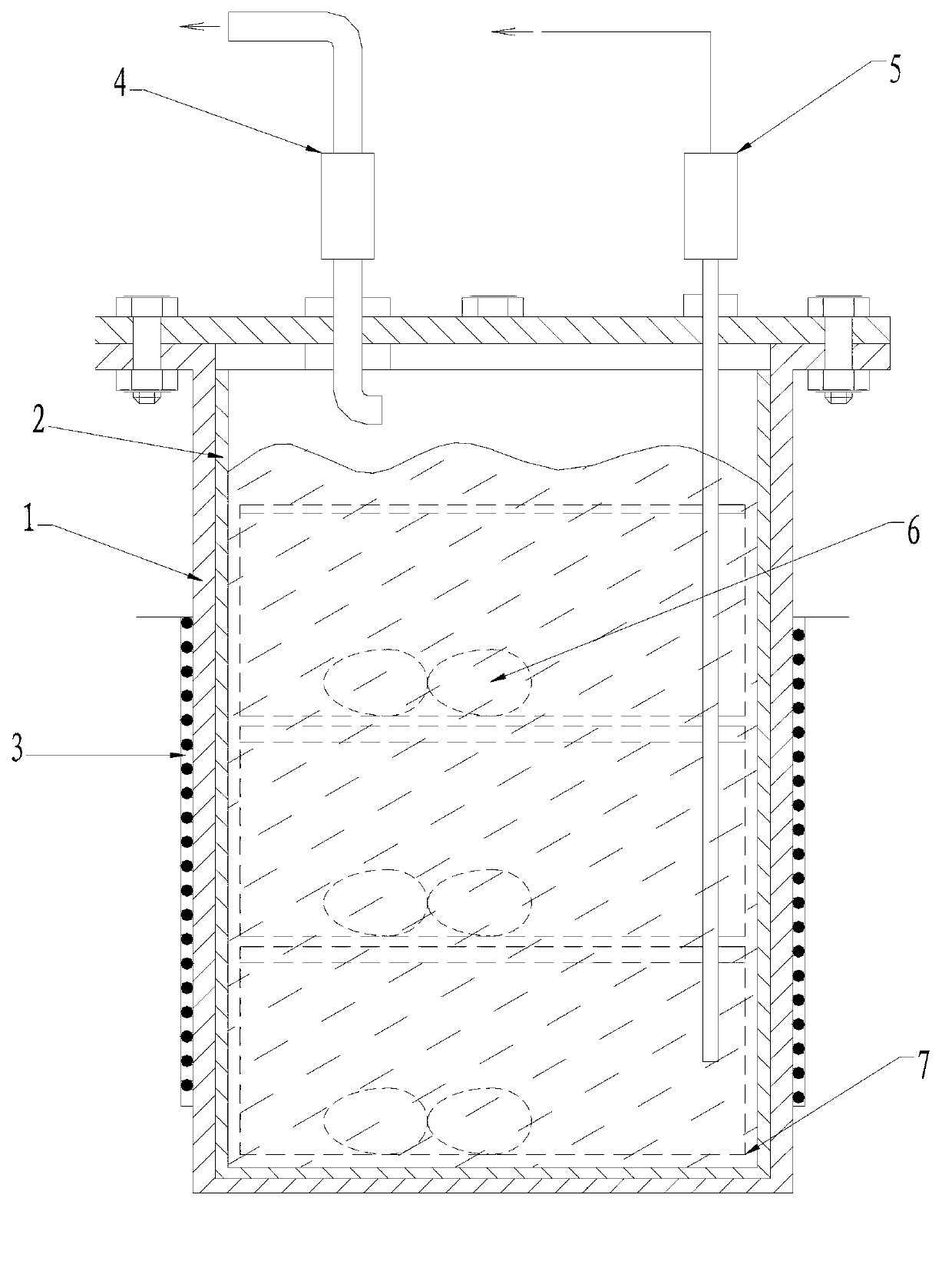

[0025] like figure 1 As shown, the fully automatic pressure pickling tank is composed of a pressure-resistant tank body 1 and a stainless steel inner tank 2. It is generally a barrel shape with an upper opening or a side opening. As a production equipment, the minimum capacity is 40L, and the large capacity can be selected according to the production scale. This special equipment does not need to withstand high pressure, and replaces the widely used water tanks, cement pools and plastic buckets as various open containers for pickling tools. The outer surface of the pressure-resistant tank body 1 is provided with a heating belt 3, which is controlled and heated by the control circuit PLC to control the temperature in the tank body; if the tank body has an upper opening, the top is a sealed tank cover, whic...

Embodiment 2

[0035] Embodiment 2: a kind of quick salted egg pickling production method, with the equipment of embodiment 1, comprising:

[0036] (1) Directly put the qualified eggs 6 that have been processed by the traditional pickling production preparation process (egg, pickling, cleaning) into the plastic turnover box 7, and the plastic turnover box together with the eggs are put into the stainless steel inner tank, and then add saturated The salt pickling liquid, cover the jar, start to pressurize, pressurize and heat to 30℃±2℃ for pickling.

[0037] (2) Cyclic addition and decompression control mode.

[0038] The air pressure in the sealed pressure pickling tank is controlled by a control system connected by air compression pump, pipeline, electromagnetic valve and PLC. The pressure pickling step is to control the compressed air pump through PLC, so that the pressure in the tank is between 0.1Mpa and 0.15 The cycle changes between Mpa, the time is 50 hours ± 10 hours, the 0.15Mpa pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com