Fast processing method of salted duck eggs

A processing method and technology of salted duck eggs, applied in the field of rapid processing of salted duck eggs, can solve the problems of poor concentration and long pickling cycle, achieve good taste, shorten the pickling cycle, and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

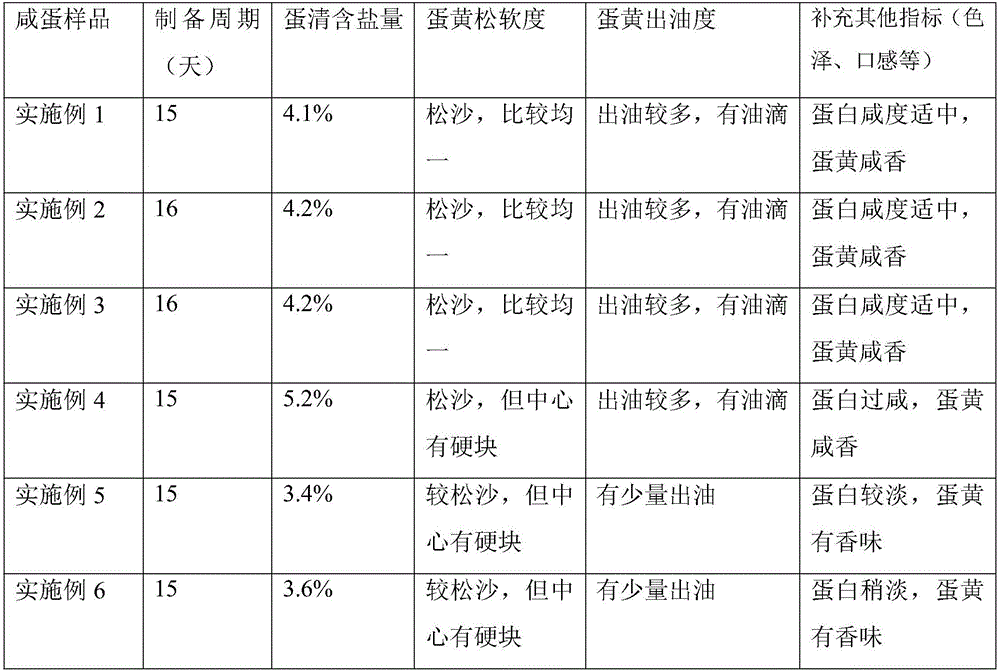

Examples

Embodiment 1

[0026] ① 50kg fresh eggs are washed, and broken eggs are selected and graded according to weight. ②Place fresh eggs of the same weight class in an ultrasonic container, add water to submerge the fresh eggs, and perform ultrasonic pretreatment for 25 minutes. The ultrasonic frequency used is 80KHz, the ultrasonic power is 100w, and it is advisable to add water volume to submerge fresh eggs. ③The preparation of pickling solution A: 100L of water, 30kg of salt (the mass fraction of salt is about 23%), 180g of citric acid, and 2L of food-grade alcohol. ④ Pour solution A into the pickling tank containing the fresh eggs that have been pretreated by ultrasonic waves, press the eggs with a bamboo net to prevent them from floating, and seal them for the first stage of pickling. After 7 days, release the pickling solution A. ⑤ Determine the salt concentration of liquid A released in the previous step to be about 20%, dilute it 5 times, that is, add 4 times the volume of water, add 144g...

Embodiment 2

[0028] ① 80kg fresh eggs are washed, and broken eggs are selected and classified according to weight. ②Put fresh eggs of the same weight class in an ultrasonic container, add water to submerge the fresh eggs, and perform ultrasonic pretreatment for 30 minutes. The ultrasonic frequency used is 100KHz, the ultrasonic power is 150w, and it is advisable to add water volume to submerge fresh eggs. 3. Preparation of pickling solution A liquid: 160L of water, 50kg of salt (the mass fraction of salt is about 24%), 250g of citric acid, and 3L of food-grade alcohol. ④ Pour liquid A into the pickling tank containing the fresh eggs that have been pretreated by ultrasound, press the eggs with a bamboo net to prevent them from floating, and seal them for the first stage of pickling. After 8 days, release the pickling solution A. ⑤ Measure the salt concentration of liquid A released in the previous step to be about 20%, dilute it 5 times, that is, add 4 times the volume of water, add 200g c...

Embodiment 3

[0030] ① 100kg of fresh eggs are washed, and broken eggs are selected and graded according to weight. ②Put fresh eggs of the same weight class in an ultrasonic container, add water to submerge the fresh eggs, and perform ultrasonic pretreatment for 30 minutes. The ultrasonic frequency used is 100KHz, the ultrasonic power is 150w, and it is advisable to add water volume to submerge fresh eggs. 3. The preparation of pickling solution A liquid: 200L of water, 60kg of salt (the mass fraction of salt is about 23%), 350g of citric acid, and 5L of food-grade alcohol. ④ Pour liquid A into the pickling tank containing the fresh eggs that have been pretreated by ultrasound, press the eggs with a bamboo net to prevent them from floating, and seal them for the first stage of pickling. After 8 days, release the pickling solution A. ⑤ Determine that the salt concentration of liquid A released in the previous step is about 20%, dilute it 5 times, that is, add 4 times the volume of water, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com