Graphene conductive paste and preparation method thereof

A conductive paste, graphene technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve problems affecting the electrical performance and stability of electronic devices, and achieve good flexibility and photothermal degradation resistance, improving mechanical properties, reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

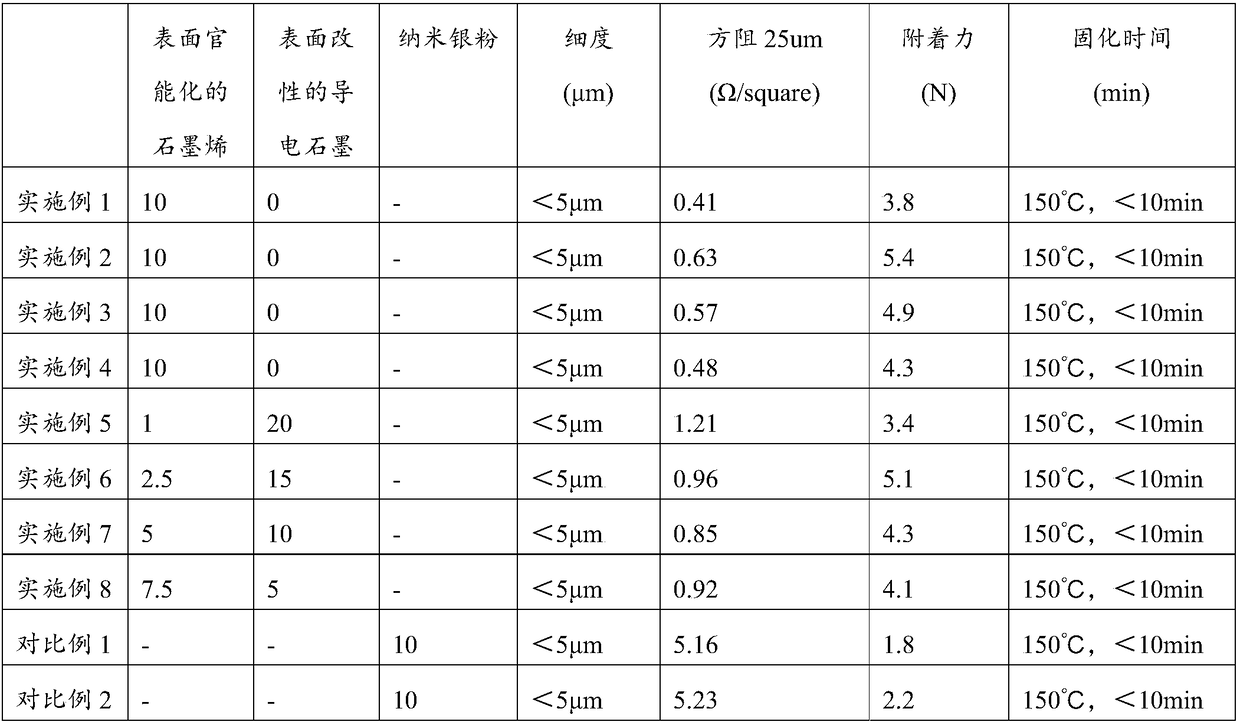

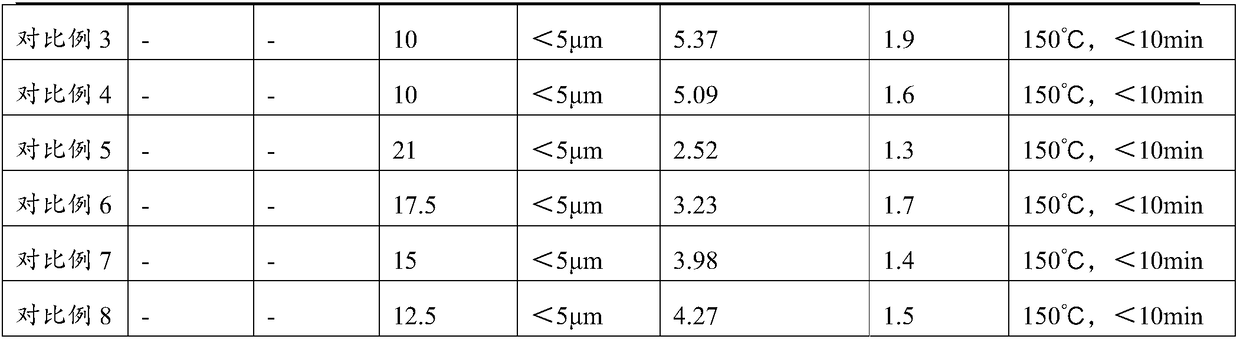

Examples

Embodiment 1

[0039] In this embodiment, the epoxy resin carrying out epoxy functionalization to graphene, the epoxy resin carrying out epoxy modification to siloxane and the epoxy resin as one of the main components of graphene conductive paste all adopt Bisphenol A type epoxy resin. The bisphenol A epoxy resin was purchased from Shenzhen Jiadida Chemical Co., Ltd., and the model was NPEL-128E.

[0040] Add 2g of graphene powder (highly conductive graphene powder prepared by Shenzhen Shiwang New Material Technology Co., Ltd.), 3.5g of bisphenol A epoxy resin and 200g of absolute ethanol into the medium and high-speed rotating chamber testing machine middle. The high-speed rotating cavity testing machine is equipped with an ultrasonic generator and a heating constant temperature device. The mixture is rotated at 20-120°C, 1600rpm at high speed and 2000W, frequency 80KHz ultrasonic waves are shaken for 1-8h for 1-8 hours, then vacuum filtered and dried at a temperature lower than 50°C, and...

Embodiment 2

[0044] In this embodiment, the epoxy resin carrying out epoxy functionalization to graphene, the epoxy resin carrying out epoxy modification to siloxane and the epoxy resin as one of the main components of graphene conductive paste all adopt Bisphenol F type epoxy resin replaces the bisphenol A type epoxy resin in embodiment 1, and the rest are the same as embodiment 1. The bisphenol F epoxy resin was purchased from Shenzhen Jiadida Chemical Co., Ltd., and the model was NPEF-170.

Embodiment 3

[0046] In the present embodiment, the epoxy resin carrying out epoxy functionalization to graphene and the epoxy resin carrying out epoxy modification to siloxane all adopt the bisphenol A type epoxy resin in embodiment 1, as graphene conductive The epoxy resin of one of the main components of the slurry is the bisphenol F epoxy resin in Example 2, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com