Timepiece face and timepiece

A clock and dial technology, which is applied to the clock face and the field of clocks, can solve the problems of the beautiful appearance of the clock face (decreased design, mixed air bubbles, etc., and achieves the effect of good bonding strength and preventing the generation of air bubbles).

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

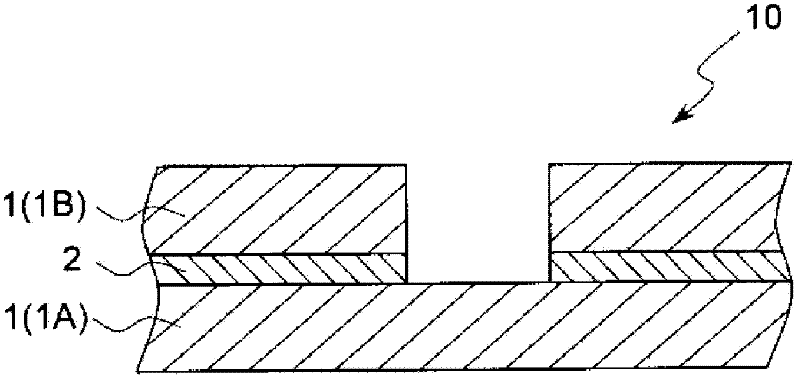

[0034] figure 1 It is a sectional view showing the first embodiment of the timepiece dial of the present invention. In the description below, figure 1 (about the later figure 2 , image 3 The upper side in the same) is representatively described for the case of facing the viewer's side when the watch dial is used, and the upper side in the figure is referred to as "upper" or "upper", and the lower side is referred to as "upper". Down" or "Below".

[0035] As shown in the figure, the timepiece dial 10 includes a first substrate 1A and a second substrate 1B as a plurality of substrates 1 mainly made of polycarbonate, and a bonding layer 2 for bonding the first substrate 1A and the second substrate 1B. In addition, the bonding layer 2 is composed of an adhesive elastomer composition having a thickness of 50 μm to 200 μm, an elongation of 50% to 350%, and a light transmittance of 80% or more in the thickness direction. It is obtained by irradiating ultraviolet rays to crossl...

no. 2 Embodiment approach

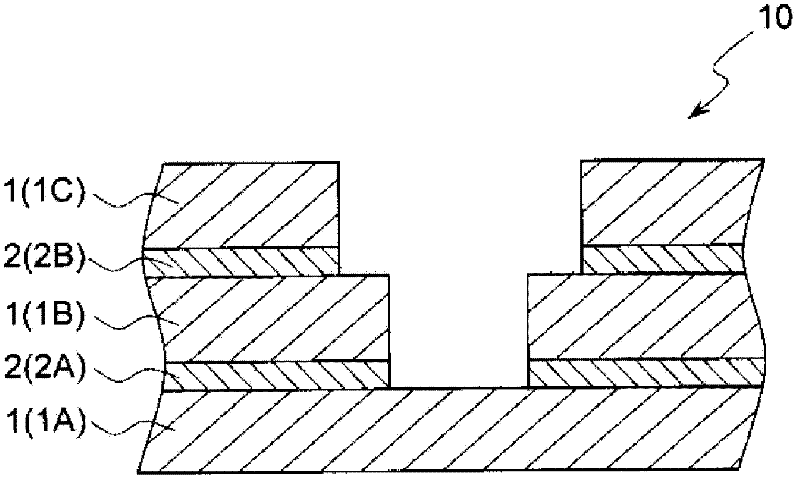

[0074] figure 2 It is a sectional view showing the second embodiment of the timepiece dial of the present invention. Hereinafter, the timepiece dial of the second embodiment will be described focusing on differences from the above-described embodiment, and descriptions of the same contents will be omitted.

[0075] The timepiece dial 10 of this embodiment has a first substrate 1A mainly composed of polycarbonate, a first bonding layer 2A, a second substrate 1B mainly composed of polycarbonate, a second bonding layer 2B, and a substrate mainly composed of polycarbonate are laminated in this order. The structure of the third substrate 1C made of carbonate. That is, the timepiece dial 10 of the present embodiment has a first substrate 1A, a second substrate 1B, and a third substrate 1C as the substrate 1, a first bonding layer 2A for bonding the first substrate 1A and the second substrate 1B, and a bonding layer for bonding the second substrate 1A. The second bonding layer 2B ...

Embodiment 1

[0140] First, polycarbonate is used to produce a disc-shaped base material by injection molding, and then the desired position is punched out, and unnecessary flashes are cut and ground to obtain multiple substrates.

[0141] The thus-obtained substrate had a diameter of 27 mm x an average thickness of 200 μm, and had a hole for inserting the axis of the hands (hour hand, minute hand, and second hand) at the center in a planar view. The substrate thus obtained was used as a first substrate. In addition, by performing punching processing on the above-mentioned substrate (first substrate), in addition to forming a hole for inserting the axis of the hands (hour hand, minute hand, and second hand) in the central part in plan view, other parts are also Holes are formed to obtain a second substrate.

[0142] On the other hand, the laminate obtained in Preparation Example 1 above was punched into the same shape as the second substrate.

[0143] One film was peeled off from the punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com