Wood adhesive

An adhesive and wood technology, applied in the directions of adhesive additives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as human health hazards, and achieve widened application environment, excellent bonding strength, good water resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

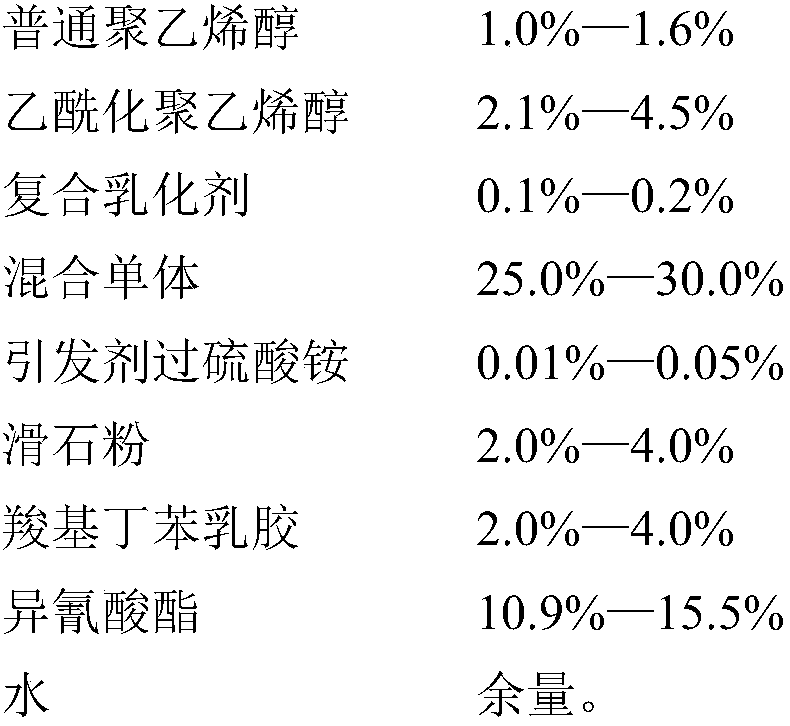

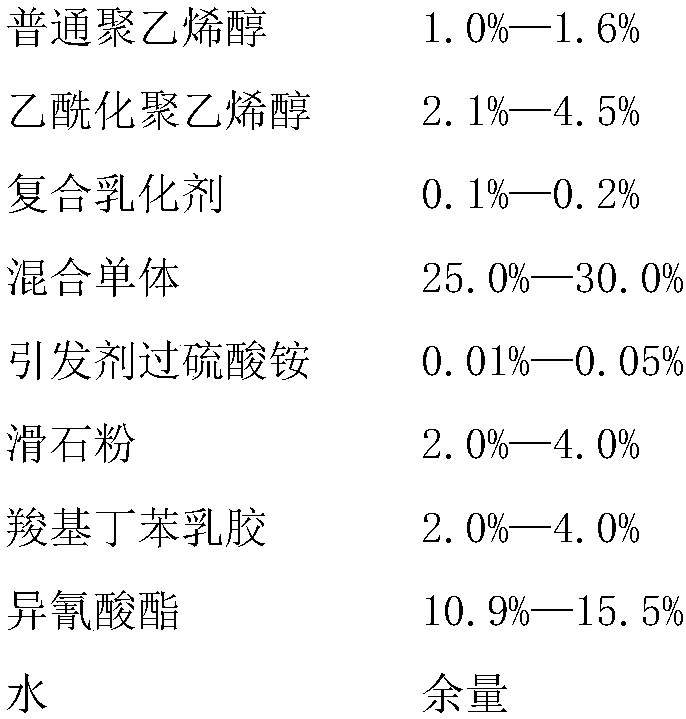

[0013] A wood adhesive, comprising the following ingredients in weight percentage: 1.0% of ordinary polyvinyl alcohol, 2.0% of acetylated polyvinyl alcohol, 0.1% of compound emulsifier, 24.5% of mixed monomer, 0.01% of initiator ammonium persulfate, talcum powder 1.8%, carboxylated styrene-butadiene latex 1.5%, emulsified polyisocyanate 5.9%, high-functionality polyisocyanate 4.0%, water 59.19%.

Embodiment II

[0015] A wood adhesive, comprising the following ingredients in weight percentage: 1.7% of ordinary polyvinyl alcohol, 5.0% of acetylated polyvinyl alcohol, 0.2% of composite emulsifier, 31.4% of mixed monomer, 0.05% of initiator ammonium persulfate, talcum powder 4.5%, carboxylated styrene-butadiene latex 4.3%, emulsified polyisocyanate 8.9%, high-functionality polyisocyanate 7.7%, water 40.95%.

Embodiment III

[0017] A wood adhesive, comprising the following ingredients in weight percentage: 1.3% of ordinary polyvinyl alcohol, 3.7% of acetylated polyvinyl alcohol, 0.13% of composite emulsifier, 27.8% of mixed monomer, 0.03% of initiator ammonium persulfate, talcum powder 3.2%, carboxylated styrene-butadiene latex 3.1%, emulsified polyisocyanate 6.9%, high-functionality polyisocyanate 6.5%, water 47.34%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com