Rapid reformed egg manufacturing system and method using medium-high voltage electric field

A high-voltage electric field, medium-high voltage technology, applied in the field of food science, can solve the problems of the operator's respiratory tract and the environment, the traditional salted egg processing cycle is long, and the research on the preserved salted egg process is less, so as to shorten the salting cycle and have a simple structure. , the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

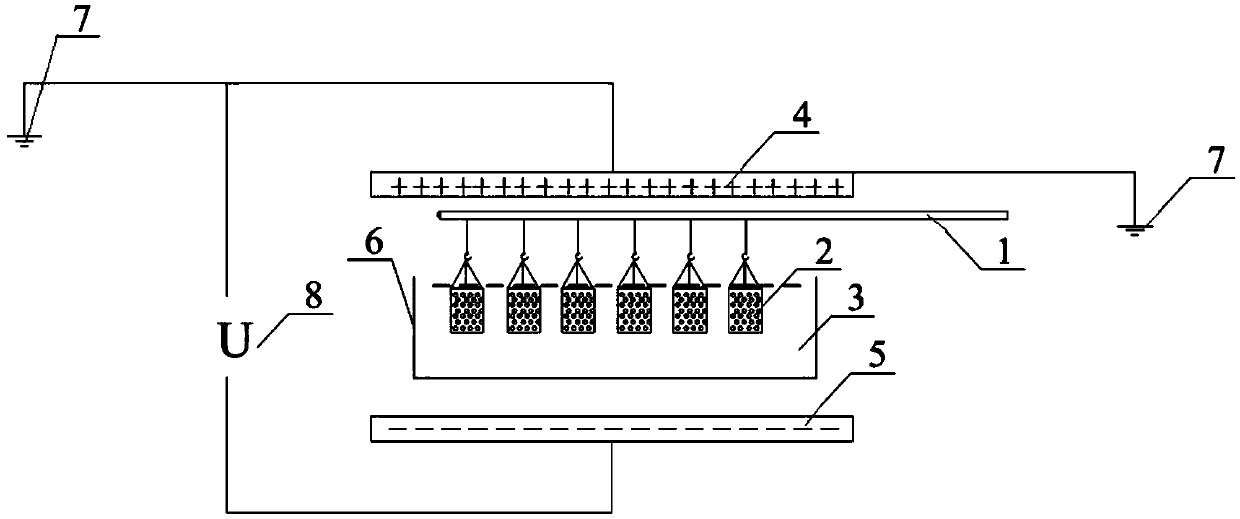

[0058] A kind of method for making lead-free preserved egg rapidly by middle and high voltage electric field method, its concrete steps are as follows:

[0059] (1) Egg selection and egg cleaning: Strictly select fresh duck eggs, remove damaged eggs, cracks, oil shells, steel shells and other inferior eggs, then clean, disinfect and air-dry;

[0060] (2) Frame loading: put the washed duck eggs on the plastic egg tray through the vacuum suction cup manipulator and move them into the plastic egg frame;

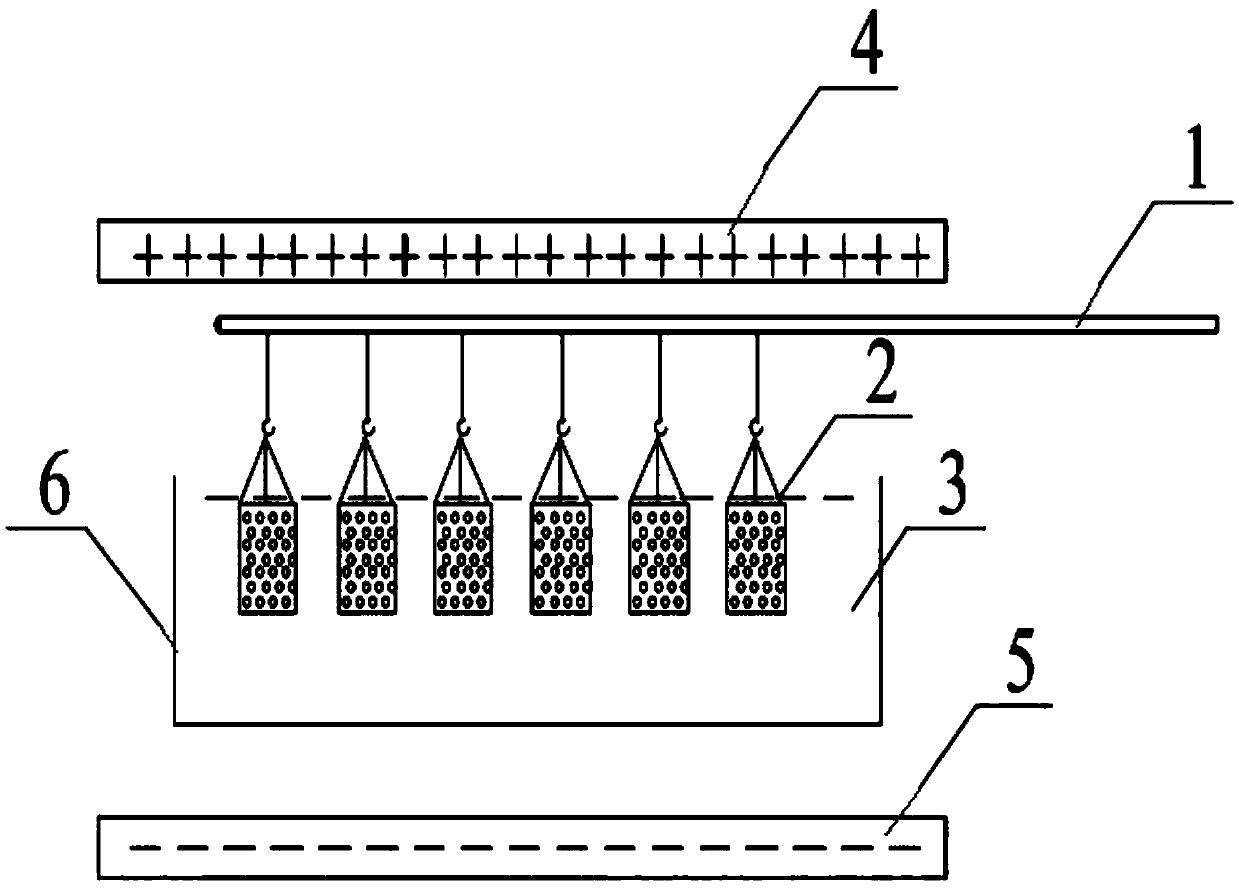

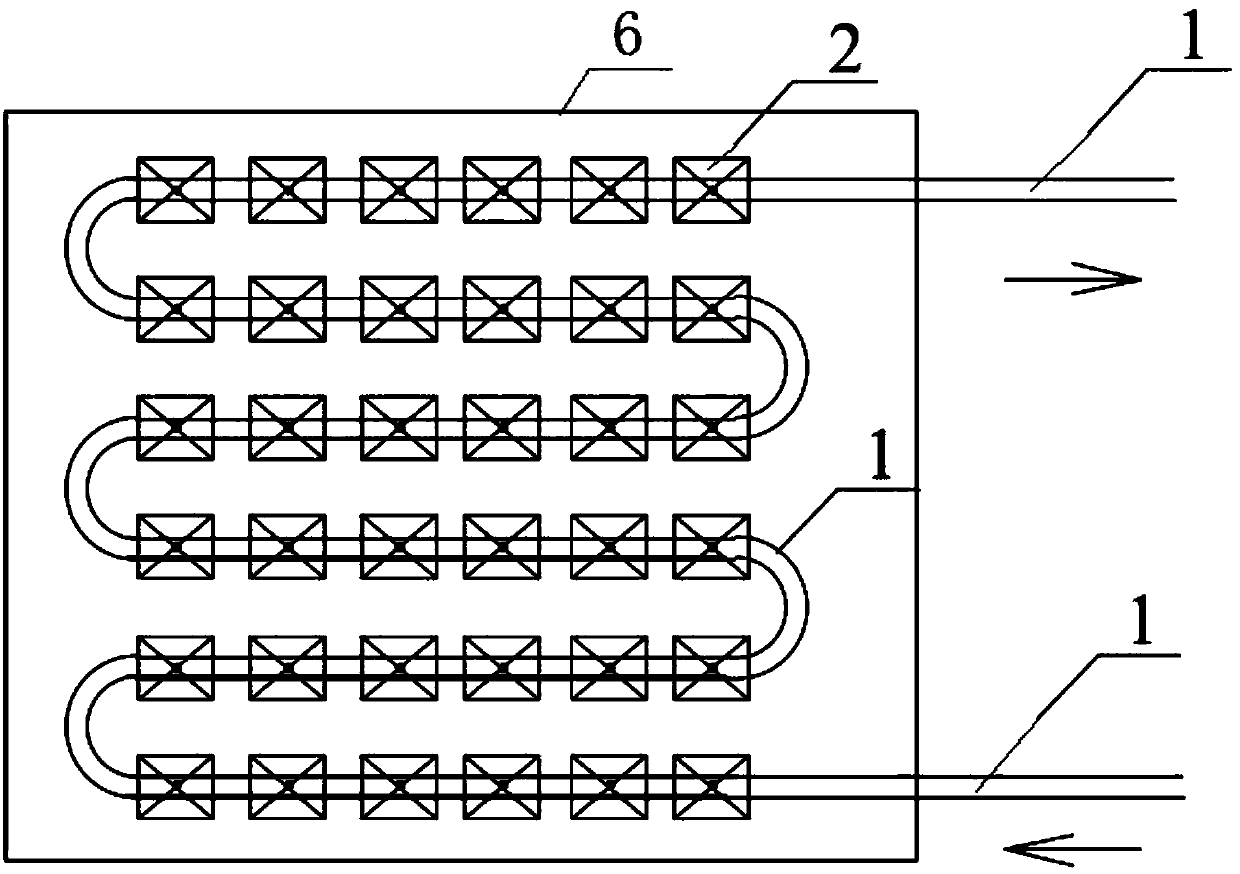

[0061] (3) Conveying: fix the egg cartons full of fresh eggs and then transfer them to the conveying system through the lifting system; enter the pickling tank with medium and high voltage electric field through the hanging rail conveying system, and the whole egg cartons are soaked in the pickling solution. The egg box moves slowly along the conveyor rail under the action of the conveyor system.

[0062] In this step, the four corners of the egg frame are fixed with hanging ro...

Embodiment 2

[0071] A kind of method for rapidly making salted duck eggs by medium and high voltage electric field method, its concrete steps are as follows:

[0072] (1) Egg selection and egg cleaning: Strictly select fresh duck eggs, remove damaged eggs, cracks, oil shells, steel shells and other inferior eggs, then clean, disinfect and air-dry;

[0073] (2) Frame loading: put the washed duck eggs on the plastic egg tray and move them into the plastic egg frame through the vacuum suction cup type mechanical claw;

[0074] (3) Conveying: After fixing the egg boxes full of fresh eggs (to prevent the eggs from floating and colliding with each other), they are transported to the conveying system through the lifting system, and under the action of the conveying system, they pass through the pickling tank with medium and high voltage electric fields .

[0075] In this step, the four corners of the egg frame are fixed with hanging ropes, and the hooks connected to the guide rails hook the hangin...

Embodiment 3

[0084] A kind of method for making salted preserved egg rapidly by middle and high voltage electric field method, its specific steps are as follows:

[0085] (1) Egg selection and egg cleaning: Strictly select fresh eggs, remove damaged eggs, cracks, oil shells, steel shells and other bad eggs, then clean, disinfect and air-dry;

[0086] (2) Frame loading: put the washed duck eggs on the plastic egg tray and move them into the plastic egg frame through the vacuum suction cup type mechanical claw;

[0087] (3) Conveying: After the egg cartons filled with fresh eggs are fixed, they are transported to the conveying system through the lifting system, and under the action of the conveying system, they pass through the pickling tank applied with medium and high voltage electric fields.

[0088] In this step, the four corners of the egg frame are fixed with hanging ropes, and the hooks connected to the guide rails hook the hanging ropes to move the egg frame at a constant speed.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com