Method for cowpea sauce product with low salt

A technology of cowpea sauce and products, applied in the field of food processing, to achieve the effects of high nutritional value, reduced salt consumption, and pure sauce color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

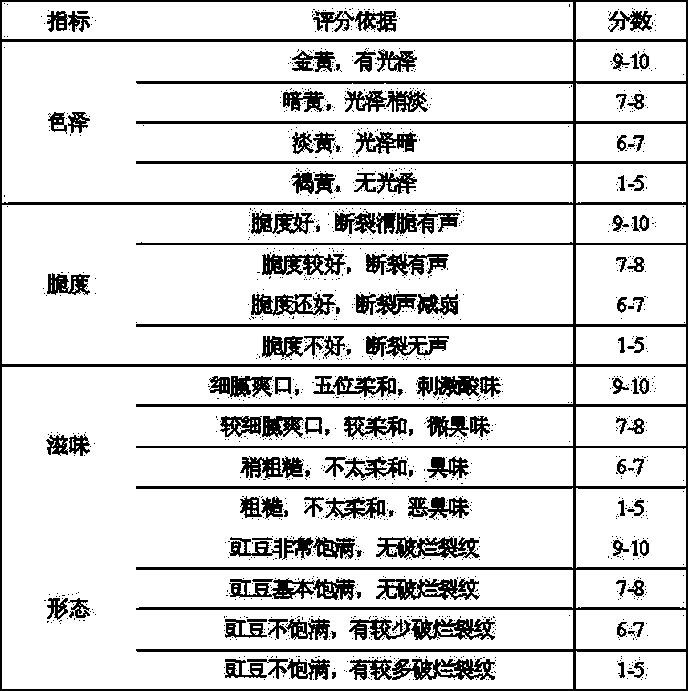

Image

Examples

Embodiment 1

[0021] A cowpea paste product and a low-salt pickling method thereof, the steps are as follows:

[0022] (1) Select 480g of fresh and tender long cowpea, pinch off the root, wash it, and soak it in a mixture of 0.1% (w / v) calcium chloride and 0.1% (w / v) calcium lactate for 10 hours;

[0023] (2) Wash and dry the cowpea, add 10% salt according to the net weight of the cowpea, mix well, marinate at 65°C for 24 hours, and the ambient humidity is 75%;

[0024] (3) Take out the cowpea, rinse and desalt it with sterile water, add 6% salt according to the net weight of the cowpea, mix well, marinate at 40°C for 24 hours, and the ambient humidity is 60%;

[0025] (4) Rinse cowpea with sterile water, add 3% salt by weight, add 30 g red pepper, 10 g prickly ash, 30 g garlic, 16 g cardamom, 18 g laurel, and insert Lactococcus lactis ( CICC23610) bacterial liquid, fermented at 10°C for 10 days;

[0026] (5) After the fermentation is completed, add 60 g of bean paste, 8 g of sesame oil, ...

Embodiment 2

[0028] A cowpea paste product and a low-salt pickling method thereof, the steps are as follows:

[0029] (1) Select 500g of fresh and tender long cowpea, pinch off the root, wash it, and soak it in a mixture of 1% (w / v) calcium chloride and 1% (w / v) calcium lactate for 14 hours;

[0030] (2) Wash and dry the cowpea, add 12% salt according to the net weight of the cowpea, mix well, marinate at 70°C for 36 hours, and the ambient humidity is 85%;

[0031] (3) Take out the cowpea, rinse and desalt it with sterile water, add 8% salt according to the net weight of the cowpea, mix well, marinate at 45°C for 48 hours, and the ambient humidity is 75%;

[0032] (4) Rinse cowpea with sterile water, add 5% salt by weight, add 45 g of red pepper, 20 g of pepper, 40 g of garlic, 28 g of cardamom, and 28 g of laurel, and insert Lactococcus lactis according to the inoculation amount of 6%. (CICC23610) bacterial liquid, fermented at 15°C for 20 days;

[0033] (5) After the fermentation is co...

Embodiment 3

[0035] A cowpea paste product and a low-salt pickling method thereof, the steps are as follows:

[0036] (1) Select 490g of fresh and tender long cowpea, pinch off the root, wash it, and soak it in a mixture of 0.5% (w / v) calcium chloride and 0.5% (w / v) calcium lactate for 12 hours;

[0037] (2) Wash and dry the cowpea, add 10% salt according to the net weight of the cowpea, mix well, marinate at 68°C for 30 hours, and the ambient humidity is 80%;

[0038] (3) Take out the cowpea, rinse and desalt it with sterile water, add 7% salt according to the net weight of the cowpea, mix well, marinate at 42°C for 36 hours, and the ambient humidity is 70%;

[0039] (4) Rinse the cowpea with sterile water, add 4% salt by weight, add 38g of red pepper, 15g of pepper, 35g of garlic, 20g of cardamom, 23g of laurel, and insert Lactococcus lactis (CICC23610) bacteria according to the inoculation amount of 4%. liquid, fermented at 12°C for 15 days;

[0040] (5) After the fermentation is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com