Pickled radish product and low-salt three-section pickling method

A technology for radish sauce and products, which is applied in the field of sauce product processing to achieve the effects of reducing salt content, pure color and stabilizing blood pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

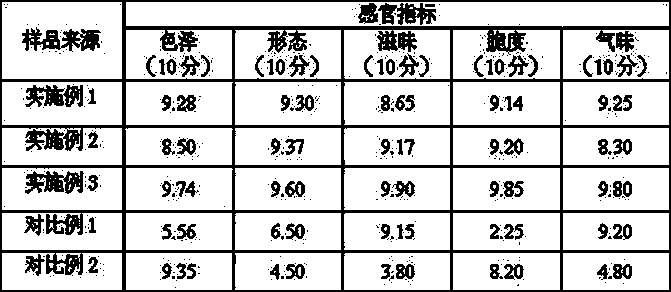

Examples

Embodiment 1

[0028] A radish paste product and a low-salt three-stage pickling method thereof, the steps of which are as follows:

[0029] (1) Select 250g of fresh and round white radish and 250g of carrot, remove the roots, wash, cut into finger-sized strips, add 0.1% citric acid, 0.1% calcium chloride, 0.1% calcium lactate, 0.1% propionic acid Soak in the calcium mixture for 4 hours to protect the color and crispness;

[0030] (2) Wash and drain the radish, add 5% salt according to the net weight of the radish, mix well, marinate at 80°C for 48 hours, and the ambient humidity is 80%;

[0031] (3) Take out the radish, rinse with sterile water to desalinate, add 3% salt according to the net weight of the radish, mix well, and marinate at 45°C for 48 hours under temperature control, and the ambient humidity is 70%;

[0032] (4) Rinse the radish with sterile water, add 2% salt and 1% lactose according to the weight ratio, and add 4% of the inoculum into the mixed culture solution of lactic ...

Embodiment 2

[0035] A radish paste product and a low-salt three-stage pickling method thereof, the steps of which are as follows:

[0036] (1) Select 280g of fresh and round white radish and 280g of carrot, remove the roots, wash, cut into finger-sized strips, add 1% citric acid, 1% calcium chloride, 1% calcium lactate, 1% propionic acid Soak in the calcium mixture for 12 hours to protect the color and crispness;

[0037] (2) Wash and drain the radish, add 6% salt according to the net weight of the radish, mix well, marinate at 85°C for 72 hours, and the ambient humidity is 90%;

[0038] (3) Take out the radish, rinse with sterile water to desalinate, add 5% salt according to the net weight of the radish, mix well, and marinate at 50°C for 72 hours under temperature control, and the ambient humidity is 80%;

[0039] (4) Rinse the radish with sterile water, add 4% salt and 2% lactose according to the weight ratio, and add a 2:1 CFU ratio of lactic acid bacteria and yeast mixed bacteria sol...

Embodiment 3

[0042] A radish paste product and a low-salt three-stage pickling method thereof, the steps of which are as follows:

[0043] (1) Select 270g of fresh and round white radish and 260g of carrot, remove the roots, wash, cut into finger-sized strips, add 0.5% citric acid, 0.5% calcium chloride, 0.5% calcium lactate, 0.5% propionic acid Soak in the calcium mixture for 8 hours to protect the color and crispness;

[0044] (2) Wash and drain the radish, add 5.5% salt according to the net weight of the radish, mix well, and marinate at a temperature of 83°C for 60 hours, and the ambient humidity is 85%;

[0045](3) Take out the radish, rinse with sterile water to desalinate, add 4% salt according to the net weight of the radish, mix well, and marinate at 48°C for 60 hours under temperature control, and the ambient humidity is 75%;

[0046] (4) Rinse the radish with sterile water, add 3% salt and 1.5% lactose according to the weight ratio, and add a 1.5:1 CFU ratio of lactic acid bact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com