AGM (absorptive glass mat) switch on-off storage battery positive plate curing process

A curing process and positive plate technology, which is applied to the electrodes of lead-acid batteries, can solve the problems of low curing temperature, affecting the performance stability of the plate, and high porosity, so as to improve production efficiency, shorten the curing cycle, improve cycle life and The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

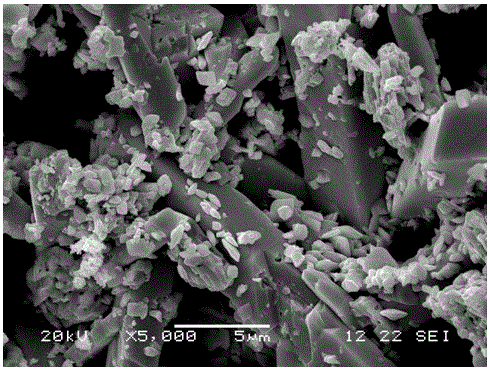

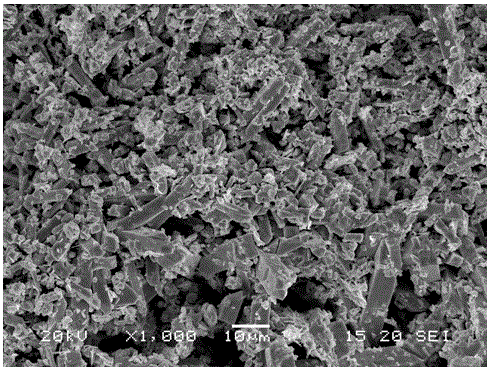

Image

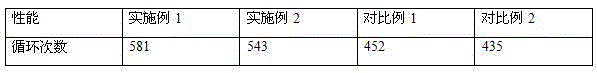

Examples

Embodiment 1

[0026] A kind of AGM start-stop storage battery positive plate solidification process, comprises the following steps:

[0027] In the stage of medium temperature and high humidity, the relative humidity in this stage is 96-100%, and the temperature gradually rises from 45°C to 62°C within 50 minutes, then keeps at 62°C for 3 hours, and the temperature slowly drops from 62°C to 50°C within 3 hours;

[0028] In the stage of low temperature and high humidity, the temperature in this stage is 50°C, and after the relative humidity is kept at 96-100% for 3 hours, it will slowly drop from 96-100% to 90-92% within 3 hours, and then slowly rise to 96-100% within 3 hours , the relative humidity will slowly drop from 96-100% to 90-92% within 8 hours;

[0029] In the medium temperature dehumidification stage, the temperature in this stage is 60°C, and the relative humidity slowly decreases from 90-92% to 80% within 6 hours, and then slowly decreases to 50% within 5 hours;

[0030] In the...

Embodiment 2

[0035] A kind of AGM start-stop storage battery positive plate solidification process, comprises the following steps:

[0036] In the stage of medium temperature and high humidity, the relative humidity in this stage is 96-100%, the temperature is maintained at 50-55°C for 5 hours, and then the temperature is slowly increased from 55°C to 65°C within 2 hours;

[0037] In the low temperature and high humidity stage, the temperature in this stage is 55°C, and after the relative humidity is kept at 96-100% for 3 hours, it will slowly drop from 96-100% to 90-92% within 11 hours;

[0038] In the medium temperature dehumidification stage, the temperature in this stage is 60°C, and the relative humidity slowly drops from 90-92% to 80% within 8 hours, and then slowly drops to 20% within 5 hours;

[0039] In the high-temperature drying stage, the relative humidity is 5-15%, the temperature rises slowly from 60°C to 80°C within 2 hours, and then keeps at 80°C for 6 hours;

[0040] Afte...

Embodiment 3

[0044] A kind of AGM start-stop storage battery positive plate solidification process, comprises the following steps:

[0045] In the medium temperature and high humidity stage, the relative humidity is 96-100%, the temperature is kept at 45-50°C for 2 hours, and then the temperature is slowly raised to 65°C within 3 hours;

[0046] In the low temperature and high humidity stage, the temperature in this stage is 52°C, and after the relative humidity is kept at 96-100% for 5 hours, it will slowly drop from 96-100% to 90-92% within 15 hours;

[0047] In the medium temperature dehumidification stage, the temperature in this stage is 65°C, and the relative humidity slowly drops from 90-92% to 80% within 7 hours, and then slowly drops to 15% within 8 hours;

[0048] In the high-temperature drying stage, the relative humidity is 5-15%, the temperature rises slowly from 65°C to 85°C within 5 hours, and then keeps at 85°C for 10 hours;

[0049] After the high-temperature drying stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com