Patents

Literature

97results about How to "Improve displacement effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of cross-linked polymer microsphere-polymer composite deep control and drive agent and its application method

InactiveCN102286274AImprove the spread factorDelay one-way breakthroughFluid removalDrilling compositionPolymer scienceMicrosphere

The invention provides a cross-linked polymer microsphere-polymer composite deep water control agent and a using method thereof. The control and drive agent includes water-soluble cross-linked polymer microspheres, water-soluble polymers and water; in the composite deep-seated control and drive agent, the mass percentage of the water-soluble cross-linked polymer microspheres is 0.01% to 0.3%, The mass percent content of the water-soluble polymer is 0.05%-0.5%, and the balance is water. The cross-linked polymer microsphere-polymer composite deep control and flooding agent provided by the present invention has a higher liquid flow redirection ability than conventional polymer flooding, can delay the one-way breakthrough of the polymer solution in the application process, and improve the efficiency of polymer flooding. The sweep coefficient has a higher ability to improve the oil-water phase mobility ratio than the conventional cross-linked polymer solution, and improves the displacement ability of the cross-linked polymer solution, which is more suitable for water injection development reservoirs with heterogeneous porous media.

Owner:CHINA NAT OFFSHORE OIL CORP +2

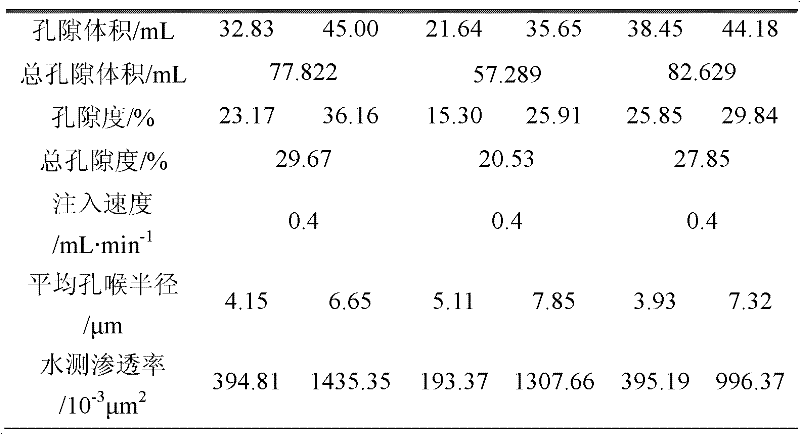

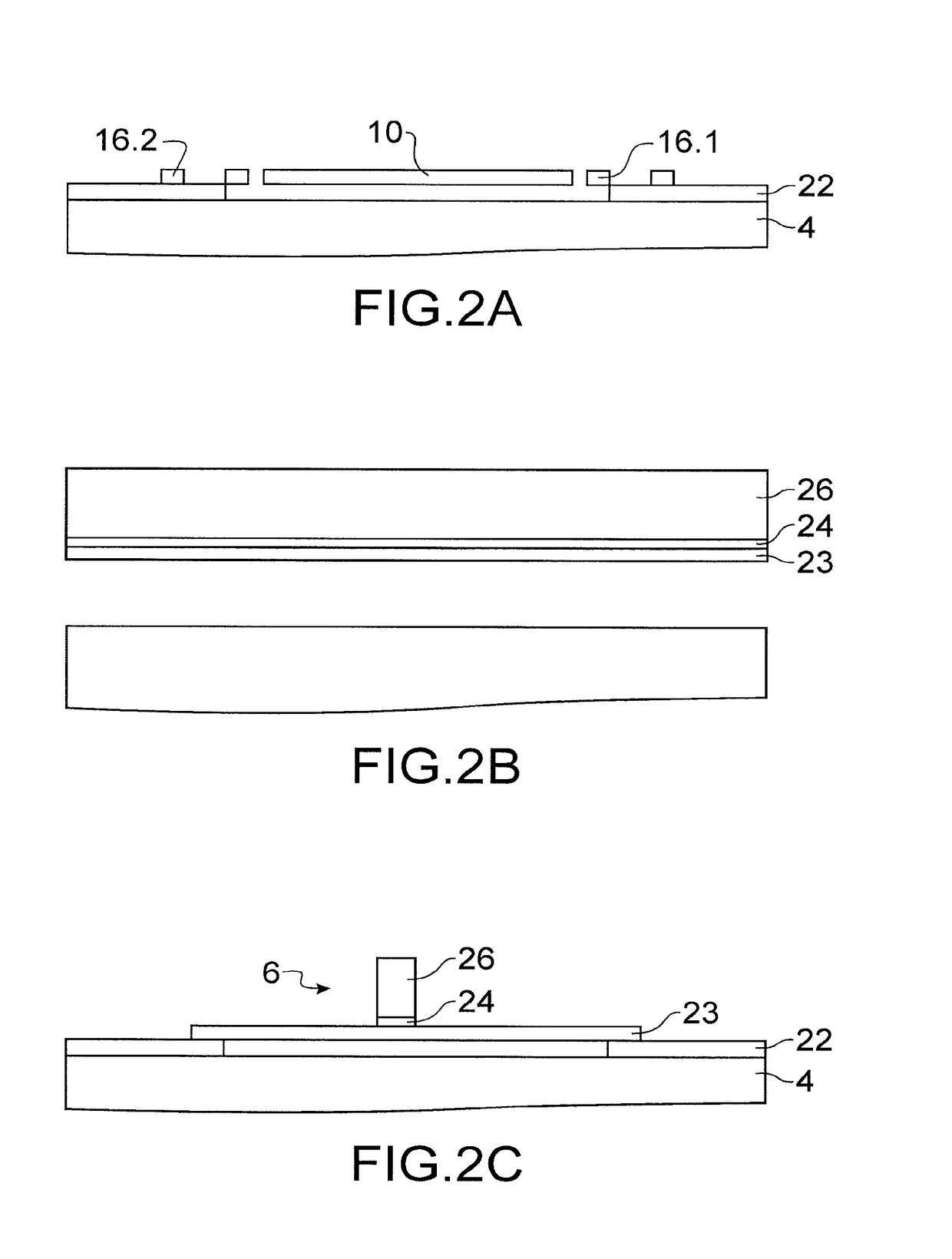

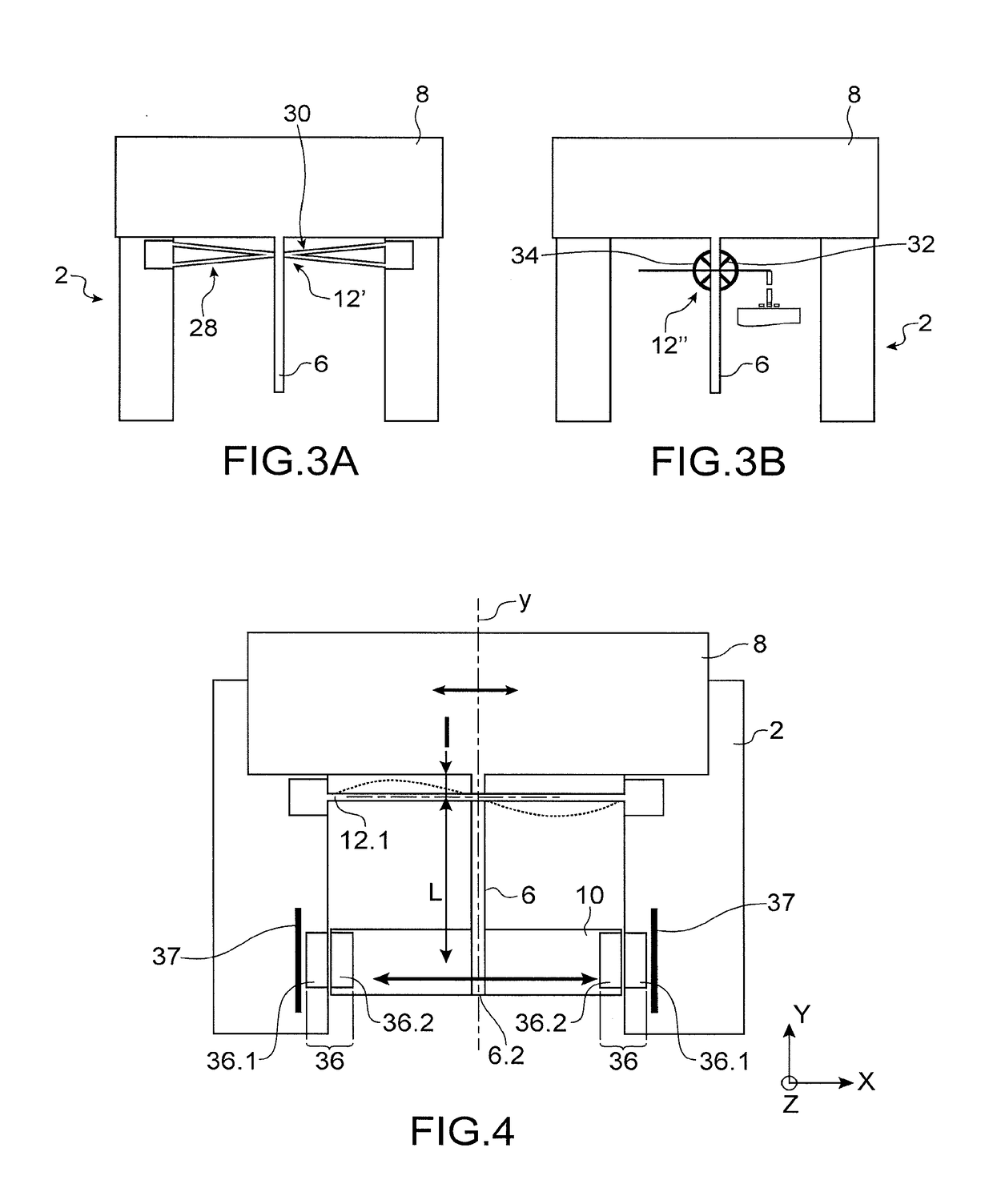

Opto-mechanical physical sensor with an improved sensitivity

ActiveUS20170089944A1High sensitivityHigh detection sensitivityAcceleration measurement using interia forcesResonatorOptical resonance

A physical sensor comprising a substrate (4), a movable mass (8), said mass (8) being able to be moved by an external force, a first optical resonator (16.1), a light wave guide (18.1) for measurement and a light wave guide for detection, a rigid plate (10) which are able to modify the optical resonance frequency of said optical resonator (16.1) by moving closer and away the same, a lever arm (6) rotatably hinged to the substrate (4) by a pivot connection (12) and the mass (8) being movably integral with the transmitting means (6), the rigid plate (10) being disposed relative to the mass (8) and to the pivot connection (12) such that the lever arm (6) transmits to the rigid plate (10), in an amplified manner, the displacement of the mass (8).

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

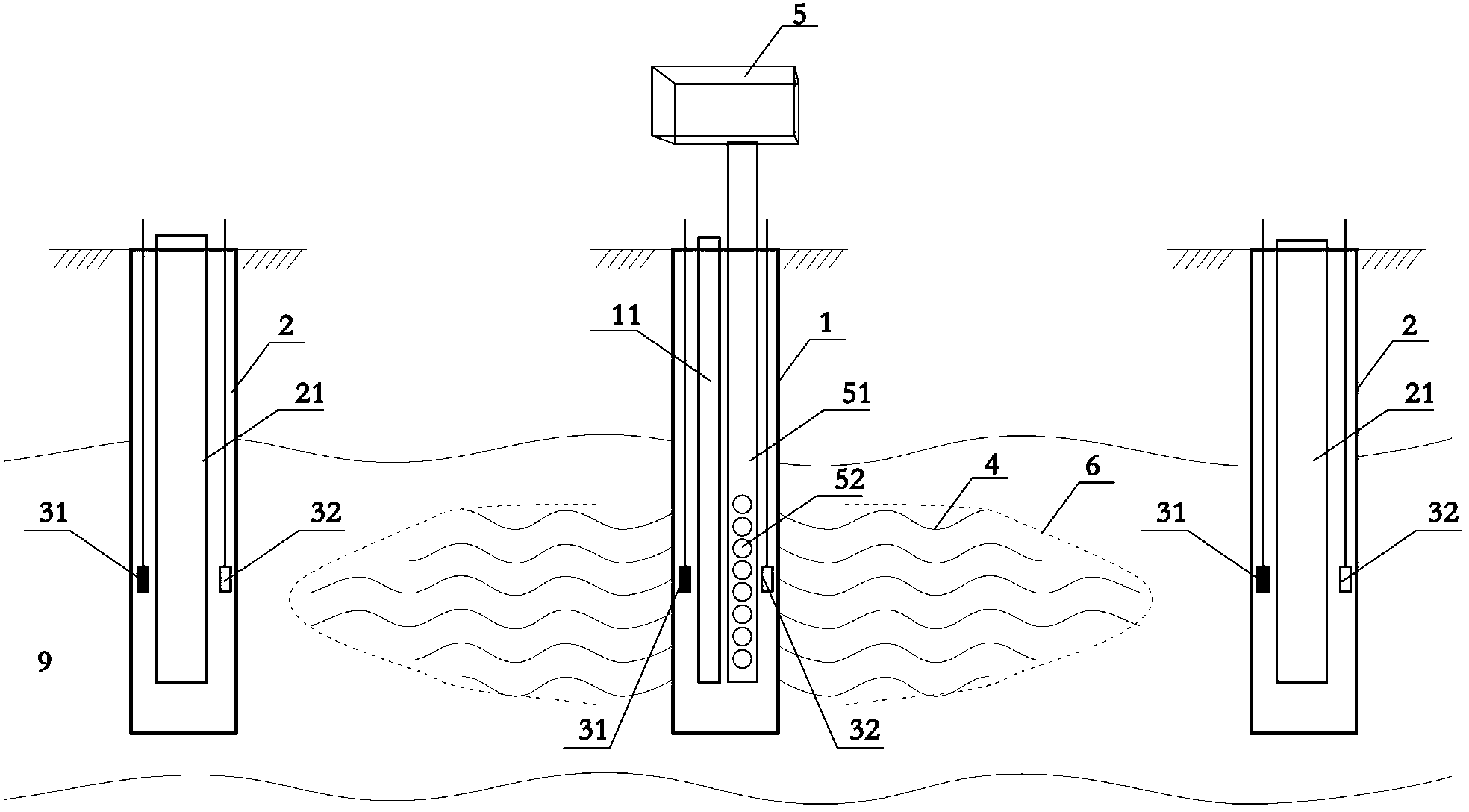

Exploitation method of vaporizing formation water and displacing heavy oil by microwaves in situ

ActiveCN103225497AIncrease specific volumeSolve the problem of dryness lossFluid removalWater vaporHeat losses

The invention provides an exploitation method of vaporizing formation water and displacing heavy oil by microwaves in situ. The exploitation method comprises the following steps: selecting an old well in the heavy oil reservoir huff and puff old well area to serve as a displacement well, and selecting a plurality of old wells adjacent to the displacement well to serve as recovery wells, wherein the recovery wells form an injection and production well group; performing fracturing and crack construction on the target oil layer in the displacement well; injecting silicon carbide particles into the cracks; arranging microwave generating equipment at the wellhead and in the interior of the displacement well; and continuously performing microwave radiation heating on the silicon carbide particles through microwaves with certain power, and further heating the oil layer, so as to enable the underground stored water generated in the huff and puff process to be vaporized in situ, displace the crude oil of which the temperature is increased and the viscosity is reduced in the well, and enable the crude oil to enter the bottoms of the recovery wells to be exploited out. The exploitation method utilizes the silicon carbide particles in the cracks to heat the oil layer, so as to vaporize the underground stored water and displace the remaining oil after huff and puff, solve the problem of loss of steam quality due to steam injection at the wellhead, reduce heat loss, improve the downhole steam quality and steam swept volume at unit mass, and improve the exploitation effect of heavy oil reservoir after huff and puff.

Owner:PETROCHINA CO LTD

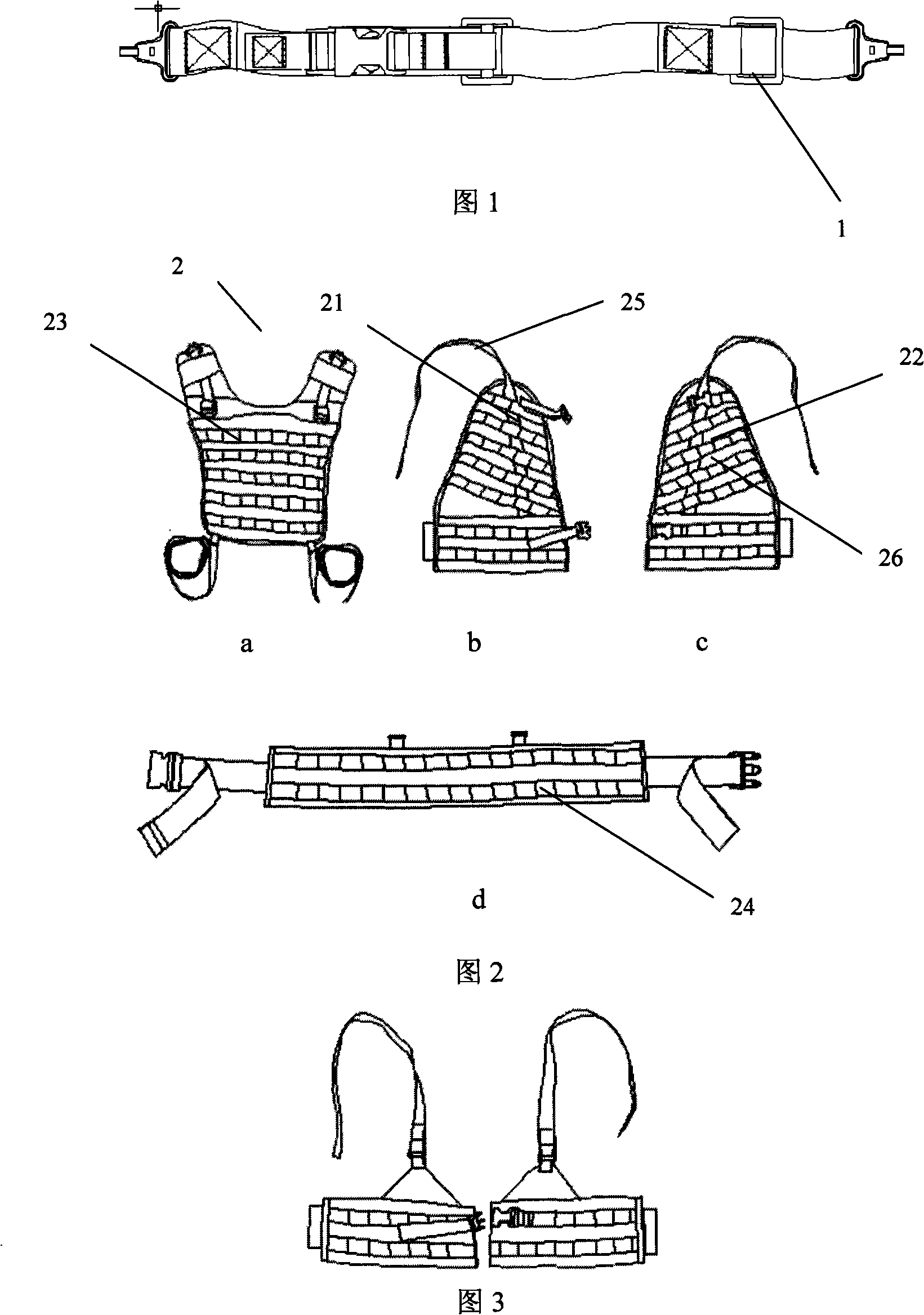

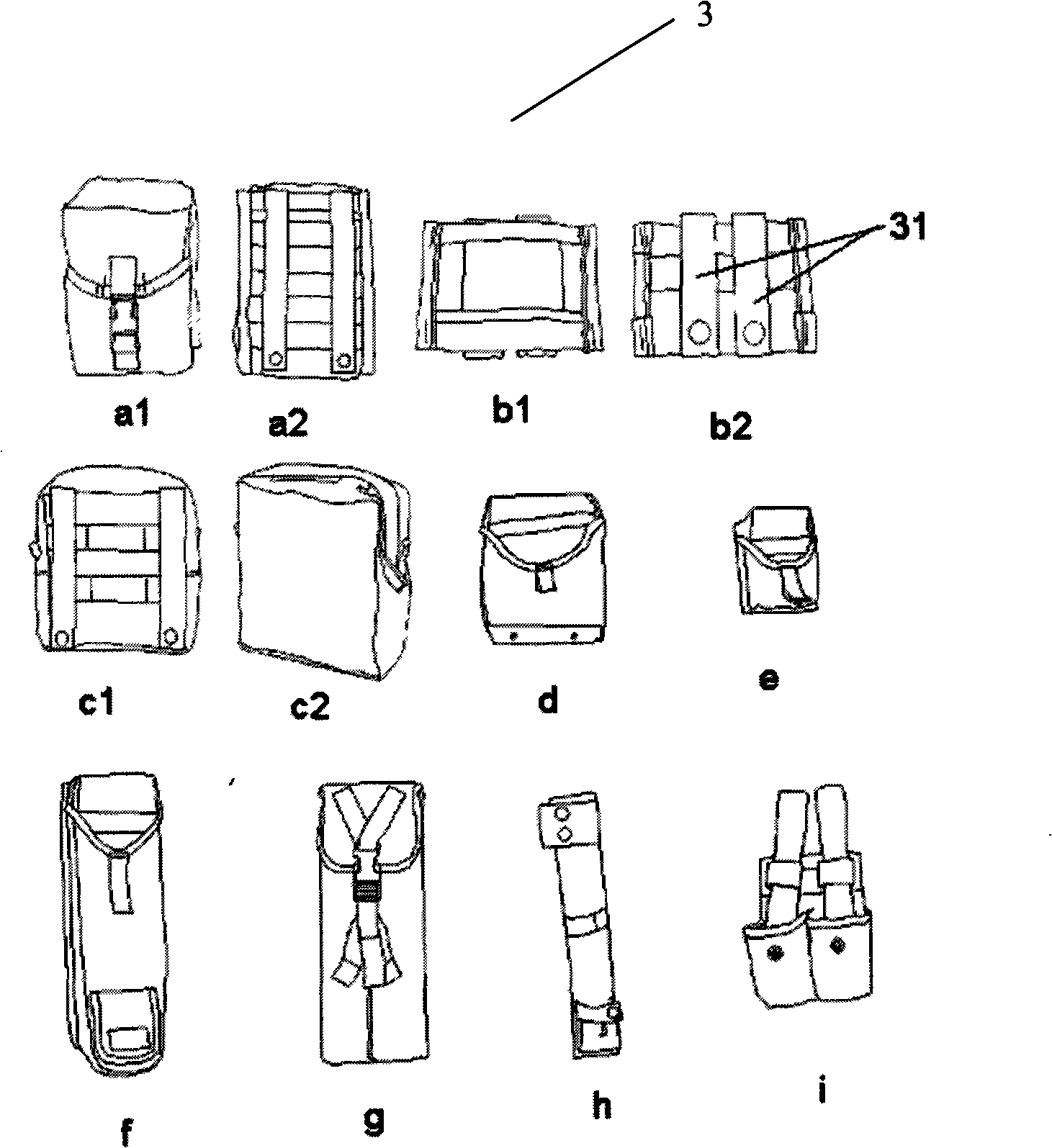

Multifunctional universal back harness for single soldier

The invention discloses a multi-functional individual general back apparel, which comprises a general gun sling, a tactical vest and subsystems. The tactical vest is composed of a left front piece, a right front piece, a shoulder pad and a waist belt. The left front piece, the right front piece and the shoulder pad are combined together through the respective connecting belt and the waist belt. A group of fixation bands with joints are sewed on surfaces of the left front piece, the right front piece, the shoulder pad and the waist belt of the tactical vest, and inserting loops and fixation bands with joints are sewed on the rear faces of the subsystems for adapting to the joints of the fixation bands of the tactical vest, and the subsystems and sockets of the fixation bands are connected on the tactical vest through the inserting loops by means of interleaving, weaving and insertion. Each subsystem of the invention is mobile and flexible and can be assembled and disassembled quickly as well as assembled at will in need of wartime. Each subsystem can be replaced in time and conveniently if damaged, thereby extremely improving the replacement performance of products. The tactical vest of the multi-functional individual general back apparel fits different statures of soldiers and meets the requirements of different seasons, thereby improving the battle effectiveness.

Owner:NANJING JIHUA 3521 SPECIAL EQUIP

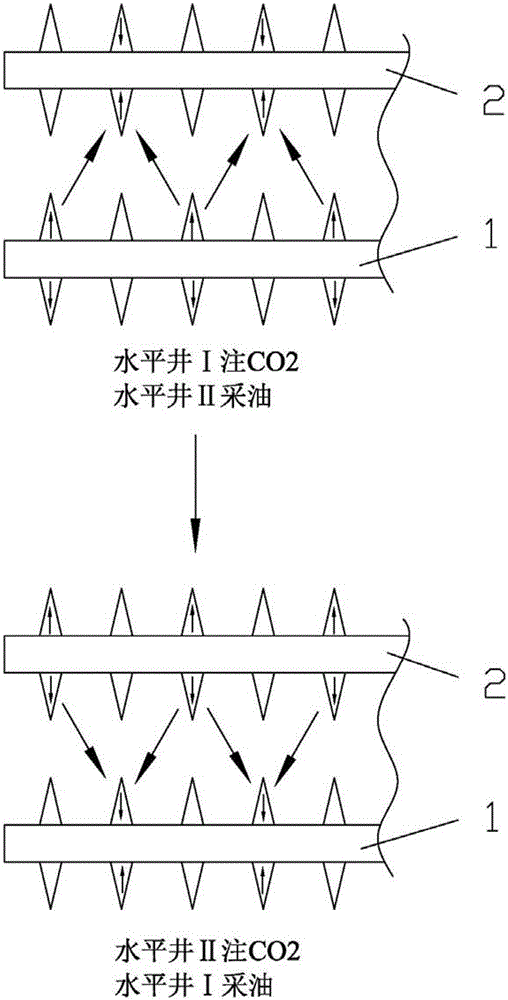

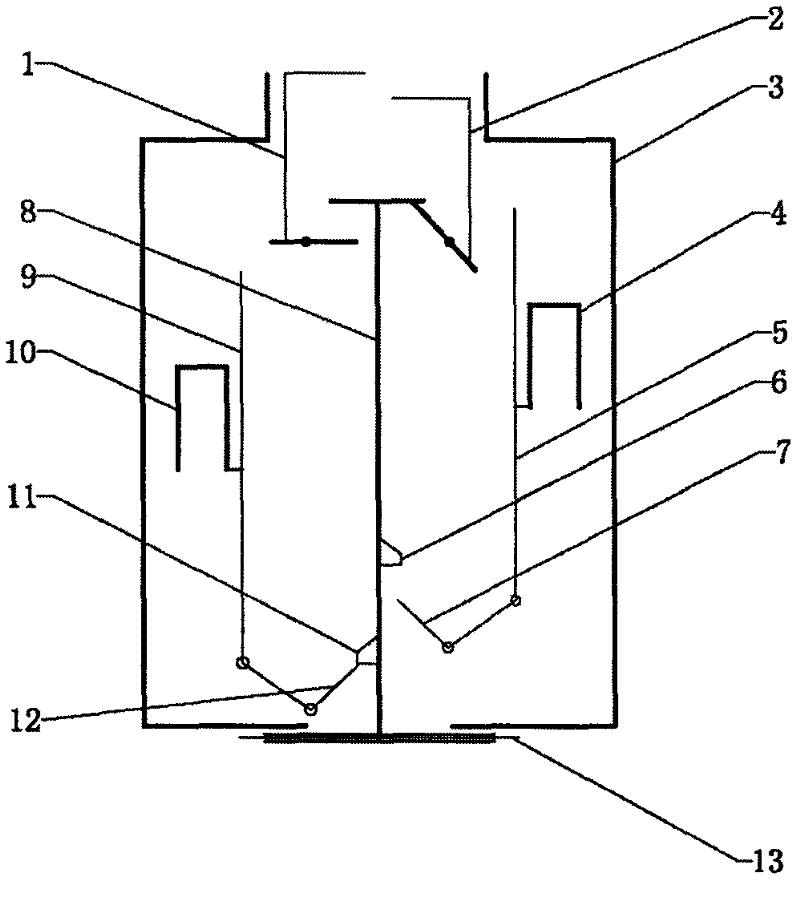

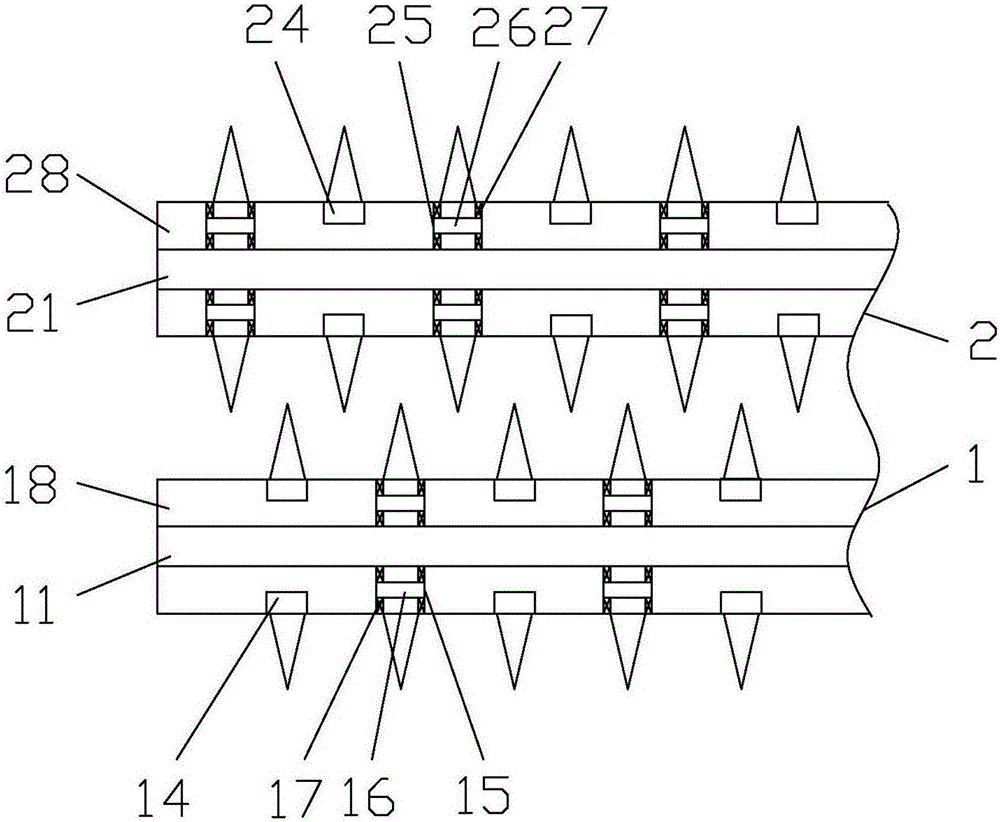

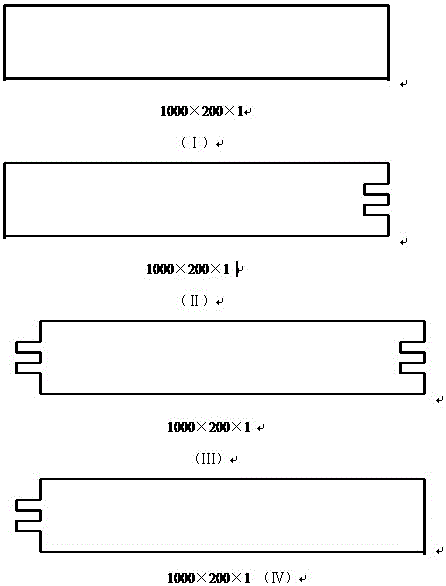

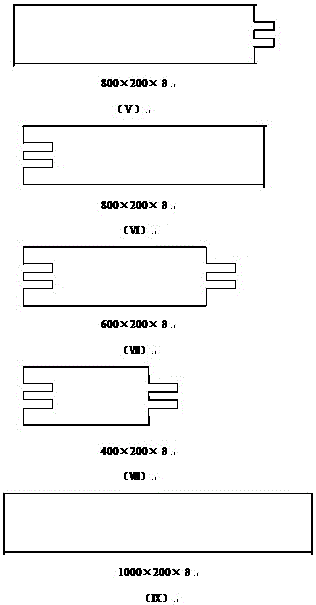

Different-well asynchronous CO2-injecting oil extracting method adopting symmetric-type crack distributing

ActiveCN106761606ASolve the problem of difficult water injectionDisplacement is effectiveFluid removalHorizontal wellsResidual oil

The invention relates to a different-well asynchronous CO2-injecting oil extracting method adopting symmetric-type crack distributing. The different-well asynchronous CO2-injecting oil extracting method comprises the following steps that a well opening oil extracting valve of a horizontal well I is closed, and CO2 is injected into an oil sleeve annular space I and enters an odd stage crack; a well opening of the horizontal well I is closed, and two horizontal wells are simultaneously stewed; a well opening of a horizontal well II is opened to extract oil, and crude oil is generated from an even stage crack and pumped into an oil sleeve annular space II; a well opening oil extracting valve of a horizontal well II is closed, and CO2 is injected into an oil pipe II and enters an annular space formed by a flow guiding pipe II, a casing pipe II and the oil pipe II through a perforating hole II and then enters the odd stage crack; the well opening of the horizontal well II is closed, and the two horizontal wells are simultaneously stewed; and the well opening of the horizontal well I is opened to extract the oil, and the crude oil is generated from the even stage crack and enters an annular space formed by a flow guiding pipe I, a casing pipe I and an oil pipe I and then enters the oil pipe I through a perforating hole I. The different-well asynchronous injecting and extracting method can effectively displace residual oil between the wells, between the cracks and in a dead oil area.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

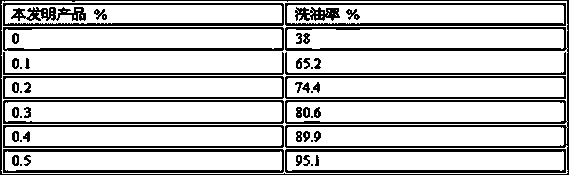

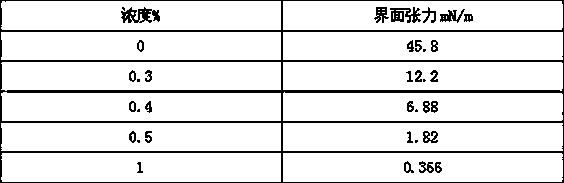

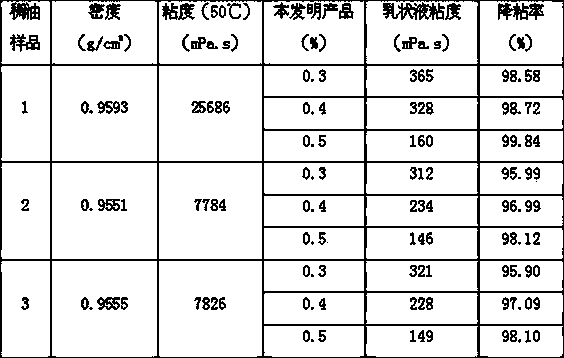

Surfactant complex-based high temperature-resistant solvent

InactiveCN103992783AImprove liquidityImprove permeabilityDrilling compositionInorganic saltsThermodynamics

The invention discloses a surfactant complex-based high temperature-resistant solvent. The surfactant complex-based high temperature-resistant solvent is used for unconventional energy thickened oil steam-injection thermal recovery and through the surfactant complex-based high temperature-resistant solvent, a steam-chemical assistant combined exploitation method is formed. The surfactant complex-based high temperature-resistant solvent comprises a dispersant, a surfactant complex and an inorganic salt, and concretely, the surfactant complex-based high temperature-resistant solvent comprises, by mass, 5-10 parts of the dispersant, 10-30 parts of the surfactant complex, 5-10 parts of the inorganic salt and 80-50 parts of water. Through compounding of a fluorocarbon surfactant and a hydrocarbon surfactant, the surfactant complex-based high temperature-resistant solvent can resist a temperature of 300 DEG C and can improve steam transmission efficiency and stripping, viscosity reduction and displacement effects on thickened oil in thickened oil steam-injection recovery and especially in thickened oil steam assisted gravity drainage (SAGD).

Owner:KARAMAY XINRONG TECH

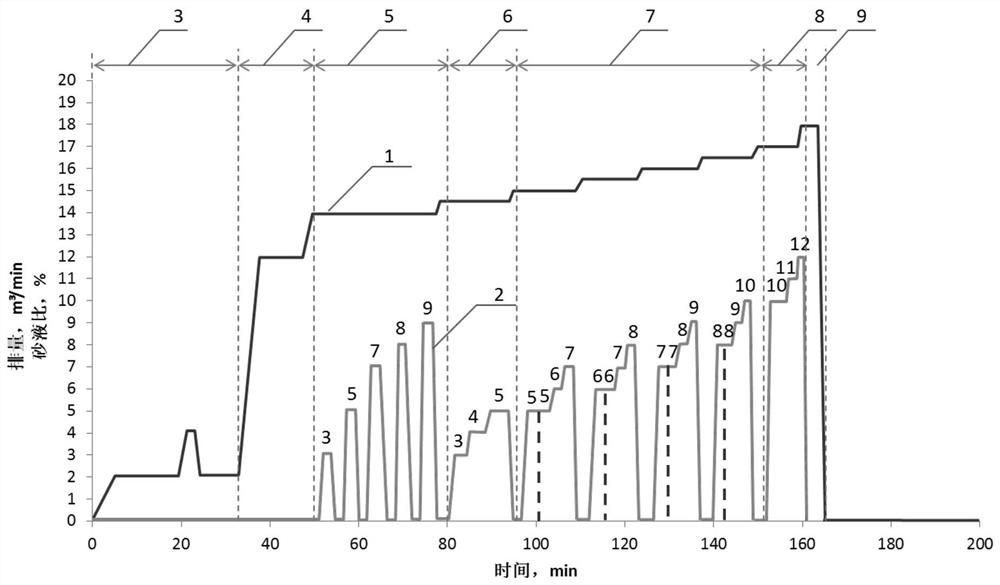

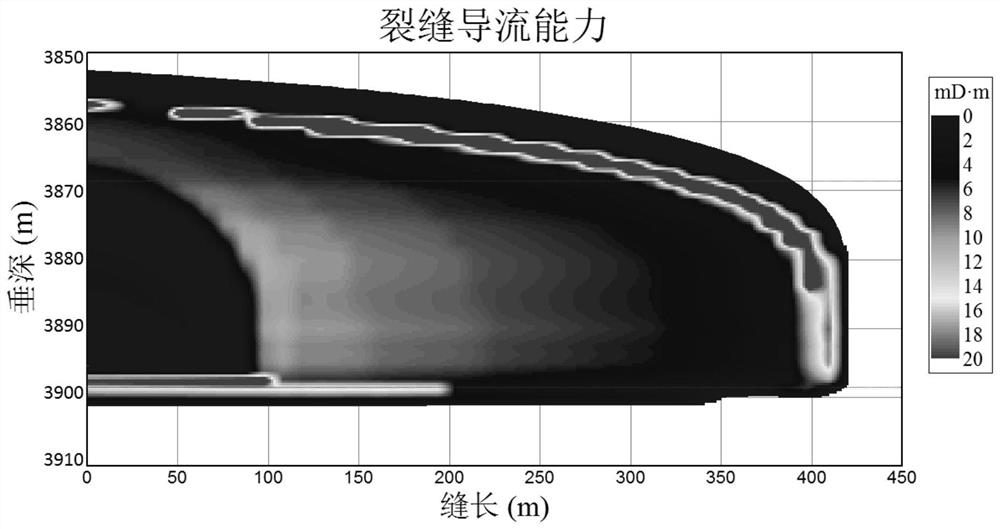

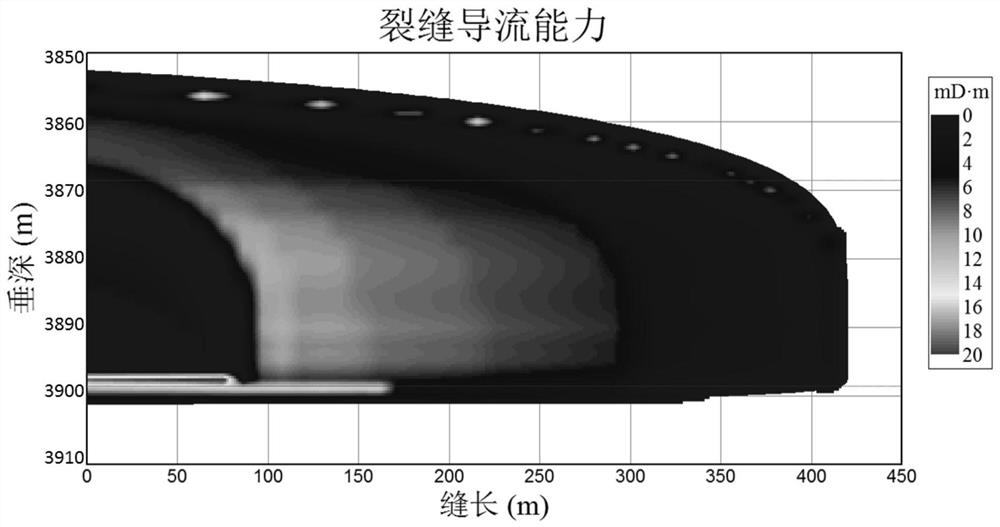

Shale gas fracturing and sand adding method

ActiveCN112240191APrevent the effect of adding sandImprove displacement effectSurveyData processing applicationsPre treatmentShale gas

The invention discloses a shale gas fracturing and sand adding method. The shale gas fracturing and sand adding method comprises the steps of (1) optimizing crack parameters and fracturing construction parameters; (2) optimizing cluster perforation parameters; (3) acid pretreatment; (4) variable-viscosity and variable-displacement prepad fluid fracture forming; (5) small-particle-size proppant slug type sand adding; (6) adding sand into a 40-70 mesh proppant low-sand-liquid-ratio long-section plug at a first section for fracturing; (7) mixing powder ceramic with a 40-70 mesh proppant in a following manner, adding sand and fracturing; (8) fracturing and filling the proppant with high sand-liquid ratio and large particle size; and (9) conducting large-flow-rate displacement under wellhead pressure limiting. According to the shale gas fracturing and sand adding method, the uniform transformation degree and the sand adding amount of multi-cluster perforation in the section can be increased, uniform transformation of multi-cluster cracks in the section and effective increase of the dosage scale of the proppant are achieved, so that the filling degree of the proppant in small-crack wide-scale cracks is improved, and the flow conductivity of a crack system is improved. And the method is particularly suitable for sand fracturing transformation of deep and complex-structure shale and stratified-fracture-development shale gas reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrophobic polymer graft modified acrylamide polymer and preparation method thereof

ActiveCN103539946AGood temperature and salt resistanceImprove anti-aging propertiesDrilling compositionPolymer scienceAging resistance

The invention provides a hydrophobic polymer graft modified acrylamide polymer and a preparation method thereof, mainly for solving the problem in the prior art that general acrylamide polymers have poor temperature resistance, poor resistance to salinity, poor ageing-resistance performance and poor displacement effect. The chemical general formula of the hydrophobic polymer graft modified acrylamide polymer is P-g-X, wherein P is polyacrylamide or acrylamide polymer, X is hydrophobic polymer the molecular chain structure of which is in a form of homopolymerisation, random copolymerization or block copolymerization, and the viscosity average molecular weight of the graft compound is more than or equal to seventeen million. The adoption of the hydrophobic polymer graft modified acrylamide polymer and the preparation method thereof well solves the problem in the prior, and the technical scheme can be used in industrial production and displacement of reservoir oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multi-stage pressure pilot drain valve

ActiveCN102296680ASolve the problem of uncontrollable large discharge volumeImprove displacement effectFlushing devicesWater storageWater saving

The invention discloses a multistage pressure guide drainage valve which comprises a button body, a large drainage button, a small drainage button, a small drainage floater, a small drainage sliding rod, a small drainage positioning tooth, a small drainage button clamp, a button main shaft, a large drainage sliding rod, a large drainage floater, a large drainage button clamp, a large drainage positioning tooth, a sealing sheet and the like, wherein the floaters for controlling large drainage water consumption and small drainage water consumption can be used for freely regulating height on respective sliding rods for controlling the water consumptions. According to the invention, the problems of finely regulating the water storage height by the large drainage fixed floater of the traditional drainage valve according to the size of a water inlet and being incapable of controlling large drainage quantity because too much water is filled in the traditional water tank are overcome so that the water pressure advantage of the height of the water tank is fully developed, therefore, purposes of vigorous washing, clean replacing and water saving are fully realized.

Owner:FOSHAN HEGII SANITARY WARES

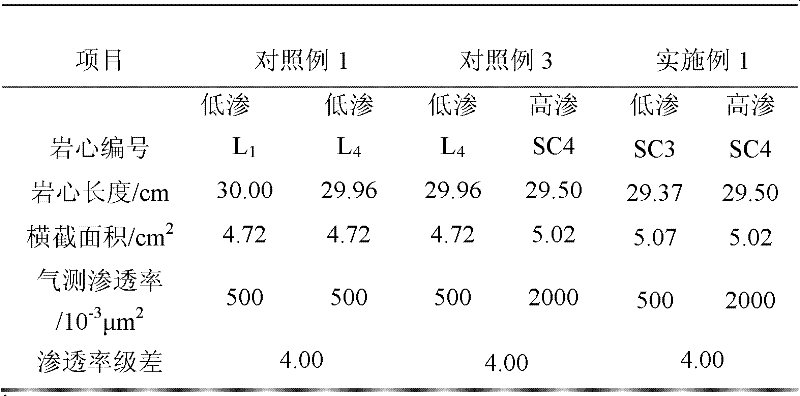

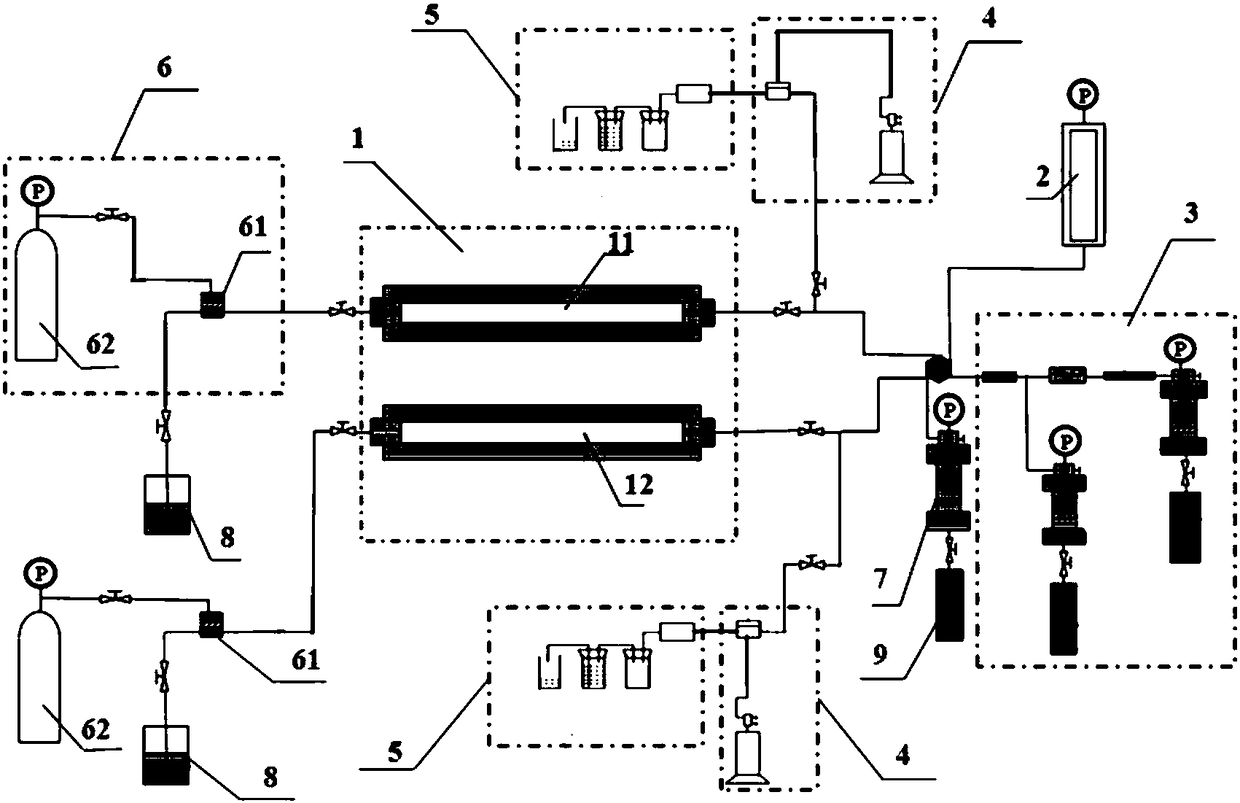

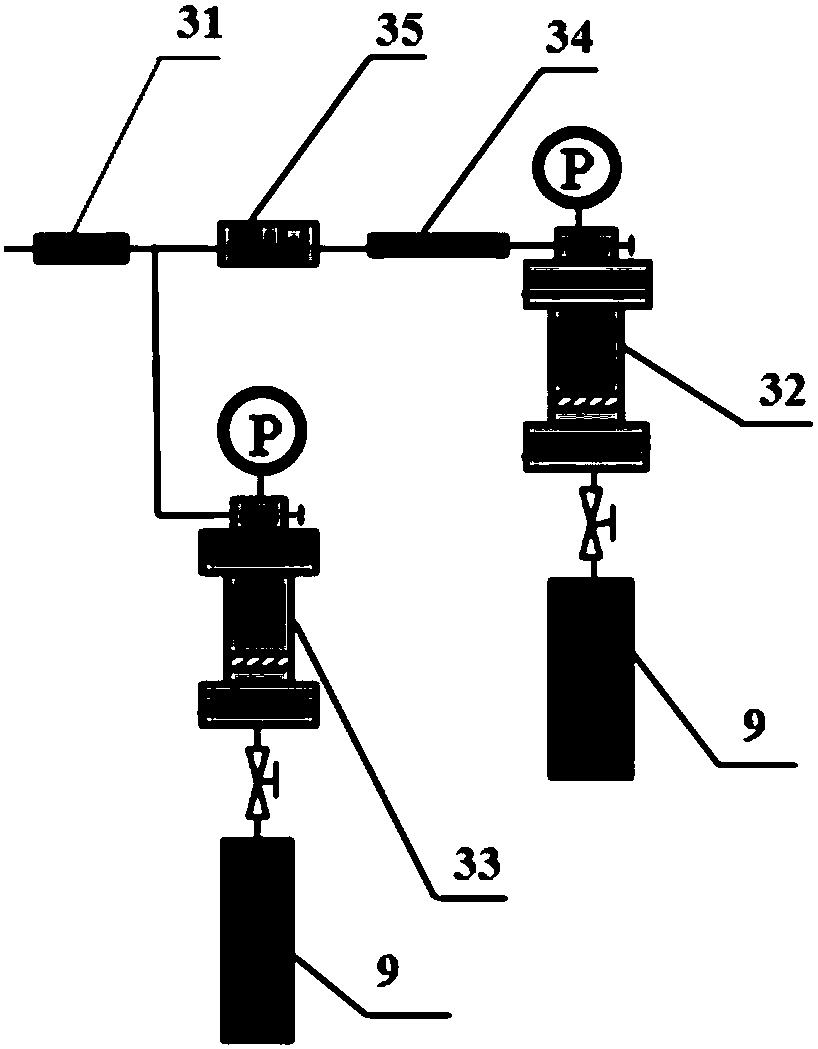

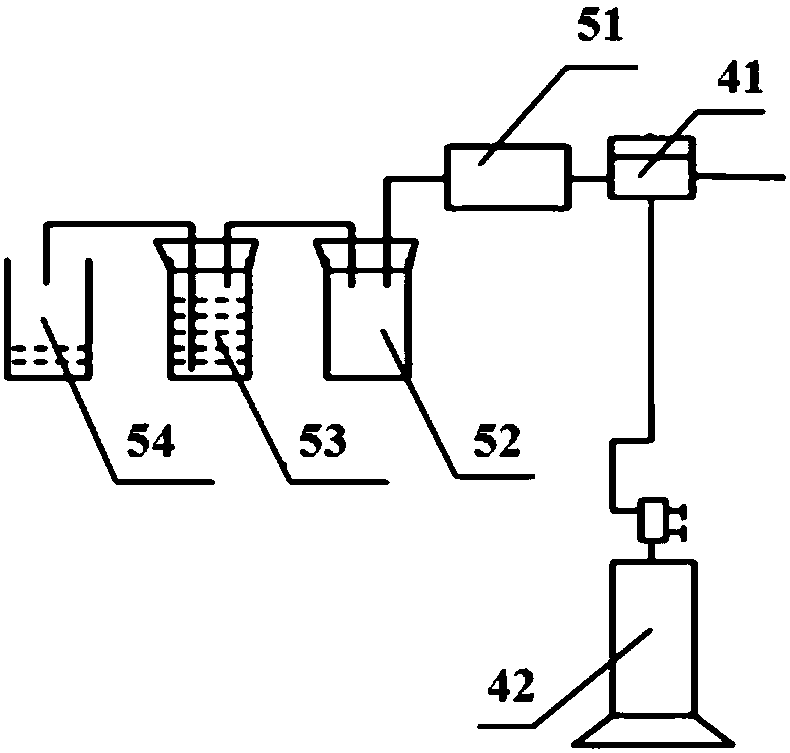

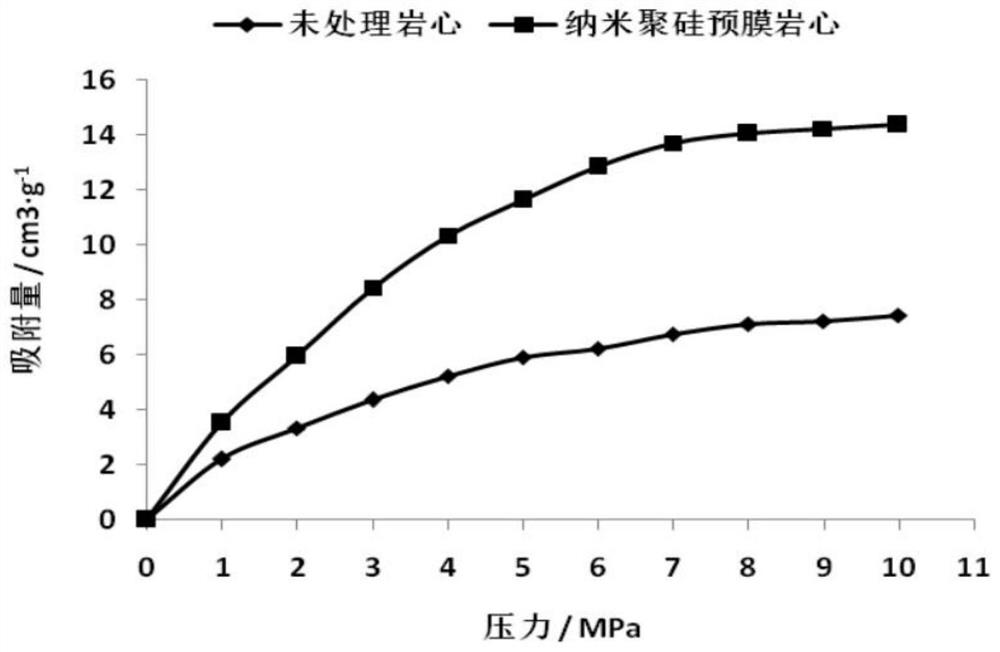

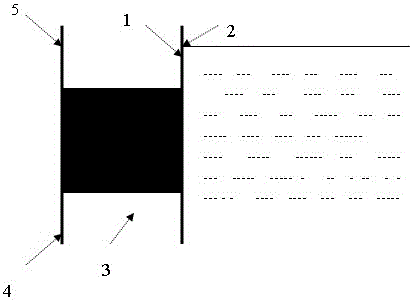

System and method for evaluating the effect of CO2 emulsion on oil reservoir displacement

PendingCN108868716AImprove mining efficiencyImprove displacement effectFluid removalOther gas emission reduction technologiesEmulsionProcess engineering

The invention provides a system and method for evaluating the effect of CO2 emulsion on oil reservoir displacement. The system comprises a high temperature steam generating device for injecting high temperature steam into a simulated heterogeneous core model; an emulsion generator for injecting CO2 emulsion into the simulated heterogeneous core model; a first pressure control device for regulatingthe pressure of the simulated heterogeneous core model to the exploiting pressure; a drainage gas collection device for collecting and measuring exploitation products. The present invention also provides a method for evaluating the effect of CO2 emulsion on reservoir displacement. By simulating the high-temperature steam-assisted CO2 emulsion throughput, the displacement effect of the reservoir in the heterogeneous core model is evaluated to provide guidance for the application of high-temperature steam-assisted CO2 emulsion stimulation to produce heterogeneous heavy oil.

Owner:PETROCHINA CO LTD

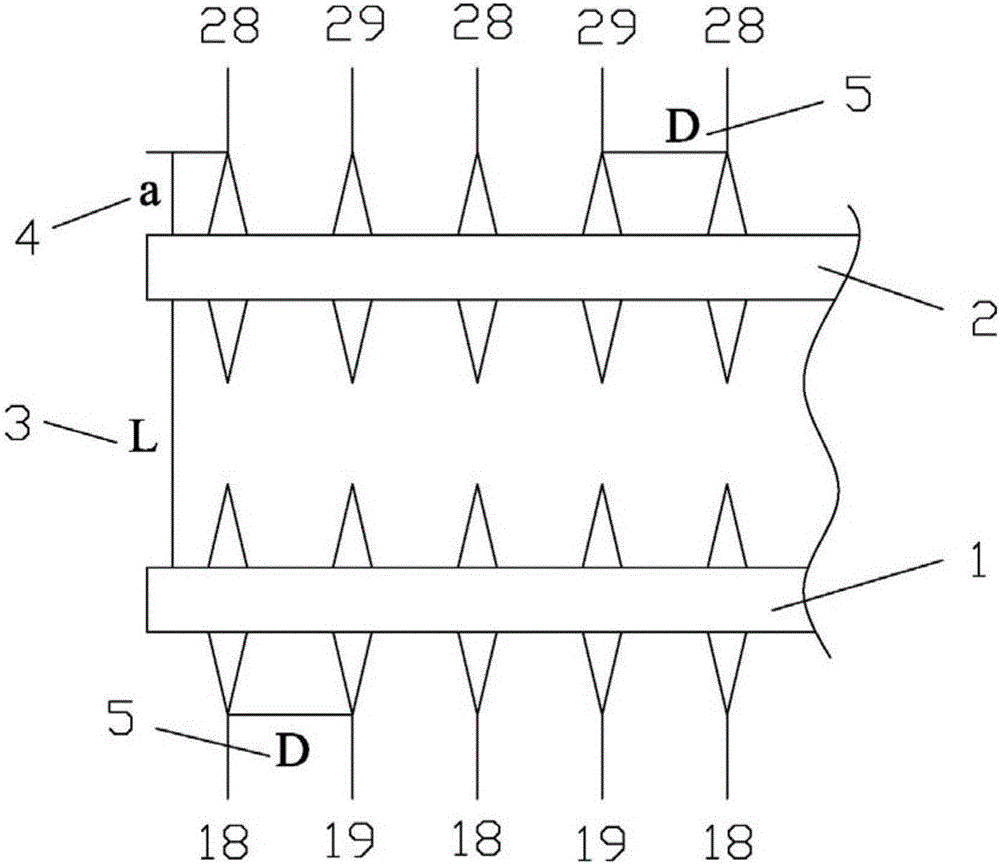

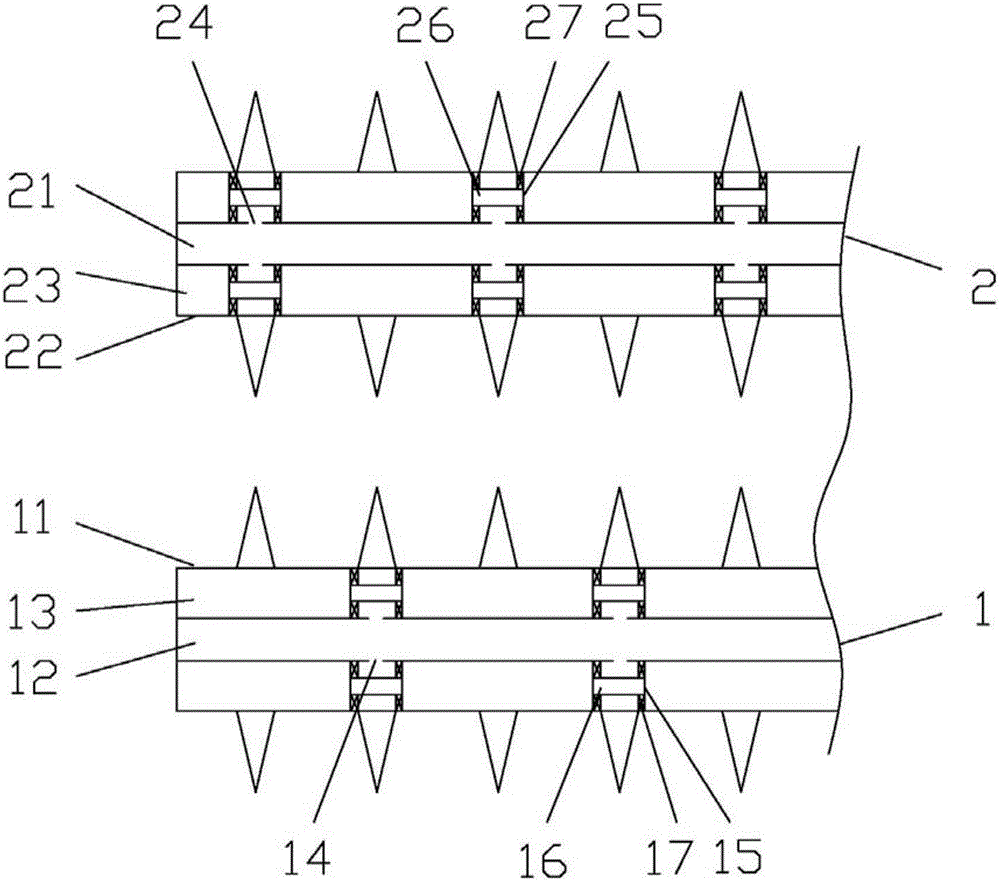

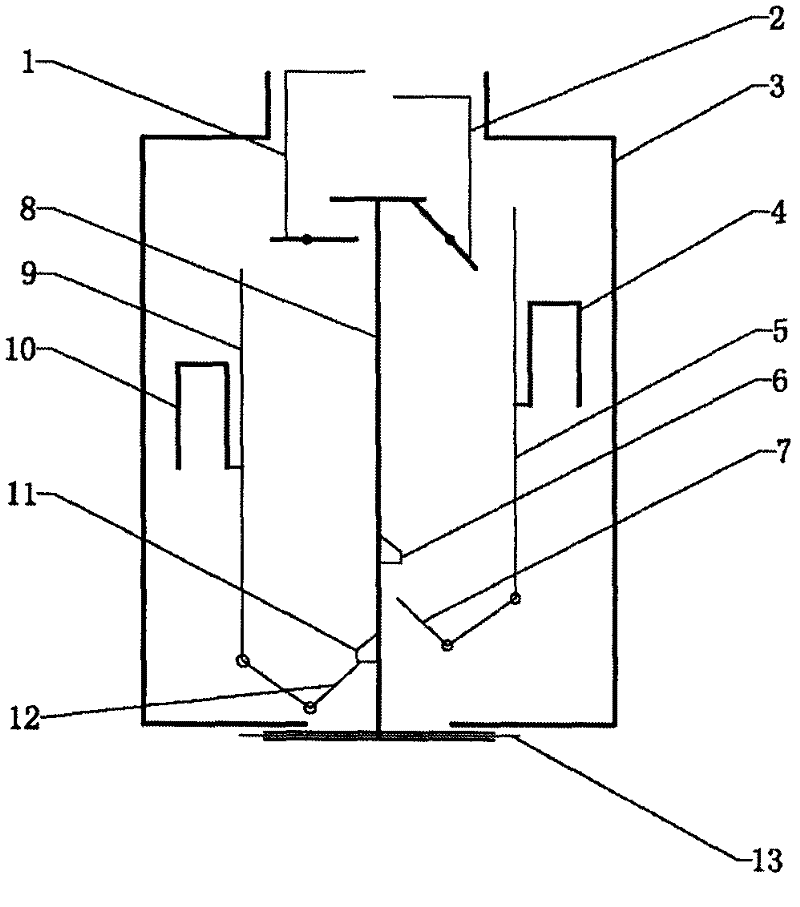

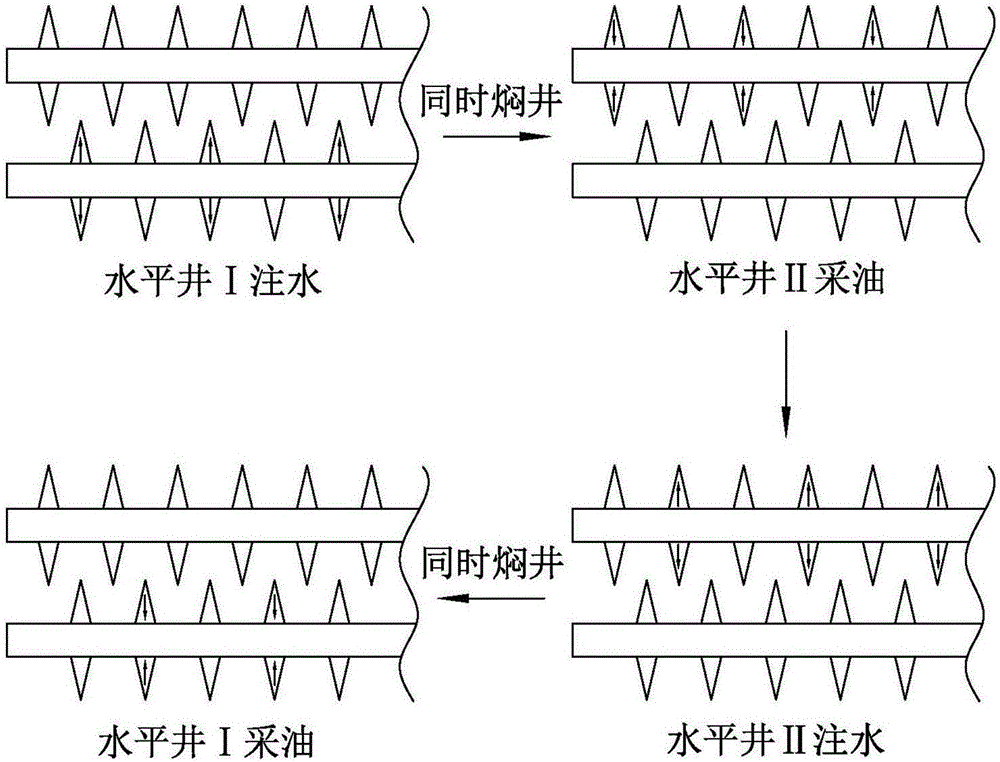

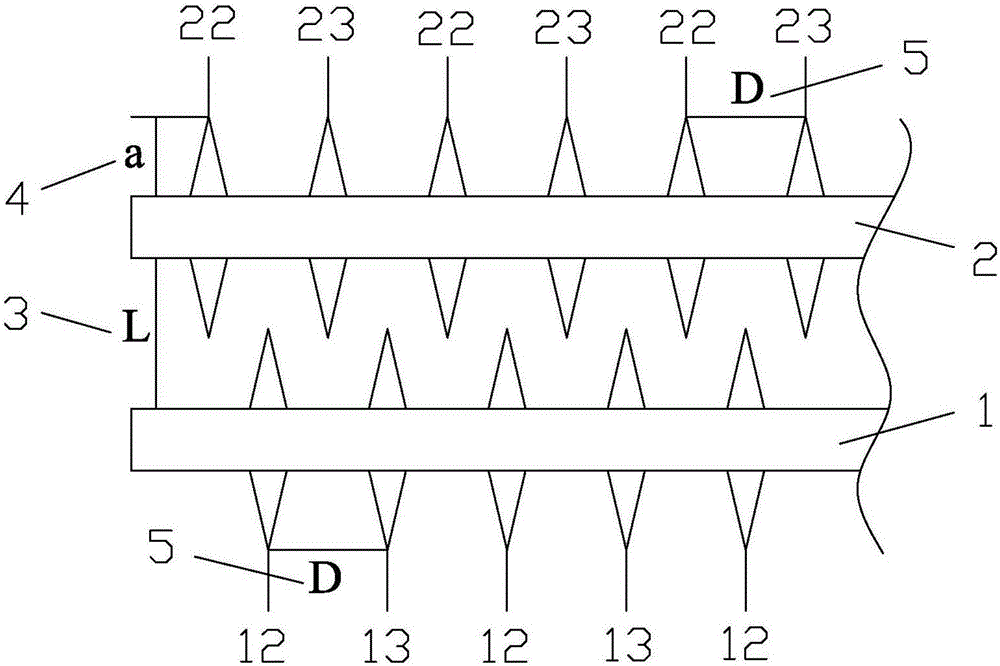

Different-well asynchronous water injecting oil extracting method for double fracturing horizontal wells through zipper-type crack distributing

ActiveCN106761612AImprove displacement effectDisplacement is effectiveFluid removalHorizontal wellsResidual oil

The invention relates to a different-well asynchronous water injecting oil extracting method for double fracturing horizontal wells through zipper-type crack distributing. The different-well asynchronous water injecting oil extracting method comprises the following steps that in an initial production stage, the two horizontal wells are simultaneously exploited for a period of time through natural energy; oil pipes of the two horizontal wells are taken out, and an injection allocation valve and an injection and extracting separating device are installed on a special position; a well opening oil extracting valve of the horizontal well I is closed, the injection allocation is opened, water is injected into an oil sleeve annular space, and the injected water enters an odd stage crack; the well opening of the horizontal well I is closed to stew the corresponding well, and crude oil and the injected water are imbibed and replaced; a well opening of the horizontal well II is opened to extract the oil; a well opening oil extracting valve of the horizontal well II is closed, the injection allocation valve is opened, and water is injected into the oil sleeve annular space, and the injected water enters an even stage crack; the well opening of the horizontal well II is closed to stew the corresponding well, and the crude oil and the injected water are imbibed and replaced; and the well opening of the horizontal well I is opened to extract the oil. The different-well asynchronous injecting and extracting method can effectively displace residual oil between the wells, between the cracks and in a dead oil area, and the swept volume is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

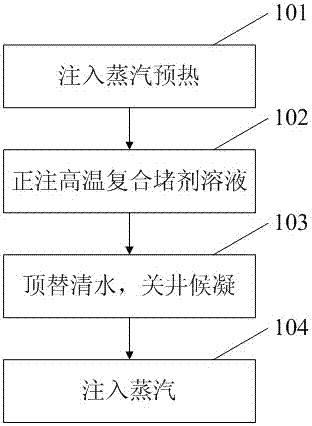

Plugging control method for treating steam channeling during steam huff and puff

InactiveCN107288599AStable waterHigh apparent viscosityFluid removalSealing/packingFoaming agentNitrogen

The invention provides a plugging control method for treating steam channeling during steam huff and puff. The plugging control method for treating steam channeling during steam huff and puff comprises the steps that firstly, steam is injected into a steam huff and puff well in which steam channeling occurs for preheating before steam injection; secondly, a high-temperature composite plugging agent solution is positively injected into an oil tube of the steam huff and puff well in which steam channeling occurs; thirdly, clear water is used for replacement after the high-temperature composite plugging agent solution is positively injected, and the well is closed for solidification; and fourthly, steam is injected into the steam huff and puff well in which steam channeling occurs, and nitrogen and a high-temperature foaming agent are injected during the steam injection process. According to the plugging control method for treating steam channeling during steam huff and puff, a high-permeability strip-shaped zone can be effectively plugged, the situation that the steam permeates into other production wells along the high-permeability zone, and consequently the permeability of the high-permeability zone is decreased is prevented, and steam channeling is well controlled.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reinforcing method of vacuum preloading lead pipe pile gas injection carbonized super-soft foundation

ActiveCN110512591AImprove compactionImprove displacement effectSoil preservationSites treatmentResource utilization

The invention discloses a reinforcing method of a vacuum preloading lead pipe pile gas injection carbonized super-soft foundation, and belongs to the technical field of super-soft foundation reinforcing treatment of geotechnical engineering. The reinforcing method comprises the steps of site treatment and exploration, first pile group construction and beating, spraying mixing equipment placement and debugging, curing agent spraying and mixing, first treatment system layout, vacuum preloading-gas injection carbonized treatment, first site treatment completing, continuous construction, final treatment and the like. The reinforcing method has the advantageous of a vacuum preloading method, a magnesium oxide carbonization curing method and a pipe pile composite foundation, the drainage efficiency and the infiltration diffusion efficiency of carbon dioxide are greatly improved through coordination work of vacuum preloading and pipe pile gas injection, the compacting displacement action of apipe pile on soft soil is fully utilized, mud soil is effectively glued through hydration products and carbonization products, thus the intensity of the soft soil composite foundation is enhanced, and the stability is improved. The reinforcing method has the characteristics that the treatment effect is good, the period is short, and low-carbon and environmentally-friendly and economic efficiencyare achieved, and resource utilization of industrial waste in soft foundation treatment is achieved.

Owner:NANJING FORESTRY UNIV

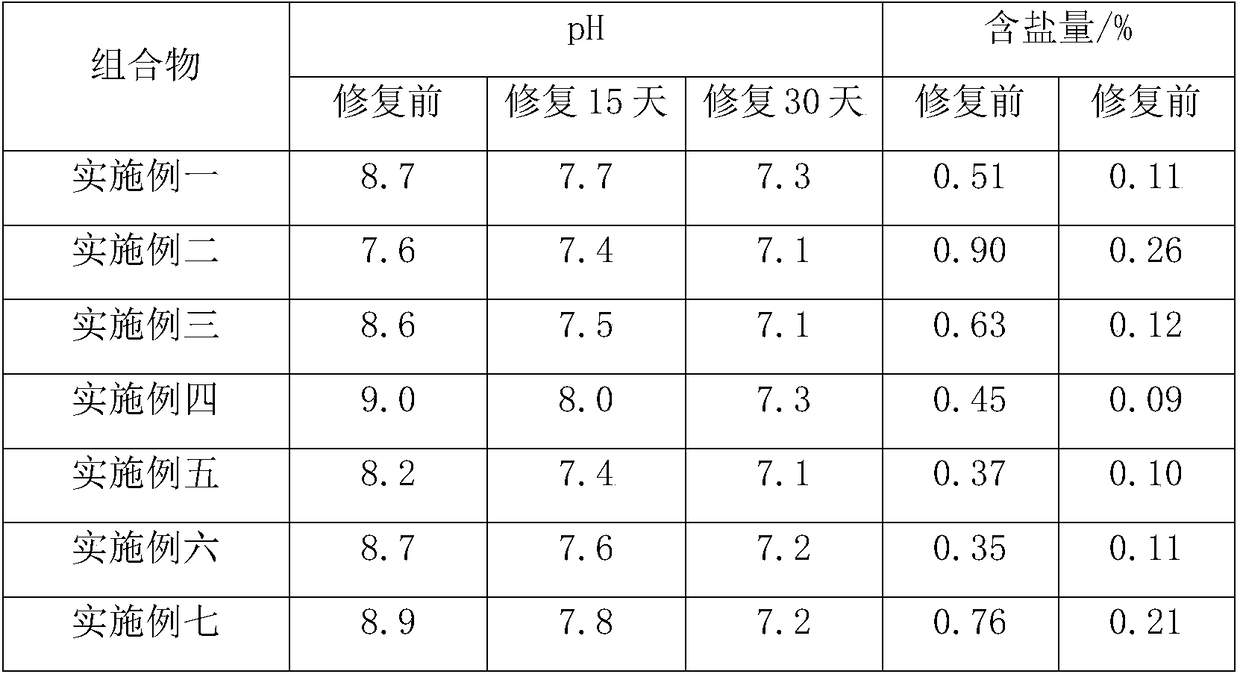

Composition for improving saline-alkali soil and preparation method thereof

InactiveCN108559520AQuick Alkalinity AdjustmentLower pH valueOther chemical processesOrganic fertilisersAlkali soilCyclodextrin

The invention discloses a composition for improving saline-alkali soil, and belongs to the technical field of improvement of saline-alkali soil. The composition is prepared from, by weight, 40-80 parts of cyclodextrin, 40-80 parts of polylactic acid, 20-70 parts of calcium sulfate, 20-70 parts of magnesium sulfate, 10-20 parts of aluminum sulfate, 30-50 parts of ammonium sulfate, 0.5-1.5 parts ofyeast, 0.5-1.5 parts of lactic acid bacteria, 0.5-1.5 parts of acetobacter, 0.5-1.5 parts of gluconobacter, 0.5-1.5 parts of aspergillus niger, 10-30 parts of peptone and 10-30 parts of glucose. The composition rapidly adjusts the alkalinity of the saline-alkali soil by inorganic strong acid weak base salt, and the pH value of the saline-alkali soil is continuously adjusted by the action of microorganisms.

Owner:四川川能环保科技有限公司

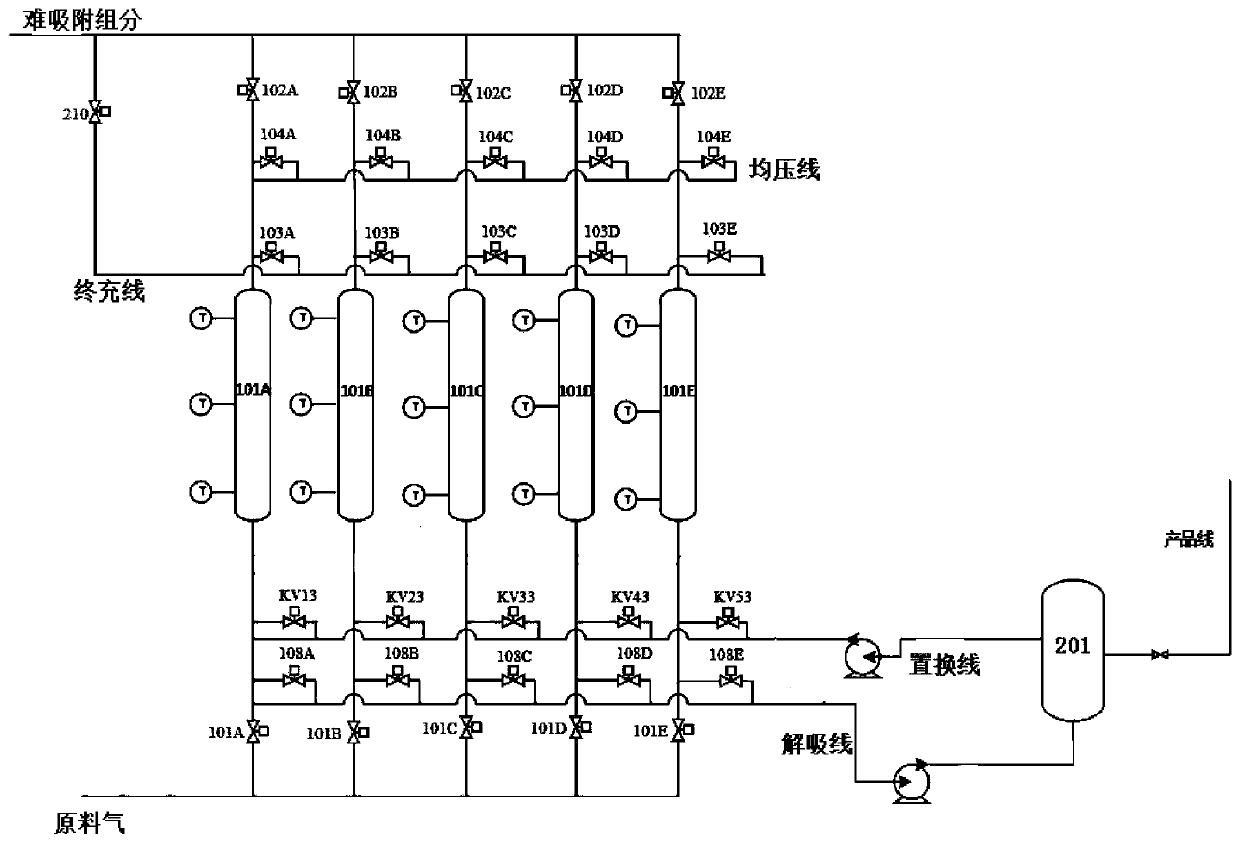

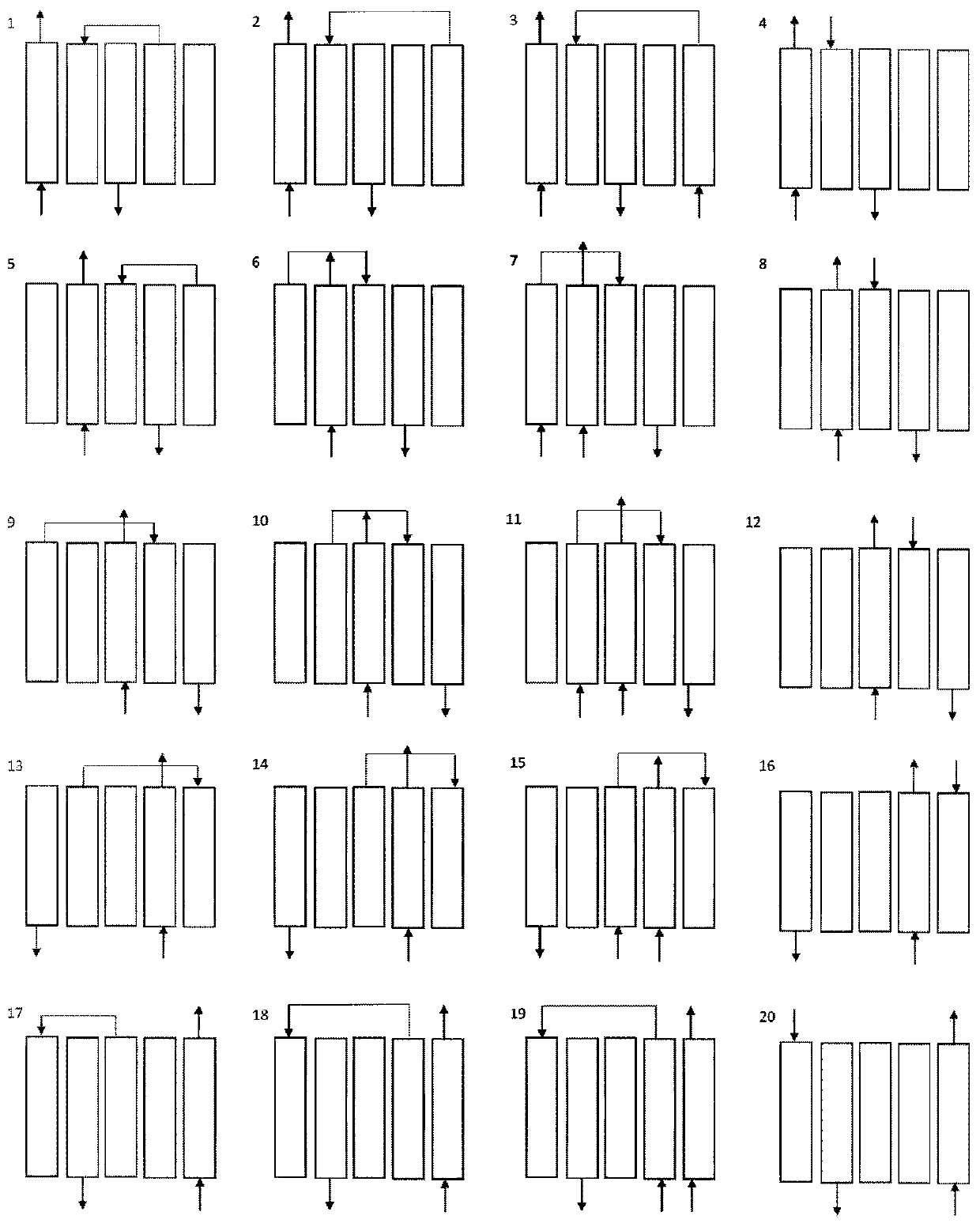

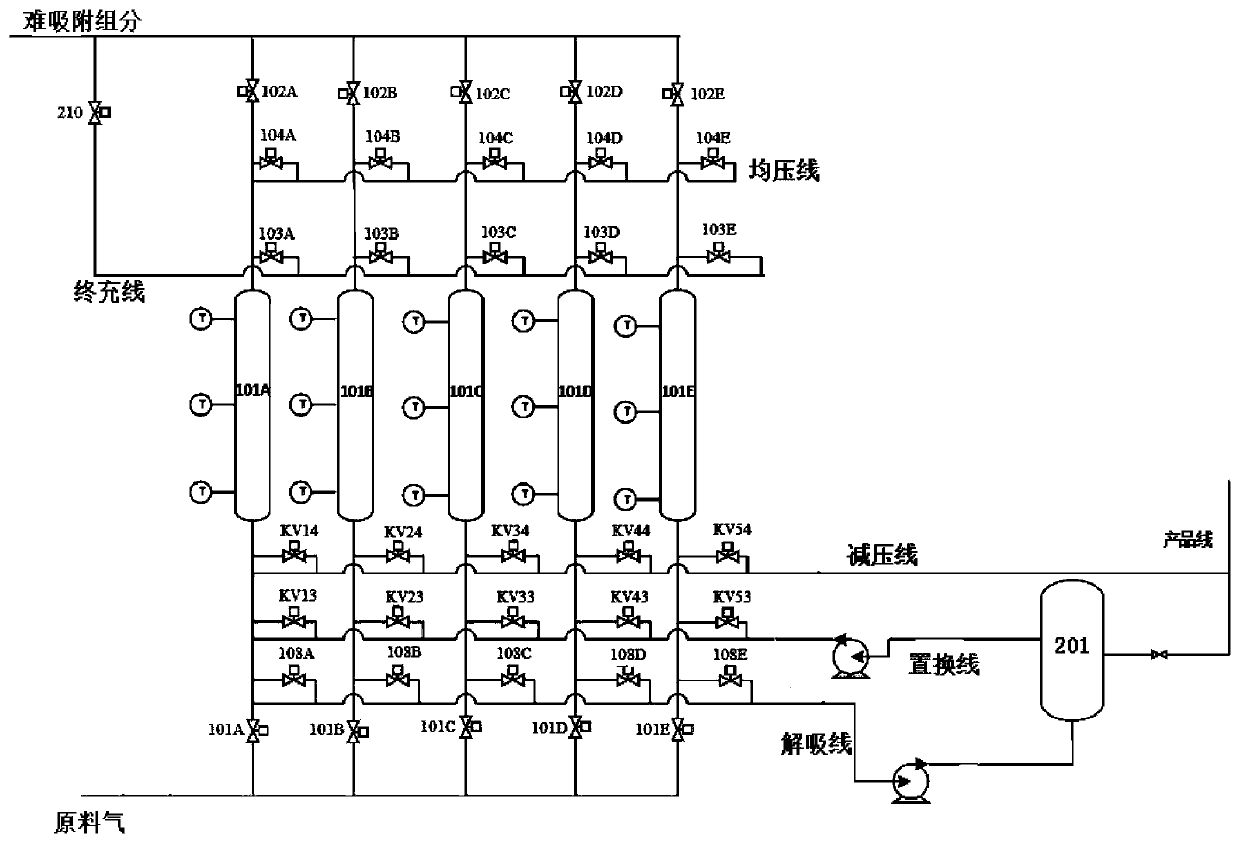

Method for increasing concentration of gas easy to adsorb by using pressure swing adsorption method

ActiveCN110354637ATo achieve mutual cooperationIncrease processing rateDispersed particle separationSorbentDesorption

The invention provides a method for increasing the concentration of a gas easy to adsorb by using a pressure swing adsorption method. The method comprises the following steps: (1) feeding a raw material gas into a first adsorption tower, and performing adsorption operation till an adsorbent is saturated; (2) performing pressure equalizing operation on a first adsorption tower after adsorption; (3)introducing a product gas into an unadsorbed gas for exchange, and blowing an exchanged gas into other adsorption towers; (4) performing pressure equalizing operation on the first adsorption tower after exchange for a second time; (5) performing vacuum desorption on the first adsorption tower so as to obtain a product gas; (6) pressurizing the first adsorption tower after desorption. Through theprocedures, multiple adsorption towers cooperate to achieve concentration increase of the gas easy to adsorb, particularly the product gas is adopted as an exchange gas, the exchanged gas is fed intoother adsorption towers, and pressure equalizing operation is implemented after exchange, so that not only is the exchange effect improved, but also the concentration and the recycling rate of a component easy to adsorb can be increased.

Owner:盖氏科技 +1

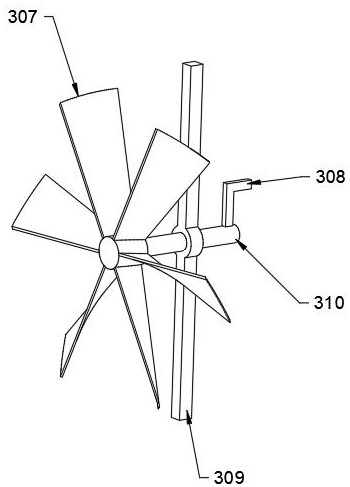

Downhole rotational flow shearing generator

ActiveCN102787823ALow viscosityReduce the power requiredFlushingSealing/packingPetroleumEnergy conversion efficiency

The invention discloses a downhole rotational flow shearing generator, comprising a coupling, an outer barrel and a guide holder and relating to the cementing technical field in the petroleum engineering. The downhole rotational flow shearing generator is characterized in that a shearing rotor is arranged in the outer barrel, the shearing rotor is provided with a blade grid, a locking screw is used for fixing a guide stator, the guide stator plays a flow guiding role, the guide stator is provided with a plurality of guide oblique holes, the flowing direction of the fluid is changed by the guide oblique holes, the fluid hits on the rotational flow rotor vertically, the energy conversion efficiency is increased, the rotational flow rotor generates the high-speed rotation, the spiral fluid continues to be under a shearing and stirring action and finally flows out through the guide seat arranged at the end part of the outer barrel in the shape of a large-intensity spiral flow. The downhole rotational flow shearing generator has the beneficial effects of reasonable structure and high intensity, after the downhole rotational flow shearing generator is arranged in the well cementing process, the peripheral shearing drive force of the well wall can be increased through the spiral flow of the downhole rotational flow shearing generator, the rock debris can be effectively carried, and the well wall can be washed more effectively, the interface cementing strength can be increased, the displacement effect of the cement paste to the drilling fluid can be increased by 5%-7%; the initial jelling time of the cement paste is shorted by 10%-15%, the cementing strength of the well cementing bi-interface is increased by 20%-30%, the compressive strength of the cement stone is increased by 15%-22%, and the cementing quality of the second interface is obviously better than the conventional cementing.

Owner:王震

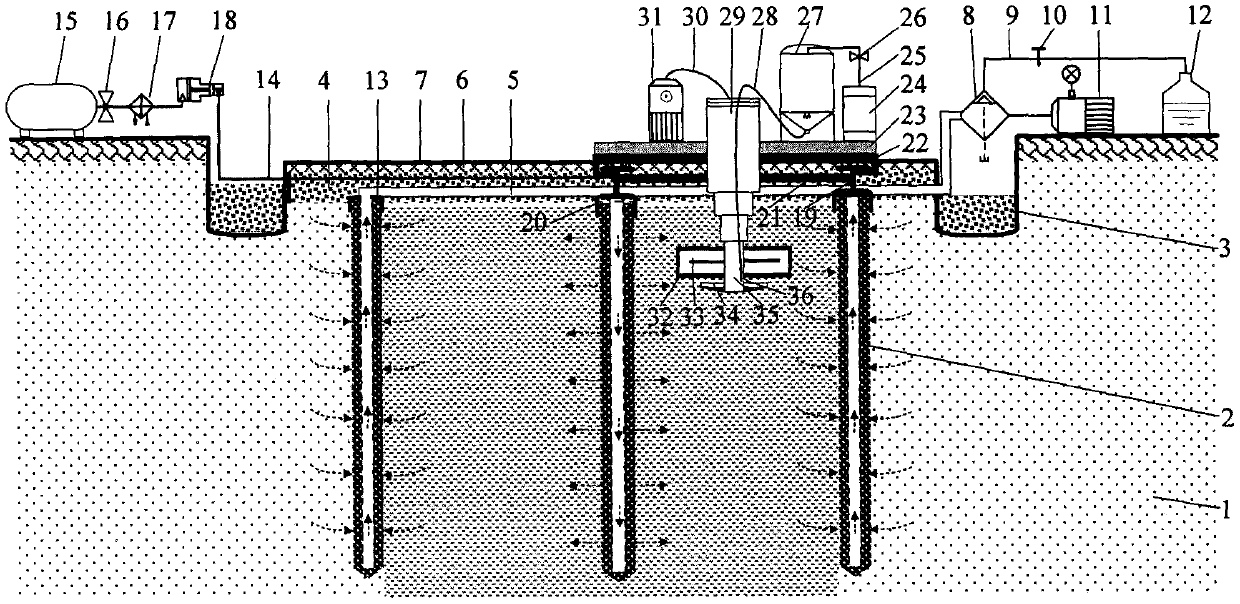

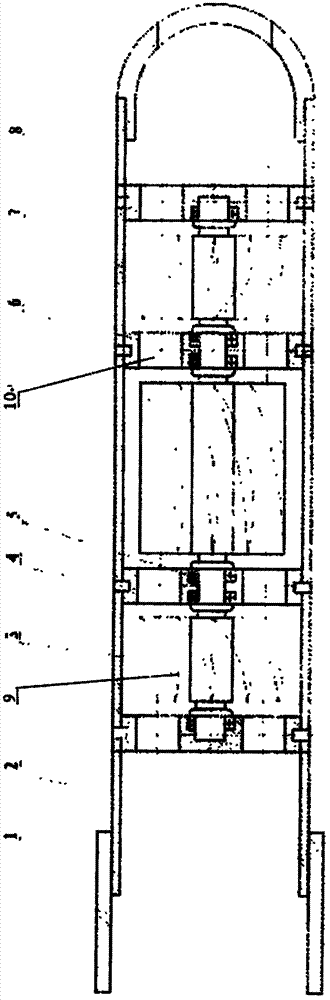

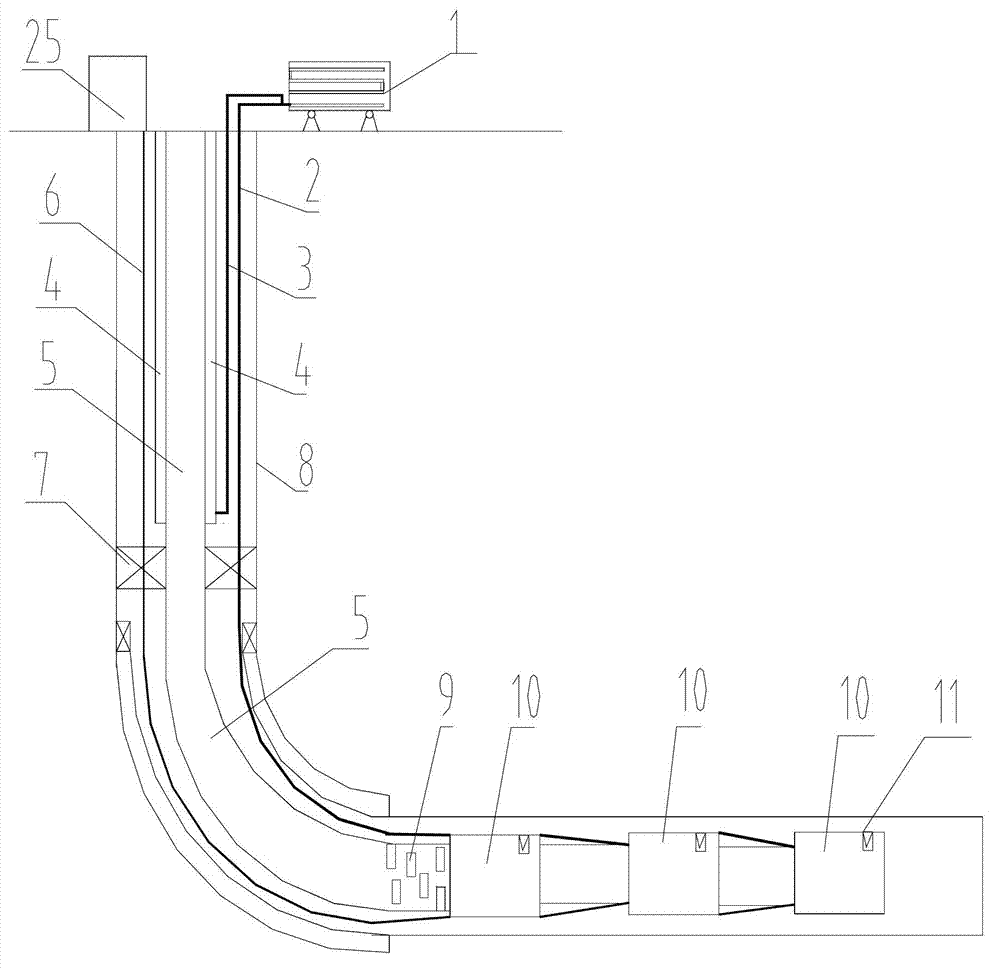

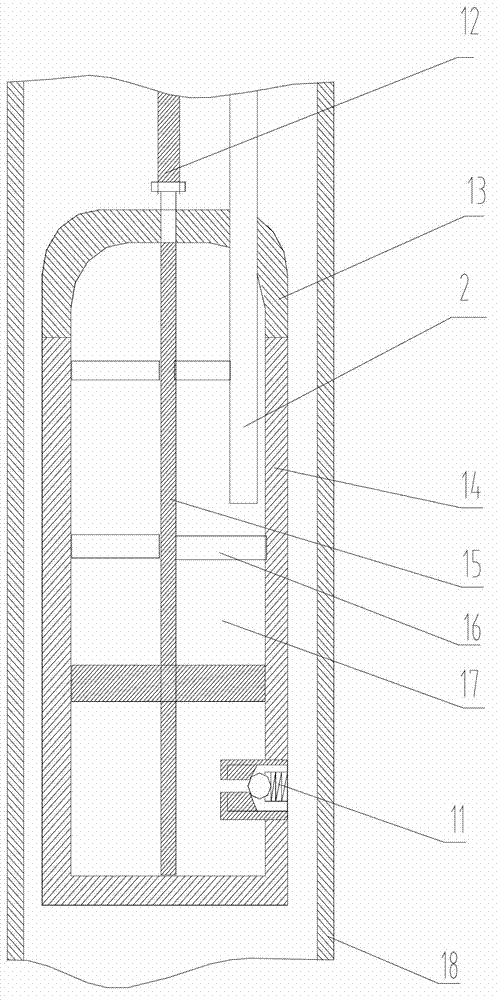

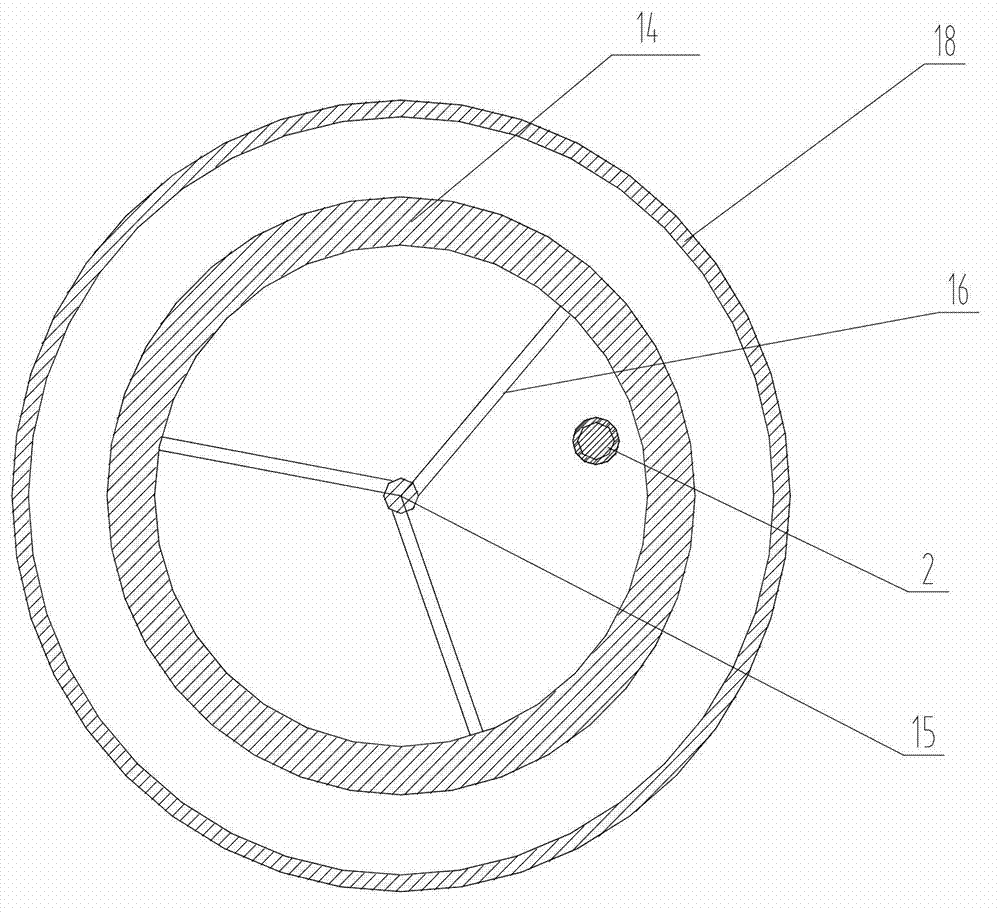

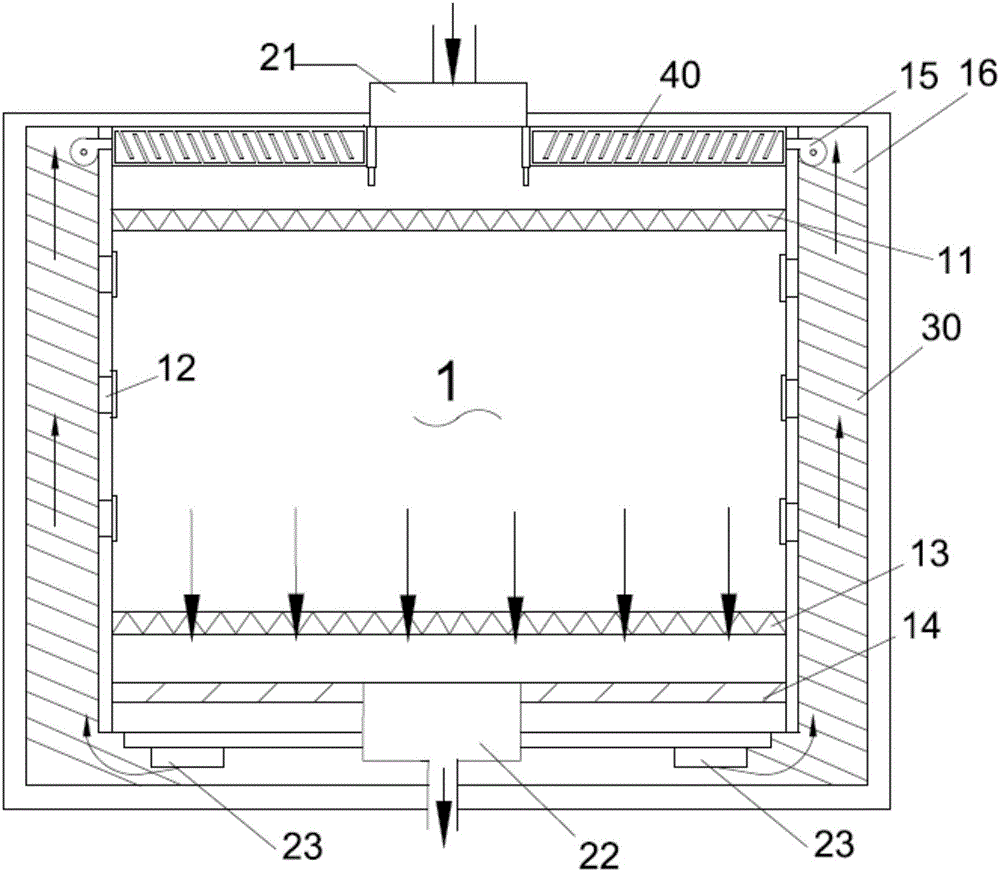

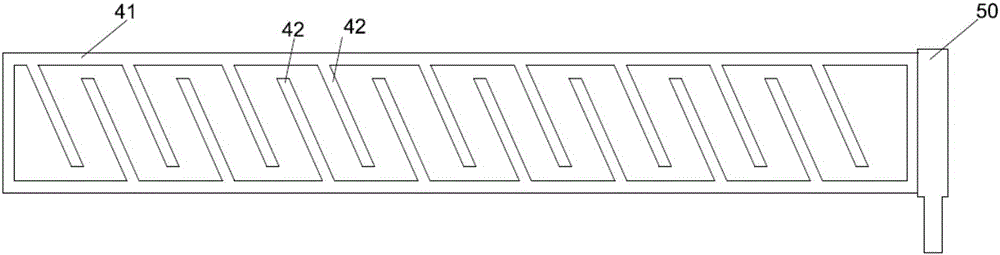

Steam heavy oil thermal recovery equipment and method thereof

Steam heavy oil thermal recovery equipment comprises a ground device and a downhole device. The downhole device comprises at least one steam generator. The steam heavy oil thermal recovery equipment further comprises an oil pipe, a water delivering pipe and a cable, wherein the upper ends of the oil pipe, the water conveying pipe and the cable are connected with the ground device, the oil pipe, the water conveying pipe and the cable in a wellhole extend to a horizontal well section, the lower end of the oil pipe is positioned in an oil layer, and the lower ends of the water delivering pipe and the cable are respectively connected with the steam generators which are arranged above or in the oil layer. The invention further provides a method for steam heavy oil thermal recovery. Steam generated by the steam generators in an embodiment of the steam heavy oil thermal recovery equipment is directly used for heating heavy oil, temperature of the steam can be increased, recovering degree of the heavy oil is greatly improved, the steam is not required to be delivered to the oil layer section from the ground via the wellhole, so that steam leakage and heat loss during delivering are avoided. And the steam heavy oil thermal recovery equipment and the method thereof are particularly applicable to offshore oilfields and other fields with limited borders.

Owner:CHINA NAT OFFSHORE OIL CORP +1

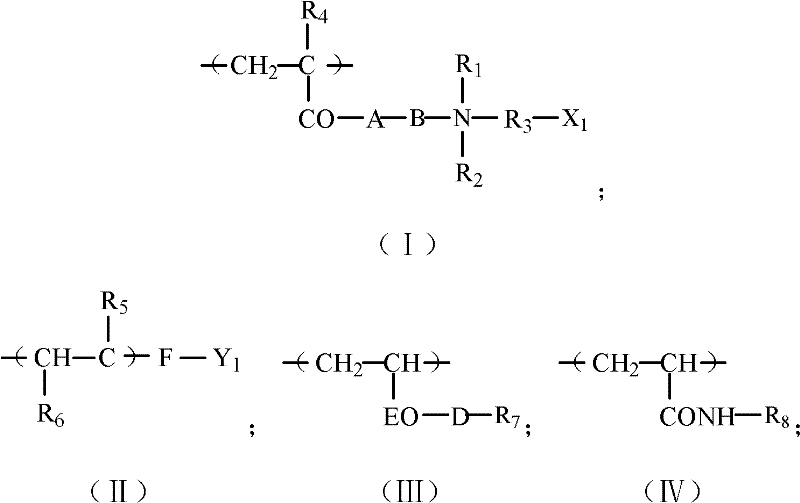

Amphoteric cross-linked polymer microsphere-hydrophobic associative polymer profiling/flooding agent and application thereof

ActiveCN106467733AHigh mechanical strengthSufficient deformabilityDrilling compositionCross-linkPolymer science

The invention relates to an amphoteric cross-linked polymer microsphere-hydrophobic associative polymer profiling / flooding agent and an application thereof. The profiling / flooding agent comprises 0.01-0.5% of amphoteric cross-linked polymer microspheres, 0.01-0.5% of water-soluble hydrophobic associative polymer and balance of water. The amphoteric cross-linked polymer microspheres are prepared through a polymerization reaction in an inert environment. In the reaction system of the polymerization reaction, polymerization monomers account for 1.0-40% of the reaction system by mass; cross-linking monomer accounts for 0.001-3% of the reaction system by mass; the polymerization monomers are anionic monomer, cationic monomer and nonionic monomer, wherein a molar ratio of the anionic monomer to the cationic monomer to the nonionic monomer to the cross-linking monomer is 2.5-25: 2.5-25: 50.0-95: 0.1-6. With the composite deep profiling / flooding agent provided by the invention, water injected reservoir recovery rate can be substantially improved. The profiling / flooding agent is more suitable for waterflooding reservoirs with nonuniform porous media.

Owner:CHINA NAT OFFSHORE OIL CORP +1

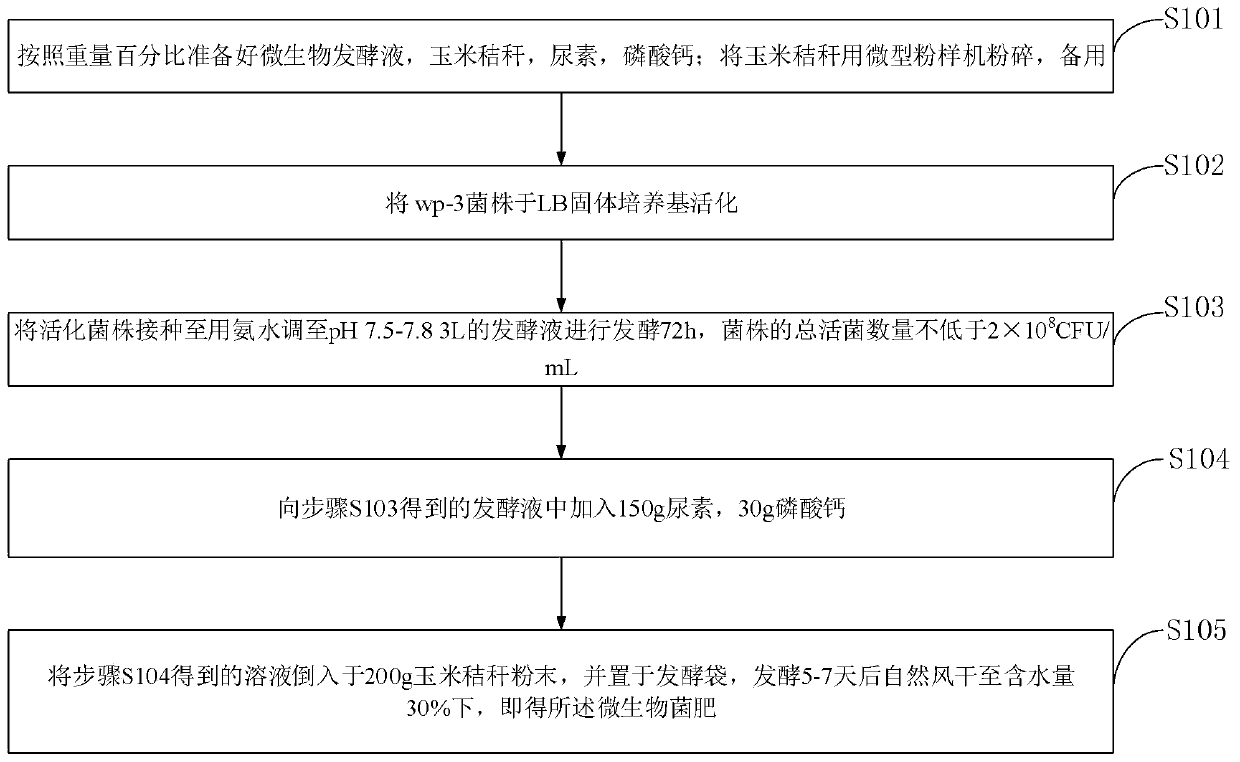

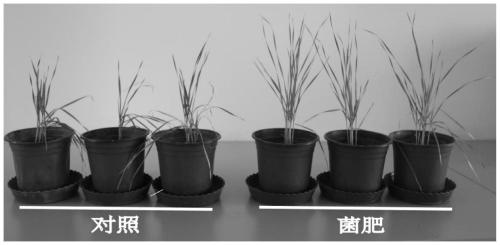

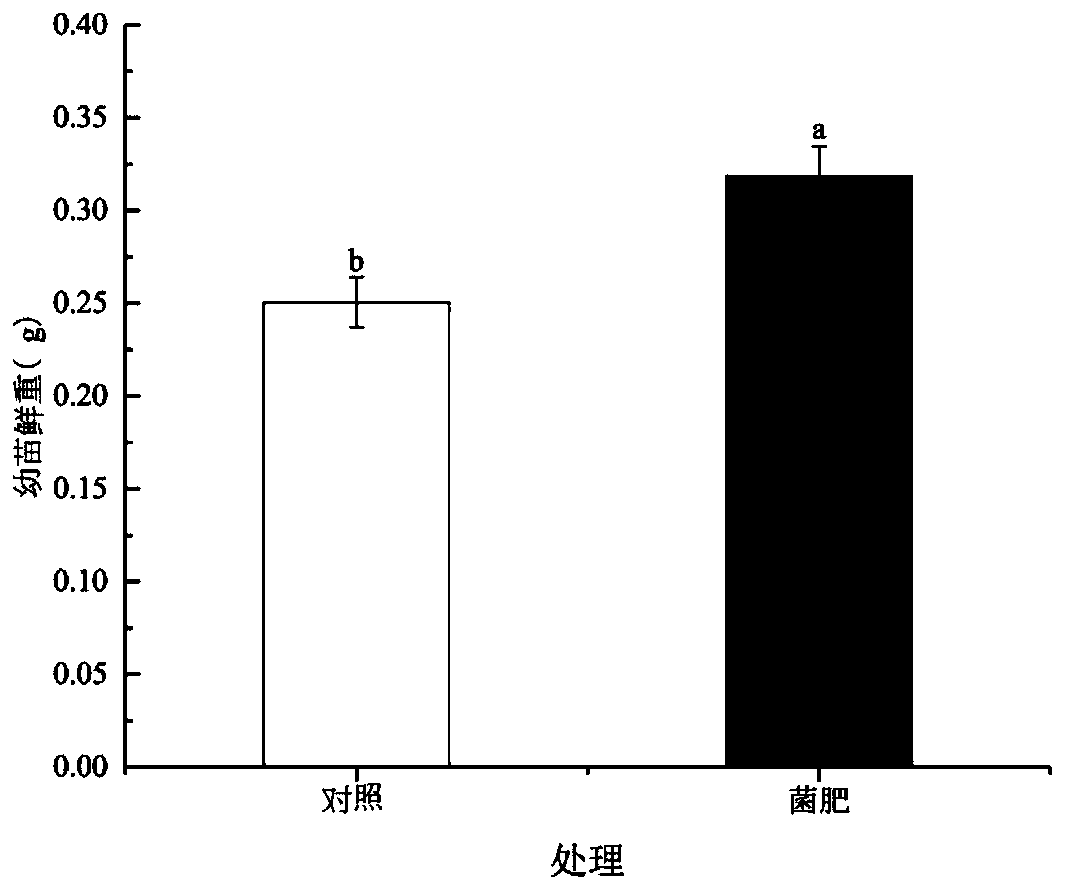

Microbial fertilizer for improving saline-alkali soil and preparation method and application thereof

PendingCN111039726AReduce compactionPromote absorptionBio-organic fraction processingAlkali orthophosphate fertiliserBiotechnologyAlkali soil

The invention belongs to the technical field of saline-alkali soil improvement, and discloses microbial fertilizer for improving saline-alkali soil and a preparation method and application thereof. The microbial fertilizer comprises the following components by weight: 85-90% of a microbial fermentation liquor, 6-7% of corn straw, 4-5% of urea, and 1-2% of calcium phosphate. The microbial fermentation liquor is prepared by fermentation of salt-tolerant growth-promoting bacteria staphylococcus wp-3. The microbial fertilizer provided by the invention is remarkable in soil improvement effect and capable of promoting crop growth. According to the application of the microbial fertilizer in wheat growth, the microbial fertilizer has a promoting effect on wheat growth, and the fresh weight of seedlings, the fresh weight of roots, the plant height and the root length are remarkably increased compared with those of a contrast, the pH of the soil is remarkably reduced by 3.6 percent, and the contents of quick-acting phosphorus, quick-acting potassium, organic matters and alkaline hydrolysis nitrogen are remarkably increased by 240.05 percent, 545.47 percent, 75.80 percent and 44.35 percent respectively.

Owner:SHIHEZI UNIVERSITY +1

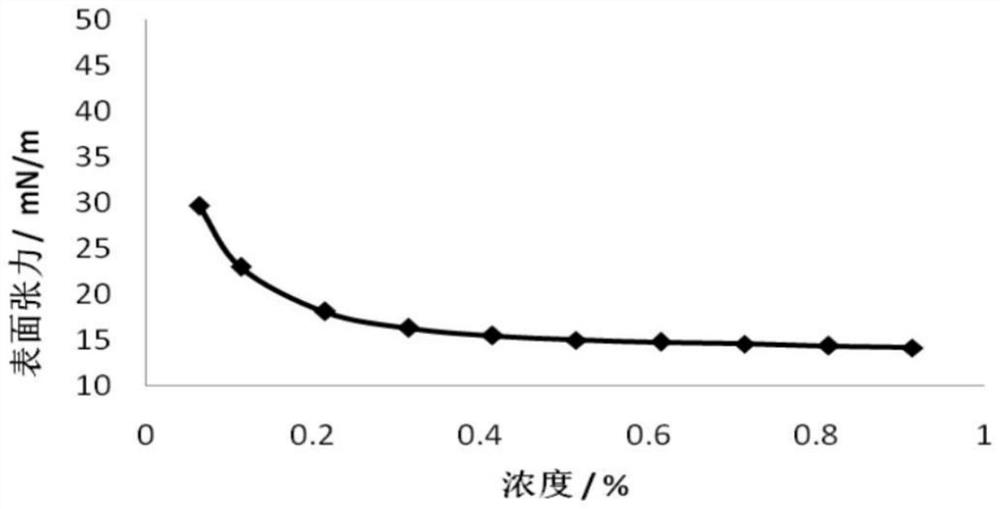

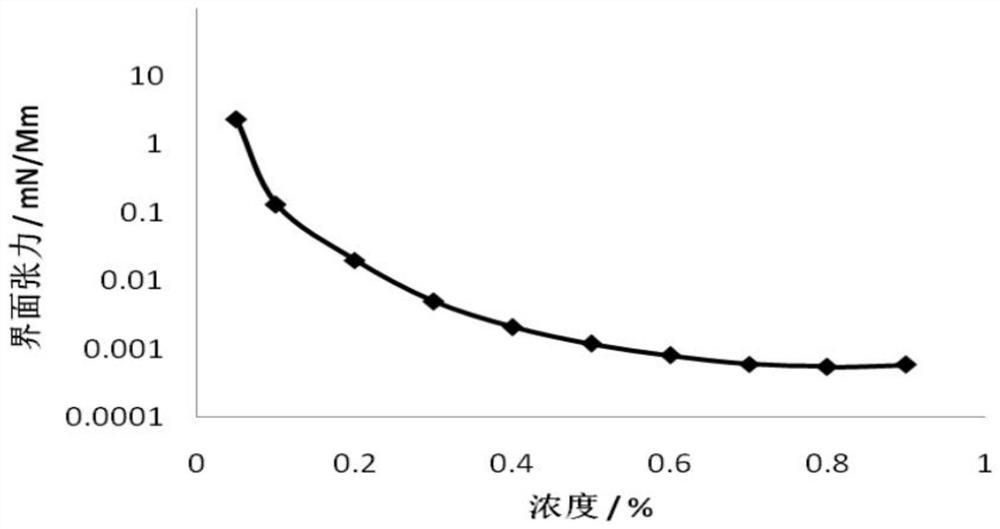

Formula and preparation method of low-pressure gas field old well re-production liquid locking removal treatment agent

ActiveCN112029490ARealize the goal of resuming production and increasing productionReduce surface tensionDrilling compositionActive agentSurface-active agents

The invention discloses a formula and a preparation method of a low-pressure gas field old well re-production liquid locking removal treatment agent. The low-pressure gas field old well re-productionliquid locking removal treatment agent comprises the following components by weight: 0.1-0.4% of a surface treatment agent, 0.05-0.3% of a nanometer material, 3-8% of a dispersant, 10-18% of a cleaning agent, 18-32% of a mutual solvent, 2-12% of a wetting reversal agent, and the balance industrial tap water. The treating agent can reduce liquid surface tension and oil-water interfacial tension ofa near wellbore area, reduce capillary resistance of a liquid, improve the contact angle of the liquid and rock and change rock surface wettability, and the effective period of the treated rock surface is prolonged through the dual adsorption effect of a nano material and a surfactant.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

I-shaped film repairing technology for underwater concrete crack

ActiveCN105696523AEasy to handleReduce the impact of precipitationMarine site engineeringAfter treatmentCofferdam

An I-shaped film repairing technology for an underwater concrete crack comprises the following steps of (1) determining a technical scheme, (2) installing a composite outer wrapping plate, (3) installing an inner wrapping plate on the surface facing water, (4) installing an outer wrapping plate on the surface back onto water, (5) conducting grouting and (6) conducting acceptance inspection. According to the I-shaped film repairing technology for the underwater concrete crack, the defects in the prior art are overcome, the high-difficulty and high-requirement procedures of grooving, chip removal, blocking and the like are reduced, template construction is formed, the construction speed is greatly increased, the construction difficulty is greatly reduced, an anti-permeability system is greatly improved, the anti-permeability effect is greatly improved, and firm connection is further enhanced. Meanwhile, according to the scheme, an elastic formwork and a rigid formwork are combined, rigid blocking materials are replaced, and the impact resistance, corrosion resistance and replaceability of coverings on the surface of the crack are improved. The rainfall influence on a lot of reservoir and port engineering cofferdams is reduced, the complexity of underwater construction is reduced, the concrete crack can be effectively treated at the early stage, and meanwhile maintenance work is easily carried out after treatment.

Owner:山西鑫明科技有限公司

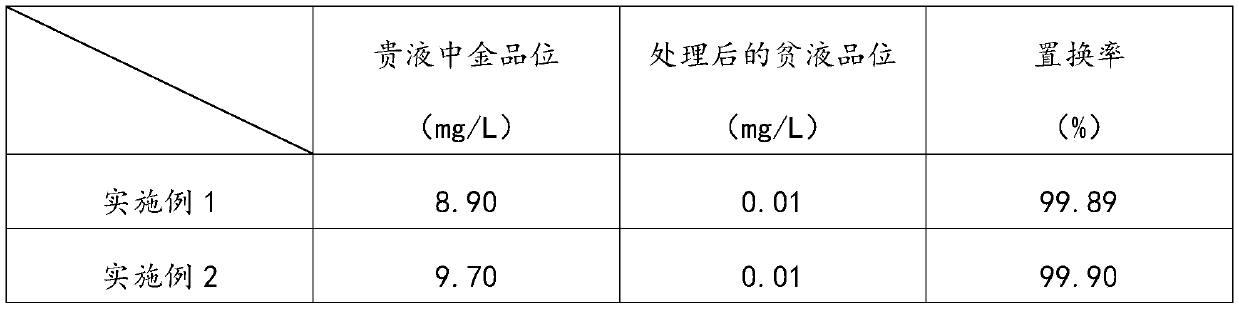

Method for recycling gold from gold-containing pregnant solution

InactiveCN111270071AEfficient removalReduce the impactProcess efficiency improvementPhysical chemistryProcess engineering

The invention relates to a method for recycling gold from a gold-containing pregnant solution, and belongs to the technical field of metallurgy. The method comprises the following steps of S1, preparing the pregnant solution; S2, purifying the pregnant solution; S3, conducting deoxidation on the pregnant solution; S4, pretreating the pregnant solution, wherein the pregnant solution which is obtained after deoxidation treatment in S3, sodium hydroxide, sodium sulfide and ammonium bicarbonate are mixed to prepare a solution, the solution is adjusted to be alkaline, and then uniform stirring is conducted to obtain a pretreated pregnant solution; and S5, conducting replacement on the pregnant solution, wherein the pretreated pregnant solution obtained in S4 and zinc powder are added into a replacer for a replacement rection, and then solid-liquid separation is conducted to obtain a solid, namely the product. According to the method, by adding the agents sodium hydroxide, sodium sulfide andammonium bicarbonate into the pregnant solution, impurity ions in the pregnant solution can be effectively removed, the possible influence on the zinc powder is lowered, the replacement efficiency ofthe zinc powder is improved, the production quality of gold mud is improved, and the production efficiency of the process is improved.

Owner:ZHAOJIN MINING

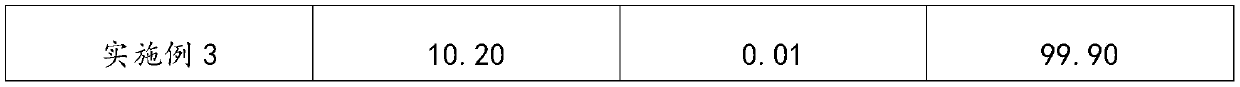

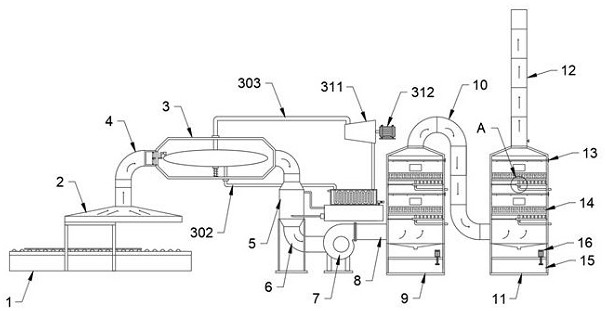

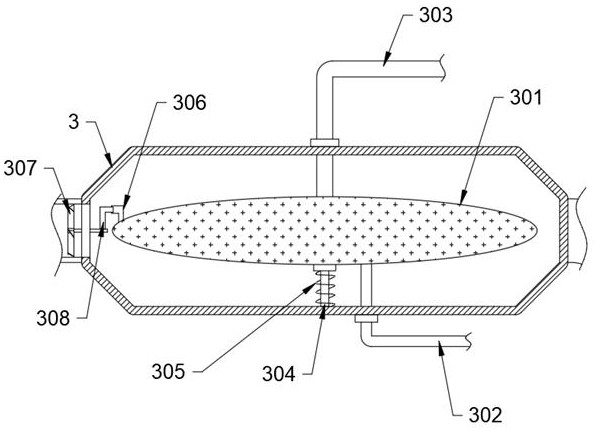

Environment-friendly oil smoke treatment device capable of realizing heat energy recovery

ActiveCN113758293ATo achieve hierarchical utilizationAchieve high temperature utilizationFeed water supplyIncreasing energy efficiencyHeat energyElectric generator

The invention discloses an environment-friendly oil smoke treatment device capable of realizing heat energy recovery, and relates to the technical field of annealing furnace smoke treatment. The environment-friendly oil smoke treatment device comprises an annealing furnace, a heat exchange pipe, a cooler, a fan, a first spray tower and a second spray tower, a suction hood is arranged above the annealing furnace, a steam generation mechanism is arranged on the inner wall of the heat exchange pipe, multiple flow dividing pipes are sleeved with the inner wall of a flow dividing opening, a heat dissipation accelerating assembly is installed on the outer wall of a flow dividing sleeve, and the outer wall of the cooler is sleeved with a water cooling mechanism. Water is added into the inner wall of an ellipsoidal water tank in advance through a water return pipe, smoke can heat the water on the inner wall of the ellipsoidal water tank until the water is boiled, high-pressure steam generated during boiling is supplied into a steam turbine through a steam pipe to drive blades to rotate to drive a generator to generate electricity, the high-heat part of the smoke is recovered in advance, then the smoke enters a subsequent heat exchange device, graded utilization of heat in the smoke is achieved, high-temperature utilization of the smoke is achieved, the environmental protection property is good, and the heat collection efficiency is improved.

Owner:温州宪江防腐设备有限公司

Manufacturing method of automobile ABS (acrylonitrile-butadiene-styrene) induction counting tooth ring

The invention discloses a manufacturing method of an automobile ABS (acrylonitrile-butadiene-styrene) induction counting tooth ring, which can implement high-efficiency mass production of automobile ABS induction counting tooth rings. The technical scheme is as follows: the method comprises the following steps: filling a uniformly mixed alloy powder material with the particle size of at least 10 meshes into a precast mold, wherein the alloy powder material preferably comprises the following components in percentage by weight: 3-4% of Cu, 1.5-2.5% of Ni, 1.3-1.7% of Cr, 2.2-2.8% of sulfur manganese, 2.5-3.5% of rare-earth element, 0.65-0.75% of C, 0.45-0.55% of zinc stearate and the balance of Fe powder; pressing into an alloy steel blank under the pressure of 7-8 tf / cm<2>; carrying out high-temperature sintering on the blank at 1100-1110 DEG C, and keeping the temperature in reducing gas and nitrogen for 3.3-3.8 hours; cooling to room temperature, and putting the formed blank in a finishing mold for further extrusion, wherein the external diameter of the extrusion allowance is 53-58 mu m, and the internal diameter is 65-75 mu m; carrying out partial slight turning and trimming for formation; and finally, carrying out Dacromet treatment on the surface.

Owner:TAIZHOU XINCHENG NEW MATERIAL TECH

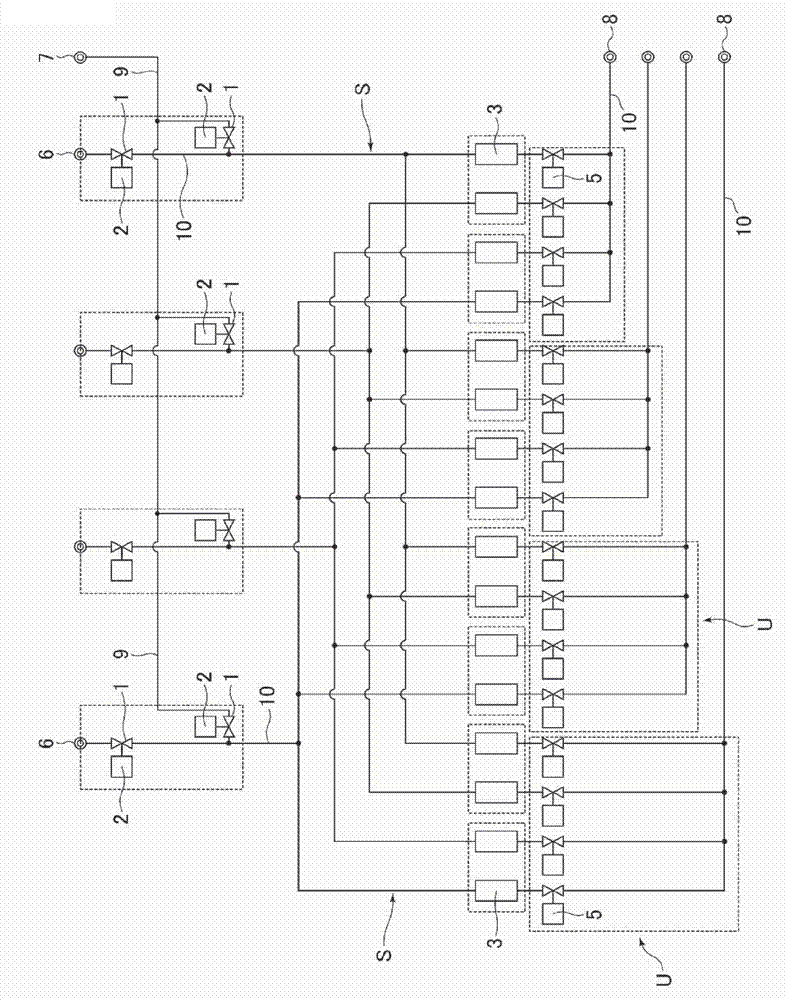

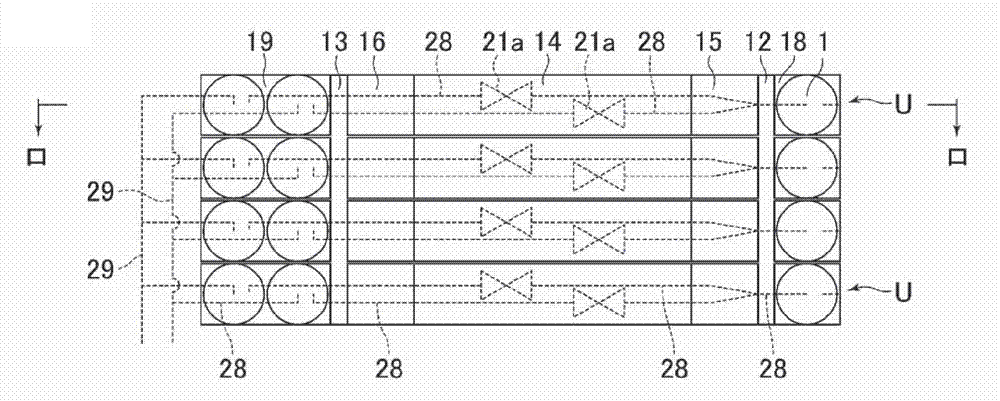

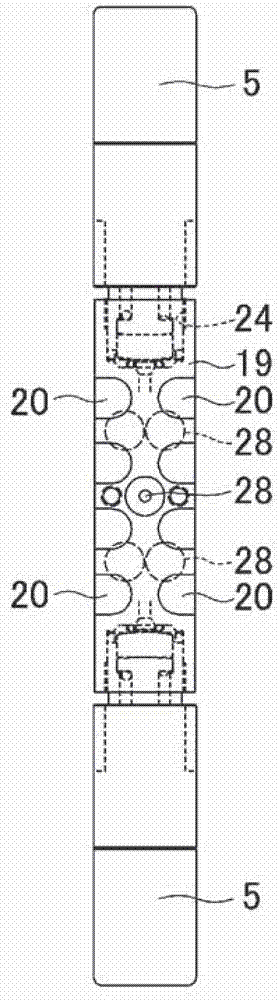

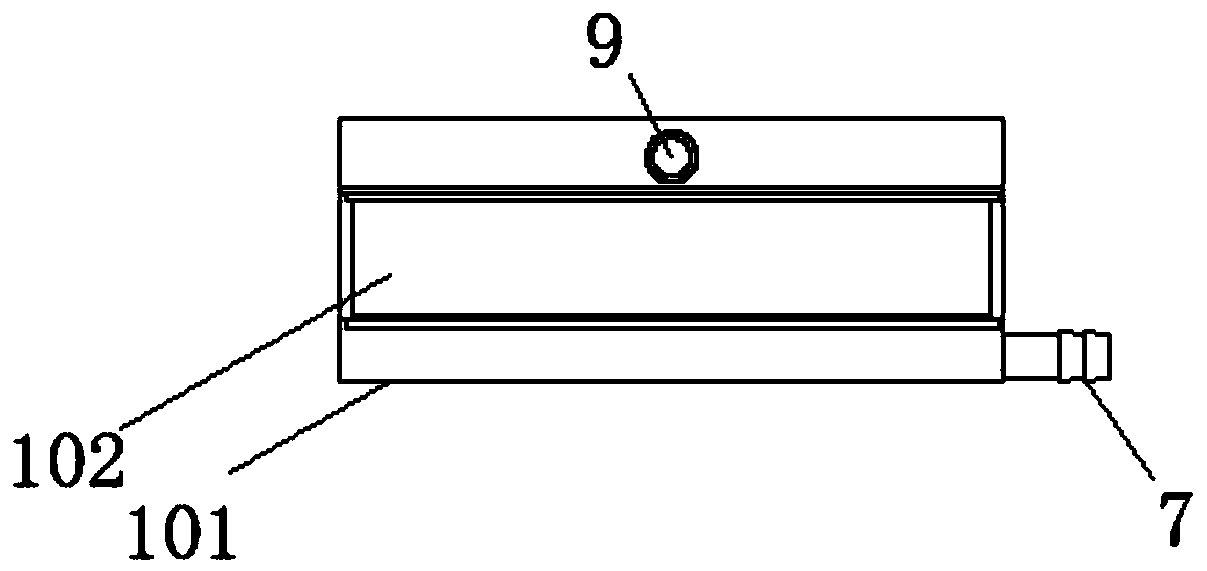

Accumulation-type gas supply device

InactiveCN104737086ASmall volumeImprove displacement effectServomotor componentsThin material handlingManufactured apparatusProcess engineering

The purpose of the present invention is to increase the number of gas supply lines in an accumulation-type gas supply device for a semiconductor manufacturing apparatus, to reduce the size of the device, and to reduce the internal volume of the gas channels inside the device while enhancing the gas replacement properties of the device, minimizing installation space, and making various equipment easier to maintain. Two flow control devices (3) provided with a plurality of flow controllers are secured in a mutually opposed combination to a gas-inlet-side block (12) and a gas-outlet-side block (13) set apart from one another as viewed from above, and the flow control devices (3) are provided with an inlet opening / closing valve (1) and an outlet opening / closing valve (5), whereby a gas supply unit (U) provided with at least four gas supply lines (S) is formed, and a plurality of the gas supply units (U) are secured in a stacked configuration.

Owner:FUJIKIN INC

Air purifying system with loop-current cyclone dust removal

ActiveCN105920966ARealize circulation utilizationDoes not take up external spaceCombination devicesCycloneAir filter

The invention discloses an air purifying system with loop-current cyclone dust removal. The air purifying system comprises an inlet air filter set, a cyclone mixing device, a gas washing device, a first return air filter and a second return air filter, wherein the lower end of the inlet air filter set is provided with a top channel; the cyclone mixing device is arranged in a sandwich layer of an indoor side wall; the inlet end of the cyclone mixing device communicates with the upper end of the top channel; the outlet end of the cyclone mixing device communicates with the top channel; indoor return air treated by the cyclone mixing device is transmitted into the gas washing device; the first return air filter is arranged on the center of the indoor bottom; the first return air filter communicates with the air inlet of an air regulating system; the second return air filter is arranged at the two sides of the indoor bottom; the second return air filter is used for treating indoor air and directly transmitting the treated indoor air into the cyclone mixing device. The air purifying system solves the technical problem of great space usage and low treatment efficiency of the air purifying system.

Owner:苏州艾尔新净化科技有限公司

CO2-driving corrosion and scale inhibitor suitable for high-mineralization-degree and high-barium-strontium environment

ActiveCN106047326AImprove protectionChanged lipophilic wettabilityDrilling compositionBorehole/well accessoriesDiethylenetriamineOxygen

The invention relates to a CO2-driving corrosion and scale inhibitor suitable for a high-mineralization-degree and high-barium-strontium environment. The CO2-driving corrosion and scale inhibitor is composed of a modified oxazoline derivative, diyne oxygen methyl amine quaternary ammonium salt, sodium pentamethylenephosphonate diethylenetriamine, isodecanol polyoxyethylene ether, isopropyl alcohol and water. An absorption membrane formed by the corrosion and scale inhibitor effectively isolates a corrosive medium, and a good protection function on a tubular column is achieved; meanwhile, effective scale inhibiting ingredients and Ba2<+> / Sr2<+> ions form a chelate high in stability, and scaling is prevented; nonionic ingredients contained in a formula change oleophylic wettability of the rock core, and the displacement result of CO2-driving on remaining oil is improved. The CO2-driving corrosion and scale inhibitor has the advantages that the chemical adding process is simple and convenient, less dosage is needed, and practicability is high; it is verified by experiments that a good corrosion-resistant and scaling-resistant effect is achieved on a CO2-driving shaft in the high-mineralization-degree and high-barium-strontium environment of a west oil field, the problem of hidden danger of corrosion and scaling of the shaft existing in the CO2-driving implementation process in a dual environment of corrosion and scaling is solved, and a technical guarantee is provided for raising the yield of CO2-driving.

Owner:PETROCHINA CO LTD

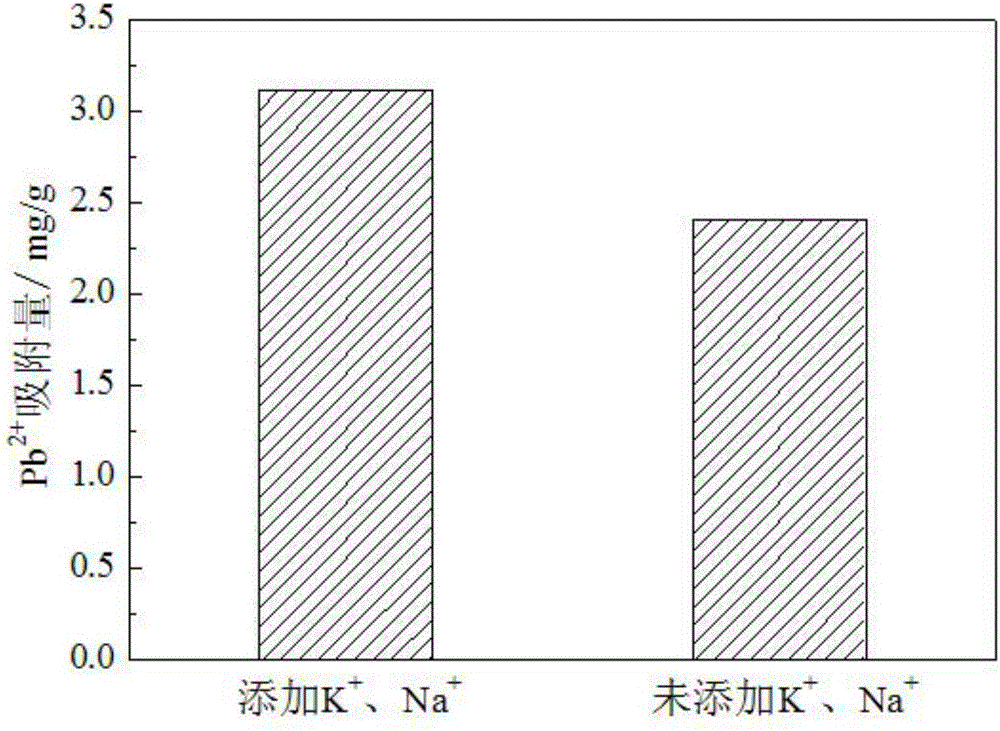

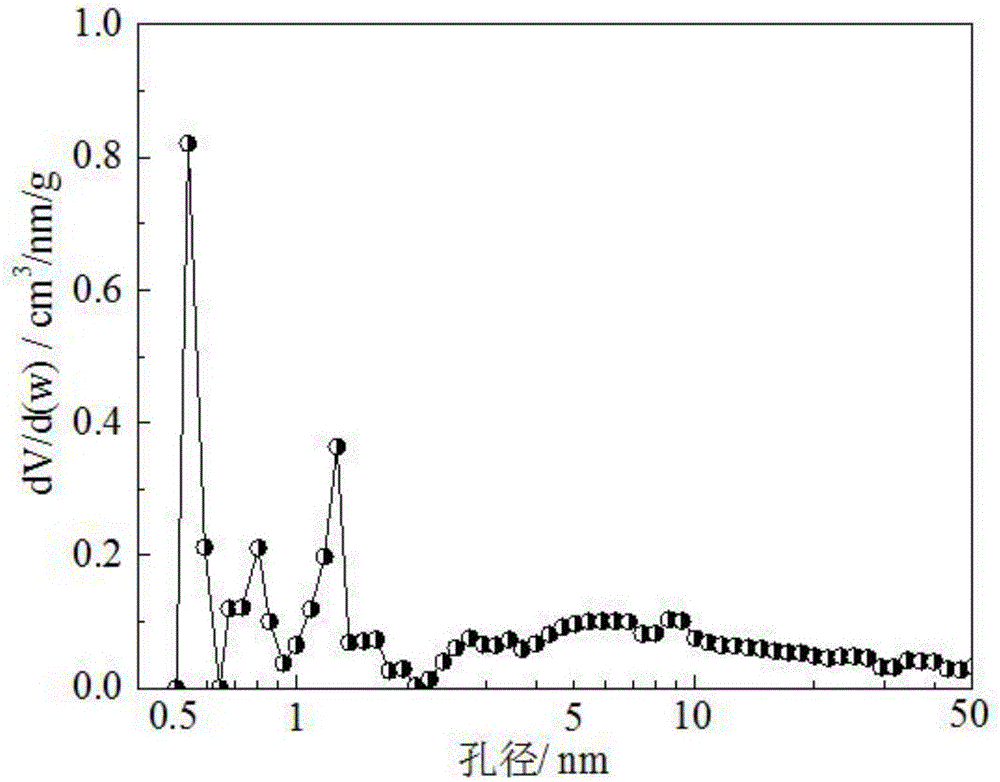

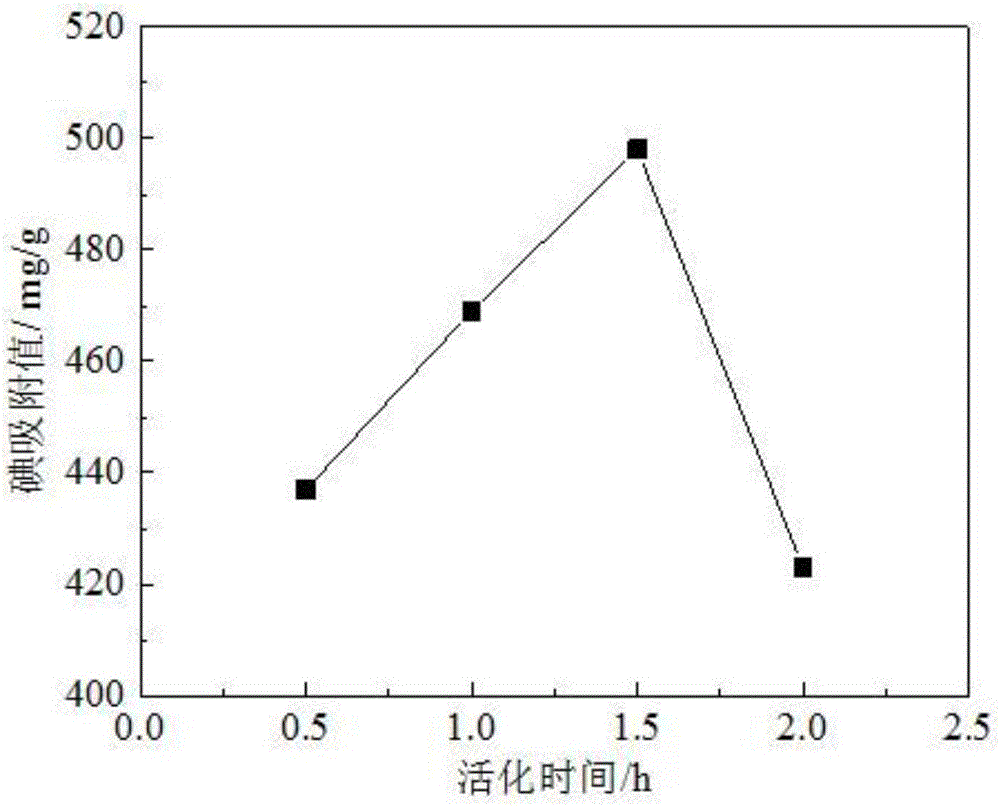

Sewage treatment sludge active carbon having continuous pore size distribution, and preparation method thereof

ActiveCN106560236AReduce lossesIncrease K

<sup>+</sup>

contentCarbon compoundsOther chemical processesActivated sludgeSorbent

The invention discloses sewage treatment sludge active carbon having continuous pore size distribution, and a preparation method thereof. According to the preparation method, ZnCl2, phosphoric acid, K2S and NaCl form a compound activator in anoxic atmosphere to activate sludge, wherein the mesoporous structure is developed mainly by using the phosphoric acid, and the K<+> content and the Na<+> content of the sludge active carbon are increased so as to easily enhance the replacement with heavy metal ions in sewage; and activation is performed with water vapor to generate rich micro-pores in the mesoporous surface, such that the BET specific surface area of the finally obtained sludge active carbon is not less than 400 m<2> / g, and the pore size is continuously distributed within 0.5-50 nm. According to the present invention, the prepared sludge active carbon adopted as the sewage treatment adsorbent adsorbs heavy metal ions using Pb<2+> as the representative and macromolecular pollutants in the sewage, and has good effects.

Owner:TIANJIN CHENGJIAN UNIV

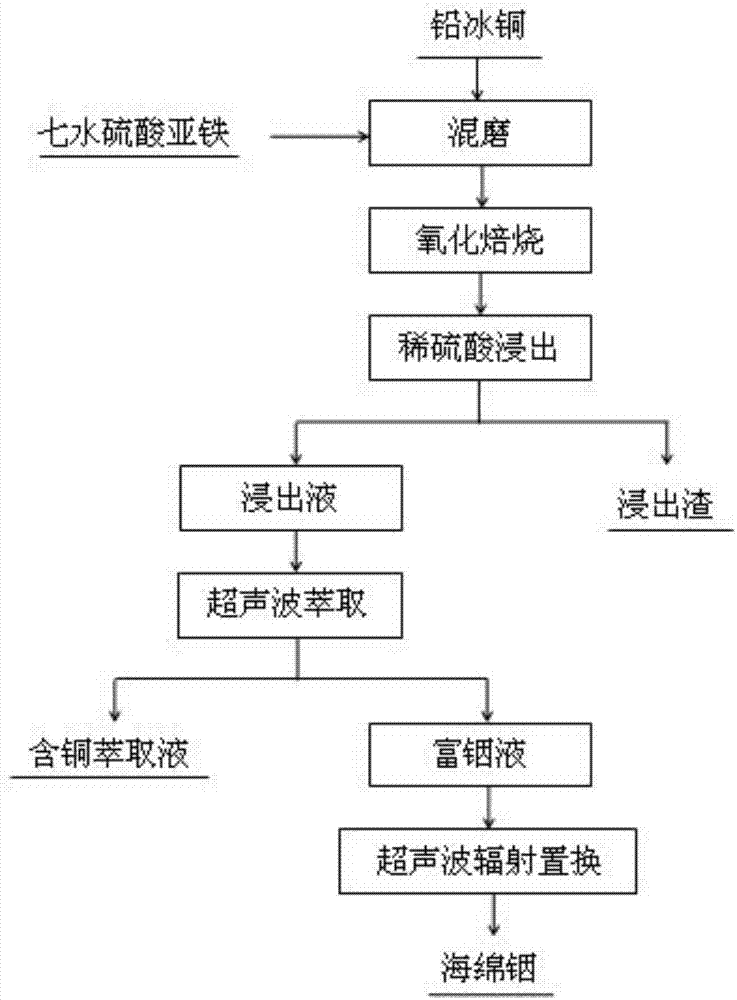

Method for extracting indium from lead copper matte

ActiveCN107034368AHigh recovery rateEliminate emulsificationProcess efficiency improvementIndium metalPregnant leach solution

The invention discloses a method for extracting indium from lead copper matte. The method comprises the following steps that A, the lead copper matte and ferrous sulfate are mixed and ground, and the mass ratio of the lead copper matte to the ferrous sulfate is (0.1-1.5):1 according to the mass ratio; B, the mixed and ground materials are put into a tube furnace to be subjected to oxidizing roasting through oxygen containing gas, and roasting matter is obtained; C, the roasting matter is leached through dilute sulphuric acid, then filtering and washing are carried out, and leaching residues and lixivium are obtained; D, the lixivium is subjected to indium extraction under ultrasonic radiation, and copper containing extraction liquid and indium-enriched liquid are obtained; and E, metal replacement is adopted by the indium-enriched liquid under ultrasonic radiation to obtain sponge indium. According to the method, the leaching rate and the recovery rate of the indium are increased; meanwhile, ultrasonic waves are introduced in the extraction process, and the emulsification problem of the indium in the extraction process is eliminated; the ultrasonic waves are introduced in the indium metal replacement process, the replacement effect is improved, and the replacement time is shortened; and the whole-process technology is simple, industrialization can be achieved easily, and good industrial application prospects are achieved.

Owner:昆明寰世科技开发有限公司

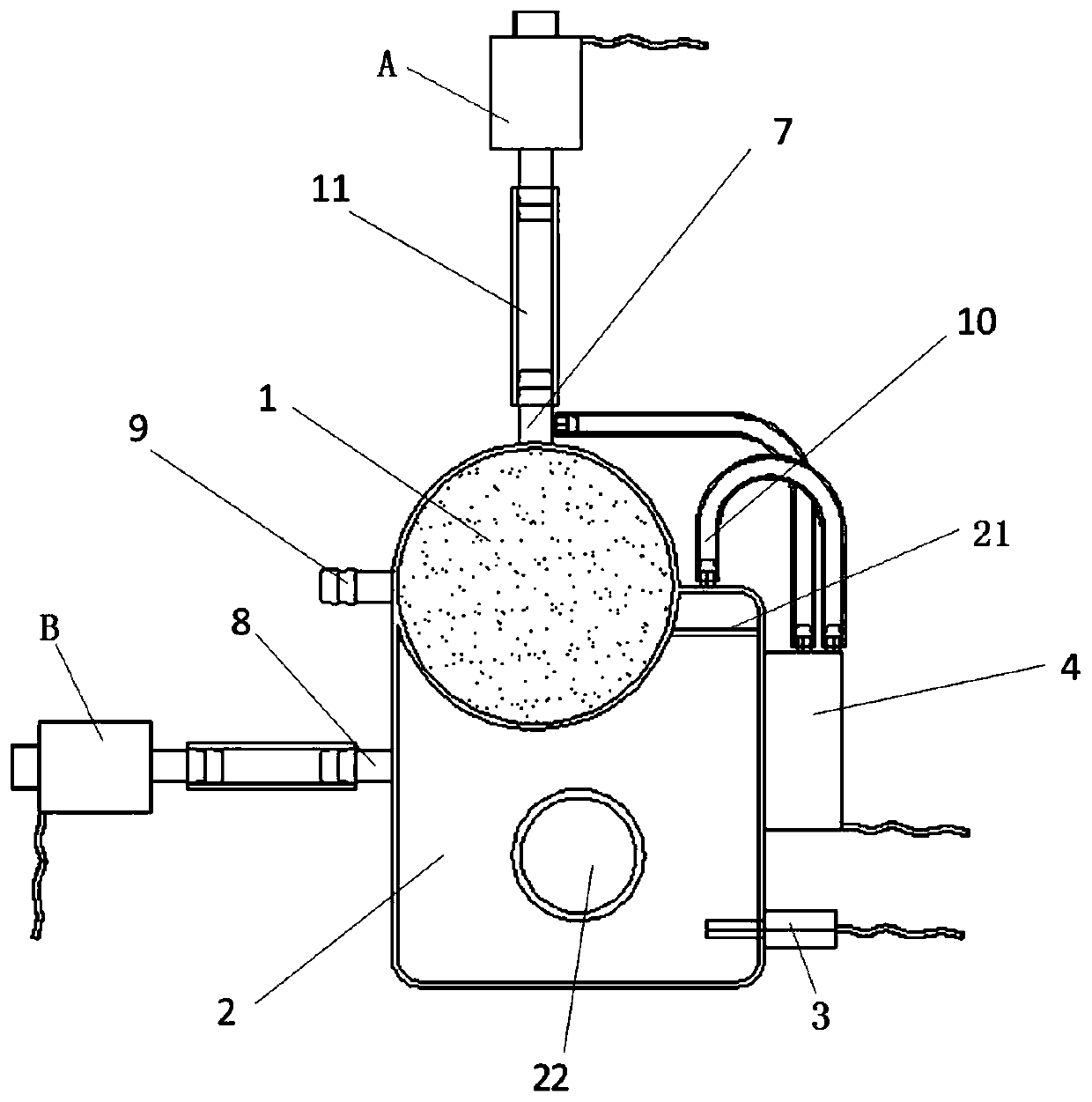

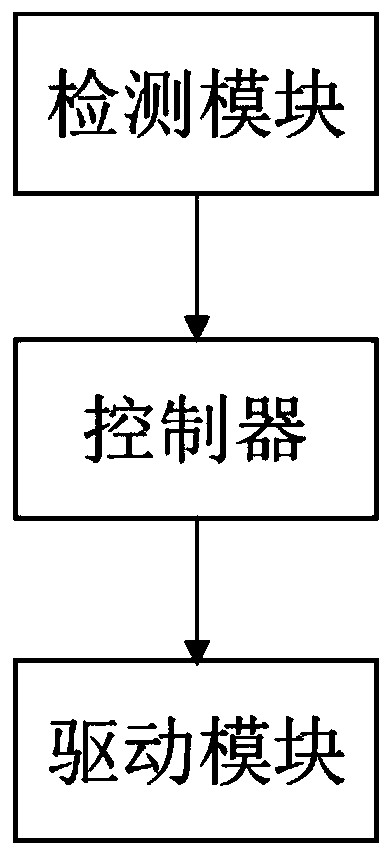

Water softening device and soft water treatment control method

PendingCN110054256AImprove displacement effectSoft water effect is goodLevel controlSpecific water treatment objectivesIonIon exchange

The invention discloses a water softening device and a soft water treatment control method. The water softening device comprises an ion exchanger, a salt cavity, a water pump, a detection module and acontroller. The ion exchanger is used for softening water, the salt cavity is communicated with the ion exchanger, the water pump pumps solution from the salt cavity into the ion exchanger, the detection module is used for detecting activity of a material in the ion exchanger, and the controller controls the water pump according to feedback signals of the detection module. The water softening device and the soft water treatment control method have advantages that the content of metal ions in soft water in the ion exchanger can be monitored, timely regeneration of resin is realized, and by arrangement of a spiral flexible tube in the ion exchanger and filling of resin in the flexible tube, resin regeneration time is increased, so that quality of the soft water is improved.

Owner:周小波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com