Patents

Literature

118results about How to "Does not take up external space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

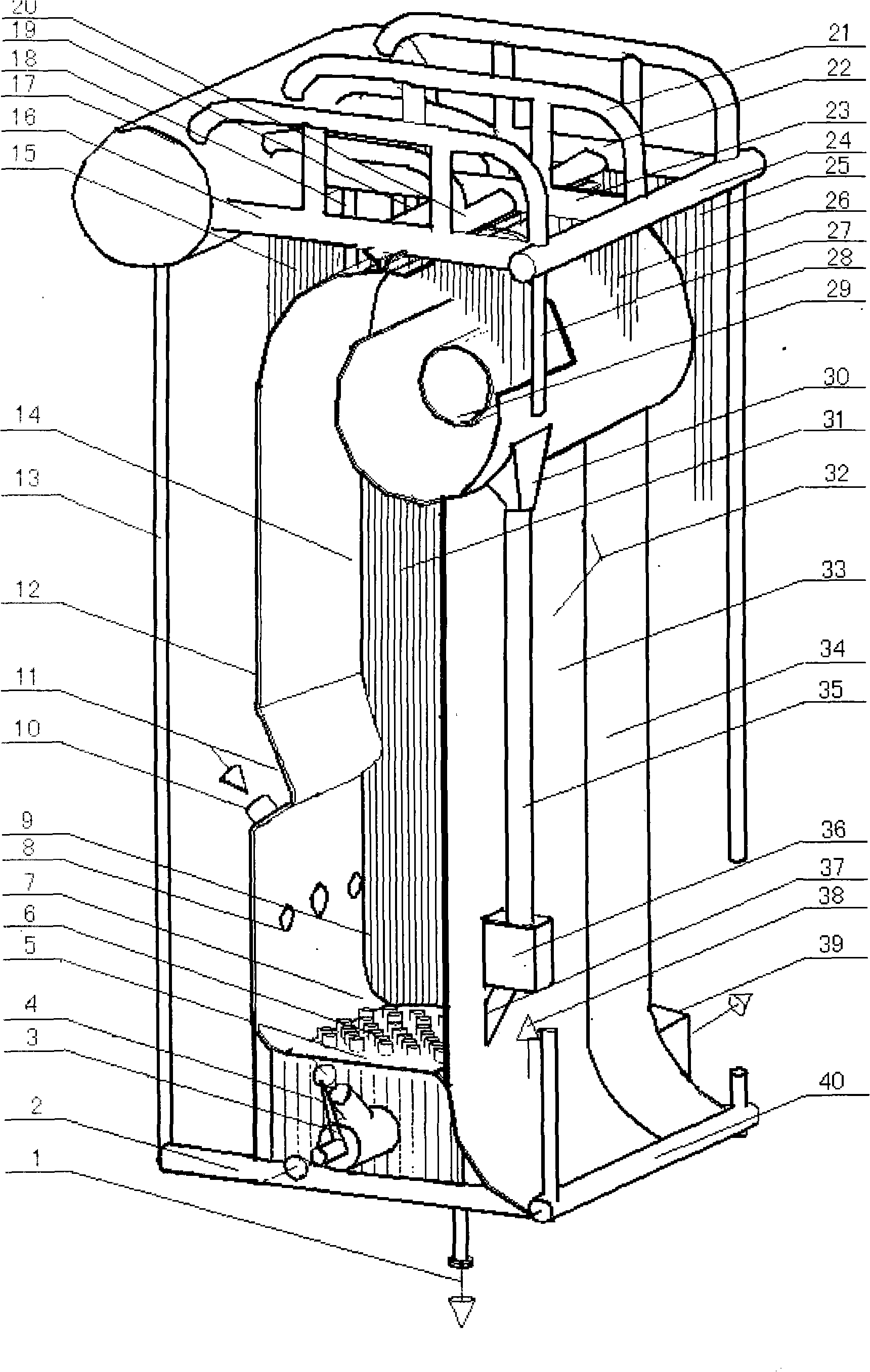

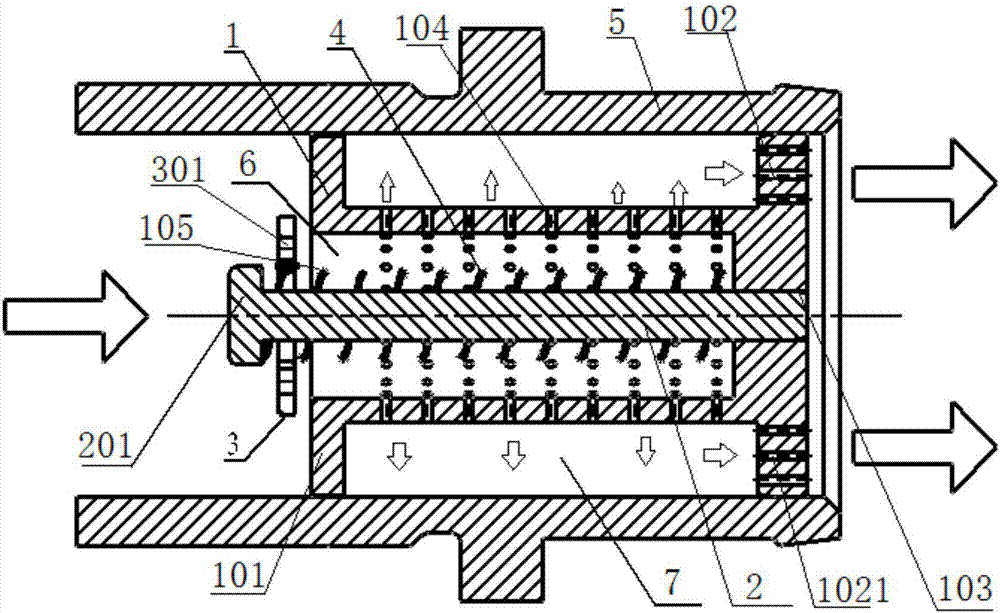

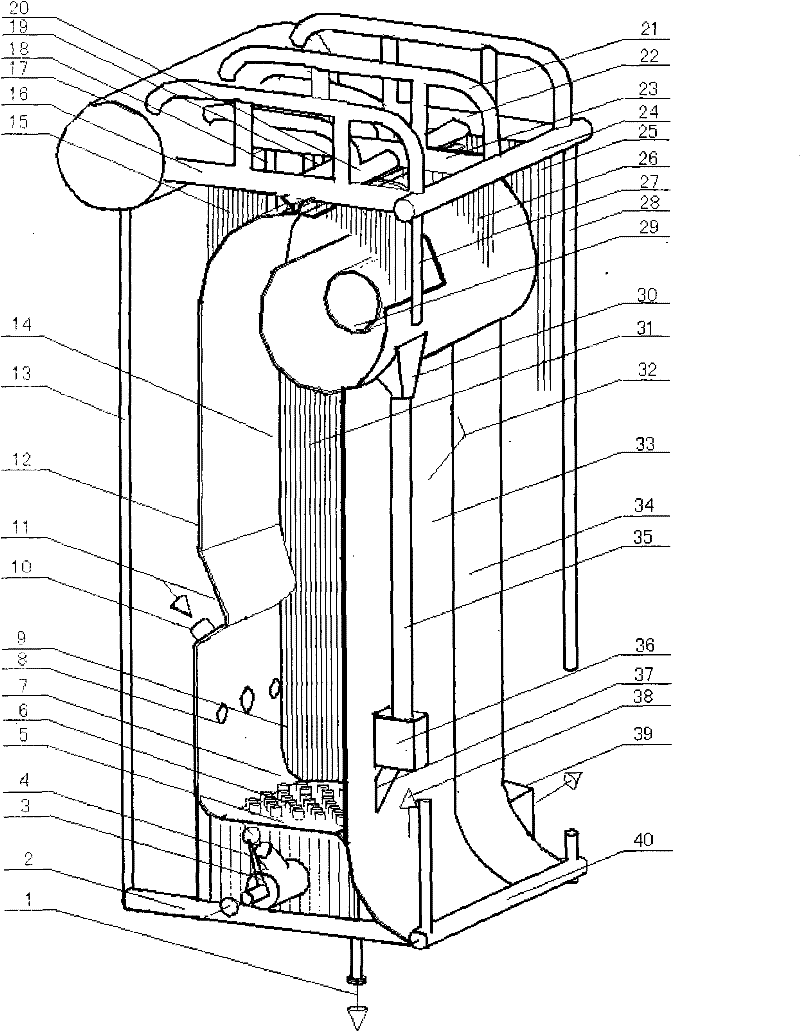

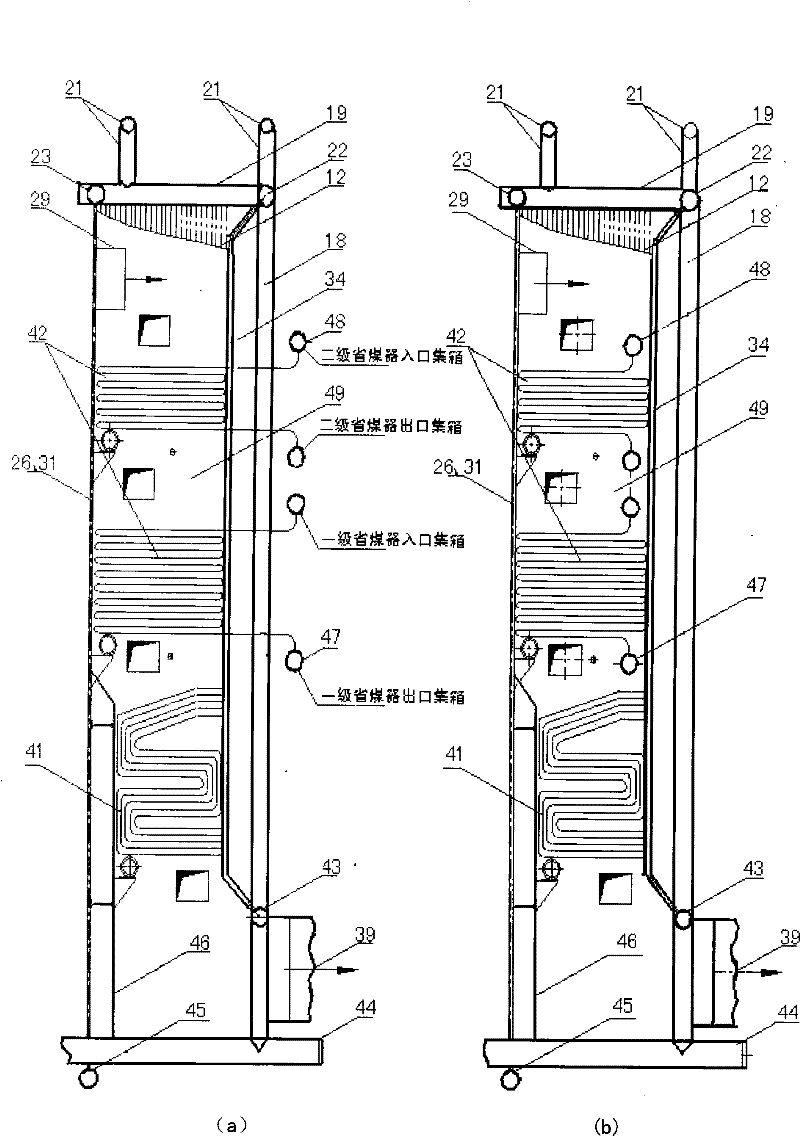

Inclined porch-free corner-tube full film-type wall-circulating fluidized bed boiler

InactiveCN101514811ACompact structureDoes not take up external spaceFluidized bed combustionBoiler water tubesCycloneCombustion chamber

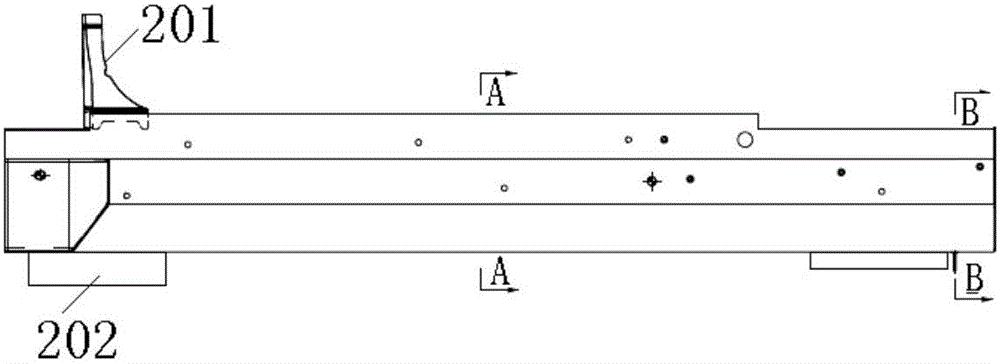

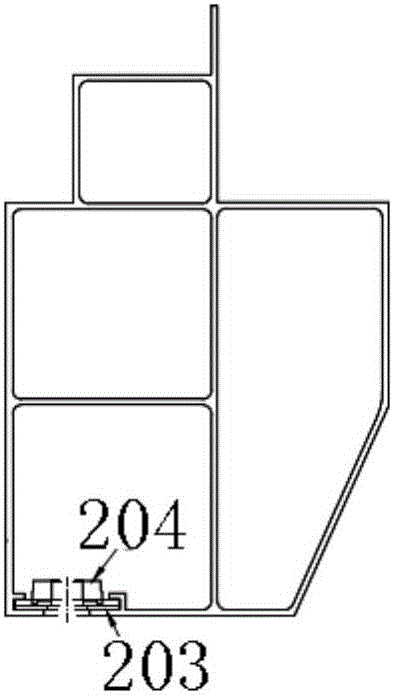

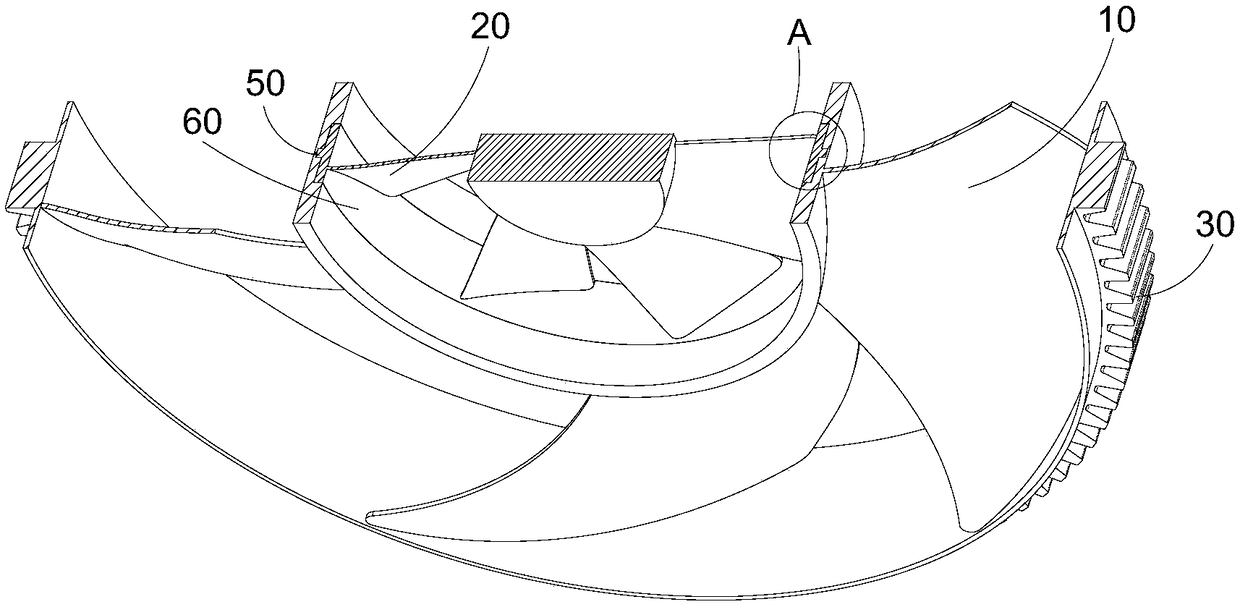

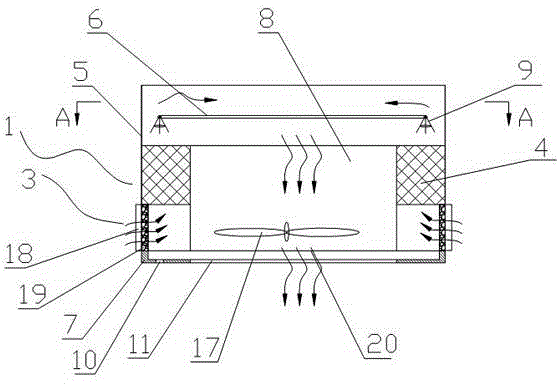

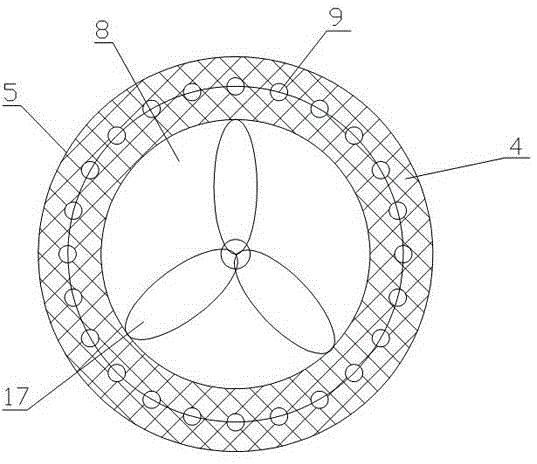

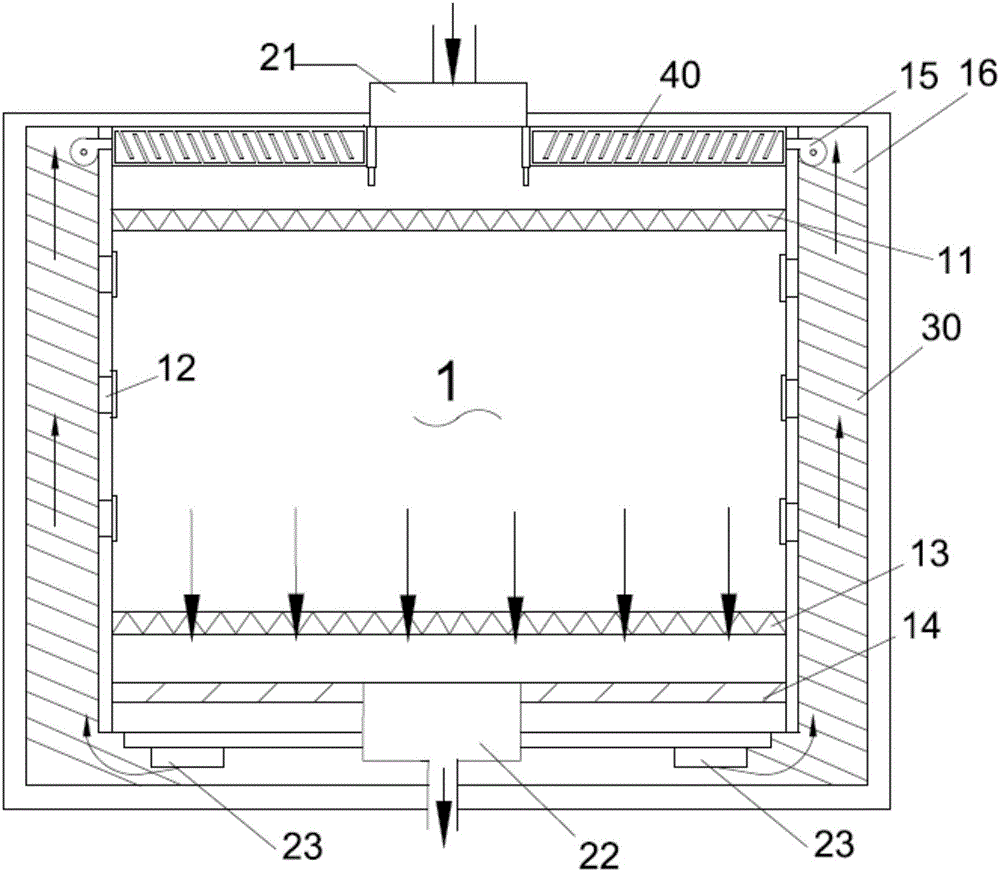

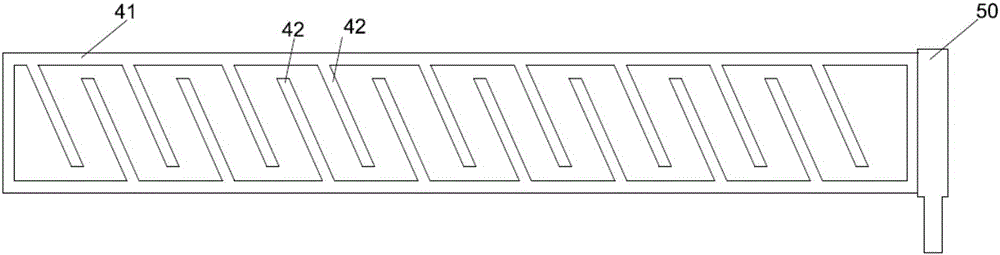

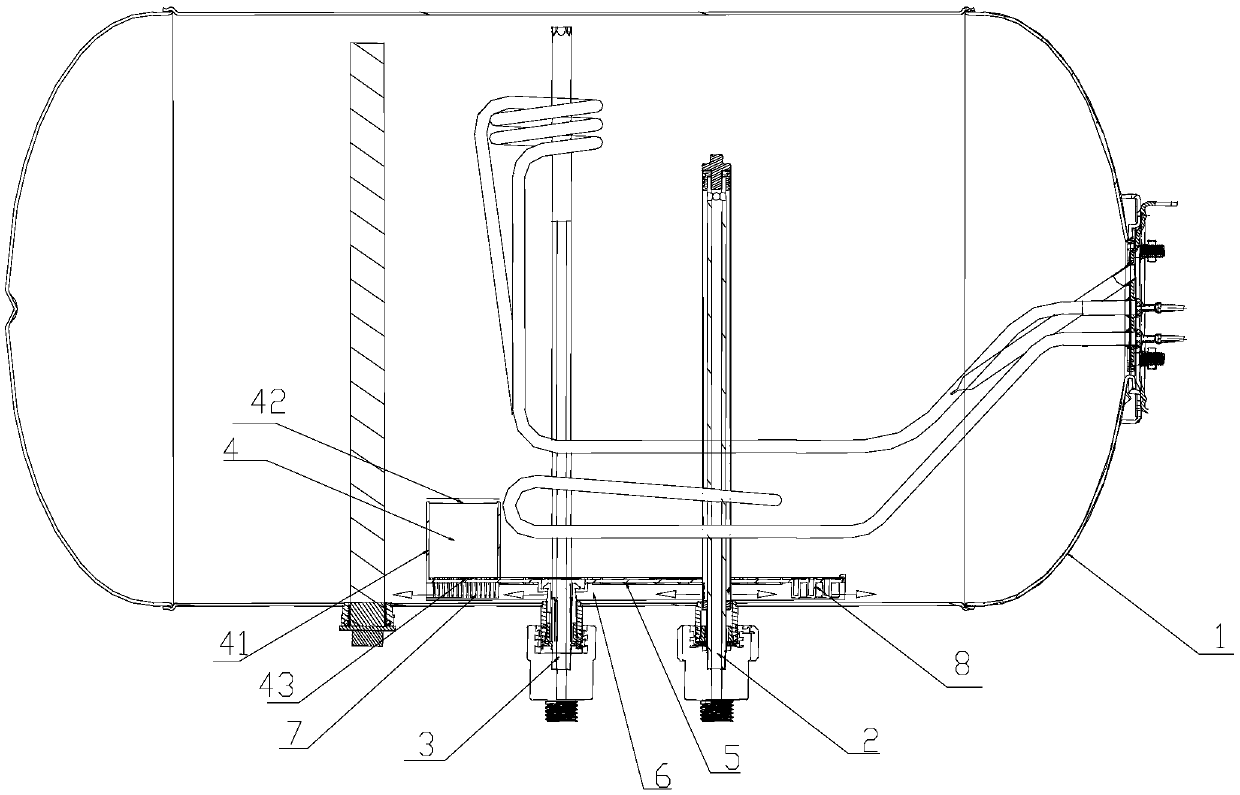

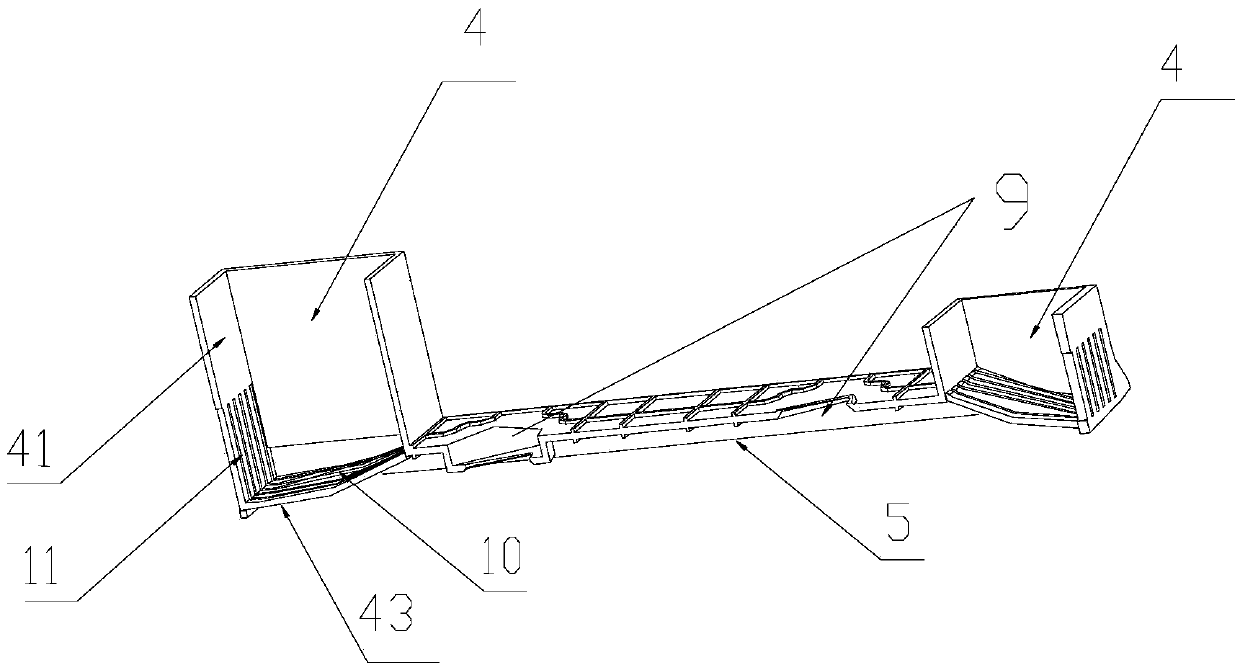

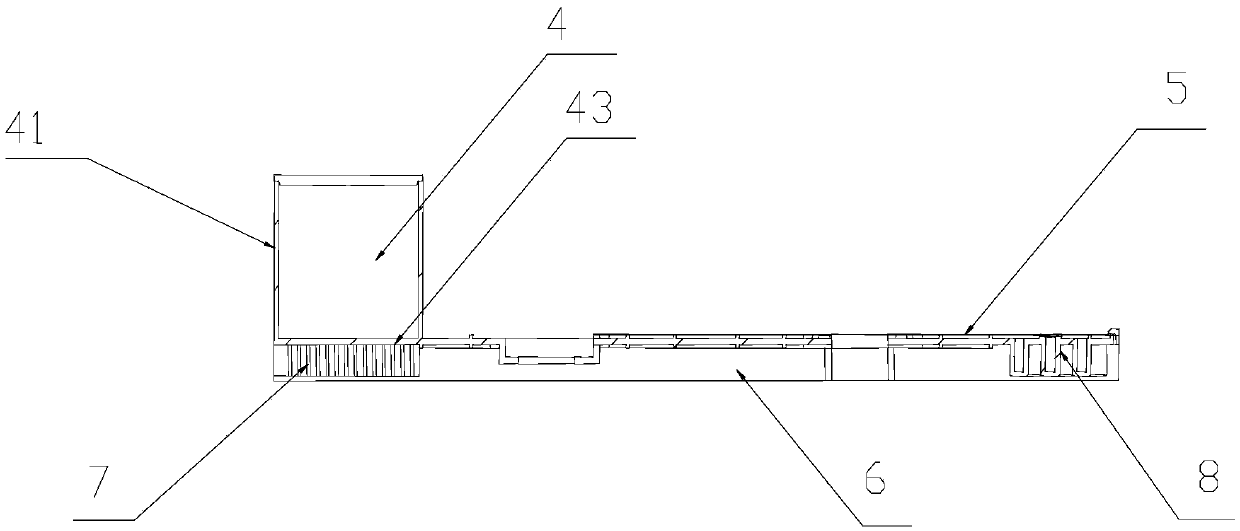

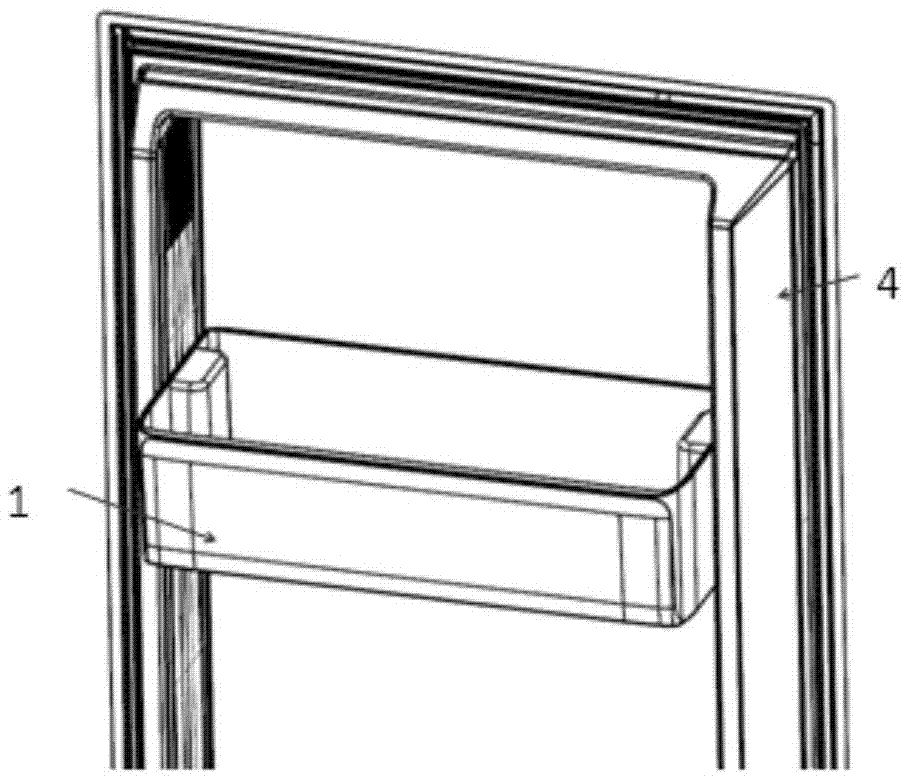

The invention disclosed an inclined porch-free corner-tube full film-type wall-circulating fluidized bed boiler, which employs a corner-tube self-support structure, an inclined porch-free arrangement and water-cooling built-in horizontal volute cyclone separator structure, a combustion chamber and a convection vertical shaft employ a full film-type water-cooling wall structure, the convection vertical shaft is internally provided with a screen-type evaporation heating surface, a flag-type or serpentine tube-type convection heating surface; the structure is compact in the arrangement, smooth in the flow of smoke gases and diminished in flow resistance; the structure is liable for being systematized in design, standardized in manufacturing, integrated in conveying components and modularized in on-site installation; the structure, with short installation period at the construction site, can greatly save material and has the characteristics of high combustion efficiency and small power consumption of an induced draft fan.

Owner:XI AN JIAOTONG UNIV

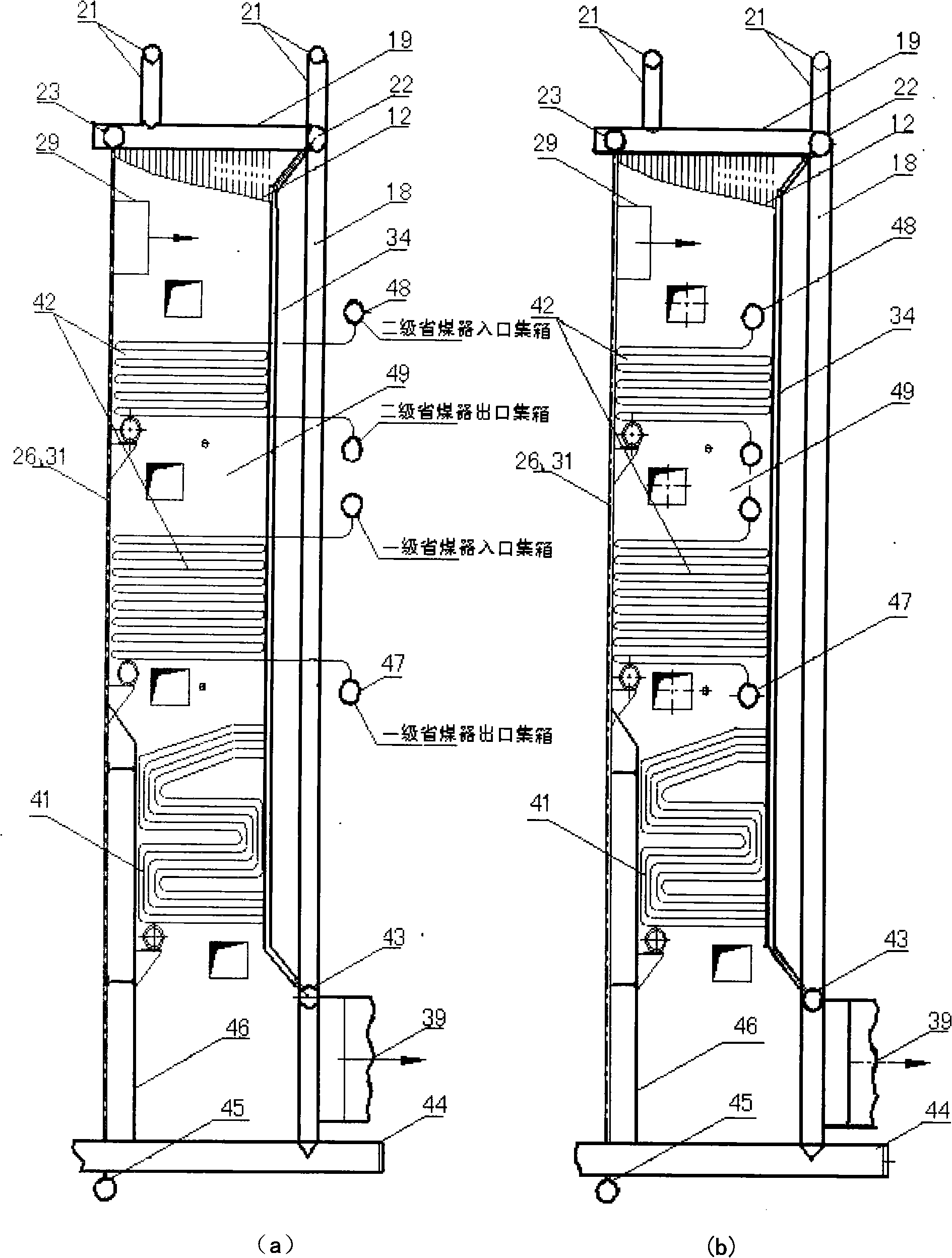

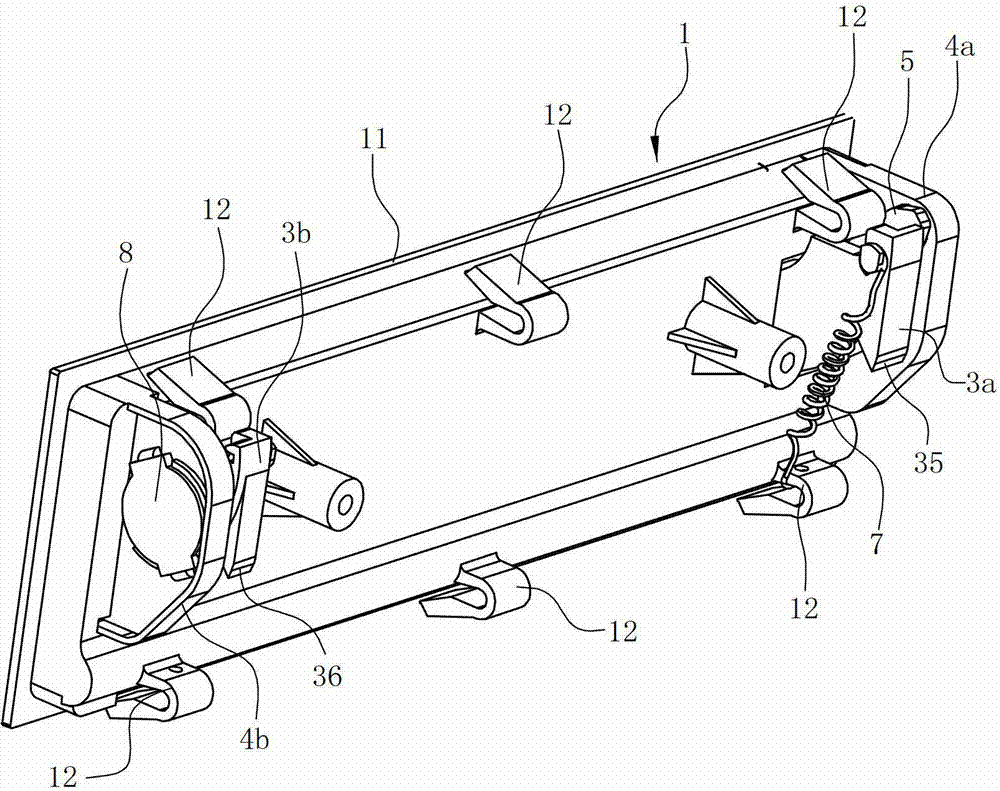

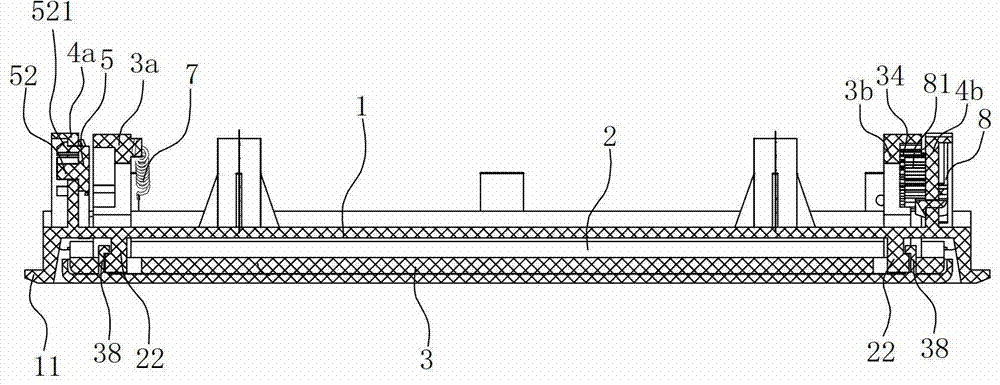

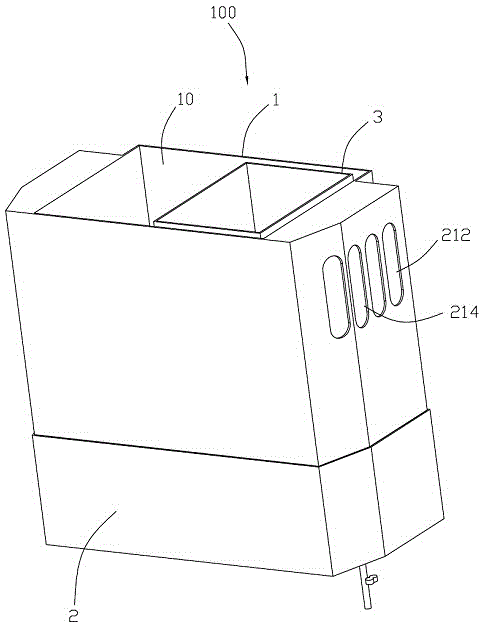

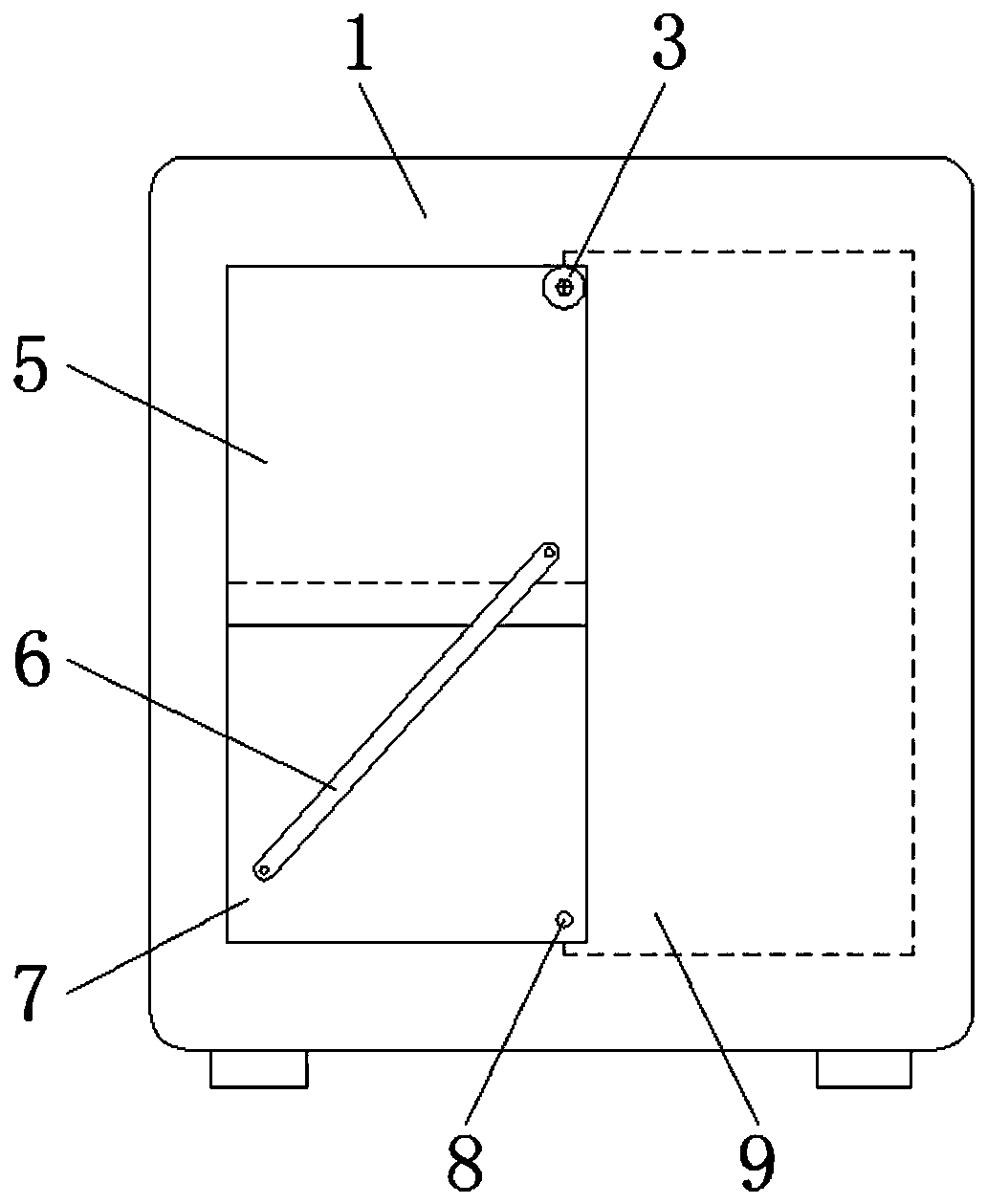

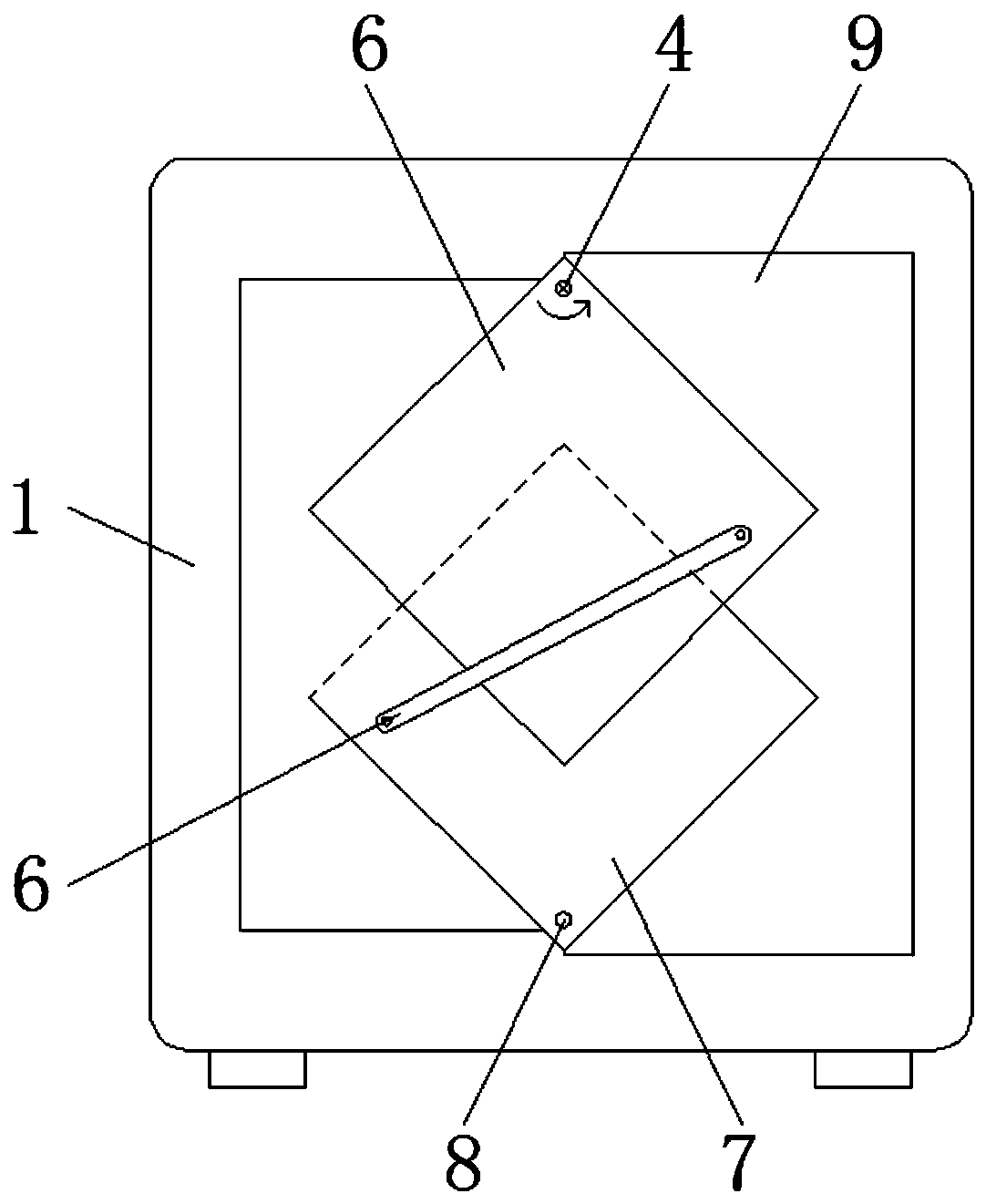

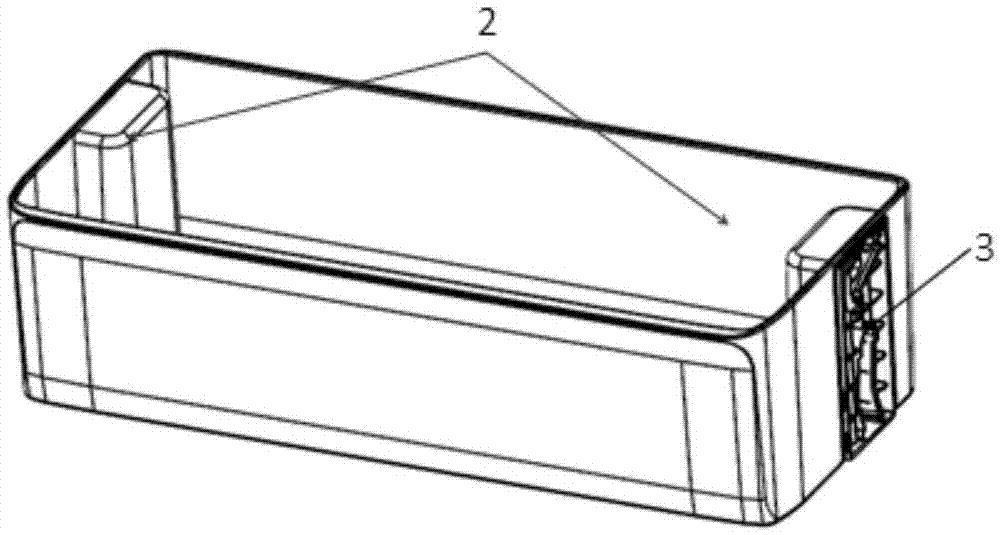

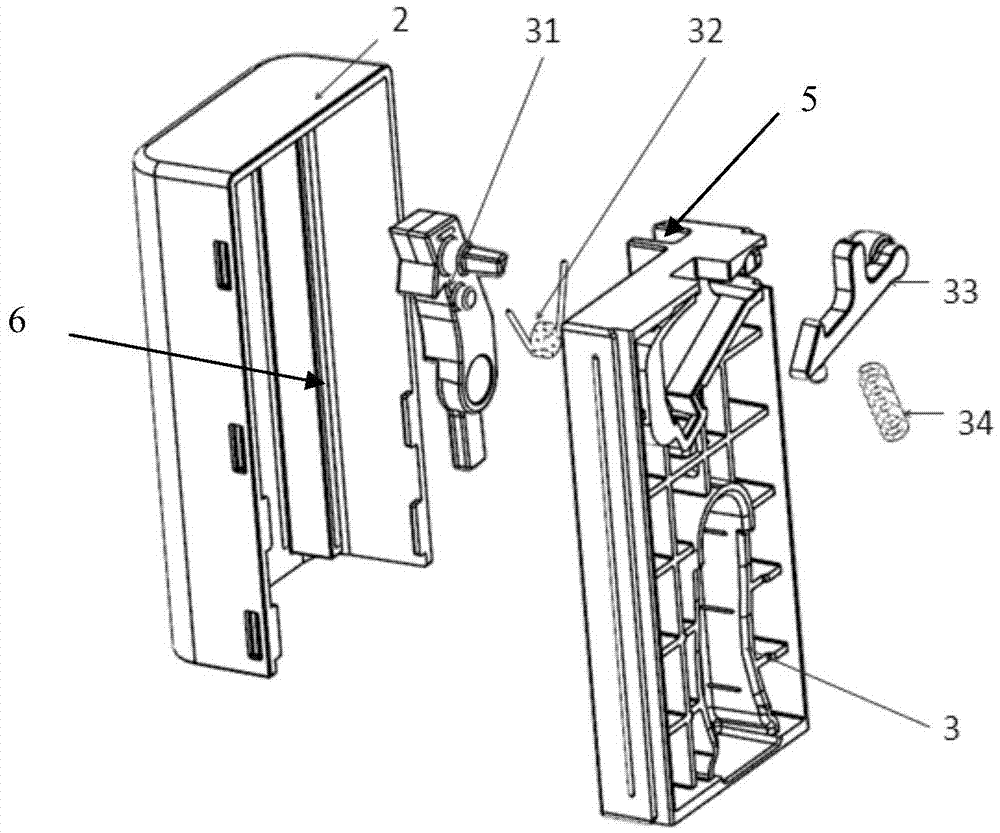

Concealed handle

ActiveCN103206109AAvoid accumulationImprove the decorative effectWing handlesFittingEngineeringMechanical engineering

The invention relates to a concealed handle which is characterized by comprising a body. The body is embedded in a mounting surface, an accommodating cavity is arranged on the front end surface of the body, a turning cover is rotationally arranged in the accommodating cavity, the shape of the turning cover is matched with that of the accommodating cavity, elastic structures and locking structures are arranged between the turning cover and the body, the lower portion of the turning cover keeps in an outwardly turning trend by the aid of the elastic structures, and the turning cover is locked in the accommodating cavity by the locking structures. When the locking structures are unlocked, the turning cover is outwardly turned under the actions of the elastic structures and can be used as a handle; and when the turning cover rotates and then is concealed in the accommodating cavity, the turning cover and the body are locked by the locking structures. The concealed handle has the advantages that when not used, the turning cover is concealed in the accommodating cavity and is fixed to the body by the aid of the locking structures, the outer surface of the turning cover can be completely flush with the outer mounting surface, accordingly, the concealed handle is good in appearance decoration feature, does not occupy external space and is convenient to transport and package, collision is effectively prevented, bacteria and dust further can be prevented from being accumulated on the concealed handle, and the concealed handle is particularly suitable for disinfection cabinets; and during usage, only the locking structures need to be unlocked, so that the turning cover can be turned outwardly and used as the handle.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

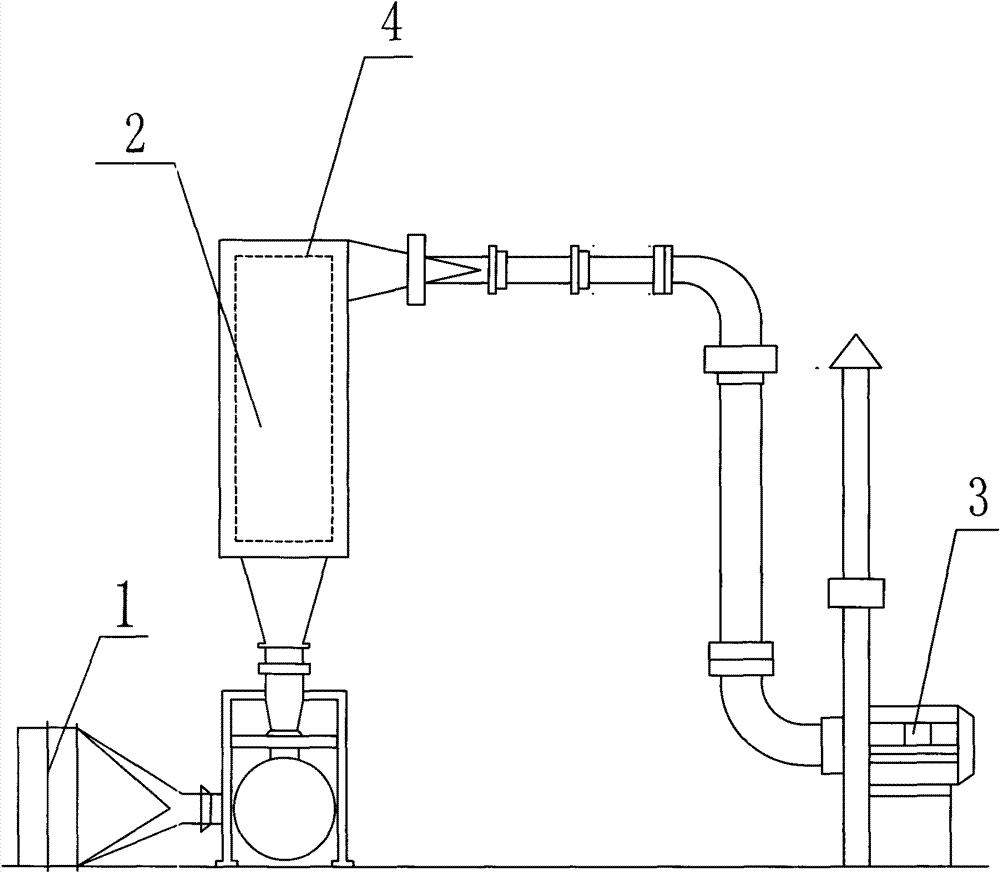

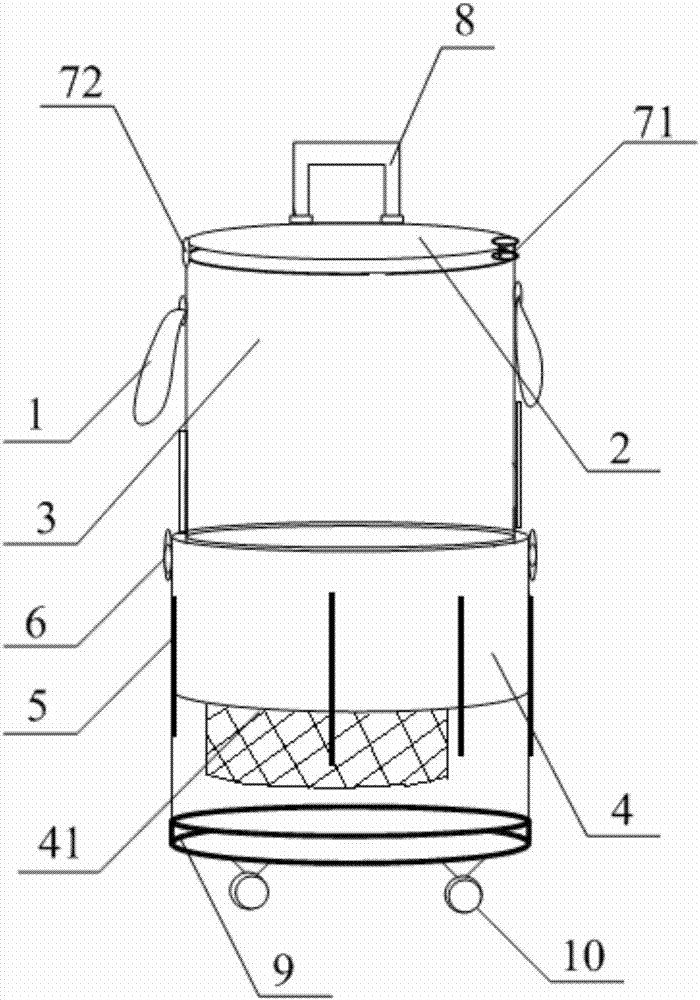

Boiling dryer

InactiveCN102735021ABlocking dischargeDoes not take up external spaceDrying solid materials with heatHearth type furnacesPulp and paper industry

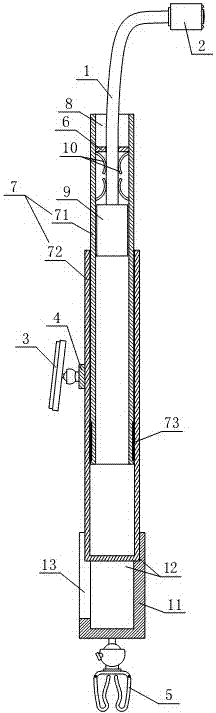

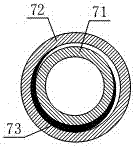

The invention relates to drying equipment and particularly relates to a boiling dryer comprising a heater, a dryer mainframe and a draught fan, wherein a dedusting cloth bag used for preventing dust from escaping is arranged in the dryer mainframe. The dedusting cloth bag is arranged in the dryer mainframe of the boiling dryer, so that the dust of dried wet materials can be effectively prevented from being discharged from an air outlet, and the boiling dryer has low manufacturing cost and saves external space.

Owner:金伟均

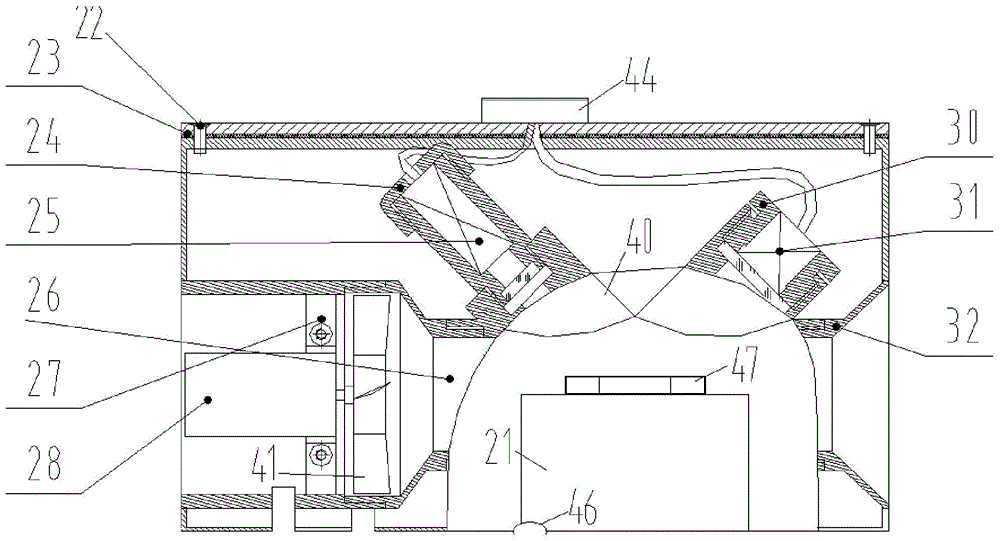

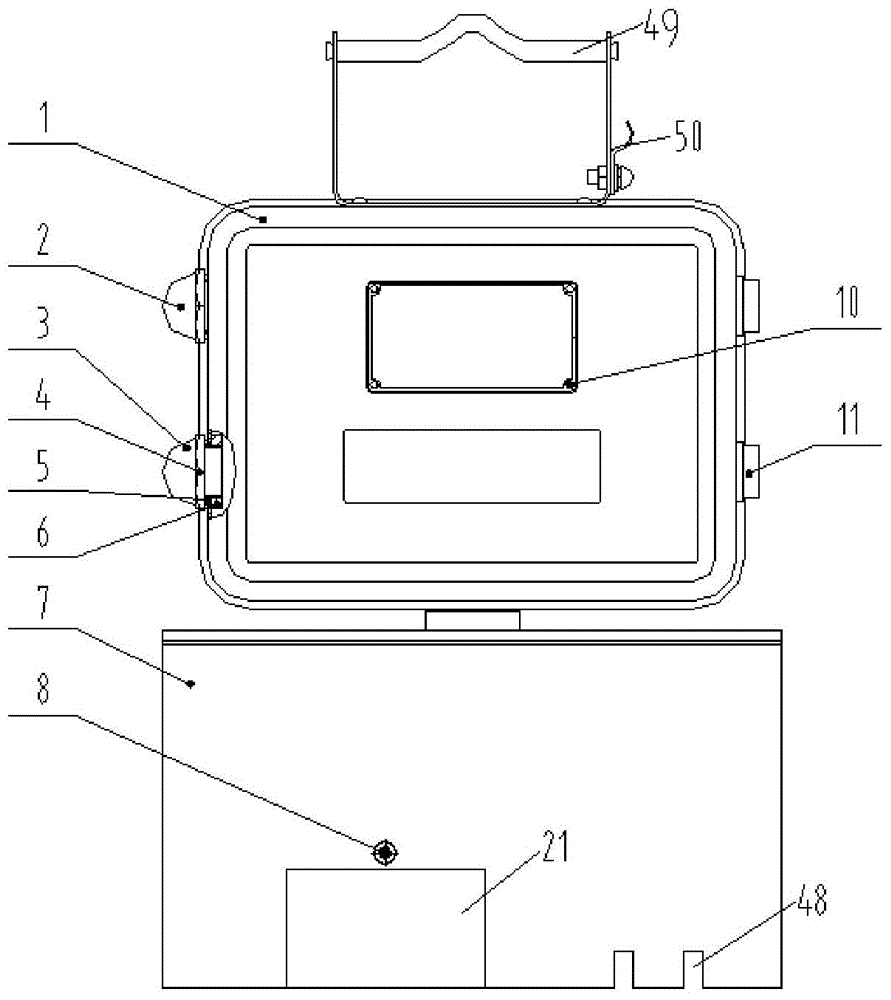

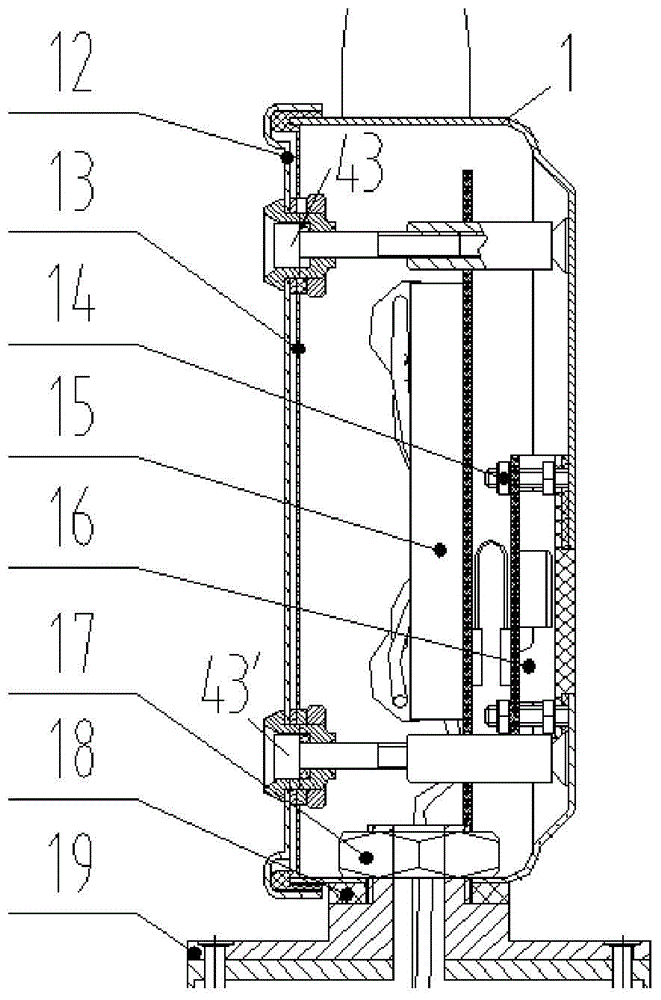

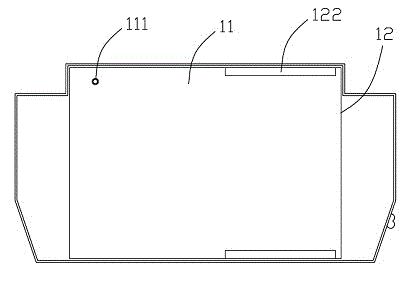

Easily maintainable optical dust concentration detection device

ActiveCN104155222AReduce pollutionEasy to lock and observeParticle suspension analysisMeasuring instrumentElectric machinery

The invention discloses an easily maintainable optical dust concentration detection device. The easily maintainable optical dust concentration detection device is characterized in that an upper shell 1 is coated with an upper shell cover group 12, the periphery of the upper shell cover group 12 is sealed with the upper shell 1 through an upper shell cover group sealing gasket 13 so that the upper shell 1 is formed into a sealed chamber for mounting a dust concentration detection system, the lower part of the upper shell 1 is connected to the upper part of a lower shell 7 through a connecting column 44, an air inlet is formed in one end of the lower shell 7, while an air outlet is formed in the other end of the lower shell 7, an optical measuring instrument 40 is fixed on the lower shell 7 between the air outlet and the air inlet and used for detecting the dust concentration, a fan is mounted at the end of the air outlet and fixed through a fan fixing cylinder 27, a motor 28 is arranged at one end of the fan and connected with an exhaust fan 41, an observing and cleaning opening 21 is formed in the lower part of the lower shell 7, and the shape of the observing and cleaning opening 21 is matched with that of the lower shell 7.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

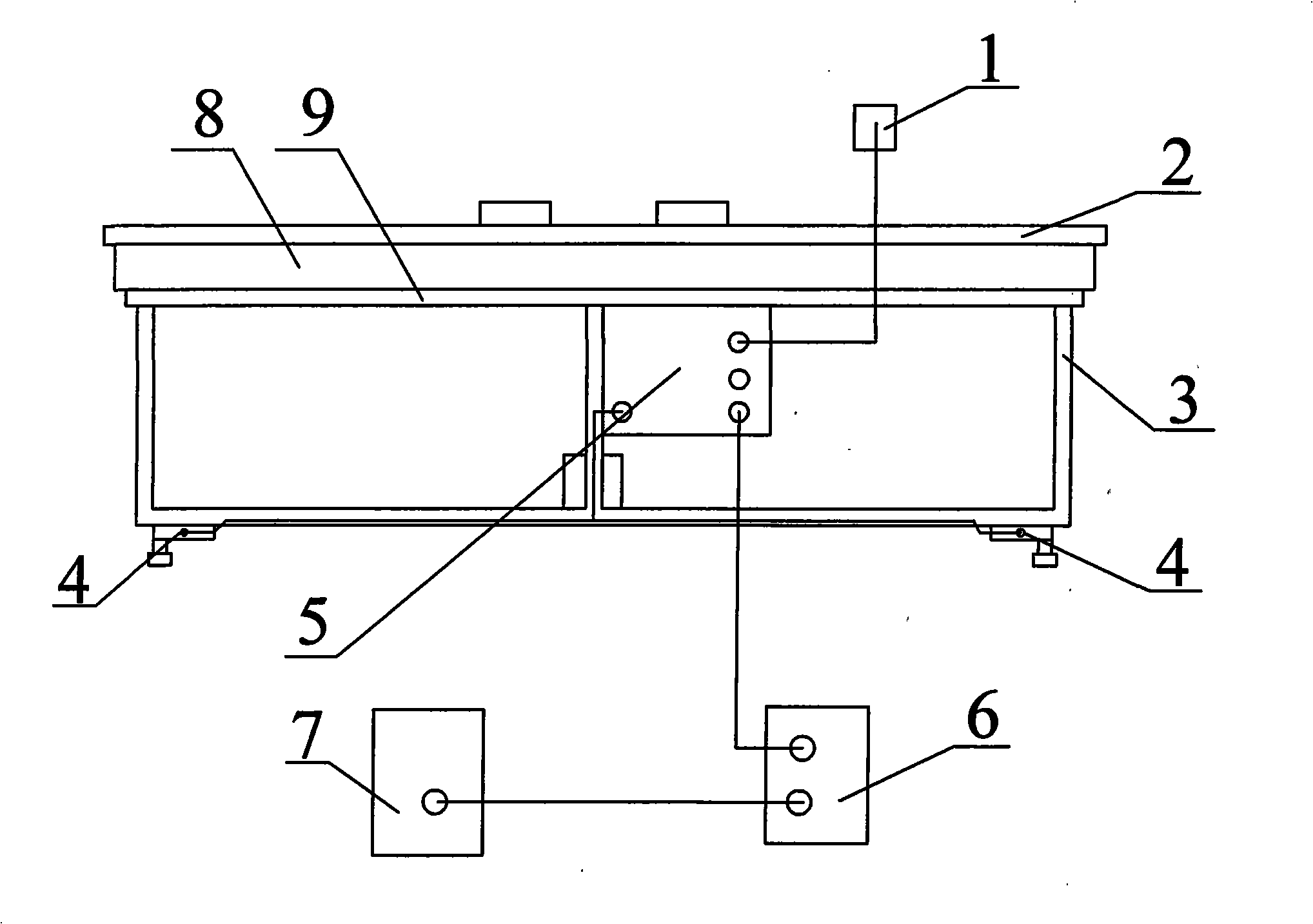

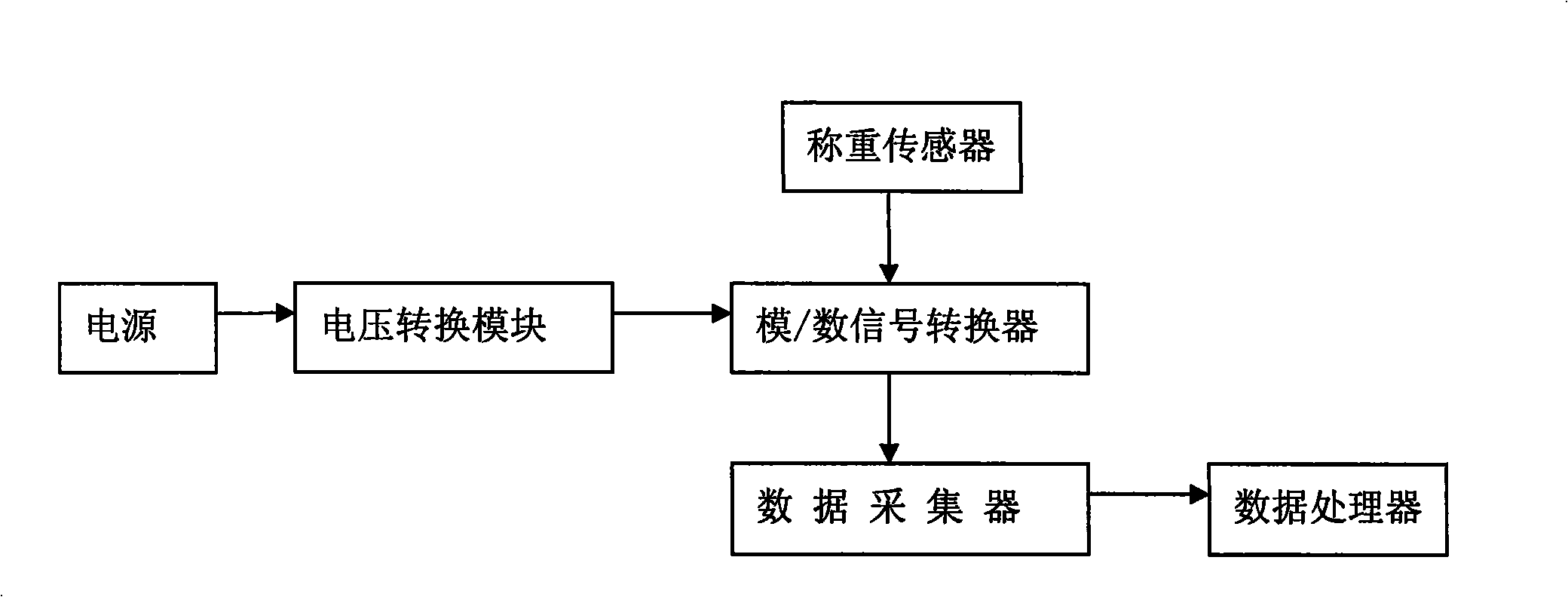

Electronic weighing system

InactiveCN101514917AAcquisition speed is fastEnsure timeliness and sensitivityWeighing apparatus using elastically-deformable membersMaterial weighingThermal radiationEngineering

The invention discloses an electronic weighing system aiming at providing a highly sensitive electronic weighing system which can improve data collecting speed and accuracy and accurately reflect mass loss in the process of burning in real time. A supporting plate is fixed at a metal support, a thermal baffle which can prevent thermal radiation is placed on the supporting plate, a loading tray is placed on the thermal baffle, weighing sensors are respectively arranged at legs of the metal support, each weighing sensor is respectively connected with an analog / digital signal converter, each analog / digital signal converter is respectively connected with a voltage transformation module and a data acquisition unit, the data acquisition unit is connected with a data processor. The outdoor part of the weighing system of the invention is simply structured and is easy to be transported and the sensor is highly sensitive, while the indoor part thereof features rapid data acquisition and real time recording, thus greatly improving accuracy of data acquisition and being capable of accurately reflecting changes of mass loss in the process of burning in real time.

Owner:TIANJIN UNIV OF COMMERCE

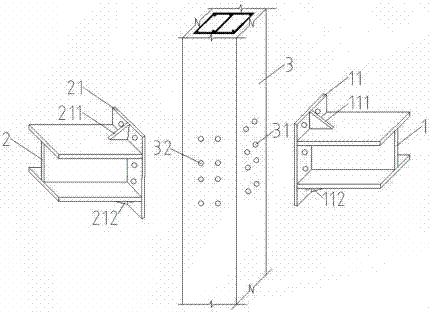

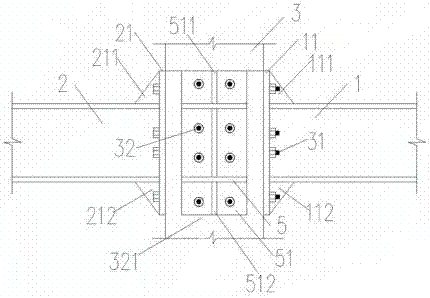

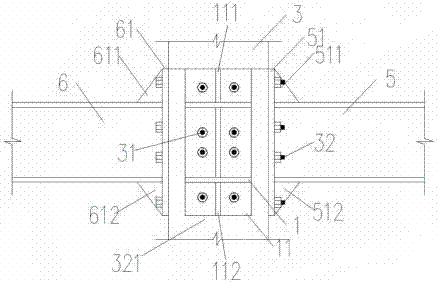

Novel assembly type reinforcing steel bar concrete column and steel beam connecting joints

InactiveCN107476430AAvoid damageReduce consumptionBuilding constructionsReinforced concrete columnSteel bar

The invention discloses novel assembly type reinforcing steel bar concrete column and steel beam connecting joints, and relates to the field of construction steel structure, civil construction technology and mechanical assembly. An end plate with reserved bolt holes is welded on the end part of a steel beam and the end plate is connected with a joint part where a pre-embedded high strength penetrating bolt is connected with the steel pipeline reinforced concrete column through high-strength bolts. According to the novel assembly type reinforcing steel bar concrete column and the steel beam connecting joints, bolt assembly is adopted, prefabricating and welding work is completed in a factory, and the quality is reliable; the anti-seismic performance is excellent, ductility and energy consumption capacity of the joints can be improved significantly; and plastic hinges are moved outward to avoid appearing at the beam end; and repairing or replacing after an earthquake is convenient.

Owner:南京清骐筑宇建筑科技有限公司

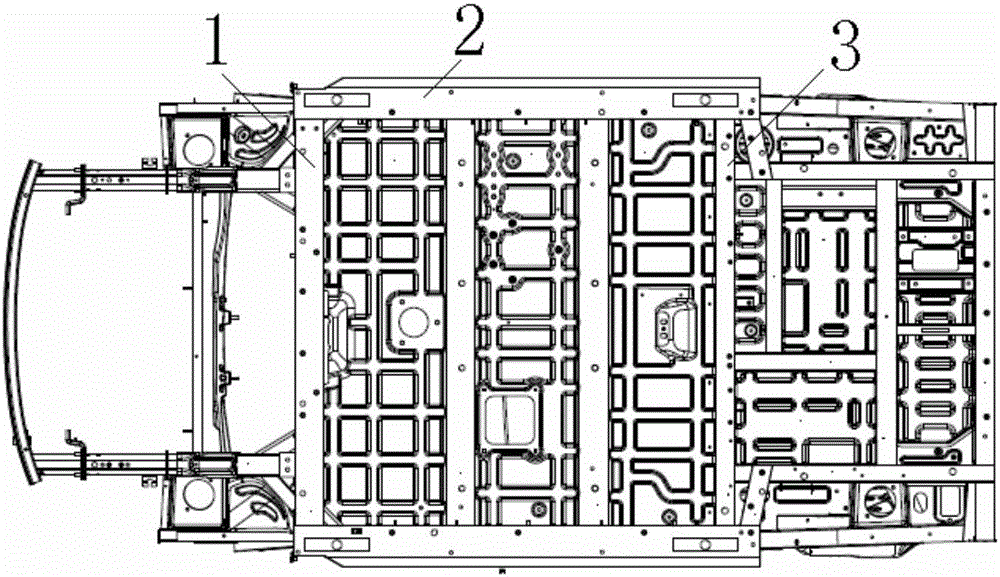

Electric automobile battery pack mounting structure

ActiveCN106184414AMiniaturizationImprove battery lifeElectric propulsion mountingSuperstructure subunitsAutomotive batteryMechanical engineering

The invention discloses an electric automobile battery pack mounting structure which comprises a pair of doorsill beams, a front baffle lower cross beam and a rear floor front cross beam. The front baffle lower cross beam is arranged at the front ends of the doorsill beams, and the rear floor front cross beam is arranged at the rear ends of the doorsill beams. The doorsill beams, the front baffle lower cross beam and the rear floor front cross beam are all of hollow aluminum profile structures and each internally provided with a nut plate mounting strip. A battery mounting nut plate is arranged on each nut plate mounting strip. Through holes corresponding to screw holes in the battery mounting nut plates are formed in bottom plates of the doorsill beams, a bottom plate of the front baffle lower cross beam and a bottom plate of the rear floor front cross beam correspondingly. Each nut plate mounting strip is of an aluminum batten structure, the weight is low, lightweight of an electric automobile is facilitated, and the driving mileage of the electric automobile can be effectively prolonged; and the overall stress is uniform, batteries are reliably fixed and conveniently mounted, and mounting structures are located inside the beams correspondingly, so that no external space is occupied.

Owner:奇瑞新能源汽车股份有限公司

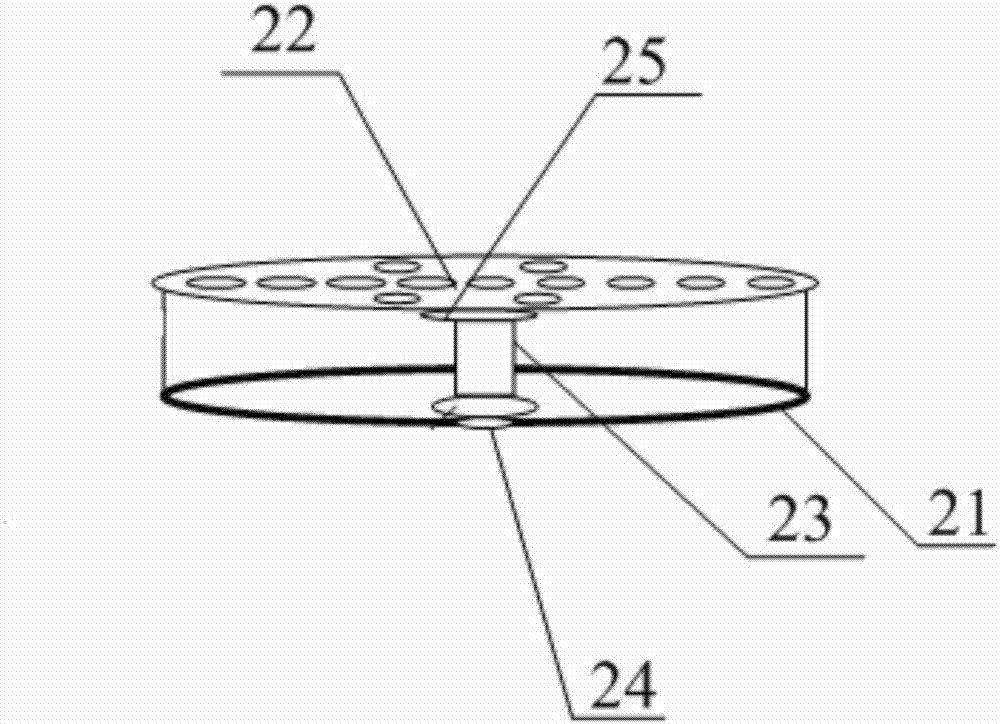

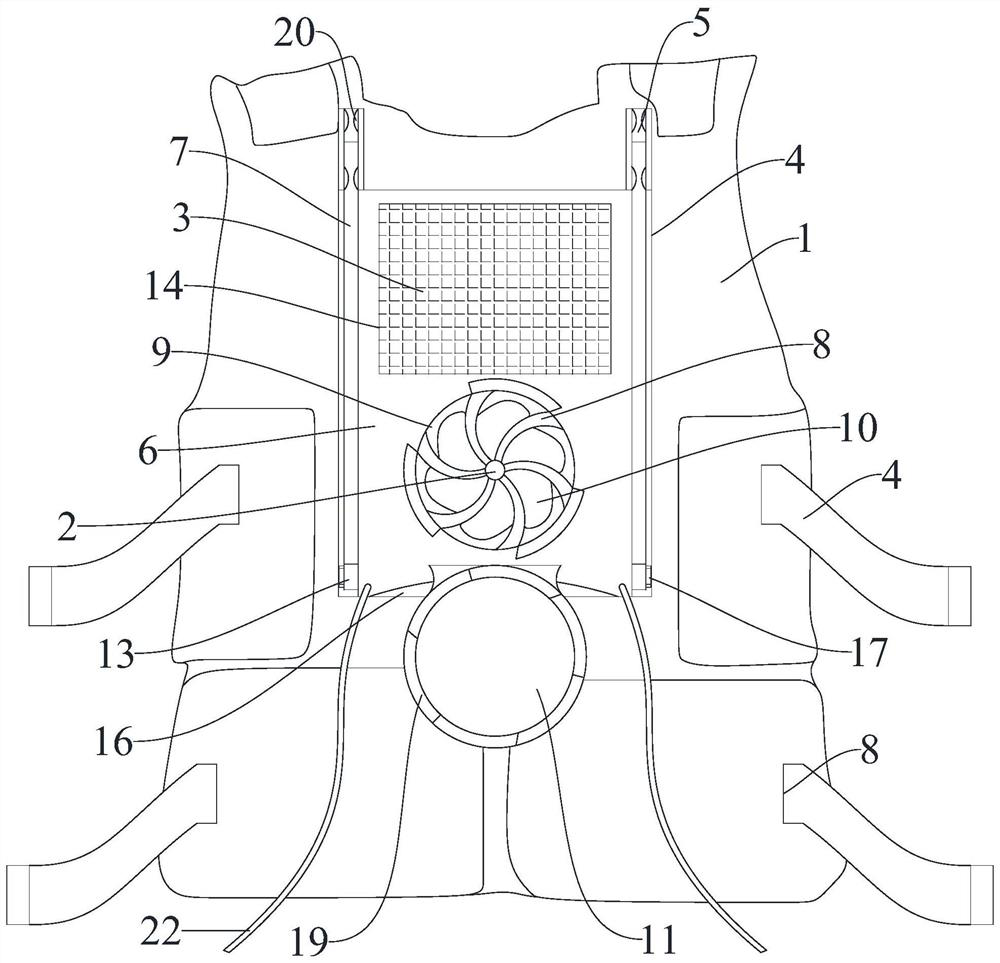

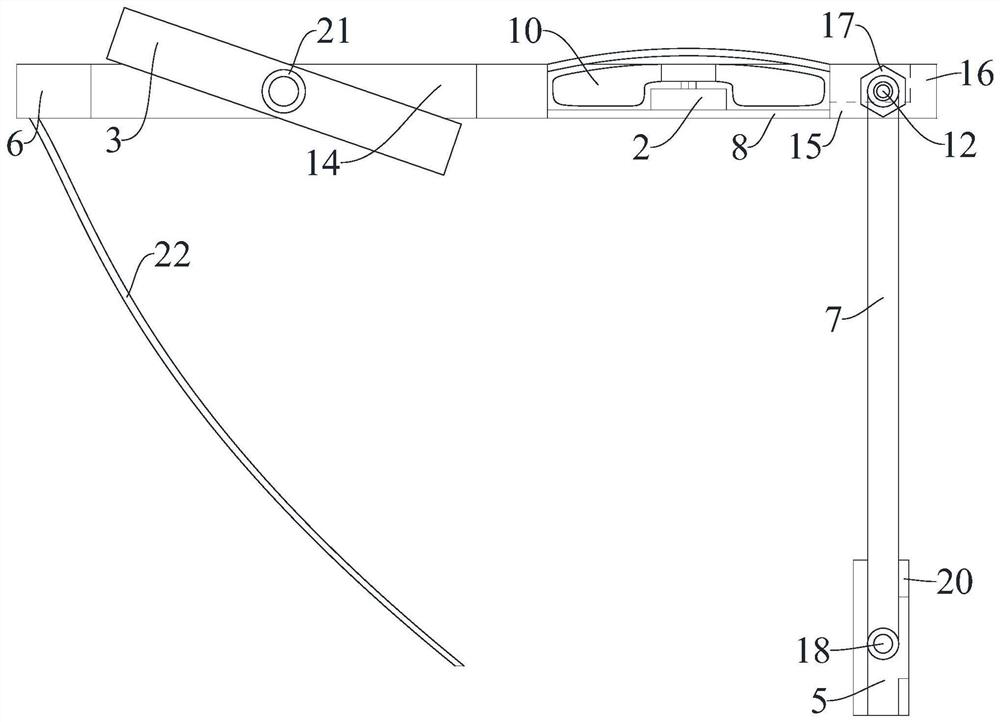

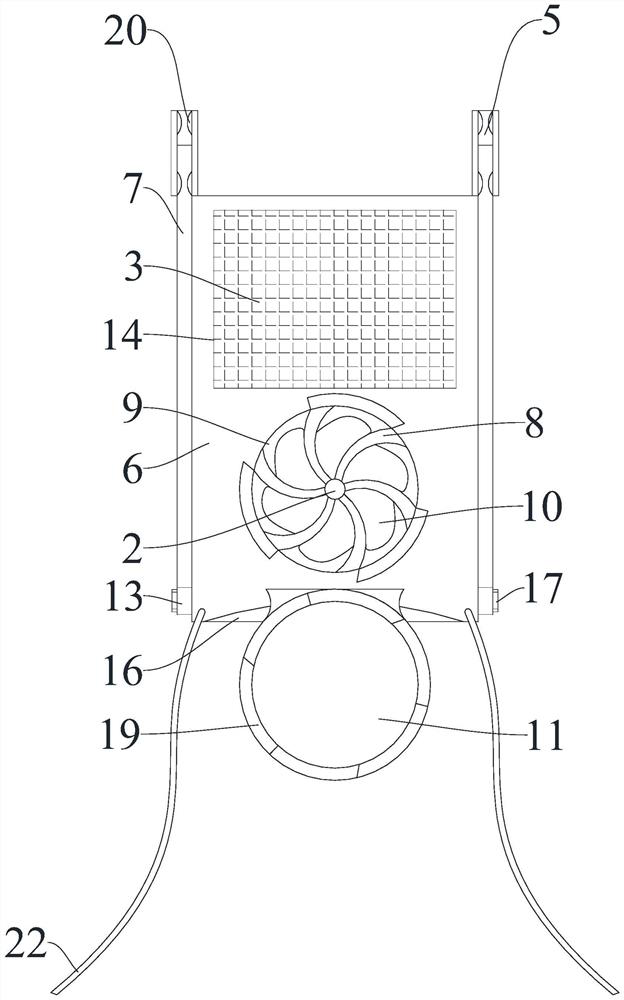

Axial air supply device, fan, air conditioner and air supply control method

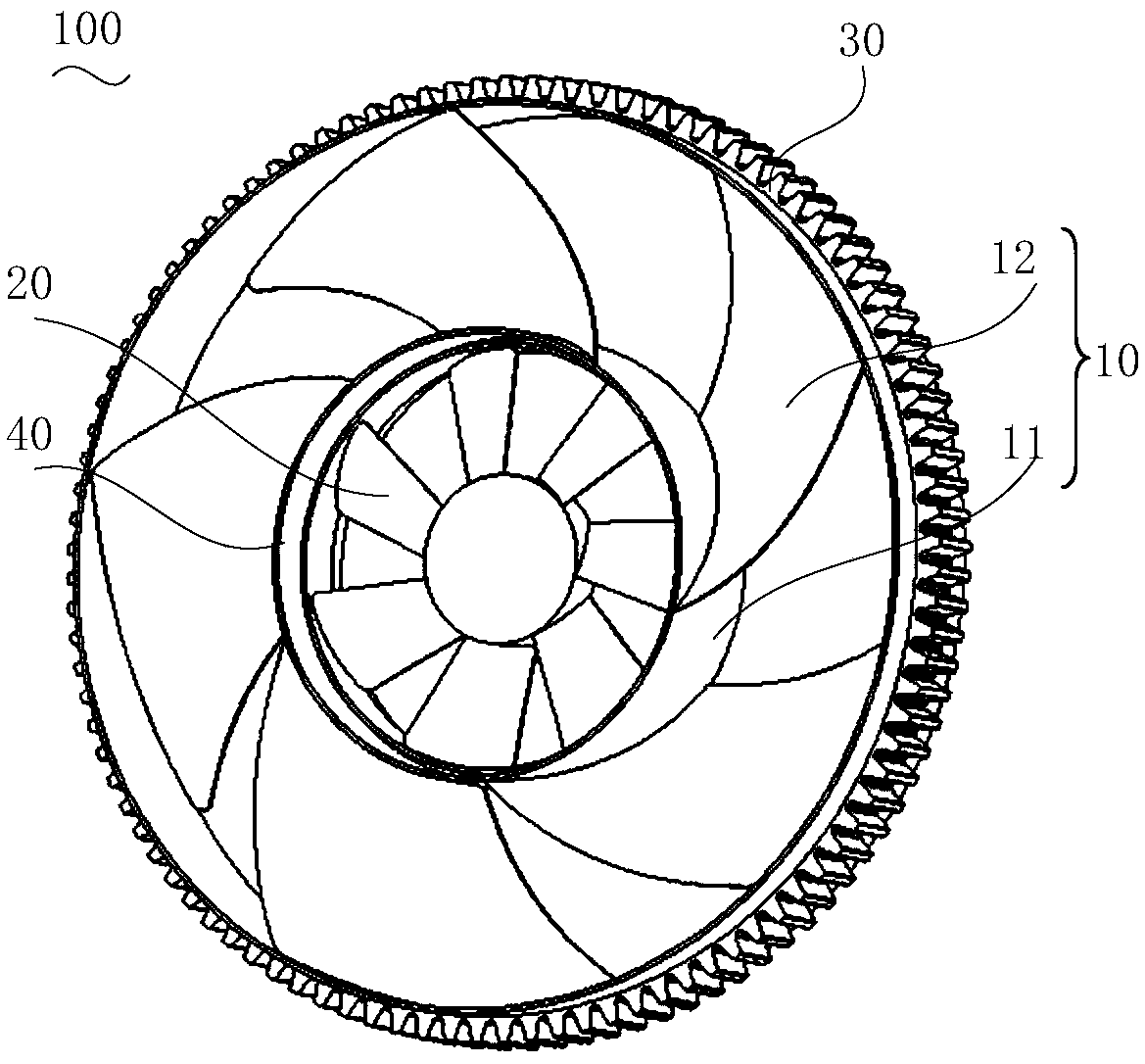

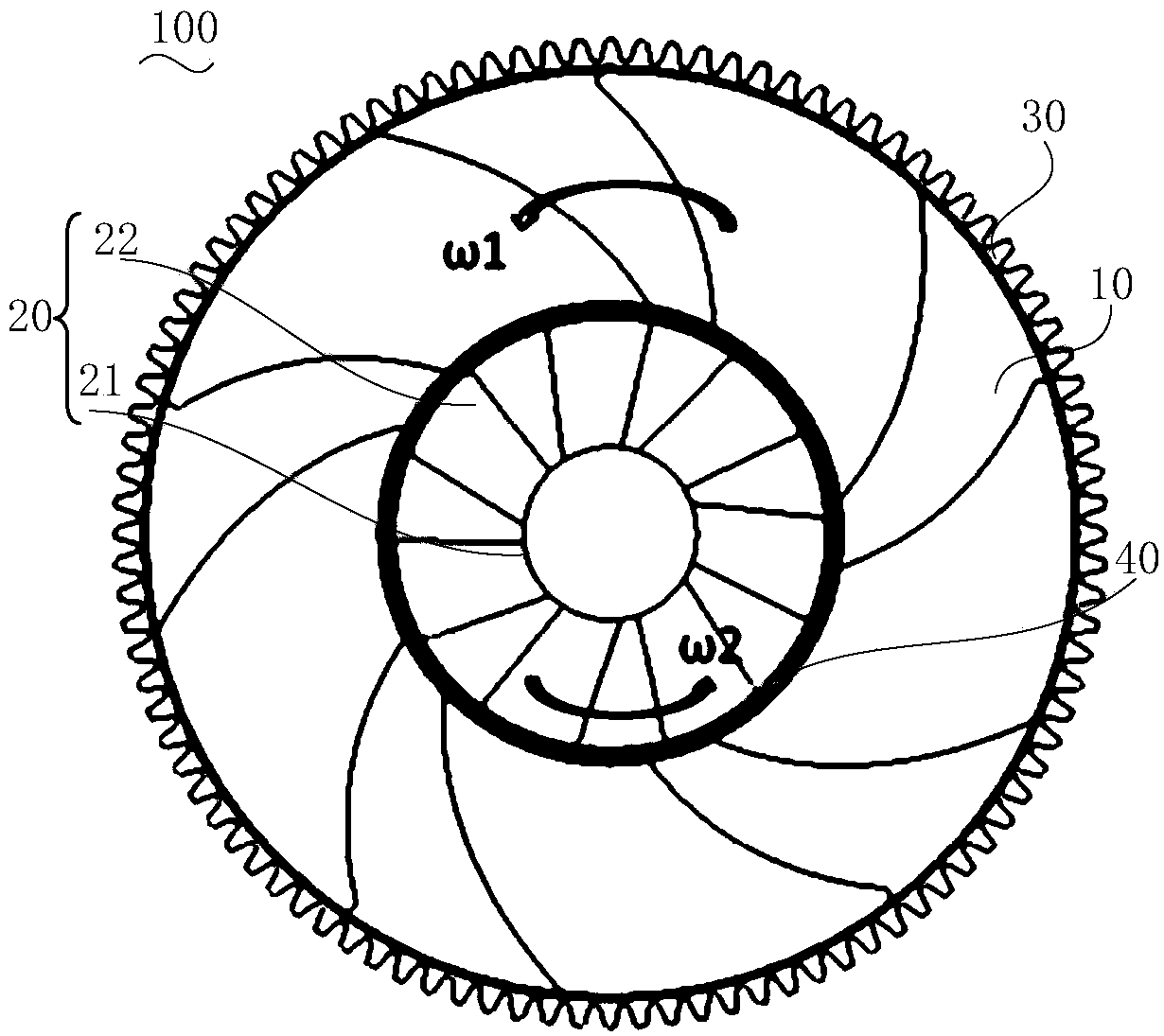

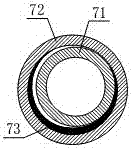

PendingCN108953176AReduce volumeRealize positive and negative air supplyPump componentsPump controlEngineeringFan blade

The invention relates to an axial air supply device, a fan, an air conditioner and an air supply control method. The axial air supply device comprises a first axial fan blade, a second axial fan blade, a first driving mechanism and a second driving mechanism, wherein the second axial fan blade is rotatably arranged in the first axial fan blade; the first driving mechanism is connected with the first axial fan blade and is used for driving the first axial fan blade to do a rotary motion relative to the second axial fan blade; and the second driving mechanism is connected with the second axial fan blade and is used for driving the second axial fan blade to do a rotary motion relative to the first axial fan blade. The positive and negative air supply of the axial air supply device can be independently controlled; additionally, according to the axial air supply device, the second axial fan blade is arranged in the first axial fan blade, and the second axial fan blade does not occupy the external space, so that the size of the whole axial air supply device is small.

Owner:GREE ELECTRIC APPLIANCES INC

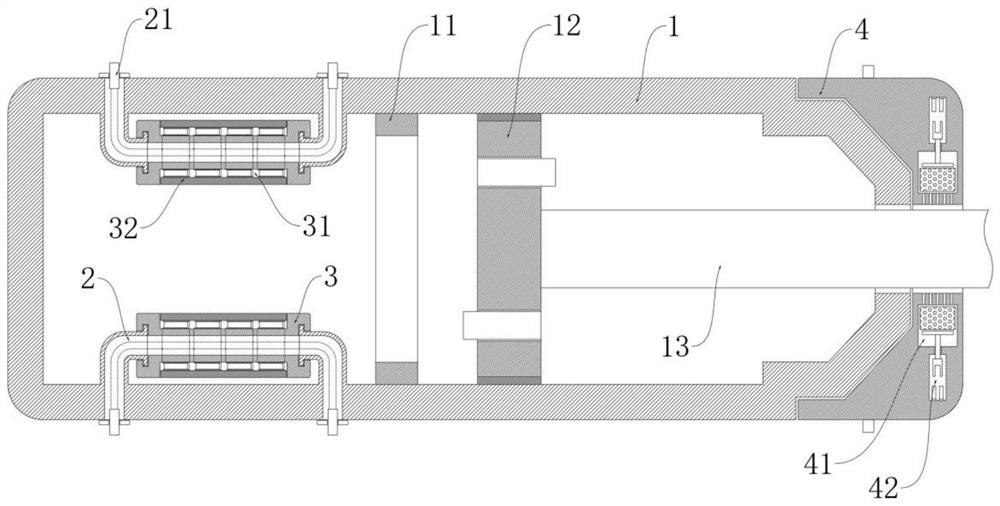

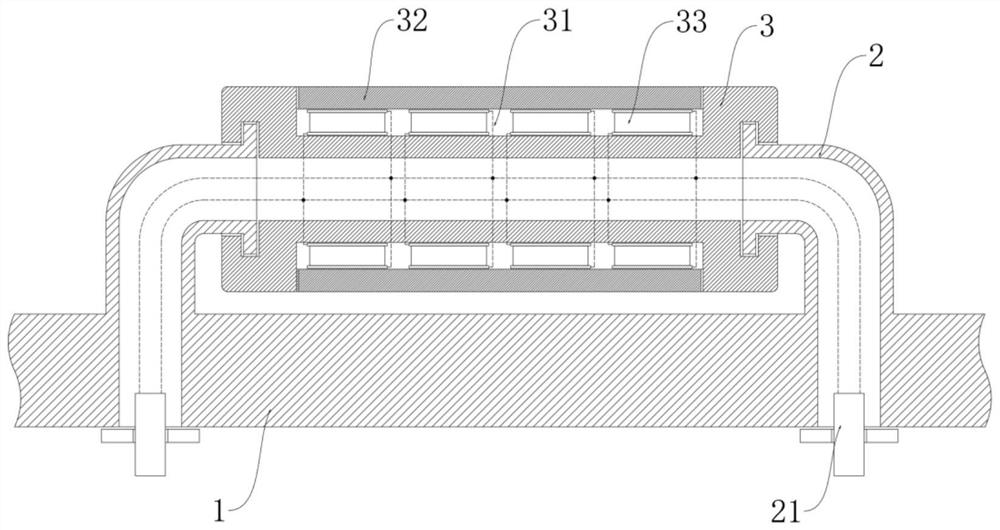

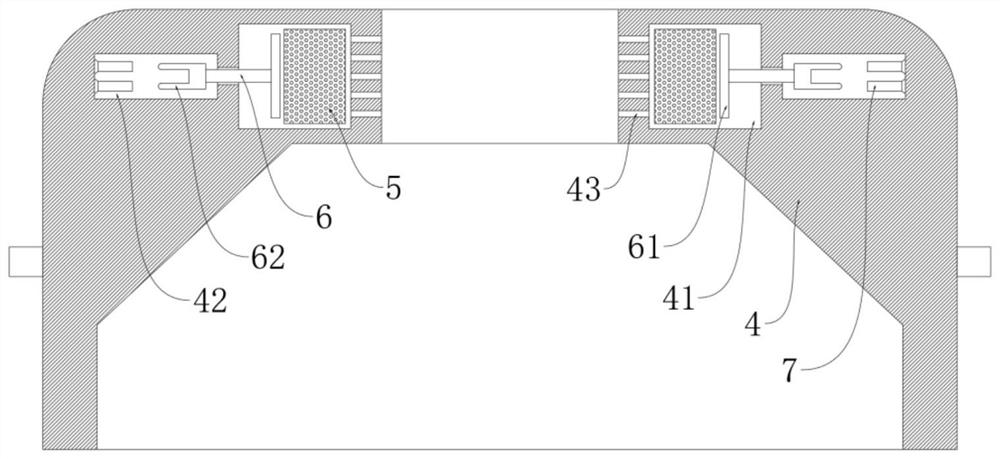

Electrical connector

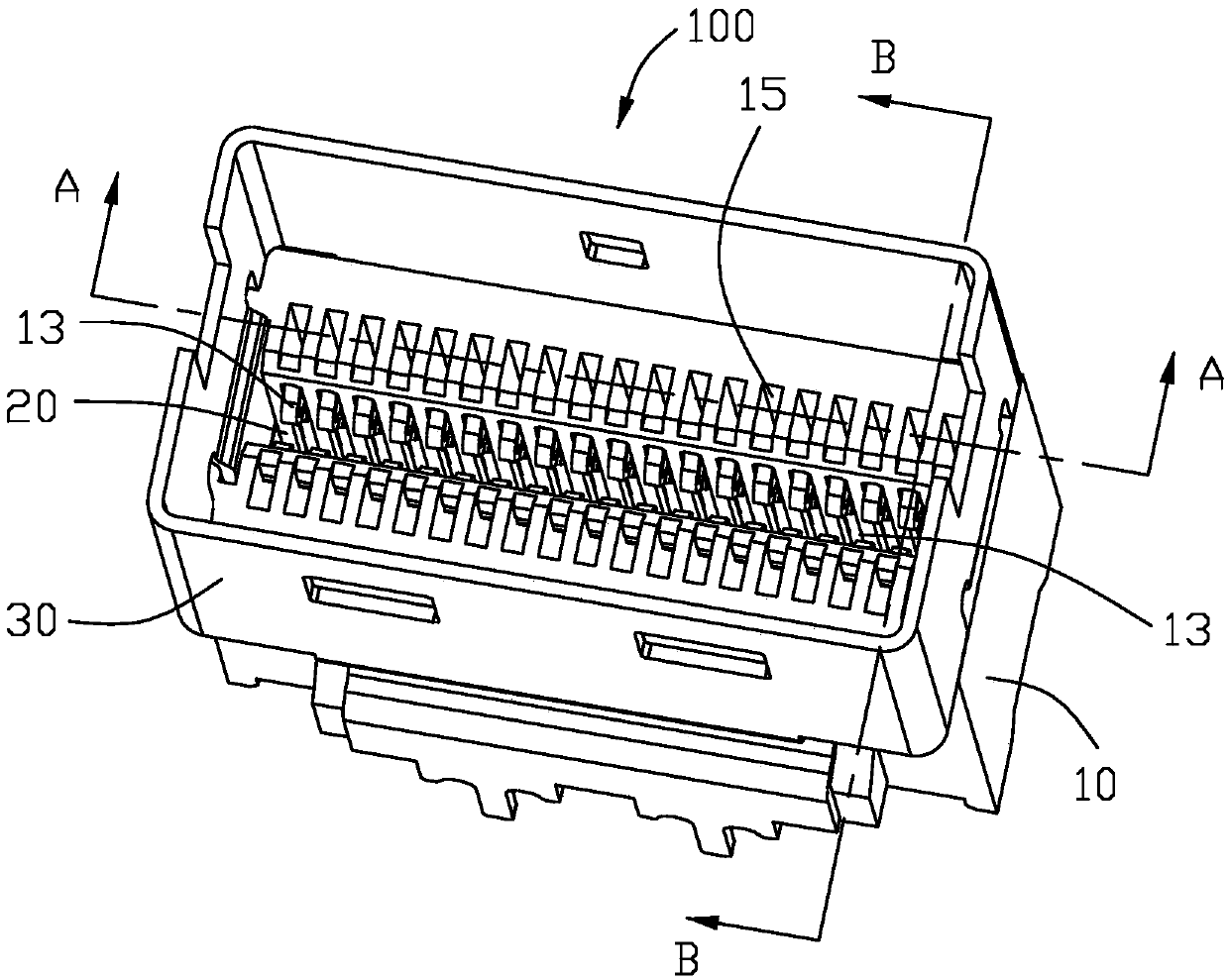

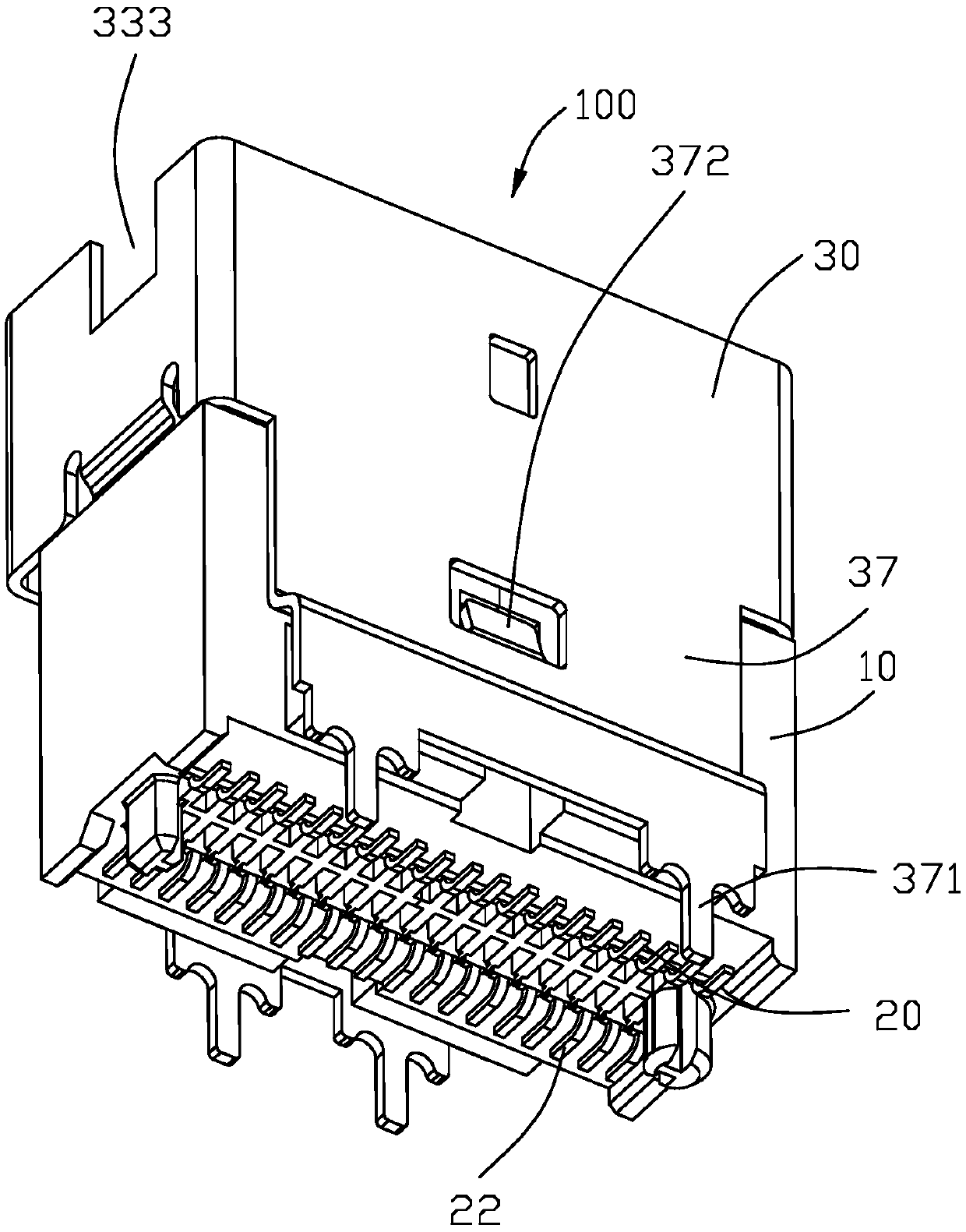

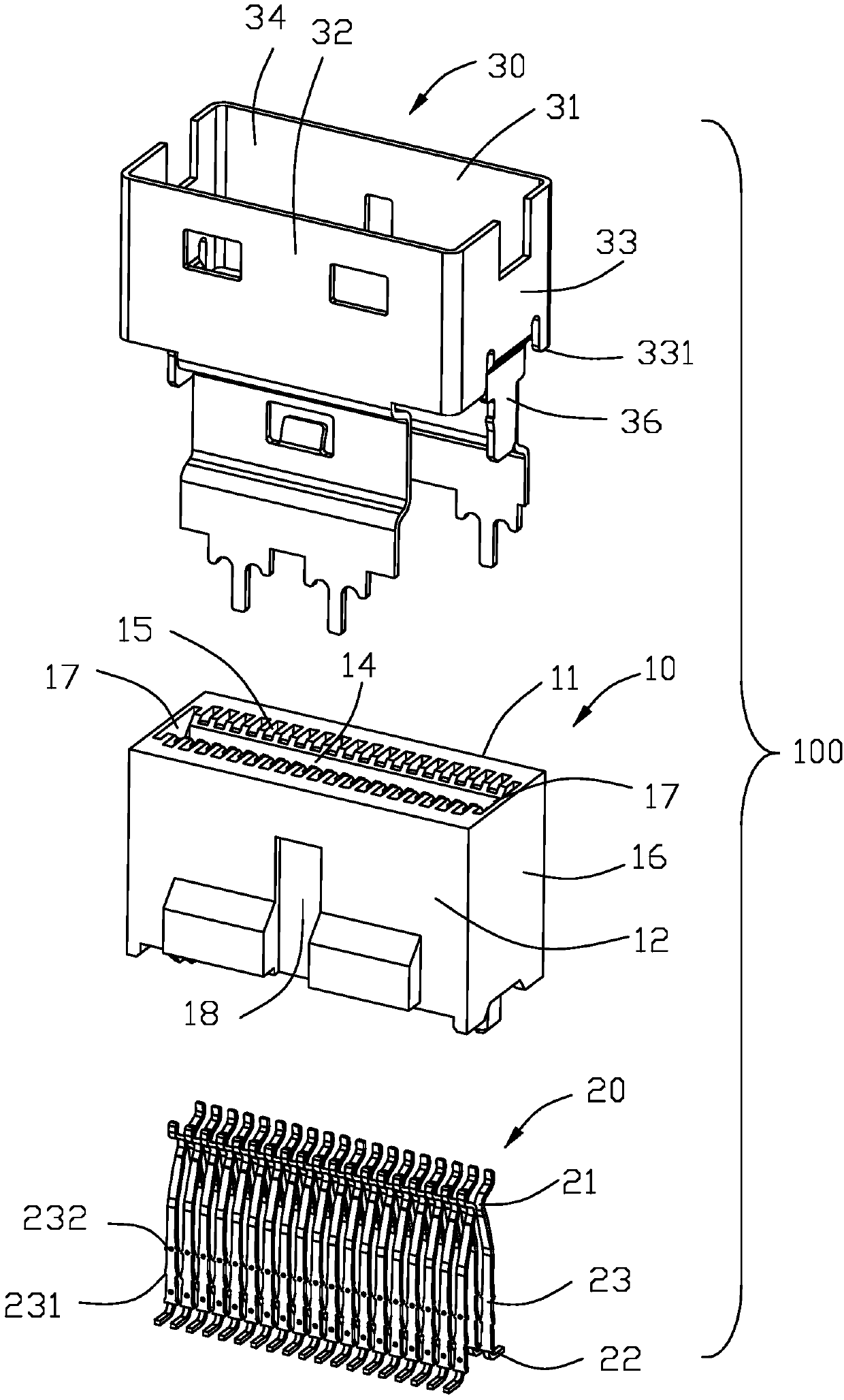

ActiveCN110391518AReduce volumeMiniaturizationCoupling device detailsTwo-part coupling devicesElectrical connectorMechanical engineering

The invention discloses an electrical connector. The electrical connector includes an insulation body, multiple conductive terminals and a metal shell; the insulation body includes a first plate part,a second plate part and docking grooves; the docking grooves are located between the first plate part and the second plate part and form openings penetrating outward on one end of the insulation body; the first plate part and the second plate part are provided with multiple terminal grooves; the conductive terminals are provided with contact parts and tail parts; the metal shell includes a firstwall, a pair of sidewalls extending from the two sides of the first wall, and an accommodating chamber; the insulation body is provided with a pair of inserting grooves; the two sidewalls of the metalshell are respectively provided with guiding parts and reinforcement parts; and the two reinforcement parts are accommodated in the corresponding inserting grooves and enclosed to form the docking grooves with the first plate part and the second plate part, so that a docking connector can be prevented from damaging the insulation body when entering the openings and after entering the docking grooves.

Owner:FUDING PRECISION COMPONENTS SHENZHEN +1

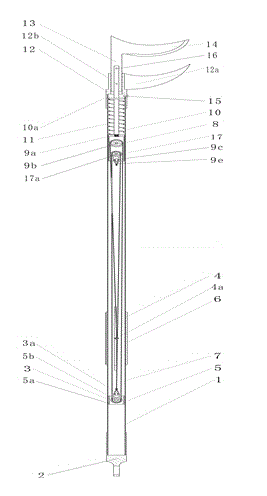

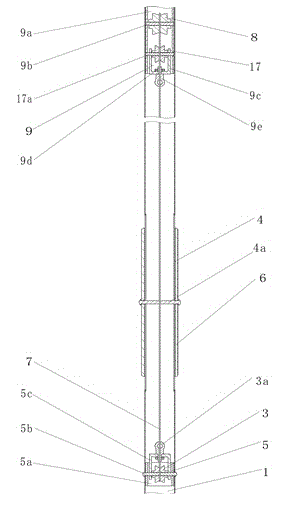

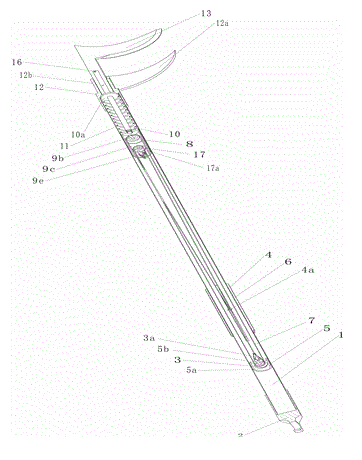

Slip handle labor saving lopper machine

InactiveCN104885797ADoes not take up external spaceEasy to operateCuttersCutting implementsEngineeringSpiral line

The invention discloses a slip handle labor saving lopper machine. The slip handle labor saving lopper machine is characterized in that a slide chute is arranged on a grip handle, a slip handle sleeves a grip rod, a pin rod passes through the slip handle in the radial direction, and is connected with the slip handle, movable pulleys and fixed pulleys are respectively installed on a movable pulley installation piece and a fixed pulley installation piece, the movable pulley installation piece can slide in the grip handle, the fixed pulley installation piece is fixedly connected in the grip rod, one end of a pulling rope is connected with an installation piece, the other end of the pulling rope is wound around the pulleys in sequence according to a spiral line mode, and then is connected with a slip handle pin rod, the pulleys are arranged in the axial direction of the grip rod, axles of the pulleys are parallel to one another, a baffle disc is arranged on a transmission bar, the inner end of the transmission bar is connected with the movable pulley installation piece, a reset spring sleeves the transmission bar, one end of the reset spring is pressed against the movable pulley installation piece, the other end of the reset spring is pressed against the baffle disc on the transmission bar, a connection head of a shear head sleeves the end of the grip handle, one end of the connection head is connected with a slide groove with a fixing tool, a slip sheet is connected with the slide groove in slip mode, the upper portion of the slip sheet is provided with a moving tool, and the lower portion of the slip sheet is connected with the transmission bar. A user pulls the slip handle, and the shear head is driven to work in labor saving mode. The slip handle labor saving lopper machine can select different labor saving multiples by selecting the number of the pulleys where the pulling rope is wound.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Engine pressure release valve exhaust noise elimination device

ActiveCN107476913ASave energyReduce irregular movementInternal combustion piston enginesIntake silencers for fuelInlet channelEngineering

The invention provides an engine pressure release valve exhaust noise elimination device. The engine pressure release valve exhaust noise elimination device comprises an air inlet cavity and an air outlet cavity; the air inlet cavity is provided with an air inlet channel, the air outlet cavity is provided with an air outlet channel, a connecting channel is arranged between the air inlet cavity and the air outlet cavity, and a flow disturbing device is arranged in the air inlet cavity. According to the engine pressure release valve exhaust noise elimination device, a flow disturbing resonance effect on air flow can be achieved through the flow disturbing device, energy of the air flow can be reduced, and first-time noise reduction is achieved; irregular motion of the air flow is reduced in the process that the air flow penetrates through micro holes formed in the middle cylinder wall to enter the air flow exhaust cavity, and second-time noise reduction is achieved; after the energy and the mobility of the air flow in the air flow exhaust cavity of a noise elimination cylinder are controlled, noise generated by the air flow exhausted through the micro holes is reduced again, and third-time noise reduction of the noise elimination device is achieved; the air flow flows away along with an air exhaust pipeline, the purpose of pressure release valve exhaust noise elimination is achieved, and the device is installed in the air exhaust pipeline and does not occupy external space.

Owner:贵州新安航空机械有限责任公司

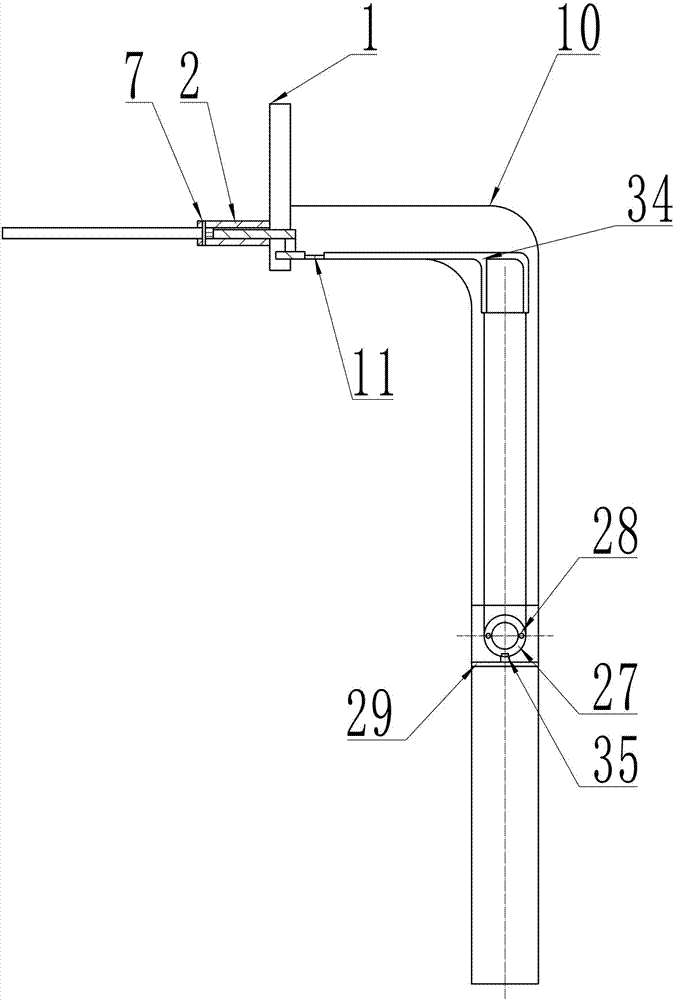

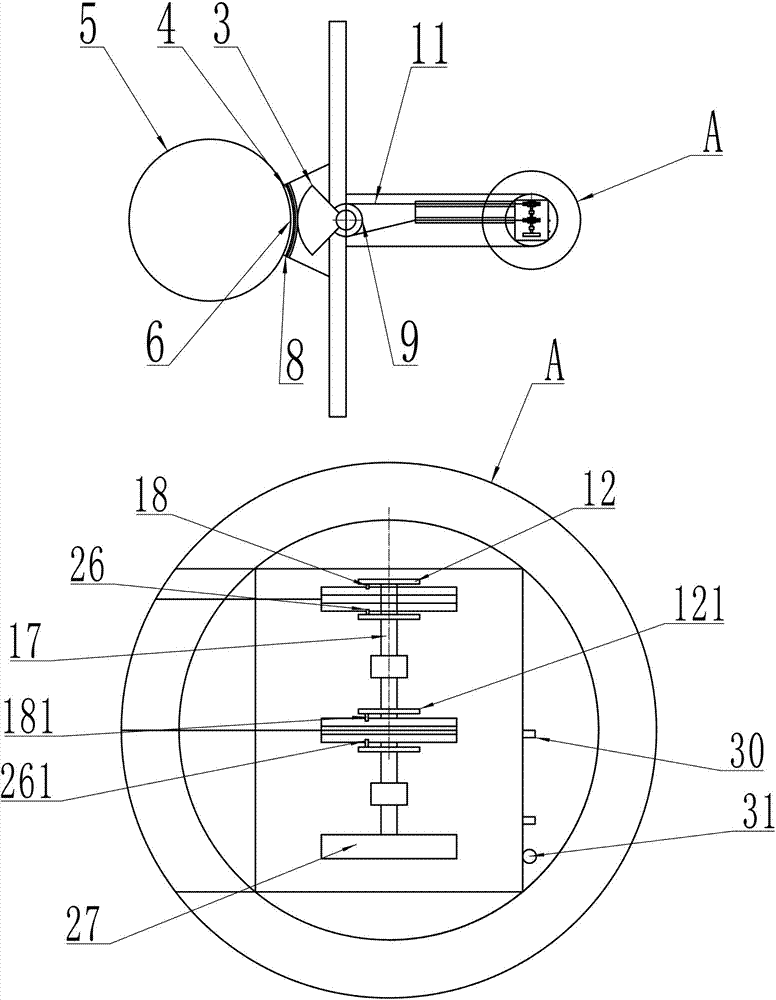

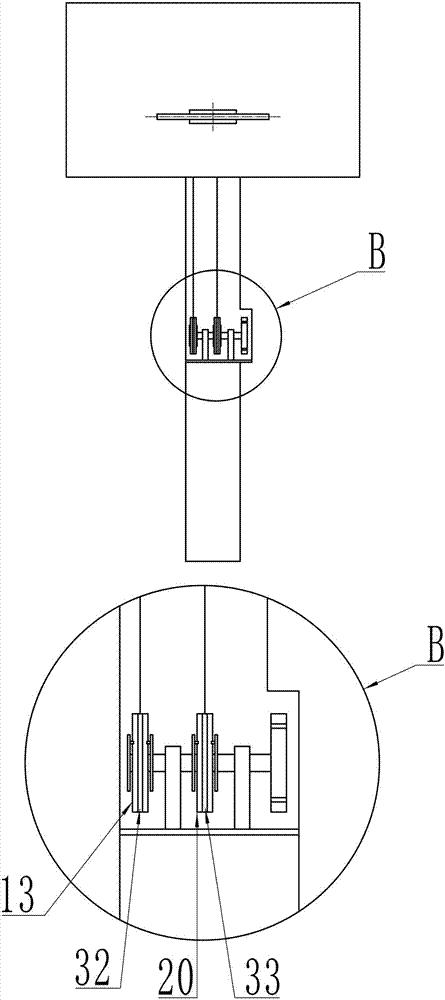

Anti-clamping basketball stand

ActiveCN106984021ASolve the ball stuck phenomenonDoes not take up external spaceBall sportsDrive wheelGear wheel

The invention relates to an anti-clamping basketball stand. The problem that a basketball clamped in an existing basketball stand is not easily taken down is effectively solved. According to the technical scheme, the anti-clamping basketball stand comprises a backboard, and is characterized in that a supporting plate is fixed to the backboard, the supporting plate is provided with a sector gear, an arc-shaped rack is arranged outside the sector gear, the arc-shaped rack is attached and fixed to the outer side of a ring, a first transmission wheel is arranged below the sector gear, the first transmission wheel is connected with a second transmission wheel and a third transmission wheel through the two ends of a steel wire rope, a driving wheel is arranged right ahead the third transmission wheel, the driving wheel is connected with a driving device, the driving wheel drives the driving wheel to drive the second transmission wheel and the third transmission wheel to rotate, and therefore the sector gear is driven to drive the ring to rotate; the basketball clamped between the ring and the backboard falls off through rotation of the ring; the basketball clamped on the basketball stand is more convenient to take down through the anti-clamping basketball stand.

Owner:济宁高新科达科技项目服务有限公司

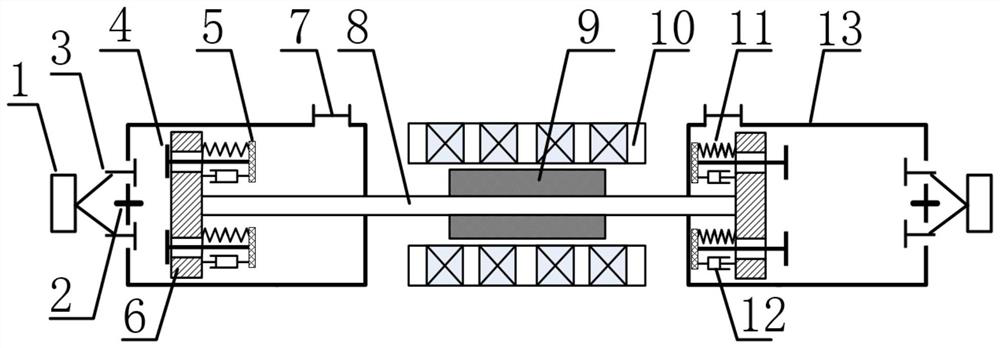

Two-stroke high expansion ratio free piston internal combustion engine generator

InactiveCN111852650AImprove ventilation efficiencyRealize straight-line ventilationPistonsFree piston enginesFree-piston engineInlet valve

The invention relates to a two-stroke high expansion ratio free piston internal combustion engine generator, and belongs to the field of energy and power. The generator mainly includes a free piston engine, a linear generator, and a connecting rod. A plurality of air inlet channels are opened in pistons, an air inlet door is arranged on each air inlet channel, and air inlet door springs and air inlet door damping are arranged between air inlet door gaskets and the pistons. Moments of opening and closing of the air inlet doors can be optimized by adjusting the relative position of the air inletdoor gaskets and the bottom of a cylinder and damping factors of the air inlet door damping, low compression ratio and high expansion ratio can be achieved on the two-stroke free piston engine, and the circulation heat efficiency can be further improved.

Owner:SHANDONG JIAOTONG UNIV

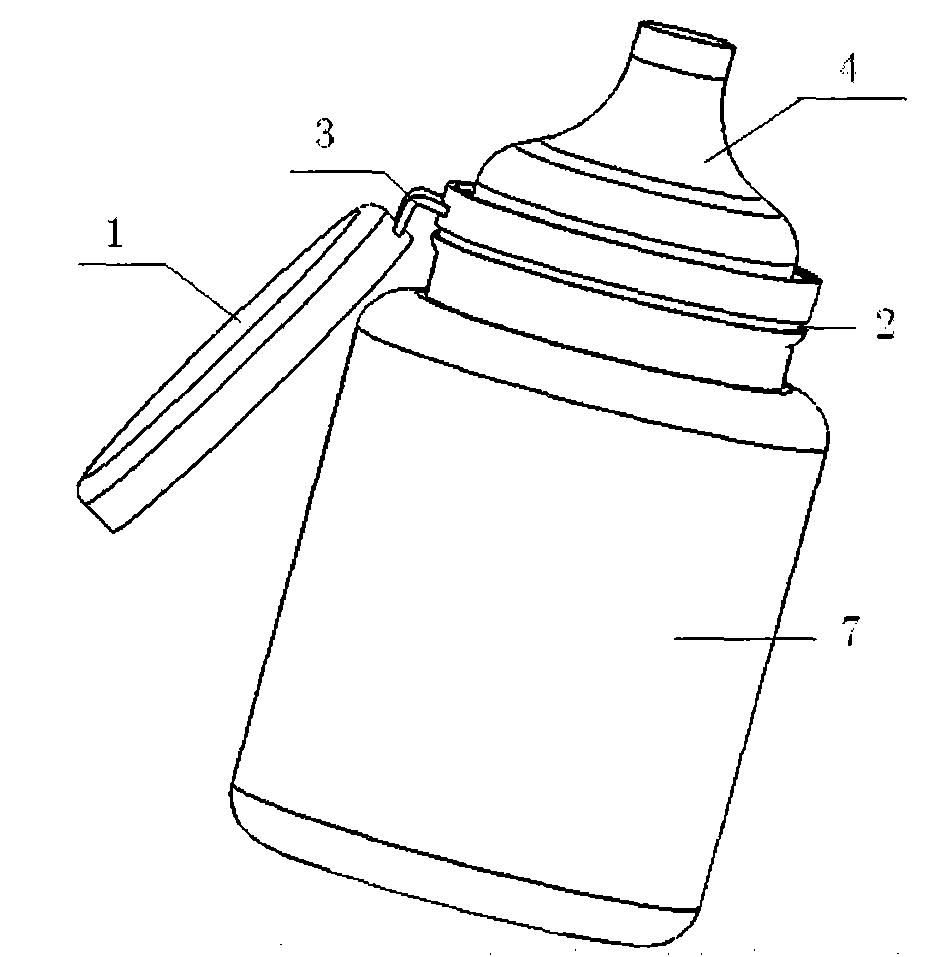

Multifunctional portable household storage barrel

The invention discloses a multifunctional portable household storage barrel, comprising a pulling barrel, a bottom barrel, a storage barrel cover and a base, wherein the inner wall of the bottom barrel is provided snapping grooves along the height direction of the bottom barrel; the outer wall of the pulling barrel is provided with slide blocks along the height direction of the pulling barrel; the pulling barrel is arranged in the bottom barrel; the slide blocks are snapped in the snapping grooves; the pulling barrel can slide upward and downward along the snapping grooves relative to the bottom barrel; the storage barrel cover is provided with a battery, a switch and an ultraviolet germicidal lamp; the ultraviolet germicidal lamp is located on the side, close to the pulling barrel, of the storage barrel cover; and battery, the switch and the ultraviolet germicidal lamp are successively tandem via leads so as to form a loop; and the storage barrel cover is provided with air-vents. The storage space of the storing multifunctional portable household storage barrel can be changed as needed, and operation is simple; the storage space of the storage barrel is small and enclosed and is prone to propagation of bacteria, so the ultraviolet germicidal lamp can be turned on regularly so as to realize sterilization of stored items and the storage space, which is beneficial for human health.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

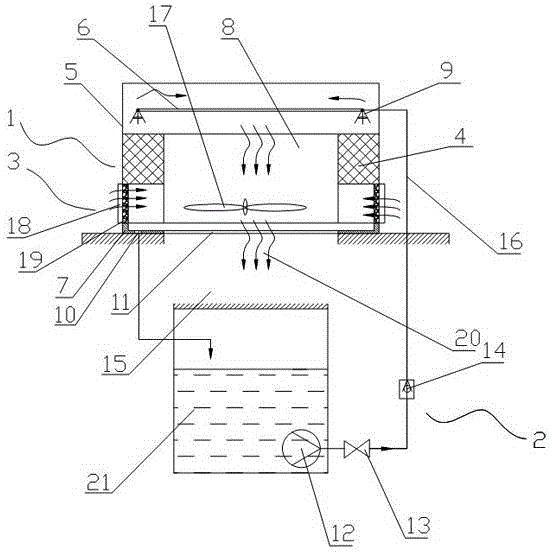

Evaporative cooling air conditioning device utilizing wash water of flush toilet

ActiveCN104976716ACool wind speedReduce the temperatureLighting and heating apparatusAir conditioning systemsFlush toiletWater supply

The invention discloses an evaporative cooling air conditioning device utilizing wash water of a flush toilet. The evaporative cooling air conditioning device is characterized in that the evaporative cooling air conditioning device is arranged on a roof over the flush toilet and comprises an evaporative cooling air conditioning device body, a water supply and return device and an air inlet and outlet device; the water supply and return device is communicated with the evaporative cooling air conditioning device body; the air inlet and outlet device is arranged in the evaporative cooling air conditioning device body, over against a person using the flush toilet; and the evaporative cooling air conditioning device body is internally provided with a water directly-evaporating cooling member utilizing reverse circulation heat and moisture exchange between the wash water and air. The evaporative cooling air conditioning device is arranged on the roof of a restroom, occupies a small space, is simple in structure and very convenient to mount and use, and does not affect the overall attractive appearance of the restroom; the cooling capacity of the wash water of the flush toilet in the restroom is used fully, so that the wash water can be comprehensively utilized; and the evaporative cooling air conditioning device is high in cooling rate, energy-saving, economical and practical, is suitable for substantial popularization and application, and effectively solves the problem that an ordinary air conditioner cannot be suitably mounted in the general domestic restroom.

Owner:HANGZHOU SUOFAN ENERGY SAVING TECH

Multifunctional test bar

ActiveCN107202911AConvenient wiring operationDoes not take up external spaceClosed circuit television systemsMeasurement instrument housingEngineeringPower flow

The invention relates to a multifunctional test bar. The multifunctional test bar comprises a hollow length adjustable bar body, a universal locating flexible tube is connected to the top end of the bar body and is installed in an inner cavity in the top part of the bar body in a sliding manner, a flexible tube clamping and locating mechanism is arranged in the inner cavity in the top end part of the bar body, a camera box is installed at the outer extending end of the universal locating flexible tube, a camera is installed on the camera box, the test bar further comprises display screen equipment in wireless communication connection with the camera, the display screen equipment is handheld or is detachably clamped on the bar body through a clamping seat, a spring cable clamp is installed at the bottom end of the bar body, and a current detection wire and a voltage detection wire are led out from the spring cable clamp. The multifunctional test bar helps to read a name plate rapidly, assists in wiring, is simple in structure, is flexible to operate, and is quite convenient to carry and use.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

Refrigerator quick-cooling device

ActiveCN103822425AFast coolingReduce volumeLighting and heating apparatusCooling fluid circulationWater circulationWater pipe

The invention relates to a refrigerator quick-cooling device and a refrigerator with the same. The refrigerator quick-cooling device comprises a cooling box with an accommodating cavity and a cooling mechanism arranged on periphery of the cooling box. The cooling mechanism comprises an air duct arranged on the outer side of the cooling box and communicated with the inside of a refrigerator chamber, a fan arranged at the position of an air inlet in the air duct, cooling fins arranged in the air duct and located between the fan and the air outlet of the air duct, a water circulating system arranged in the air duct and communicated with the accommodating cavity, and a control device controlling the fan and the water circulating system to work. The water circulating system comprises a water guide pipe communicated with the accommodating cavity and passing through the cooling fans, and a water pump arranged on a pipeline of the water guide pipe. The water guide pipe is provided with a water inlet communicated with the accommodating cavity and a water return port communicated with one side, away from the water inlet, of the accommodating cavity. The water pump is arranged between the water return port and the cooling fins.

Owner:HAIER GRP CORP +1

Air purifying system with loop-current cyclone dust removal

ActiveCN105920966ARealize circulation utilizationDoes not take up external spaceCombination devicesCycloneAir filter

The invention discloses an air purifying system with loop-current cyclone dust removal. The air purifying system comprises an inlet air filter set, a cyclone mixing device, a gas washing device, a first return air filter and a second return air filter, wherein the lower end of the inlet air filter set is provided with a top channel; the cyclone mixing device is arranged in a sandwich layer of an indoor side wall; the inlet end of the cyclone mixing device communicates with the upper end of the top channel; the outlet end of the cyclone mixing device communicates with the top channel; indoor return air treated by the cyclone mixing device is transmitted into the gas washing device; the first return air filter is arranged on the center of the indoor bottom; the first return air filter communicates with the air inlet of an air regulating system; the second return air filter is arranged at the two sides of the indoor bottom; the second return air filter is used for treating indoor air and directly transmitting the treated indoor air into the cyclone mixing device. The air purifying system solves the technical problem of great space usage and low treatment efficiency of the air purifying system.

Owner:苏州艾尔新净化科技有限公司

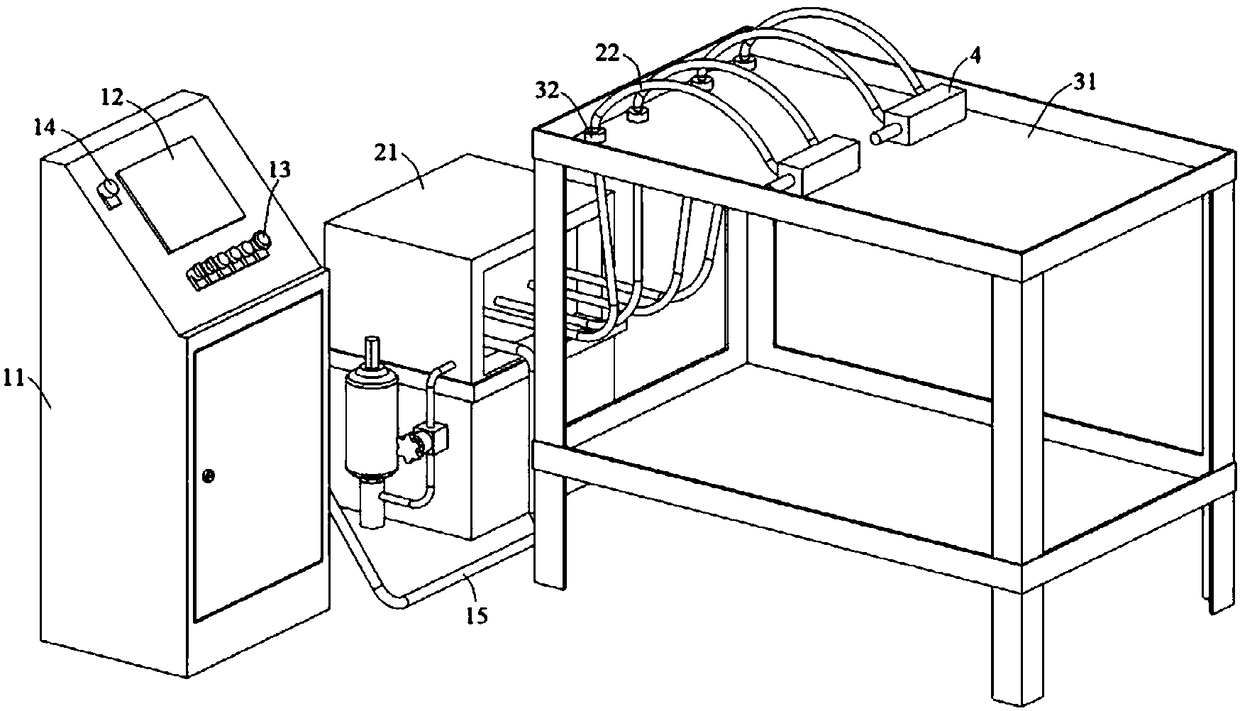

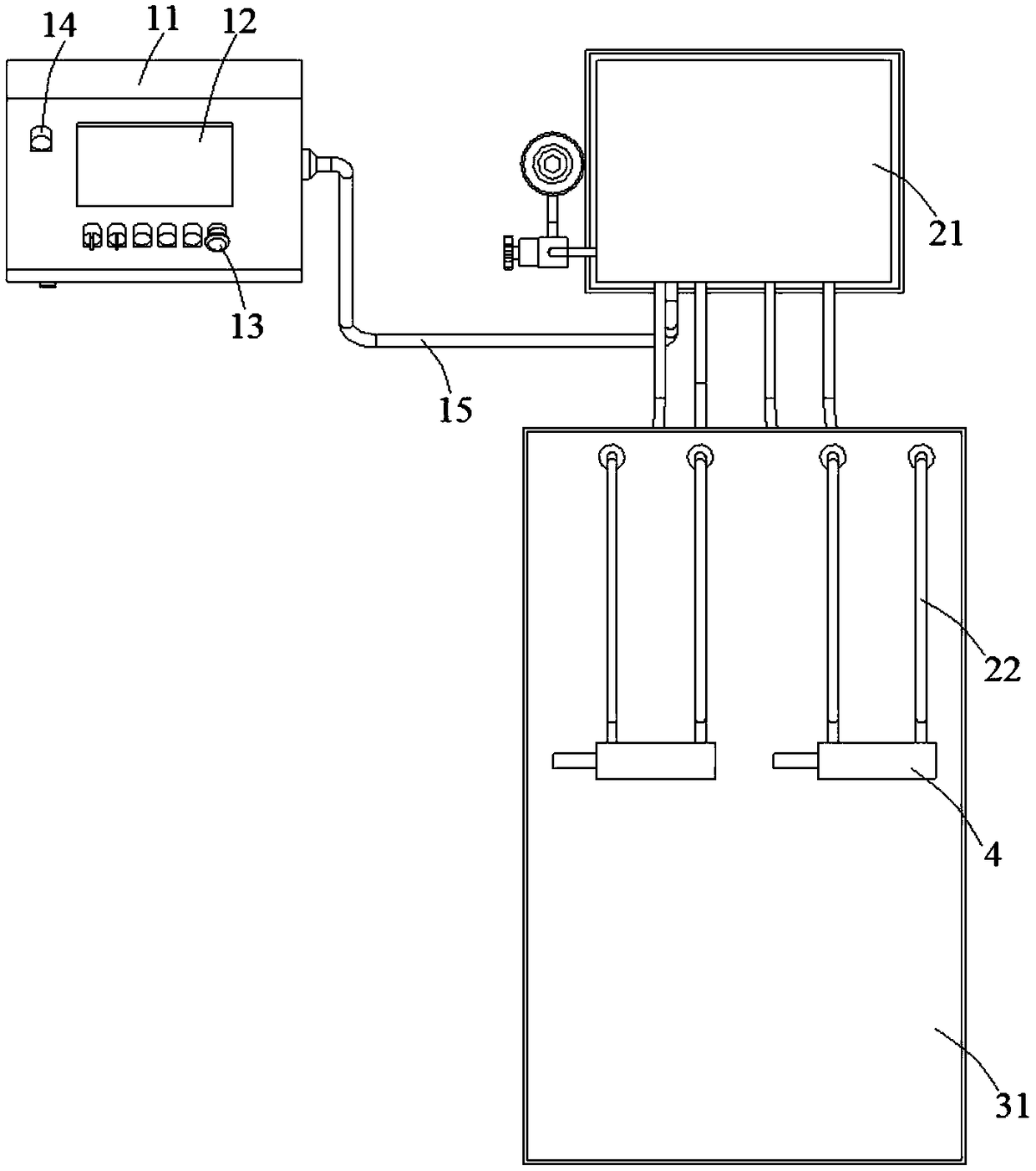

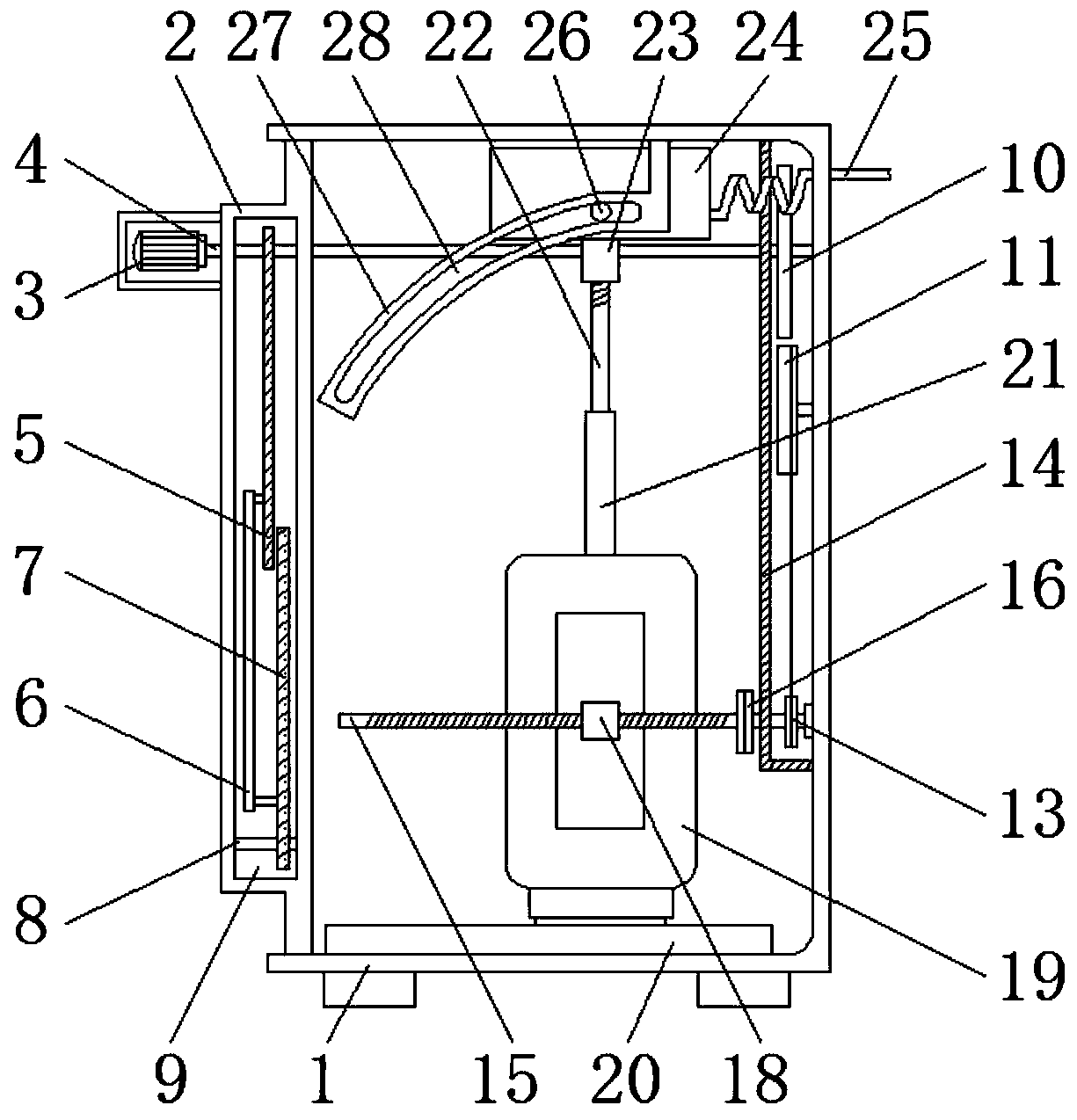

Testing platform for combined machine tool hydraulic cylinder

InactiveCN108105205ARealize automated detectionLabor savingFluid-pressure actuator testingHydraulic cylinderControl system

The invention discloses a testing platform for a combined machine tool hydraulic cylinder and belongs to the technical field of hydraulic cylinder performance detection. The testing platform for the combined machine tool hydraulic cylinder comprises a cabinet body, a control panel, a hydraulic station, an oil conveying pipeline and a PLC control system, wherein the PLC control system is arranged inside the cabinet body, the output end of the PLC control system is connected with the hydraulic station through a control line, the control panel is used for controlling the hydraulic station, and the hydraulic station is connected with the hydraulic cylinder through the oil conveying pipeline. By means of the testing platform for the combined machine tool hydraulic cylinder, whether the hydraulic cylinder leaks oil or not is automatically detected, labor is greatly saved, and the situation that an unqualified hydraulic cylinder is installed into a machine tool and consequently the machine tool breaks down and needs to be disassembled for maintenance is avoided.

Owner:马鞍山市恒永利机械科技有限公司

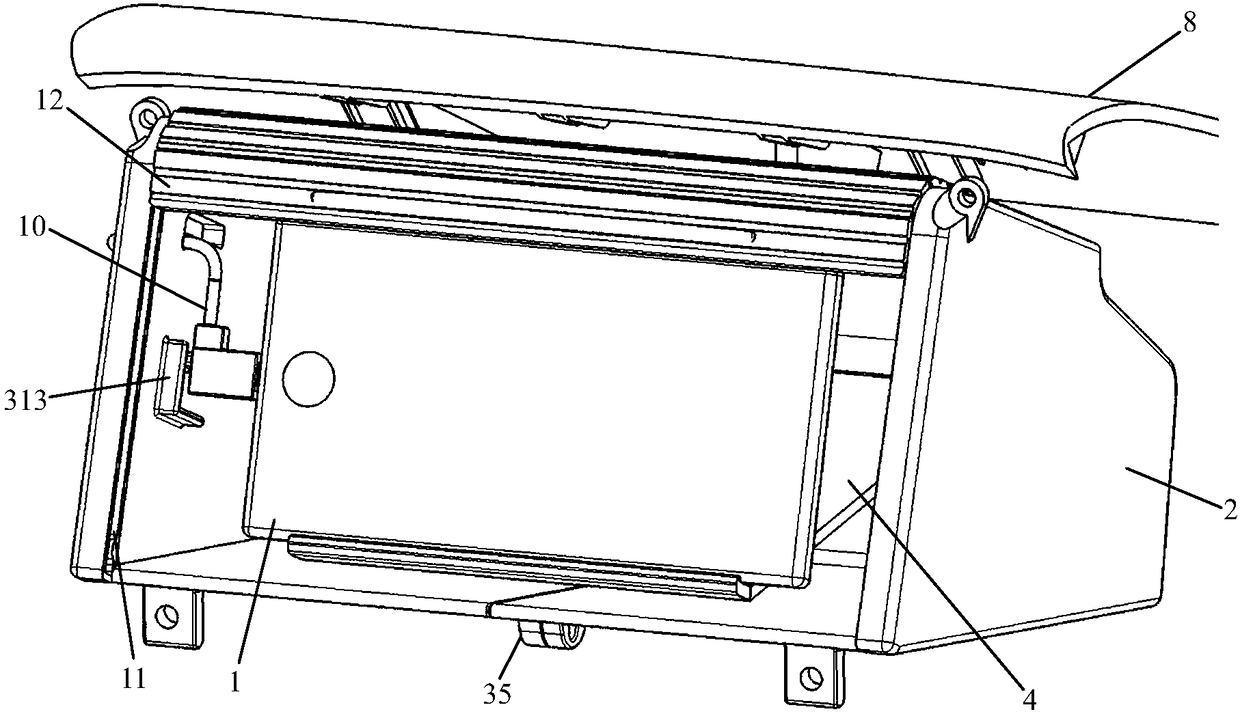

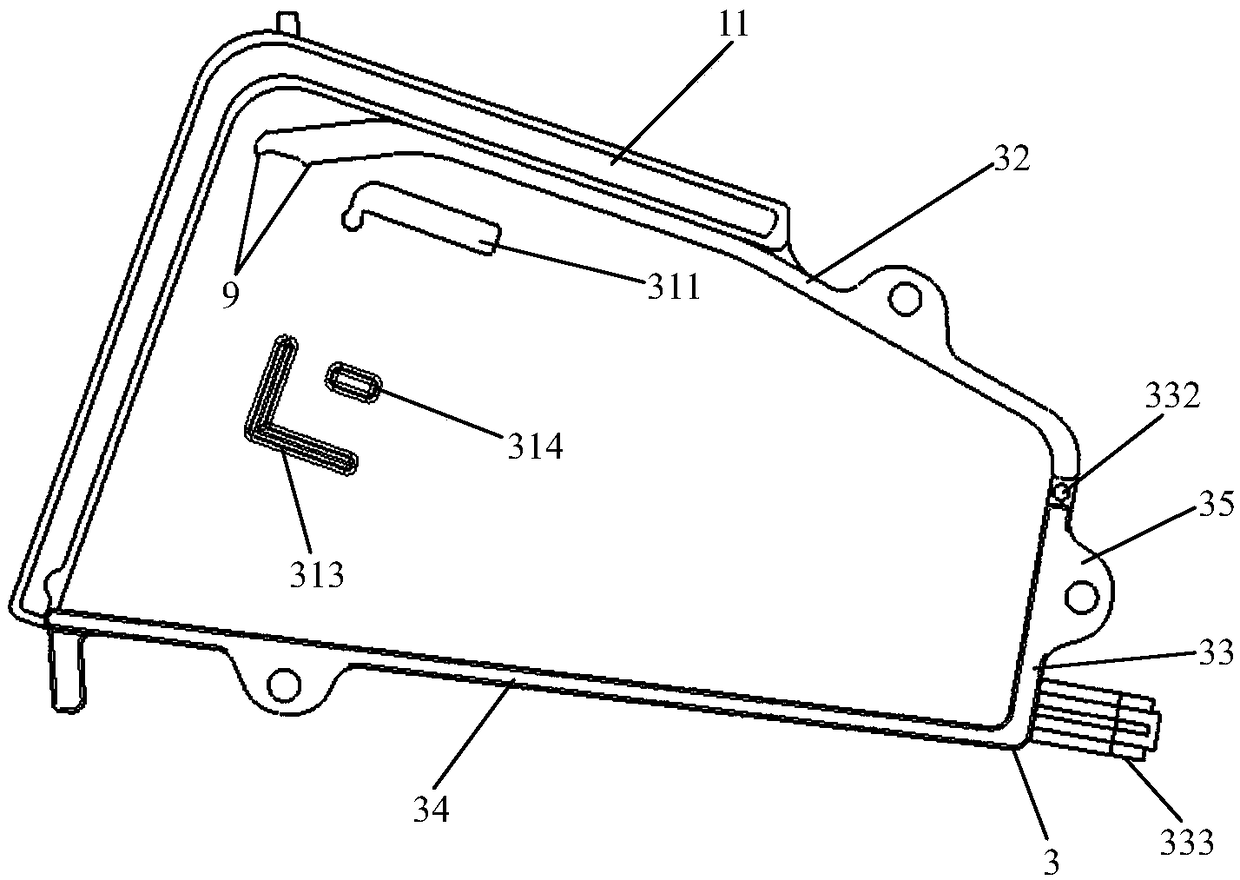

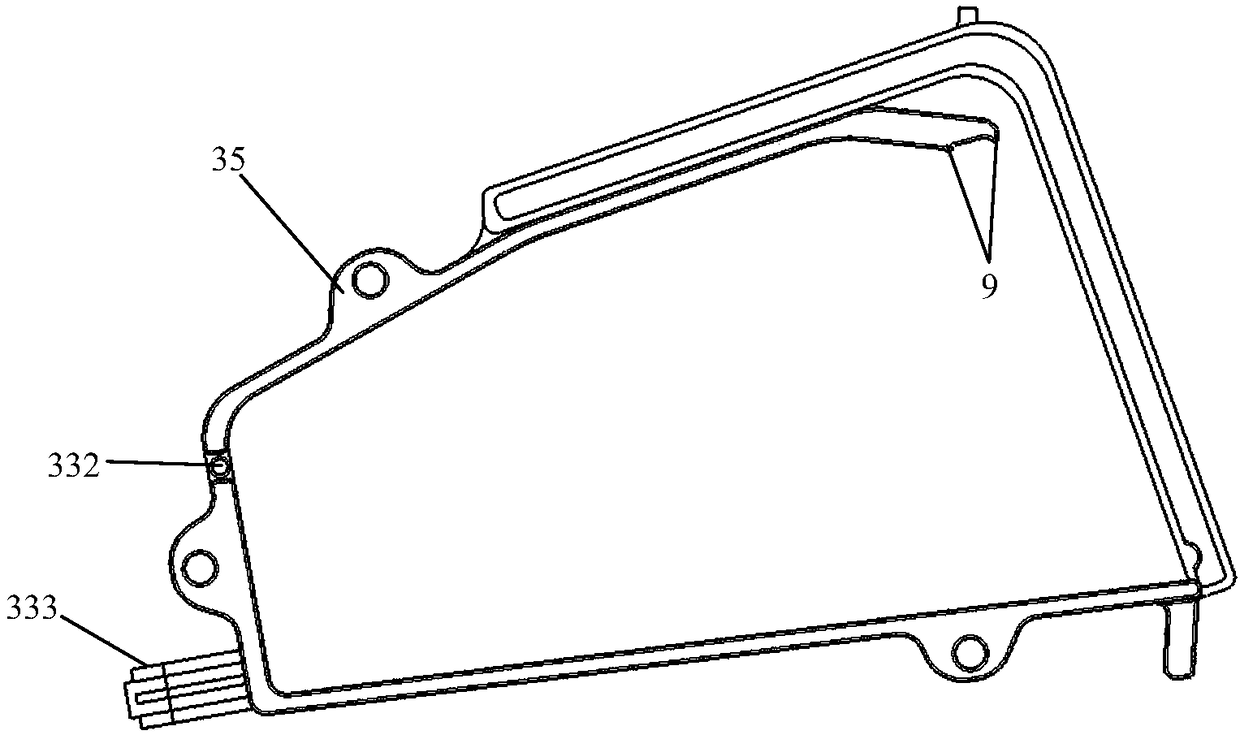

Device for fixing and monitoring vehicle-mounted mobile phone

ActiveCN108099806AAvoid forgettingEasy to observeVehicle componentsTelephone set constructionsElectricityEngineering

The invention belongs to the technical field of automobiles, and particularly relates to a device for fixing and monitoring a vehicle-mounted mobile phone. The device comprises a storage box body withthe open front end, and further comprises a clamping plate, a return torsion spring and a micro switch which is electrically connected with a vehicle-mounted computer and used for monitoring taking and placing conditions of the mobile phone. The clamping plate is hinged to the storage box body, the rear end of the clamping plate penetrates out from the storage box body, the front end of the clamping plate is located in the storage box body and matched with the top wall of the storage box body to clamp and fix the mobile phone, the two ends of the return torsion spring are fixedly connected with the storage box body and the rear end of the clamping plate respectively, and the micro switch is fixedly installed on a top plate of an instrument and provided with a driving rod sensing the position where the rear end of the clamping plate is located. With the device, the mobile phone can be firmly clamped and fixed inside a vehicle-mounted storage box so as to be conveniently observed and operation, does not occupy external space of the storage box, and can be charged through vehicle-mounted equipment; meanwhile, in cooperation with the vehicle-mounted computer, the device can remind anowner to take back the mobile phone before the owner leaves from a vehicle, and therefore the mobile phone can be prevented from being forgotten in the vehicle.

Owner:DONGFENG MOTOR CORP HUBEI

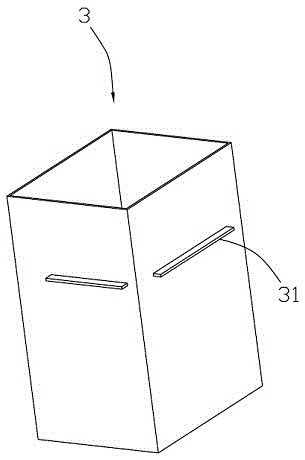

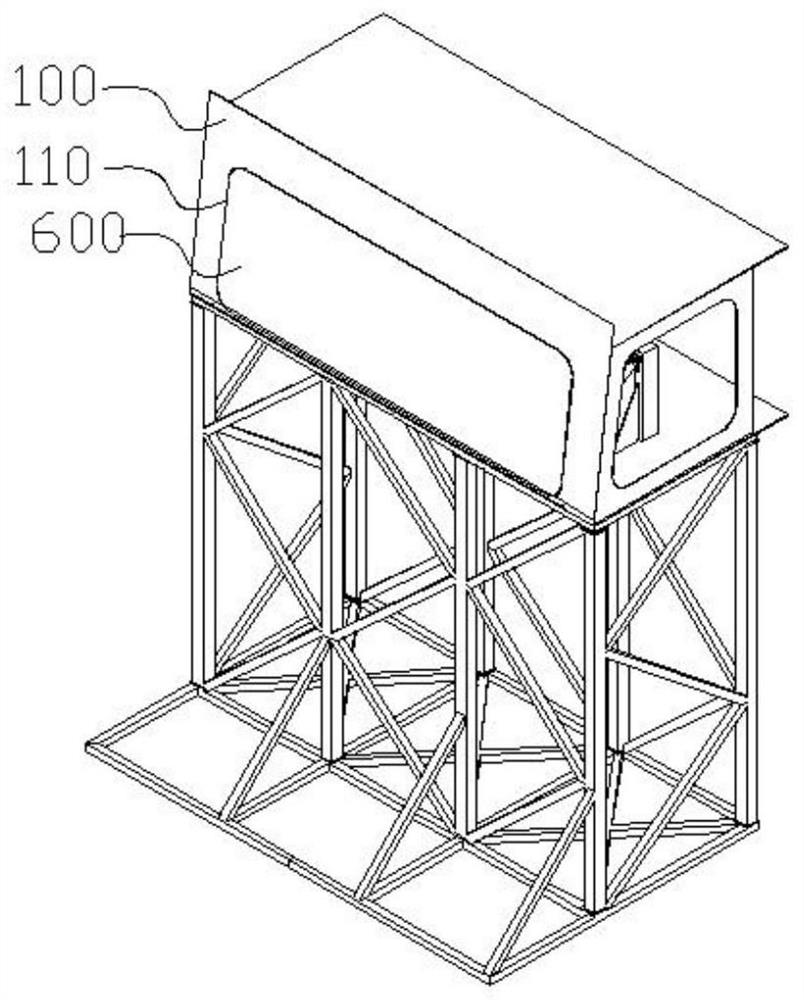

Box-type transformer facilitating maintenance of internal device

ActiveCN110504085ADoes not take up external spaceAchieve openTransformers/reacts mounting/support/suspensionTransformers/inductances casingsTransformerEngineering

The invention discloses a box-type transformer facilitating maintenance of an internal device. The box-type transformer comprises a box, a servo motor, a transformer body and a cooling fan, wherein aside plate is arranged on one side face of the box, a first sealing door is installed at one end of a motor shaft, a lower corner of a second sealing door is connected with the side plate through a movable shaft, the other end of the motor shaft is sleeved with a first gear, a second gear is connected with a third gear through a chain, a connecting shaft penetrates through the third gear, the outer side of the connecting shaft is sleeved with a sleeve block, a fixed cylinder is fixed to the top of the transformer body, the top of a connecting rod is connected with a line storage box through aconnecting block, and a fixed rod is fixed to one side of the line storage box. Through the box-type transformer facilitating maintenance of the internal device, the transformer body in the box can beautomatically driven to slide out, the situation that a large amount of manpower needs to be consumed in a maintenance process is avoided, and the open sealing doors cannot occupy outside space.

Owner:LANGFANG POWER SUPPLY COMPANY STATE GRID JIBEI ELECTRIC POWER COMPANY +1

Safety life jacket with rear-mounted folding mechanism

ActiveCN111994227AAvoid dehydration discomfortImprove survival rateBatteries circuit arrangementsBody suitsMarine engineeringElectric machinery

The invention relates to the technical field of marine lifesaving, and particularly relates to a safety life jacket with a rear-mounted folding mechanism. The safety life jacket comprises a life jacket body, a driving motor and a solar cell panel for supplying power to the driving motor. According to the safety life jacket with the rear-mounted folding mechanism, a rear-mounted containing groove internally provided with a top overturning baffle and lateral supporting pipes and a longitudinal assembling groove internally provided with an assembling frame are formed in the back surface of the life jacket body; the height and the position of the top overturning baffle are changed through upward and downward overturning of the lateral supporting pipes, a sun-shading mechanism is conveniently formed above a wearer, dehydration discomfort of a drowning person in a long-time exposure state is avoided, and a drowning survival rate is increased; the solar cell panel is used for supplying powerto an electric control spiral drainage device, people can conveniently move in water, and more time and labor are saved; the operation can be completed by one person, which is very simple and convenient; and storage is convenient.

Owner:东台市海鸥航海设备有限公司

Built-in piezoelectric energy storage type oil leakage detection and early warning hydraulic shock absorber

InactiveCN112343956ADoes not take up external spaceImprove reliabilitySpringsPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric tubePressure difference

The invention discloses a built-in piezoelectric energy storage type oil leakage detection and early warning hydraulic shock absorber. The hydraulic shock absorber comprises a piston cylinder. A piston plate is installed in the piston cylinder in a sealed and sliding mode, a piston rod is inserted into one end of the piston cylinder in a sealed and sliding mode, the end, close to the piston plate,of the piston rod extends into the piston cylinder and is fixed to the piston plate, a plurality of right-angle elbows are symmetrically arranged on the inner wall of the piston cylinder, piezoelectric tubes are jointly welded between every two opposite right-angle elbows in a sealed mode, an energy storage detection sleeve is installed at the end, away from the piezoelectric tubes, of the pistoncylinder, and the piston rod is rotatably inserted into the energy storage detection sleeve. According to the hydraulic shock absorber, a plurality of arc-shaped piezoelectric patches on the piezoelectric tubes generate electric energy through the continuously changing pressure difference generated by the work of the shock absorber, an external function is not needed, and the electric intubationtube realizes the functions of real-time detection and timely alarm through the conduction of an electric fork by utilizing the characteristics of oil absorption and expansion of annular expansion resin.

Owner:范爱斌

Water heater

ActiveCN110966751AImprove water flowLow volume saturationWater heatersMechanical engineeringWater heater

The invention belongs to the field of water heaters, and particularly discloses a water heater. The water heater comprises an inner container and a water inlet pipe. The water inlet pipe is arranged in the inner container, and a scale inhibiting device is further included and is located in the inner container and arranged on the water inlet pipe. The scale removing device comprises a storage chamber containing a scale inhibitor, and after the scale inhibitor in the storage chamber is dissolved, the scale inhibitor is mixed with water flowing out of the water inlet pipe to enter the inner container. According to the water heater, the scale inhibiting device is arranged in the inner container, no external space is occupied, the water inlet pipe is not influenced, and the situation that the water inlet pipe is blocked is avoided; and meanwhile the scale inhibiting device is high in scale inhibiting efficiency, good in scale inhibiting effect and long in service life.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER

Bottle rack lifting mechanism and refrigerator containing same

InactiveCN106895652AEasy to operateEnable mobilityLighting and heating apparatusSupportEngineeringBottle

The invention discloses a bottle rack lifting mechanism. Height adjusting of bottle racks in the vertical direction is achieved through matching of bottle rack supports and guide supports. The bottle racks can reset automatically after rising to the largest height, reverse operation is not needed, and operation is convenient. Mechanism parts are all arranged inside the bottle rack supports, so that external space is not occupied, and the appearance is attractive. The bottle racks are moved and locked by arranging a lifting connecting rod and a stop connecting rod to be matched with springs, reliability is high, and the service life is long. A clamping groove is formed in the front end of a pushing rod and matched with a clamping block on the lifting connecting rod. When the bottle rack supports move to the highest position of the guide supports, the clamping block is positioned in the clamping groove to limit upward moving of the bottle rack supports, the situation that the bottle racks separate from the mechanism and fall off is prevented, the mechanism has the limiting and stop moving functions, and using safety is guaranteed.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

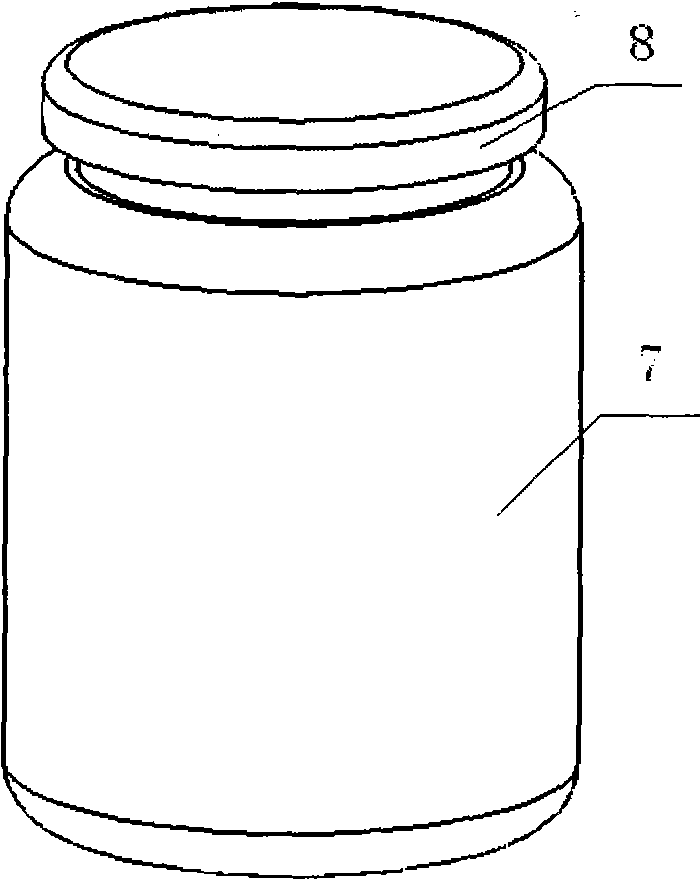

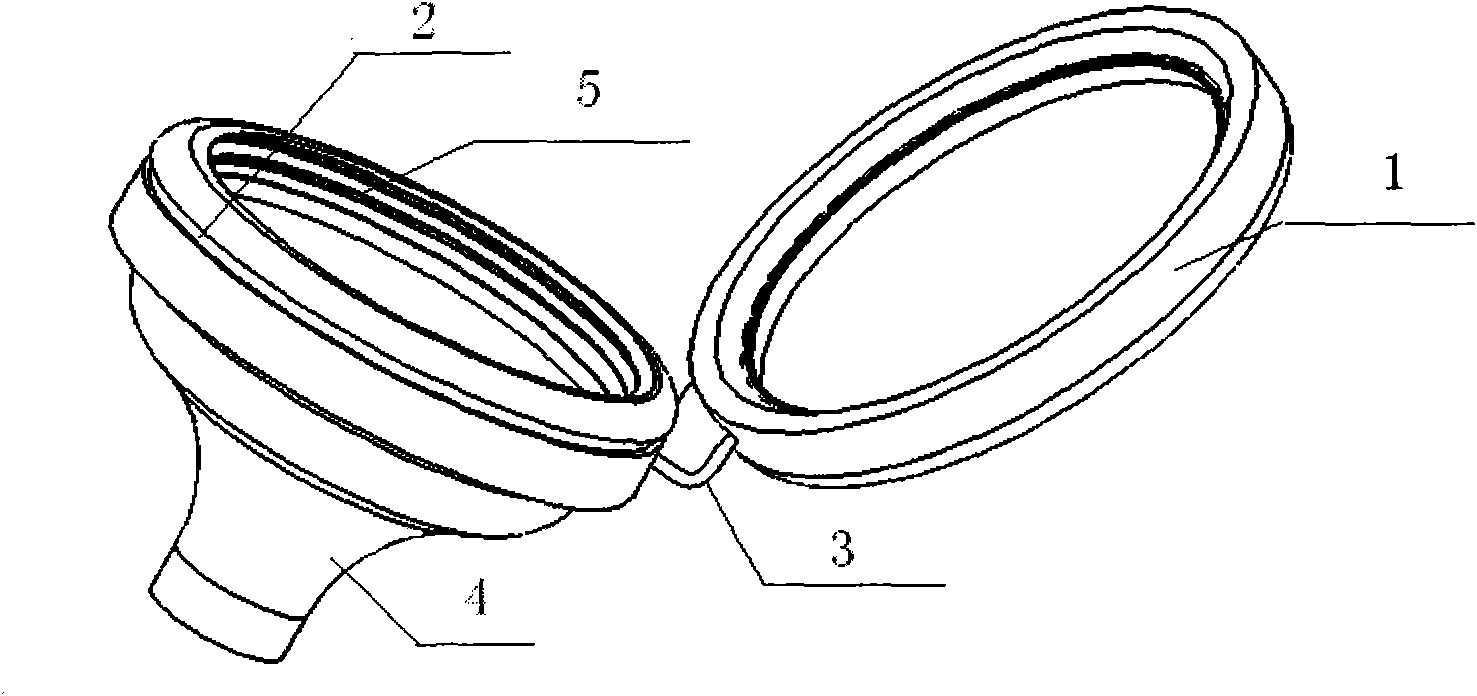

Multifunctional toner bottle cap

The invention is applied to the field of laser printers and provides a toner bottle cap. The toner bottle cap comprises a sealing cap and a bottle cap of a sealing platform, wherein the sealing cap is mutually connected with the side end of the sealing platform; the sealing platform is in a funnel-shaped structure, the front end and the bottom end of which are opened; the inside of a larger opening respectively contains threads; and the outside of the larger opening is provided with a layer of sealing ring. The invention has the advantages of convenient use, safety and good sealing performance.

Owner:FOREVER TECH

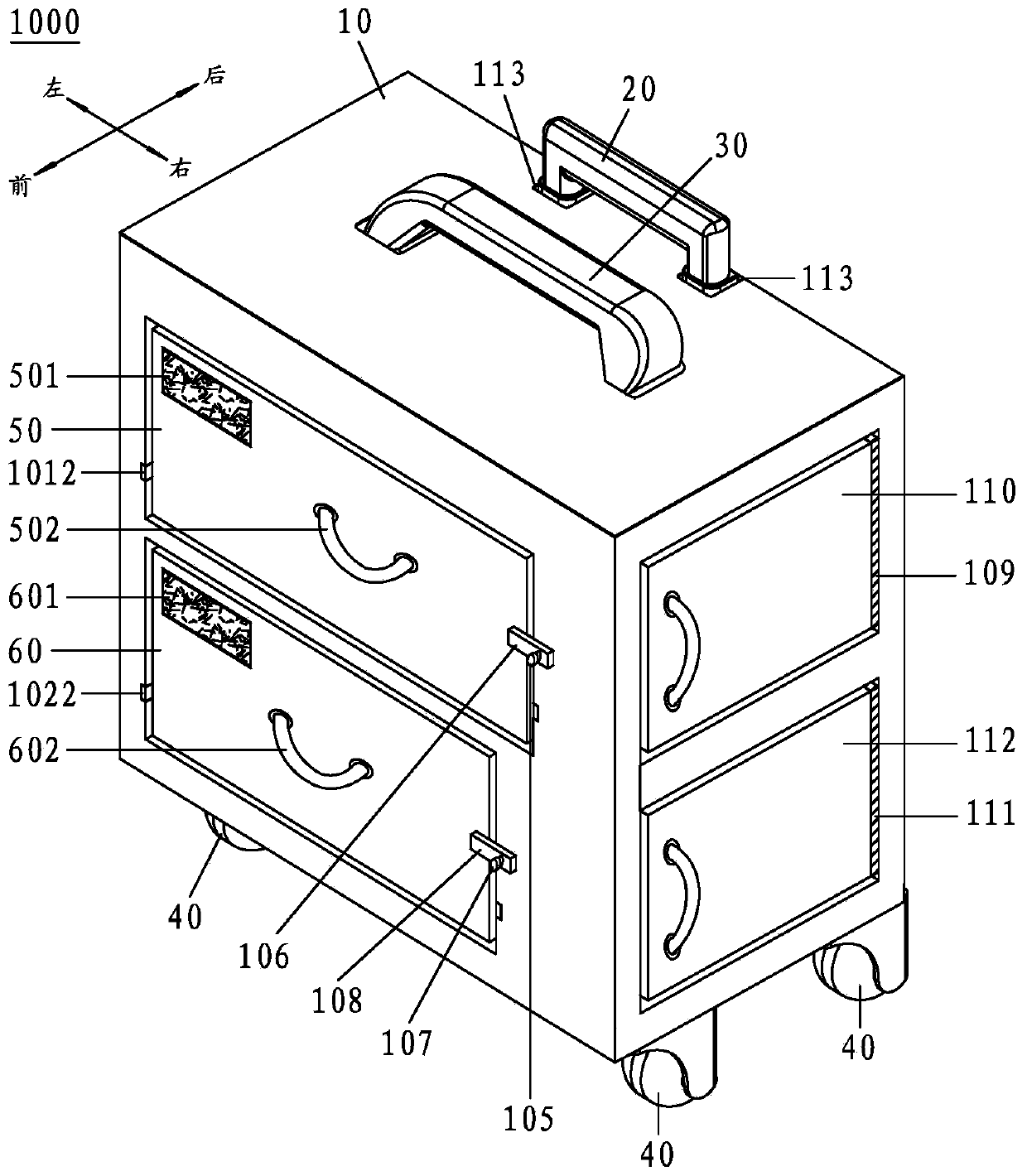

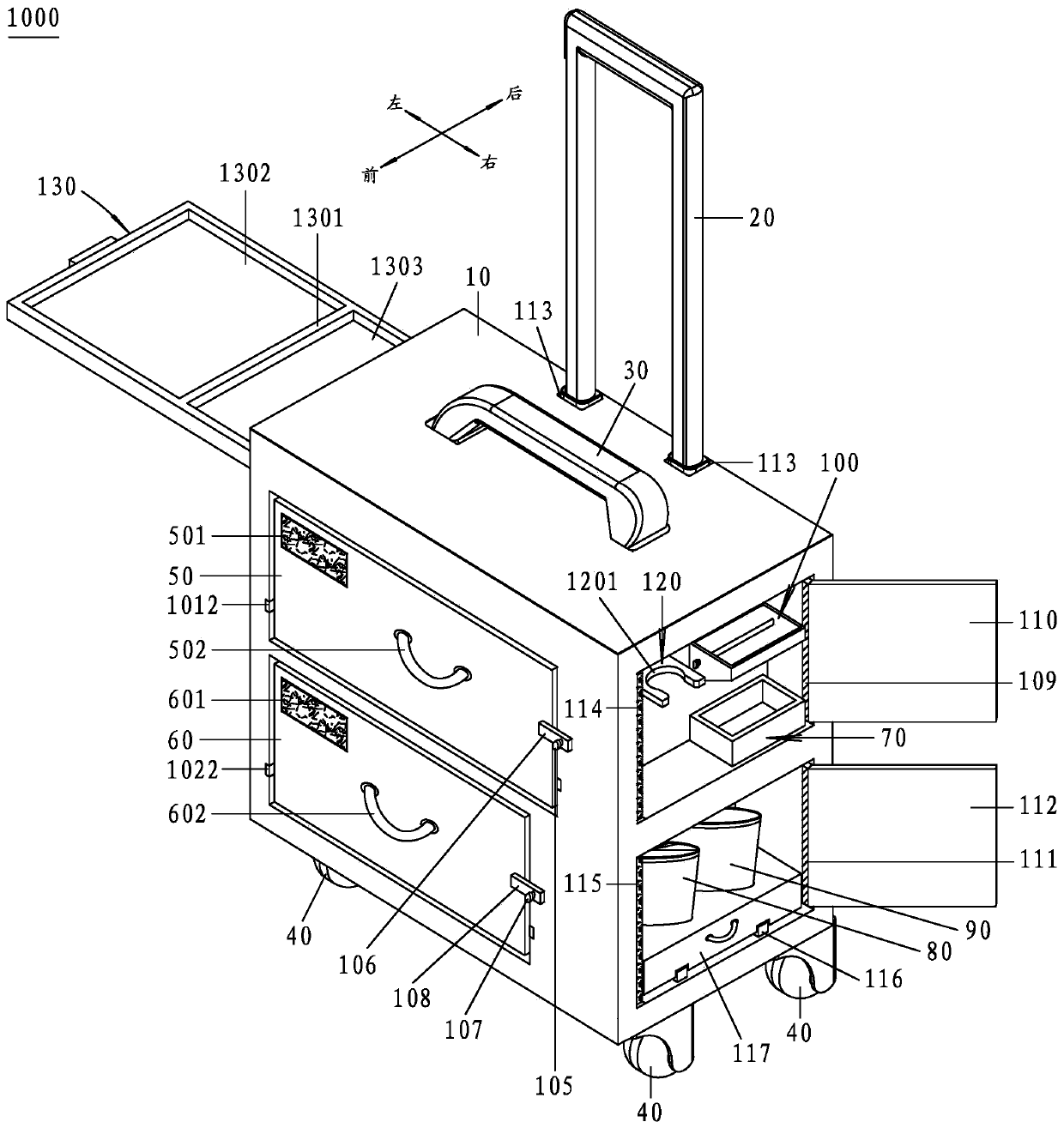

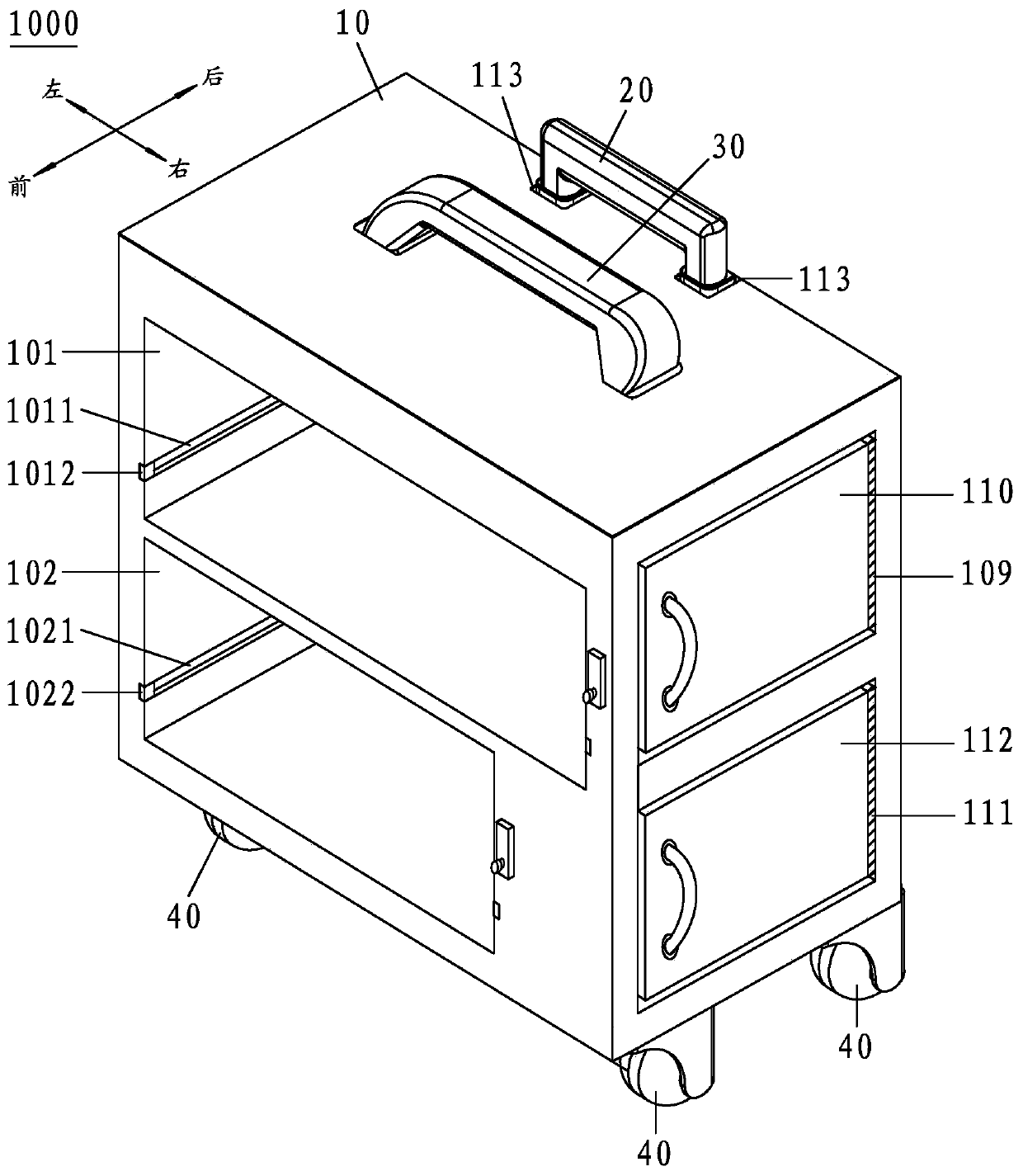

Push-pull PICC maintenance outcalls case

PendingCN110584793ARelieve fatigueAvoid cross infectionSurgical furniturePush pullSoftware engineering

The invention discloses a push-pull PICC maintenance outcalls case. The outcalls case comprises a case body, a telescopic pull rod, a lifting handle and rollers; the case body is divided into a left upper accommodating cavity, a left lower accommodating cavity, a right upper accommodating cavity and a right lower accommodating cavity; an upper drawing opening penetrating through the left upper accommodating cavity and a lower drawing opening penetrating through the left lower accommodating cavity are formed on a front end surface of the case body, and an upper side opening penetrating throughthe right upper accommodating cavity and a lower side opening penetrating through the right upper accommodating cavity are formed on the right surface; an upper layer-layer storage drawer is arrangedat the left upper accommodating cavity, and a lower-layer storage drawer is arranged at the left lower accommodating cavity; a wet tissue storage box is arranged at the right upper accommodating cavity, and a medical sharp collection box and a medical waste storage box are arranged at the right lower accommodating cavity. The outcalls case disclosed by the invention can be portable and push-pull,so that the carry is convenient and power-saving; the aseptic articles for PICC maintenance are stored in the upper-layer storage drawer, and the conventional articles for PICC maintenance are storedin the lower-layer storage drawer, so that the aseptic articles and the conventional articles can be effectively isolated; the medical sharp collection box and the medical waste storage box are arranged at the right lower accommodating cavity so as to be used after being pulled out, and the use of the outcalls case is convenient.

Owner:PEKING UNIV SHENZHEN HOSPITAL

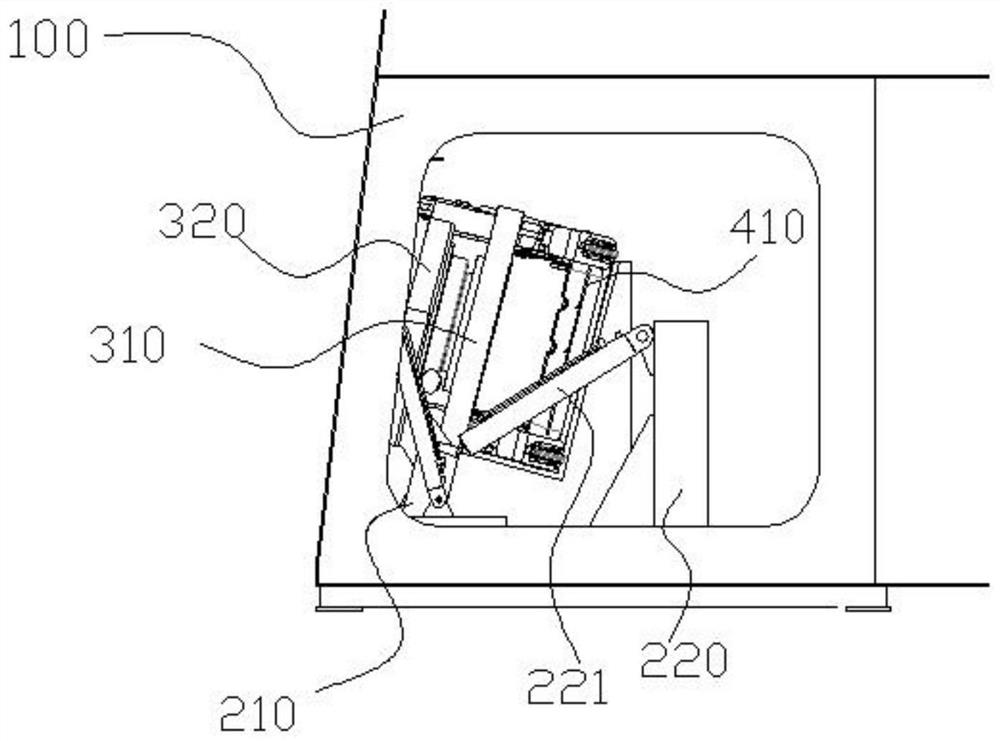

Full-membrane wall circulating fluidized bed boiler without corridor corner tube

InactiveCN101514811BCompact structureDoes not take up external spaceFluidized bed combustionBoiler water tubesCyclonePetroleum engineering

The invention discloses a corner tube type full-membrane wall circulating fluidized bed boiler without a corridor, which adopts a corner tube self-supporting structure, a corridor-free arrangement and a water-cooled built-in horizontal volute cyclone separator structure, a furnace and convection The shaft adopts a full-membrane water-cooled wall structure, and the convection shaft is equipped with a screen-type evaporation heating surface and a flag-type or serpentine tube-type convection heating surface; the structure is compact, the flue gas flows smoothly, and the flow resistance is reduced; the design is easy to series It is easy to standardize in manufacturing, easy to assemble parts in transportation, easy to modularize in field installation, short installation period on site, can greatly save materials, has the characteristics of high combustion efficiency and low power consumption of induced draft fans.

Owner:XI AN JIAOTONG UNIV

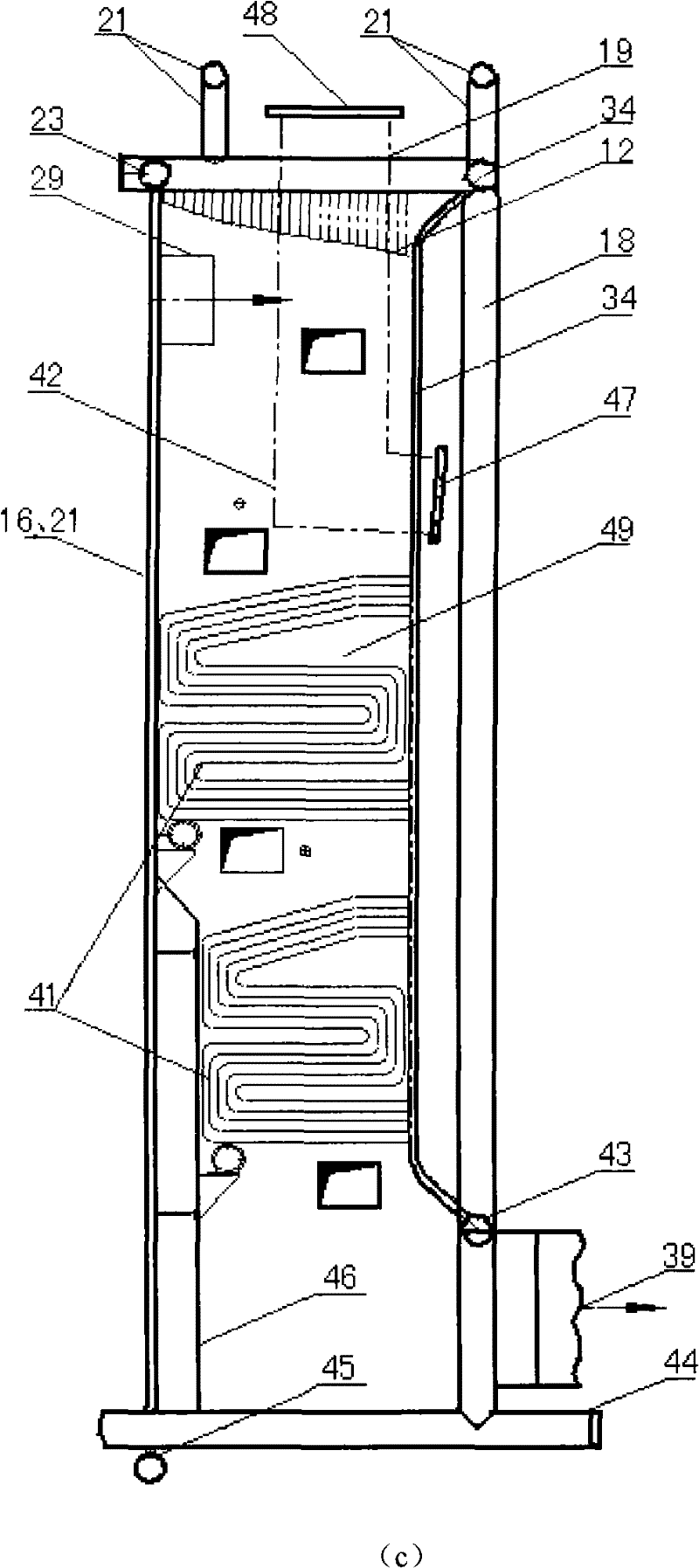

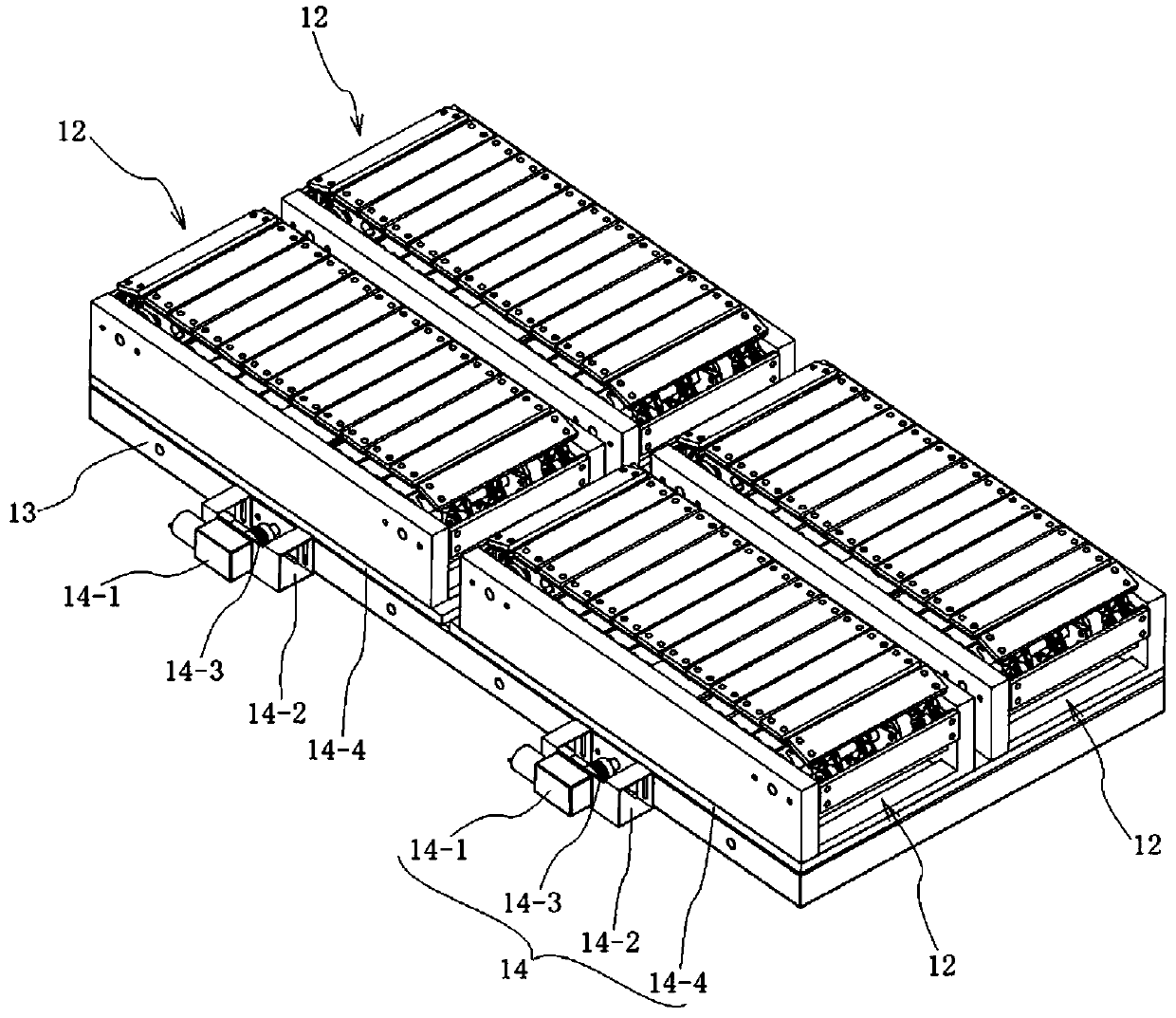

Four-wheel adjusting type vehicle parking automatic deviation rectifying device and deviation rectifying method thereof

InactiveCN110792310APrecise position detectionDoes not affect withdrawalParkingsControl theoryDistance sensors

The invention discloses a four-wheel adjusting type vehicle parking automatic deviation rectifying device and a deviation rectifying method of the four-wheel adjusting type vehicle parking automatic deviation rectifying device, and belongs to the field of parking equipment. The automatic deviation rectifying device comprises a deviation rectifying actuating mechanism assembly and a position detecting mechanism assembly, wherein the deviation rectifying actuating mechanism assembly utilizes four sets of rolling deviation rectifying modules to cooperate with a lateral adjusting mechanism to achieve deviation rectifying adjustment of the parking position of a vehicle, the structure design is simple and compact, and the deviation rectifying action is more stable and reliable; the position detecting mechanism assembly detects the parking position of the vehicle by using a distance sensor capable of doing ascending and descending movement, the distance deviation of the same side of the vehicle is detected by the distance sensor to determine the torsion angle required to be adjusted, and the deviation distance of the front-rear direction or the left-right direction of the vehicle is determined by the detection value of the distance sensor on the opposite side, so that the vehicle position detection is comprehensive and accurate, the use cost is lower, and the parking of the vehicle isnot influenced. Good data support is provided for automatic deviation rectifying of the vehicle, and accuracy and stability of deviation rectifying adjustment of the vehicle are improved.

Owner:CHANGZHOU INST OF TECH

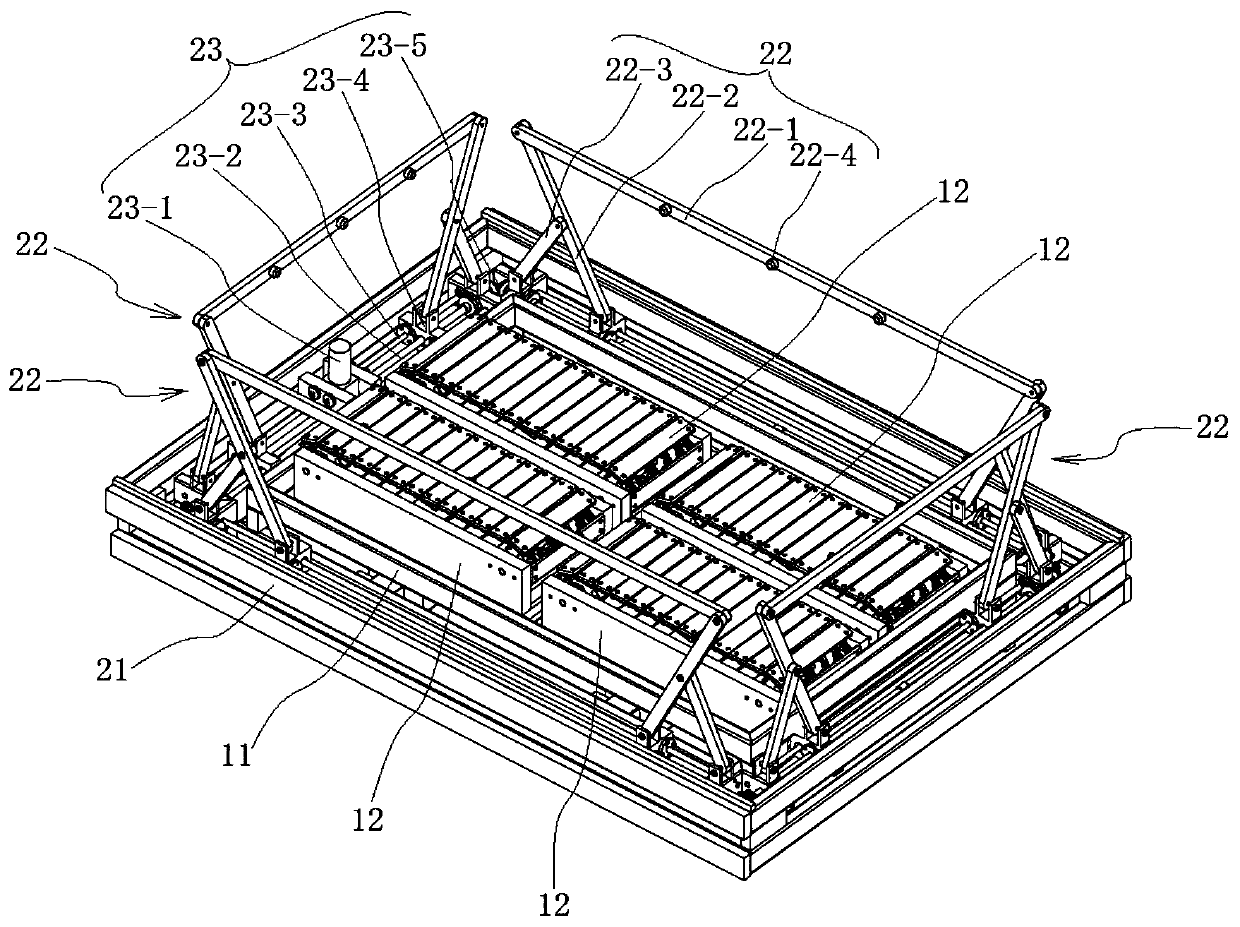

Foldable embarking device and control method

PendingCN112141273ADoes not take up external spaceSmall footprintCargo handling apparatusPassenger handling apparatusStructural engineeringMechanical engineering

The invention discloses a foldable embarking device. The foldable embarking device comprises a cabin, a turnover mechanism, a rotating mechanism and an embarking mechanism, wherein an opening is formed in a side surface of the cabin; the turnover mechanism comprises a turnover platform and a turnover driving device; the rotating mechanism comprises a rotating platform and a rotary driving device for connecting the rotating platform and the turnover platform; the embarking mechanism comprises an embarking ladder and a pitch driving device for connecting the embarking ladder to the rotating platform, and the embarking ladder is in hinged connection to the rotating platform; the pitch driving device is connected to the embarking ladder to drive the embarking ladder to rotate so as to change an included angle between the embarking ladder and a horizontal plane; the turnover mechanism is arranged to turn over the embarking ladder outside the cabin, the rotating mechanism is arranged to adjust orientation of the embarking ladder, the pitch driving device is arranged to adjust the included angle between the embarking ladder and the horizontal plane, and the embarking device can be suitable for sea and land embarking environments. After embarkment, the embarking device can be folded in the cabin, so that the foldable embarking device is small in occupied space.

Owner:SHANGHAI LINGYAO SHIP ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com