Slip handle labor saving lopper machine

A technology of high branch shears and sliding handle, applied in the field of high branch shears, can solve the problems of easily damaged pull rope, tripping damage, not compact, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

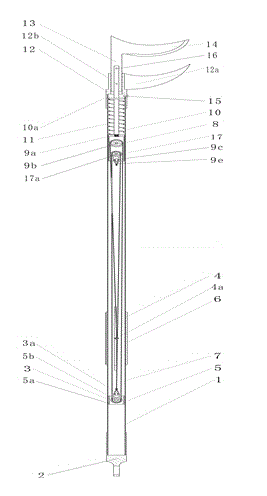

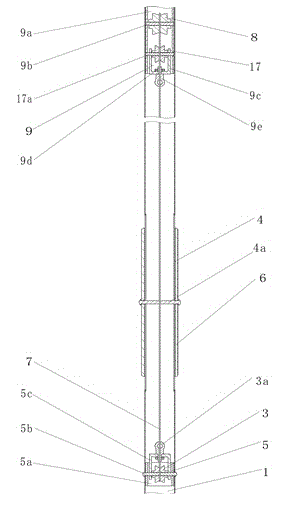

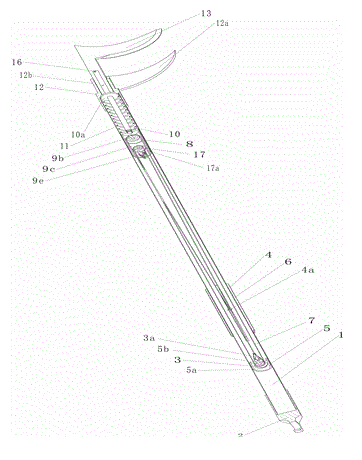

[0022] figure 1 , figure 2 , image 3 It is an embodiment of the labor-saving high-branch shears with a sliding handle. The grip bar 1 is a long tube, and one end of the grip bar 1 is provided with a hanging sleeve 18, and a screw hole is opened on the tube wall at the other end. A through hole passing through the axis is arranged on the grip bar 1 on the top of the groove 4 . The handle 2 is sleeved on the handle bar 1 for easy handling. The sliding handle 6 is a tubular part held by one hand, and a sliding handle pin rod 4a is radially connected to the two walls, and the sliding handle 6 is sleeved on the handle bar 1 . The transmission rod 10 is a rod-shaped member, and a stop plate 10a is arranged in the middle of the transmission rod 10 . The back-moving spring 11 is a stage clip that can be loaded into the grip bar 1 .

[0023] The pulley assembly includes movable pulley 8, small movable pulley 17, fixed pulley 3, fixed pulley mounting part 5, movable pulley moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com