Multifunctional toner bottle cap

A multi-functional, toner bottle technology, applied in the direction of closing, packaging, transportation and packaging, etc., can solve the problems of taking up too much space, flying toner, inconvenience, etc., and achieve small space occupation, convenient storage and transportation, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

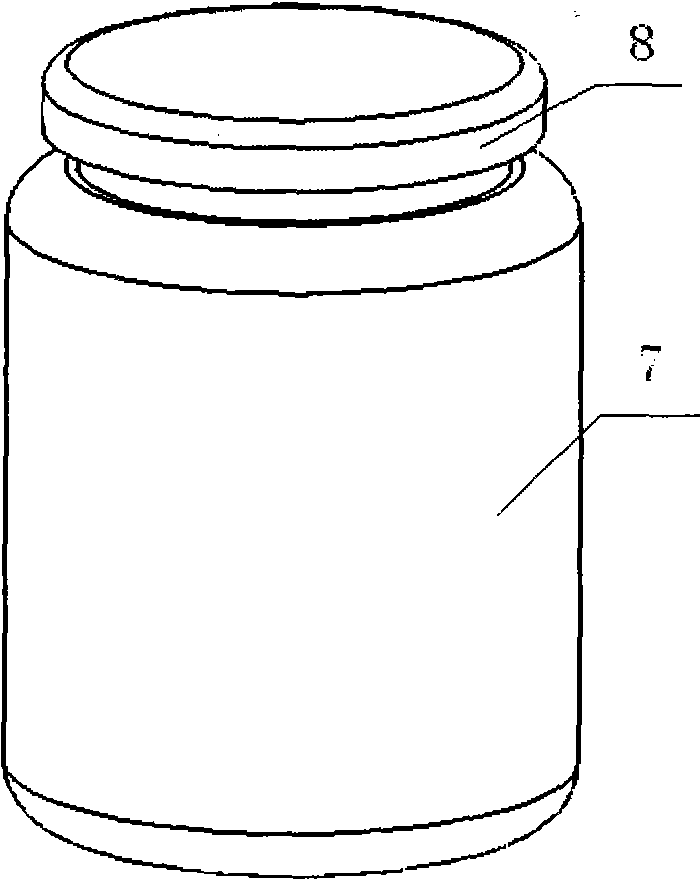

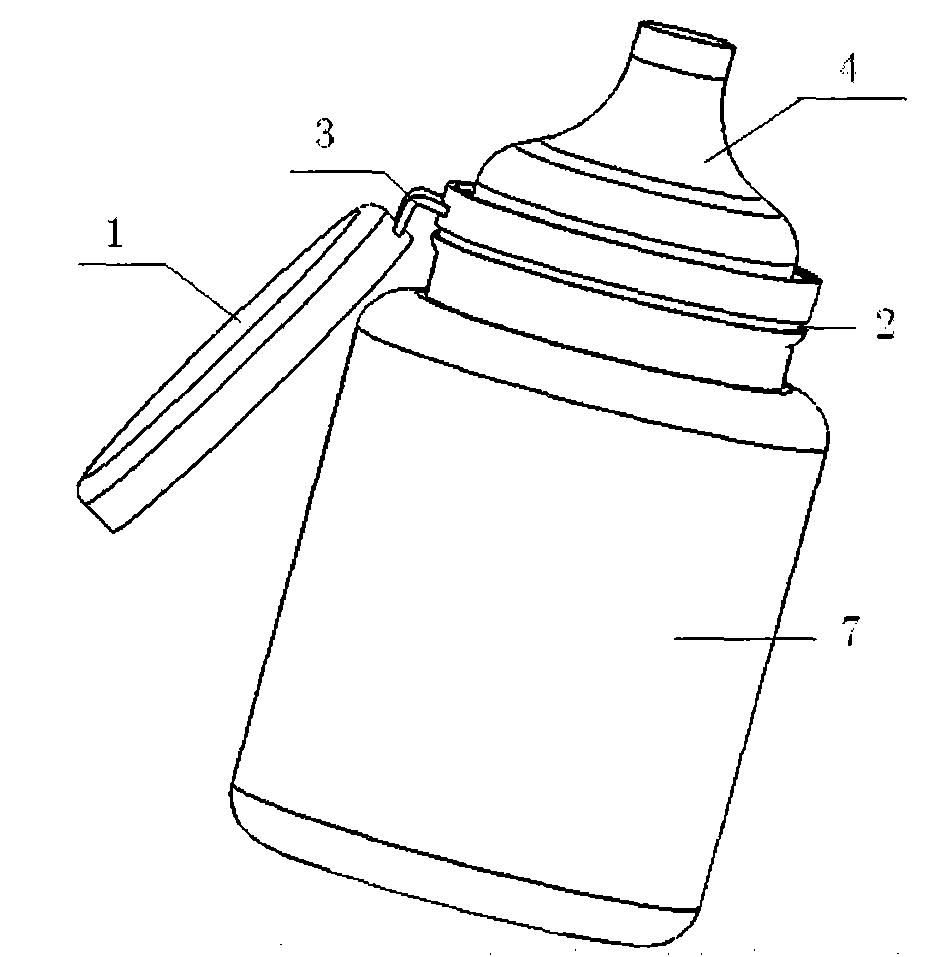

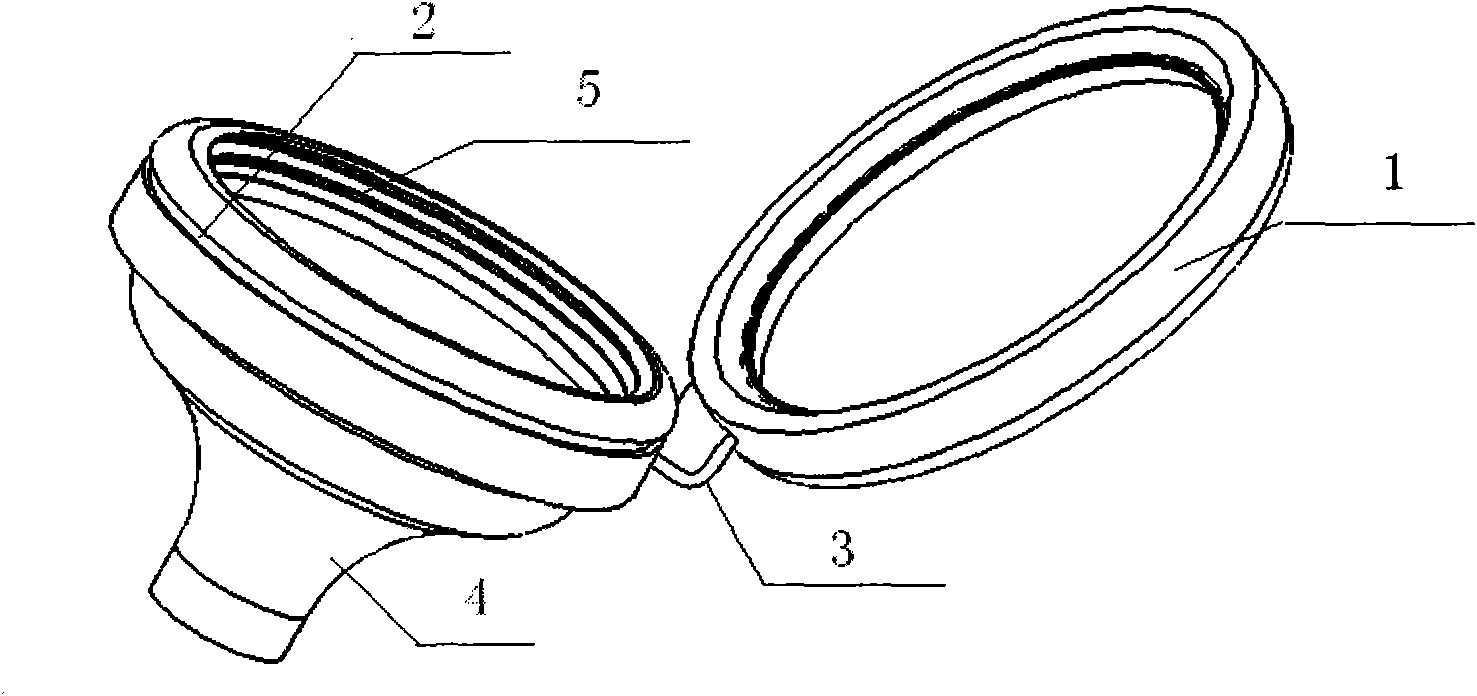

[0016] In the most preferred design, when the bottle cap is only used for sealing, the first thread (5) in the sealing table (2) is screwed together with the thread of the bottle mouth of the toner bottle. When powder needs to be filled, unscrew the bottle cap (8) first, open the sealing cap (1), turn the bottle cap (8) upside down and screw it into the toner bottle again, so that the second thread (6) is screwed with the mouth of the toner bottle. and. The smaller opening end (4) of the sealing table is used as the carbon powder outlet, so that the carbon powder can be smoothly taken out from the bottle. At this time, the sealing cap (1) is connected to one side of the toner bottle by using the connecting strip (3) so as not to be lost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com